Introduction: Navigating the Global Market for belt backing

In an increasingly interconnected world, sourcing high-quality belt backing can pose significant challenges for international B2B buyers. Whether you are operating in the textile, fashion, or industrial sectors, understanding the nuances of belt backing materials is crucial for ensuring product quality and operational efficiency. This guide aims to demystify the complex landscape of belt backing, covering various types, applications, and sourcing strategies that are particularly relevant to buyers from regions such as Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Brazil.

The comprehensive scope of this guide includes detailed insights into the diverse types of belt backing, from cloth-covered options to leather and synthetic variants. We will explore their specific applications, helping you determine the best fit for your unique business needs. Additionally, we will provide actionable advice on vetting suppliers, evaluating costs, and understanding market trends to empower informed purchasing decisions.

By equipping you with the knowledge necessary to navigate the global market for belt backing, this guide serves as a valuable resource for optimizing your supply chain and enhancing your product offerings. You will gain the confidence to make strategic decisions that align with your business objectives, ultimately driving growth and success in your industry.

Table Of Contents

- Top 5 Belt Backing Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for belt backing

- Understanding belt backing Types and Variations

- Key Industrial Applications of belt backing

- 3 Common User Pain Points for ‘belt backing’ & Their Solutions

- Strategic Material Selection Guide for belt backing

- In-depth Look: Manufacturing Processes and Quality Assurance for belt backing

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt backing’

- Comprehensive Cost and Pricing Analysis for belt backing Sourcing

- Alternatives Analysis: Comparing belt backing With Other Solutions

- Essential Technical Properties and Trade Terminology for belt backing

- Navigating Market Dynamics and Sourcing Trends in the belt backing Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of belt backing

- Strategic Sourcing Conclusion and Outlook for belt backing

- Important Disclaimer & Terms of Use

Understanding belt backing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cloth Backing | Made from various fabrics like cotton and polyester; flexible and durable. | Apparel, fashion accessories, upholstery. | Pros: Versatile, comfortable, and aesthetically pleasing. Cons: May not be as strong as synthetic options. |

| Leather Backing | High durability and strength; offers a premium look and feel. | High-end fashion, belts, and luxury goods. | Pros: Long-lasting, classic appearance. Cons: Higher cost and maintenance. |

| Plastic Backing | Lightweight, moisture-resistant; often used in lower-cost applications. | Budget apparel, casual belts, and craft projects. | Pros: Economical, easy to work with. Cons: Less durable and can degrade over time. |

| Paper Backing | Lightweight, often reinforced for added strength; available in various weights. | Industrial applications, packaging, and crafts. | Pros: Cost-effective, suitable for short-term use. Cons: Limited durability and moisture resistance. |

| Composite Backing | Combination of materials for enhanced strength and flexibility. | Heavy-duty applications, automotive, and industrial uses. | Pros: Excellent tensile strength, versatile. Cons: Can be more expensive and may require specialized handling. |

What Are the Key Characteristics of Cloth Backing?

Cloth backing is a popular choice for various applications, particularly in the fashion and apparel industries. Made from materials like cotton or polyester, it offers flexibility and durability, making it suitable for belts and accessories that require comfort and style. When purchasing cloth backing, buyers should consider the fabric weight, as heavier weights often provide better durability. Additionally, the aesthetic appeal of cloth can enhance the overall design of the product, making it a preferred choice for brands focused on fashion.

Why Choose Leather Backing for Premium Products?

Leather backing is renowned for its strength and luxurious appearance, making it a staple in high-end fashion and accessories. Its natural texture and durability give products a premium feel, appealing to discerning consumers. However, buyers should be aware of the higher cost associated with leather and the need for regular maintenance to preserve its quality. When sourcing leather backing, consider the thickness and type of leather, as these factors influence both the look and longevity of the final product.

Illustrative image related to belt backing

How Does Plastic Backing Benefit Cost-Conscious Buyers?

Plastic backing provides an economical solution for businesses looking to produce budget-friendly products without sacrificing too much quality. Its lightweight and moisture-resistant properties make it ideal for casual belts and craft projects. However, buyers should be cautious about its longevity, as plastic can degrade over time. When selecting plastic backing, it is essential to evaluate the thickness and material specifications to ensure it meets the desired application requirements.

What Are the Advantages of Using Paper Backing in Industrial Applications?

Paper backing is often utilized in industrial settings due to its lightweight nature and cost-effectiveness. It is typically reinforced to enhance strength, making it suitable for temporary applications such as packaging and crafts. However, its durability and moisture resistance are limited compared to other materials. Buyers should consider the weight and type of paper when sourcing, as these factors affect performance in specific applications.

When Is Composite Backing the Right Choice for Heavy-Duty Applications?

Composite backing combines various materials to deliver enhanced strength and flexibility, making it ideal for heavy-duty applications in industries such as automotive and manufacturing. This type of backing can withstand significant wear and tear, offering a long-lasting solution for demanding environments. However, buyers should be prepared for potentially higher costs and the need for specialized handling during production. When evaluating composite backing, consider the specific material combinations and their suitability for the intended application.

Key Industrial Applications of belt backing

| Industry/Sector | Specific Application of belt backing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Textile & Fashion | Custom Fabric Belts | Enhances brand identity with bespoke designs | Quality of materials, customization options, and pricing |

| Abrasives Manufacturing | Wide Belt Abrasive Products | Improves efficiency in sanding and finishing processes | Backing material durability, weight classification, and compatibility with machinery |

| Automotive | Belt Reinforcement in Accessories | Ensures longevity and reliability of automotive parts | Material specifications, tensile strength, and environmental resistance |

| Leather Goods | Belt Backing for Custom Leather Products | Provides structural support while maintaining aesthetics | Sourcing genuine leather, thickness, and width options |

| Packaging | Belt Backing for Strapping and Binding | Offers strength and stability in securing packages | Material strength, resistance to environmental factors, and cost-effectiveness |

How is Belt Backing Used in the Textile and Fashion Industry?

In the textile and fashion sector, belt backing is utilized to create custom fabric belts that align with specific garment designs. This application allows brands to enhance their identity by offering unique products tailored to consumer preferences. B2B buyers should focus on sourcing high-quality materials that offer durability and a range of customization options, ensuring that the belts meet both aesthetic and functional requirements.

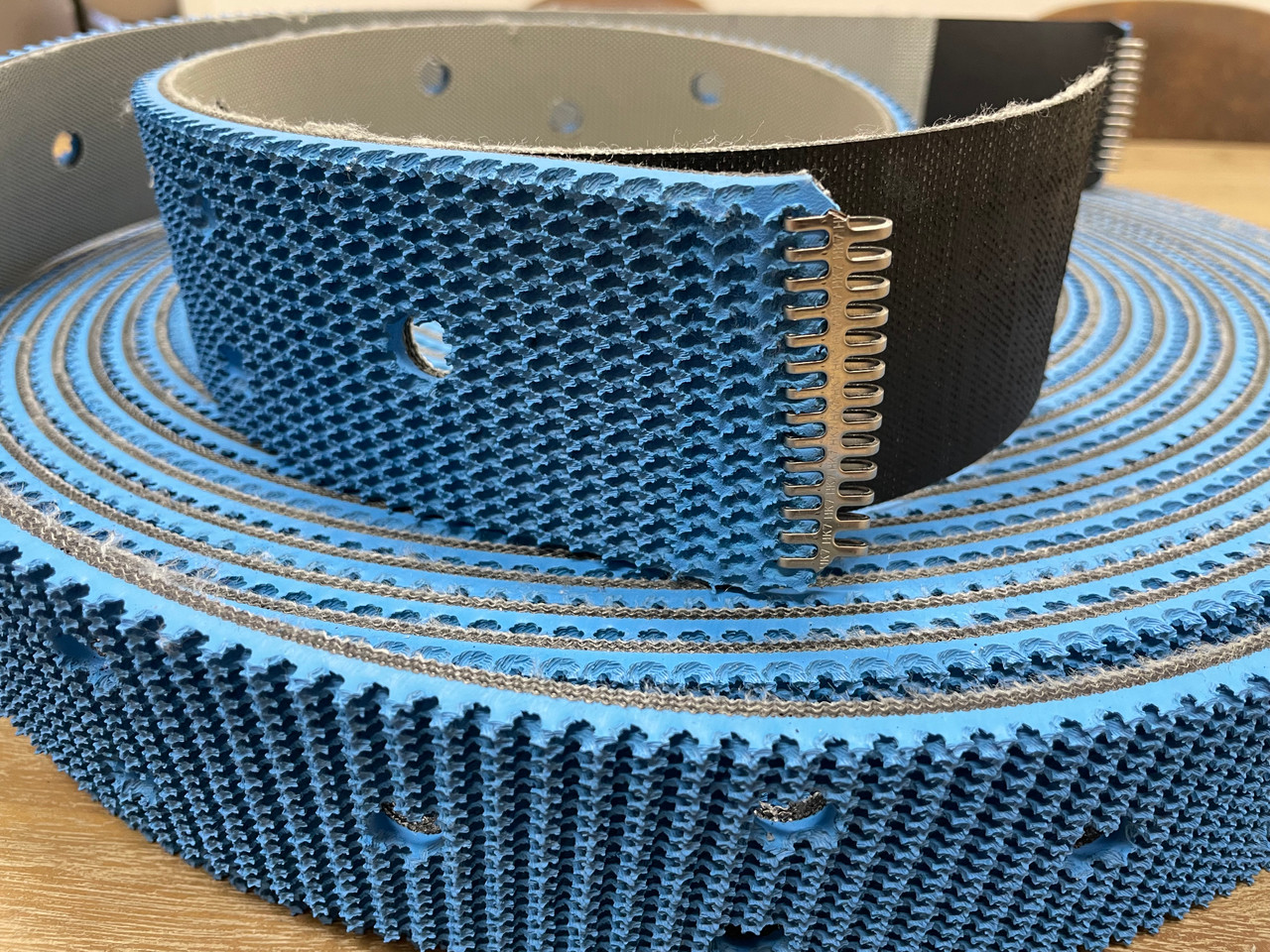

What Role Does Belt Backing Play in Abrasives Manufacturing?

Belt backing is crucial in the production of wide belt abrasive products, which are essential for sanding and finishing operations in various industries. The backing must possess high tensile strength to withstand the rigors of the sanding process, thereby improving efficiency and reducing downtime. Buyers should consider the durability of the backing material, its weight classification, and how well it integrates with existing machinery to ensure optimal performance.

Illustrative image related to belt backing

How is Belt Backing Beneficial in the Automotive Industry?

In the automotive sector, belt backing is used to reinforce accessories such as seat belts and other components, ensuring they can withstand wear and tear. This application is vital for maintaining the reliability and safety of automotive parts. Buyers need to prioritize sourcing materials that meet specific tensile strength requirements and environmental resistance standards, as these factors significantly impact the longevity and performance of the final products.

Why is Belt Backing Important in Leather Goods Production?

Belt backing in leather goods serves as a structural support system for custom leather products, such as belts and straps. This backing not only enhances the durability of the items but also contributes to their overall appearance. When sourcing for this application, buyers should focus on obtaining genuine leather with the right thickness and width options to meet their design specifications while ensuring quality and sustainability.

How Does Belt Backing Enhance Packaging Solutions?

In the packaging industry, belt backing is employed for strapping and binding materials, providing the necessary strength and stability to secure products during transit. This application is critical for minimizing damage and ensuring that packages arrive intact. Buyers should consider the backing’s material strength, resistance to environmental factors, and cost-effectiveness to ensure that their packaging solutions are both reliable and economical.

3 Common User Pain Points for ‘belt backing’ & Their Solutions

Scenario 1: Inconsistent Quality of Belt Backing Materials

The Problem: Many B2B buyers in the belt manufacturing sector face challenges with inconsistent quality in the belt backing materials they procure. This inconsistency can lead to product failures, increased returns, and ultimately damage customer relationships. For instance, a manufacturer might receive a shipment of belt backing that varies in thickness or tensile strength, leading to difficulties in production and affecting the final product’s durability and performance.

The Solution: To mitigate quality issues, it is critical for buyers to establish strong relationships with reliable suppliers who offer consistent quality control practices. Buyers should request detailed specifications for each batch of belt backing, including tensile strength and material composition. Implementing a standardized testing protocol upon receipt can also help ensure that the materials meet the required specifications. Additionally, leveraging suppliers who provide certifications for their materials can add an extra layer of assurance. Regular audits and supplier assessments can also help maintain quality over time, ensuring that your products remain reliable and meet customer expectations.

Scenario 2: Difficulty in Sourcing the Right Size and Type of Belt Backing

The Problem: Sourcing the appropriate size and type of belt backing can be a complex challenge, especially for businesses that require custom specifications. Buyers often struggle to find suppliers that can provide the exact dimensions and material types they need for specific applications, leading to delays in production and increased costs. This scenario is particularly prevalent in markets where diverse belt designs are required, such as in the fashion or industrial sectors.

The Solution: To streamline the sourcing process, buyers should engage with suppliers who offer a wide range of belt backing options, including custom sizes and materials. Utilizing online platforms that provide detailed catalogs and allow for easy filtering by size, type, and application can significantly enhance the procurement process. Furthermore, establishing a collaborative relationship with suppliers can facilitate the development of custom solutions tailored to specific needs. Buyers should also maintain an updated inventory of their most commonly used sizes and materials to expedite future orders and reduce lead times.

Scenario 3: Environmental Concerns and Material Sustainability

The Problem: As global awareness of environmental issues increases, many B2B buyers are facing pressure to source sustainable belt backing materials. This shift can present challenges, particularly for companies that have traditionally relied on synthetic or less eco-friendly materials. The difficulty lies not only in finding sustainable options but also in verifying the claims made by suppliers regarding the environmental impact of their products.

The Solution: To address sustainability concerns, buyers should prioritize suppliers who are transparent about their sourcing practices and can provide evidence of sustainability certifications. Engaging with suppliers who specialize in eco-friendly materials, such as organic cotton or recycled synthetics, can help meet environmental goals. Additionally, buyers should consider implementing a sustainability assessment framework that evaluates suppliers based on their environmental impact, production processes, and material sourcing. Regularly reviewing and updating procurement policies to include sustainability criteria can also help foster responsible sourcing practices that resonate with environmentally conscious consumers. By taking these steps, buyers can ensure that their belt backing materials align with their corporate sustainability goals while still meeting performance standards.

Strategic Material Selection Guide for belt backing

What Are the Key Properties of Common Belt Backing Materials?

When selecting materials for belt backing, it is essential to consider the specific properties that will affect performance in various applications. Here, we analyze four common materials: leather, cloth, plastic, and paper. Each material has distinct characteristics that influence its suitability for different environments and applications.

How Does Leather Perform as a Belt Backing Material?

Leather is a traditional choice for belt backing due to its natural strength and durability. Key properties include high tensile strength, flexibility, and resistance to wear. Leather can withstand a wide range of temperatures and pressures, making it suitable for various applications, from fashion accessories to industrial uses.

Illustrative image related to belt backing

Pros: Leather offers excellent durability and a premium aesthetic, which is appealing in high-end markets. It is also biodegradable, making it a more environmentally friendly option.

Cons: The cost of leather can be significantly higher than synthetic options, and its manufacturing process can be complex due to tanning requirements. Additionally, leather may not perform well in highly humid environments, as it can absorb moisture.

Impact on Application: Leather is compatible with a wide range of media, including textiles and metals. However, its moisture sensitivity may limit its use in wet environments.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of compliance with local regulations regarding animal products, as well as preferences for sustainable sourcing.

Illustrative image related to belt backing

What Advantages Does Cloth Offer in Belt Backing?

Cloth, often made from cotton or synthetic fibers, is another popular choice for belt backing. It provides good flexibility and can be produced in various weights and textures, allowing for customization.

Pros: Cloth is generally less expensive than leather and can be manufactured in large quantities with relatively low complexity. It is also available in various colors and patterns, making it suitable for fashion applications.

Cons: While cloth is flexible, it may not offer the same level of durability as leather or plastic. It can also be susceptible to wear and tear, especially in abrasive environments.

Impact on Application: Cloth is compatible with a range of media, particularly in textile applications. However, its durability may be a concern in heavy-duty industrial settings.

Considerations for International Buyers: Buyers should consider local textile regulations and standards, such as ASTM or DIN, particularly in regions like Europe, where compliance can be stringent.

Illustrative image related to belt backing

How Does Plastic Compare as a Belt Backing Material?

Plastic belt backing, often made from PVC or other polymers, is known for its versatility and resistance to moisture and chemicals. It offers a high level of durability and can withstand harsh conditions.

Pros: Plastic is lightweight, cost-effective, and resistant to corrosion and chemicals, making it ideal for industrial applications. It also provides good dimensional stability.

Cons: The environmental impact of plastic is a significant concern, as it is not biodegradable. Additionally, plastic may not have the same aesthetic appeal as leather or cloth.

Impact on Application: Plastic is suitable for a variety of media, particularly in industrial settings where moisture resistance is critical. However, it may not be suitable for high-temperature applications.

Considerations for International Buyers: Buyers should be aware of regulations regarding plastic materials, especially in regions like the EU, where there are strict guidelines on plastic use and recycling.

Illustrative image related to belt backing

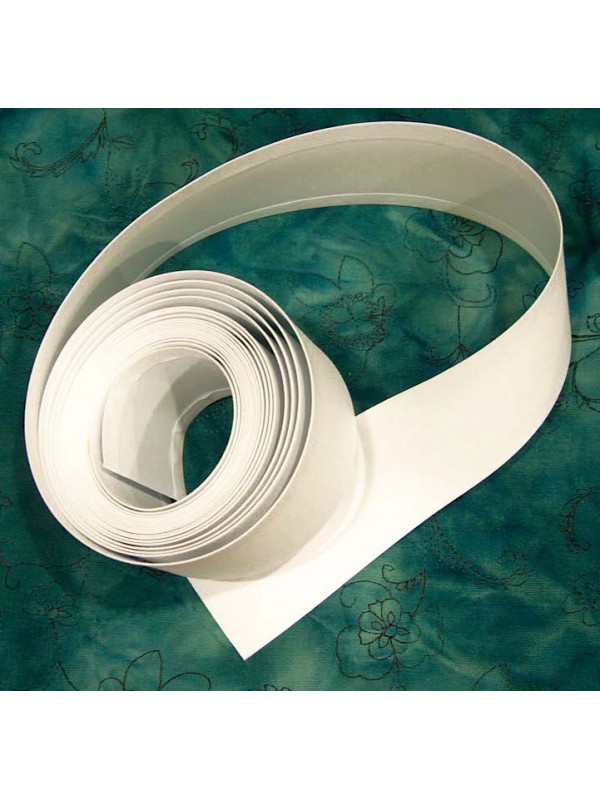

What Role Does Paper Play in Belt Backing?

Paper backing is often used in lower-cost applications and is typically reinforced for added strength. It is lightweight and can be produced in various weights.

Pros: Paper is one of the most cost-effective options for belt backing and is readily available. It is also lightweight, which can reduce shipping costs.

Cons: Paper lacks the durability of other materials and is susceptible to moisture damage. It may not be suitable for heavy-duty applications.

Impact on Application: Paper is often used in applications where cost is a primary concern, but its fragility limits its use in demanding environments.

Considerations for International Buyers: Compliance with local standards for paper products is essential, particularly regarding sustainability and recyclability.

Summary Table of Belt Backing Materials

| Material | Typical Use Case for belt backing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | High-end fashion belts, industrial applications | Excellent durability and aesthetic appeal | Higher cost and complex manufacturing | High |

| Cloth | Fashion belts, light-duty applications | Cost-effective and customizable | Less durable than leather or plastic | Medium |

| Plastic | Industrial belts, moisture-resistant applications | Lightweight and corrosion-resistant | Environmental concerns and aesthetic limitations | Low |

| Paper | Low-cost applications, disposable belts | Very cost-effective and readily available | Susceptible to moisture and less durable | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for belt backing

What Are the Key Manufacturing Processes for Belt Backing?

The manufacturing of belt backing involves several critical stages, ensuring the final product meets both functional and quality standards. The main stages include material preparation, forming, assembly, and finishing. Each stage employs specific techniques that enhance the durability and performance of the belt backing.

How Is Material Prepared for Belt Backing Production?

Material preparation is the initial phase, where raw materials such as fabric, leather, or synthetic materials are sourced and inspected. Suppliers typically conduct a thorough evaluation of the material’s tensile strength, flexibility, and durability. For instance, high-quality cotton or polyester fabrics are often chosen for their resilience. In some cases, materials may undergo treatments to enhance properties such as water resistance or anti-static characteristics.

Preliminary tests are conducted to ensure compliance with international standards. For example, materials may be tested for GSM (grams per square meter) to determine weight consistency, which is crucial for maintaining the integrity of the belt backing during usage.

Illustrative image related to belt backing

What Forming Techniques Are Commonly Used in Belt Backing Production?

Once the materials are prepared, they move on to the forming stage. Techniques such as cutting, molding, and laminating are employed to shape the belt backing. For fabric-based backings, cutting machines are used to create uniform pieces, ensuring consistency across production batches.

In the case of leather or synthetic materials, molding techniques may be utilized to create specific shapes or thicknesses. Laminating involves bonding multiple layers of materials to enhance strength and flexibility. This is particularly important for belts intended for heavy-duty applications, where increased durability is essential.

How Is the Assembly Process Conducted for Belt Backing?

The assembly process focuses on integrating various components of the belt backing. This may involve sewing fabric layers together or attaching buckles and other hardware. Assembly is typically done using industrial sewing machines that ensure precision and speed.

Illustrative image related to belt backing

Quality checks during assembly are crucial. Each piece is inspected for defects such as misalignment or stitching errors, which could compromise the functionality of the final product. Additionally, automated systems can be employed to maintain high standards of quality and efficiency during this phase.

What Finishing Techniques Are Applied to Belt Backing Products?

Finishing techniques are the final step in the manufacturing process, enhancing the appearance and performance of the belt backing. This may include processes like dyeing, coating, or applying protective finishes. For instance, a UV-resistant coating may be applied to synthetic backings to extend their lifespan in outdoor applications.

Quality control at this stage is vital. Finished products are often subjected to visual inspections and functional tests to ensure they meet design specifications. This can include stress tests to evaluate how well the backing can withstand various environmental conditions.

How Is Quality Assurance Implemented in Belt Backing Manufacturing?

Quality assurance (QA) is a cornerstone of the manufacturing process, ensuring that every belt backing product meets stringent international and industry-specific standards. The main QA practices revolve around compliance with ISO 9001 and other relevant certifications.

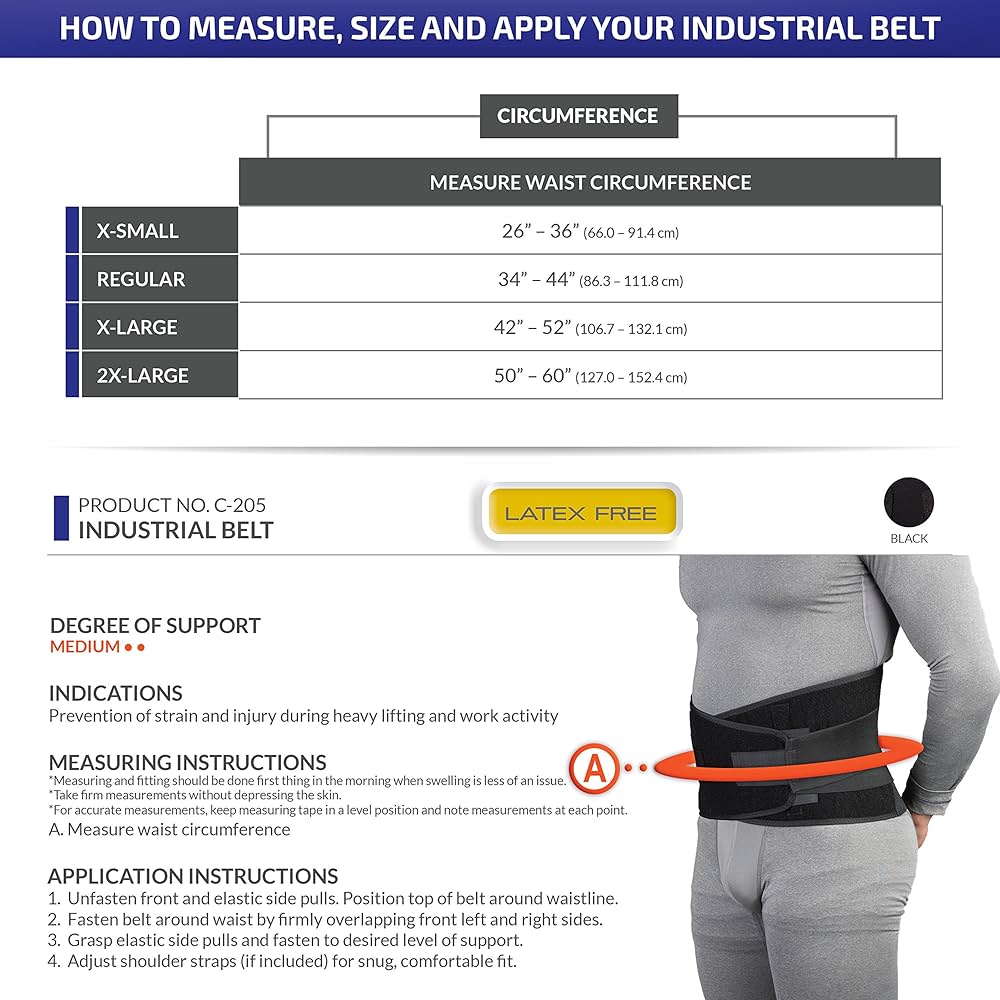

What International Standards Should B2B Buyers Consider?

ISO 9001 is a globally recognized standard that outlines the requirements for a quality management system. Manufacturers of belt backing should demonstrate adherence to these standards, ensuring consistent product quality and customer satisfaction.

Illustrative image related to belt backing

In addition to ISO, industry-specific standards such as CE marking for products sold in Europe or API standards for industrial applications may also be applicable. Understanding these standards is crucial for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Quality Control Checkpoints?

Quality control is integrated into various stages of production, commonly categorized into three checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials upon arrival to ensure they meet specified standards.

- IPQC occurs during the manufacturing process, where samples may be taken at various intervals to check for consistency and quality.

- FQC is the final inspection stage, where finished products undergo rigorous testing before being shipped.

Common testing methods include tensile strength tests, dimensional checks, and durability assessments. These tests ensure that the belt backing will perform as expected in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Buyers should conduct audits, request quality assurance reports, and consider third-party inspections.

Supplier audits can provide insights into the manufacturing environment, staff training, and adherence to quality standards. Quality assurance reports should detail the results of quality tests and any corrective actions taken. Third-party inspections offer an unbiased assessment of the supplier’s quality control processes, ensuring that products meet the required specifications.

Illustrative image related to belt backing

What Are the Nuances of Quality Control for International Buyers?

International buyers must also be aware of the nuances in quality control across different regions. For instance, certification requirements may vary significantly between countries. In Europe, CE marking is essential for compliance, while in some African nations, local standards may be more lenient.

Buyers should also consider the logistical aspects of quality control, such as shipping regulations and import/export standards, which can impact product quality upon arrival. Establishing clear communication with suppliers about quality expectations and compliance requirements is crucial for successful international transactions.

Conclusion

Understanding the manufacturing processes and quality assurance measures for belt backing is vital for B2B buyers. By focusing on material preparation, forming techniques, assembly processes, and finishing methods, buyers can better assess suppliers’ capabilities. Additionally, familiarity with international quality standards and verification practices will empower buyers to make informed decisions, ultimately ensuring the procurement of high-quality belt backing products that meet their specific needs.

Illustrative image related to belt backing

Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt backing’

When sourcing belt backing, a systematic approach is essential for ensuring that you acquire high-quality materials that meet your specific needs. This guide provides a step-by-step checklist to help international B2B buyers navigate the procurement process effectively, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements for belt backing. Consider factors such as material type (e.g., leather, plastic, or cloth), dimensions, thickness, and intended application. Specificity in your requirements helps in narrowing down options and ensures compatibility with your production processes.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in belt backing. Look for manufacturers with a strong reputation in the market, especially those who have experience exporting to your region. Utilize industry directories, trade shows, and online platforms to compile a list of candidates.

Step 3: Evaluate Supplier Certifications and Quality Standards

It’s crucial to verify that your chosen suppliers meet industry certifications and quality standards. Certifications such as ISO 9001 can indicate a commitment to quality management practices. Additionally, inquire about their quality control processes and request samples to assess the material quality before placing a bulk order.

Step 4: Request Samples and Compare Options

Once you have shortlisted suppliers, request samples of their belt backing products. This allows you to evaluate the material’s durability, flexibility, and overall quality. Make comparisons based on price, quality, and lead times to determine which supplier best aligns with your needs.

Step 5: Negotiate Pricing and Payment Terms

Engage in negotiations with your selected suppliers to establish favorable pricing and payment terms. Be transparent about your order volume, as bulk purchases may qualify for discounts. Additionally, clarify payment methods and conditions to avoid any misunderstandings later in the procurement process.

Step 6: Confirm Shipping and Delivery Logistics

Discuss shipping options and delivery timelines with your chosen supplier. Understanding the logistics is vital to ensure timely delivery, especially if you have production deadlines. Confirm the shipping costs and any potential customs duties that may apply when importing goods into your country.

Step 7: Establish a Long-Term Relationship

Once you have successfully sourced belt backing, consider establishing a long-term relationship with your supplier. Regular communication can foster trust and reliability, which can lead to better pricing, priority service, and the ability to respond quickly to your changing needs in the future.

By following this checklist, B2B buyers can streamline their sourcing process for belt backing, ensuring they find the best materials for their production needs while fostering beneficial supplier relationships.

Comprehensive Cost and Pricing Analysis for belt backing Sourcing

What Are the Key Cost Components in Belt Backing Sourcing?

When sourcing belt backing, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost of belt backing. Common materials include cloth, leather, and synthetic options. For instance, cloth-covered plastic backing may cost around $1.45 per yard, while genuine leather options can exceed $2.00 per yard based on thickness and width.

-

Labor: Labor costs vary depending on the complexity of manufacturing processes. Skilled labor is often required for high-quality leather backing, which may increase overall production costs.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Custom tooling for specific belt sizes or designs can incur additional expenses. Buyers should consider the amortization of these costs over larger production runs.

-

Quality Control (QC): Investing in rigorous QC processes is essential for ensuring product consistency and compliance with international standards. This may involve additional costs, but it can prevent costly returns and reputational damage.

-

Logistics: Shipping and handling costs can vary widely based on the origin of materials, shipping methods, and destination. International shipping, especially to regions like Africa or South America, may introduce tariffs or increased freight charges.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding industry standards for margins can help buyers negotiate better prices.

How Do Price Influencers Affect Belt Backing Costs?

Several factors can influence the pricing of belt backing:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to lower per-unit costs. Buyers should assess their needs and consider negotiating for better rates based on anticipated order volumes.

-

Specifications and Customization: Custom designs or specifications can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials or certifications (such as ISO standards) can command premium prices. However, they may also lead to longer-lasting products, offering better value in the long run.

-

Supplier Factors: The reliability and reputation of the supplier can affect pricing. Established suppliers may charge more but often provide better service and quality assurance.

-

Incoterms: Understanding delivery terms is critical. Incoterms define responsibilities for shipping, insurance, and tariffs, which can significantly impact overall costs.

What Are Effective Buyer Tips for Sourcing Belt Backing?

International buyers, particularly from regions such as Africa, South America, and the Middle East, should consider the following strategies:

Illustrative image related to belt backing

-

Negotiation: Engage suppliers in open discussions regarding pricing, especially for bulk orders. Leverage market research to support your negotiation position.

-

Cost-Efficiency: Assess total cost of ownership rather than just initial pricing. Factor in durability, maintenance, and potential returns when evaluating belt backing options.

-

Pricing Nuances: Be aware of regional pricing variations. For instance, sourcing from local suppliers may reduce shipping costs and tariffs but could limit material options.

-

Understand the Market: Familiarize yourself with current market trends and competitor pricing. This knowledge can empower you to make informed purchasing decisions.

-

Consider Long-Term Partnerships: Building long-term relationships with suppliers can lead to better pricing, reliability, and customized solutions over time.

Conclusion

In conclusion, a comprehensive understanding of the cost structure and pricing influencers in belt backing sourcing is essential for B2B buyers. By considering the outlined components and strategies, international buyers can make informed decisions that align with their operational needs and budgetary constraints. It is crucial to remember that the prices mentioned are indicative and can vary based on market conditions and specific supplier agreements.

Alternatives Analysis: Comparing belt backing With Other Solutions

In the realm of manufacturing and custom garment creation, selecting the right backing solution is crucial. While belt backing is a popular choice, there are several alternatives that may better suit specific applications or budgetary constraints. This section evaluates the primary aspects of belt backing against other viable solutions.

| Comparison Aspect | Belt Backing | Cloth Covered Plastic Backing | Genuine Leather Backing |

|---|---|---|---|

| Performance | Durable and flexible, suitable for various fabrics. | Moderate durability; ideal for lightweight applications. | High durability and premium aesthetics; offers excellent wear resistance. |

| Cost | Affordable, typically ranging from $4.95 to $6.45 per yard. | Generally lower cost, around $1.45 per yard. | Higher price point, approximately $2.04 per piece, but varies by size. |

| Ease of Implementation | Easy to cut and apply; compatible with standard sewing techniques. | Simple to handle and cut, but may require additional tools for application. | Requires specialized tools for cutting and finishing, which may complicate the process. |

| Maintenance | Low maintenance; typically requires occasional cleaning. | Moderate maintenance; may wear out faster and need replacement. | Low maintenance; retains quality over time if properly cared for. |

| Best Use Case | Ideal for custom belts, especially in fashion and garment industries. | Best for lightweight belts and temporary solutions. | Excellent for high-end belts where aesthetics and durability are paramount. |

What Are the Pros and Cons of Cloth Covered Plastic Backing?

Cloth covered plastic backing is an economical alternative to traditional belt backing. It is lightweight and flexible, making it suitable for applications where minimal weight is essential. However, its moderate durability may limit its use in heavy-duty applications. While it is easy to work with, the longevity of cloth covered plastic is often lower than that of other materials, necessitating more frequent replacements.

Why Consider Genuine Leather Backing as an Alternative?

Genuine leather backing stands out for its superior durability and aesthetic appeal. It is ideal for high-end products, providing an upscale look and feel. Leather’s natural properties offer excellent wear resistance, making it suitable for heavy usage. However, the higher cost and the need for specialized tools can be a barrier for some manufacturers. Additionally, proper care is essential to maintain its quality over time.

How Should B2B Buyers Decide on the Right Solution?

When choosing between belt backing and its alternatives, B2B buyers should consider several factors. Evaluate the specific application requirements, including performance, cost constraints, and desired aesthetic. For fashion-focused projects, belt backing provides a cost-effective and versatile option. If the project demands a premium look and durability, genuine leather backing may be the best fit. Conversely, for budget-sensitive or lightweight applications, cloth covered plastic backing could be the most practical choice. Understanding these nuances will enable buyers to make informed decisions that align with their operational needs and market positioning.

Essential Technical Properties and Trade Terminology for belt backing

What Are the Critical Technical Properties of Belt Backing?

Understanding the essential technical properties of belt backing is crucial for B2B buyers, particularly those in manufacturing and retail sectors. Here are some key specifications that define the quality and suitability of belt backing materials:

-

Material Grade

The material grade refers to the quality and type of material used for the belt backing, which can range from cardboard to various plastics and leather. Higher-grade materials offer better durability, flexibility, and resistance to wear. For B2B buyers, selecting the right material grade is essential to ensure longevity and performance in specific applications. -

Width and Thickness

Belt backings come in various widths (e.g., 3/4″, 1″, 2″) and thicknesses (commonly measured in millimeters). The width affects the belt’s fit and function, while thickness impacts strength and flexibility. Buyers should match these dimensions to their specific machinery and application requirements to optimize performance. -

Tensile Strength

This property indicates the maximum amount of tensile (stretching) force that a belt backing can withstand before failing. It is typically measured in pounds per square inch (psi) or Newtons per square millimeter (N/mm²). For B2B buyers, understanding tensile strength is vital as it directly correlates with the durability and reliability of the belt in industrial applications. -

Heat Resistance

Heat resistance is the ability of the belt backing to maintain its structural integrity under high temperatures. This property is particularly important in applications involving friction or heat generation. Buyers must consider heat resistance when selecting belt backings for environments with elevated temperatures to prevent premature failure. -

Flexibility and Bend Radius

Flexibility refers to how easily the belt can be bent or shaped without breaking. The minimum bend radius is the smallest radius a belt can be bent without damage. This property is crucial for applications requiring tight turns or complex configurations. Buyers should assess flexibility to ensure compatibility with their machinery and processes. -

Chemical Resistance

Chemical resistance indicates how well the belt backing can withstand exposure to various substances, such as oils, solvents, and acids. This property is essential for belts used in environments where chemical exposure is likely, as it prevents degradation and extends the lifespan of the backing.

What Are Common Trade Terms Related to Belt Backing?

Familiarity with industry jargon can significantly enhance communication and negotiation processes in the B2B environment. Here are some common trade terms associated with belt backing:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end products. Understanding OEM specifications is vital for buyers looking to integrate belt backings into their machinery or finished goods. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to understand, as it affects purchasing decisions, inventory management, and overall supply chain costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. For buyers, submitting an RFQ is an important step in the procurement process, as it allows for comparison of offers and negotiation of terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B transactions, especially for buyers involved in international sourcing. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. Understanding lead times is crucial for B2B buyers to ensure timely delivery and to plan production schedules effectively. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the quality and performance of a product. For buyers, understanding warranty terms is essential to mitigate risks associated with product defects and to ensure product reliability.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions that enhance their operational efficiency and product quality in the competitive marketplace.

Navigating Market Dynamics and Sourcing Trends in the belt backing Sector

What Are the Key Trends Driving the Belt Backing Market?

The belt backing sector is experiencing dynamic changes driven by various global trends. One significant driver is the increasing demand for customizable and high-quality belt solutions across diverse industries, including fashion, manufacturing, and construction. As businesses seek to differentiate their products, suppliers are offering a wider range of materials such as leather, cloth, and synthetic options, catering to specific aesthetic and functional requirements.

Technological advancements in manufacturing processes are also reshaping the market. Automation and digital tools enable suppliers to optimize production efficiency, reduce lead times, and enhance product consistency. This trend is particularly important for international buyers from regions like Africa and South America, where time-to-market can be critical for competitive advantage.

Furthermore, the rise of e-commerce platforms has transformed sourcing practices, allowing businesses to connect with suppliers globally. Buyers can now access a broader selection of products and negotiate better terms through online marketplaces. Additionally, the increasing importance of transparency in supply chains is driving companies to seek suppliers who can provide detailed information about their sourcing practices, including material origins and production methods.

How Is Sustainability Influencing the Belt Backing Supply Chain?

Sustainability is becoming a central theme in the belt backing sector, influencing sourcing strategies and supplier selection. Environmental concerns are prompting businesses to adopt more sustainable practices, such as using eco-friendly materials and minimizing waste during production. Buyers are increasingly looking for suppliers who utilize sustainable raw materials, such as organic cotton or recycled plastics, to meet consumer demand for environmentally responsible products.

Ethical sourcing is also gaining prominence, with companies recognizing the importance of ensuring that their supply chains are free from exploitation and adverse environmental impact. Buyers are encouraged to look for suppliers with certifications like Global Organic Textile Standard (GOTS) or Fair Trade, which can provide assurance of ethical practices in the supply chain. By prioritizing sustainability and ethical sourcing, businesses can enhance their brand reputation and appeal to environmentally conscious consumers.

Illustrative image related to belt backing

How Has the Belt Backing Market Evolved Over Time?

The evolution of the belt backing market is marked by significant advancements in materials and manufacturing techniques. Initially dominated by simple leather and fabric options, the industry has expanded to include a variety of synthetic materials, each offering unique properties and benefits. The introduction of new technologies has enabled manufacturers to create more durable and lightweight backing materials, enhancing the functionality of belts across different applications.

In recent decades, the focus has shifted towards customization and personalization, driven by changing consumer preferences. As fashion trends evolve, so too do the demands for diverse belt styles and functionalities, prompting suppliers to innovate continuously. This evolution reflects a broader trend in the B2B landscape, where flexibility and responsiveness to market demands are crucial for success.

In summary, as international B2B buyers navigate the complexities of the belt backing market, staying informed about key trends, sustainability practices, and historical developments will be essential for making informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of belt backing

-

How do I choose the right belt backing material for my application?

Choosing the appropriate belt backing material involves assessing your specific application requirements. Consider factors such as the type of material being processed, desired durability, and the operational conditions (e.g., wet or dry environments). For instance, if you’re working with heavier materials, a backing with higher tensile strength, like polyester or a heavy paper blend, may be ideal. Additionally, evaluate compatibility with your equipment and any specific finish requirements to ensure optimal performance. -

What are the most common types of belt backing materials available?

Belt backings come in various materials including cloth, paper, and plastic. Cloth backings, often made from cotton or polyester, offer flexibility and durability, making them suitable for most applications. Paper backings are typically used for lighter-duty applications, while plastic backings provide water resistance and are ideal for wet environments. Understanding the characteristics of each type will help you select the best option for your production needs. -

What factors should I consider when vetting suppliers of belt backing?

When vetting suppliers, prioritize their industry experience, product quality, and reliability. Request samples to assess the backing’s performance and durability. Inquire about their manufacturing processes, quality assurance measures, and certifications (e.g., ISO). Additionally, consider their logistics capabilities, responsiveness to inquiries, and customer service history to ensure a smooth purchasing experience. -

What is the minimum order quantity (MOQ) for belt backing, and how does it vary by supplier?

MOQs for belt backing can vary significantly based on the supplier and material type. Typically, suppliers may require a minimum order of 50 to 100 yards, especially for custom sizes or specialized materials. It’s crucial to discuss your needs with potential suppliers to determine their specific MOQs, as some may offer flexibility for larger or repeat orders. -

What payment terms are commonly offered by belt backing suppliers?

Payment terms can vary widely among suppliers, but common options include net 30, net 60, or upfront payment. Many suppliers may offer discounts for early payments or larger orders. It’s advisable to negotiate payment terms that align with your cash flow and procurement cycles. Additionally, inquire about acceptable payment methods, including wire transfers, letters of credit, or online payment platforms. -

How can I ensure the quality of belt backing I receive?

To ensure product quality, establish clear specifications with your supplier, including dimensions, material properties, and performance standards. Request samples prior to placing a bulk order to evaluate the quality firsthand. Consider conducting periodic quality checks during production and upon delivery. Additionally, ask about the supplier’s quality assurance processes and certifications to gain confidence in their product consistency. -

What are the logistics considerations when sourcing belt backing internationally?

Logistics considerations include shipping methods, transit times, and customs regulations. Understand the supplier’s shipping capabilities and whether they can handle international freight. Calculate total landed costs, including shipping, tariffs, and taxes, to accurately assess your budget. Collaborating with a freight forwarder can streamline the process, ensuring compliance with local regulations and timely delivery to your facility. -

Can I customize the size and specifications of belt backing for my needs?

Yes, many suppliers offer customization options for belt backing, allowing you to specify dimensions, thickness, and material types. When requesting custom products, provide detailed specifications and any necessary technical drawings. Keep in mind that custom orders may have higher MOQs and longer lead times, so plan accordingly to meet your production schedule. Be sure to confirm the supplier’s capabilities and experience in handling custom requests.

Top 5 Belt Backing Manufacturers & Suppliers List

1. WeSewRetro – Belt Buckle Kits

Domain: shop.wesewretro.com

Registered: 2011 (14 years)

Introduction: Belt Making Supplies available at WeSewRetro include various belt buckle kits and belt backing kits. Key products include: 1″ Buckle to Cover Kit (BK-70/2) – $6.45, 3/4″ Buckle to Cover Kit (BK-315) – $6.45, 1.5″ Buckle to Cover Kit (BK-100) – $6.45, 2″ Buckle to Cover Kit (BK-110) – $6.45, 3″ Buckle to Cover Kit (BK-9700) – $7.75 (sold out), 1.5″ Belting with Eyelets Kit (BB-11/2) – $6.45, 3/4″ B…

2. GAN – Belt Backing

Domain: gotanotion.shop

Introduction: {“product_name”: “Belt Backing”, “brand”: “GAN – Got A Notion”, “prices”: [{“size”: “3/4” , “type”: “YD”, “price”: “$4.95”}, {“size”: “3/4”, “type”: “ROLL”, “price”: “Sold Out”}, {“size”: “1”, “type”: “YD”, “price”: “$5.95”}, {“size”: “1”, “type”: “ROLL”, “price”: “Sold Out”}, {“size”: “1 1/4”, “type”: “YD”, “price”: “$5.95”}, {“size”: “1 1/4”, “type”: “ROLL”, “price”: “Sold Out”}, {“size”: “2”, “…

3. Country Store Fabrics – Cloth Covered Plastic Belt Backing

Domain: countrystorefabrics.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Cloth Covered Plastic Belt Backing”, “product_code”: “100323”, “availability”: “In Stock”, “price”: “$1.45”, “size”: “3 inch black”, “minimum_order”: “1 yard”, “purchase_options”: “fraction of a yard available”, “conversion_chart”: {“1/4 Yard”: “.25”, “1/3 Yard”: “.33”, “1/2 Yard”: “.5”, “2/3 Yard”: “.67”, “3/4 Yard”: “.75”}}

4. Dritz – Belt Backing Alternatives

Domain: sewing.patternreview.com

Registered: 2001 (24 years)

Introduction: Dritz belting/belt backing: hard, compact, curved, plastic laminate; used for substantial self-fabric belts. Disappeared from stores and online suppliers. Maxant single-belt packs found as an alternative. BanRol: stiff, good for waistbands and belts; available in 1 inch and wider widths. Sources mentioned: The Sewing Place, Create for Less, Wawak, Goods Variety Store in Versailles Missouri, Fabric…

5. Peace Applique – Belt Backing 3/4in

Domain: peacenapplique.com

Registered: 2001 (24 years)

Introduction: Belt Backing 3/4in – 850632001407

Strategic Sourcing Conclusion and Outlook for belt backing

As the global market for belt backing continues to evolve, strategic sourcing has become essential for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Understanding the diverse materials and options available—from cloth and leather to innovative synthetic alternatives—allows businesses to tailor their offerings to meet specific customer needs. Emphasizing quality and sustainability in sourcing practices not only enhances product performance but also strengthens brand reputation.

The demand for customized solutions is rising, driven by a growing emphasis on aesthetics and functionality in fashion and industrial applications alike. By leveraging strategic partnerships with reliable suppliers, companies can ensure a steady supply of high-quality materials that align with their operational goals.

Illustrative image related to belt backing

Looking ahead, the opportunities in the belt backing market are promising. International buyers should actively seek out innovative suppliers and manufacturers who prioritize quality and sustainability. By doing so, they can position themselves for success in a competitive landscape while meeting the increasing consumer demand for bespoke and eco-friendly products. Embrace this opportunity to enhance your sourcing strategy and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to belt backing