Introduction: Navigating the Global Market for cracked leather

In the competitive landscape of the global leather market, sourcing high-quality cracked leather presents unique challenges for international B2B buyers. Understanding the intricacies of this material is essential, particularly for businesses in regions such as Africa, South America, the Middle East, and Europe, where demand for durable and aesthetically appealing leather goods continues to rise. Cracked leather, often perceived as a flaw, can be transformed into a valuable asset with the right knowledge and techniques, enhancing product offerings and customer satisfaction.

This comprehensive guide delves into the various types of cracked leather, their applications across industries, and effective methods for repair and maintenance. Additionally, it provides insights into supplier vetting processes, cost considerations, and the latest trends influencing the market. By equipping buyers with actionable information, this resource empowers them to make informed purchasing decisions that align with their business objectives and regional preferences.

As you navigate the complexities of sourcing cracked leather, this guide serves as a roadmap, offering expert insights that facilitate strategic investments. Whether you are a retailer looking to enhance your inventory or a manufacturer aiming to improve product quality, understanding the nuances of cracked leather will elevate your business in an increasingly competitive global market.

Table Of Contents

- Top 4 Cracked Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for cracked leather

- Understanding cracked leather Types and Variations

- Key Industrial Applications of cracked leather

- 3 Common User Pain Points for ‘cracked leather’ & Their Solutions

- Strategic Material Selection Guide for cracked leather

- In-depth Look: Manufacturing Processes and Quality Assurance for cracked leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘cracked leather’

- Comprehensive Cost and Pricing Analysis for cracked leather Sourcing

- Alternatives Analysis: Comparing cracked leather With Other Solutions

- Essential Technical Properties and Trade Terminology for cracked leather

- Navigating Market Dynamics and Sourcing Trends in the cracked leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of cracked leather

- Strategic Sourcing Conclusion and Outlook for cracked leather

- Important Disclaimer & Terms of Use

Understanding cracked leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Surface Cracks | Fine, superficial cracks primarily affecting the finish. | Fashion accessories, upholstery | Pros: Easily repairable; minimal impact on durability. Cons: May require frequent maintenance. |

| Deep Cracks | Noticeable fissures that penetrate deeper into the leather. | High-end furniture, automotive interiors | Pros: Can be restored with proper techniques; maintains luxury appeal. Cons: More expensive to repair; may compromise aesthetics if untreated. |

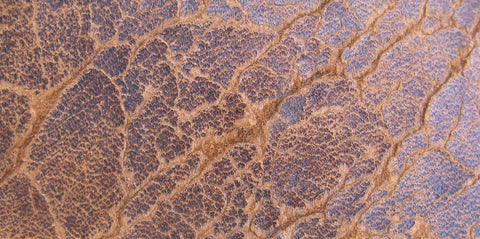

| Alligator Cracking | Distinct, large cracks resembling alligator skin. | High-end fashion, luxury goods | Pros: Unique appearance can be desirable; adds character. Cons: Difficult to repair; can signify aging or poor care. |

| Dry Cracking | Cracks resulting from lack of moisture and conditioning. | Leather goods manufacturing | Pros: Preventable with proper care; can be treated effectively. Cons: Indicates neglect; potential for further damage if untreated. |

| Patterned Cracking | Cracks forming in a specific pattern, often decorative. | Specialty leather goods, artisan products | Pros: Unique aesthetic appeal; can enhance product value. Cons: Repair can alter the intended design; may require specialized skills. |

What Are the Characteristics of Surface Cracks in Leather?

Surface cracks are typically fine, hairline fissures that affect only the outer layer of leather. These cracks often arise from environmental factors such as exposure to sunlight and dryness. They are most commonly found in fashion accessories and upholstery. For B2B buyers, these cracks are relatively easy to repair with conditioners or creams, making them less of a liability. However, frequent maintenance is necessary to keep the leather looking its best, which may incur additional costs over time.

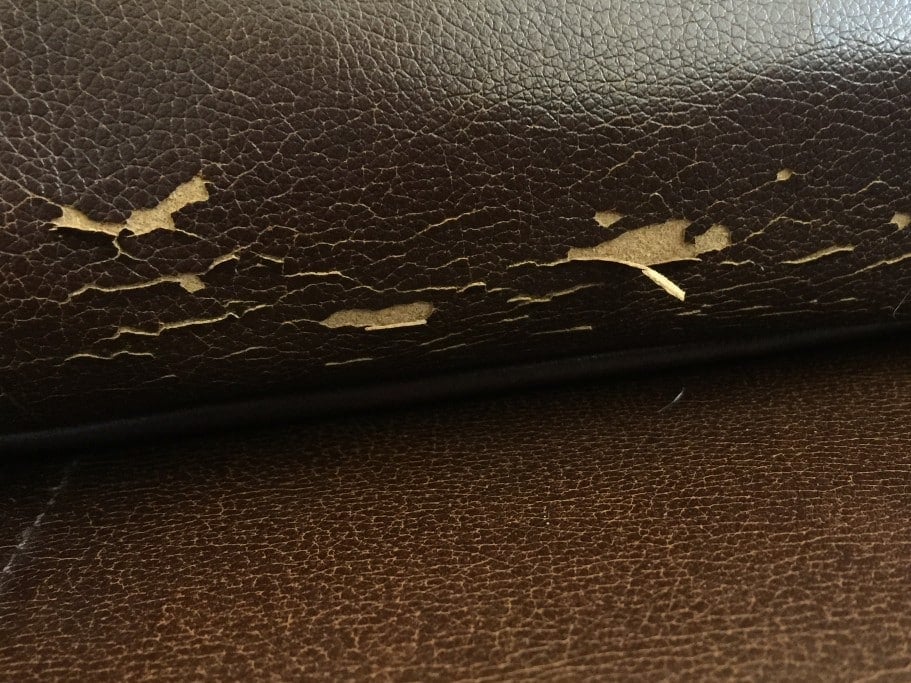

How Do Deep Cracks Differ from Other Types of Cracking?

Deep cracks are significantly more pronounced, penetrating into the leather’s structure. They can arise from prolonged neglect or excessive wear and tear, making them more challenging to repair. Commonly found in high-end furniture and automotive interiors, deep cracks may require specialized repair techniques, such as leather fillers and dyes. While they can be restored to maintain the product’s luxury appeal, the repair costs can be substantial, and untreated deep cracks may compromise the overall aesthetics of the leather item.

Illustrative image related to cracked leather

What Are the Unique Features of Alligator Cracking?

Alligator cracking features larger, more distinct fissures that resemble the skin of an alligator. This type of cracking often occurs in older leather products or those that have not been properly maintained. Found in high-end fashion and luxury goods, alligator cracking can add character to an item, making it appealing to certain buyers. However, its unique appearance can also indicate aging or poor care, and repairing such cracks can be complex and costly, requiring specialized skills.

Why Does Dry Cracking Occur, and How Can It Be Prevented?

Dry cracking is a result of insufficient moisture and conditioning, leading to brittle leather. This type of cracking can be easily prevented through regular maintenance, including the application of high-quality conditioners. B2B buyers in the leather goods manufacturing sector should prioritize moisture retention techniques to prevent dry cracking, as neglecting this can lead to further damage and increased repair costs in the long run.

What Is Patterned Cracking, and Where Is It Commonly Used?

Patterned cracking occurs in specific designs, often enhancing the aesthetic appeal of leather products. This type of cracking can be seen in specialty leather goods and artisan products, where the design intention is to create a unique look. While this can add value, it may complicate repairs, as altering the crack can change the intended design. Buyers should consider the craftsmanship involved and the potential need for specialized repair services when purchasing patterned leather items.

Illustrative image related to cracked leather

Key Industrial Applications of cracked leather

| Industry/Sector | Specific Application of cracked leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Handbags and Accessories | Unique aesthetic appeal and cost-effective sourcing | Quality assurance, durability, and style compatibility |

| Automotive | Upholstery for Classic Cars | Restoration of vintage vehicles for resale value | Material authenticity, color matching, and texture |

| Furniture | Upholstered Seating | Cost-effective repairs for high-end furniture | Matching existing leather, flexibility, and comfort |

| Footwear | Boots and Shoes Repair | Enhances longevity and sustainability of products | Compatibility with existing designs, durability, and comfort |

| Home Decor | Decorative Items | Adds character and vintage appeal to interiors | Sourcing from reliable suppliers, color variations, and maintenance requirements |

How is Cracked Leather Used in the Fashion & Apparel Industry?

In the fashion and apparel industry, cracked leather is commonly utilized in the production of handbags and accessories. This material offers a unique aesthetic that appeals to consumers seeking vintage or distressed looks. For B2B buyers, sourcing cracked leather can provide cost savings while meeting market demand for stylish yet affordable products. Key considerations include ensuring the leather’s quality and durability to withstand wear and tear, as well as its compatibility with various design styles.

What Role Does Cracked Leather Play in the Automotive Sector?

Cracked leather finds significant application in the automotive sector, particularly for upholstery in classic cars. Restoring vintage vehicles often requires sourcing high-quality cracked leather that maintains the original aesthetic. For international buyers, particularly in markets like Africa and South America, the focus should be on material authenticity and color matching to preserve the vehicle’s value. Additionally, understanding the leather’s flexibility and durability is crucial for ensuring a successful restoration.

How Can Cracked Leather Benefit the Furniture Industry?

In the furniture industry, cracked leather is often used for upholstered seating solutions. This application allows businesses to perform cost-effective repairs on high-end furniture, extending its lifespan while enhancing its visual appeal. B2B buyers should prioritize sourcing materials that match existing leather in terms of texture and color to maintain a cohesive look. Moreover, understanding the leather’s flexibility will help ensure comfort and usability in furniture applications.

Why is Cracked Leather Important for Footwear Manufacturing?

Cracked leather is increasingly utilized in footwear, particularly for repairing boots and shoes. By using this material, manufacturers can enhance the longevity and sustainability of their products, appealing to environmentally conscious consumers. For buyers, it is essential to consider compatibility with existing designs, as well as the durability and comfort of the leather used in footwear. This ensures that the final product meets both aesthetic and functional requirements.

Illustrative image related to cracked leather

How Does Cracked Leather Enhance Home Decor?

In home decor, cracked leather is valued for its ability to add character and vintage appeal to decorative items. This application can transform ordinary spaces into stylish environments, making it a sought-after material for interior designers and decorators. B2B buyers should focus on sourcing from reliable suppliers to ensure quality and variety in color options. Additionally, understanding the maintenance requirements of cracked leather can help in making informed sourcing decisions that align with customer expectations.

3 Common User Pain Points for ‘cracked leather’ & Their Solutions

Scenario 1: Deteriorating Product Quality Due to Cracked Leather

The Problem: B2B buyers in industries such as fashion, furniture, and automotive often face the challenge of sourcing leather products that meet quality standards. Cracked leather not only detracts from the aesthetic appeal of a product but also raises concerns about durability and longevity. Buyers may find themselves in a position where they have to return or discount products due to visible damage, leading to financial losses and reputational harm. Moreover, sourcing replacement materials can be time-consuming and costly, especially if the leather is integral to the brand’s identity.

The Solution: To mitigate the risks associated with cracked leather, it’s vital for buyers to establish robust quality control measures at the sourcing stage. This includes selecting suppliers who provide leather with a history of durability and resilience. Buyers should request samples and conduct thorough inspections to identify potential weaknesses. Additionally, employing a comprehensive leather conditioning and maintenance program can help prolong the life of leather products. This involves advising end-users on regular conditioning routines and providing high-quality leather care products as part of the sales package, which can enhance customer satisfaction and minimize returns.

Illustrative image related to cracked leather

Scenario 2: Increased Customer Complaints Due to Cracked Leather

The Problem: In the retail sector, particularly for businesses that sell high-end leather goods, customer satisfaction is paramount. When customers receive products with cracked leather, it leads to complaints, returns, and potential loss of brand loyalty. This not only affects sales but also requires additional resources for handling returns and customer service inquiries. The challenge is heightened in regions where climate conditions can exacerbate leather deterioration, such as high humidity or extreme dryness, making it crucial for retailers to ensure the quality of leather products they sell.

The Solution: Retailers can address this issue by implementing a proactive customer education strategy. This includes providing detailed care instructions with each leather product sold. Furthermore, collaborating with manufacturers to develop climate-resilient leather can significantly reduce the incidence of cracks. Buyers should also consider investing in training programs for staff to identify early signs of leather wear and educate customers on preventive measures, such as proper storage and maintenance. By fostering a culture of care and providing quality products, businesses can enhance customer satisfaction and loyalty.

Scenario 3: Supply Chain Disruptions from Cracked Leather Issues

The Problem: B2B buyers often rely on a complex supply chain for sourcing leather products. When issues such as cracked leather arise during production or shipping, it can lead to significant delays and disruptions. This not only affects inventory levels but also compromises the ability to meet customer demand, resulting in lost sales opportunities and strained relationships with clients. Buyers may struggle to find quick replacements, particularly if they are dealing with specialized leather types that have longer lead times.

The Solution: To counteract supply chain disruptions caused by cracked leather, buyers should prioritize building strong relationships with multiple suppliers. This diversification allows for quicker sourcing alternatives when issues arise. Additionally, implementing a rigorous quality assurance process during production can help catch cracks before products are shipped. Buyers should also consider investing in technology that allows for real-time tracking of product conditions during transit, such as climate-controlled shipping containers. By proactively managing the supply chain and ensuring consistent quality, businesses can minimize disruptions and maintain a steady flow of products to their customers.

Strategic Material Selection Guide for cracked leather

What Are the Key Materials Used in Cracked Leather Repair?

When dealing with cracked leather, selecting the right materials for repair and maintenance is crucial for ensuring durability and aesthetic appeal. Below, we analyze several common materials used in the repair of cracked leather, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to cracked leather

Which Leather Conditioners Are Effective for Repairing Cracked Leather?

Leather conditioners are formulated to penetrate the leather fibers, restoring moisture and flexibility.

- Key Properties: High-quality conditioners often contain natural oils, waxes, and emulsions that nourish the leather. They typically have a temperature resistance suitable for indoor and outdoor applications, ensuring they do not degrade under varying environmental conditions.

- Pros & Cons: These products are generally easy to apply and can significantly improve the appearance of light cracks. However, they may not be effective for deep cracks, and frequent application is necessary to maintain leather health, which can add to long-term costs.

- Impact on Application: Conditioners are compatible with most leather types but may not work well with synthetic leathers or heavily treated surfaces.

- Considerations for International Buyers: Different regions may have varying preferences for natural versus synthetic conditioners. Compliance with local regulations regarding chemical content is essential, especially in regions like Europe where stringent standards exist.

How Do Leather Fillers Function in Repairing Deep Cracks?

Leather fillers are used to fill and seal deep cracks, restoring the leather’s surface.

- Key Properties: These fillers are typically made from polymers and resins, providing a flexible yet durable finish. They can withstand pressure and temperature variations, making them suitable for items like bags and furniture.

- Pros & Cons: Fillers can effectively restore the structural integrity of cracked leather, but they require careful application and drying time. They may also be more expensive than other repair options and can complicate the repair process if not applied correctly.

- Impact on Application: Fillers are best used on genuine leather and may not adhere well to synthetic materials, limiting their application.

- Considerations for International Buyers: Buyers should ensure that fillers meet local safety standards and are compatible with the leather types prevalent in their markets. For instance, compliance with ASTM or DIN standards can be crucial in Europe.

What Role Do Leather Dyes Play in Enhancing Cracked Leather?

Leather dyes are often used in conjunction with fillers to restore color and appearance to repaired areas.

- Key Properties: Dyes are available in various formulations, including water-based and solvent-based options. They typically offer good adhesion and colorfastness, ensuring longevity of the repair.

- Pros & Cons: Dyes can effectively mask imperfections and enhance the overall appearance of leather. However, they may require multiple applications for even coverage, and improper application can lead to uneven coloring.

- Impact on Application: Dyes are suitable for both genuine and synthetic leather, although the results may vary based on the leather’s finish.

- Considerations for International Buyers: Buyers should be aware of the environmental regulations regarding dye usage in their countries. For example, some dyes may not comply with EU REACH regulations, which could restrict their use in certain markets.

How Important Are Leather Sealants in Protecting Repaired Areas?

Leather sealants are critical for protecting repaired areas from future damage.

- Key Properties: Sealants create a protective barrier that resists moisture and stains. They are typically designed to withstand various environmental conditions, including UV exposure.

- Pros & Cons: Sealants enhance the longevity of repairs and help maintain the leather’s appearance. However, they can alter the texture of the leather if not applied carefully, and some may require reapplication over time.

- Impact on Application: Sealants are compatible with most leather types but should be tested on a small area first to ensure compatibility.

- Considerations for International Buyers: Buyers should consider local climate conditions, as sealants may perform differently in humid versus dry environments. Additionally, ensuring compliance with local chemical regulations is crucial.

Summary Table of Material Selection for Cracked Leather Repair

| Material | Typical Use Case for Cracked Leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather Conditioner | Surface repair for light cracks | Easy application and improves appearance | Not effective for deep cracks; frequent use needed | Medium |

| Leather Filler | Repair for deep cracks | Restores structural integrity | Requires careful application; higher cost | High |

| Leather Dye | Color restoration post-repair | Effective for masking imperfections | May require multiple applications; uneven results | Medium |

| Leather Sealant | Protection of repaired areas | Enhances longevity and appearance | Can alter texture; may need reapplication | Medium |

This strategic material selection guide provides essential insights for B2B buyers in various regions, enabling informed decisions when addressing cracked leather issues.

In-depth Look: Manufacturing Processes and Quality Assurance for cracked leather

What Are the Key Stages in the Manufacturing Process of Cracked Leather?

The production of cracked leather involves several critical stages, ensuring that the final product maintains both aesthetic appeal and functional integrity. Understanding these stages can help B2B buyers make informed decisions when sourcing leather goods.

Illustrative image related to cracked leather

1. Material Preparation: How Is the Raw Leather Processed?

The journey of cracked leather begins with the selection of high-quality animal hides, which are typically sourced from cattle, sheep, or goats. The hides undergo a rigorous preparation process that includes:

- Cleaning and Soaking: Fresh hides are cleaned to remove any blood, hair, and other organic materials. Soaking in water rehydrates the skin, making it pliable for further processing.

- Tanning: This crucial step replaces the natural moisture with tanning agents, preserving the leather’s structure. Common methods include vegetable tanning, which uses natural materials, and chrome tanning, which employs chemical agents. The choice of tanning affects the leather’s flexibility and durability.

- Conditioning: After tanning, the leather is treated with oils and waxes to enhance its suppleness. This step is vital for preventing future cracking, as it adds moisture back into the leather fibers.

2. Forming: What Techniques Are Used to Shape Leather?

Once the leather is prepared, it is cut and shaped into the desired product. Key techniques during this stage include:

- Cutting: Leather is cut into specific shapes using dies or patterns. Precision is essential to ensure that the pieces fit together seamlessly during assembly.

- Stitching: Skilled artisans or machines stitch the leather pieces together. High-quality stitching techniques, such as saddle stitching, are often employed to ensure durability and prevent seams from splitting.

- Molding: Some products may require molding to achieve specific shapes. Heat and moisture are applied to the leather to create a tailored fit.

3. Assembly: How Are Different Components Joined Together?

The assembly stage involves combining various components, such as linings, zippers, and hardware. Attention to detail is critical here:

- Layering: Multiple layers of leather or other materials may be used to enhance strength and appearance.

- Attachment of Hardware: Zippers, buckles, and other hardware are securely attached using rivets or stitching, ensuring they withstand daily wear and tear.

4. Finishing: What Processes Enhance the Aesthetic and Protective Qualities?

The finishing process is where leather products gain their final characteristics, including color, texture, and protective coatings. Key finishing techniques include:

Illustrative image related to cracked leather

- Dyeing: Leather can be dyed to achieve various colors. This process requires expertise to ensure even coloration without compromising the leather’s natural qualities.

- Sealing: A protective sealant may be applied to enhance water resistance and durability. This step is crucial for preventing future cracking and prolonging the life of the leather.

- Polishing: Finally, the leather is polished to achieve a luxurious sheen, enhancing its visual appeal.

What Quality Assurance Measures Are Essential for Cracked Leather Products?

Quality assurance (QA) is integral to the leather manufacturing process, ensuring that products meet international standards and buyer expectations. Here’s a breakdown of the QA measures relevant to B2B buyers.

Relevant International Standards: What Should Buyers Look For?

Buyers should ensure that their suppliers comply with international quality standards. Key certifications include:

- ISO 9001: This standard focuses on quality management systems and is vital for ensuring consistent quality in manufacturing processes.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: In industries such as oil and gas, API standards may apply to leather goods used in specialized applications, ensuring durability and safety.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial inspection occurs when raw materials arrive at the facility. It ensures that hides meet specified standards for size, thickness, and quality.

- In-Process Quality Control (IPQC): During production, continuous monitoring of the manufacturing process helps identify defects early. This includes checking stitching quality, dye consistency, and assembly integrity.

- Final Quality Control (FQC): Once production is complete, a thorough inspection of the finished product is conducted. This includes visual inspections for cracks, color consistency, and overall craftsmanship.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Buyers should take proactive steps to verify their suppliers’ quality control measures:

1. Conducting Supplier Audits: What to Look For?

Regular audits of suppliers can reveal their commitment to quality. Key aspects to assess include:

- Documentation of Processes: Suppliers should maintain clear records of their manufacturing processes, including QC checkpoints and corrective actions taken.

- Employee Training: Evaluate how suppliers train their staff in quality assurance practices and leather handling techniques.

2. Requesting Quality Control Reports: What Information Is Critical?

Suppliers should provide detailed QC reports that outline:

- Test Results: Results from tests conducted on raw materials and finished products, including tensile strength, water resistance, and flexibility.

- Defect Rates: Historical data on defect rates in production can indicate a supplier’s reliability.

3. Utilizing Third-Party Inspections: How Can They Enhance Confidence?

Engaging third-party inspection services adds an extra layer of verification. These independent entities can:

- Conduct Random Sampling: Inspect a sample of products from the production line to ensure they meet specified standards.

- Provide Objective Feedback: Offer unbiased assessments of the quality of leather products, enhancing buyer confidence.

What Nuances Should International Buyers Consider in Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, there are specific nuances to consider:

Illustrative image related to cracked leather

- Cultural Differences in Quality Standards: Understanding regional differences in quality expectations can help in negotiations and setting standards.

- Logistical Challenges: Consider how transportation and storage conditions may impact leather quality. It’s essential to establish clear guidelines for handling during transit.

- Regulatory Compliance: Be aware of local regulations regarding leather products, such as chemical use and waste disposal, to avoid compliance issues.

By thoroughly understanding the manufacturing processes and quality assurance measures for cracked leather, B2B buyers can make informed decisions, ensuring they source high-quality leather products that meet their needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cracked leather’

This guide aims to provide B2B buyers with a practical checklist for sourcing cracked leather effectively. Whether for manufacturing or resale, understanding the nuances of cracked leather can enhance procurement decisions, ensuring quality and sustainability.

Step 1: Identify Your Requirements

Before initiating the procurement process, clearly define your needs regarding the type of cracked leather. Consider the specific applications, such as fashion accessories, furniture, or automotive interiors. This clarity will help you communicate effectively with suppliers and ensure that the leather meets your functional and aesthetic expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in cracked leather. Look for companies with a proven track record in the leather industry and positive reviews from other B2B buyers. Utilize platforms like trade directories and industry forums to gather insights and recommendations.

Illustrative image related to cracked leather

- Tip: Focus on suppliers located in regions known for quality leather production, such as Italy or Brazil.

Step 3: Evaluate Supplier Certifications

Verify the certifications and standards that suppliers adhere to, such as ISO certifications or compliance with environmental regulations. These certifications can indicate the quality of the leather and the ethical practices of the supplier.

- Consider: Certifications that ensure sustainable sourcing and animal welfare can enhance your brand’s reputation and align with consumer preferences.

Step 4: Request Samples for Quality Assessment

Always request samples of the cracked leather before making bulk purchases. This step allows you to evaluate the texture, color, and overall quality. Inspect the samples for consistency in color and the extent of cracking to ensure they meet your standards.

- Check for: Uniformity in the crack patterns and the leather’s response to conditioning treatments, as these factors will affect the final product.

Step 5: Negotiate Pricing and Terms

Engage in discussions with your selected suppliers to negotiate pricing, payment terms, and delivery schedules. Be prepared to discuss your volume needs and any long-term partnership opportunities, as this can influence pricing strategies.

- Advice: Ensure you understand all costs involved, including shipping and potential tariffs, especially when sourcing internationally.

Step 6: Assess After-Sales Support and Warranty

Inquire about after-sales support and any warranty options offered by the supplier. A reliable supplier should provide guidance on maintaining and repairing cracked leather, which can be crucial for your end customers.

- Look for: Detailed care instructions and availability of conditioning products to ensure longevity and maintain the leather’s appearance.

Step 7: Establish a Long-Term Relationship

Once you have successfully sourced cracked leather, consider establishing a long-term relationship with your supplier. This can lead to better pricing, priority service, and access to exclusive products.

- Tip: Regularly communicate with your supplier about market trends and your evolving needs, fostering a partnership that benefits both parties.

By following these steps, B2B buyers can navigate the complexities of sourcing cracked leather with greater confidence, ensuring they procure high-quality materials that meet their business objectives.

Illustrative image related to cracked leather

Comprehensive Cost and Pricing Analysis for cracked leather Sourcing

What Are the Key Cost Components in Cracked Leather Sourcing?

When sourcing cracked leather, understanding the cost structure is essential for B2B buyers. The main cost components include:

-

Materials: The type of leather significantly impacts the cost. Vegetable-tanned leathers, known for their durability and quality, generally come at a higher price point compared to lower-grade alternatives. Sourcing from regions with a strong leather industry, such as Italy or Brazil, can also influence material costs.

-

Labor: Labor costs vary by region. Countries with lower labor costs may offer cheaper options, but quality can be compromised. Skilled labor is essential for the intricate processes involved in repairing and treating cracked leather, which can increase overall costs.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses. Factories with modern equipment and efficient processes may have higher overhead but can produce better quality leather, leading to potential cost savings in the long run.

-

Tooling: The initial investment in tools and machinery for leather treatment and repair can be substantial. However, well-maintained tools can enhance production efficiency and product quality, ultimately affecting the pricing structure.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the leather meets the desired specifications. This can add to the cost but is crucial for maintaining brand reputation, especially in markets that prioritize quality.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and current fuel prices. Buyers should consider the total logistics costs when evaluating suppliers, particularly for international sourcing.

-

Margin: Suppliers typically add a margin on top of their costs. This margin can fluctuate based on market demand, competition, and the supplier’s positioning in the market.

What Price Influencers Should B2B Buyers Be Aware Of?

Several factors can influence the pricing of cracked leather:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically reduce the per-unit cost. Buyers should negotiate MOQs to achieve better pricing and consider the impact of bulk purchasing on overall logistics.

-

Specifications and Customization: Custom treatments or specifications can raise costs. Buyers should be clear about their requirements and explore the cost implications of customization versus standard offerings.

-

Material Quality and Certifications: Higher quality materials often come with certifications that validate their provenance and sustainability. These certifications can justify a higher price but are essential for maintaining quality standards.

-

Supplier Factors: The supplier’s reputation, reliability, and past performance can affect pricing. Established suppliers may charge more, but they often offer better quality assurance.

-

Incoterms: Understanding shipping terms is vital. Incoterms determine who is responsible for costs and risks at various points in the shipping process, which can impact the total cost.

How Can Buyers Negotiate for Cost-Efficiency?

To achieve cost-efficiency in sourcing cracked leather, buyers should consider the following tips:

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing, especially for repeat orders. Regular communication and transparency can foster trust and collaboration.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the upfront cost, consider the TCO, which includes maintenance, repair, and potential resale value. High-quality leather may have a higher initial cost but can save money in the long term.

-

Research Market Trends: Stay informed about market fluctuations and trends. Understanding when to buy can help buyers take advantage of price dips or promotional offers.

-

Be Prepared to Walk Away: Having alternative suppliers in mind can strengthen negotiating positions. If a supplier is unwilling to meet cost expectations, being ready to explore other options can lead to better deals.

What Are the Pricing Nuances for International Buyers?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, several pricing nuances must be considered:

-

Currency Fluctuations: Exchange rates can significantly impact costs. Buyers should factor in potential currency risks when negotiating contracts.

-

Import Duties and Taxes: Be aware of any import duties or taxes that may apply, as these can add to the overall cost of sourcing leather.

-

Cultural Considerations: Understanding cultural differences in negotiation styles can enhance communication and lead to better outcomes.

Disclaimer on Indicative Prices

Prices for cracked leather sourcing can vary widely based on the factors mentioned above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing aligned with their specific needs.

Illustrative image related to cracked leather

Alternatives Analysis: Comparing cracked leather With Other Solutions

Introduction: Understanding Alternatives in Leather Solutions

When it comes to addressing the issue of cracked leather, B2B buyers must consider various alternatives that can provide comparable aesthetics and functionality. Alternatives may involve different materials, technologies, or methods that can either prevent cracking or restore leather to its original condition. This analysis will explore viable options to help businesses make informed decisions based on performance, cost, and ease of implementation.

Comparison Table

| Comparison Aspect | Cracked Leather | Synthetic Leather | Vinyl Leather |

|---|---|---|---|

| Performance | High-quality appearance but suffers from durability issues due to cracking | Excellent durability and resistance to wear | Good durability but less breathable than leather |

| Cost | High initial investment with potential restoration costs | Generally lower cost than genuine leather | Typically the lowest cost option |

| Ease of Implementation | Requires specialized repair techniques and products | Readily available and easy to manufacture | Easy to clean and maintain, no special treatments needed |

| Maintenance | Regular conditioning needed to prevent further damage | Minimal maintenance required | Low maintenance, but may require occasional cleaning |

| Best Use Case | Luxury items where aesthetics are paramount | Everyday use items like bags and shoes | Budget-conscious products or temporary applications |

Detailed Breakdown of Alternatives

Synthetic Leather

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), provides an excellent alternative to cracked leather. Its durability and resistance to wear make it suitable for a wide range of applications, from fashion accessories to furniture. The primary advantage of synthetic leather is its lower cost compared to genuine leather, making it an attractive option for businesses looking to minimize expenses. However, while synthetic leather can mimic the look and feel of real leather, it may lack the same level of breathability, leading to discomfort in warmer climates.

Vinyl Leather

Vinyl leather is another cost-effective alternative that offers a sleek appearance and substantial durability. It is especially popular in industries where affordability is a priority, such as in the production of budget-friendly goods or temporary applications. Vinyl is easy to clean and maintain, requiring little more than a damp cloth for upkeep. However, it is important to note that vinyl leather may not deliver the same luxurious feel and appearance as cracked leather, which could deter buyers seeking high-end products.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, selecting the appropriate leather solution hinges on understanding the specific requirements of their target market. If the focus is on luxury and aesthetics, investing in high-quality leather with proper maintenance may be worthwhile, despite the potential for cracking. Conversely, if cost-effectiveness and durability are paramount, synthetic or vinyl leather presents viable alternatives that can meet the demands of everyday use. Ultimately, evaluating factors such as performance, cost, and maintenance will guide businesses in making the best choice tailored to their customer needs.

Illustrative image related to cracked leather

Essential Technical Properties and Trade Terminology for cracked leather

What Are the Key Technical Properties of Cracked Leather?

Understanding the technical properties of cracked leather is essential for B2B buyers to make informed decisions. Here are some critical specifications:

1. Material Grade

Material grade refers to the quality classification of leather based on its source and processing. Higher grades indicate fewer imperfections and better durability. In the context of cracked leather, knowing the material grade helps buyers assess the potential for restoration and longevity. For example, vegetable-tanned leather typically offers better repairability compared to lower-grade, corrected grain leathers.

2. Crack Depth and Width

This specification measures the severity of cracks within the leather. Crack depth can be classified as light (surface-level) or deep (affecting the structural integrity). Understanding these dimensions is vital for selecting appropriate repair techniques and products, such as conditioners or fillers. Buyers must consider these factors to determine whether the leather can be effectively restored or needs to be replaced.

3. Flexibility and Softness

Flexibility refers to how easily leather can bend without breaking, while softness relates to its tactile feel. Cracked leather may lose both properties, indicating a need for conditioning treatments. B2B buyers should evaluate these characteristics to ensure the leather meets their end-use requirements, whether for fashion goods or functional items like bags and upholstery.

4. Moisture Content

Moisture content is crucial for leather’s flexibility and overall health. High moisture levels can lead to mold, while low levels can cause cracking. Buyers should inquire about the moisture treatment processes used in leather production. This knowledge aids in assessing the leather’s potential durability and the effectiveness of any restoration efforts.

5. Durability Rating

This rating indicates how well the leather can withstand wear and tear over time. A durable leather will resist cracking and other forms of damage. B2B buyers can use this information to make decisions regarding product lifecycle and warranty offerings, ensuring that they source materials that meet their performance expectations.

What Are Common Trade Terms Related to Cracked Leather?

Familiarity with industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In leather goods, OEMs may provide finished products or components that require specific properties, such as crack resistance or repairability.

2. MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers, as it affects inventory management and cost considerations. For cracked leather products, MOQs can vary based on the quality and treatment processes involved.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products. This is especially relevant in the leather industry, where variations in quality and treatment can lead to significant price differences. A well-defined RFQ can help buyers secure competitive pricing for cracked leather materials.

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of sellers and buyers in international transactions. Knowledge of Incoterms is crucial for buyers sourcing cracked leather globally, as they determine who bears the risk and costs during shipping.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This is particularly important in the leather industry, where the processing of cracked leather for repair or manufacturing can vary. Understanding lead time helps buyers plan their inventory and production schedules effectively.

Illustrative image related to cracked leather

By grasping these essential technical properties and trade terms, B2B buyers can make more informed purchasing decisions, ensuring they source the right cracked leather products for their needs.

Navigating Market Dynamics and Sourcing Trends in the cracked leather Sector

What Are the Current Market Dynamics and Key Trends in the Cracked Leather Sector?

The cracked leather market is witnessing significant evolution, driven by a blend of economic and consumer behavior changes. As global demand for leather goods continues to rise, particularly in emerging markets in Africa, South America, the Middle East, and Europe, there is a corresponding increase in the need for high-quality leather products. Buyers are increasingly seeking durable materials that can withstand the rigors of daily use while maintaining aesthetic appeal. A notable trend is the shift towards premium, vegetable-tanned leathers, which offer both luxury and longevity, appealing to discerning consumers who value craftsmanship.

Technological advancements are also shaping the sourcing landscape. Innovations in leather treatment and repair technologies, such as eco-friendly conditioners and fillers, are becoming essential for maintaining product quality. B2B buyers are now more inclined to partner with suppliers who offer comprehensive solutions for leather care, reflecting a growing awareness of product lifecycle management. Additionally, e-commerce platforms are facilitating direct sourcing, allowing buyers from regions like Nigeria and Vietnam to connect with suppliers globally, thereby enhancing market accessibility.

Another key trend is the rise of customization and personalization in leather products. Buyers are increasingly looking for unique offerings that reflect their brand identity or personal style, which opens opportunities for suppliers to innovate in their product lines. The demand for cracked leather items, such as bags and furniture, is also being fueled by a growing trend for vintage and distressed aesthetics, which allows suppliers to cater to diverse consumer preferences.

How Is Sustainability and Ethical Sourcing Impacting the Cracked Leather Industry?

Sustainability is becoming a cornerstone of the cracked leather sector, as environmental concerns drive both consumer and corporate behavior. The tanning process, traditionally resource-intensive and often harmful to the environment, is undergoing scrutiny. Buyers are increasingly prioritizing suppliers who adhere to sustainable practices, such as using biodegradable tanning agents and recycling water in production processes. This shift not only mitigates environmental impact but also aligns with the values of ethically conscious consumers.

Illustrative image related to cracked leather

The importance of ethical supply chains cannot be overstated. B2B buyers are now more vigilant about the sourcing practices of their suppliers, seeking transparency and accountability. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are gaining traction, serving as benchmarks for sustainable and ethical practices. These certifications assure buyers that the leather products they source are not only of high quality but also produced with respect for labor rights and environmental standards.

In addition to ethical sourcing, the use of ‘green’ materials in the production of cracked leather items is on the rise. Organic dyes, plant-based conditioners, and recycled materials are increasingly being incorporated into leather production, appealing to a market that values sustainability. By aligning with these trends, B2B buyers can enhance their brand reputation and appeal to a growing segment of eco-conscious consumers.

How Has the Cracked Leather Market Evolved Over Time?

The cracked leather market has undergone significant transformation over the decades. Historically, leather was viewed primarily as a luxury material, reserved for high-end fashion and artisanal goods. However, the advent of mass production and globalization has democratized access to leather products, making them more widely available across various price points and applications.

In recent years, the market has shifted towards sustainability and ethical practices, reflecting broader societal changes. Buyers are no longer just concerned with the aesthetics and functionality of leather; they are also considering the environmental and ethical implications of their purchases. This evolution has led to a resurgence of interest in traditional tanning techniques and natural treatments, as consumers seek products that align with their values.

As the market continues to evolve, international B2B buyers will need to stay attuned to these trends, ensuring that their sourcing strategies reflect both current consumer preferences and emerging sustainability standards. By doing so, they can position themselves favorably in a competitive landscape while contributing to a more responsible leather industry.

Illustrative image related to cracked leather

Frequently Asked Questions (FAQs) for B2B Buyers of cracked leather

-

How do I repair cracked leather products?

Repairing cracked leather involves assessing the severity of the damage. For light cracks, a high-quality leather conditioner can restore moisture and flexibility. Clean the leather first, then apply the conditioner and allow it to absorb. For deeper cracks, use a leather crack filler followed by dye to blend the repaired area with the rest of the leather. Ensure proper drying conditions to avoid further damage. Regular maintenance, including conditioning, can prevent future cracking. -

What is the best leather conditioner for cracked leather?

The best leather conditioner for cracked leather is one that contains natural oils and waxes, such as lanolin and carnauba wax. These ingredients help restore moisture and flexibility while providing a protective barrier. Look for products specifically designed for the type of leather you are working with, as different leather types may require different formulations. Regular application of a high-quality conditioner can significantly extend the life of your leather products. -

What are the common causes of leather cracking?

Leather cracking is typically caused by a loss of moisture due to environmental factors like heat, sunlight, and low humidity. Over time, the natural oils in leather diminish, leading to stiff fibers that can crack under stress. Poor storage conditions, lack of maintenance, and exposure to harsh chemicals can also contribute to the deterioration of leather. Understanding these factors is crucial for effective prevention and maintenance strategies. -

How can I verify the quality of cracked leather before purchasing?

To verify the quality of cracked leather, inspect the texture, flexibility, and overall appearance. High-quality leather should feel supple and have a consistent grain. Request samples to check for durability and to ensure that the leather has been properly conditioned and treated. Additionally, inquire about the sourcing and tanning process, as these factors significantly affect quality. Establishing a relationship with reputable suppliers can also provide assurance of quality. -

What is the minimum order quantity (MOQ) for cracked leather?

Minimum order quantities for cracked leather can vary significantly based on the supplier and the type of leather. Many suppliers may set MOQs ranging from 50 to 500 square feet, depending on their production capabilities and inventory. It’s advisable to discuss your specific needs with potential suppliers to negotiate favorable terms. Understanding the MOQ is essential for budgeting and planning your inventory effectively. -

What payment terms should I expect when sourcing cracked leather internationally?

Payment terms for international sourcing of cracked leather typically include options like advance payment, letter of credit, or partial payments upon shipment. Common practices involve a 30% deposit with the balance due before shipment or upon delivery. It’s essential to clarify these terms upfront to avoid misunderstandings. Consider using secure payment methods and ensure that all terms are documented in the purchase agreement to protect your interests. -

How can I ensure quality assurance (QA) for cracked leather shipments?

To ensure quality assurance for cracked leather shipments, establish clear quality standards with your supplier before production. Implement a thorough inspection process, which may include pre-shipment inspections or third-party quality checks. Request detailed product specifications and samples before finalizing orders. Additionally, consider using contracts that specify QA measures, allowing for returns or replacements if the leather does not meet agreed-upon standards. -

What are the logistics considerations when importing cracked leather?

Logistics considerations for importing cracked leather include understanding shipping methods, customs regulations, and potential tariffs. Choose reliable freight forwarders experienced in handling leather products to ensure safe and timely delivery. Familiarize yourself with import duties and documentation required by customs in your country. Efficient logistics management is crucial for minimizing delays and costs associated with international shipping. Always factor in lead times when planning your inventory replenishment.

Top 4 Cracked Leather Manufacturers & Suppliers List

1. Carl Friedrik – Leather Cream

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: Carl Friedrik Leather Cream is a luxurious blend of oils, wax emulsions, and softeners designed to nourish and maintain leather. Key ingredients include carnauba wax, known for its shine and hypoallergenic properties, and lanolin, which locks in moisture and prevents water loss.

2. Bick 4 – Conditioner

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Bick 4 conditioner, Saphir Renovateur, Pommadier Cream Polish, Huberds, Obenauf, Nikwax, Moore’s leather dressing, olive oil.

3. Buffalo Jackson – Cracked Leather Repair Guide

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Cracked Leather Repair: A guide to restoring cracked leather items. Key steps include: 1. Cleaning the leather with a soft brush and leather cleaner or saddle soap. 2. Smoothing the cracks with mink oil or neatsfoot oil. 3. Treating the leather with a conditioner to maintain its quality. Regular conditioning is recommended to prevent future cracking.

4. Leatherworker – Ecoflow Pro Dye 8oz Leather

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: 8oz leather, Ecoflow dye, alcohol-based Pro Dye, rifle case for a saddle, 1.5″ strap

Strategic Sourcing Conclusion and Outlook for cracked leather

As the global demand for high-quality leather continues to rise, understanding the nuances of cracked leather is essential for international B2B buyers. Strategic sourcing plays a pivotal role in ensuring that your supply chain not only delivers premium materials but also provides effective solutions for leather maintenance and repair. By prioritizing suppliers who offer quality leather care products and repair services, businesses can enhance their product longevity, reduce waste, and maximize their investments.

Investing in preventative measures, such as quality conditioners and proper storage techniques, is crucial in mitigating the risks associated with leather cracking. Furthermore, understanding the repair processes—from light surface treatments to deep crack restoration—empowers buyers to take proactive steps in maintaining their inventory.

Looking ahead, the market for cracked leather presents opportunities for innovation and collaboration. B2B buyers, particularly from emerging markets in Africa, South America, the Middle East, and Europe, should leverage this knowledge to forge partnerships with suppliers who prioritize quality and sustainability. Embrace these insights, and position your business at the forefront of the leather industry’s future. Take action today to secure reliable sourcing and elevate your leather offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.