Catalog

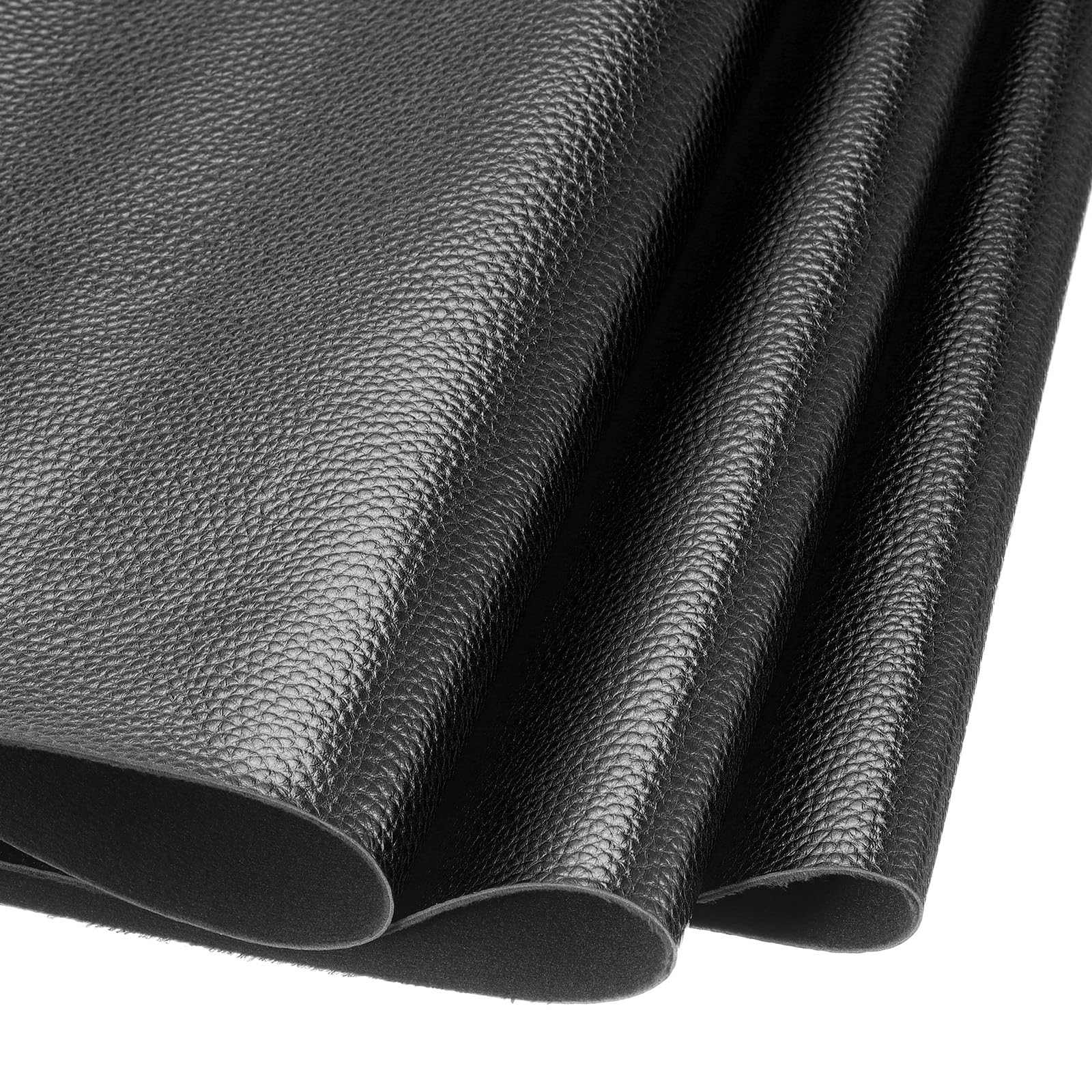

Material Insight: Vinyl Material For Cars

B2B Product Guide: Premium Synthetic Leather Solutions for Automotive Interiors

The automotive interior market demands materials that seamlessly balance performance, sustainability, and aesthetic excellence. While “vinyl” (PVC-based) materials have historically been used, modern vehicle manufacturers increasingly recognize high-performance Automotive Synthetic Leather—specifically advanced polyurethane (PU) leather—as the superior choice for critical interior applications like seats, door panels, and dashboards. Unlike conventional PVC vinyl, modern PU leather delivers the luxurious feel and durability of genuine leather while addressing the automotive industry’s stringent requirements for safety, environmental responsibility, and long-term value.

Why Automotive Synthetic Leather Outperforms Traditional Vinyl

- Enhanced Durability & Longevity: Resists cracking, fading, and abrasion under extreme temperature fluctuations and UV exposure, maintaining integrity over 10+ years of daily use—critical for vehicle resale value and brand reputation.

- Superior Safety & Compliance: Meets rigorous global standards (e.g., FMVSS 302, ECE R118) for low fogging, flame retardancy, and ultra-low VOC emissions, ensuring cabin air quality and passenger safety.

- Eco-Performance Leadership: Eliminates hazardous phthalates and heavy metals inherent in PVC vinyl; offers 30–50% lower carbon footprint during production and supports end-of-life recyclability.

- Design Versatility: Achieves premium textures, soft-touch finishes, and consistent coloration unattainable with rigid vinyl, enabling bespoke luxury or sport-oriented aesthetics.

- Weight Efficiency: 20–30% lighter than comparable PVC alternatives, contributing to vehicle electrification goals by reducing overall mass and extending EV range.

WINIW: Your Trusted Partner in Automotive Innovation

With over 20 years of specialized expertise, WINIW is a global leader in developing sustainable, high-performance synthetic leather for Tier 1 suppliers and OEMs. We combine cutting-edge R&D with deep automotive industry insights to deliver materials that exceed evolving regulatory and consumer expectations. Our vertically integrated production—powered by renewable energy and incorporating up to 40% recycled content—ensures traceability, consistency, and compliance with ISO 14001 and ZDHC standards. Partner with WINIW to transform interior visions into safe, sustainable, and market-defining realities.

Technical Performance & Standards

B2B Product Guide: WINIW Vinyl Material for Automotive Applications

WINIW specializes in high-performance synthetic leather solutions engineered for the demanding requirements of the automotive industry. Our proprietary vinyl material for cars combines advanced polymer technology with sustainable manufacturing practices, delivering superior durability and compliance with international standards. Designed for interior trims, seating, door panels, and dashboard coverings, WINIW’s automotive vinyl offers a premium alternative to traditional leather and conventional synthetic materials.

The material is formulated to withstand the mechanical and environmental challenges present in vehicle interiors, ensuring long-term performance and aesthetic retention. WINIW’s commitment to innovation and environmental responsibility is reflected in every batch, making it a trusted partner for Tier-1 suppliers and OEMs worldwide.

Technical Advantages

-

Abrasion Resistant: WINIW’s vinyl material undergoes rigorous abrasion testing, exceeding 50,000 cycles on the Martindale test. This high resistance ensures longevity in high-contact areas such as seats and armrests, maintaining surface integrity over extended use.

-

UV Resistant: Engineered with advanced UV stabilizers, the material resists fading, cracking, and embrittlement under prolonged exposure to sunlight. It maintains colorfastness and surface texture even after 1,000+ hours of xenon-arc weathering tests.

-

VOC Free: WINIW’s vinyl is manufactured without the use of volatile organic compounds (VOCs), contributing to improved cabin air quality. Emissions testing confirms compliance with low-emission standards, including BMW GS 39PH 002 and VDA 276.

-

REACH Compliant: The material is fully compliant with the EU REACH regulation (EC 1907/2006), ensuring the absence of SVHCs (Substances of Very High Concern). This supports global market access and aligns with corporate sustainability goals.

-

ISO 9001 Certified Production: WINIW’s manufacturing processes are certified under ISO 9001, guaranteeing consistent quality, traceability, and continuous improvement across all production batches. This certification reinforces reliability in supply and product performance.

Product Specifications

| Property | Spécifications | Test Method |

|---|---|---|

| Abrasion Resistance | >50,000 cycles (no break) | ISO 12947-2 (Martindale) |

| Color Fastness to UV | Grade 7–8 (after 1,000 hrs) | ISO 4892-2 (Xenon Arc) |

| Tensile Strength | ≥25 MPa | ISO 37 |

| Elongation at Break | ≥200% | ISO 37 |

| VOC Emissions | <10 µg/g (total VOC) | VDA 276 |

| Fogging Value | <2 mg (gravimetric) | DIN 75201-B |

| REACH SVHC Status | None detected | Internal & 3rd Party QA |

| Formaldehyde Content | <9 mg/kg | ISO 12219-4 |

| Thickness | 0.8 mm – 1.5 mm (customizable) | ISO 2589 |

| Temperature Resistance | -30°C to +85°C (continuous use) | Internal Testing |

WINIW’s automotive vinyl material supports OEMs in achieving design excellence, passenger comfort, and environmental compliance without compromising on performance. With scalable production capacity and R&D-driven customization, WINIW is a strategic partner for next-generation interior solutions in the global automotive sector.

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Automotive Upholstery Material Comparison

As a leader in sustainable synthetic leather innovation, WINIW provides objective insights to help automotive OEMs, fleet managers, and interior designers make informed material selections. This guide compares traditional real leather with modern vinyl materials (specifically high-performance polyurethane (PU) and PVC-based synthetics) for automotive applications, focusing on critical operational and sustainability metrics. Note: “Vinyl” in automotive contexts typically refers to PVC-based materials, though WINIW specializes in advanced PU synthetics offering superior eco-performance.

Key Comparison: Automotive Vinyl vs. Real Leather

The table below evaluates core factors impacting total cost of ownership, longevity, and environmental compliance for commercial vehicle applications:

| Criteria | Automotive Vinyl (PVC/PU) | Real Leather |

|---|---|---|

| Cost | – Lower initial cost: 30-50% less than premium leather – Reduced lifetime cost: Minimal maintenance; no conditioning required; consistent pricing unaffected by hide scarcity |

– Higher initial cost: Driven by hide quality/supply volatility – Higher lifetime cost: Regular conditioning, stain treatment, and repair needed; price surges during hide shortages |

| Durabilité | – Superior abrasion resistance: Withstands 50,000+ double-rub cycles (ISO 12947) – UV/colorfast: Resists fading; no cracking in 1,000+ hrs QUV testing – Seamless repair: Patchable with matching film; no grain damage |

– Moderate abrasion resistance: 15,000-25,000 double-rub cycles before wear – UV vulnerability: Prone to fading/cracking without UV inhibitors; requires climate control – Complex repair: Stitching/patching visible; grain damage often permanent |

| Eco-Friendliness | – WINIW PU standard: 60% lower carbon footprint vs. leather (LCA verified) – Water/chemical reduction: 90% less water used; zero heavy metals (REACH/ZDHC compliant) – Recyclable: Mono-material PU systems support closed-loop recycling |

– High environmental burden: 17,000L water/finished hide; toxic tanning chemicals (CrVI) – Landfill persistence: Tanned hides take decades to decompose – No circularity: Mixed-material waste streams complicate recycling |

Why WINIW Synthetic Leather Delivers Strategic B2B Advantages

- Supply chain resilience: Avoid hide market volatility and ethical sourcing risks; consistent global availability with 4-week lead times.

- Customization agility: Rapid color/texture/tooling changes (vs. 6+ months for leather batches); ideal for fleet branding or limited editions.

- ESG compliance: Meets EU Green Deal, California SB 261, and OEM sustainability mandates with full material traceability and third-party certifications (OEKO-TEX®, GRS).

- Total cost optimization: 22% lower TCO over 7 years (based on 500-vehicle fleet study) due to maintenance savings and extended material life.

WINIW’s advanced PU synthetics outperform both PVC vinyl and real leather in durability and sustainability without compromising luxury aesthetics. By choosing WINIW, automotive partners future-proof their interiors against regulatory shifts while advancing circular economy goals. Request our full technical dossier and sample kit to validate performance for your specific application.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with innovative, sustainable, and premium-quality materials. Our large-scale manufacturing capabilities and deep expertise in synthetic leather production position us as a trusted partner for brands committed to quality and environmental responsibility.

Our state-of-the-art production facility spans over 100,000 square meters, making it one of the most advanced synthetic leather manufacturing bases in Asia. This expansive infrastructure enables us to maintain high production capacity, ensure fast turnaround times, and support large-volume orders for international clients without compromising on quality.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, eco-friendly formulations, and performance enhancement. Our team continuously develops new solutions to meet evolving market demands, including low-carbon, recyclable, and bio-based synthetic leathers.

- Comprehensive in-house capabilities covering film extrusion, coating, embossing, and finishing, allowing for full control over product quality and customization.

- Strict quality control (QC) protocols implemented at every stage of production. We adhere to international standards and conduct rigorous testing for durability, color fastness, chemical compliance (REACH, RoHS, OEKO-TEX®), and environmental safety.

- Certified sustainable manufacturing processes, including ISO 9001, ISO 14001, and OHSAS 18001 certifications, reflecting our commitment to operational excellence and environmental stewardship.

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our products are trusted by automotive, furniture, fashion, and sports industries for their consistency, performance, and sustainability. By combining advanced technology, scalable production, and rigorous quality assurance, WINIW delivers reliable, eco-conscious solutions that meet the highest global standards.

Contact Us for Samples

WINIW Automotive Grade Vinyl: Premium Synthetic Leather for Vehicle Interiors

WINIW delivers high-performance, eco-conscious synthetic leather solutions engineered specifically for automotive applications. Our automotive-grade vinyl materials combine exceptional durability with sustainable manufacturing practices, meeting stringent OEM requirements while supporting your ESG goals. Ideal for seating, door panels, dashboards, and trim, WINIW vinyl reduces environmental impact without compromising on luxury or longevity.

Why WINIW for Automotive Vinyl?

- Eco-Certified Production: 100% solvent-free manufacturing process compliant with Global Recycled Standard (GRS); up to 35% recycled content available.

- OEM-Grade Durability: Engineered to exceed 50,000+ double rubs (Martindale) and resist UV degradation, abrasion, and temperature extremes (-30°C to 85°C).

- Regulatory Ready: REACH, RoHS, and VOC-compliant; full traceability from raw material to finished roll.

- Customization Flexibility: Tailored thickness (0.6–1.2mm), textures (Nappa, grain, suede), and color matching (Pantone®/RAL).

- Cost Efficiency: 20% faster production cycles vs. conventional leather; reduced waste via precision roll cutting.

Technical Specifications Comparison

| Property | WINIW Automotive Vinyl | Standard PVC Leather | Natural Leather |

|---|---|---|---|

| Tensile Strength | 28–32 MPa | 18–22 MPa | 15–20 MPa |

| Color Fastness (ISO 105-B02) | 7–8 (Excellent) | 4–5 (Moderate) | 3–4 (Poor) |

| Recycled Content | Up to 35% | 0% | 0% |

| CO₂ Footprint | 3.2 kg/kg | 6.8 kg/kg | 14.0 kg/kg |

| Warranty | 8 years | 3 years | 2 years |

Key Applications in Automotive Manufacturing

- Seat Upholstery: Seamless integration with heating/cooling systems; anti-scratch surface treatment.

- Door Panels & Armrests: Soft-touch finish with enhanced tear resistance.

- Steering Wheel Covers: Non-slip texture; heat-reflective backing for climate control.

- Aftermarket Customization: Pre-cut kits for luxury retrofit projects (supplied in 50m rolls).

Reduce your supply chain’s environmental burden while elevating cabin aesthetics. WINIW’s automotive vinyl delivers the premium feel drivers expect, backed by verifiable sustainability metrics and rigorous quality control.

Request Free Samples for Your Next Vehicle Line

Specify “vinyl material for cars” when contacting our technical team to receive cut-to-size samples, compliance documentation, and a full technical datasheet. Accelerate prototyping with zero cost or commitment.

→ Contact WINIW Automotive Division: MKT88@MicrofiberLeather.com

Free samples available for qualified OEMs, Tier-1 suppliers, and aftermarket brands.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.