Introduction: Navigating the Global Market for leather manufacturers in usa

In the competitive landscape of global sourcing, finding reliable leather manufacturers in the USA can be a significant challenge for international B2B buyers. With increasing demand for high-quality leather goods across various industries, from fashion to automotive, understanding the nuances of the American leather market is crucial for making informed purchasing decisions. This guide serves as a comprehensive resource, covering the diverse types of leather products available, their applications, and essential insights into supplier vetting processes.

By examining factors such as production capabilities, pricing structures, and quality assurance practices, this guide empowers buyers from regions like Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Germany—to navigate their sourcing journey with confidence. Additionally, it addresses common concerns such as ethical sourcing and compliance with international standards, ensuring that buyers can align their procurement strategies with their corporate values and market demands.

Through this detailed exploration, you will gain valuable insights that not only facilitate better negotiations but also enhance your overall supply chain efficiency. Whether you are looking for bespoke leather products or bulk supplies, this guide is designed to equip you with the knowledge necessary to engage effectively with manufacturers and secure the best possible outcomes for your business.

Table Of Contents

- Top 6 Leather Manufacturers In Usa Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather manufacturers in usa

- Understanding leather manufacturers in usa Types and Variations

- Key Industrial Applications of leather manufacturers in usa

- 3 Common User Pain Points for ‘leather manufacturers in usa’ & Their Solutions

- Strategic Material Selection Guide for leather manufacturers in usa

- In-depth Look: Manufacturing Processes and Quality Assurance for leather manufacturers in usa

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather manufacturers in usa’

- Comprehensive Cost and Pricing Analysis for leather manufacturers in usa Sourcing

- Alternatives Analysis: Comparing leather manufacturers in usa With Other Solutions

- Essential Technical Properties and Trade Terminology for leather manufacturers in usa

- Navigating Market Dynamics and Sourcing Trends in the leather manufacturers in usa Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather manufacturers in usa

- Strategic Sourcing Conclusion and Outlook for leather manufacturers in usa

- Important Disclaimer & Terms of Use

Understanding leather manufacturers in usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Grain Leather Manufacturers | Use the highest quality hides with natural grain intact | Luxury goods, high-end fashion, upholstery | Pros: Superior durability and aesthetics. Cons: Higher cost. |

| Suede Leather Manufacturers | Create soft, napped leather with a velvety finish | Apparel, footwear, and accessories | Pros: Unique texture and appearance. Cons: Less durable than full-grain leather. |

| Synthetic Leather Manufacturers | Produce eco-friendly alternatives to natural leather | Fashion, automotive interiors, furniture | Pros: Cost-effective and versatile. Cons: Often less breathable than natural leather. |

| Vegetable-Tanned Leather Makers | Use natural tannins for a more environmentally friendly process | Crafting, high-end bags, and belts | Pros: Eco-friendly and develops a patina. Cons: Requires more care and maintenance. |

| Chrome-Tanned Leather Suppliers | Utilize chemical tanning for faster production | Mass production of bags, shoes, and accessories | Pros: Quick production and uniformity. Cons: Environmental concerns and potential toxicity. |

What Are the Characteristics of Full-Grain Leather Manufacturers?

Full-grain leather manufacturers focus on producing leather from the top layer of the hide, which retains the natural grain. This type of leather is known for its durability and breathability, making it ideal for luxury goods such as high-end handbags and furniture. B2B buyers should consider the long-term investment, as full-grain leather products often age beautifully, developing a rich patina. However, the premium quality comes with a higher price point, making it essential for buyers to assess their budget against the desired quality.

Illustrative image related to leather manufacturers in usa

How Do Suede Leather Manufacturers Differ?

Suede leather manufacturers specialize in creating leather with a soft, napped finish, offering a unique aesthetic appeal. Suede is popular in apparel, footwear, and accessories, appealing to buyers looking for stylish and comfortable products. While suede provides a distinctive look, it is generally less durable than full-grain leather and requires careful maintenance to prevent staining and damage. B2B buyers should weigh the trade-offs between appearance and longevity when sourcing suede products.

What Should B2B Buyers Know About Synthetic Leather Manufacturers?

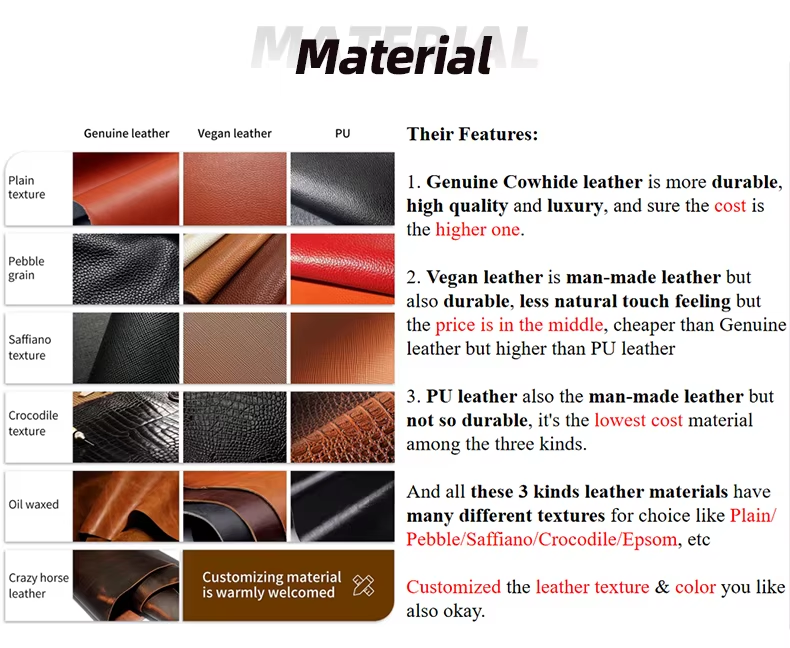

Synthetic leather manufacturers offer cost-effective alternatives to natural leather, appealing to a wide range of industries including fashion and automotive. These products are often made from polyurethane (PU) or polyvinyl chloride (PVC), providing versatility in design and application. While synthetic leather can mimic the appearance of natural leather, it may lack breathability and durability. B2B buyers should consider the intended use and lifecycle of the product to ensure synthetic options meet their needs.

Why Choose Vegetable-Tanned Leather Makers?

Vegetable-tanned leather makers use natural tannins derived from plants, offering an eco-friendly option for leather goods. This method produces leather that is not only sustainable but also develops a unique character over time. Suitable for crafting high-end bags and belts, vegetable-tanned leather appeals to environmentally conscious buyers. However, it requires more maintenance to preserve its quality. B2B buyers should assess their target market’s values and preferences when considering vegetable-tanned options.

What Are the Benefits of Working with Chrome-Tanned Leather Suppliers?

Chrome-tanned leather suppliers utilize chemical processes for rapid tanning, resulting in a product that is consistent in quality and color. This type of leather is widely used in mass production for bags, shoes, and various accessories. While chrome-tanned leather is often more affordable and available in a wide range of colors, there are environmental concerns associated with the tanning process. B2B buyers should evaluate their sustainability goals when considering chrome-tanned products to align with their brand values.

Key Industrial Applications of leather manufacturers in usa

| Industry/Sector | Specific Application of Leather Manufacturers in USA | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior Upholstery and Trim | Enhances vehicle aesthetics and comfort | Quality of leather, durability, customization options |

| Fashion and Accessories | Handcrafted Leather Goods (bags, wallets, belts) | Offers unique, high-quality products that stand out | Sourcing sustainable materials, design flexibility |

| Furniture | Upholstery for Sofas and Chairs | Provides durability and luxury, appealing to high-end markets | Leather grades, color matching, fire retardant treatments |

| Medical | Protective Leather Gear for Healthcare Workers | Ensures safety and compliance with industry standards | Compliance with health regulations, ease of maintenance |

| Sporting Goods | Leather Equipment (gloves, balls, protective gear) | Enhances performance and durability in sports applications | Weight, grip, and moisture resistance properties |

How are Leather Manufacturers in the Automotive Sector Meeting Demand?

Leather manufacturers in the automotive industry focus on producing high-quality upholstery and trim materials that enhance both the aesthetic appeal and comfort of vehicles. These manufacturers address challenges such as durability and maintenance, ensuring that their products can withstand wear and tear while providing a luxurious feel. International buyers, particularly from regions like Africa and the Middle East, should consider the leather’s quality, customization options, and compliance with local automotive standards when sourcing.

Illustrative image related to leather manufacturers in usa

What Role Does Leather Play in Fashion and Accessories?

In the fashion and accessories sector, leather manufacturers in the USA are renowned for their handcrafted goods, including bags, wallets, and belts. These products are not only stylish but also durable, appealing to consumers seeking unique items. Buyers from Europe and South America should prioritize sustainable sourcing practices and the ability to customize designs to meet local market trends, ensuring their products resonate with their target audience.

How is Leather Used in Furniture Upholstery?

Leather’s application in furniture involves creating upholstery for sofas and chairs, where it serves to provide both durability and an upscale look. Manufacturers cater to high-end markets, where quality and aesthetics are paramount. Buyers should focus on the grade of leather, available colors, and whether the leather meets fire safety regulations, particularly in regions with strict compliance standards, such as Germany.

What Are the Applications of Leather in the Medical Field?

In the medical industry, leather manufacturers supply protective gear designed for healthcare workers, such as gloves and aprons. These products are essential for ensuring safety and compliance with health regulations. International buyers must consider the ease of maintenance and the materials’ compliance with health standards, especially in regions where healthcare regulations are stringent.

Illustrative image related to leather manufacturers in usa

Why is Leather Important in Sporting Goods?

Leather is widely used in sporting goods, particularly for items like gloves, balls, and protective gear. Manufacturers focus on creating products that enhance performance through durability and moisture resistance. Buyers should evaluate the weight, grip, and specific performance requirements of the leather products, ensuring they meet the needs of athletes and sports enthusiasts in their respective markets.

3 Common User Pain Points for ‘leather manufacturers in usa’ & Their Solutions

Scenario 1: Difficulty in Quality Assurance for Leather Products

The Problem: B2B buyers often face significant challenges when it comes to ensuring the quality of leather products from manufacturers. Leather varies widely in terms of type, grade, and finish, making it difficult to determine if the materials meet their specific requirements. This issue is exacerbated when dealing with international suppliers, where variations in standards and practices can lead to discrepancies in product quality. Buyers may receive shipments that do not match their specifications, resulting in wasted resources and potential damage to their business reputation.

The Solution: To effectively manage quality assurance, B2B buyers should implement a comprehensive sourcing strategy that includes thorough vetting of potential manufacturers. Begin by requesting samples of the leather products to evaluate the quality firsthand. Establish clear specifications that outline the required leather type, finish, and any additional treatments (such as waterproofing or colorfastness). Utilize third-party quality control services to conduct inspections during production and prior to shipment. This proactive approach not only mitigates risks but also fosters a collaborative relationship with the manufacturer, ensuring both parties are aligned on quality expectations.

Scenario 2: Long Lead Times and Supply Chain Delays

The Problem: One common frustration for B2B buyers is the long lead times associated with leather manufacturing. Many manufacturers may struggle with supply chain delays due to factors such as sourcing raw materials, production bottlenecks, or shipping issues. This can lead to missed deadlines, which may jeopardize contracts or product launches, especially in competitive markets. Buyers need to be able to depend on timely deliveries to maintain their own schedules and commitments.

The Solution: To combat lead time issues, buyers should prioritize establishing strong relationships with multiple suppliers. Diversifying the supply chain can provide flexibility and reduce dependency on a single manufacturer. Additionally, implementing just-in-time (JIT) inventory practices can help buyers align their orders more closely with production schedules, thereby minimizing excess inventory and associated costs. Regular communication with manufacturers about production timelines and potential delays is crucial. Consider utilizing technology, such as supply chain management software, to track orders and improve transparency throughout the process.

Illustrative image related to leather manufacturers in usa

Scenario 3: Navigating Compliance and Ethical Sourcing Issues

The Problem: Increasingly, B2B buyers are required to navigate complex compliance and ethical sourcing issues when dealing with leather manufacturers. Factors such as environmental regulations, labor practices, and sustainability are becoming critical to purchasing decisions. Buyers often find it challenging to assess whether their suppliers adhere to these standards, which can lead to reputational risks and regulatory penalties if not managed properly.

The Solution: To address compliance and ethical sourcing concerns, B2B buyers should develop a checklist of industry standards and certifications relevant to leather manufacturing, such as ISO certifications, leather working group standards, and environmental compliance (e.g., REACH, RoHS). Engage in discussions with potential suppliers about their sourcing practices, labor conditions, and environmental impacts. Request documentation that verifies compliance and consider conducting audits or site visits to gain firsthand insights into the manufacturing processes. By prioritizing transparency and accountability, buyers can make informed decisions that align with their corporate values and mitigate risks associated with unethical sourcing.

Strategic Material Selection Guide for leather manufacturers in usa

What Are the Key Properties of Common Leather Materials for Manufacturers in the USA?

When selecting materials for leather manufacturing, it is crucial to understand the properties and performance characteristics of the most commonly used types. This knowledge enables manufacturers to align their offerings with the specific needs of international B2B buyers.

Illustrative image related to leather manufacturers in usa

1. Vegetable-Tanned Leather

Key Properties: Vegetable-tanned leather is made using natural tannins derived from plant sources. It is known for its breathability and ability to absorb moisture, making it suitable for various applications.

Pros & Cons: This type of leather is durable and develops a rich patina over time, enhancing its aesthetic appeal. However, it can be more expensive than other tanning methods and may require more complex manufacturing processes. Additionally, it is less resistant to water and stains compared to chrome-tanned leather.

Impact on Application: Vegetable-tanned leather is ideal for products that benefit from its natural look and feel, such as belts, wallets, and bags. However, it may not be suitable for applications requiring high water resistance.

Considerations for International Buyers: Buyers from regions like Africa and South America may prefer vegetable-tanned leather for its eco-friendly properties. Compliance with international standards such as ASTM for leather quality can also influence purchasing decisions.

2. Chrome-Tanned Leather

Key Properties: Chrome-tanned leather is processed with chromium salts, resulting in a softer, more pliable material. It is known for its resistance to water, heat, and wear.

Illustrative image related to leather manufacturers in usa

Pros & Cons: This leather type is widely favored for its durability and color retention. However, the tanning process involves chemicals that may raise environmental concerns, leading to stricter regulations in some regions.

Impact on Application: Chrome-tanned leather is suitable for high-performance applications, including automotive interiors and footwear, where durability and flexibility are paramount.

Considerations for International Buyers: Buyers from Europe, particularly Germany, may require compliance with stringent environmental regulations like REACH. Understanding local preferences for leather types is essential for successful market entry.

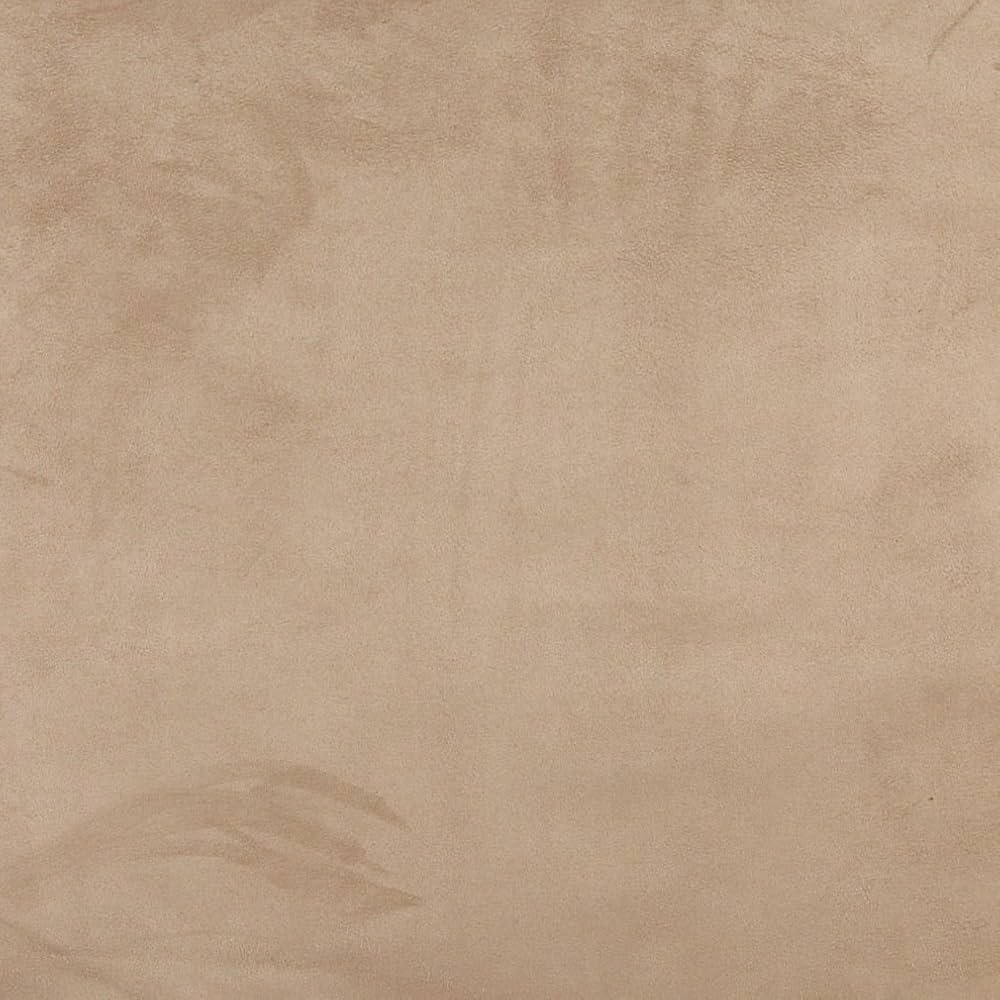

3. Suede Leather

Key Properties: Suede is made from the underside of animal hides, resulting in a soft, textured finish. It is less durable than full-grain leather but offers a unique aesthetic.

Illustrative image related to leather manufacturers in usa

Pros & Cons: Suede is lightweight and comfortable, making it popular for clothing and accessories. However, it is more susceptible to stains and requires careful maintenance, which can complicate manufacturing and end-user care.

Impact on Application: Suede is often used in fashion items, such as jackets and shoes, where its luxurious feel adds value. However, its lower durability may limit its use in more rugged applications.

Considerations for International Buyers: Buyers from the Middle East may appreciate the luxurious appeal of suede but should be aware of its maintenance requirements. Understanding regional climate conditions can also inform the suitability of suede for specific applications.

Summary Table of Common Leather Materials

| Material | Typical Use Case for leather manufacturers in usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Belts, wallets, bags | Eco-friendly and develops a rich patina | More expensive and less water-resistant | High |

| Chrome-Tanned Leather | Automotive interiors, footwear | Durable and water-resistant | Environmental concerns due to chemicals | Medium |

| Suede Leather | Fashion items, jackets, shoes | Luxurious feel and lightweight | Susceptible to stains and less durable | Medium |

Understanding the properties, pros and cons, and specific considerations for each material type is essential for international B2B buyers. This knowledge enables manufacturers to make informed decisions that align with market demands and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for leather manufacturers in usa

What Are the Main Stages of Manufacturing Processes for Leather Manufacturers in the USA?

The manufacturing processes for leather products in the USA involve several critical stages, each essential for ensuring high-quality output. Understanding these stages can help international B2B buyers identify reliable suppliers.

-

Material Preparation: The journey begins with the selection of raw hides, which can be sourced from various animals, including cows, goats, and sheep. The hides undergo a rigorous selection process where defects are identified, and only the best quality hides proceed. The preparation involves soaking the hides to remove any residual salt and dirt, followed by liming to soften the hides and facilitate hair removal.

-

Forming: Once prepared, the hides are cut into specific shapes according to the product requirements. This stage can involve techniques such as die-cutting or manual cutting, depending on the complexity of the design. Advanced technologies like CAD (Computer-Aided Design) may be employed to optimize the cutting process and minimize waste.

-

Assembly: After forming, the leather pieces are stitched together using industrial sewing machines. This stage may also involve adding components such as zippers, buckles, or rivets, depending on the product type. Attention to detail in stitching and assembly is crucial, as it affects the product’s durability and aesthetic appeal.

-

Finishing: The final stage involves applying treatments to enhance the leather’s appearance and durability. This can include dyeing, polishing, and applying protective coatings. Various finishing techniques can be used, such as aniline finishing for a natural look or pigmented finishes for enhanced durability. The finishing process not only affects aesthetics but also the leather’s resistance to wear and tear.

How Do Quality Assurance Measures Ensure Product Excellence in Leather Manufacturing?

Quality assurance (QA) is paramount in leather manufacturing, ensuring that the products meet international standards and client specifications. Here’s an overview of how QA is integrated into the manufacturing process.

-

Adherence to International Standards: Many leather manufacturers in the USA comply with international quality standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards demonstrates a commitment to quality and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) may be relevant for products exported to Europe.

-

Quality Control Checkpoints: Quality control is typically divided into several checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival. Hides are checked for defects and compliance with specifications.

– In-Process Quality Control (IPQC): During production, samples are taken at various stages to ensure that manufacturing processes are followed correctly. This may include checking stitching quality, dye consistency, and adherence to design specifications.

– Final Quality Control (FQC): After production, finished goods undergo a thorough inspection for overall quality, including aesthetic checks and functionality tests. -

Common Testing Methods: Various testing methods are employed to assess leather quality, including:

– Tensile strength tests to measure durability.

– Flexural tests to evaluate how the leather performs under repeated bending.

– Colorfastness tests to ensure that dyes do not bleed or fade over time.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control (QC) processes is crucial to ensuring a reliable partnership.

-

Supplier Audits: Conducting or requesting audits can provide insights into a manufacturer’s QC processes. These audits assess compliance with international standards and internal quality protocols. Buyers should consider visiting manufacturing sites to witness processes firsthand.

-

Quality Reports and Certifications: Requesting documentation, such as quality reports or certificates, can help buyers understand the manufacturer’s commitment to quality. Reports should detail the results of various testing methods and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These services often conduct pre-shipment inspections to ensure that products meet the agreed-upon specifications.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers must navigate specific nuances in quality control when sourcing leather products. Understanding these can help mitigate risks associated with cross-border transactions.

-

Cultural and Regulatory Differences: Different regions may have varying expectations regarding quality standards and product specifications. Buyers should familiarize themselves with local regulations that may impact the quality of leather products, especially when importing into regions with stringent requirements, such as the EU.

-

Language Barriers and Communication: Effective communication is crucial in ensuring that quality expectations are met. Buyers should establish clear lines of communication with suppliers and consider employing translators or local agents if necessary.

-

Logistics and Supply Chain Considerations: Quality can be impacted by logistics, including transportation and storage conditions. Buyers should ensure that suppliers have robust logistics practices to maintain product integrity throughout the supply chain.

By understanding the manufacturing processes and quality assurance measures in place, international B2B buyers can make informed decisions when sourcing from leather manufacturers in the USA, ultimately ensuring high-quality products that meet their specific needs.

Illustrative image related to leather manufacturers in usa

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather manufacturers in usa’

Introduction

Sourcing leather manufacturers in the USA requires a strategic approach to ensure quality, compliance, and alignment with your business needs. This guide provides a step-by-step checklist designed for international B2B buyers looking to procure leather goods effectively. By following these steps, you can streamline your sourcing process, minimize risks, and foster successful partnerships.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the first step in sourcing leather manufacturers. This includes detailing the type of leather (e.g., full-grain, top-grain, suede), thickness, finish, and intended use of the products. Having precise specifications helps suppliers understand your requirements and reduces the likelihood of miscommunication during production.

- Consider your market needs: Are you targeting luxury markets or cost-sensitive segments? This will influence the quality and type of leather you select.

Step 2: Research Potential Suppliers

Begin your search by compiling a list of potential leather manufacturers in the USA. Utilize online directories, trade shows, and industry reports to identify reputable companies. Look for manufacturers with proven experience in your specific product category.

- Assess supplier reputation: Check online reviews, customer testimonials, and industry ratings to gauge the reliability and quality of potential suppliers.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that the suppliers hold relevant certifications, such as ISO, REACH, or Leather Working Group certifications. These accreditations indicate compliance with quality and environmental standards, ensuring that your products meet international requirements.

- Ask for documentation: Request copies of certifications and audit reports to confirm authenticity and adherence to industry standards.

Step 4: Request Samples

Once you have shortlisted potential suppliers, request product samples to assess quality firsthand. Analyzing the samples will allow you to evaluate the leather’s texture, durability, and finish, which are critical for your end products.

Illustrative image related to leather manufacturers in usa

- Compare samples: Evaluate multiple samples from different suppliers to make informed comparisons regarding quality and pricing.

Step 5: Negotiate Terms and Conditions

Effective negotiation is essential to establish favorable terms and conditions. Discuss pricing, minimum order quantities, lead times, payment terms, and warranty provisions. Clear agreements can prevent misunderstandings and ensure smoother transactions.

- Document everything: Ensure that all negotiated terms are documented in a formal contract to protect both parties and provide a reference for future transactions.

Step 6: Conduct Factory Visits

If possible, visit the manufacturing facilities of your shortlisted suppliers. A factory visit provides insights into their production processes, quality control measures, and overall operational capabilities. This step can also help build trust and rapport with the supplier.

- Observe working conditions: Pay attention to the factory’s working environment and employee welfare, which can reflect the company’s ethical standards.

Step 7: Establish Communication Protocols

Finally, establish clear communication protocols to facilitate ongoing collaboration with your chosen manufacturer. Determine the primary points of contact and preferred communication channels to ensure efficient updates and feedback throughout the production process.

- Set expectations: Discuss frequency and format of updates (e.g., weekly reports, video calls) to maintain transparency and address any potential issues promptly.

By following this comprehensive checklist, you can enhance your sourcing process for leather manufacturers in the USA, ensuring you find reliable partners that meet your business needs and quality expectations.

Illustrative image related to leather manufacturers in usa

Comprehensive Cost and Pricing Analysis for leather manufacturers in usa Sourcing

What Are the Key Cost Components for Leather Manufacturers in the USA?

When sourcing leather products from manufacturers in the USA, understanding the cost structure is crucial. The main components contributing to the total cost include:

-

Materials: The type of leather—whether it’s vegetable-tanned, chrome-tanned, or synthetic—plays a significant role in pricing. Premium hides often command higher prices due to their quality and characteristics. For instance, eco-friendly options may also be available at a premium.

-

Labor: Labor costs in the USA can be higher than in other regions due to wage standards and regulations. Skilled artisans who specialize in leather crafting typically demand higher wages, impacting the overall production cost.

-

Manufacturing Overhead: This includes utilities, rent, and other operational expenses that manufacturers incur. Overhead costs can vary significantly depending on the location of the facility and the efficiency of the production process.

-

Tooling: Initial setup costs for tooling and machinery can be substantial, particularly for custom or specialized products. This cost is usually amortized over the production run, influencing unit pricing.

-

Quality Control (QC): Implementing stringent quality control processes is essential, especially for high-end leather goods. The costs associated with QC can affect the final pricing, as manufacturers may need to invest in testing and certification to meet industry standards.

-

Logistics: Shipping and handling costs should not be overlooked. These can vary based on the destination, shipping method, and any tariffs or duties applicable to international shipments.

-

Margin: Manufacturers typically add a margin to cover risks and ensure profitability. This margin can fluctuate based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect Leather Sourcing Decisions?

Several factors can influence pricing when sourcing leather products:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit prices. Understanding the MOQ can help buyers negotiate better terms.

-

Specifications and Customization: Custom designs or specifications can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., eco-friendly processes) can justify higher prices. Buyers should assess whether these factors align with their brand image and customer expectations.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers may charge more due to their proven track record.

-

Incoterms: Understanding international shipping terms is vital. Different Incoterms can affect the total cost, including who is responsible for shipping, insurance, and duties.

What Tips Can Help International B2B Buyers Optimize Costs?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, navigating the complexities of sourcing leather can be challenging. Here are some actionable tips:

-

Negotiate Effectively: Building a good relationship with suppliers can lead to better pricing and terms. Don’t hesitate to negotiate based on volume, long-term partnerships, or bundled purchases.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Evaluate factors such as durability, maintenance, and potential resale value when assessing costs.

-

Be Aware of Pricing Nuances: Currency fluctuations can impact pricing, especially for international transactions. Establishing fixed pricing agreements can mitigate this risk.

-

Research Local Regulations: Be informed about import regulations, tariffs, and certifications required in your country to avoid unexpected costs.

-

Utilize Technology: Leverage digital tools for sourcing and communication to streamline the procurement process, reduce lead times, and potentially lower costs.

Disclaimer on Indicative Prices

Prices for leather goods can vary widely based on the aforementioned factors. It is advisable for buyers to obtain quotes from multiple suppliers and conduct thorough due diligence to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing leather manufacturers in usa With Other Solutions

Introduction to Alternative Solutions in Leather Manufacturing

When sourcing leather products, international B2B buyers often face the challenge of selecting the right manufacturing solution. While leather manufacturers in the USA are renowned for their quality and craftsmanship, there are alternative solutions worth considering. These alternatives may offer distinct advantages in performance, cost, or specific use cases, catering to diverse business needs across various markets.

Comparison Table of Leather Manufacturing Solutions

| Comparison Aspect | Leather Manufacturers in USA | Synthetic Leather Solutions | Importing Leather from Other Countries |

|---|---|---|---|

| Performance | High durability and aesthetics; natural feel | Varies; often less durable but can mimic leather’s look | Quality varies; can be high or low based on source |

| Cost | Higher due to quality and craftsmanship | Generally lower; affordable options available | Cost-effective depending on the country of origin and tariffs |

| Ease of Implementation | May require longer lead times for custom orders | Often readily available, especially in bulk | Can involve complex logistics and import regulations |

| Maintenance | Requires regular care for longevity | Low maintenance; easy to clean | Varies; natural leather needs care, synthetic may be easier |

| Best Use Case | High-end products, luxury goods | Fashion items, upholstery, and budget-friendly products | Cost-sensitive markets, large-scale production needs |

Detailed Breakdown of Alternatives

Synthetic Leather Solutions

Synthetic leather, often made from materials like polyurethane (PU) or polyvinyl chloride (PVC), provides a viable alternative to traditional leather. The primary advantages include lower cost and ease of maintenance, making it suitable for fashion items and upholstery. However, while synthetic leather can closely mimic the look and feel of genuine leather, it often lacks the durability and longevity associated with natural leather. For buyers focused on budget constraints or those targeting fast fashion markets, synthetic options may be an ideal choice.

Importing Leather from Other Countries

Importing leather from countries known for their leather production, such as Italy, Brazil, or India, can be a cost-effective solution. This option allows access to a variety of leather types and qualities, often at lower prices than domestic manufacturers. However, it comes with challenges, including navigating complex import regulations and potential delays in shipping. Buyers must also consider the variability in quality, as not all international suppliers adhere to the same standards as U.S. manufacturers. This solution is best for businesses looking to scale quickly or those operating in price-sensitive markets.

Conclusion: Choosing the Right Leather Manufacturing Solution

Selecting the appropriate leather manufacturing solution requires a thorough understanding of your business’s specific needs and market demands. While U.S. leather manufacturers offer unparalleled quality and craftsmanship, alternatives like synthetic leather and international sourcing can provide valuable benefits, particularly in terms of cost and availability. B2B buyers should evaluate performance, cost, ease of implementation, and maintenance to make informed decisions that align with their operational goals and customer expectations. Ultimately, the right choice will depend on balancing quality with budgetary constraints while ensuring timely delivery to meet market demands.

Essential Technical Properties and Trade Terminology for leather manufacturers in usa

What Are the Essential Technical Properties for Leather Manufacturers in the USA?

When engaging with leather manufacturers in the USA, understanding the technical properties of leather is crucial for making informed purchasing decisions. Here are some key specifications that every international buyer should be aware of:

1. Material Grade

Material grade refers to the quality classification of leather based on its characteristics, such as texture, finish, and durability. Common grades include full-grain, top-grain, genuine leather, and bonded leather. Buyers should prioritize higher grades like full-grain for products requiring durability and aesthetic appeal, as these are less prone to wear and tear.

2. Thickness (Gauge)

The thickness of leather is typically measured in ounces or millimeters. A thicker leather (usually over 3 ounces) is often more durable and suitable for heavy-duty applications like bags and upholstery. Conversely, thinner leather (under 2 ounces) is ideal for products like wallets or garments. Understanding the thickness helps buyers choose the appropriate leather for their specific needs.

3. Tolerance

Tolerance refers to the acceptable variation in dimensions and properties of leather during production. It is crucial for maintaining consistency in product quality. For manufacturers, tighter tolerances often mean higher costs, but they also ensure that the final product meets precise specifications. Buyers should inquire about tolerance levels to ensure compatibility with their production processes.

4. Finish

Leather finishes can significantly affect both appearance and performance. Common finishes include aniline, semi-aniline, and pigmented. Aniline leather is dyed with transparent dyes, showcasing the natural grain but is less resistant to stains. In contrast, pigmented leather is coated with a protective layer, making it more durable and easier to clean. Buyers should consider the intended use of the leather when selecting a finish.

5. Weight

The weight of leather is an important factor, particularly for products that require specific handling characteristics. Heavier leather is typically used for items like belts and bags that need to withstand significant stress, while lighter leather is suitable for fashion items. Knowing the weight helps buyers align their product design with consumer expectations.

What Are Common Trade Terms in the Leather Industry?

Familiarizing yourself with industry jargon is essential for effective communication with leather suppliers. Here are some common trade terms that B2B buyers should understand:

Illustrative image related to leather manufacturers in usa

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s final product. In the leather industry, this could mean a manufacturer supplying leather for a brand’s handbags. Understanding OEM relationships can help buyers identify potential suppliers that can meet specific design and production needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it impacts inventory management and cost efficiency. Manufacturers may impose MOQs to ensure that production costs are covered. Buyers should negotiate MOQs to align with their purchasing capabilities.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This is essential for comparing costs and understanding the terms of sale. Including detailed specifications in an RFQ can lead to more accurate quotes and help in decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Terms like FOB (Free On Board) and CIF (Cost, Insurance, and Freight) specify who bears the risk and cost at various stages of transport. Understanding Incoterms can help buyers mitigate risks associated with international shipping.

Illustrative image related to leather manufacturers in usa

5. Tannage

Tannage is the chemical process used to convert raw animal hides into leather. Different tanning methods, such as chrome and vegetable tanning, impact the leather’s characteristics. Buyers should be aware of the tanning process as it affects the leather’s durability, appearance, and environmental impact.

By grasping these technical properties and trade terminologies, international buyers can navigate the complexities of sourcing leather from manufacturers in the USA with greater confidence and efficiency.

Navigating Market Dynamics and Sourcing Trends in the leather manufacturers in usa Sector

What Are the Current Market Dynamics and Key Trends in the Leather Manufacturing Sector in the USA?

The leather manufacturing sector in the USA is experiencing a dynamic transformation driven by several global factors. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable suppliers, they must navigate a landscape influenced by technological advancements, shifting consumer preferences, and sustainability pressures. Key trends include the increasing adoption of automation and AI in production processes, enhancing efficiency and reducing lead times. Additionally, there is a notable rise in demand for customized leather products, as buyers seek unique offerings that cater to specific markets, such as high-end fashion or specialized industrial applications.

Illustrative image related to leather manufacturers in usa

Emerging technologies, such as blockchain for supply chain transparency and advanced analytics for demand forecasting, are becoming essential tools for manufacturers. These innovations not only streamline operations but also build trust with buyers by ensuring product authenticity and quality. Furthermore, the market is witnessing a shift towards direct-to-consumer models, where manufacturers are increasingly engaging with end-users through online platforms, thus redefining traditional distribution channels.

How Is Sustainability and Ethical Sourcing Reshaping the Leather Industry?

Sustainability and ethical sourcing are critical considerations for B2B buyers in the leather industry. The environmental impact of traditional leather production methods, including water usage and chemical pollution, has prompted many manufacturers to adopt greener practices. This includes the use of vegetable-tanned leathers and eco-friendly dyes, which minimize harmful emissions and waste.

For international buyers, understanding the importance of ethical supply chains is paramount. They are increasingly prioritizing suppliers who can demonstrate sustainable practices, such as sourcing hides from responsible farms and utilizing renewable energy in production. Certifications like the Leather Working Group (LWG) and the Global Organic Textile Standard (GOTS) serve as benchmarks for ethical sourcing, providing assurance to buyers that their suppliers adhere to high environmental and social standards.

Illustrative image related to leather manufacturers in usa

As buyers from regions like Nigeria and Germany emphasize sustainability, manufacturers must not only comply with these demands but also actively communicate their sustainability efforts. This transparency not only enhances brand reputation but also aligns with the growing consumer preference for ethically produced goods.

What Is the Evolution of the Leather Manufacturing Sector in the USA?

The leather manufacturing sector in the USA has a rich history, evolving significantly from its origins in artisanal craftsmanship to the modern, technology-driven industry it is today. Initially, leather production was a localized craft, with artisans using traditional techniques to create bespoke items. However, the industrial revolution introduced mechanization, leading to mass production and a broader range of products.

In recent decades, the industry has faced challenges due to globalization and competition from synthetic alternatives. Yet, it has adapted by focusing on quality, innovation, and sustainability. The rise of luxury brands and the global demand for high-quality leather goods have further propelled the sector forward, making it a vital player in the global market. Today, USA leather manufacturers are not only competing on quality but are also at the forefront of sustainable practices, positioning themselves as leaders in the ethical production of leather goods.

By understanding these dynamics, international B2B buyers can make informed sourcing decisions that align with their values and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of leather manufacturers in usa

-

How do I evaluate the quality of leather from manufacturers in the USA?

To assess leather quality, request samples from potential suppliers. Examine the texture, grain, and finish of the leather, as well as its durability and resistance to wear and tear. Additionally, inquire about the tanning process used, as this can significantly affect the leather’s quality. It’s also beneficial to check for certifications or compliance with industry standards, such as environmental sustainability practices. Gathering feedback from other businesses that have sourced from the manufacturer can provide valuable insights into their product quality. -

What customization options are available when sourcing leather products from US manufacturers?

Many US leather manufacturers offer extensive customization options, including size, color, and design. Depending on the supplier, you may also be able to request specific materials, stitching styles, or finishes. When discussing customization, provide detailed specifications and visual references to ensure your vision is accurately captured. Additionally, confirm the manufacturer’s capabilities regarding minimum order quantities (MOQs) for customized products, as these can vary significantly. -

What are the typical minimum order quantities (MOQs) for leather products from US manufacturers?

MOQs can vary widely among leather manufacturers in the USA, often ranging from as low as 50 units to several hundred. Factors influencing MOQs include the type of leather product, customization requirements, and the manufacturer’s production capacity. It’s advisable to communicate your needs clearly and explore the possibility of lower MOQs for sample orders or trial runs, especially if you’re entering a new market. -

What payment terms should I expect when working with US leather manufacturers?

Payment terms can vary by manufacturer but typically include options such as 30% upfront deposit and 70% upon shipment. Some suppliers may offer net 30 or net 60 payment terms after establishing a relationship. It’s crucial to discuss and agree on payment methods, whether through bank transfers, letters of credit, or other secure options, to ensure a smooth transaction process. Always ensure that the terms are documented in your contract. -

How can I ensure compliance with international trade regulations when sourcing leather from the USA?

To navigate international trade regulations, familiarize yourself with both US export laws and the import regulations of your country. This includes understanding tariffs, quotas, and any specific documentation required for leather products. Engaging a customs broker can streamline the process and ensure compliance. Additionally, verify that your suppliers provide necessary certificates, such as origin or quality certifications, to facilitate customs clearance. -

What quality assurance measures should I look for in a leather manufacturer?

A reputable leather manufacturer should have a robust quality assurance program that includes regular inspections during various production stages. Ask about their quality control processes, such as testing for durability, colorfastness, and overall craftsmanship. Certifications from recognized industry standards can also indicate a commitment to quality. Establishing a clear agreement on quality expectations and inspection rights in your contract can help protect your interests. -

What logistics considerations should I keep in mind when importing leather products from the USA?

Logistics play a crucial role in importing leather products. Consider factors such as shipping methods, lead times, and costs. Discuss with your supplier about their shipping practices and whether they handle logistics or if you need to coordinate with a freight forwarder. Ensure you account for potential customs delays and plan your inventory levels accordingly. Additionally, confirm the shipping insurance options available to protect your investment during transit. -

How can I find reliable leather manufacturers in the USA?

To find trustworthy leather manufacturers, start by conducting thorough online research using platforms like ThomasNet or industry directories. Attend trade shows and exhibitions focused on leather goods to meet manufacturers in person. Networking with industry contacts and seeking recommendations can also lead to reputable suppliers. Once you identify potential manufacturers, request references and samples to assess their credibility and product quality before making commitments.

Top 6 Leather Manufacturers In Usa Manufacturers & Suppliers List

1. Tandy Leather – Leather Materials & Supplies

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Leather Materials & Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Hide & Leather House – Leather Hides

Domain: hidehouse.com

Registered: 1996 (29 years)

Introduction: The Hide & Leather House, Inc. offers a wide range of leather products including: 1. Leather Hides – Over 3,000 types in stock, including: – Bags & Personal Leather Gear – Belting & Strapping – Chap & Motorcycle Hides – Eco Friendly Tannage – Footwear & Shoe Hides – Garment Hides – Hair on Hides – Lining & Orthopedic Hides – Nonstock Leather Hides – Saddlery, Veg-Tan & Latigo Hides – Up…

3. Garrett Leather – Cielo Olive Tanned Leather

Domain: garrettleather.com

Registered: 1996 (29 years)

Introduction: Cielo: Olive tanned leather, climate neutral, sustainable, high-performance, suitable for high-traffic areas, available in 20 colors, meets durability test requirements for private aviation, ideal for hospitality, corporate, residential, and luxury yacht interiors. LeatherShield classification for high-traffic durability. Guaranteed in stock for popular collections, shipping within two business da…

4. Stonestreet Leather – Leather Supplies & Finished Goods

Domain: stonestreetleather.com

Registered: 2019 (6 years)

Introduction: Stonestreet Leather offers a variety of leather supplies and finished goods. Key product categories include: Cowhide (Vegetable Tanned, Colored Vegetable Tanned, Chrome Tanned, Embossed, Water Buffalo), Strips, Straps, & Belt Blanks (Alligator Embossed, Colored Vegetable Tanned, Oxford Xcel, Water Buffalo), Scrap Bags (Vegetable Tanned, Embossed, Chrome Tanned, Buffalo, Oxford Xcel), Leather Shape…

5. GNN International – Premium Leather Goods

Domain: gnninternational.com

Registered: 2002 (23 years)

Introduction: GNN International offers premium leather goods manufacturing services, specializing in private label leather products. Their product portfolio includes: Men’s Leather Wallets, Women’s Leather Wallets, Leather Handbags & Totes, Leather Travel Bags, Leather Laptop Bags, Custom Leather Backpacks, Leather Belts & Dog Collars, and Fine Leather Accessories. They focus on high-quality materials, includin…

6. Cromwell Leather Group – Bonded Leather

Domain: cromwellgroup.com

Registered: 1996 (29 years)

Introduction: Cromwell Leather Group offers a variety of leather products including Bonded Leather, Eurobond®, Excel-Tan®, Taratan II®, and ReNatura®. They provide over 300 sample items available for immediate shipment and have a commitment to quality and reliability. Their products are in stock and ready to ship from warehouses in North America, Asia, and Europe, with options for custom production. Cromwell em…

Strategic Sourcing Conclusion and Outlook for leather manufacturers in usa

In navigating the dynamic landscape of leather manufacturing in the USA, international B2B buyers must prioritize strategic sourcing to unlock competitive advantages. Key takeaways from this guide emphasize the importance of understanding supplier capabilities, product diversity, and the ability to customize offerings to meet specific market demands. The U.S. leather industry is characterized by a rich heritage of craftsmanship, innovation, and sustainability, making it a valuable partner for global enterprises.

Illustrative image related to leather manufacturers in usa

Strategic sourcing not only enhances procurement efficiency but also fosters relationships with reliable manufacturers who can adapt to evolving trends and consumer preferences. By leveraging the unique strengths of U.S. leather manufacturers, buyers can ensure high-quality products that align with their brand values and market expectations.

Looking ahead, we encourage international buyers from regions like Africa, South America, the Middle East, and Europe to engage with U.S. suppliers actively. Explore partnerships that can drive mutual growth and innovation, as the global demand for quality leather goods continues to rise. Embrace the opportunity to collaborate with manufacturers who share your vision for excellence and sustainability in the leather industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to leather manufacturers in usa