Introduction: Navigating the Global Market for leather factory florence

In the dynamic landscape of international trade, sourcing high-quality leather products from Florence can pose significant challenges for B2B buyers. The leather factory Florence represents not just a geographical location but a hub of craftsmanship, tradition, and innovation in leather production. This guide serves as an essential tool for international buyers looking to navigate the complexities of sourcing leather goods, including handbags, apparel, and accessories. It delves into various aspects such as supplier vetting, cost considerations, customization options, and the unique attributes of Florentine leather that distinguish it in the global marketplace.

Florence’s rich history in leather craftsmanship, combined with its modern manufacturing capabilities, makes it a prime destination for businesses seeking premium leather products. This guide empowers B2B buyers from diverse regions—including Africa, South America, the Middle East, and Europe—to make informed purchasing decisions. By addressing critical questions about quality assurance, logistical considerations, and market trends, we aim to enhance your sourcing strategy.

Whether you are looking to establish long-term partnerships with reliable suppliers or seeking insights into the latest product innovations, this comprehensive resource will equip you with the knowledge needed to successfully navigate the global leather market. The journey to sourcing exceptional leather begins here, and we are committed to guiding you every step of the way.

Table Of Contents

- Top 8 Leather Factory Florence Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather factory florence

- Understanding leather factory florence Types and Variations

- Key Industrial Applications of leather factory florence

- 3 Common User Pain Points for ‘leather factory florence’ & Their Solutions

- Strategic Material Selection Guide for leather factory florence

- In-depth Look: Manufacturing Processes and Quality Assurance for leather factory florence

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather factory florence’

- Comprehensive Cost and Pricing Analysis for leather factory florence Sourcing

- Alternatives Analysis: Comparing leather factory florence With Other Solutions

- Essential Technical Properties and Trade Terminology for leather factory florence

- Navigating Market Dynamics and Sourcing Trends in the leather factory florence Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather factory florence

- Strategic Sourcing Conclusion and Outlook for leather factory florence

- Important Disclaimer & Terms of Use

Understanding leather factory florence Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| High-End Fashion Leather | Premium quality, unique designs, artisan craftsmanship | Luxury fashion brands, boutiques | Pros: Exceptional quality; unique styles. Cons: Higher cost; longer lead times. |

| Customizable Leather Goods | Personalized designs, various leather types, bespoke options | Wholesalers, retailers, private labels | Pros: Tailored products; brand differentiation. Cons: Complexity in order management. |

| Eco-Friendly Leather | Sustainable sourcing, vegetable-tanned, environmentally conscious | Eco-conscious brands, niche markets | Pros: Appeals to sustainability-focused consumers; compliance with regulations. Cons: Potentially higher prices; limited availability. |

| Artisan Leather Accessories | Handcrafted items, traditional techniques, intricate detailing | Gift shops, specialty stores | Pros: Unique, high-quality products; cultural authenticity. Cons: Limited production capacity; higher price points. |

| Industrial Leather Supplies | Bulk production, standardized products, various leather types | Manufacturing, upholstery, automotive | Pros: Cost-effective; large quantities available. Cons: Less customization; potential quality variability. |

What are the Characteristics of High-End Fashion Leather?

High-end fashion leather is characterized by its premium quality and unique designs crafted by skilled artisans. This type of leather is often used in luxury fashion brands, where the emphasis is on exclusivity and craftsmanship. B2B buyers in this sector should consider the supplier’s reputation for quality, the uniqueness of designs, and the materials used, as these factors significantly influence marketability and consumer demand. While the investment is higher, the potential for high retail margins can justify the cost.

Why Consider Customizable Leather Goods for Your Business?

Customizable leather goods offer a unique advantage for B2B buyers looking to differentiate their product offerings. These items can be tailored to meet specific market demands, with options for different leather types, colors, and designs. This flexibility is particularly appealing to wholesalers and private label retailers. Buyers should assess the manufacturer’s ability to handle customization requests efficiently, as well as the potential for longer lead times. While customization can enhance brand identity, it requires careful management to ensure timely delivery.

Illustrative image related to leather factory florence

What Makes Eco-Friendly Leather an Attractive Option?

Eco-friendly leather is sourced sustainably and often made using vegetable tanning methods, making it a popular choice for brands that prioritize environmental responsibility. This type of leather appeals to niche markets and eco-conscious consumers, providing B2B buyers with a competitive edge in an increasingly sustainability-focused marketplace. However, buyers must consider the potentially higher costs and limited availability associated with these products. Ensuring compliance with environmental regulations can also be an essential factor in purchasing decisions.

How Do Artisan Leather Accessories Stand Out?

Artisan leather accessories are handcrafted, showcasing traditional techniques and intricate detailing that reflect cultural authenticity. These products are often sought after by gift shops and specialty stores looking to offer unique items. B2B buyers should prioritize suppliers with a strong history of craftsmanship and a commitment to quality. While the production capacity may be limited and prices higher, the unique appeal of these accessories can justify the investment and attract discerning customers.

What are the Benefits of Industrial Leather Supplies for Manufacturers?

Industrial leather supplies cater to businesses requiring bulk production of standardized products, suitable for various applications such as upholstery and automotive. This type of leather is typically more cost-effective, allowing manufacturers to maintain competitive pricing. B2B buyers should evaluate the supplier’s capacity for large orders and consistency in quality, as these factors are crucial for maintaining production schedules. However, the trade-off may involve less customization and variability in product quality, which buyers must carefully consider.

Illustrative image related to leather factory florence

Key Industrial Applications of leather factory florence

| Industry/Sector | Specific Application of leather factory florence | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | High-end leather clothing production | Access to premium, artisanal craftsmanship that enhances brand value | Certifications, customization options, lead times, material sourcing |

| Luxury Handbags & Accessories | Custom leather handbags and accessories | Unique, personalized products that attract affluent clientele | Minimum order quantities, branding options, quality control processes |

| Automotive | Leather interiors for luxury vehicles | Enhanced aesthetic appeal and comfort, increasing vehicle value | Compliance with automotive standards, durability, and color matching |

| Furniture & Home Décor | Leather upholstery for furniture | High-quality materials that elevate product offerings | Customization capabilities, material certifications, delivery timelines |

| Sporting Goods | Leather goods for sports equipment (e.g., gloves, bags) | Durability and performance enhancements for competitive products | Sourcing of specific leather types, functional design requirements |

How is Leather from Florence Used in Fashion and Apparel?

Florence’s leather factories are pivotal for the fashion and apparel industry, particularly for high-end clothing. The craftsmanship involved in producing leather garments ensures that each piece is not only stylish but also durable. International buyers from regions like Africa and South America often seek unique designs that reflect local cultures while maintaining the luxury associated with Italian leather. Key considerations include lead times and the ability to customize designs to meet specific market trends.

What Are the Applications for Custom Leather Handbags and Accessories?

The luxury handbag sector thrives on the bespoke offerings from Florence’s leather factories. These artisans create customized handbags that cater to discerning customers looking for exclusivity. B2B buyers in the Middle East and Europe can leverage this to differentiate their product lines. Important sourcing considerations include minimum order quantities and options for branding, such as embossed logos or personalized tags, which can significantly enhance market appeal.

How Does Leather from Florence Enhance Automotive Interiors?

Florentine leather is renowned for its quality, making it a preferred choice for luxury automotive interiors. The use of high-grade leather not only elevates the aesthetic appeal of vehicles but also adds to their comfort and resale value. Automotive manufacturers and suppliers must consider compliance with industry standards and the durability of the leather, ensuring it withstands wear and tear while maintaining its luxurious appearance.

In What Ways is Leather Applied in Furniture and Home Décor?

In the furniture industry, leather from Florence is used for upholstery, providing a sophisticated finish that attracts consumers seeking high-quality home décor. Buyers looking to source leather for furniture must prioritize customization capabilities and the availability of various textures and colors. Ensuring that the leather meets specific certifications for safety and durability is also critical, especially for international markets.

How is Leather Utilized in Sporting Goods Production?

Leather from Florence is also integral to the production of sporting goods, including gloves and bags. The durability and performance characteristics of this leather enhance the functionality of sports equipment, making it a sought-after material for manufacturers. Buyers must focus on the specific leather types required for different sports, ensuring that the sourcing aligns with performance standards and design requirements to meet consumer expectations.

Illustrative image related to leather factory florence

3 Common User Pain Points for ‘leather factory florence’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Leather Sourcing

The Problem: B2B buyers often grapple with ensuring the quality of leather products sourced from factories in Florence. The challenge lies in the inconsistency of quality across different suppliers, which can lead to product returns, customer dissatisfaction, and damage to a brand’s reputation. Buyers may find it difficult to verify the authenticity of claims regarding the craftsmanship and materials used, especially when sourcing from international suppliers without the opportunity for on-site inspections.

The Solution: To effectively navigate quality assurance challenges, buyers should establish a thorough vetting process for potential leather factories in Florence. This involves requesting samples of the leather and finished products before committing to larger orders. Engaging in direct communication with factory representatives can provide insights into their production processes and quality control measures. Additionally, buyers should consider visiting the factories if possible, or utilizing third-party inspection services that specialize in leather goods. This proactive approach ensures that the products meet specified standards, reducing the risk of quality discrepancies upon delivery.

Scenario 2: Overcoming Customization Limitations in Leather Production

The Problem: International buyers often encounter limitations when seeking customized leather products from factories in Florence. Many factories may have rigid templates or designs, making it difficult for buyers to implement their unique branding or specific product modifications. This limitation can hinder a buyer’s ability to differentiate their offerings in a competitive market, particularly in regions where tailored solutions are highly valued.

The Solution: To overcome customization challenges, buyers should clearly articulate their specific requirements early in the sourcing process. It is beneficial to compile a detailed specification sheet that outlines desired features, materials, colors, and branding elements. Engaging with factories that emphasize flexibility in production, such as those offering private label services, can also facilitate customization. Additionally, fostering a collaborative relationship with the artisans can lead to innovative solutions that fulfill the buyer’s vision while respecting traditional craftsmanship. Regular feedback during the prototype phase will help ensure that the final product aligns with the buyer’s expectations.

Scenario 3: Managing Lead Times and Production Schedules Effectively

The Problem: One of the most pressing concerns for B2B buyers in the leather industry is managing lead times and production schedules. Delays in production can lead to missed market opportunities and stock shortages, particularly for seasonal products or limited-edition lines. Buyers may find it challenging to coordinate timelines with the factory, especially if communication issues arise or if the factory is overwhelmed with orders.

Illustrative image related to leather factory florence

The Solution: To manage lead times effectively, buyers should establish clear timelines and communicate them upfront during negotiations with the leather factory. Implementing a detailed project management tool or timeline that outlines key milestones, such as sample approval, production start dates, and shipping schedules, can enhance transparency and accountability. Buyers should also consider building a buffer into their timelines to accommodate unforeseen delays. Regular check-ins with the factory throughout the production process will keep all parties aligned and allow for timely adjustments if necessary. Establishing a strong partnership with the factory can also lead to prioritization of orders, ensuring that production schedules are met consistently.

By addressing these common pain points with actionable strategies, B2B buyers can enhance their sourcing experience with leather factories in Florence, leading to successful partnerships and high-quality product offerings.

Strategic Material Selection Guide for leather factory florence

What Are the Key Materials Used in Leather Production in Florence?

Florence is synonymous with high-quality leather craftsmanship, and the materials selected play a crucial role in the final product’s performance and appeal. Below, we analyze four common materials used in leather production, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Vegetable-Tanned Leather?

Vegetable-tanned leather is a traditional material that uses natural tannins from plant sources. This type of leather is known for its durability and environmental friendliness.

Illustrative image related to leather factory florence

- Key Properties: Vegetable-tanned leather exhibits excellent breathability and moisture resistance, making it suitable for various applications, including bags and apparel. It can withstand temperature variations, though it is not as resistant to water as chrome-tanned leather.

- Pros & Cons: The primary advantage of vegetable-tanned leather is its sustainability and ability to develop a rich patina over time. However, it can be more expensive and requires longer production times due to the tanning process.

- Impact on Application: This leather is ideal for products that benefit from aging, such as high-end handbags and belts. However, it may not be the best choice for items exposed to harsh weather conditions.

- Considerations for International Buyers: Buyers from regions with strict environmental regulations, such as Europe, may prefer this leather due to its eco-friendly properties. Compliance with standards like REACH is essential.

How Does Chrome-Tanned Leather Compare in Performance?

Chrome-tanned leather is treated with chromium salts, making it more pliable and resistant to water and heat.

- Key Properties: This material is highly resistant to wear and tear and can withstand high temperatures, making it suitable for various applications, including footwear and upholstery.

- Pros & Cons: The main advantage is its quick production time and versatility. However, the environmental impact of chrome tanning raises concerns, especially in markets focused on sustainability.

- Impact on Application: Chrome-tanned leather is ideal for products requiring water resistance and durability, such as jackets and outdoor gear. Its softness also makes it a preferred choice for high-fashion items.

- Considerations for International Buyers: Buyers in regions like Africa and South America may find this leather appealing due to its affordability and durability. However, awareness of environmental regulations is crucial, as compliance with standards like ASTM may be required.

What Are the Benefits of Suede Leather in Luxury Goods?

Suede leather, made from the underside of animal hides, offers a unique texture and aesthetic appeal.

- Key Properties: Suede is soft and flexible, providing a luxurious feel. However, it is less durable than other types of leather and is more susceptible to staining and water damage.

- Pros & Cons: The softness and aesthetic appeal are significant advantages, making it popular for luxury goods. On the downside, it requires more care and maintenance, which can be a drawback for some consumers.

- Impact on Application: Suede is often used in high-end fashion items and accessories, where texture and appearance are paramount. Its limitations in durability may restrict its use in everyday items.

- Considerations for International Buyers: Buyers from Europe and the Middle East may appreciate suede’s luxury appeal, but they should consider the additional care required. Compliance with textile standards may also be necessary.

How Does Nappa Leather Stand Out in Quality?

Nappa leather is a type of full-grain leather known for its softness and smooth texture.

- Key Properties: This leather is highly durable and resistant to wear, making it suitable for high-end products. It also offers excellent color retention and is less prone to fading.

- Pros & Cons: The primary advantage is its luxurious feel and appearance, making it ideal for premium products. However, it can be more expensive than other leather types, which may deter some buyers.

- Impact on Application: Nappa leather is commonly used in luxury handbags, clothing, and automotive interiors, where both aesthetics and durability are essential.

- Considerations for International Buyers: Buyers from affluent markets, such as Europe and the Middle East, may prioritize Nappa leather for its quality. Compliance with luxury product standards is crucial for maintaining brand reputation.

Summary Table of Leather Materials for B2B Buyers

| Material | Typical Use Case for leather factory florence | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-end handbags, belts | Eco-friendly and durable | Longer production time | High |

| Chrome-Tanned Leather | Footwear, outdoor gear | Quick production and versatile | Environmental concerns | Medium |

| Suede Leather | Luxury fashion items | Soft texture and aesthetic | Less durable, requires care | Medium |

| Nappa Leather | Premium handbags, automotive interiors | Luxurious feel and durability | Higher cost | High |

This guide serves as a valuable resource for international B2B buyers, helping them make informed decisions about material selection based on performance, application, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for leather factory florence

What Are the Main Stages in the Manufacturing Process of Leather Goods in Florence?

The manufacturing process of leather goods in Florence involves several key stages, each contributing to the final product’s quality and craftsmanship. Understanding these stages is crucial for B2B buyers who seek high-quality leather products for their businesses.

Material Preparation: How Is Leather Selected and Processed?

The journey begins with the careful selection of raw materials. Florentine manufacturers primarily use vegetable-tanned leather, known for its durability and eco-friendliness. The leather is sourced from reputable tanneries that adhere to European regulations, ensuring both quality and compliance with international standards.

Illustrative image related to leather factory florence

After selection, the leather undergoes a preparation phase, which includes soaking, cleaning, and conditioning. This step is vital as it prepares the leather for further processing, ensuring that it remains supple and free of defects. Skilled artisans inspect each hide for flaws, such as scars or inconsistencies, which could affect the final product.

Forming: What Techniques Are Used to Shape Leather Products?

Once the leather is prepared, the next stage is forming. This involves cutting the leather into specific patterns required for the product. Advanced techniques such as laser cutting may be employed alongside traditional hand-cutting methods, ensuring precision and reducing material waste.

Artisans then shape the leather using wooden molds or by hand, depending on the complexity of the design. This stage is critical for defining the product’s structure, whether it be a handbag, jacket, or accessory. Techniques like embossing may also be used to add unique designs or textures, enhancing the product’s aesthetic appeal.

Illustrative image related to leather factory florence

Assembly: How Are Leather Goods Assembled?

Assembly is where the different components of the leather product come together. Artisans meticulously sew the leather pieces, often using high-quality threads that match or contrast with the leather color. Techniques such as double-stitching are commonly applied to enhance durability.

During this stage, additional features like zippers, linings, and pockets are incorporated. Quality craftsmanship is essential, as the assembly process directly influences the product’s functionality and longevity. Artisans often perform this step by hand, allowing for greater control and attention to detail.

Finishing: What Are the Final Touches Applied to Leather Products?

The finishing stage is where the product receives its final touches. This includes coloring, polishing, and applying protective coatings to enhance the leather’s appearance and durability. Various finishing techniques, such as hand-burnishing, are used to achieve a smooth and refined surface.

At this point, quality checks are conducted to ensure that the products meet the required standards. This includes inspecting the seams, edges, and overall appearance of the item. Each piece is often subjected to a final quality assurance process before it is deemed ready for sale.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a critical aspect of the manufacturing process in leather factories. For B2B buyers, understanding the relevant international standards and industry-specific certifications is essential for ensuring that the products meet their expectations.

Illustrative image related to leather factory florence

Which International Standards Are Important for Leather Manufacturing?

The ISO 9001 standard is widely recognized in the leather industry, focusing on quality management systems. Factories that are ISO 9001 certified demonstrate a commitment to consistent quality and customer satisfaction. Additionally, other certifications such as CE marking ensure that products comply with European health and safety regulations.

For specific leather goods, buyers may look for certifications related to environmental impact, such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG) certification, which evaluates the environmental practices of tanneries.

What Are the Key Quality Control Checkpoints in Leather Manufacturing?

Quality control (QC) is integrated at various stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the production process helps identify defects early, allowing for timely corrections.

- Final Quality Control (FQC): A comprehensive inspection of finished products ensures they meet all quality standards before shipment.

Common testing methods include tensile strength tests, colorfastness tests, and assessments of physical properties such as softness and flexibility. These tests help verify that the products can withstand the rigors of use.

Illustrative image related to leather factory florence

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are several strategies to ensure the reliability of potential partners:

- Conduct Audits: Schedule regular audits of the manufacturing facility to assess their adherence to quality standards and production practices.

- Request Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, testing results, and any corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the products and processes, providing additional assurance of quality.

What Are the Nuances of Quality Control for International Buyers?

When dealing with suppliers from Florence, international buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of certain nuances in quality control:

- Cultural Considerations: Understand that communication styles and expectations may differ. Building a strong relationship with suppliers can facilitate better quality assurance practices.

- Regulatory Compliance: Ensure that the products comply with the regulations of the importing country, which may differ from those in Italy. This is particularly important for markets in Africa and South America, where compliance requirements can vary significantly.

- Flexibility in Customization: Many Florentine manufacturers offer customization options. Buyers should clearly communicate their specifications and expectations to avoid misunderstandings and ensure the final product meets their needs.

By understanding the manufacturing processes and quality assurance practices of leather factories in Florence, B2B buyers can make informed decisions, ensuring they procure high-quality leather products that meet their business requirements.

Illustrative image related to leather factory florence

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather factory florence’

The following guide serves as a comprehensive checklist for B2B buyers interested in sourcing leather products from factories in Florence. This step-by-step approach will ensure that you make informed decisions, ensuring quality and reliability in your procurement process.

Step 1: Identify Your Product Requirements

Before engaging with suppliers, clearly define what you need. This includes specific types of leather goods, such as handbags, jackets, or accessories, along with desired materials, colors, and styles. Establishing these parameters will streamline your search and help you communicate effectively with potential suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of reputable leather factories in Florence. Utilize online directories, trade shows, and industry associations to identify manufacturers. Look for those that have a strong reputation for quality craftsmanship and have been in business for several years, as longevity often correlates with reliability.

Illustrative image related to leather factory florence

- Key Resources:

- Websites of established factories.

- Industry publications and reviews.

- Recommendations from other businesses.

Step 3: Evaluate Supplier Certifications

Ensure that the suppliers you consider meet necessary industry standards and certifications. This may include ISO certifications, environmental compliance, and ethical labor practices. These certifications provide assurance that the factory adheres to quality and sustainability standards, which is increasingly important for B2B buyers.

- What to Look For:

- Documentation of certifications.

- Evidence of ethical sourcing practices.

- Compliance with local and international regulations.

Step 4: Request Samples

Before making a bulk order, request samples of the products you wish to procure. This will allow you to assess the quality of materials and craftsmanship firsthand. Pay attention to details such as stitching, finishing, and the feel of the leather.

- Sample Considerations:

- Request samples in the specific styles and colors you are interested in.

- Evaluate the durability and overall quality during inspection.

Step 5: Understand Pricing and Terms

Engage with suppliers to understand their pricing structure and payment terms. Transparency in costs is vital to avoid unexpected expenses later on. Discuss bulk order discounts, shipping fees, and payment options to ensure they align with your budget and cash flow.

- Negotiation Points:

- Minimum order quantities.

- Payment terms (e.g., upfront, net 30).

- Shipping costs and timelines.

Step 6: Assess Production Capabilities

Inquire about the factory’s production capacity and lead times. Understanding their ability to meet your order volume and deadlines is crucial to your planning. Assess whether the factory can scale production if your demand increases.

- Questions to Ask:

- What is the typical lead time for orders?

- Can they handle rush orders if needed?

- What is their production capacity for your specific products?

Step 7: Establish Communication Channels

Set up clear communication channels with your chosen supplier. Effective communication is key to a successful partnership, especially when discussing design modifications, order updates, or resolving issues. Ensure they have a reliable point of contact who understands your business needs.

- Best Practices:

- Agree on preferred communication methods (email, phone, etc.).

- Schedule regular updates or check-ins during the production process.

- Ensure language barriers are addressed for smoother interactions.

Following this checklist will empower you to make informed decisions when sourcing leather products from Florence, ensuring that you partner with manufacturers who meet your quality and business standards.

Comprehensive Cost and Pricing Analysis for leather factory florence Sourcing

What Are the Key Cost Components in Sourcing from Leather Factories in Florence?

When engaging with leather factories in Florence, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality of leather significantly affects pricing. High-end leather, such as vegetable-tanned or nappa leather, is sourced from trusted suppliers, which can elevate costs. Additionally, specialized treatments or finishes can increase material expenses.

-

Labor: Florence is renowned for its skilled artisans who bring a wealth of craftsmanship to leather production. Labor costs may be higher due to the skilled nature of the work, but this often translates to superior quality products. The artisan’s experience and the complexity of the craftsmanship can also impact labor costs.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and maintenance of equipment. Given the traditional methods used in many Florentine leather factories, overhead may be higher than in mass-production environments.

-

Tooling: Custom tooling for specific designs or patterns can be a significant upfront cost. Buyers should consider whether they require bespoke molds or designs, as these can increase initial investment.

-

Quality Control (QC): Rigorous quality checks are often integrated into the manufacturing process. Investing in QC ensures that products meet international standards, which can mitigate long-term costs associated with returns or defects.

-

Logistics: Transportation and shipping costs should be factored into the total price. Depending on the destination, international shipping can add significant expenses. Additionally, customs duties and taxes may apply.

-

Margin: Finally, the margin added by the factory will depend on their business model and market positioning. High-end brands may command larger margins due to perceived value, while others may offer competitive pricing to attract bulk orders.

What Influences Pricing in Florentine Leather Sourcing?

Several factors can influence pricing when sourcing leather goods from Florence:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for volume discounts. Understanding the MOQ is essential, as it can affect the overall cost per unit.

-

Specifications and Customization: Custom designs or unique specifications can lead to increased costs. Buyers should clarify their needs upfront to avoid unexpected charges later in the process.

-

Material Quality and Certifications: Products made from high-quality, certified materials may come at a premium. Certifications can assure buyers of the leather’s authenticity and environmental compliance, which is particularly important in markets sensitive to sustainability.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established brands may have higher prices due to their market positioning and brand equity.

-

Incoterms: Understanding Incoterms is crucial for international buyers. These terms define responsibilities regarding shipping, insurance, and tariffs, which can impact the total cost.

What Are the Best Negotiation Tips for B2B Buyers in International Markets?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to better pricing and terms:

Illustrative image related to leather factory florence

-

Research and Benchmarking: Understand market prices and conditions before entering negotiations. This knowledge allows for more informed discussions and strengthens your bargaining position.

-

Focus on Total Cost of Ownership (TCO): When assessing pricing, consider the TCO, including shipping, tariffs, and potential maintenance costs. This holistic view helps to identify the most cost-effective options.

-

Build Relationships: Developing a strong relationship with suppliers can lead to better pricing and terms. Long-term partnerships often yield more favorable conditions and access to exclusive offers.

-

Flexibility in Orders: If possible, show flexibility in order sizes or specifications. This can create opportunities for suppliers to offer better pricing or terms that align with their production schedules.

-

Understand Cultural Nuances: Be aware of cultural differences in negotiation styles. Tailoring your approach to the local business etiquette can foster better communication and outcomes.

Conclusion: What Should Buyers Keep in Mind?

While the leather market in Florence offers exceptional quality, understanding the cost structure and pricing nuances is essential for effective sourcing. By considering the outlined components and strategies, international buyers can make informed decisions that align with their business needs. Always remember that prices can vary widely based on the specifics of your order, so maintaining clear communication with suppliers is key to achieving the best possible terms.

Alternatives Analysis: Comparing leather factory florence With Other Solutions

Understanding Alternatives in Leather Production

When considering leather production solutions, B2B buyers have various options beyond traditional leather factories in Florence. This section explores alternatives that provide different benefits, whether in terms of cost, production efficiency, or specific product offerings. Understanding these alternatives helps buyers make informed decisions tailored to their business needs.

Comparison Table of Leather Production Solutions

| Comparison Aspect | Leather Factory Florence | Alternative 1: Asian Leather Manufacturers | Alternative 2: Local Artisanal Workshops |

|---|---|---|---|

| Performance | High-quality craftsmanship with a focus on detail and style. | Mass production with varied quality levels. | Unique, high-quality products with personalized service. |

| Cost | Premium pricing due to skilled labor and high-quality materials. | Generally lower costs due to cheaper labor. | Moderate pricing, often higher than mass production but lower than luxury brands. |

| Ease of Implementation | Requires longer lead times due to custom orders. | Faster turnaround times for bulk orders. | Longer timelines for bespoke items, depending on the artisan’s schedule. |

| Maintenance | High durability but requires specific care. | Varies widely based on quality; lower quality may wear out quickly. | High-quality materials often lead to greater durability. |

| Best Use Case | High-end fashion and luxury goods targeting discerning clients. | Bulk orders for retail chains or mass-market products. | Customized goods for niche markets or local businesses. |

In-Depth Analysis of Alternatives

Alternative 1: Asian Leather Manufacturers

Asian manufacturers, particularly in countries like China and Vietnam, have become prominent players in the leather market. They offer competitive pricing due to lower labor costs, making them attractive for bulk orders. However, the trade-off often comes in quality, where mass production may sacrifice craftsmanship and durability. For businesses focused on large-scale operations and cost-efficiency, Asian manufacturers can be a viable option, but they may not meet the quality standards expected by luxury brands.

Alternative 2: Local Artisanal Workshops

Local artisanal workshops offer a unique approach to leather production, emphasizing craftsmanship and personalization. These workshops often create bespoke items that reflect local culture and artistry, appealing to consumers looking for authenticity. While the cost may be higher than mass-produced items, buyers benefit from the high quality and individual attention given to each piece. However, lead times can be extended, making this option less suitable for businesses needing quick turnaround times or large quantities.

Conclusion: Choosing the Right Leather Production Solution

Selecting the right leather production solution depends on the specific needs and goals of your business. For high-end, luxury items, a leather factory in Florence offers unparalleled craftsmanship and quality, making it ideal for discerning clientele. Conversely, if cost and speed are priorities, Asian manufacturers may provide the necessary scalability, albeit with potential compromises on quality. Local artisanal workshops serve a niche market, offering customized products that resonate with consumers seeking unique and high-quality items. By carefully evaluating these options, B2B buyers can align their production choices with their brand identity and market demands, ensuring a successful partnership in leather sourcing.

Illustrative image related to leather factory florence

Essential Technical Properties and Trade Terminology for leather factory florence

What Are the Key Technical Properties of Leather from Florence?

When sourcing leather products from Florence, understanding the technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

-

Material Grade

The material grade refers to the quality of the leather used in production. Florence is known for high-grade leather, often vegetable-tanned, which is more environmentally friendly and offers superior durability and aesthetics. Buyers should prioritize material grade to ensure product longevity and customer satisfaction. -

Thickness

Leather thickness is measured in millimeters and affects both the durability and flexibility of the finished product. Common thicknesses range from 0.8mm to 2.5mm, with thicker leathers being more robust. Understanding the required thickness is vital for specific applications, such as handbags versus jackets, ensuring the final product meets end-user expectations. -

Tanning Process

The tanning process affects the leather’s texture, color, and durability. Florentine leather often undergoes vegetable tanning, which is a traditional method that enhances the leather’s natural beauty and makes it biodegradable. Buyers should inquire about the tanning process to align with sustainability goals and quality standards. -

Finish Type

The finish type refers to the final treatment applied to the leather, which can range from matte to high-gloss. This affects not only the look but also the leather’s resistance to water and stains. Knowing the desired finish type is crucial for matching the product with market trends and customer preferences. -

Colorfastness

Colorfastness measures how well the leather retains its color when exposed to light and moisture. High-quality Florentine leathers are treated to ensure excellent color retention, which is particularly important for products subjected to outdoor conditions. Buyers should confirm colorfastness ratings to avoid returns and enhance customer satisfaction.

What Are Common Trade Terms Used in the Leather Industry?

Understanding industry jargon is essential for effective communication and negotiation. Here are some common terms relevant to B2B transactions in the leather sector:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces goods that are then branded and sold by another company. In the leather industry, many manufacturers in Florence may operate as OEMs, allowing buyers to offer unique products under their brand. Knowing about OEM options can provide flexibility in product offerings. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to produce or sell. This term is crucial for buyers as it directly affects inventory management and cash flow. Understanding the MOQ helps businesses plan their orders effectively and avoid overstocking or understocking issues. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain price quotes for specific products. In the leather industry, providing detailed specifications in an RFQ ensures that suppliers can deliver accurate pricing and timelines. This is essential for budgeting and project planning. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is vital for international transactions, as they dictate who bears the risk and cost during transit. -

Lead Time

Lead time refers to the time it takes from placing an order to delivery. In the leather industry, lead times can vary based on production schedules and customization requirements. Understanding lead times is crucial for inventory planning and meeting customer demands.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can enhance their decision-making processes, ensuring they procure high-quality leather products that meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the leather factory florence Sector

What Are the Current Market Dynamics and Key Trends in the Leather Factory Florence Sector?

The leather industry in Florence has experienced significant transformations, driven by global demand for high-quality, artisanal products. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly seeking out unique leather goods that reflect craftsmanship and heritage. The rise of e-commerce has facilitated access to these markets, enabling B2B buyers to source products directly from manufacturers like AJ Leather Factory and Pierotucci.

Key trends include a growing emphasis on personalization and customization, allowing clients to tailor products to their specifications. This is particularly appealing to markets in Africa and South America, where cultural preferences for unique designs are prevalent. Additionally, advancements in technology are influencing production processes, with automation being integrated into traditional craftsmanship to enhance efficiency without sacrificing quality. As global supply chains become more interconnected, buyers are also placing a premium on transparency and traceability in sourcing practices, ensuring that they understand the origins of the materials used in their products.

Illustrative image related to leather factory florence

How Is Sustainability and Ethical Sourcing Shaping the Leather Factory Florence Sector?

Sustainability has emerged as a crucial consideration for B2B buyers in the leather sector. The environmental impact of leather production, particularly concerning water usage and chemical treatments, has prompted a shift towards more sustainable practices. Florentine leather factories are increasingly adopting vegetable-tanned leather and other environmentally friendly materials that align with ethical sourcing standards.

Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential for companies aiming to demonstrate their commitment to sustainable practices. Buyers are encouraged to inquire about these certifications when sourcing leather products, as they provide assurance of ethical labor practices and environmentally responsible production methods. The growing consumer preference for sustainable products is influencing purchasing decisions, making it critical for B2B buyers to align with suppliers who prioritize ethical sourcing.

What Is the Historical Context of the Leather Industry in Florence?

Florence has a rich heritage in leather craftsmanship that dates back to the Middle Ages. The city’s strategic location along the Arno River provided the necessary resources for tanning, establishing Florence as a center for leather production. Over the centuries, the artisanal techniques have been preserved and refined, resulting in high-quality leather goods that are sought after globally.

Illustrative image related to leather factory florence

Today, manufacturers like Pelletteria Peroni continue this tradition, blending time-honored methods with modern innovation. The evolution of the leather industry in Florence reflects a balance between maintaining artisanal quality and responding to contemporary market demands, positioning the city as a leader in the global leather market. This historical context not only enriches the narrative of the products but also adds value for B2B buyers seeking authentic and culturally significant goods.

Frequently Asked Questions (FAQs) for B2B Buyers of leather factory florence

-

How do I ensure quality when sourcing leather from factories in Florence?

To ensure quality, request samples from potential suppliers before placing a bulk order. Evaluate the leather’s texture, durability, and finish. You can also inquire about the tanning process, as vegetable-tanned leather is often of higher quality. Building a relationship with the supplier is crucial; consider visiting the factory to observe their production process and quality control measures. Additionally, ask for certifications or references from previous clients to validate their reputation. -

What are the customization options available for leather products?

Most leather factories in Florence offer extensive customization options. These can include changes in design, color, size, and material types. You can also request custom branding, such as hot stamping or embossed logos. Discuss your specific requirements with the supplier to understand their capabilities and any associated costs. Ensure to have clear communication regarding your design specifications and timelines for customization. -

What is the minimum order quantity (MOQ) for leather products?

The MOQ for leather products can vary significantly depending on the manufacturer and the type of product. Generally, it ranges from 50 to 100 units for custom orders. However, some factories may offer lower MOQs for standard items. It’s advisable to communicate your needs clearly to the supplier and negotiate terms that fit your business model. Understanding the MOQ is essential for budgeting and inventory planning. -

What payment terms should I expect when working with leather suppliers in Florence?

Payment terms can vary by supplier, but many will require a deposit of 30-50% upfront before production begins, with the balance due upon completion or delivery. It’s essential to clarify payment methods accepted, such as bank transfers or letters of credit. Some suppliers may offer discounts for early payments or larger orders. Always ensure that payment terms are documented in the contract to avoid misunderstandings. -

How can I assess the reliability of a leather factory in Florence?

To assess reliability, start by researching the factory’s history and customer reviews. Look for testimonials or case studies that highlight their experience with international buyers. Request references from other B2B clients, particularly those in your region. Additionally, consider visiting the factory if possible or utilizing third-party inspection services to evaluate their operations and product quality. -

What logistics options are available for shipping leather goods internationally?

When sourcing leather goods from Florence, suppliers typically offer various logistics solutions, including air and sea freight. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Discuss with your supplier about their preferred logistics partners and whether they handle customs clearance. Ensure you understand shipping costs, insurance options, and estimated delivery times to plan accordingly for your inventory. -

What quality assurance processes should I look for in a leather factory?

Quality assurance is crucial in leather production. Look for factories that implement rigorous quality control measures throughout the manufacturing process. This includes inspections of raw materials, in-process checks, and final product evaluations. Ask about their quality certifications, such as ISO, and whether they follow industry standards for leather production. A factory with a strong QA process will help minimize defects and ensure consistent product quality. -

How do I handle communication and language barriers with suppliers in Florence?

Effective communication is key to successful B2B relationships. Many leather factories in Florence have staff who speak English, but it’s wise to confirm this before engaging. Utilize clear and concise language, avoiding jargon that may cause confusion. If language barriers persist, consider hiring a translator or using translation tools to facilitate discussions. Establishing a clear communication channel will help ensure that all specifications and expectations are understood and met.

Top 8 Leather Factory Florence Manufacturers & Suppliers List

1. AJ Leather Factory – High-End Leather Clothing

Domain: ajleatherfactory.it

Registered: 2014 (11 years)

Introduction: AJ Leather Factory specializes in high-end leather clothing production in Florence, Italy, with over a decade of experience. They produce clothing for men and women, as well as handbags and craft accessories in leather. The products are known for their original and refined features, top-quality materials, and high-level manufacturing, appealing to a demanding clientele. Collections include ASTRONO…

2. Pierotucci – Guided Leather Factory Tour

Domain: pierotucci.com

Registered: 1998 (27 years)

Introduction: Free Guided Leather Factory Tour; Free shipping over 350 €; Ship to: USA; Tour includes observation of skilled artisans at work; Explanation of leather production process; Opportunity to shop at Pierotucci Leather Store (TAX FREE shopping available); Tour available in multiple languages (Italian, English, Spanish, Japanese, Russian); Located 15 minutes from Florence; Factory tours available Monday…

3. Leonardo Leather and Gold – Handmade Leather Goods

Domain: leonardoleatherandgold.com

Registered: 2016 (9 years)

Introduction: Handmade Leather Goods from Florence Italy. Free shipping over: Europe €100, USA + Canada €200, Australia + New Zealand + Asia €250. Categories include: Men’s and Women’s Jackets, Bags, Wallets, Belts, Stationery, Journals, Jewelry (Rings, Bracelets, Necklaces & Chains). New collection items include: Florentine ‘vacchetta’ RFID cards holder/wallet (€72.95), GRAIN PRINTED CALF WALLET (€130.33), Flo…

4. Florence Leather Factory – Handbags, Suitcases & Leather Belts

Domain: florenceleatherfactory.it

Registered: 2014 (11 years)

Introduction: Manufacturer of handbags, suitcases, and leather belts since the early 80s. Located in Tuscany, Italy. Products include various handbags (SKU: 5140-5146, 5132-5137), backpacks (SKU: 5138), travel bags (SKU: 5134), and shoulder bags (SKU: 5133). All items can be customized, including inner labels, tags, liners, and hot stamping. Products are made from top-level materials certified according to Euro…

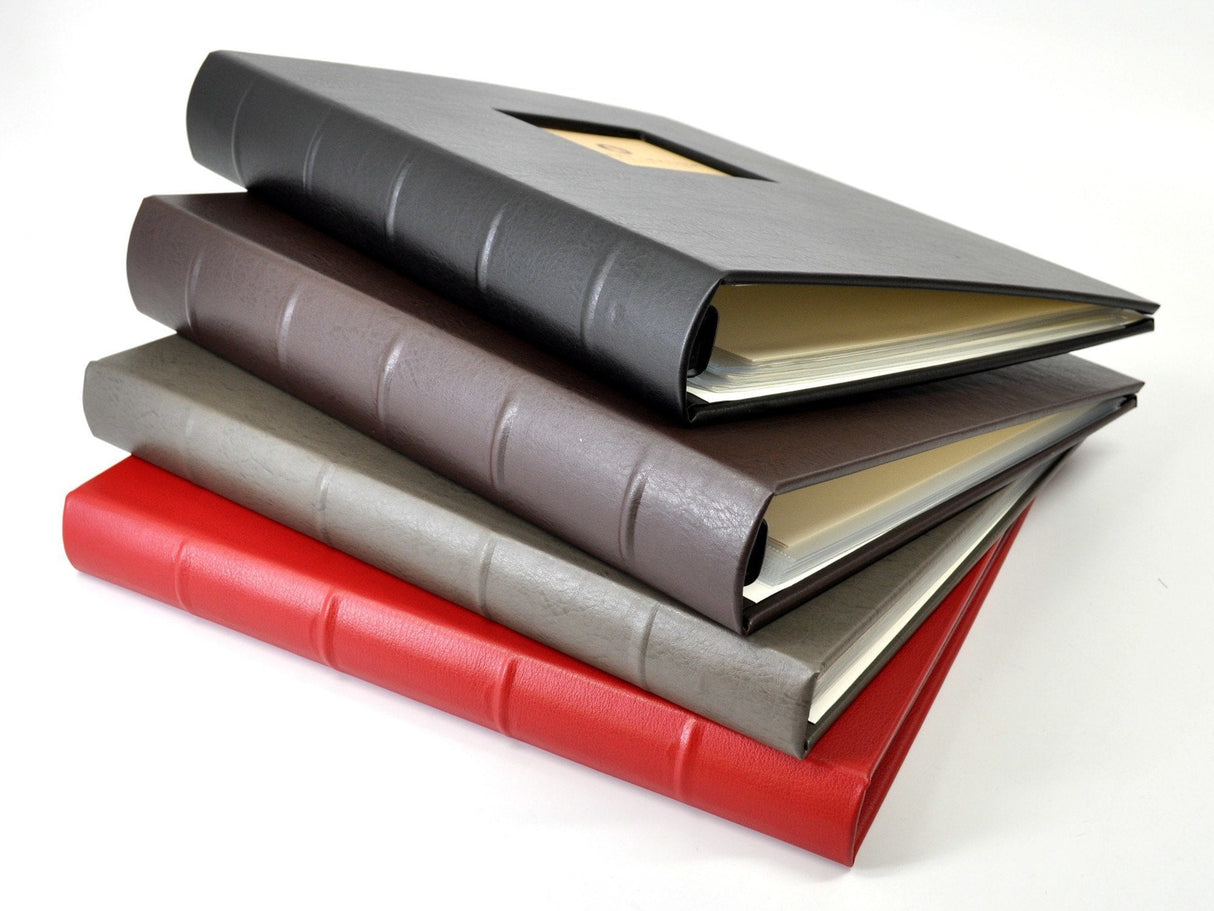

5. Peroni – Handcrafted Leather Goods

Domain: peronifirenze.com

Registered: 2016 (9 years)

Introduction: Pelletteria Peroni specializes in handcrafted leather goods made in Florence since 1956. Their product range includes bags (suitcases, briefcases, handbags, iPad holders), folders, travel cases, accessories (belts, necklaces, bracelets), business and credit card holders, wallets, keychains, eyeglasses cases, pen cases, gift items, smokers’ articles, gaming articles, sporting goods, flasks, furnitu…

6. Casini – Leather Jackets & INFINITY Bag

Domain: visitflorence.com

Registered: 2002 (23 years)

Introduction: Top Places to Buy Italian Leather in Florence: 1. Casini (Piazza de Pitti, 30, Firenze) – Known for a wide selection of leather jackets for men and women, and a unique bag called INFINITY made from one long piece of calf leather. 2. Bemporad (Via Calzaiuoli 11/15/17/B Firenze) – Established in 1885, offers handcrafted leather garments and classic leather jackets, focusing on sleek, classic lines. …

7. Peruzzi Firenze – Luxury Leather Goods

Domain: peruzzifirenze.com

Registered: 2013 (12 years)

Introduction: Peruzzi Firenze offers a range of luxury leather products including leather jackets, leather bags, and leather accessories. The product categories include: Men’s Accessories (bags, belts, wallets, clothing, jackets, coats), Women’s Accessories (bags & purses, wallets, belts, clothing, coats, jackets), and Lifestyle products. The brand emphasizes high fashion and Italian craftsmanship, with product…

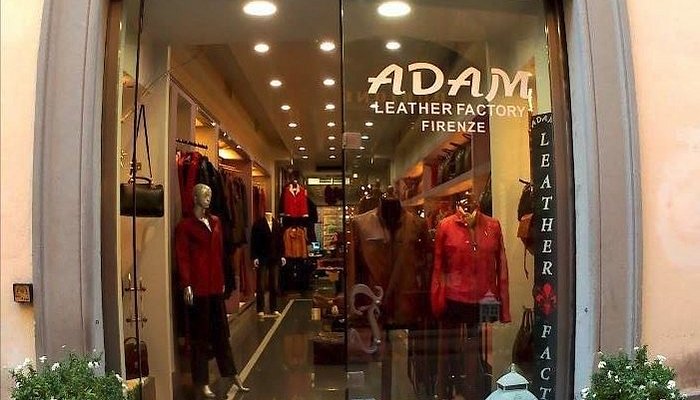

8. Adam Leather Factory – Affordable Leather Goods

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Adam Leather Factory – Affordable Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for leather factory florence

In the competitive landscape of leather manufacturing, Florence stands out as a beacon of quality and craftsmanship. International B2B buyers seeking premium leather products should recognize the unique advantages of sourcing from this historic city. The blend of traditional artisanship with modern innovations allows for a diverse range of customizable products, from high-end clothing to bespoke accessories. Collaborating with Florentine factories not only guarantees superior materials—such as vegetable-tanned leather—but also supports sustainable practices that appeal to today’s conscious consumers.

Strategic sourcing from Florence offers buyers the opportunity to tap into a rich heritage of leather craftsmanship while ensuring compliance with European quality standards. By fostering relationships with local artisans and manufacturers, businesses can gain access to exclusive designs and materials that differentiate their offerings in the marketplace.

As you consider your sourcing strategies, look toward Florence for a reliable partnership that combines artistry with innovation. Explore the potential for collaboration and elevate your product line with authentic Italian leather. Connect with Florentine factories today and take the first step towards enriching your brand’s identity with unparalleled quality and style.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to leather factory florence

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.