Introduction: Navigating the Global Market for basketball leather

In the rapidly evolving global market for basketball leather, sourcing high-quality materials that meet both performance and durability standards presents a significant challenge for international B2B buyers. With the demand for premium basketballs on the rise, understanding the nuances of basketball leather—its types, applications, and sourcing options—becomes crucial. This comprehensive guide delves into various leather types used in basketball production, highlighting their unique properties and suitability for different manufacturing processes.

From the renowned Horween leather used by top brands to innovative alternatives emerging from diverse geographical markets, this guide equips buyers with the insights needed to make informed decisions. We will explore essential factors such as supplier vetting processes, cost considerations, and quality assurance measures. This resource is particularly tailored for buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Saudi Arabia—where the demand for high-quality sports equipment is surging.

By providing actionable insights and strategic sourcing advice, this guide empowers B2B buyers to navigate the complexities of the basketball leather market confidently. Understanding these elements will not only enhance product quality but also optimize procurement processes, ensuring that businesses can meet the growing expectations of athletes and consumers alike.

Table Of Contents

- Top 5 Basketball Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for basketball leather

- Understanding basketball leather Types and Variations

- Key Industrial Applications of basketball leather

- 3 Common User Pain Points for ‘basketball leather’ & Their Solutions

- Strategic Material Selection Guide for basketball leather

- In-depth Look: Manufacturing Processes and Quality Assurance for basketball leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘basketball leather’

- Comprehensive Cost and Pricing Analysis for basketball leather Sourcing

- Alternatives Analysis: Comparing basketball leather With Other Solutions

- Essential Technical Properties and Trade Terminology for basketball leather

- Navigating Market Dynamics and Sourcing Trends in the basketball leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of basketball leather

- Strategic Sourcing Conclusion and Outlook for basketball leather

- Important Disclaimer & Terms of Use

Understanding basketball leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Horween Basketball Leather | Premium quality, 2.0/2.2mm thickness, embossed finish | High-end basketball manufacturing | Pros: Superior durability, excellent grip. Cons: Higher cost compared to alternatives. |

| Synthetic Composite Leather | Lightweight, water-resistant, and affordable | Entry-level and recreational balls | Pros: Cost-effective, versatile. Cons: Less durability and performance than genuine leather. |

| Full-Grain Leather | Natural grain, rich texture, and breathability | Professional-grade basketballs | Pros: Exceptional feel and performance. Cons: Requires more maintenance to preserve quality. |

| Pebbled Leather | Textured surface for enhanced grip and control | Training and practice basketballs | Pros: Improved handling, good for training. Cons: Can be less visually appealing. |

| Nubuck Leather | Soft, velvety texture, durable and water-resistant | Specialty basketballs and custom orders | Pros: Unique aesthetic, comfortable grip. Cons: Higher maintenance due to sensitivity to moisture. |

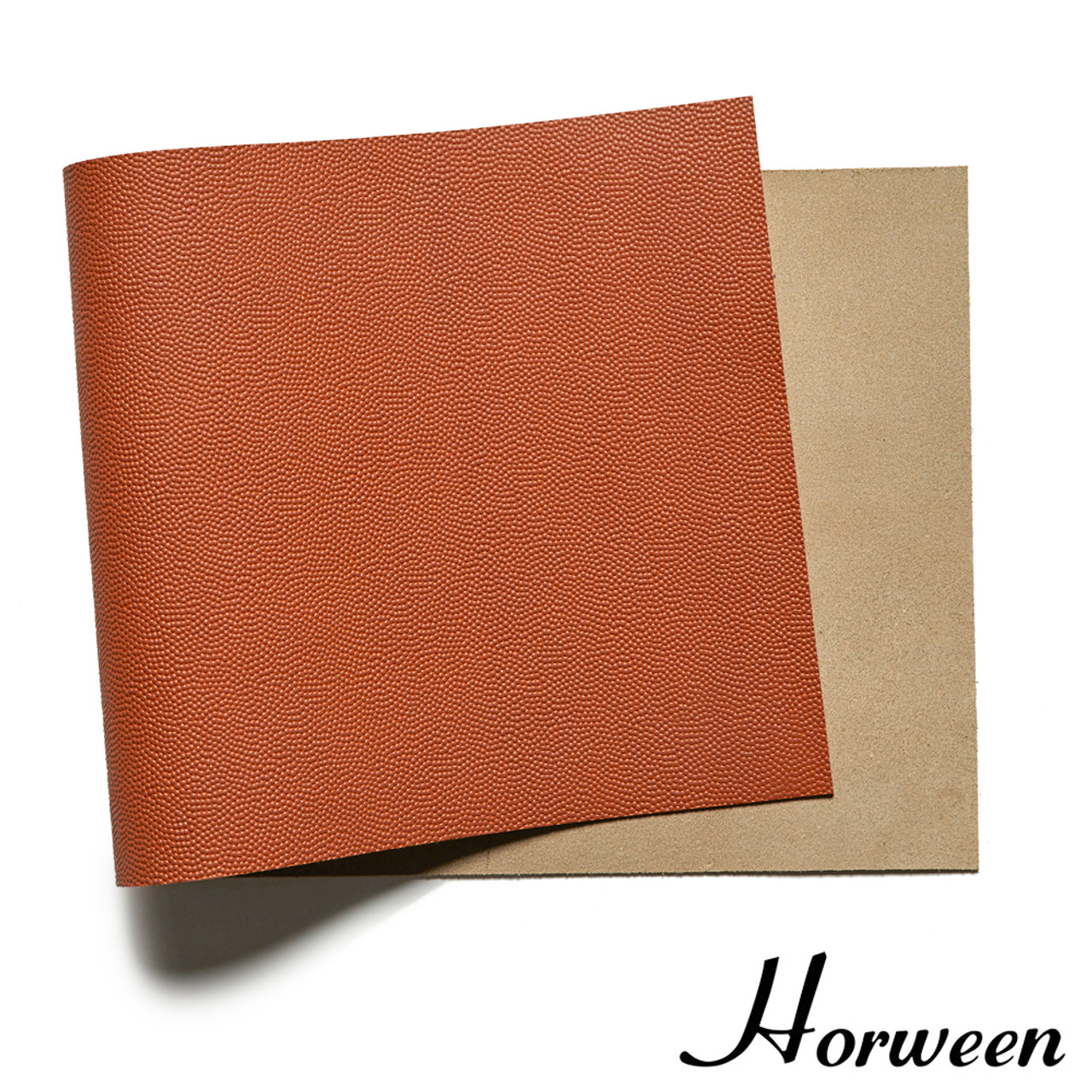

What are the Characteristics and Suitability of Horween Basketball Leather?

Horween Basketball Leather is known for its premium quality, typically featuring a thickness of 2.0/2.2mm and an embossed finish that enhances its grip. This type of leather is primarily used in high-end basketball manufacturing, including professional leagues. B2B buyers should consider its durability and performance benefits, although the higher price point may be a barrier for some.

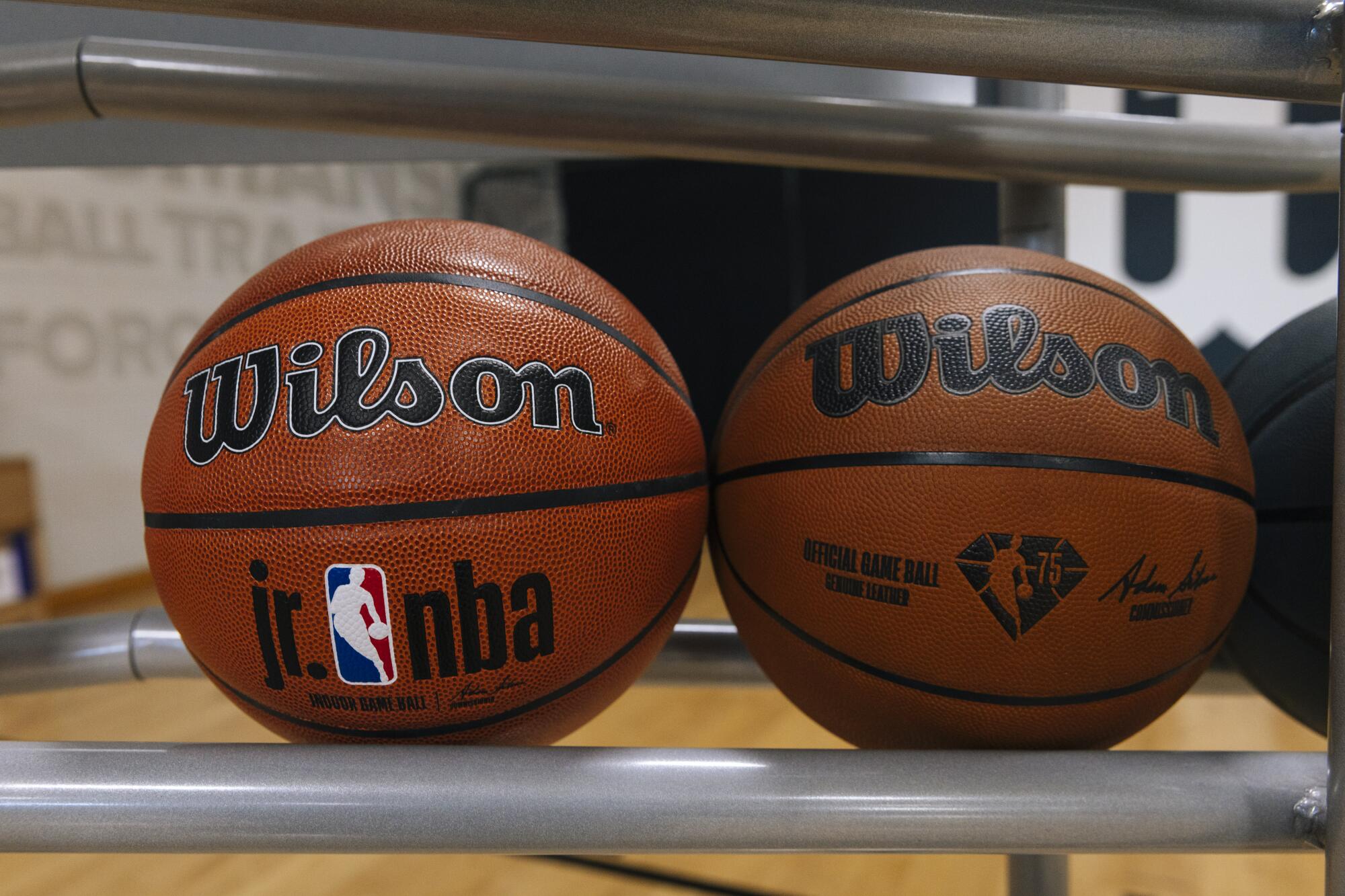

How Does Synthetic Composite Leather Compare for Entry-Level Applications?

Synthetic Composite Leather is designed to be lightweight and water-resistant, making it a popular choice for entry-level and recreational basketballs. Its affordability attracts a wide range of buyers, including schools and community sports programs. However, while it offers versatility, it may lack the durability and performance characteristics found in genuine leather options, which could affect long-term usage.

Illustrative image related to basketball leather

What Makes Full-Grain Leather a Preferred Choice for Professional-Grade Basketballs?

Full-Grain Leather boasts a natural grain and rich texture that provides excellent breathability and feel during play. It is favored for professional-grade basketballs due to its superior performance attributes. B2B buyers must keep in mind that while it offers an exceptional playing experience, it requires more maintenance to preserve its quality over time, making it essential to educate end-users on proper care.

Why Choose Pebbled Leather for Training and Practice Balls?

Pebbled Leather features a textured surface that enhances grip and control, making it ideal for training and practice basketballs. This type is often used in educational institutions and training facilities. While it provides improved handling, it may not have the same visual appeal as other leather types, which could be a consideration for branding and presentation in commercial applications.

What are the Unique Features of Nubuck Leather for Specialty Basketballs?

Nubuck Leather is characterized by its soft, velvety texture, offering both durability and water resistance. It is often used for specialty basketballs and custom orders, appealing to niche markets. Buyers should note that while its unique aesthetic and comfortable grip are advantages, Nubuck requires higher maintenance due to its sensitivity to moisture, necessitating careful handling to maintain its appearance and functionality.

Key Industrial Applications of basketball leather

| Industry/Sector | Specific Application of Basketball Leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sporting Goods Manufacturing | Production of High-Quality Basketballs | Enhances product durability and performance, attracting professional athletes | Ensure consistent quality, thickness specifications, and compliance with international standards |

| Custom Leather Goods | Crafting Premium Leather Accessories and Apparel | Provides a unique selling point through high-quality materials, appealing to niche markets | Source from reputable tanneries, verify leather origin, and confirm customization options |

| Educational Institutions | Development of Training Equipment and Sports Gear | Improves the quality of training tools, fostering better performance among students | Consider bulk purchasing options and specific leather grades suitable for educational use |

| Retail and E-commerce | Selling Luxury Basketballs and Leather Goods | Increases brand prestige and customer loyalty through exclusive offerings | Focus on branding, packaging, and the ability to meet diverse customer demands |

| Sporting Events and Promotions | Creation of Branded Merchandise for Events | Enhances event visibility and engagement, creating lasting impressions on attendees | Ensure timely delivery, customization capabilities, and adherence to event branding guidelines |

How is Basketball Leather Used in Sporting Goods Manufacturing?

Basketball leather is primarily utilized in the production of high-quality basketballs. Manufacturers seek leather that is durable, weather-resistant, and capable of withstanding rigorous play. For international buyers, particularly from regions like Africa and South America, ensuring the leather meets specific performance standards is critical. This involves sourcing from reputable tanneries that can guarantee consistent quality and compliance with industry regulations. The right leather not only enhances the ball’s lifespan but also improves grip and handling, making it more appealing to professional athletes.

What Role Does Basketball Leather Play in Custom Leather Goods?

In the custom leather goods sector, basketball leather is used to create premium accessories such as wallets, bags, and apparel. The unique texture and high-quality finish provide a distinctive appeal that can differentiate products in a competitive market. Buyers in Europe and the Middle East should prioritize sourcing from established tanneries that offer customization options, ensuring that the leather’s characteristics align with their product vision. This application not only elevates the product’s quality but also caters to consumers looking for luxury items that stand out.

How is Basketball Leather Beneficial for Educational Institutions?

Educational institutions often use basketball leather to develop training equipment, including practice basketballs and training aids. The use of high-quality leather can significantly enhance the durability and performance of these tools, which is crucial for fostering athletic skill development among students. When sourcing for schools in regions like Nigeria or Saudi Arabia, it’s essential to consider bulk purchasing options that ensure affordability without compromising on quality. Institutions should also verify the leather grades suitable for educational use to ensure safety and performance.

In What Ways Does Basketball Leather Enhance Retail and E-commerce?

In the retail and e-commerce sectors, basketball leather is leveraged to create luxury basketballs and related leather goods. Retailers benefit from the material’s ability to attract discerning customers who value quality and craftsmanship. For businesses targeting markets in Europe and the Middle East, focusing on branding and packaging can create a premium perception. Additionally, retailers should consider their supply chain logistics to ensure they can meet diverse customer demands while maintaining product integrity.

How Can Basketball Leather Be Used for Sporting Events and Promotions?

Basketball leather is also utilized in creating branded merchandise for sporting events, such as promotional basketballs or giveaways. This application enhances event visibility and engagement, creating memorable experiences for attendees. For international event organizers, timely delivery and the ability to customize products to align with branding guidelines are crucial considerations. Ensuring that the leather used is of high quality will leave a lasting impression, encouraging brand loyalty among participants and spectators alike.

3 Common User Pain Points for ‘basketball leather’ & Their Solutions

Scenario 1: Sourcing High-Quality Basketball Leather for Competitive Products

The Problem: For B2B buyers in the sports manufacturing sector, sourcing high-quality basketball leather can be a daunting task. Many suppliers offer leather that may not meet the rigorous standards necessary for professional-grade basketballs. Buyers often face challenges such as inconsistent quality, lack of detailed specifications, and inadequate customer support. This can lead to wasted resources and potential damage to their brand reputation if the final product does not perform as expected on the court.

Illustrative image related to basketball leather

The Solution: To overcome this challenge, buyers should prioritize partnerships with reputable tanneries known for producing basketball leather specifically designed for high-performance applications. For instance, companies like Horween, which supply leather for NBA basketballs, provide consistent quality and detailed product specifications. When contacting suppliers, request samples to evaluate the leather’s texture, thickness, and durability. Additionally, establish a clear communication channel with the supplier to discuss specific requirements, such as weight and finish. This proactive approach will help ensure that the leather sourced will meet the needs of skilled athletes who depend on high-quality equipment.

Scenario 2: Understanding the Technical Specifications of Basketball Leather

The Problem: B2B buyers often struggle with the technical specifications of basketball leather, such as weight, thickness, and tanning processes. This lack of understanding can lead to ordering materials that are unsuitable for their manufacturing processes or the intended use of the final products. For instance, leather that is too thick may not provide the necessary grip, while leather that is too thin might not withstand the rigors of play, resulting in high return rates and customer dissatisfaction.

The Solution: To address this pain point, buyers should invest time in understanding the various specifications associated with basketball leather. Key metrics to focus on include the weight (measured in ounces), thickness (in millimeters), and the type of tanning process (chrome or vegetable). Engaging with technical representatives from tanneries can provide valuable insights into how these specifications affect performance. Furthermore, participating in industry workshops or webinars can enhance knowledge about selecting the right leather. By becoming more informed, buyers can make better decisions that align with their product development goals and ensure that they order the correct leather for their specific applications.

Scenario 3: Managing Supply Chain Challenges with Basketball Leather Procurement

The Problem: Global supply chain issues can significantly impact the availability of basketball leather, leading to delays in production schedules and increased costs. Buyers in regions like Africa, South America, and the Middle East may face additional challenges due to logistics complexities, tariffs, and varying quality standards across suppliers. This situation can create uncertainty and disrupt the timely delivery of finished products to retailers or end-users, ultimately affecting sales and profitability.

The Solution: To mitigate supply chain risks, B2B buyers should diversify their supplier base and consider establishing relationships with multiple tanneries in different regions. This strategy not only provides alternatives in case of disruptions but also allows buyers to compare prices and quality. Additionally, implementing a just-in-time inventory system can help manage stock levels more effectively, reducing the risk of over-ordering or stockouts. Maintaining open lines of communication with suppliers regarding lead times and potential delays is also crucial. By proactively managing their supply chain and being flexible in sourcing, buyers can better navigate the complexities associated with basketball leather procurement and ensure consistent product availability.

Strategic Material Selection Guide for basketball leather

When selecting materials for basketball leather, international B2B buyers must consider various factors that influence product performance, manufacturing processes, and market preferences. Here, we analyze four common materials used in basketball leather, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Cowhide Leather for Basketballs?

Cowhide leather is the most prevalent material used in basketball production. It offers excellent durability and a natural grip, making it ideal for high-performance sports. Key properties include a thickness of 2.0 to 2.2 mm, which provides a firm handle and a semi-bright finish. Additionally, cowhide leather can withstand varying temperatures and pressures, making it suitable for both indoor and outdoor use.

Illustrative image related to basketball leather

Pros: Cowhide leather is highly durable, resistant to wear and tear, and provides a superior grip, enhancing player performance. It is also relatively easy to source and process, which can reduce manufacturing complexity.

Cons: The primary drawback is its cost, which can be higher than synthetic alternatives. Additionally, cowhide may require more maintenance to preserve its quality over time.

Impact on Application: Cowhide leather is compatible with various basketball types, including those used in professional leagues. Buyers should consider compliance with international standards like ASTM and JIS, particularly for markets with strict quality regulations.

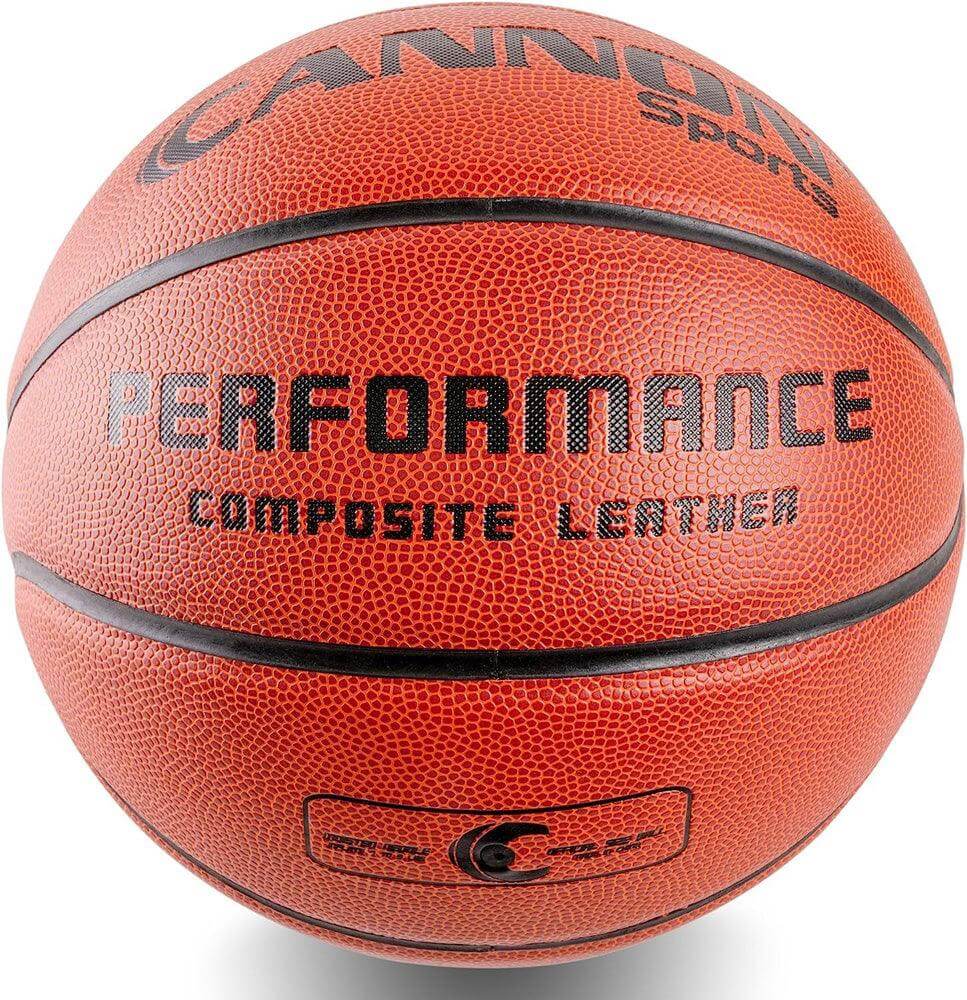

How Does Synthetic Leather Compare to Natural Leather?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is another popular choice for basketballs. It is designed to mimic the properties of natural leather while offering additional benefits.

Pros: Synthetic leather is generally more affordable than cowhide, lightweight, and resistant to moisture and UV rays. Its uniform texture allows for consistent performance across different batches.

Illustrative image related to basketball leather

Cons: While synthetic leather is durable, it may not provide the same level of grip and feel as natural leather. Additionally, it can degrade more quickly under extreme conditions, impacting long-term performance.

Impact on Application: Synthetic leather is often preferred for recreational or training basketballs. Buyers in regions with humid climates, such as parts of Africa and South America, should consider the moisture resistance of synthetic options.

What Are the Advantages of Using Horween Leather for Basketballs?

Horween leather, specifically developed for basketballs, is known for its premium quality and performance characteristics. This leather is produced by one of the oldest tanneries in the U.S. and is used by top manufacturers like Spalding.

Pros: Horween leather offers exceptional durability and a unique feel, enhancing player control. Its rigorous tanning process ensures consistent quality and performance, making it a favored choice for professional-grade basketballs.

Cons: The primary limitation is its high cost, which may not be feasible for all manufacturers. Additionally, sourcing Horween leather requires navigating specific supplier relationships.

Illustrative image related to basketball leather

Impact on Application: Horween leather is compliant with high standards, making it suitable for professional leagues. Buyers in Europe and the Middle East may find this leather aligns with their market expectations for premium products.

What Is the Role of Specialty Leathers in Basketball Manufacturing?

Specialty leathers, such as embossed or distressed varieties, are increasingly used to create unique basketball designs. These materials can add aesthetic value and differentiate products in a competitive market.

Pros: Specialty leathers can enhance the visual appeal of basketballs, attracting consumers looking for distinctive products. They also allow for creative branding opportunities.

Cons: The manufacturing complexity increases with specialty leathers, potentially raising production costs and time. Additionally, performance may vary based on the specific treatment of the leather.

Impact on Application: Buyers should be aware of market trends and consumer preferences for unique designs, particularly in regions with a strong sports culture, such as South America and Europe.

| Material | Typical Use Case for basketball leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide Leather | Professional basketballs | Excellent durability and grip | Higher cost compared to synthetics | High |

| Synthetic Leather | Recreational and training basketballs | Cost-effective and moisture-resistant | May lack the feel and grip of natural leather | Medium |

| Horween Leather | Premium professional basketballs | Exceptional quality and performance | High sourcing and production costs | High |

| Specialty Leathers | Unique and branded basketballs | Aesthetic appeal and differentiation | Increased manufacturing complexity | Medium to High |

This strategic material selection guide provides a comprehensive overview for B2B buyers, enabling informed decisions based on regional preferences, compliance standards, and product performance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for basketball leather

What Are the Key Stages in the Manufacturing Process of Basketball Leather?

The manufacturing process of basketball leather involves several critical stages, each aimed at ensuring that the final product meets the high-performance standards required by professional athletes. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is Basketball Leather Initially Processed?

The journey of basketball leather begins with the selection of high-quality cowhides, which are known for their durability and flexibility. The hides undergo a thorough cleaning process to remove any impurities and contaminants. This is followed by tanning, a crucial step that preserves the leather and enhances its properties. In the case of basketball leather, chrome tanning is commonly used due to its ability to produce leather with a firm handle and semi-bright finish, essential for the dynamic nature of basketball.

Illustrative image related to basketball leather

Forming: What Techniques Are Employed to Shape the Leather?

Once the leather is tanned, it is cut into specific shapes and sizes required for basketball panels. The forming stage utilizes advanced cutting techniques to ensure precision. For instance, manufacturers often use die-cutting methods that allow for uniformity across multiple pieces, essential for mass production. The leather is then prepped for assembly, where it is treated with conditioners and other agents to enhance its grip and performance.

Assembly: How Are the Components of Basketball Leather Products Joined?

During the assembly stage, the cut leather pieces are stitched together. This is typically done using heavy-duty thread to withstand the stress of gameplay. Manufacturers may also employ bonding agents in addition to stitching to enhance durability. Quality assurance is integral at this stage, as the assembled panels are inspected for any defects or inconsistencies.

Finishing: What Processes Are Involved to Ensure Quality and Aesthetic Appeal?

The finishing process involves applying a protective coating to the leather, which not only enhances its appearance but also extends its lifespan. Various techniques, including embossing and dyeing, may be used to achieve the desired look. For basketball leather, a smooth and uniform finish is critical, as it affects both the aesthetic and functional qualities of the ball.

Illustrative image related to basketball leather

What Quality Assurance Measures Are in Place for Basketball Leather?

Quality assurance is paramount in the production of basketball leather, ensuring that the final product meets international and industry-specific standards. This section outlines the relevant quality standards, checkpoints, testing methods, and verification processes that B2B buyers should consider.

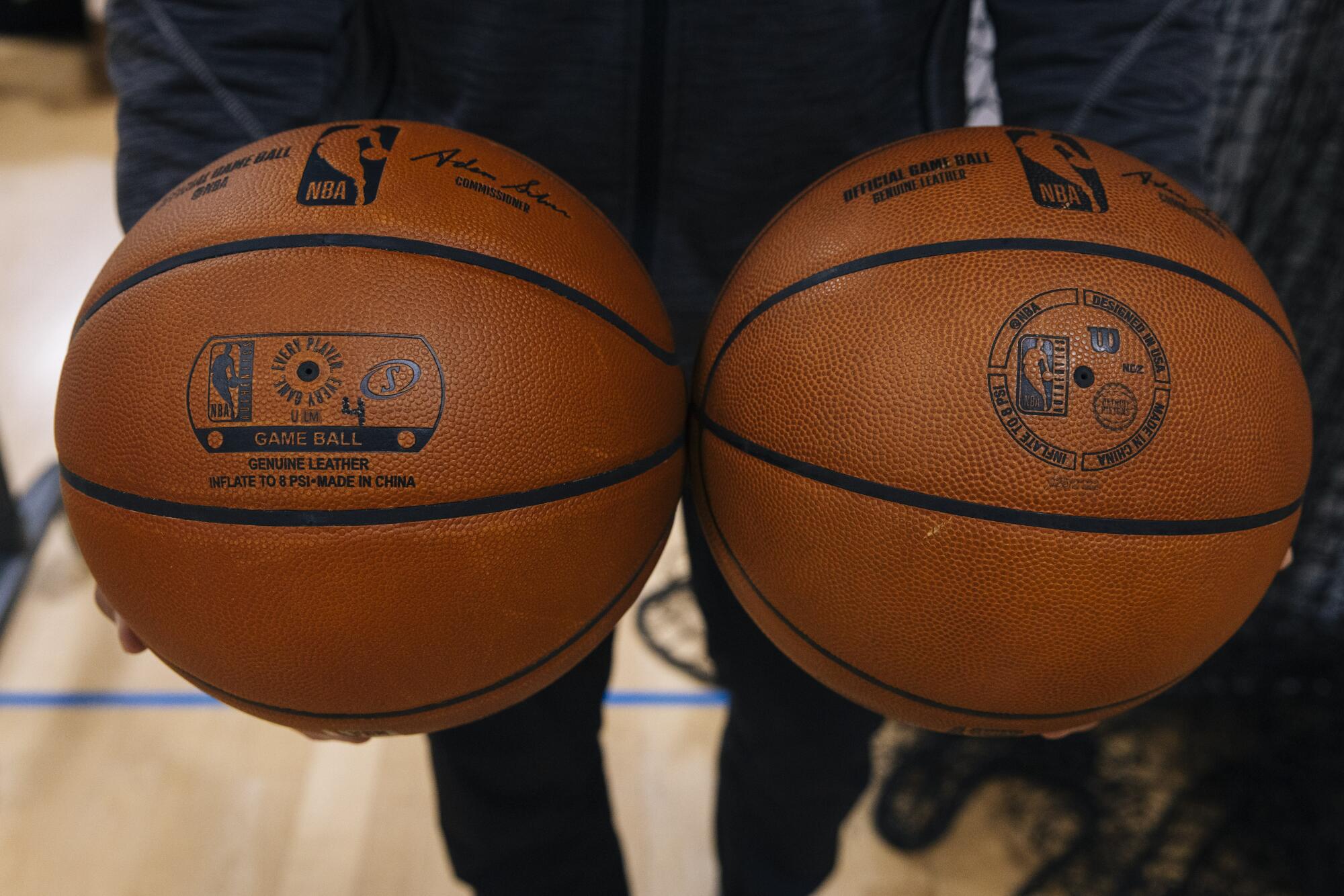

Which International Standards Are Relevant for Basketball Leather Quality?

International standards such as ISO 9001 are essential benchmarks for quality management systems in manufacturing. Compliance with ISO 9001 indicates that a manufacturer has established processes for consistent quality and customer satisfaction. Additionally, industry-specific certifications like CE (Conformité Européene) and API (American Petroleum Institute) may apply depending on the intended use of the leather.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials (cowhides) before they enter the production line. It ensures that only the highest quality materials are used.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC monitors the production process to identify and rectify any issues in real-time. This includes checking the consistency of cuts and the quality of stitching.

-

Final Quality Control (FQC): At this stage, the finished products are thoroughly inspected for defects, such as uneven seams or surface imperfections. This final check is crucial to ensure that the basketball leather meets the required performance standards.

What Common Testing Methods Are Used to Validate Basketball Leather Quality?

Various testing methods are employed to assess the quality of basketball leather, including:

-

Tensile Strength Tests: To evaluate the durability and strength of the leather under stress.

-

Flexibility Tests: Assessing how well the leather maintains its shape and integrity during use.

-

Water Resistance Tests: Ensuring that the leather can withstand exposure to moisture, which is essential for outdoor use.

-

Colorfastness Tests: To determine how well the leather retains its color after prolonged use and exposure to elements.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential for ensuring the integrity of their purchases.

What Steps Should Buyers Take to Ensure Supplier Compliance?

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with industry standards. Buyers should request access to audit reports and certifications to assess a supplier’s reliability.

-

Requesting Quality Control Reports: Buyers should ask for detailed QC reports that outline the results of various testing methods performed on the leather. This transparency can help in making informed purchasing decisions.

-

Utilizing Third-Party Inspection Services: Engaging third-party inspection agencies can provide an unbiased evaluation of the leather quality and adherence to specifications. This is particularly important for buyers importing goods from different countries.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers need to be aware of specific nuances related to quality control that may vary across regions. For instance, certain countries may have stricter regulations regarding leather production and animal welfare, impacting the sourcing of materials. Additionally, cultural differences in business practices may influence the level of transparency and communication during the purchasing process.

By understanding these factors, B2B buyers can make more informed decisions when sourcing basketball leather, ensuring they align with both quality expectations and regulatory requirements.

Illustrative image related to basketball leather

Practical Sourcing Guide: A Step-by-Step Checklist for ‘basketball leather’

This guide serves as a practical checklist for B2B buyers looking to procure high-quality basketball leather. Whether you are sourcing for manufacturing basketballs or other sports equipment, following these steps will help ensure you make informed decisions and establish reliable supplier relationships.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for basketball leather. This includes the desired thickness (typically 2.0 to 4.5 oz), finish (e.g., embossed or smooth), and color preferences. By defining these specifications upfront, you can streamline communication with suppliers and avoid misunderstandings that could lead to costly mistakes.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers known for quality basketball leather. Look for manufacturers with a solid reputation, particularly those who have experience supplying major brands or sports organizations. Prioritize suppliers who can provide detailed product descriptions and specifications to ensure they meet your needs.

- Tip: Utilize online B2B marketplaces and industry forums to find supplier recommendations and reviews.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers have the necessary certifications to guarantee the quality and sustainability of their leather. Look for certifications such as ISO 9001 for quality management systems or environmental certifications that ensure ethical sourcing practices. These certifications not only ensure product quality but also align with global standards that are increasingly important in international trade.

Illustrative image related to basketball leather

Step 4: Request Samples for Evaluation

Once you have identified potential suppliers, request leather samples to assess their quality firsthand. This step is crucial as it allows you to evaluate the texture, durability, and appearance of the leather. Pay attention to how the leather feels and performs under different conditions, as this can significantly impact the final product quality.

- Tip: Consider testing samples in real-world conditions to better understand their performance in your specific application.

Step 5: Negotiate Pricing and Terms

Engage in discussions with your selected suppliers to negotiate pricing, payment terms, and delivery schedules. Understanding the cost structure is vital for budgeting and maintaining profitability. Ensure that you clarify any additional costs associated with shipping, customs, or minimum order quantities to avoid unexpected expenses.

Step 6: Establish Quality Control Procedures

Implement quality control measures to ensure the leather you receive meets your specifications. This may involve setting up inspection processes upon delivery, such as checking for defects or inconsistencies in color and texture. A robust quality control system helps maintain the integrity of your product and builds trust with your customers.

Step 7: Build Long-term Relationships

Finally, focus on establishing long-term relationships with your suppliers. Open lines of communication and consistent feedback can lead to better service, priority handling for orders, and potential discounts for future purchases. Building a rapport with suppliers can also enhance collaboration on product development and innovation.

By following these steps, B2B buyers can navigate the complexities of sourcing basketball leather effectively, ensuring they acquire high-quality materials that meet their business needs.

Illustrative image related to basketball leather

Comprehensive Cost and Pricing Analysis for basketball leather Sourcing

What Are the Key Cost Components in Sourcing Basketball Leather?

When sourcing basketball leather, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The quality of leather significantly influences the cost. Premium options, such as Horween leather, can range from $257 to $278 per side, depending on the weight and finish. The leather’s origin, thickness (often between 2.0 to 4.5 oz), and treatment processes (like chrome tanning) also impact pricing.

-

Labor: Skilled labor is required for tanning, cutting, and finishing the leather. Regions with higher labor costs, such as Europe and North America, may see increased prices. Conversely, sourcing from countries with lower labor costs can provide savings but may impact quality.

-

Manufacturing Overhead: This includes costs associated with running the tannery, equipment maintenance, and utilities. Manufacturers often pass these costs onto buyers, particularly if they are producing smaller batches.

-

Tooling: Custom tooling for specific designs or patterns adds to the overall cost. For unique or bespoke basketball designs, buyers should expect to pay additional fees for mold creation and setup.

-

Quality Control (QC): Implementing strict QC measures ensures that the leather meets specified standards. This process can incur additional costs, especially if third-party inspections are involved.

-

Logistics: Transportation costs vary significantly based on location. International shipping, customs duties, and tariffs can add substantial costs, particularly for buyers in Africa, South America, and the Middle East. Incoterms play a critical role in determining who bears these costs.

-

Margin: Suppliers typically add a margin to cover their expenses and profit. Understanding the average margins within the industry can help buyers gauge if they are being charged fairly.

How Do Price Influencers Affect Basketball Leather Sourcing?

Several factors can influence the price of basketball leather, making it crucial for buyers to understand these dynamics:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs). Larger orders can lead to volume discounts, making it more cost-effective per unit. Buyers should negotiate for better rates based on their expected consumption.

-

Specifications and Customization: Custom requests, such as specific colors or textures, can increase costs. Buyers should have clear specifications to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher-quality leathers come with certifications that guarantee their origin and treatment. Buyers seeking sustainable or certified materials may pay a premium but can enhance their brand’s value.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality and service may charge higher prices but offer assurance of consistency.

-

Incoterms: Understanding Incoterms is vital for international transactions. They dictate responsibility for shipping costs and risks, affecting the total cost of acquisition.

What Are Some Effective Buyer Tips for Negotiating Basketball Leather Prices?

For international B2B buyers, especially from regions like Africa, South America, and the Middle East, effective negotiation and cost-efficiency strategies are essential:

Illustrative image related to basketball leather

-

Research and Benchmarking: Before negotiations, research market prices for various leather types. Benchmark against multiple suppliers to identify competitive pricing.

-

Total Cost of Ownership (TCO): Consider not just the upfront cost of leather but the TCO, including shipping, duties, and long-term durability. Investing in higher-quality leather may yield lower replacement costs over time.

-

Negotiate Terms: Be prepared to negotiate payment terms, delivery schedules, and warranties. Suppliers may be willing to offer better terms for larger orders or repeat business.

-

Leverage Relationships: Building a strong relationship with suppliers can lead to better pricing and terms. Regular communication and transparency can foster trust and encourage favorable negotiations.

-

Stay Informed About Market Trends: Keep an eye on market trends, such as fluctuations in raw material prices or changes in trade regulations, which can impact costs. Being informed allows for timely decisions and adjustments.

Disclaimer on Indicative Prices

The prices mentioned are indicative and subject to change based on market conditions, supplier agreements, and specific buyer requirements. Always consult suppliers directly for the most accurate and current pricing information.

Alternatives Analysis: Comparing basketball leather With Other Solutions

Understanding Alternatives to Basketball Leather

When considering materials for basketball production, it is essential to evaluate various alternatives to basketball leather. Each option has its unique characteristics, advantages, and drawbacks. This analysis aims to compare basketball leather with two viable alternatives: synthetic leather and rubber composite materials. By understanding these options, B2B buyers can make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | Basketball Leather | Synthetic Leather | Rubber Composite Materials |

|---|---|---|---|

| Performance | High durability and grip; ideal for professional use | Good performance; less durable than leather | Offers good bounce and grip; less realistic feel |

| Cost | Higher cost ($257 per side) | Moderate cost ($150 – $200 per ball) | Lower cost ($30 – $80 per ball) |

| Ease of Implementation | Requires skilled labor for crafting | Easier to manufacture; less specialized | Simple production processes |

| Maintenance | Requires regular conditioning | Low maintenance; easy to clean | Minimal maintenance needed |

| Best Use Case | Professional leagues and high-end recreational use | Youth leagues and casual play | Training sessions and informal games |

Pros and Cons of Alternatives

Synthetic Leather

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), serves as a popular alternative to traditional basketball leather. Its main advantage lies in its cost-effectiveness and ease of production. Synthetic leather can mimic the appearance and feel of real leather while being more resistant to moisture and easier to clean. However, it tends to be less durable than genuine leather, which can lead to performance degradation over time, particularly under rigorous use.

Illustrative image related to basketball leather

Rubber Composite Materials

Rubber composite materials are commonly used for budget-friendly basketballs. They offer excellent bounce and grip, making them suitable for training and casual play. The primary benefit of rubber composite is its affordability, often costing significantly less than both leather and synthetic alternatives. However, the trade-off is a less authentic feel and lower durability, which may not meet the performance standards required for professional-level play.

Conclusion: How to Choose the Right Material for Basketballs

Selecting the appropriate material for basketball production hinges on various factors, including performance requirements, budget constraints, and intended use cases. For professional leagues and high-end recreational play, basketball leather remains the gold standard due to its durability and superior grip. In contrast, synthetic leather is ideal for youth leagues or casual players seeking affordability with decent performance. Rubber composite materials serve well for training and informal games where cost is a significant concern. By carefully assessing these aspects, B2B buyers can choose the best solution that aligns with their operational needs and target market preferences.

Essential Technical Properties and Trade Terminology for basketball leather

What Are the Key Technical Properties of Basketball Leather?

When sourcing basketball leather, understanding its technical properties is crucial for making informed purchasing decisions. Below are some of the most critical specifications that B2B buyers should consider:

-

Material Grade

The material grade of basketball leather refers to the quality and type of hide used, typically sourced from cowhide. Higher grades indicate better durability and performance, essential for high-stakes environments such as professional sports. Selecting a superior grade can significantly affect the longevity of the basketballs produced, thus enhancing customer satisfaction and reducing replacement costs. -

Substance (Thickness)

The thickness of basketball leather is measured in ounces or millimeters, with common specifications ranging from 2.0 to 4.5 oz. This property impacts the leather’s flexibility, durability, and overall feel. A thicker leather can provide better grip and resilience against wear, making it suitable for high-performance basketballs. Buyers must match the thickness to their intended product use to ensure optimal performance. -

Average Skin Size

Basketball leather typically comes in sides ranging from 18 to 22 square feet. Understanding the average skin size is vital for manufacturers to estimate how many basketballs can be produced from a single hide. This information aids in inventory management and cost calculation, allowing businesses to optimize their production processes and minimize waste. -

Tannage Process

The tanning process, which can be chrome or vegetable-based, affects the leather’s final properties, including softness, color retention, and water resistance. Chrome-tanned leather is generally more durable and flexible, making it ideal for sports applications. Buyers should inquire about the tanning process to ensure that the leather meets their performance requirements. -

Finish and Characteristics

The finish of the leather can vary, with options including embossed, matte, or semi-bright. Each finish contributes to the aesthetics and grip of the basketballs. For example, an embossed finish may offer enhanced grip for players, while a matte finish could provide a more classic look. Understanding the characteristics of the leather helps buyers select the right product for their brand image and target market.

What Are Common Trade Terminology and Jargon Used in Basketball Leather Procurement?

Navigating the procurement of basketball leather requires familiarity with specific trade terms. Here are some essential jargon terms relevant to B2B transactions:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of basketball leather, an OEM might be a tannery that supplies leather specifically for basketball production. Understanding OEM relationships can help buyers identify quality sources and ensure product consistency. -

MOQ (Minimum Order Quantity)

MOQ denotes the minimum amount of product a supplier is willing to sell. For basketball leather, this could mean a specific number of hides or square footage. Knowing the MOQ helps buyers plan their orders effectively and gauge supplier flexibility, which is especially important for businesses looking to scale production. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for a specific product or service. For basketball leather, an RFQ should detail the required specifications, such as grade, thickness, and finish. This process enables buyers to compare offers and negotiate better deals. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) dictate who bears the cost and risk at various stages of the shipping process. Understanding Incoterms is crucial for B2B buyers engaging in international trade to avoid unexpected costs. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. This timeframe is vital for planning production schedules and inventory levels. Buyers should communicate with suppliers about expected lead times to ensure timely delivery of basketball leather, especially during peak seasons.

By understanding these technical properties and trade terms, B2B buyers can make better-informed decisions when sourcing basketball leather, ensuring high-quality products that meet market demands.

Navigating Market Dynamics and Sourcing Trends in the basketball leather Sector

What Are the Current Market Dynamics and Key Trends in the Basketball Leather Sector?

The global basketball leather market is witnessing significant growth, driven by increasing participation in basketball across various regions, particularly in Africa, South America, the Middle East, and Europe. The rising popularity of basketball as a sport is leading to heightened demand for high-quality basketballs, which in turn fuels the need for superior leather. Manufacturers are increasingly collaborating with established tanneries like Horween to produce premium leather that meets the performance standards expected by athletes.

Technological advancements in leather processing are also shaping sourcing trends. Innovations such as automated tanning processes and quality control systems enhance the consistency and quality of leather products. Furthermore, the advent of e-commerce platforms is simplifying the procurement process for B2B buyers, allowing them to source products directly from manufacturers or tanneries without intermediaries.

Emerging trends include a growing focus on customization, where brands are offering bespoke basketballs tailored to specific customer preferences. This trend is particularly relevant for markets in Africa and South America, where local manufacturers are exploring unique designs and finishes to cater to regional tastes. Additionally, the integration of sustainable practices in the sourcing of basketball leather is becoming increasingly important, with buyers looking for suppliers that prioritize ethical production methods.

Illustrative image related to basketball leather

How Is Sustainability and Ethical Sourcing Influencing the Basketball Leather Supply Chain?

Sustainability is a critical concern for today’s B2B buyers in the basketball leather sector. The environmental impact of leather production—particularly in terms of water usage, chemical waste, and carbon emissions—has prompted a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers that adopt eco-friendly tanning methods and utilize renewable energy sources in their production processes.

Ethical sourcing is also gaining traction, with an emphasis on fair labor practices and transparency within supply chains. Buyers are looking for partners who can provide certifications that demonstrate compliance with environmental and social governance standards. Certifications like the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) ensure that the leather products meet stringent environmental criteria.

In addition, the use of alternative materials, such as plant-based leathers and recycled materials, is emerging as a viable option for manufacturers aiming to reduce their carbon footprint. This trend not only appeals to eco-conscious consumers but also provides B2B buyers with a unique selling proposition in increasingly competitive markets.

Illustrative image related to basketball leather

How Has the Basketball Leather Sector Evolved Over Time?

The basketball leather sector has undergone significant transformations since the inception of the sport. Early basketballs were crafted from rubber, but the introduction of leather in the mid-20th century marked a pivotal shift towards enhancing performance and durability. Tannery innovations, such as chrome tanning, have allowed for the development of high-quality leather that meets the rigorous demands of professional play.

Over the decades, collaborations between tanneries and manufacturers, such as the partnership between Horween and Spalding, have raised the bar for quality and craftsmanship in basketball leather. As the sport continues to grow globally, the emphasis on performance, sustainability, and ethical sourcing is likely to define the future of the basketball leather sector, making it crucial for B2B buyers to stay informed about these evolving dynamics.

In conclusion, the basketball leather market is rapidly adapting to meet the demands of a changing landscape. Buyers who prioritize quality, sustainability, and innovation will be well-positioned to capitalize on emerging opportunities in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of basketball leather

-

How do I choose the right basketball leather for my products?

Selecting the appropriate basketball leather involves considering several factors such as thickness, texture, and intended use. For manufacturing high-quality basketballs, look for leather that is durable and has a suitable grip. Generally, leather with a thickness of 2.0 to 4.5 oz is preferred for optimal performance. It’s advisable to request samples from suppliers to evaluate the leather’s characteristics firsthand. Additionally, consider the supplier’s reputation and their experience in producing leather specifically for sporting goods. -

What are the common minimum order quantities (MOQs) for basketball leather?

Minimum order quantities can vary significantly among suppliers. Typically, MOQs for basketball leather range from 100 square feet to larger quantities for bulk orders. Some suppliers may allow smaller sample orders for evaluation, but it’s essential to confirm these details upfront. When sourcing internationally, consider that shipping costs may affect your total order size and pricing, so it’s wise to align your order with your production needs to optimize costs. -

What payment terms should I expect when sourcing basketball leather internationally?

Payment terms can differ based on the supplier and the nature of the transaction. Common practices include a 50% upfront deposit, with the balance due before shipment. Some suppliers may offer credit terms or discounts for larger orders. It’s crucial to clarify these terms in advance and consider using secure payment methods to protect your investment. Be aware of potential currency exchange fees and ensure that the payment method aligns with your financial operations. -

How can I ensure the quality of basketball leather before making a large purchase?

To ensure quality, request samples from suppliers to assess the leather’s texture, durability, and overall appearance. Conduct tests such as grip and flexibility to determine suitability for your intended use. Additionally, inquire about the supplier’s quality assurance processes and certifications. Establishing a clear communication channel with the supplier can help address any concerns before placing a significant order, thus minimizing risks associated with quality discrepancies. -

What are the logistics considerations when importing basketball leather?

When importing basketball leather, consider shipping methods, customs duties, and lead times. Air freight is faster but more expensive, while sea freight can be cost-effective for larger shipments but may take longer. Ensure you understand the import regulations of your country and any documentation required. Collaborating with a reliable freight forwarder can streamline the process, helping you navigate customs and ensuring timely delivery. -

How do I vet suppliers for basketball leather?

Vetting suppliers is crucial to ensure reliability and quality. Start by researching their background, including years in business, client testimonials, and product certifications. Request references and conduct background checks to verify their credibility. If possible, arrange a factory visit or audit to assess their manufacturing capabilities and quality control processes. Online platforms and trade shows can also provide insights into a supplier’s reputation within the industry. -

Can I customize basketball leather for my brand?

Yes, many suppliers offer customization options for basketball leather, including color, texture, and branding. Discuss your specific requirements with the supplier to see what options are available. Customization may involve additional costs and longer lead times, so it’s essential to factor these into your planning. Ensure that the supplier can meet your design specifications while maintaining the quality standards necessary for your products. -

What are the best practices for storing basketball leather?

Proper storage is essential to maintain the quality of basketball leather. Store it in a cool, dry place away from direct sunlight to prevent drying or fading. Avoid stacking heavy items on top of the leather to prevent deformation. If the leather is not used immediately, consider wrapping it in breathable fabric to protect it from dust and moisture. Regularly inspect stored leather for any signs of damage or deterioration to ensure it remains in optimal condition for production.

Top 5 Basketball Leather Manufacturers & Suppliers List

1. Horween – Basketball Leather

Domain: thetanneryrow.com

Registered: 2011 (14 years)

Introduction: Product Name: Horween Basketball Leather

Price: $257.00

Description: Horween produces high-quality leather for footballs, basketballs, and ball gloves, emphasizing excellence and quality. They collaborate with top sporting goods manufacturers to develop these leathers, ensuring no detail is overlooked.

Specifications:

– Sides range between 18-22 sq ft

– Normally produced in 4.5 oz (inquire for d…

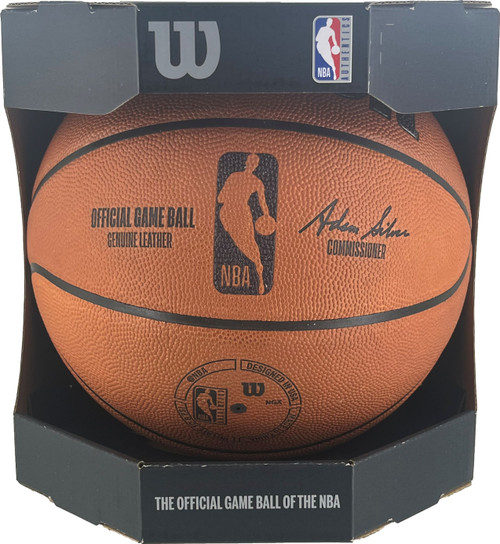

2. Buckleguy – Horween NBA Basketball Leather Panel

Domain: buckleguy.com

Registered: 2002 (23 years)

Introduction: {“Product Name”:”Horween NBA Basketball Leather Panel, Orange”,”Price”:”$9.20″,”Tannage”:”Chrome Tanned”,”Type”:”Sports Leather”,”Tannery”:”Horween”,”Weight/Thickness”:”4.5/5oz (1.8-2.0mm)”,”Cut”:”Panel”,”Firmness”:”Semi-Soft”,”Sizes”:[{“Size”:”0.5 Square Foot”,”Dimensions”:”6.5 inch x 11 inch”},{“Size”:”1.0 Square Foot”,”Dimensions”:”13 inch x 11 inch”},{“Size”:”1.5 Square Foot”,”Dimensions”:”19….

3. Horween – Basketball Leather

Domain: aacrack.com

Registered: 2006 (19 years)

Introduction: Product Name: HORWEEN BASKETBALL – BLACK – 2.0/2.2mm

Characteristics: Embossed, Firm Handle, Semi Bright

Substance: 2.0/2.2mm

Average Skin Size: 18 – 22 sqft

Animal: Cow

Cut Section: Side/Half Hide

Tannage: Chrome

Produced by: American tannery Horween

Usage: Exclusively made for sporting goods manufacturer Spalding, supplying the NBA with its balls. Developed for easier use in manufacturing compar…

4. Reddit – Genuine Leather Basketball

5. Spalding – Composite Leather Basketballs

Domain: spalding-basketball.com

Registered: 2003 (22 years)

Introduction: Composite leather basketballs are made from a man-made material designed to replicate the look and feel of genuine leather. They offer a softer grip and more consistent performance, especially on indoor courts, without the need for break-in time or maintenance. Composite leather combines the best features of rubber and genuine leather, providing a soft feel, reliable grip, and immediate playabilit…

Strategic Sourcing Conclusion and Outlook for basketball leather

What Are the Key Takeaways for Sourcing Basketball Leather?

Strategic sourcing of basketball leather is critical for businesses aiming to deliver high-quality sporting goods. Key factors to consider include the leather’s origin, treatment processes, and specifications that meet performance standards. For instance, premium options like Horween basketball leather are renowned for their durability and performance, making them a preferred choice for top manufacturers. Understanding the nuances of leather types, such as weight and finish, can help buyers align their products with market demands while ensuring superior quality.

How Can International Buyers Benefit from Strategic Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can lead to competitive advantages. Establishing relationships with reputable suppliers not only ensures access to quality materials but also opens avenues for customization and bulk pricing. This is crucial for meeting local market preferences and enhancing brand reputation.

Illustrative image related to basketball leather

What Is the Future Outlook for Basketball Leather Sourcing?

Looking ahead, the demand for high-quality basketball leather is expected to rise, driven by increased participation in sports and evolving consumer preferences. Buyers are encouraged to stay ahead of trends and invest in sustainable sourcing practices. By collaborating with trusted manufacturers, businesses can ensure they are well-positioned to meet future challenges and capitalize on emerging opportunities in the global market. Consider reaching out to suppliers today to secure your position in this dynamic industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.