Introduction: Navigating the Global Market for leather goods manufacturer italy

In an increasingly competitive global marketplace, sourcing high-quality leather goods from Italy presents both an opportunity and a challenge for international B2B buyers. As the demand for premium leather products continues to rise, particularly in regions such as Africa, South America, the Middle East, and Europe, navigating the complexities of supplier selection becomes essential. This comprehensive guide on leather goods manufacturers in Italy addresses critical factors including types of products, applications, supplier vetting processes, and cost considerations.

By delving into the rich tapestry of Italian craftsmanship, buyers will gain insights into the diverse offerings—from luxurious handbags to bespoke accessories—that exemplify the renowned Italian aesthetic. Additionally, this guide empowers B2B buyers to make informed purchasing decisions by providing actionable insights into the nuances of quality assurance, production timelines, and sustainability practices.

Armed with this knowledge, businesses can confidently identify and collaborate with reputable manufacturers that align with their brand ethos and market demands, ensuring a competitive edge in their respective sectors. Whether you are a retailer seeking unique products or a brand looking to expand your portfolio, this guide serves as a vital resource for navigating the vibrant Italian leather goods market.

Table Of Contents

- Top 2 Leather Goods Manufacturer Italy Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather goods manufacturer italy

- Understanding leather goods manufacturer italy Types and Variations

- Key Industrial Applications of leather goods manufacturer italy

- 3 Common User Pain Points for ‘leather goods manufacturer italy’ & Their Solutions

- Strategic Material Selection Guide for leather goods manufacturer italy

- In-depth Look: Manufacturing Processes and Quality Assurance for leather goods manufacturer italy

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather goods manufacturer italy’

- Comprehensive Cost and Pricing Analysis for leather goods manufacturer italy Sourcing

- Alternatives Analysis: Comparing leather goods manufacturer italy With Other Solutions

- Essential Technical Properties and Trade Terminology for leather goods manufacturer italy

- Navigating Market Dynamics and Sourcing Trends in the leather goods manufacturer italy Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather goods manufacturer italy

- Strategic Sourcing Conclusion and Outlook for leather goods manufacturer italy

- Important Disclaimer & Terms of Use

Understanding leather goods manufacturer italy Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Artisan Leather Goods | Handcrafted, high-quality materials, traditional techniques | Luxury brands, bespoke items | Pros: Unique products, high craftsmanship. Cons: Higher costs, longer lead times. |

| Mass Production Leather Goods | Streamlined processes, standardized designs, cost-effective | Retail chains, bulk orders | Pros: Lower prices, faster delivery. Cons: Less customization, potential quality variability. |

| Vegan Leather Manufacturers | Eco-friendly materials, innovative production methods | Sustainable fashion brands, eco-conscious retailers | Pros: Appeals to green consumers, diverse material options. Cons: Perceived lower quality compared to genuine leather. |

| Custom Leather Goods | Tailored designs, personalized branding, flexible order quantities | Corporate gifting, promotional items | Pros: Brand differentiation, tailored solutions. Cons: Requires clear communication, potentially longer timelines. |

| Specialty Leather Goods | Unique designs, niche markets, often limited production runs | High-end boutiques, artisanal markets | Pros: Exclusive offerings, high brand value. Cons: Limited availability, higher price point. |

What are Artisan Leather Goods and Their B2B Suitability?

Artisan leather goods are characterized by their handcrafted nature, using high-quality materials and traditional techniques. These products often attract luxury brands looking for unique items that embody craftsmanship and authenticity. For B2B buyers, investing in artisan goods means offering products that stand out in the market, appealing to consumers seeking quality and exclusivity. However, buyers should be prepared for higher costs and longer lead times associated with artisanal production.

How Do Mass Production Leather Goods Serve B2B Needs?

Mass production leather goods are manufactured using streamlined processes that allow for standardized designs at scale. This type of manufacturing is ideal for retail chains and businesses requiring bulk orders at competitive prices. B2B buyers benefit from lower costs and quicker delivery times; however, they may sacrifice some degree of customization and risk variability in quality, which is crucial for maintaining brand reputation.

Illustrative image related to leather goods manufacturer italy

What are the Benefits of Partnering with Vegan Leather Manufacturers?

Vegan leather manufacturers focus on creating eco-friendly products using synthetic or plant-based materials. This segment is increasingly popular among sustainable fashion brands and eco-conscious retailers. For B2B buyers, partnering with these manufacturers can enhance brand image and appeal to environmentally aware consumers. However, it’s essential to communicate the perceived quality differences compared to traditional leather, as some buyers may have reservations about durability.

Why Choose Custom Leather Goods for Your Business?

Custom leather goods offer tailored designs that can incorporate a company’s branding and specific requirements. This flexibility is particularly advantageous for businesses seeking unique promotional items or corporate gifts. B2B buyers should consider the importance of clear communication during the design process and be aware that custom orders may require more time to fulfill compared to standard products. The investment can lead to significant brand differentiation in competitive markets.

What Makes Specialty Leather Goods Attractive for Niche Markets?

Specialty leather goods are often produced in limited runs with unique designs aimed at niche markets. These products can command higher prices due to their exclusivity and artistry, making them ideal for high-end boutiques and artisanal markets. B2B buyers looking to stock specialty items should be prepared for limited availability and potentially higher costs, but the unique offerings can significantly enhance their product range and appeal to discerning customers.

Key Industrial Applications of leather goods manufacturer italy

| Industry/Sector | Specific Application of leather goods manufacturer italy | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Production of luxury handbags and accessories | High-quality craftsmanship enhances brand image | Authenticity of materials, flexibility in designs, lead times |

| Automotive | Interior leather upholstery for vehicles | Improved aesthetics and comfort in vehicles | Quality standards for durability, customization options |

| Hospitality & Retail | Custom leather goods for hotels and boutiques | Unique branding opportunities and customer appeal | Customization capabilities, sustainability practices |

| Sports & Outdoor Equipment | Leather goods for sports gear (e.g., gloves, bags) | Enhanced performance and durability | Material sourcing for specific performance needs, compliance with regulations |

| Corporate & Promotional Gifts | Personalized leather gifts and corporate branding items | Strengthened client relationships and brand loyalty | Customization options, minimum order quantities, delivery timelines |

How Can Fashion & Apparel Brands Benefit from Italian Leather Goods Manufacturers?

In the fashion and apparel sector, Italian leather goods manufacturers are renowned for producing high-quality luxury handbags and accessories. By leveraging the artistry and heritage of Italian craftsmanship, brands can enhance their image and appeal to discerning customers. B2B buyers in this sector should consider the authenticity of materials, the flexibility in design options, and the reliability of lead times to ensure their products meet market demands.

Why is Automotive Interior Leather Upholstery Important for Vehicle Manufacturers?

Automotive manufacturers often seek Italian leather goods for vehicle interiors to improve aesthetics and comfort. High-quality leather upholstery not only elevates the vehicle’s luxury appeal but also contributes to the overall driving experience. When sourcing leather for automotive applications, businesses should prioritize quality standards for durability, customization options to fit various vehicle models, and compliance with industry regulations to ensure safety and longevity.

Illustrative image related to leather goods manufacturer italy

How Can the Hospitality & Retail Sector Utilize Custom Leather Goods?

In the hospitality and retail sectors, custom leather goods can serve as unique branding opportunities. Hotels and boutiques can offer personalized leather products that enhance customer experiences and promote brand loyalty. For B2B buyers, it’s essential to evaluate customization capabilities, sustainability practices of manufacturers, and the ability to meet specific design requirements to align with brand values.

What Role Do Leather Goods Play in Sports & Outdoor Equipment?

Leather goods manufacturers in Italy also cater to the sports and outdoor equipment industries, producing items like gloves and bags that require durability and high performance. This application is critical for enhancing the functionality and longevity of sports gear. Buyers should focus on material sourcing for specific performance needs, ensuring compliance with relevant regulations, and understanding the importance of durability in their sourcing decisions.

How Do Corporate Gifts Benefit from Personalized Leather Items?

Personalized leather goods are increasingly popular in corporate gifting, as they can strengthen client relationships and enhance brand loyalty. Italian manufacturers offer bespoke options that allow businesses to customize leather gifts with logos or personal messages. B2B buyers must consider customization options, minimum order quantities, and delivery timelines when sourcing these products to ensure they meet corporate gifting strategies effectively.

3 Common User Pain Points for ‘leather goods manufacturer italy’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Leather Goods Production

The Problem: Many B2B buyers are concerned about the quality of leather goods, especially when sourcing from manufacturers abroad. This is particularly true for buyers from regions like Africa and South America, where the standards of leather craftsmanship may differ significantly. The fear of receiving subpar products that don’t meet the specifications can lead to significant financial loss and damage to brand reputation.

The Solution: To mitigate quality concerns, buyers should implement a robust quality assurance process. Start by requesting samples from the manufacturer before committing to larger orders. This allows you to evaluate the craftsmanship, leather quality, and overall design. Establish clear quality standards and specifications in a detailed contract, including expectations for materials and finishes. Utilizing a third-party inspection service can also provide an unbiased quality assessment before shipment, ensuring that the products meet both your standards and those expected in your market.

Illustrative image related to leather goods manufacturer italy

Scenario 2: Managing Supply Chain Timelines Effectively

The Problem: Timeliness is a critical concern for B2B buyers dealing with leather goods manufacturers in Italy. Delays in production or shipping can result in missed deadlines, particularly for seasonal product launches or retail campaigns. Buyers may find it challenging to coordinate their inventory needs with the production schedules of manufacturers, leading to potential stockouts or excess inventory.

The Solution: To enhance supply chain efficiency, establish a clear communication protocol with your Italian manufacturer. Discuss lead times upfront and build a detailed production timeline that includes key milestones. Consider leveraging technologies such as project management tools that allow for real-time tracking of production progress. Setting up regular check-ins can help identify any potential delays early on. Additionally, consider placing orders well in advance of your peak seasons to buffer against unexpected delays and to secure priority in production schedules.

Scenario 3: Understanding Cultural Nuances in Business Practices

The Problem: International buyers often encounter cultural differences that can complicate negotiations and collaboration with Italian manufacturers. Misunderstandings regarding business etiquette, communication styles, and negotiation tactics can lead to frustration and missed opportunities.

Illustrative image related to leather goods manufacturer italy

The Solution: To effectively bridge cultural gaps, invest time in understanding Italian business culture. Familiarize yourself with common practices, such as the emphasis on building personal relationships before discussing business. Engaging a local representative or consultant who understands both cultures can facilitate smoother negotiations. During meetings, be prepared to allow for more informal discussions and social interactions, as these are vital in establishing trust. Additionally, ensuring clear, respectful communication can prevent misunderstandings and foster a collaborative relationship with your manufacturer.

Strategic Material Selection Guide for leather goods manufacturer italy

What Are the Key Materials Used in Leather Goods Manufacturing in Italy?

When selecting materials for leather goods, Italian manufacturers often consider a variety of options, each with unique properties and applications. Understanding these materials is crucial for international B2B buyers who seek quality and compliance in their products. Here, we analyze four common materials used in leather goods manufacturing in Italy.

How Does Genuine Leather Perform in Leather Goods Manufacturing?

Genuine leather, derived from animal hides, is a staple in the leather goods industry. Its key properties include high durability, breathability, and a luxurious feel, making it ideal for high-end products such as handbags, wallets, and belts. Genuine leather can withstand significant wear and tear, offering a long lifespan when properly cared for.

Pros: The aesthetic appeal and tactile quality of genuine leather are unmatched, providing a premium feel that enhances brand perception. It also ages beautifully, developing a unique patina over time.

Cons: The main drawbacks are its cost and the complexity of sourcing sustainable hides, which can lead to ethical concerns. Additionally, genuine leather requires specific care to maintain its appearance and durability.

For international buyers, compliance with animal welfare standards and sourcing certifications is essential, particularly in regions sensitive to ethical sourcing like Europe and parts of Africa.

What Role Does Vegan Leather Play in Modern Leather Goods?

Vegan leather, often made from synthetic materials like polyurethane (PU) or natural fibers like cork, is gaining popularity. Its key properties include water resistance and ease of cleaning, making it suitable for various applications in the fashion industry.

Pros: Vegan leather is generally more affordable than genuine leather and appeals to environmentally conscious consumers. It can be produced in various colors and textures, offering versatility in design.

Cons: While it is durable, vegan leather may not match the longevity or premium feel of genuine leather. Additionally, some synthetic variants can be less breathable, leading to discomfort in certain products.

Illustrative image related to leather goods manufacturer italy

International buyers should consider the environmental impact of synthetic materials and ensure that their products comply with relevant sustainability standards, especially in markets like Europe where eco-consciousness is prevalent.

How Do Suede and Nubuck Enhance the Aesthetic of Leather Goods?

Suede and nubuck, both made from the outer layer of animal hides, offer a soft texture and luxurious appearance. Suede is more porous and less durable than nubuck, which is sanded to create a finer finish.

Pros: Both materials provide a unique aesthetic appeal and are often used in high-fashion items. They are lightweight and can be dyed easily, allowing for creative designs.

Cons: However, suede and nubuck are less water-resistant and more susceptible to stains, requiring careful maintenance. Their durability is lower compared to full-grain leather, which can limit their use in certain applications.

For B2B buyers, understanding the maintenance requirements and ensuring compliance with care standards is crucial, particularly in regions with varying climates like Africa and South America.

What Are the Benefits of Using High-Quality Hardware in Leather Goods?

The hardware used in leather goods, including zippers, clasps, and buckles, is often made from metals such as brass or stainless steel. These materials provide essential properties like corrosion resistance and strength.

Pros: High-quality hardware enhances the functionality and durability of leather goods, contributing to the overall quality of the product. It also allows for intricate designs that can elevate the product’s appeal.

Cons: The cost of quality hardware can be significant, impacting the overall price of the final product. Additionally, sourcing sustainable metal options can pose challenges.

Illustrative image related to leather goods manufacturer italy

International buyers should prioritize suppliers who adhere to relevant standards for metal quality and environmental impact, especially in markets like Europe where regulations are stringent.

Summary Table of Material Selection for Leather Goods Manufacturing

| Material | Typical Use Case for leather goods manufacturer italy | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Handbags, wallets, belts | Luxurious feel and durability | High cost and ethical sourcing concerns | High |

| Vegan Leather | Fashion accessories, bags | Affordable and eco-friendly | Less durable and may lack premium feel | Med |

| Suede/Nubuck | High-fashion items, shoes | Unique aesthetic and lightweight | Less water-resistant and requires careful care | Med |

| High-Quality Hardware | Zippers, clasps, buckles | Enhances functionality and durability | Higher cost and sourcing challenges | Med |

This strategic material selection guide aims to provide international B2B buyers with essential insights for making informed decisions when sourcing leather goods from Italy. Understanding these materials will help ensure compliance with industry standards while meeting the demands of various markets.

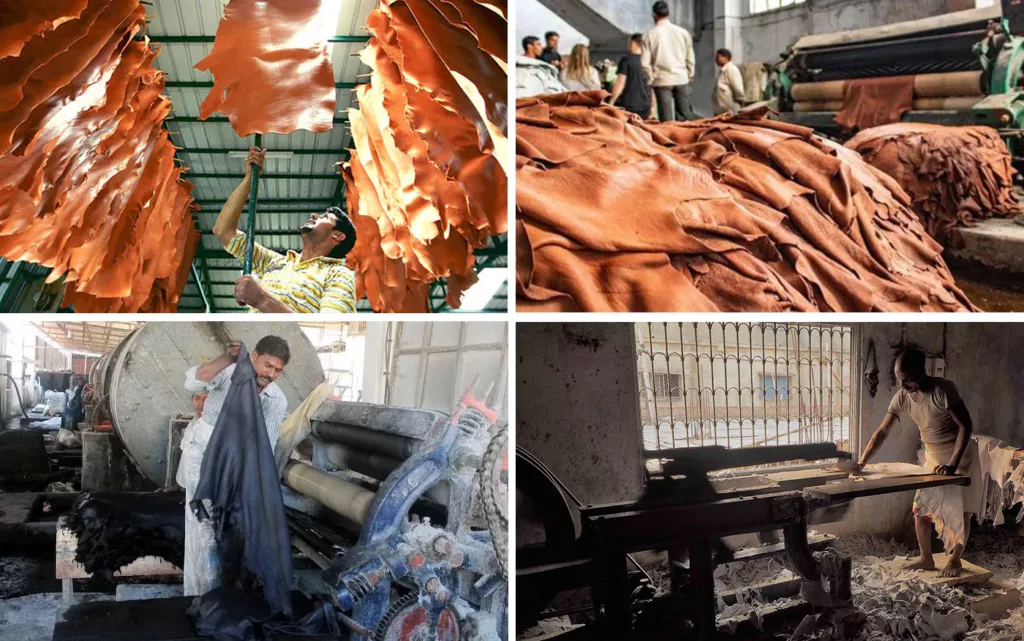

In-depth Look: Manufacturing Processes and Quality Assurance for leather goods manufacturer italy

What Are the Key Stages in the Manufacturing Process of Italian Leather Goods?

The manufacturing process of leather goods in Italy is marked by a blend of traditional craftsmanship and modern techniques. This meticulous approach ensures that every product meets the high standards expected in the luxury market. The main stages of manufacturing typically include:

-

Material Preparation: The journey begins with the selection of high-quality leather, often sourced from renowned tanneries in Italy. Leather is evaluated for its texture, grain, and durability. Additional materials such as linings, threads, and hardware are also chosen at this stage to complement the leather.

-

Forming: Once the materials are ready, artisans create patterns based on design specifications. This involves paper pattern making and tech pack development, ensuring that every detail aligns with the designer’s vision. Using cutting-edge tools, the leather is carefully cut into the required shapes, maintaining precision to minimize waste.

-

Assembly: The assembly phase involves stitching, gluing, and reinforcing the leather pieces. Highly skilled craftsmen employ various techniques to ensure strong seams and perfect alignment. This stage may include the installation of hardware such as zippers, clasps, and decorative elements, which are crucial for both aesthetics and functionality.

-

Finishing: The final touches are applied to enhance the product’s appearance and durability. This may involve polishing, dyeing, or adding protective coatings. Quality control checks are integrated into this stage to ensure that the product meets both aesthetic and functional standards before it moves to packaging.

How Is Quality Assurance Implemented in Italian Leather Goods Manufacturing?

Quality assurance in the Italian leather goods industry is paramount, particularly given the high expectations of international B2B buyers. Manufacturers often adhere to several international and industry-specific standards to guarantee product excellence.

-

Relevant International Standards: Many Italian leather goods manufacturers are certified under ISO 9001, which sets the criteria for a quality management system. This certification ensures that organizations consistently provide products that meet customer and regulatory requirements. Additionally, compliance with CE marking is crucial for products sold within Europe, ensuring they meet safety and health standards.

-

Quality Control Checkpoints: Effective quality control involves various checkpoints throughout the production process:

– Incoming Quality Control (IQC): This phase verifies the quality of raw materials upon arrival. Leather, hardware, and other components are inspected for defects before they enter the production line.

– In-Process Quality Control (IPQC): During assembly, craftsmen conduct regular checks to ensure that each step meets the required standards. This may involve measuring dimensions, assessing stitching quality, and confirming that design specifications are met.

– Final Quality Control (FQC): Before shipping, each item undergoes a thorough inspection. This includes checking for aesthetic flaws, functional performance, and packaging integrity. Products that do not meet quality standards are reworked or discarded. -

Common Testing Methods: Various testing methods are employed to ensure the leather goods’ durability and performance. These may include:

– Abrasion resistance tests to evaluate wear over time.

– Colorfastness tests to ensure dye stability under different conditions.

– Water resistance tests to check for moisture infiltration.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. Here are several strategies to ensure that the manufacturing partner adheres to high standards:

-

Audits: Conducting regular audits can provide insights into a manufacturer’s processes and quality control practices. Buyers can request access to audit reports or even arrange for third-party audits to evaluate compliance with international standards.

-

Quality Control Reports: Suppliers should be willing to provide documentation that details their quality control processes. This may include reports on IQC, IPQC, and FQC outcomes, showcasing the measures taken to ensure product quality.

-

Third-Party Inspections: Engaging independent inspection services can offer an unbiased evaluation of the manufacturing processes and final products. This is particularly beneficial for international transactions, as it mitigates risks associated with distance and communication barriers.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the quality control nuances is crucial for international B2B buyers, especially those from diverse markets. Here are a few considerations:

Illustrative image related to leather goods manufacturer italy

-

Cultural Differences in Quality Standards: Different markets may have varying expectations regarding quality. Buyers should communicate their specific quality requirements clearly and ensure that manufacturers understand these expectations.

-

Sustainability and Ethical Sourcing: Increasingly, buyers are prioritizing sustainability in their purchasing decisions. It’s essential to inquire about the sourcing of materials, manufacturing practices, and the company’s commitment to ethical standards, including labor practices.

-

Post-Purchase Support: Quality assurance doesn’t end with delivery. Buyers should establish clear channels for after-sales support and warranty claims. Understanding the manufacturer’s policy on returns, repairs, and replacements can significantly impact long-term satisfaction.

In conclusion, the manufacturing processes and quality assurance practices of Italian leather goods manufacturers are designed to uphold the prestigious reputation of “Made in Italy” products. By understanding these processes and implementing effective verification strategies, international B2B buyers can ensure they partner with reliable manufacturers who deliver exceptional quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather goods manufacturer italy’

To assist international B2B buyers in procuring leather goods from manufacturers in Italy, this guide offers a step-by-step checklist. By following these actionable steps, buyers can ensure a smooth sourcing process, leading to high-quality products that meet their specific needs.

Step 1: Define Your Product Specifications

Begin by detailing the specific leather goods you require, including types, sizes, and design elements. This clarity will facilitate better communication with potential manufacturers and help them provide accurate quotes. Consider factors such as:

– Material preferences: Are you looking for genuine leather, vegan options, or a specific type of hide?

– Design intricacies: Do you have particular styles or features in mind, such as pockets, closures, or hardware?

Step 2: Research and Shortlist Manufacturers

Conduct thorough research to identify reputable Italian manufacturers specializing in leather goods. Look for companies with a strong portfolio and positive reviews. Utilize resources such as:

– Industry directories and trade associations.

– Online marketplaces and platforms that showcase manufacturer profiles.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Key aspects to consider include:

– Experience and expertise: How long have they been in business, and do they specialize in your required product?

– Quality certifications: Look for ISO certifications or other quality assurances that indicate a commitment to excellence.

Step 4: Request Samples

Always request samples of their work to evaluate quality firsthand. This step is essential to ensure that the materials, craftsmanship, and overall finish align with your expectations. When assessing samples:

– Check material authenticity: Ensure the leather meets your quality standards.

– Inspect craftsmanship: Look for attention to detail, stitching quality, and overall design execution.

Step 5: Negotiate Terms and Conditions

Once you have selected a potential supplier, engage in discussions to negotiate terms. This includes pricing, minimum order quantities, lead times, and payment terms. Important points to clarify:

– Flexibility: Understand their policies on order adjustments or customizations.

– Delivery timelines: Confirm their ability to meet your required deadlines.

Step 6: Verify Compliance and Ethical Standards

Ensure that the manufacturer adheres to ethical practices and complies with local and international regulations. This is particularly crucial if you are sourcing from regions with strict labor and environmental standards. Key checks include:

– Labor practices: Confirm that workers are treated fairly and work in safe conditions.

– Sustainability: Inquire about their environmental policies and waste management practices.

Step 7: Establish a Communication Protocol

Effective communication is vital for a successful partnership. Set up a clear communication protocol to ensure that both parties remain aligned throughout the production process. Consider:

– Regular updates: Schedule updates to discuss progress and address any issues.

– Point of contact: Designate a specific contact person on both sides to streamline communication.

By adhering to this checklist, B2B buyers can confidently navigate the sourcing process for leather goods manufacturers in Italy, ensuring high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for leather goods manufacturer italy Sourcing

What Are the Key Cost Components in Sourcing Leather Goods from Italian Manufacturers?

When sourcing leather goods from Italy, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to leather goods manufacturer italy

-

Materials: The choice of leather significantly impacts costs. High-quality Italian leather can be more expensive due to its superior characteristics and sourcing from reputable tanneries. Moreover, the inclusion of additional materials such as hardware and linings will further influence the overall material cost.

-

Labor: Italian craftsmanship is renowned for its quality, which means labor costs can be higher compared to other regions. Skilled artisans are essential for maintaining the craftsmanship that Italian leather goods are known for, and their wages reflect this expertise.

-

Manufacturing Overhead: Overhead costs encompass the expenses related to the production facility, utilities, and administrative costs. Italian manufacturers often invest in maintaining high standards of production, which can affect overhead.

-

Tooling: Initial tooling costs for custom designs can be substantial, as they involve creating patterns and molds specific to the product. This is particularly relevant for bespoke items and can be amortized over larger production runs.

-

Quality Control: Rigorous QC processes are vital in ensuring that the final products meet the high standards expected of Italian leather goods. This adds to the overall cost but is essential for maintaining brand reputation.

-

Logistics: Shipping and customs duties can vary significantly based on the destination. For international buyers, especially those in Africa, South America, and the Middle East, understanding these logistics costs is critical.

-

Margin: Manufacturers typically add a margin to cover their costs and profit. This can vary based on brand positioning, market demand, and the exclusivity of the products.

How Do Price Influencers Affect Sourcing Decisions for Leather Goods?

Several factors can influence the pricing of leather goods, impacting overall costs for international buyers.

-

Volume/MOQ: The minimum order quantity (MOQ) plays a significant role in pricing. Larger orders often result in lower per-unit costs due to economies of scale, whereas smaller orders may incur higher rates.

-

Specifications and Customization: Custom designs and specific material requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Quality and Certifications: Products that meet higher quality standards or possess certifications (e.g., eco-friendly materials) may carry a premium price. Understanding the implications of these factors can help buyers assess the value.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established manufacturers with a track record of quality may charge more but also provide assurance of product consistency.

-

Incoterms: The choice of Incoterms (International Commercial Terms) determines the responsibilities of buyers and sellers regarding shipping and costs. Understanding these terms is essential for managing logistics expenses.

What Tips Can Help International Buyers Negotiate Cost-Efficient Deals?

-

Negotiation: Engage in discussions with manufacturers about pricing structures. Being informed about market rates and competitor pricing can provide leverage during negotiations.

-

Cost-Efficiency: Consider total cost of ownership (TCO) rather than just initial purchase price. Factors such as durability, maintenance, and potential resale value can influence long-term costs.

-

Pricing Nuances: Be aware of regional pricing differences. For example, costs may vary significantly between European suppliers and those in Africa or South America, influenced by factors like tariffs and import duties.

-

Clear Communication: Provide detailed specifications and requirements upfront. This minimizes the risk of unforeseen costs arising from changes or misunderstandings later in the process.

-

Seek Multiple Quotes: Obtaining quotes from various manufacturers can provide a clearer picture of the market and help identify the best overall deal.

Disclaimer

Prices for leather goods manufacturing can vary widely based on the aforementioned factors. The figures provided in this analysis are indicative and should be confirmed with individual manufacturers for accurate quotations based on specific requirements.

Alternatives Analysis: Comparing leather goods manufacturer italy With Other Solutions

Exploring Alternatives to Italian Leather Goods Manufacturing

When considering options for sourcing leather goods, businesses must evaluate various manufacturers to find the best fit for their needs. Italian leather manufacturers are renowned for their craftsmanship and quality, but there are alternative solutions that may align more closely with specific requirements, such as cost efficiency or sustainability. This analysis will compare Italian leather goods manufacturers with two viable alternatives: synthetic leather production and local artisanal workshops.

| Comparison Aspect | Leather Goods Manufacturer Italy | Synthetic Leather Production | Local Artisanal Workshops |

|---|---|---|---|

| Performance | High-quality craftsmanship, durability, and aesthetic appeal | Varied quality; can mimic leather but may lack longevity | Unique, handcrafted items, often with regional appeal |

| Cost | Higher price point due to quality and craftsmanship | Generally lower cost, especially for mass production | Variable; often higher than mass-produced items due to labor-intensive processes |

| Ease of Implementation | Requires careful selection and often longer lead times | Quick production turnaround; scalable for large orders | Limited scalability; may require more time for custom orders |

| Maintenance | Requires specific care to maintain quality | Easier to maintain, generally more resistant to wear | Varies by item; often requires similar care as genuine leather |

| Best Use Case | Luxury brands seeking high-end products | High-volume retailers needing cost-effective solutions | Niche markets looking for unique, artisanal goods |

Synthetic Leather Production: Pros and Cons

Synthetic leather, often referred to as faux or vegan leather, is produced using plastic-based materials. The primary advantage of synthetic leather is its cost-effectiveness and ease of production, making it suitable for large-scale retailers. However, the performance can vary significantly, as lower-quality synthetic options may not withstand the test of time like genuine leather. Additionally, while synthetic leather is generally easier to maintain, it lacks the luxurious feel and aesthetic that many consumers associate with genuine leather products.

Local Artisanal Workshops: Pros and Cons

Local artisanal workshops can provide a unique alternative for businesses looking to source leather goods. These workshops often focus on handmade, bespoke items that can cater to specific customer requests. The craftsmanship can result in high-quality products, but the scalability is limited compared to larger manufacturers. Costs may be higher due to labor intensity, and the time to deliver products can be longer. However, these workshops can appeal to consumers seeking unique, culturally significant goods, making them an excellent choice for niche markets.

Illustrative image related to leather goods manufacturer italy

Conclusion: Choosing the Right Solution for Your Business

When selecting a leather goods manufacturer, B2B buyers must consider various factors, including performance, cost, ease of implementation, and maintenance. Italian manufacturers excel in craftsmanship and quality, ideal for luxury markets, while synthetic leather production offers cost-effective solutions for high-volume needs. Local artisanal workshops provide unique, handcrafted products but may lack scalability. Understanding these alternatives allows buyers to make informed decisions based on their specific market demands and customer preferences, ensuring a successful procurement strategy.

Essential Technical Properties and Trade Terminology for leather goods manufacturer italy

What Are the Critical Technical Properties in Leather Goods Manufacturing?

When sourcing leather goods from Italian manufacturers, understanding the essential technical properties is crucial for ensuring product quality and meeting specific business needs. Here are some key specifications to consider:

-

Material Grade

Material grade refers to the quality and type of leather used in production. Common grades include full-grain, top-grain, genuine leather, and bonded leather. Full-grain leather, for instance, is the highest quality, retaining the natural grain and durability. For B2B buyers, specifying the material grade ensures that the final products meet the desired aesthetic and functional requirements, such as longevity and resistance to wear. -

Tannery Certification

Tannery certification indicates that the leather has undergone a standardized tanning process, often adhering to environmental regulations and quality standards. Certifications like LWG (Leather Working Group) signify that the tannery meets sustainable practices. For businesses, partnering with certified tanneries can enhance brand reputation and appeal to eco-conscious consumers. -

Stitching Tolerance

Stitching tolerance refers to the precision in the stitching process, which affects the overall durability and appearance of the leather goods. High-quality leather products typically have a stitching tolerance of 2-3 mm, ensuring strength and aesthetic appeal. B2B buyers should prioritize manufacturers who implement strict quality control measures for stitching to prevent product failure. -

Color Fastness

Color fastness is the ability of the leather to retain its color when exposed to light, water, and rubbing. This property is vital for maintaining the product’s appearance over time. For buyers, understanding color fastness ratings helps in selecting products that will not fade quickly, enhancing customer satisfaction and reducing returns. -

Finish and Texture

The finish and texture of leather can range from smooth and polished to distressed or textured. These characteristics affect not only the aesthetic but also the tactile experience of the product. B2B buyers should communicate their specific finish and texture preferences to ensure alignment with branding and market positioning.

What Are the Common Trade Terms in Leather Goods Manufacturing?

Navigating the B2B landscape requires familiarity with industry-specific terminology. Here are some essential trade terms relevant to leather goods manufacturing:

Illustrative image related to leather goods manufacturer italy

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products based on specifications provided by another company, often under the latter’s brand name. For buyers, understanding OEM relationships can lead to better pricing and customization options, as well as a streamlined production process. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of products a manufacturer is willing to produce for a single order. This term is critical for buyers, as it affects inventory management and cash flow. Knowing the MOQ helps businesses plan their orders according to production capabilities and market demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. By issuing an RFQ, buyers can compare costs and services from multiple manufacturers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers to mitigate risks and ensure smooth logistics in international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the finished goods. For businesses, understanding lead times is vital for inventory planning and meeting customer expectations, especially in seasonal markets. -

Quality Control (QC)

Quality control is a systematic process to ensure that products meet specified requirements and standards. For buyers, a robust QC process is crucial for minimizing defects and ensuring that the final products align with brand expectations and customer satisfaction.

By familiarizing themselves with these technical properties and trade terminology, B2B buyers can make informed decisions when sourcing leather goods from Italian manufacturers, ensuring high-quality products that meet their market demands.

Navigating Market Dynamics and Sourcing Trends in the leather goods manufacturer italy Sector

What Are the Key Trends Driving the Leather Goods Manufacturing Sector in Italy?

The Italian leather goods manufacturing sector is experiencing a dynamic transformation driven by various global factors. The rise of e-commerce and digital platforms is reshaping sourcing strategies, enabling international buyers from regions like Africa, South America, the Middle East, and Europe to access a wider range of products. With the increasing demand for personalized and unique leather products, manufacturers are adopting advanced technologies such as 3D printing and AI-driven design processes to streamline production and reduce lead times.

Moreover, the trend towards luxury and high-quality artisanal products remains strong, as consumers increasingly value craftsmanship over mass-produced items. This trend is particularly evident in emerging markets, where buyers are looking for authentic, high-end leather goods that reflect their cultural identity. Additionally, the integration of sustainable practices into production processes is becoming crucial, as buyers increasingly prioritize ethical sourcing and eco-friendly materials.

How Is Sustainability Shaping Sourcing Practices in the Leather Goods Sector?

Sustainability and ethical sourcing are central to the modern leather goods manufacturing landscape in Italy. As global awareness of environmental issues rises, manufacturers are increasingly adopting sustainable practices to minimize their ecological footprint. This includes using vegetable-tanned leather, which reduces harmful chemical use and supports a more sustainable leather production process.

Moreover, many manufacturers are pursuing certifications such as the Leather Working Group (LWG) certification, which ensures responsible sourcing and production practices. These certifications not only enhance brand reputation but also attract a growing segment of eco-conscious buyers who prioritize sustainability in their purchasing decisions.

Illustrative image related to leather goods manufacturer italy

Additionally, the demand for vegan and synthetic leather alternatives is on the rise, with many manufacturers exploring innovative materials that mimic the aesthetic and tactile qualities of traditional leather while offering a more sustainable option. By aligning their sourcing strategies with ethical considerations, Italian leather goods manufacturers can meet the expectations of modern consumers and international buyers who are increasingly scrutinizing supply chains for environmental and social responsibility.

What Is the Historical Context of the Italian Leather Goods Manufacturing Sector?

The Italian leather goods manufacturing industry has a rich history that significantly informs its current practices. Originating in the post-World War II era, the sector began with small artisan workshops dedicated to craftsmanship and quality. The 1960s marked a turning point as these workshops evolved into larger operations, integrating traditional techniques with modern design to cater to a growing global market.

By the 1970s, Italian leather goods were synonymous with luxury and quality, leading to increased exports and the establishment of iconic brands. Over the decades, Italian manufacturers have balanced heritage and innovation, ensuring that they remain competitive in an ever-evolving market. This historical commitment to craftsmanship, combined with contemporary advancements, positions Italy as a leader in the global leather goods sector, making it an attractive sourcing destination for international B2B buyers.

In conclusion, navigating the Italian leather goods manufacturing landscape requires an understanding of current market dynamics, sustainability trends, and the historical context that shapes the industry’s reputation for quality and craftsmanship. By leveraging these insights, international buyers can make informed sourcing decisions that align with their business values and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of leather goods manufacturer italy

-

How do I ensure quality when sourcing leather goods from Italian manufacturers?

To ensure quality, conduct thorough research on potential manufacturers. Request samples to evaluate craftsmanship and materials. Look for certifications or industry awards that demonstrate a commitment to quality. Establish clear quality control standards in your contract, including specifications for leather types, stitching, and hardware. Regular communication and site visits can also help maintain quality assurance throughout the production process. -

What are the typical minimum order quantities (MOQs) for leather goods manufacturers in Italy?

Minimum order quantities can vary significantly among manufacturers, typically ranging from 50 to 500 units per style. Larger manufacturers may offer lower MOQs for established clients, while artisanal producers might require higher quantities due to their bespoke nature. When negotiating, consider your budget and storage capabilities, and be clear about your expected order volume to find a suitable partner. -

What payment terms should I expect when dealing with Italian leather goods manufacturers?

Payment terms can vary, but many manufacturers require a deposit of 30-50% upfront, with the balance due upon completion or before shipping. Some may offer more flexible terms for established relationships. It’s essential to clarify payment methods accepted (e.g., bank transfer, credit card) and to discuss any potential penalties for late payments to avoid misunderstandings. -

How can I customize leather goods when working with an Italian manufacturer?

Customization options typically include selecting leather types, colors, designs, and hardware. Many manufacturers offer bespoke services, allowing you to provide sketches or prototypes. It’s important to communicate your vision clearly and confirm any additional costs associated with custom designs. Establish timelines for sampling and revisions to ensure that your final product meets expectations. -

What should I consider when vetting a leather goods manufacturer in Italy?

When vetting manufacturers, evaluate their experience, reputation, and production capabilities. Look for customer testimonials and case studies that highlight successful partnerships. Assess their quality control processes and ensure they can meet your specific needs, including MOQs and lead times. Additionally, consider their ability to communicate effectively in your preferred language and their openness to feedback. -

What logistics should I plan for when importing leather goods from Italy?

Logistics planning involves understanding shipping options, costs, and timelines. Work with a freight forwarder to navigate customs regulations and import duties specific to your country. Be aware of the shipping methods available, such as air freight for faster delivery or sea freight for cost-effectiveness. Ensure you have a clear agreement regarding who is responsible for shipping costs and insurance during transit. -

How do I handle potential delays in production or shipping with Italian manufacturers?

Open communication is key to managing delays. Establish a timeline at the outset and check in regularly to monitor progress. If delays arise, ask for a detailed explanation and an updated timeline. Building a buffer into your schedule can help mitigate the impact of unforeseen delays. Consider including clauses in your contract that outline penalties for significant delays to protect your interests. -

What certifications should I look for in Italian leather goods manufacturers?

Look for certifications that demonstrate compliance with industry standards, such as ISO 9001 for quality management or ISO 14001 for environmental management. Additionally, certifications related to sustainable practices, such as the Leather Working Group (LWG) certification, can indicate a commitment to responsible sourcing and production. These credentials not only enhance credibility but also align with growing consumer demand for sustainable products.

Top 2 Leather Goods Manufacturer Italy Manufacturers & Suppliers List

1. Loipell – Luxury Leather Handbags

Domain: loipell.com

Registered: 2019 (6 years)

Introduction: Loipell is a handbags manufacturer based in Florence, Italy, specializing in leather goods. Founded in 1993, the company combines traditional craftsmanship with modern technology to produce high-quality bags for prestigious luxury brands. They manage the entire production cycle internally, ensuring quality control and the ability to handle large volumes of work. Loipell emphasizes ethics, eco-sust…

2. Italian Shoe Factory – Luxury Handbag Manufacturer

Domain: italianshoefactory.com

Registered: 2005 (20 years)

Introduction: Handbag Manufacturer for luxury designer & private label brands. Handmade products, low minimum quantities, quick re-order times. Vegan leather handbags available on demand. Custom handbag and leather goods production for private label brands, individual designers & corporates. Prototyping services for handbag designs, including technical consultation, material sourcing, 2D pattern making, and com…

Strategic Sourcing Conclusion and Outlook for leather goods manufacturer italy

As the demand for high-quality leather goods continues to rise globally, strategic sourcing from Italy presents a unique opportunity for international B2B buyers. Italian manufacturers are renowned for their artisanal craftsmanship, blending tradition with innovation to produce exceptional leather products that cater to various markets. Key takeaways for buyers include the importance of understanding the production processes, from material selection to quality control, which ensures the durability and appeal of the final products.

Moreover, leveraging Italy’s rich heritage in leather goods can enhance brand positioning in competitive markets across Africa, South America, the Middle East, and Europe. Engaging with manufacturers who prioritize sustainability and ethical practices can also resonate with today’s conscious consumers, making your offerings more attractive.

Looking ahead, the Italian leather goods industry is poised for growth, driven by technological advancements and a commitment to excellence. Buyers are encouraged to explore partnerships with reputable Italian manufacturers to capitalize on these trends and elevate their product offerings. By investing in Italian craftsmanship, you are not just sourcing products; you are embracing a legacy of quality and style that will distinguish your brand in the marketplace.

Illustrative image related to leather goods manufacturer italy

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.