Introduction: Navigating the Global Market for custom leather coat makers

Navigating the complex landscape of sourcing custom leather coat makers can be a daunting task for international B2B buyers. The challenge lies not only in finding quality craftsmanship but also in ensuring that the materials and designs align with specific market demands and consumer preferences. This guide aims to demystify the process by providing an in-depth exploration of various types of custom leather coats, their applications across different sectors, and the critical steps for vetting suppliers effectively.

From understanding the intricacies of leather types—such as lambskin, goatskin, and buffalo-hide—to evaluating pricing structures and potential customization options, this comprehensive resource is tailored to empower buyers from diverse regions, including Africa, South America, the Middle East, and Europe, notably Germany and Saudi Arabia. By offering actionable insights into market trends and supplier capabilities, the guide equips businesses with the knowledge necessary to make informed purchasing decisions that not only meet aesthetic and functional requirements but also enhance brand value.

With an emphasis on quality, craftsmanship, and market alignment, this guide serves as an essential tool for any organization looking to invest in custom leather coats, ensuring a successful partnership with reputable manufacturers in the global marketplace.

Table Of Contents

- Top 8 Custom Leather Coat Makers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather coat makers

- Understanding custom leather coat makers Types and Variations

- Key Industrial Applications of custom leather coat makers

- 3 Common User Pain Points for ‘custom leather coat makers’ & Their Solutions

- Strategic Material Selection Guide for custom leather coat makers

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather coat makers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather coat makers’

- Comprehensive Cost and Pricing Analysis for custom leather coat makers Sourcing

- Alternatives Analysis: Comparing custom leather coat makers With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather coat makers

- Navigating Market Dynamics and Sourcing Trends in the custom leather coat makers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather coat makers

- Strategic Sourcing Conclusion and Outlook for custom leather coat makers

- Important Disclaimer & Terms of Use

Understanding custom leather coat makers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bespoke Leather Coats | Fully customizable designs, high-quality materials, tailored fit | High-end fashion retailers, brands | Pros: Unique offerings, premium quality; Cons: Higher cost, longer lead times. |

| Ready-to-Wear Leather Coats | Pre-designed styles available in various sizes and colors | Retail, e-commerce platforms | Pros: Quick delivery, lower cost; Cons: Limited customization, may not fit all body types. |

| Embroidered Leather Coats | Custom logos and designs embroidered onto leather | Corporate branding, promotional items | Pros: Strong brand visibility; Cons: Potentially longer production time for complex designs. |

| Printed Leather Coats | Custom artwork or designs printed on leather | Fashion, art collaborations | Pros: Unique visual appeal; Cons: Durability concerns with prints. |

| Specialty Leather Coats | Use of unique leather types (e.g., suede, exotic skins) | Niche markets, luxury retailers | Pros: Distinctive products; Cons: Higher price points and care requirements. |

What Are the Characteristics of Bespoke Leather Coats?

Bespoke leather coats are tailored to the exact specifications of the buyer, allowing for a unique style and fit. This type is characterized by high-quality materials sourced from reputable tanneries, ensuring durability and a luxurious feel. B2B buyers in high-end fashion and luxury markets often prefer bespoke options to offer exclusive products that stand out. However, the cost is significantly higher, and the production process can take longer, which may not suit all business timelines.

How Do Ready-to-Wear Leather Coats Serve B2B Buyers?

Ready-to-wear leather coats are mass-produced in standard sizes and styles, providing a quicker solution for businesses looking to stock inventory. These coats are available in various colors and designs, making them versatile for different markets. Retailers and e-commerce platforms benefit from the lower cost and faster delivery times. However, the trade-off includes limited customization options, which may not meet the specific needs of all customers.

What Are the Advantages of Embroidered Leather Coats?

Embroidered leather coats provide businesses with an opportunity to enhance brand visibility through custom logos and designs integrated into the coat’s fabric. This type is popular among corporate clients and promotional item distributors. The primary advantage is the strong branding potential, which can effectively market a company’s image. However, intricate embroidery can lead to longer production times, which may affect timely delivery.

Why Choose Printed Leather Coats for Unique Designs?

Printed leather coats allow for the application of custom artwork or designs, making them ideal for fashion brands looking to create visually striking pieces. This type is particularly popular in artistic collaborations and fashion-forward markets. While they offer a unique aesthetic that can attract attention, buyers must consider the potential durability issues associated with prints, which may require special care.

What Makes Specialty Leather Coats Stand Out?

Specialty leather coats utilize unique materials, such as suede or exotic leathers, to create distinctive products that cater to niche markets. These coats are often sought after by luxury retailers who wish to offer something different to their clientele. The appeal lies in their exclusivity and craftsmanship. However, buyers should be aware of the higher price points and specific care requirements associated with these materials, which can affect their marketability.

Key Industrial Applications of custom leather coat makers

| Industry/Sector | Specific Application of custom leather coat makers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom leather jackets for fashion brands | Unique branding opportunities and differentiation in market | Quality of leather, craftsmanship, and customization options |

| Automotive | Leather coats for automotive promotional events | Enhanced brand visibility and customer engagement | Durability, design alignment with brand image, and pricing |

| Hospitality | Custom jackets for staff uniforms in luxury hotels | Improved brand image and employee morale | Fabric quality, comfort, and customization for brand identity |

| Film and Entertainment | Costumes and leather jackets for movies and theater | Authenticity and character representation | Design expertise, material quality, and turnaround time |

| Military and Law Enforcement | Tactical leather jackets for uniformed personnel | Enhanced functionality and protection | Compliance with safety standards and customization options |

How Do Fashion and Apparel Brands Leverage Custom Leather Coats?

In the fashion and apparel industry, custom leather coat makers provide brands with the ability to create unique, high-quality leather jackets that resonate with their target audience. This not only helps in establishing a strong brand identity but also allows for differentiation in a competitive market. For international buyers, especially from Europe and the Middle East, sourcing high-quality leather with specific designs and customizations is crucial. Factors like craftsmanship, leather quality, and the ability to incorporate branding elements such as logos or unique embroidery are essential considerations.

What Role Do Custom Leather Coats Play in the Automotive Sector?

Automotive companies often utilize custom leather jackets as promotional items during events or as part of their merchandise. These jackets serve as a tool for brand visibility, creating a cohesive look for staff or promotional teams. For B2B buyers in regions like Africa and South America, the focus should be on sourcing jackets that align with the brand’s image while ensuring durability and comfort. It’s important to consider design elements that reflect the automotive brand’s ethos, as well as the pricing structures that accommodate bulk orders.

How Can Hospitality Businesses Benefit from Custom Leather Jackets?

In the hospitality sector, custom leather jackets are increasingly used for staff uniforms in luxury hotels and restaurants. These jackets enhance the overall brand image while also boosting employee morale, as they create a professional and cohesive appearance. International buyers must consider the quality of materials, ensuring that the jackets are not only stylish but also comfortable for staff to wear for extended periods. Customization options that reflect the brand’s identity, such as color schemes and logos, are also key factors in sourcing decisions.

Why Are Custom Leather Coats Important for Film and Entertainment?

The film and entertainment industry relies heavily on authentic costumes, including leather jackets that help define characters. Custom leather coat makers provide the necessary design expertise and material quality to create jackets that are visually striking and true to the character’s persona. For international buyers in this sector, understanding the turnaround times and the ability to meet specific design requirements is critical. Collaborating closely with designers ensures that the final product aligns with the creative vision of the production.

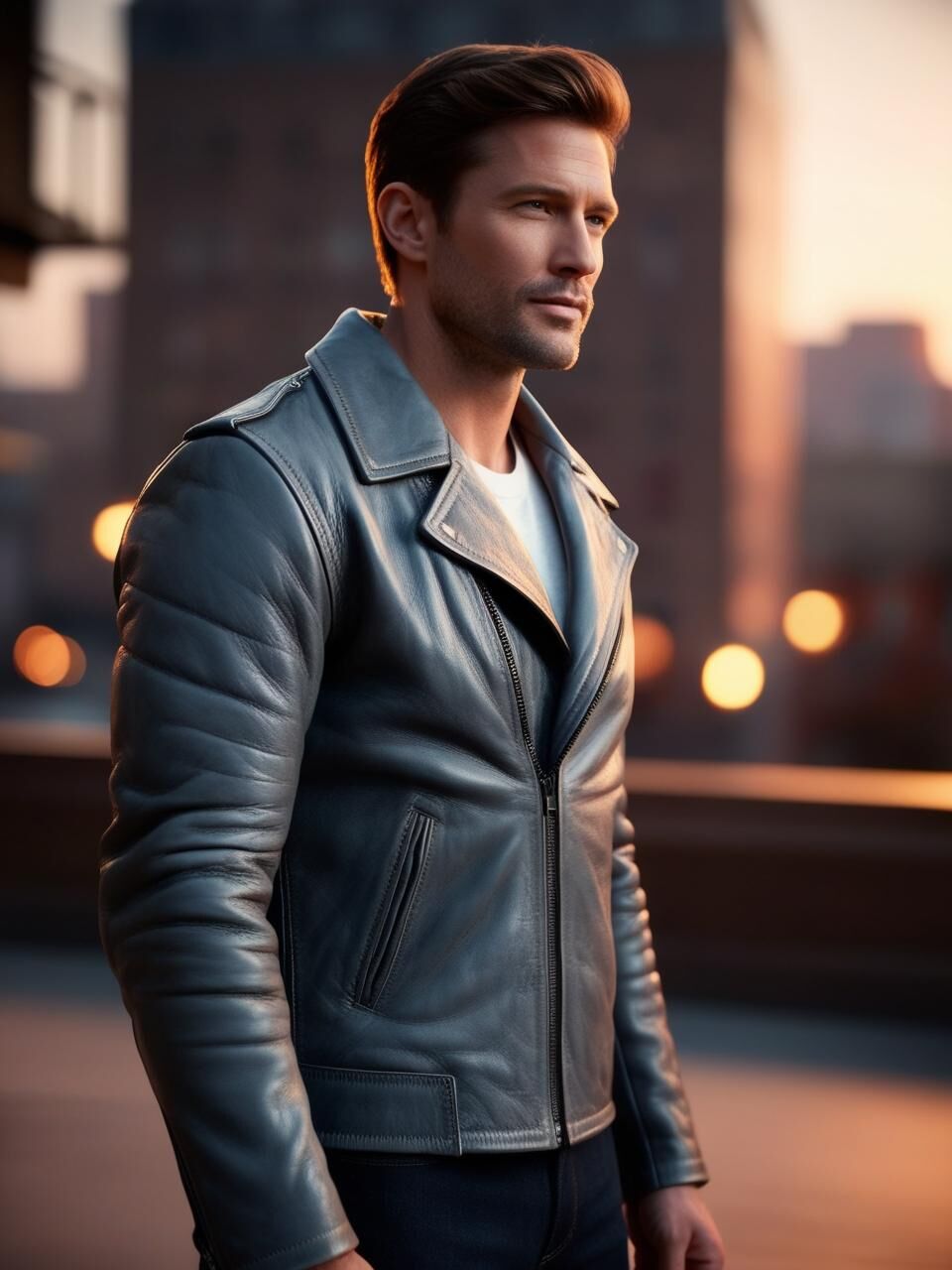

Illustrative image related to custom leather coat makers

How Do Military and Law Enforcement Utilize Custom Leather Jackets?

Custom leather jackets are essential for military and law enforcement applications, where functionality and protection are paramount. These jackets often need to meet specific safety standards while allowing for customization that reflects the organization’s identity. For B2B buyers in this sector, sourcing considerations include durability, comfort, and compliance with regulations. Additionally, the ability to customize jackets for different roles within the organization can enhance operational effectiveness and team cohesion.

3 Common User Pain Points for ‘custom leather coat makers’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Custom Leather Orders

The Problem: A B2B buyer, sourcing custom leather coats for a retail line, often faces the challenge of ensuring consistent quality across different orders. The variability in leather quality and craftsmanship can lead to discrepancies in product offerings, damaging brand reputation and customer trust. For buyers operating in diverse markets like Africa and the Middle East, where local preferences may vary significantly, this issue can be even more pronounced, leading to costly returns and wasted resources.

The Solution: To mitigate these quality concerns, buyers should establish clear quality standards and specifications before placing orders. This includes requesting samples of the leather types and craftsmanship from potential suppliers to evaluate their offerings firsthand. Additionally, implementing a thorough vetting process for custom leather coat makers is crucial. This can involve checking reviews, requesting references from previous clients, and possibly even visiting manufacturing facilities. Buyers can also set up a quality control checklist that outlines specific requirements, such as stitching patterns, leather thickness, and finish. Regular communication with the manufacturer throughout the production process can ensure adherence to these standards, allowing for adjustments before final delivery.

Scenario 2: Managing Lead Times and Delivery Schedules

The Problem: Timeliness is a critical factor in the B2B purchasing process, especially in the fashion industry, where seasonal collections dictate strict deadlines. Buyers may find themselves in a precarious situation when custom leather coat makers fail to meet agreed-upon lead times, resulting in missed sales opportunities and frustrated customers. This issue is exacerbated when dealing with international suppliers, where shipping delays can further complicate delivery schedules.

The Solution: To effectively manage lead times, B2B buyers should engage in transparent discussions with custom leather coat makers about realistic timelines from the outset. It’s beneficial to build a buffer into schedules, accounting for potential delays, especially when sourcing from overseas. Buyers should also prioritize establishing relationships with multiple suppliers to diversify risk; if one manufacturer encounters issues, another may be able to step in to fulfill orders. Implementing project management tools that allow for tracking progress in real-time can also help buyers stay informed about production status and proactively address any delays.

Scenario 3: Customization and Personalization Challenges

The Problem: As consumer demand shifts towards personalized products, B2B buyers face the challenge of sourcing custom leather coats that can accommodate specific customization requests. Buyers often struggle with finding manufacturers that can offer a wide range of options—such as different leather types, colors, and embellishments—while still maintaining the integrity and quality of the final product. This is particularly true in markets where unique cultural elements need to be incorporated into the designs, which can complicate the sourcing process.

The Solution: To tackle these customization challenges, buyers should work closely with custom leather coat makers during the initial design phase. Establishing a collaborative relationship can help clarify the range of customization options available. Buyers should provide detailed briefs that outline specific design elements and cultural considerations. Additionally, leveraging digital tools such as 3D design software can allow buyers to visualize customization options before production begins, reducing the risk of miscommunication. It’s also advantageous to negotiate flexible contracts that allow for iterative design processes, accommodating changes and refinements as needed. By fostering an open line of communication and using technology effectively, buyers can streamline the customization process and deliver products that resonate with their target market.

Strategic Material Selection Guide for custom leather coat makers

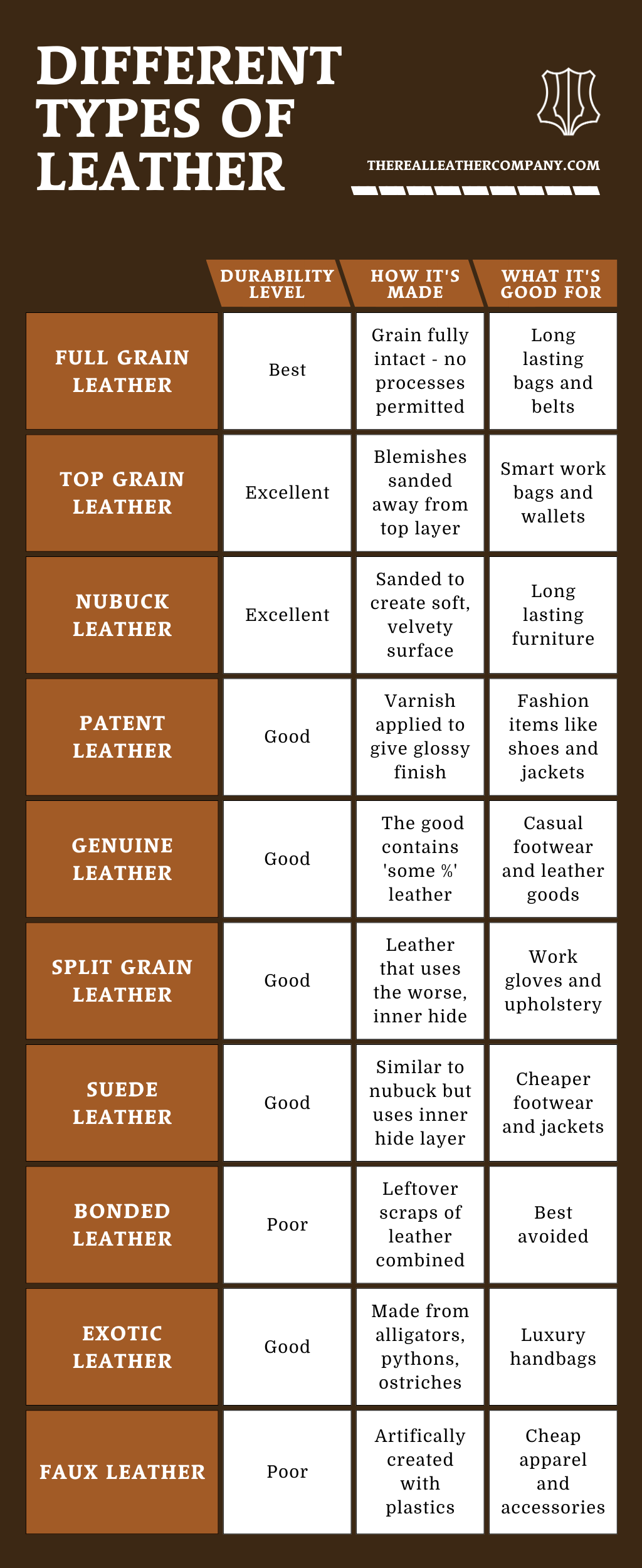

What Are the Key Properties of Different Leather Types for Custom Leather Coats?

When selecting materials for custom leather coats, understanding the properties of various leather types is crucial for meeting performance and aesthetic requirements. Here, we analyze four common leather materials: Cowhide, Lambskin, Goatskin, and Suede. Each material has unique properties that can influence the final product’s durability, comfort, and suitability for different markets.

Illustrative image related to custom leather coat makers

Cowhide: The Durable Workhorse

Cowhide is one of the most widely used leathers in the coat-making industry. It is known for its exceptional durability and resistance to wear and tear. With a high tensile strength, cowhide can withstand significant pressure and is less prone to abrasion. This makes it ideal for outdoor and heavy-duty applications, especially in regions with rugged climates.

Pros: Cowhide is relatively affordable and offers excellent longevity, making it a cost-effective choice for custom leather coats. Its robust nature means it can handle a variety of environmental conditions, which is particularly beneficial for buyers in Africa and the Middle East, where weather can be extreme.

Cons: The thickness of cowhide can limit its flexibility and comfort compared to softer leathers like lambskin. Additionally, it may require more complex manufacturing processes to achieve the desired fit and finish.

Lambskin: The Luxurious Choice

Lambskin is prized for its softness and smooth texture, making it a popular choice for high-end custom leather coats. It has a lower temperature tolerance and is less resistant to abrasion compared to cowhide, but its luxurious feel is unmatched.

Pros: The lightweight and supple nature of lambskin provides unparalleled comfort, making it ideal for fashion-focused markets in Europe, particularly Germany, where style and comfort are paramount.

Cons: Lambskin is generally more expensive than cowhide and may not be suitable for rugged outdoor use. Its lower durability means it may not perform well in harsh conditions, making it less appealing for buyers in regions with extreme climates.

Goatskin: The Versatile Alternative

Goatskin offers a unique combination of durability and softness. It is lighter than cowhide but more robust than lambskin, making it a versatile option for custom leather coats. Goatskin is also naturally water-resistant, which adds to its appeal for various applications.

Pros: Its balance of durability and comfort makes goatskin suitable for both fashion and functional coats, catering to diverse market needs across South America and Europe. Additionally, it is often available at a mid-range price point, appealing to a broad audience.

Cons: While goatskin is durable, it may not withstand extreme pressure as well as cowhide. Buyers should consider the specific use case to ensure it meets their durability requirements.

Suede: The Stylish Yet Delicate Option

Suede, made from the underside of animal hides, is known for its unique texture and aesthetic appeal. While it is softer and more flexible than traditional leather, it is also less durable and more susceptible to stains and moisture.

Pros: Suede offers a distinct look and feel, making it popular in fashion-forward markets. Its lightweight nature enhances comfort, which is appealing in warmer climates, such as those found in parts of Africa and the Middle East.

Cons: The maintenance requirements for suede are higher, and it may not be suitable for all applications due to its lower durability. Buyers must be cautious about environmental exposure, as suede can be easily damaged by water and dirt.

Summary Table of Material Selection for Custom Leather Coats

| Material | Typical Use Case for custom leather coat makers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide | Heavy-duty and outdoor coats | Exceptional durability and abrasion resistance | Less flexible and may require complex manufacturing | Medium |

| Lambskin | High-end fashion coats | Luxurious softness and comfort | Lower durability and higher cost | High |

| Goatskin | Versatile fashion and functional coats | Good balance of durability and comfort | Not as pressure-resistant as cowhide | Medium |

| Suede | Fashion-forward stylish coats | Unique texture and lightweight comfort | High maintenance and lower durability | Medium |

This guide provides strategic insights into material selection for custom leather coat makers, ensuring that international B2B buyers can make informed decisions that align with their market needs and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather coat makers

What Are the Main Stages of Manufacturing Custom Leather Coats?

The manufacturing process for custom leather coats encompasses several key stages, each critical to ensuring the final product meets quality and design specifications. The typical stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing custom leather coats is selecting high-quality leather. Different types of leather, such as lambskin, sheepskin, goatskin, buffalo-hide, and cow-hide, offer varying characteristics in terms of texture, durability, and appearance. Once the leather is chosen, it undergoes a preparation process that may include cutting, dyeing, and conditioning to enhance its properties. This stage is crucial as it sets the foundation for the quality of the final product.

How Is Leather Formed into Coats?

After preparation, the next stage is forming the leather into the desired coat shape. This involves pattern making, where templates are created based on the customer’s specifications. Skilled artisans then cut the leather according to these patterns, ensuring precision to minimize waste. Techniques such as laser cutting may be used for intricate designs, allowing for greater customization options.

What Happens During the Assembly of Custom Leather Coats?

Once the leather pieces are cut, they are stitched together. This assembly process requires experienced craftsmen who understand the nuances of leatherworking. Techniques like double stitching or reinforced seams are often employed to enhance durability. Additionally, any custom features, such as zippers, buttons, or pockets, are integrated at this stage. This meticulous attention to detail ensures that each coat not only meets aesthetic expectations but also stands the test of time.

What Are the Finishing Touches in Leather Coat Manufacturing?

The final stage of the manufacturing process involves finishing the coat. This may include treatments to enhance water resistance, applying protective coatings, and conducting final quality checks. The finishing process also includes the addition of any custom embroidery or printing, allowing for branding opportunities. A well-finished coat will not only look appealing but will also provide a longer lifespan and increased customer satisfaction.

What Quality Assurance Standards Should B2B Buyers Expect from Custom Leather Coat Makers?

Quality assurance (QA) is an essential component in the manufacturing of custom leather coats. Buyers should look for compliance with international quality standards such as ISO 9001, which outlines criteria for a quality management system. Adhering to these standards indicates that the manufacturer is committed to consistently delivering products that meet customer and regulatory requirements.

What Are the Key QC Checkpoints in Leather Coat Production?

Quality control (QC) checkpoints throughout the manufacturing process include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials upon arrival to ensure they meet specified standards before being used in production.

- IPQC takes place during the manufacturing process, where random samples are checked to ensure compliance with quality standards.

- FQC is the final inspection stage, where the completed coats are thoroughly examined for defects, functionality, and overall quality.

Implementing these checkpoints helps identify and rectify issues early, reducing the likelihood of defective products reaching the market.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to ensure the quality of custom leather coats. These may include:

Illustrative image related to custom leather coat makers

- Physical tests: Assessing the leather’s durability, flexibility, and resistance to wear and tear.

- Chemical tests: Evaluating the leather’s resistance to water, staining, and fading.

- Aesthetic assessments: Ensuring color consistency, texture quality, and overall appearance.

These tests provide measurable data that can be critical for B2B buyers when evaluating potential suppliers.

How Can B2B Buyers Verify the Quality Control Processes of Their Suppliers?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s QC processes is vital. Here are several strategies to consider:

What Are Effective Audit Practices for Ensuring Quality?

Conducting regular audits of potential suppliers can provide insight into their manufacturing and quality control processes. This can be done through:

- On-site audits: Visiting the manufacturing facility to observe operations and quality control measures firsthand.

- Documentation review: Requesting access to quality control reports, test results, and compliance certificates to assess their practices.

How Do Third-Party Inspections Enhance Supplier Reliability?

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can perform audits and testing to validate the supplier’s claims about quality and compliance with international standards. This is particularly important for B2B buyers who may not have the capacity to conduct thorough evaluations themselves.

What Are the Quality Certification Nuances for International Buyers?

Understanding the nuances of quality certifications is essential for international buyers. For instance, certifications like CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) for specific industrial applications can significantly affect marketability. Buyers should ensure that their suppliers possess relevant certifications that align with their target markets to avoid regulatory issues.

Illustrative image related to custom leather coat makers

Conclusion

In summary, the manufacturing processes and quality assurance practices of custom leather coat makers are pivotal in ensuring high-quality products that meet diverse customer demands. By understanding the stages of production, recognizing quality assurance standards, and implementing verification strategies, B2B buyers can confidently engage with suppliers, leading to successful partnerships and satisfied customers. This diligence is particularly crucial when navigating the complexities of international trade and varying regulatory environments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather coat makers’

Introduction

Sourcing custom leather coat makers requires a strategic approach to ensure quality, reliability, and alignment with your business needs. This guide provides a step-by-step checklist for B2B buyers, focusing on critical aspects that will help you make informed decisions throughout the procurement process.

Step 1: Define Your Technical Specifications

Before initiating the search for suppliers, clearly outline your technical requirements. This includes specific details about the leather type, coat style, design elements, and any custom features such as embroidery or logos. Defining these specifications upfront helps streamline the sourcing process and ensures that suppliers can meet your exact needs.

- Consider material choices: Different leathers (e.g., lambskin, cowhide, or buffalo-hide) offer varying qualities and aesthetics.

- Outline design requirements: Be clear about the styles you are interested in, whether it’s bomber jackets, biker coats, or tailored blazers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential custom leather coat makers. Utilize online directories, industry forums, and trade shows to compile a list of manufacturers. This foundational step is critical for finding suppliers who specialize in your desired product.

Illustrative image related to custom leather coat makers

- Check for industry experience: Look for suppliers with a proven track record in producing custom leather goods.

- Evaluate geographical considerations: Consider suppliers located in regions known for high-quality leather production, which may affect pricing and lead times.

Step 3: Evaluate Supplier Credentials

Before moving forward, verify the credentials of potential suppliers. Request documentation such as certifications, quality control processes, and compliance with international standards. This step is vital to ensure that the supplier operates ethically and meets quality expectations.

- Ask for certifications: Look for ISO certifications or other relevant industry standards.

- Review their production capacity: Confirm that they can meet your volume requirements without compromising quality.

Step 4: Request Samples

Always request samples of previous work or prototypes before finalizing any agreements. Samples allow you to assess the quality of craftsmanship, material, and overall design. This is a critical step to ensure the final product aligns with your expectations.

- Examine quality closely: Look for stitching quality, leather finish, and overall construction.

- Test for durability: If possible, conduct wear tests on samples to gauge longevity.

Step 5: Discuss Pricing and Payment Terms

Once you’ve narrowed down your options, engage in discussions regarding pricing and payment terms. Transparency in these discussions is essential to avoid any misunderstandings later on.

- Understand the pricing structure: Inquire whether prices vary based on order volume or customization levels.

- Negotiate payment terms: Clarify deposit requirements, payment methods, and any potential discounts for bulk orders.

Step 6: Review Production and Delivery Timelines

Establish clear timelines for production and delivery before placing an order. Understanding the lead times is crucial for planning your inventory and meeting customer demands.

Illustrative image related to custom leather coat makers

- Confirm production schedules: Ensure the supplier can meet your deadlines.

- Discuss shipping logistics: Clarify who will handle shipping and what the expected delivery timelines are.

Step 7: Establish Communication Protocols

Finally, set up communication protocols for ongoing discussions with your supplier. Clear communication is vital for resolving any issues that may arise during production or after delivery.

- Assign a point of contact: Designate individuals from both parties to facilitate smooth communication.

- Set regular check-ins: Schedule periodic updates to monitor progress and address any concerns promptly.

By following this checklist, you can effectively navigate the sourcing process for custom leather coat makers, ensuring that you select a supplier who meets your quality and business standards.

Comprehensive Cost and Pricing Analysis for custom leather coat makers Sourcing

What Are the Key Cost Components for Custom Leather Coat Makers?

When sourcing custom leather coats, understanding the cost structure is crucial for B2B buyers. The primary components influencing the total cost include:

-

Materials: The type of leather used significantly impacts the price. Premium leathers such as lambskin or buffalo-hide are more expensive than lower-grade options. Additionally, any specialized finishes or treatments can add to the material costs.

-

Labor: Skilled labor is essential in leather coat production, as craftsmanship plays a pivotal role in quality. Labor costs can vary widely based on the region, with countries known for their leather craftsmanship often commanding higher wages.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, allowing for more competitive pricing.

-

Tooling: Initial tooling costs for molds and patterns can be significant, especially for unique designs. These costs may be amortized over larger production runs, so minimum order quantities (MOQs) can influence overall pricing.

-

Quality Control (QC): Ensuring high standards through rigorous quality control can incur additional costs. However, investing in QC can minimize returns and enhance customer satisfaction.

-

Logistics: Shipping costs, customs duties, and insurance are vital to consider, particularly for international buyers. These costs can fluctuate based on the shipping method and destination.

-

Margin: Finally, manufacturers will include their profit margin in the pricing. This can vary depending on the brand’s positioning—luxury brands may have higher margins compared to mass-market producers.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence the pricing of custom leather coats, making it essential for buyers to consider them during negotiations:

-

Volume/MOQ: Larger orders typically attract lower per-unit prices due to economies of scale. Buyers should assess their needs and consider negotiating higher volumes to secure better pricing.

-

Specifications and Customization: Highly customized orders, including specific designs, colors, or features, can lead to increased costs. Buyers should be clear about their specifications to avoid unexpected surcharges.

-

Material Quality and Certifications: The sourcing of certified materials, such as eco-friendly or ethically sourced leather, can impact costs. Buyers should weigh the benefits of higher-quality materials against their budgets.

-

Supplier Factors: The manufacturer’s reputation, location, and production capabilities can influence pricing. Established suppliers may charge a premium for their expertise and reliability.

-

Incoterms: Understanding the agreed-upon Incoterms (International Commercial Terms) is crucial. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect the total cost.

What Are the Best Negotiation Strategies for B2B Buyers?

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation outcomes:

-

Total Cost of Ownership (TCO): Focus on the total cost of ownership rather than just the upfront price. Include factors like maintenance, durability, and potential resale value in your calculations to justify higher-quality investments.

-

Be Transparent About Your Needs: Clearly communicate your requirements and constraints to suppliers. This transparency can foster better relationships and may lead to more favorable pricing.

-

Utilize Competitive Bidding: Solicit quotes from multiple suppliers to encourage competitive pricing. This can provide leverage during negotiations.

-

Build Long-Term Relationships: Establishing a rapport with suppliers can lead to better terms over time. Loyalty can often yield discounts and priority treatment in future dealings.

-

Understand Regional Market Dynamics: Being aware of market conditions in your region can aid in effective negotiations. For instance, understanding seasonal demand fluctuations can provide insights into when to negotiate for better prices.

Disclaimer on Indicative Prices

Prices for custom leather coats can vary widely based on the aforementioned factors. The indicative prices noted in the market range from approximately $290 to over $2,850, depending on customization, materials, and manufacturer reputation. Buyers should conduct thorough market research and seek multiple quotes to ensure competitive pricing and value.

Alternatives Analysis: Comparing custom leather coat makers With Other Solutions

When considering the procurement of leather coats, B2B buyers often find themselves evaluating various solutions to meet their specific needs. While custom leather coat makers offer a unique blend of craftsmanship and personalization, other viable alternatives exist. Understanding these options can help buyers make informed decisions that align with their business requirements.

| Comparison Aspect | Custom Leather Coat Makers | Mass-Produced Leather Coats | Synthetic Leather Solutions |

|---|---|---|---|

| Performance | High durability and quality; tailored fit for comfort. | Good quality but may lack customization; varying durability. | Decent durability; often less breathable than leather. |

| Cost | Higher price point, typically $200-$3,000 depending on customization. | Lower cost, usually $50-$200 per item due to economies of scale. | Generally affordable, ranging from $30-$150 per item. |

| Ease of Implementation | Requires a design consultation and longer lead times. | Quick to order with immediate availability. | Easy to source and often available in bulk. |

| Maintenance | Requires care to maintain quality; regular conditioning needed. | Low maintenance; easy to clean. | Minimal maintenance but may degrade over time. |

| Best Use Case | Ideal for luxury brands or unique corporate gifts; high-end fashion. | Suitable for mass-market retailers; cost-effective solutions. | Best for environmentally-conscious brands or budget-friendly options. |

What Are the Advantages and Disadvantages of Mass-Produced Leather Coats?

Mass-produced leather coats are designed for efficiency and affordability. They cater to a wider market segment, making them an attractive option for businesses looking to stock a variety of styles without breaking the bank. However, the trade-off comes in the form of limited customization and potential variations in quality. These coats may not always provide the fit and durability that bespoke options can offer, which could be a critical factor for brands aiming for a premium image.

Illustrative image related to custom leather coat makers

How Do Synthetic Leather Solutions Compare to Custom Leather Options?

Synthetic leather solutions have gained traction due to their affordability and ethical considerations. These materials are often made from polyurethane or PVC, making them more environmentally friendly compared to traditional leather. Additionally, they require less maintenance and are often easier to clean. However, they may not offer the same level of durability or breathability as genuine leather, which can be a drawback for businesses that prioritize quality and longevity in their products.

Conclusion: How Should B2B Buyers Choose Between Custom Leather Coat Makers and Alternatives?

In choosing the right solution for leather coats, B2B buyers must assess their specific needs, including budget constraints, desired quality, and target market. Custom leather coat makers excel in providing tailored, high-quality products, making them ideal for luxury brands or those looking to offer unique corporate gifts. In contrast, mass-produced leather and synthetic leather solutions may be more suitable for businesses focused on cost-efficiency and speed. By carefully weighing these factors, buyers can make informed decisions that align with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for custom leather coat makers

What Are the Key Technical Properties for Custom Leather Coats?

Understanding the essential technical properties of leather is crucial for B2B buyers in the custom leather coat market. The choice of material directly affects the durability, aesthetic appeal, and performance of the final product. Here are some critical specifications to consider:

-

Material Grade

Material grade refers to the quality of the leather, which can range from full-grain to corrected grain. Full-grain leather, made from the top layer of the hide, is the most durable and develops a rich patina over time. In contrast, corrected grain leather undergoes more processing, making it less durable but often more affordable. For B2B buyers, selecting the right material grade can impact customer satisfaction and brand reputation. -

Thickness

The thickness of leather is measured in ounces or millimeters and influences the coat’s weight, warmth, and durability. Thicker leather offers greater protection and longevity, making it ideal for outerwear, while thinner leather provides a more tailored fit and flexibility. B2B buyers should align thickness with the intended use and target market to ensure the product meets customer expectations. -

Tensile Strength

Tensile strength measures how much force the leather can withstand when being pulled. High tensile strength is essential for custom leather coats that need to endure wear and tear over time. It ensures the product remains intact under stress, which is particularly important for active wear. Buyers should prioritize tensile strength to enhance product longevity and minimize returns. -

Finish Type

The finish of the leather can affect its appearance, texture, and resistance to elements. Common finishes include aniline, semi-aniline, and pigmented. Aniline leather showcases the natural grain and is favored for its softness, while pigmented leather offers more protection against stains and fading. Understanding the finish type helps B2B buyers communicate their product requirements effectively and align with market trends. -

Water Resistance

Water resistance is a crucial property for leather coats, particularly in regions with wet climates. Treatments can be applied to leather to enhance its water-repellent qualities without compromising breathability. Buyers should consider the environmental conditions of their target market to ensure the coats meet practical needs. -

Colorfastness

Colorfastness refers to the leather’s ability to retain its color when exposed to light, washing, or abrasion. High colorfastness is vital for maintaining the coat’s aesthetic appeal over time. B2B buyers should ensure that the leather meets industry standards for color retention to avoid customer complaints and returns.

What Are Common Trade Terms Used in the Custom Leather Coat Industry?

Familiarity with industry jargon is essential for effective communication between buyers and suppliers. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are then sold under another brand’s name. In the custom leather coat industry, buyers often work with OEMs to create unique designs that reflect their brand identity. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory and cash flow effectively, ensuring that they do not overcommit resources. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and other details for a specific order. This term is significant for B2B buyers, as it helps them gauge market prices and supplier capabilities before making purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms helps buyers understand their obligations in international transactions, such as who bears shipping costs and risks. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. For custom leather coats, understanding lead time is critical for planning inventory and meeting customer demands. -

Customization Options

This term encompasses the various choices available to buyers when designing a custom leather coat, such as material, color, and style. Clear communication of customization options can enhance customer satisfaction and drive sales.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions that align with their business goals and market demands.

Navigating Market Dynamics and Sourcing Trends in the custom leather coat makers Sector

What Are the Current Market Dynamics and Key Trends Affecting Custom Leather Coat Makers?

The custom leather coat market is witnessing a dynamic transformation driven by several global factors. Increased disposable income in emerging markets, particularly in Africa and South America, is fueling demand for high-quality, personalized leather products. Additionally, the rise of e-commerce platforms facilitates easier access to international buyers, allowing custom leather coat makers to reach a broader audience.

Technological advancements such as 3D modeling and virtual fitting rooms are enhancing the customization experience, enabling buyers to visualize products before purchase. Furthermore, the integration of Artificial Intelligence (AI) and data analytics in supply chain management is streamlining operations, optimizing inventory levels, and reducing lead times—benefits that resonate strongly with B2B buyers seeking efficiency.

In the European market, particularly in countries like Germany, there is a growing preference for bespoke products that reflect individuality and craftsmanship. This trend is echoed in the Middle East, where luxury and exclusivity are paramount. Custom leather coat makers who adopt a tailored approach to their offerings and leverage digital technologies will likely find a competitive edge in this evolving landscape.

How Is Sustainability and Ethical Sourcing Influencing Custom Leather Coat Makers?

Sustainability has become a focal point for B2B buyers in the custom leather coat sector. The environmental impact of leather production, including water usage and chemical waste, has prompted a shift towards sustainable practices. Buyers are increasingly prioritizing suppliers who adhere to eco-friendly production methods and utilize sustainably sourced materials.

Ethical supply chains are now a significant consideration, with buyers looking for transparency in sourcing. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining traction, as they assure buyers of responsible practices and high-quality leather. The demand for alternative materials—like plant-based leathers and recycled leathers—is also on the rise, appealing to environmentally conscious consumers.

Custom leather coat makers who emphasize sustainability and ethical sourcing can differentiate themselves in a crowded marketplace. This commitment not only aligns with growing consumer preferences but also enhances brand loyalty among B2B clients who are increasingly scrutinizing their supply chain choices.

What Is the Historical Context of the Custom Leather Coat Industry?

The custom leather coat industry has evolved significantly from its origins in traditional craftsmanship. Historically, leather garments were handmade, with artisans relying on skills passed down through generations. As industrialization took hold in the 19th century, mass production techniques emerged, enabling faster production but often at the expense of quality and personalization.

In recent decades, the industry has seen a resurgence of interest in bespoke and custom-made leather products, driven by a desire for unique, high-quality items. This revival has been supported by advancements in technology, allowing for more efficient customization processes while maintaining the artisanal quality that consumers value. Today, the blend of traditional craftsmanship with modern technology positions the custom leather coat sector for continued growth in the global marketplace.

Illustrative image related to custom leather coat makers

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather coat makers

-

How do I choose the right custom leather coat maker for my business?

Selecting the ideal custom leather coat maker involves evaluating several key factors. Start by reviewing their portfolio to assess the quality of craftsmanship and variety of styles. Look for manufacturers with experience in your specific market and with the type of leather you prefer. Additionally, consider their production capacity, lead times, and ability to meet your customization needs. Request references or testimonials from previous clients to gauge reliability and service quality. Finally, ensure they comply with international trade regulations to facilitate smooth transactions. -

What customization options are typically available for custom leather coats?

Custom leather coat makers generally offer a wide range of customization options, including choice of leather type (such as lambskin, cowhide, or suede), color, design, and fit. You may also have the option to add unique features like embroidery, patches, or custom logos. Some manufacturers provide online design tools that allow you to visualize your customizations. Be sure to communicate your specific requirements clearly to the manufacturer to ensure that your vision is accurately realized in the final product. -

What are the typical minimum order quantities (MOQs) for custom leather coats?

Minimum order quantities can vary significantly among custom leather coat makers, often ranging from 50 to 500 units per style. Factors influencing MOQs include the complexity of the design, the type of leather used, and the manufacturer’s production capabilities. If you are a smaller business, inquire about the possibility of lower MOQs or sample orders to assess quality before making a larger commitment. Understanding MOQs will help you plan your inventory and budget effectively. -

What payment terms should I expect when ordering custom leather coats?

Payment terms can differ by supplier but typically involve a deposit upfront, often ranging from 30% to 50% of the total order value, with the balance due before shipment. Some manufacturers may offer flexible payment options, including credit terms for established clients. It’s essential to clarify payment methods accepted (e.g., bank transfers, PayPal) and any additional fees for international transactions. Always ensure that payment terms are documented in your contract to avoid misunderstandings. -

How can I ensure quality assurance in my custom leather coat orders?

To ensure quality assurance, establish clear specifications and standards before placing an order. Request samples or prototypes to evaluate the craftsmanship and material quality. Many manufacturers offer quality control inspections during production; confirm if this is part of their process. It’s also wise to discuss return policies and warranties in case the products do not meet your standards upon delivery. Regular communication with the manufacturer throughout the production process can help address any concerns proactively. -

What are the logistics considerations when importing custom leather coats?

Logistics is a crucial aspect of importing custom leather coats. Start by understanding the shipping options available, including air and sea freight, and their respective costs and transit times. Familiarize yourself with customs regulations and duties applicable to your destination country to avoid unexpected fees. Engaging a freight forwarder can simplify the logistics process, as they can handle documentation, tariffs, and delivery. Ensure that your supplier provides the necessary shipping documents, including invoices and certificates of origin. -

What certifications should I look for in a custom leather coat maker?

When sourcing a custom leather coat maker, look for certifications that indicate quality and ethical practices, such as ISO 9001 for quality management systems and Leather Working Group (LWG) certifications for sustainable leather sourcing. Certifications for ethical labor practices, like Fair Trade or WRAP (Worldwide Responsible Accredited Production), can also be important, especially if you are targeting markets that prioritize sustainability. These certifications not only ensure product quality but also enhance your brand’s reputation. -

How can I effectively communicate my design requirements to a custom leather coat maker?

Effective communication of your design requirements begins with detailed documentation. Create a comprehensive design brief that includes sketches, color palettes, materials, and any specific features you want. Utilize visual aids, such as mood boards or digital mock-ups, to convey your ideas clearly. Schedule regular check-ins or consultations with the manufacturer to discuss progress and provide feedback. Establishing a collaborative relationship will facilitate smoother communication and help ensure the final product aligns with your expectations.

Top 8 Custom Leather Coat Makers Manufacturers & Suppliers List

1. The Jacket Maker – Custom Leather Jackets & Coats

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Custom Leather Jackets & Coats available for men and women. Options include Bomber Jackets, Biker Jackets, Suede Jackets, Varsity Jackets, Fur & Shearling Jackets, Leather Blazers, Hooded Leather Jackets, and Leather Vests. Customization options include adding embroidery, logos, and color choices. Available for bulk orders with quantity discounts. Various styles of coats such as Trench Coats, Wool…

2. Magnoli Clothiers – Custom Leather Jackets

Domain: magnoliclothiers.com

Registered: 2006 (19 years)

Introduction: Custom made leather jackets by Magnoli Clothiers, available in various styles and sizes. High-quality materials and craftsmanship ensure durability and a perfect fit. Options for personalization and customization are offered to meet individual preferences.

3. Himel Bros – Bespoke Leather Jackets

Domain: himelbros.com

Registered: 2010 (15 years)

Introduction: This company, Himel Bros – Bespoke Leather Jackets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Lusso Leather – Custom Leather Jackets

Domain: lussoleather.com

Registered: 2016 (9 years)

Introduction: Custom Leather Jackets – Design Your Own Leather Jacket

Regular Price: $484.00

Sale Price: $367.00 (Free Shipping and 30 days for Returns/Alterations)

Available Sizes: XSmall, Small, Medium, Large, XLarge, XXL, Custom Size, Custom Plus Size

Custom Plus Size Price: $431.00

Customization Options: Select from a variety of fabrics and leathers, custom embroidery, sublimation printing, logos, graphics,…

5. Reddit – Custom-Made Leather Biker Jacket

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom-made leather jacket, high-quality material and craftsmanship, premium/luxury quality, fit to measure, urban-modern style, biker jacket with slim fit, soft leathers, accordion arms, budget of $1000-$2000, preference for vendors in Europe but not a requirement.

6. LeatherCult – Custom Leather Apparel

Domain: leathercult.com

Registered: 2010 (15 years)

Introduction: LeatherCult offers a wide range of custom leather apparel for men, women, and boys, including leather jackets, blazers, long coats, vests, suits, pants, shorts, and chaps. Accessories include leather pocket squares, wristbands, hoods, belts, caps, bows, and ties. The products are handmade from premium leather, ensuring high quality and a perfect fit tailored to individual measurements. The company…

7. The Cast – Custom Leather Jackets and Vests

Domain: thecast.com

Registered: 1999 (26 years)

Introduction: The Cast offers premium Custom Leather Jackets and Vests made in NYC. Clients can choose from various styles including Bowery, Essex, Bronx, Rivington, Downtown, The ’68, or Johnnie. Customization options include selecting leather types (Cowhide, CalfSkin, Horsehide, Hair on Hide Animal Print), linings (Solid Prints, Polka Dot, Animal Print), and hardware finishes (Nickel, Antique Nickel, Matte Bl…

8. Independence Brothers – Custom Leather Jackets

Domain: independencebrothers.com

Registered: 2016 (9 years)

Introduction: Custom leather jackets designed for a perfect fit and unique style. Made from premium, ethically sourced materials, including high-quality semi-aniline leather. Features include personalized consultations, a complete leather jacket design customization tool, and options for various leather types such as lambskin and cowhide. Jackets are crafted with precision stitching and YKK zippers for durabili…

Strategic Sourcing Conclusion and Outlook for custom leather coat makers

How Can Strategic Sourcing Enhance Partnerships with Custom Leather Coat Makers?

In the dynamic world of custom leather coat production, strategic sourcing stands out as a vital component for international B2B buyers. By prioritizing quality, sustainability, and supplier reliability, businesses can ensure they are working with manufacturers who not only meet their specific design requirements but also align with ethical practices. Investing time in understanding the nuances of leather types, customization options, and supplier capabilities can significantly enhance product offerings and customer satisfaction.

Additionally, fostering strong relationships with manufacturers from diverse regions—particularly in Africa, South America, the Middle East, and Europe—can unlock unique design opportunities and competitive pricing. As global markets evolve, the ability to source high-quality leather coats from reputable suppliers will position businesses to adapt to changing consumer preferences and market demands.

Looking ahead, international buyers are encouraged to engage proactively with potential suppliers, exploring collaborative opportunities that drive innovation in design and production. This strategic approach will not only elevate brand offerings but also contribute to sustainable growth in the custom leather coat market. Embrace the potential of strategic sourcing today to secure a competitive edge in the marketplace.

Illustrative image related to custom leather coat makers

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather coat makers