Introduction: Navigating the Global Market for american leather fabrics

Navigating the complexities of sourcing high-quality American leather fabrics can pose significant challenges for international B2B buyers, particularly those in diverse markets such as Africa, South America, the Middle East, and Europe, including countries like Vietnam and Nigeria. With an abundance of options available, from various types of leathers to an array of textures and colors, understanding how to choose the right materials for your specific applications—whether for furniture, automotive, or fashion—becomes crucial. This guide aims to demystify the American leather fabric market by providing comprehensive insights into the different types available, their applications, and the vital considerations for supplier vetting and cost evaluation.

As you explore this guide, you will find actionable strategies to empower your purchasing decisions, ensuring that you not only select fabrics that meet aesthetic and functional requirements but also align with your business goals. Whether you are looking for luxurious, high-performance options or durable materials that withstand the rigors of everyday use, our expert analysis will equip you with the knowledge needed to navigate supplier relationships and make informed investments. By the end of this guide, you will have a clearer understanding of how to effectively source American leather fabrics, enhancing your product offerings and ultimately driving your business success in the global marketplace.

Table Of Contents

- Top 2 American Leather Fabrics Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for american leather fabrics

- Understanding american leather fabrics Types and Variations

- Key Industrial Applications of american leather fabrics

- 3 Common User Pain Points for ‘american leather fabrics’ & Their Solutions

- Strategic Material Selection Guide for american leather fabrics

- In-depth Look: Manufacturing Processes and Quality Assurance for american leather fabrics

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘american leather fabrics’

- Comprehensive Cost and Pricing Analysis for american leather fabrics Sourcing

- Alternatives Analysis: Comparing american leather fabrics With Other Solutions

- Essential Technical Properties and Trade Terminology for american leather fabrics

- Navigating Market Dynamics and Sourcing Trends in the american leather fabrics Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of american leather fabrics

- Strategic Sourcing Conclusion and Outlook for american leather fabrics

- Important Disclaimer & Terms of Use

Understanding american leather fabrics Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Top Grain Leather | High durability, natural grain, and softness | Luxury furniture, automotive interiors | Pros: Premium quality, ages well. Cons: Higher cost, requires maintenance. |

| Full Grain Leather | Retains natural texture and markings | High-end upholstery, fashion goods | Pros: Exceptional durability, develops unique patina. Cons: More expensive, sensitive to stains. |

| Daim | Soft texture, napped finish | Apparel, luxury accessories | Pros: Unique appearance, soft touch. Cons: Less durable, susceptible to water damage. |

| Synthetic Leather | Cost-effective, versatile, and easy to clean | Mass-market furniture, automotive | Pros: Affordable, stain-resistant. Cons: May lack the luxury feel of natural leather. |

| Performance Fabrics | Stain-resistant, durable, and easy to maintain | Commercial upholstery, family-friendly furniture | Pros: Excellent durability, wide color options. Cons: May not have the same aesthetic appeal as natural leather. |

What Are the Key Characteristics of Top Grain Leather for B2B Buyers?

Top grain leather is known for its superior quality and durability, making it a favored choice for luxury furniture and automotive interiors. Its natural grain and softness provide an elegant appearance while ensuring longevity. B2B buyers should consider that although top grain leather comes with a higher price tag, its ability to withstand wear and age beautifully justifies the investment. Regular maintenance is required to preserve its aesthetic and functional qualities.

How Does Full Grain Leather Stand Out in the Market?

Full grain leather is celebrated for retaining the hide’s natural texture and markings, offering a unique and authentic look to high-end upholstery and fashion goods. This type of leather is exceptionally durable and develops a beautiful patina over time, enhancing its character. B2B purchasers should note that while full grain leather is a premium option, its sensitivity to stains and higher cost may require careful consideration for specific applications.

What Are the Advantages and Disadvantages of Suede Leather?

Suede leather, characterized by its soft texture and napped finish, is commonly used in apparel and luxury accessories. Its unique appearance adds a distinct touch to products, appealing to consumers seeking luxury. However, B2B buyers should be aware that suede is less durable and more susceptible to water damage compared to other types of leather. This may limit its applicability in environments where durability is a priority.

Why Choose Synthetic Leather for Cost-Effective Solutions?

Synthetic leather offers a cost-effective alternative to natural leather, making it ideal for mass-market furniture and automotive applications. It is versatile, easy to clean, and often resistant to stains, which appeals to budget-conscious buyers. However, while synthetic leather is affordable, it may lack the luxurious feel and aesthetic of genuine leather, which could be a consideration for high-end markets.

What Are Performance Fabrics and Their Role in B2B Upholstery?

Performance fabrics are engineered to be stain-resistant, durable, and easy to maintain, making them an excellent choice for commercial upholstery and family-friendly furniture. These fabrics provide a wide array of color options and textures, appealing to diverse consumer preferences. B2B buyers should weigh the benefits of performance fabrics against the potential trade-off in terms of aesthetic appeal compared to natural leather options.

Key Industrial Applications of american leather fabrics

| Industry/Sector | Specific Application of American Leather Fabrics | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for high-end furniture | Enhances aesthetic appeal and durability of products | Quality assurance, fabric grades, and supplier reliability |

| Automotive | Interior coverings for luxury vehicles | Provides luxurious feel and long-lasting performance | Compliance with safety standards, color matching |

| Hospitality | Upholstery for hotel furnishings and decor | Elevates guest experience and enhances brand image | Resistance to stains, durability, and maintenance ease |

| Aviation | Seating and interior finishes for private jets | Combines luxury with lightweight performance | Weight considerations, fire resistance, and custom designs |

| Retail | Custom display fixtures and furniture | Creates an inviting shopping environment | Fabric availability, customization options, and cost |

How Are American Leather Fabrics Used in Furniture Manufacturing?

In the furniture manufacturing sector, American leather fabrics are primarily used for upholstery on high-end furniture pieces. These fabrics not only enhance the aesthetic appeal of sofas, chairs, and other furniture items but also provide exceptional durability and comfort. For international buyers, particularly from emerging markets in Africa and South America, sourcing high-quality leather can solve issues related to wear and tear, ensuring longevity in furniture offerings. Buyers should consider fabric grades and supplier reliability to maintain quality standards.

What Role Do American Leather Fabrics Play in the Automotive Industry?

In the automotive industry, American leather fabrics are utilized for interior coverings in luxury vehicles. These fabrics provide a premium feel that enhances the overall driving experience while ensuring durability against daily wear. Buyers from regions like the Middle East and Europe need to prioritize compliance with safety standards and color matching to meet local regulations and consumer preferences. The ability of these fabrics to withstand spills and stains is also a significant advantage for automotive manufacturers.

How Do American Leather Fabrics Enhance Hospitality Settings?

American leather fabrics are extensively used in the hospitality industry, specifically for upholstering hotel furnishings and decor elements. By incorporating these luxurious fabrics, hotels can elevate the guest experience and reinforce their brand image. For international buyers in competitive markets, the durability and stain resistance of these fabrics are critical considerations. Ensuring ease of maintenance can significantly reduce operational costs while maintaining a high standard of guest satisfaction.

In What Ways Are American Leather Fabrics Applied in Aviation?

In the aviation sector, American leather fabrics serve as premium materials for seating and interior finishes in private jets. The combination of luxury and lightweight performance is crucial for enhancing passenger comfort while adhering to strict weight regulations. Buyers from various international markets must consider fire resistance and customization options to meet specific design requirements. This attention to detail not only improves the aesthetic value of the aircraft but also aligns with the expectations of discerning clients.

How Are Retail Environments Enhanced by American Leather Fabrics?

In the retail sector, American leather fabrics are increasingly used for custom display fixtures and furniture. This application creates an inviting shopping environment that can significantly influence customer experience and purchasing behavior. For international buyers, particularly in developing regions, the availability of various fabric options and the potential for customization are vital. Cost considerations also play a crucial role, as businesses seek to balance quality with budget constraints while sourcing from reliable suppliers.

3 Common User Pain Points for ‘american leather fabrics’ & Their Solutions

Scenario 1: Navigating Diverse Fabric Quality Standards

The Problem: B2B buyers often encounter confusion due to the varying quality standards associated with American leather fabrics. Different manufacturers may categorize their fabrics using unique grading systems, leading to uncertainty about the actual durability and performance of the materials. For international buyers, this is particularly problematic, as they may not be familiar with the specific grading nuances, which could result in sourcing fabrics that do not meet their project requirements or customer expectations.

The Solution: To mitigate this issue, it is essential to establish clear communication with suppliers regarding fabric grades. Buyers should request detailed specifications for each fabric, including fiber content, durability ratings, and care instructions. Creating a comparison chart that includes these details can help buyers visualize differences between fabrics. Additionally, sourcing swatches is crucial; it allows buyers to assess the material’s texture, color, and overall quality firsthand. Engaging in direct discussions with manufacturers about their grading criteria can also lead to more informed decisions, ensuring that the fabrics sourced align with the intended use and aesthetic vision.

Scenario 2: Managing Long-Term Maintenance and Care

The Problem: One significant concern for B2B buyers is the long-term maintenance of American leather fabrics. Many buyers are unsure how to care for high-end leather upholstery, especially when it comes to protecting against stains, fading, and wear over time. This uncertainty can lead to costly mistakes, such as improper cleaning methods that damage the fabric or reduce its lifespan, ultimately affecting customer satisfaction and brand reputation.

The Solution: To effectively manage maintenance, buyers should prioritize sourcing fabrics that come with comprehensive care instructions and warranties. It is advisable to conduct thorough research on the different types of leather finishes available, such as light, medium, and heavy protection options. For instance, heavy protection leathers are ideal for environments with high foot traffic or families with children and pets, as they offer greater resistance to spills and stains. Buyers can also invest in training sessions for their teams on proper cleaning techniques and recommended products specific to the sourced fabrics. Providing customers with care kits and informational materials can further enhance their experience, ensuring that they maintain the beauty and integrity of the leather over time.

Scenario 3: Addressing Color and Texture Consistency in Large Orders

The Problem: When placing bulk orders for American leather fabrics, buyers often face challenges related to color and texture consistency. Variations can occur due to the natural characteristics of leather and fabric production processes. This inconsistency can be particularly concerning for projects requiring a uniform appearance, such as commercial furnishings or high-end residential installations. Discrepancies can lead to increased costs and delays as buyers may need to reorder materials to match.

The Solution: To ensure consistency in large orders, buyers should establish clear expectations with suppliers regarding color matching and texture uniformity. It is beneficial to request production samples before finalizing large purchases, allowing buyers to assess the consistency of color and texture firsthand. Additionally, implementing a quality assurance protocol during the ordering process can help catch any discrepancies early. Buyers should also consider sourcing from manufacturers who utilize advanced dyeing and finishing technologies, as these processes can significantly enhance color consistency. Maintaining open lines of communication with suppliers throughout the production process can further prevent issues, ensuring that the final delivery meets the buyer’s specifications and standards.

Strategic Material Selection Guide for american leather fabrics

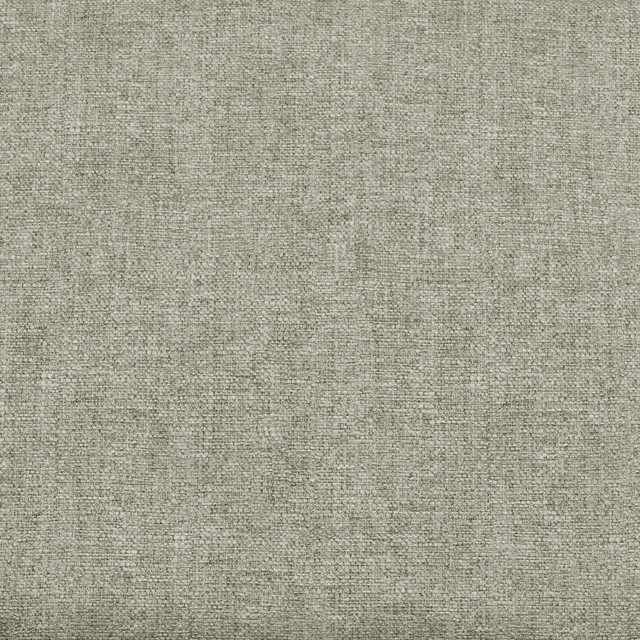

What Are the Key Properties of Common American Leather Fabrics?

American leather fabrics are renowned for their durability, aesthetic appeal, and versatility. Understanding the various materials available is crucial for international B2B buyers looking to make informed purchasing decisions. Here, we analyze four common materials used in American leather fabrics, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions.

Illustrative image related to american leather fabrics

How Does Top Grain Leather Perform in Various Applications?

Key Properties: Top grain leather is made from the uppermost layer of the hide, offering a balance of durability and softness. It typically has a temperature rating that allows it to withstand moderate heat without warping, making it suitable for various climates.

Pros & Cons: This leather is highly resistant to wear and tear, making it ideal for high-traffic areas. However, it can be more expensive than other options due to its quality and the complex tanning process required. It is also sensitive to moisture, which can lead to staining if not treated properly.

Impact on Application: Top grain leather is compatible with a range of upholstery applications, from luxury furniture to automotive interiors. Its natural beauty enhances the aesthetic appeal of any product.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards for leather quality and treatment. Familiarity with ASTM or ISO standards can help assess the suitability of top grain leather for specific applications.

What Advantages Do Performance Fabrics Like Crypton Offer?

Key Properties: Crypton fabric is engineered with stain and odor resistance, making it ideal for environments where spills are common. It can withstand high-pressure cleaning and has a high abrasion resistance rating, ensuring longevity.

Illustrative image related to american leather fabrics

Pros & Cons: The primary advantage of Crypton is its durability and ease of maintenance, which appeals to commercial buyers. However, the manufacturing process can be complex and costly, affecting the final price point.

Impact on Application: This fabric is particularly suitable for commercial settings such as hotels and restaurants, where hygiene and durability are paramount. Its compatibility with various cleaning agents makes it a preferred choice for high-use environments.

Considerations for International Buyers: Buyers in Europe and South America should verify that Crypton fabrics meet local fire safety standards, as regulations can vary significantly by region.

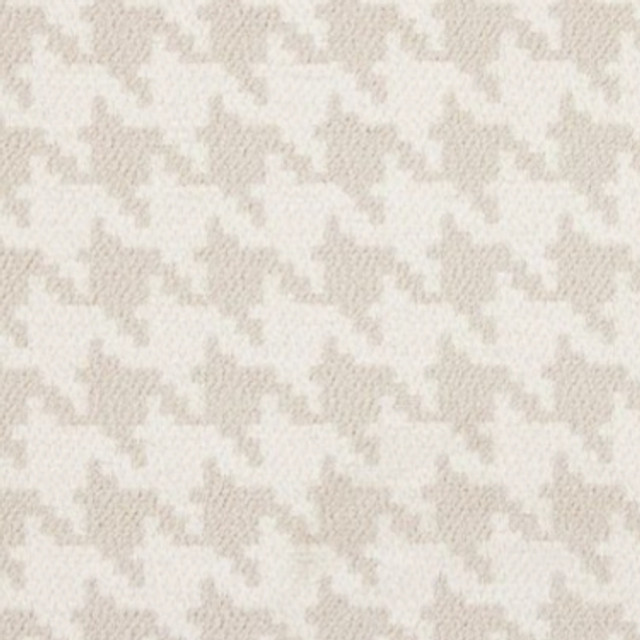

Why Is Ultrasuede a Popular Choice for Luxury Upholstery?

Key Properties: Ultrasuede is a synthetic material that mimics the look and feel of suede while offering enhanced durability. It is resistant to fading and can handle a wide range of temperatures without degrading.

Illustrative image related to american leather fabrics

Pros & Cons: The softness and luxurious appearance of Ultrasuede make it an attractive option for high-end furniture. However, it may not have the same level of breathability as natural leather, which could affect comfort in warmer climates.

Impact on Application: Ultrasuede is often used in upscale residential settings and luxury vehicles, where aesthetic appeal is crucial. Its versatility allows it to be used in various applications, from cushions to wall coverings.

Considerations for International Buyers: Buyers should check the environmental impact of synthetic materials like Ultrasuede, especially in regions where sustainability is a growing concern.

What Makes Sunbrella a Durable Option for Outdoor Use?

Key Properties: Sunbrella fabrics are designed specifically for outdoor use, offering excellent UV resistance and water repellency. They can withstand harsh weather conditions without fading or degrading.

Illustrative image related to american leather fabrics

Pros & Cons: The primary advantage of Sunbrella is its exceptional durability and ease of cleaning, making it ideal for outdoor furniture. However, it may come at a higher price point compared to standard indoor fabrics.

Impact on Application: Sunbrella is perfect for outdoor furniture and marine applications, where exposure to the elements is a concern. Its compatibility with outdoor environments makes it a go-to choice for patio and garden furniture.

Considerations for International Buyers: Buyers from tropical regions should ensure that Sunbrella fabrics comply with local UV protection standards, as prolonged exposure to sunlight can vary in intensity across different locations.

Illustrative image related to american leather fabrics

Summary Table of American Leather Fabrics

| Matériau | Typical Use Case for American Leather Fabrics | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Top Grain Leather | Luxury furniture, automotive interiors | High durability and aesthetic appeal | Sensitive to moisture | Haut |

| Crypton | Commercial upholstery, high-use environments | Stain and odor resistance | Complex manufacturing process | Med |

| Ultrasuede | High-end residential furniture, luxury vehicles | Soft and luxurious appearance | Less breathability than natural leather | Med |

| Sunbrella | Outdoor furniture, marine applications | Excellent UV resistance | Higher price point | Haut |

This strategic material selection guide provides a comprehensive overview for international B2B buyers considering American leather fabrics, ensuring they make informed decisions based on their specific needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for american leather fabrics

What Are the Main Stages of Manufacturing American Leather Fabrics?

The manufacturing process of American leather fabrics is a sophisticated journey that involves several critical stages, ensuring that the final product meets both aesthetic and functional standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the careful selection of high-quality leather hides. American Leather partners with exclusive tanneries, sourcing only the top 10% of hides available globally. This selection ensures that the raw materials possess the necessary characteristics for durability and style. During this stage, hides are inspected for defects, and any unsuitable materials are discarded.

-

Forming: Once the hides are prepared, they undergo a tanning process that stabilizes the leather, making it resistant to decay and improving its texture. Various tanning methods, including vegetable and chrome tanning, may be employed depending on the desired finish and characteristics. After tanning, the leather is dyed using environmentally friendly processes that enhance its color while maintaining its natural beauty.

-

Assembly: After forming, the leather is cut and shaped into specific patterns for various applications. The assembly process involves skilled artisans who meticulously stitch the leather pieces together, ensuring precise seams and a flawless finish. This stage is crucial as it directly affects the product’s durability and aesthetic appeal.

-

Finishing: The finishing stage involves applying protective coatings to enhance the leather’s resistance to stains, spills, and fading. Different levels of protection are available, including light, medium, and heavy protection, which cater to various lifestyle needs. This stage may also include the application of specialized treatments such as UV protection and stain resistance, which are particularly important for B2B buyers serving markets with diverse environmental conditions.

How is Quality Assurance Implemented in American Leather Fabric Production?

Quality assurance is paramount in the production of American leather fabrics, ensuring that each product meets international standards and customer expectations. The following components outline how quality is maintained throughout the manufacturing process.

-

International Standards Compliance: Adhering to international quality standards such as ISO 9001 is critical for manufacturers aiming to ensure consistent quality management systems. This standard focuses on meeting customer needs and enhancing satisfaction, which is particularly relevant for B2B buyers who require reliable suppliers.

-

Industry-Specific Standards: In addition to ISO standards, American leather fabric manufacturers often comply with industry-specific regulations, such as CE marking for products sold in Europe or API standards for performance in specific applications. These certifications provide buyers with confidence in the quality and safety of the products they are purchasing.

-

Quality Control Checkpoints: A robust quality control system is implemented through various checkpoints during the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting the raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): This stage includes continuous monitoring during the manufacturing process, allowing for immediate corrections if issues arise.

– Final Quality Control (FQC): Before products are shipped, a final inspection is conducted to verify that they meet all specifications and quality standards.

What Common Testing Methods Are Used in Quality Assurance for Leather Fabrics?

To ensure the durability and performance of leather fabrics, various testing methods are employed throughout the manufacturing process. Common testing methods include:

Illustrative image related to american leather fabrics

- Abrasion Resistance Testing: This test evaluates how well the fabric withstands wear and tear over time, which is crucial for products intended for high-use environments.

- Colorfastness Testing: This assesses the fabric’s resistance to fading due to exposure to light, washing, or rubbing, ensuring that colors remain vibrant even after prolonged use.

- Water Resistance Testing: Testing the fabric’s ability to repel water is essential, particularly for B2B buyers in regions with high humidity or rainfall.

- Flammability Testing: Compliance with fire safety regulations is critical for upholstery materials, especially in commercial settings.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must perform due diligence to verify that their suppliers adhere to rigorous quality control measures. Here are several effective methods:

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to evaluate their quality management systems, manufacturing processes, and compliance with international standards. This proactive approach helps identify potential issues before they affect product quality.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their quality control processes, testing results, and compliance with relevant standards. These reports should be reviewed thoroughly to ensure transparency and accountability.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can be scheduled at various stages of production, offering insights into the manufacturing process and identifying any areas of concern.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances when it comes to quality control and certification:

-

Regional Standards Compliance: Different regions may have varying standards for leather products. Understanding local regulations is essential for ensuring compliance and facilitating smoother import processes.

-

Cultural Sensitivities: Buyers should consider cultural preferences for leather types and finishes, which can affect product appeal in different markets. Engaging with local stakeholders can provide valuable insights into these preferences.

-

Sustainability Considerations: Increasingly, B2B buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices. Suppliers should be able to provide evidence of environmentally friendly processes, such as eco-friendly tanning methods and waste management strategies.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for American leather fabrics is essential for B2B buyers looking to make informed purchasing decisions. By focusing on quality standards, testing methods, and supplier verification processes, buyers can ensure they are sourcing high-quality products that meet their specific needs and market demands.

Illustrative image related to american leather fabrics

Practical Sourcing Guide: A Step-by-Step Checklist for ‘american leather fabrics’

In the world of B2B procurement, sourcing American leather fabrics requires a strategic approach to ensure that you find high-quality materials that meet your specific needs. This guide provides a practical checklist to help international buyers navigate the complexities of sourcing American leather fabrics effectively.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the leather fabrics you need. Consider factors such as the type of leather (top grain, full grain, etc.), finish (smooth, textured), and intended use (upholstery, accessories). Defining these specifications upfront will streamline the sourcing process and help you communicate effectively with suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of American leather fabrics. Look for companies that specialize in high-quality materials and have a strong market presence. Key indicators of reliability include:

– Industry Certifications: Check for certifications such as ISO or environmental compliance to ensure quality standards.

– Client Testimonials: Seek feedback from previous clients to gauge supplier performance and product satisfaction.

Step 3: Evaluate Product Range and Quality

Assess the product range offered by potential suppliers. A diverse selection of leather types, colors, and finishes will give you the flexibility to meet various design requirements. Pay attention to:

– Sample Requests: Request fabric swatches to evaluate texture, color accuracy, and durability firsthand.

– Fabric Grades: Understand the grading system used by the supplier to ensure you are selecting materials that align with your quality expectations.

Illustrative image related to american leather fabrics

Step 4: Understand Pricing Structures

Engage with suppliers to understand their pricing models. Pricing can vary based on factors such as material quality, order volume, and customization options. Key considerations include:

– Bulk Discounts: Inquire about discounts for larger orders, which can significantly affect your overall cost.

– Shipping Costs: Factor in shipping fees to your total budget, especially for international orders, as these can impact your bottom line.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers hold relevant certifications and comply with industry standards. This step is vital for mitigating risks associated with quality and sustainability. Look for:

– Sustainability Practices: Certifications that indicate environmentally friendly practices can enhance your brand’s reputation.

– Quality Assurance Processes: Suppliers should have established quality control measures to guarantee the consistency and reliability of their products.

Step 6: Negotiate Terms and Conditions

Before finalizing your order, negotiate terms and conditions with the supplier. This includes payment terms, delivery timelines, and return policies. Consider:

– Payment Flexibility: Discuss options such as net payment terms or installment plans to manage cash flow effectively.

– Clear Return Policies: Ensure that there are clear guidelines for returns or exchanges in case the products do not meet your specifications.

Step 7: Establish a Communication Protocol

Create a clear communication plan to maintain an open line with your supplier throughout the procurement process. Regular updates on order status, shipping details, and any potential issues will help in managing expectations and ensuring smooth transactions.

Illustrative image related to american leather fabrics

By following this checklist, B2B buyers can effectively source American leather fabrics that meet their specific needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for american leather fabrics Sourcing

What are the Key Cost Components in American Leather Fabrics Sourcing?

When sourcing American leather fabrics, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials is significant. Premium leather and high-performance fabrics like Crypton or Sunbrella can dramatically influence pricing due to their quality and durability. Buyers should expect to pay more for top-grade materials, which can affect the total cost.

-

Labor: Skilled labor is required for the crafting of leather products. Labor costs vary by region and can be influenced by local wage rates and the level of craftsmanship involved. In the U.S., labor costs are generally higher, reflecting the quality of work and expertise.

-

Manufacturing Overhead: This includes costs related to the production facilities, utilities, and administrative expenses. A well-established manufacturer may have higher overhead costs, which could be passed on to buyers.

-

Tooling: Custom tooling can add to the initial costs, particularly for bespoke orders. The investment in tooling is justified for unique designs or specifications but should be factored into the overall budget.

-

Quality Control (QC): Ensuring that the leather meets specified standards incurs additional costs. Rigorous QC processes are crucial for maintaining the quality that buyers expect, especially in luxury markets.

-

Logistics: Transportation and shipping costs can vary significantly based on the destination. Buyers in Africa, South America, the Middle East, and Europe should consider these costs, as they can add a substantial amount to the total price.

-

Margin: Finally, suppliers will include their profit margin in the pricing structure. Understanding the typical margins in the industry can aid in evaluating supplier pricing.

What Factors Influence Pricing for American Leather Fabrics?

Several factors influence the pricing of American leather fabrics, particularly for international buyers:

Illustrative image related to american leather fabrics

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically attract better pricing due to economies of scale. Buyers should negotiate MOQs that align with their purchasing capabilities to maximize cost efficiency.

-

Specifications and Customization: Custom orders often come with higher price tags. Buyers should weigh the benefits of customization against the additional costs, ensuring they align with their project requirements.

-

Material Quality and Certifications: Higher-quality materials and certifications (like eco-friendly sourcing) can elevate prices. Buyers should ensure that the materials meet their standards for durability and performance.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their products, while new entrants may offer competitive pricing to gain market share.

-

Incoterms: The chosen Incoterms can significantly influence the total landed cost. Understanding the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for budgeting accurately.

What Tips Can Help Buyers Negotiate Better Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, negotiating the best prices requires strategic approaches:

-

Conduct Market Research: Understanding the average market prices for specific fabrics helps in negotiations. This knowledge enables buyers to identify fair pricing and avoid overpaying.

-

Focus on Total Cost of Ownership (TCO): Rather than just the upfront costs, consider the TCO, which includes durability, maintenance, and potential resale value. This perspective can justify higher initial investments in premium fabrics.

-

Build Relationships: Developing strong relationships with suppliers can lead to better pricing and favorable terms over time. Trust can also facilitate negotiations regarding volume discounts or payment terms.

-

Be Clear on Requirements: Clearly communicating specifications and expectations can minimize misunderstandings that may lead to unexpected costs. This clarity helps suppliers provide accurate quotes.

-

Explore Multiple Suppliers: Requesting quotes from various suppliers can yield competitive pricing. However, ensure that comparisons are made on similar quality levels to maintain consistency.

Conclusion

Navigating the cost and pricing landscape of American leather fabrics requires a comprehensive understanding of the various components and influencers. By being informed and strategic, international buyers can optimize their sourcing efforts and achieve cost-effective solutions tailored to their needs. Note that prices can vary widely based on the factors discussed, so always seek indicative quotes before finalizing any agreements.

Alternatives Analysis: Comparing american leather fabrics With Other Solutions

Understanding Alternatives in Fabric Solutions for B2B Buyers

In the competitive landscape of upholstery materials, understanding various fabric options is crucial for B2B buyers seeking to make informed purchasing decisions. While American Leather fabrics are renowned for their quality and aesthetic appeal, alternative solutions exist that may better suit specific needs and budgets. This analysis will compare American Leather fabrics with two viable alternatives: high-performance synthetic fabrics and natural fiber blends.

Comparison Table

| Comparison Aspect | American Leather Fabrics | High-Performance Synthetic Fabrics | Natural Fiber Blends |

|---|---|---|---|

| Performance | High durability, stain resistance | Excellent durability, moisture resistance | Moderate durability, often less stain-resistant |

| Cost | Premium pricing, reflecting quality | Generally lower cost than leather fabrics | Variable cost, can be expensive for high-quality blends |

| Ease of Implementation | Requires skilled labor for upholstery | Easier to handle and install | Requires careful sourcing and handling |

| Maintenance | Requires regular conditioning | Low maintenance, easy to clean | Moderate maintenance, depends on fiber type |

| Best Use Case | Luxury furniture, high-end markets | Commercial spaces, family-friendly settings | Eco-friendly projects, high-end residential |

Detailed Breakdown of Alternatives

High-Performance Synthetic Fabrics

High-performance synthetic fabrics, such as those made from advanced polyesters or acrylics, provide a compelling alternative to American Leather fabrics. These materials are engineered to withstand heavy use, making them ideal for commercial environments or households with children and pets. Their stain and moisture resistance contribute to easy maintenance and longevity. However, while they offer practical benefits at a lower cost, they may lack the luxurious feel and aesthetic appeal of leather, which could be a critical factor for high-end applications.

Natural Fiber Blends

Natural fiber blends, typically combining materials like cotton, linen, and wool, present another alternative. These fabrics are celebrated for their breathability and organic appeal, making them suitable for eco-conscious buyers. They can offer a luxurious look and feel, often at a competitive price. However, their durability can be variable, and they may require more maintenance compared to synthetic options. Additionally, sourcing high-quality natural fibers can sometimes lead to increased costs, particularly for premium blends.

Choosing the Right Solution for Your Needs

For B2B buyers, the choice between American Leather fabrics and alternatives largely depends on specific project requirements, budget constraints, and desired aesthetic outcomes. Those seeking luxury and durability may lean towards American Leather, while buyers focused on cost-effectiveness and ease of maintenance might find synthetic fabrics more appealing. Conversely, if sustainability and a natural aesthetic are paramount, natural fiber blends could be the ideal solution. By carefully evaluating these factors, businesses can make a strategic choice that aligns with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for american leather fabrics

What Are the Key Technical Properties of American Leather Fabrics?

Understanding the technical properties of American leather fabrics is crucial for B2B buyers looking to invest in high-quality upholstery materials. Here are some key specifications that define the performance and longevity of these materials:

Illustrative image related to american leather fabrics

1. Material Grade

Material grade indicates the quality of leather used in manufacturing. It typically ranges from top-grain to bonded leather, with top-grain being the highest quality. For buyers, knowing the material grade helps assess the durability and aesthetic value, ensuring the fabric meets their specific needs for luxury and longevity.

2. Protection Level

Leather fabrics are often categorized by their protection levels: light, medium, and heavy. Light protection leathers are soft and supple but require more care. Medium protection offers a balance between softness and durability, while heavy protection leathers are designed to withstand spills and stains, making them ideal for high-traffic environments. Understanding these levels allows buyers to choose fabrics that fit their lifestyle and usage scenarios.

3. Fabric Composition

The composition of the fabric—whether it is made from natural fibers, synthetic fibers, or blends—affects its durability, appearance, and maintenance requirements. For instance, fabrics like Crypton are engineered for stain resistance, making them suitable for commercial settings. Buyers should consider fabric composition when evaluating maintenance costs and long-term performance.

4. Weight and Thickness

Weight and thickness are critical factors that influence the drape and durability of leather fabrics. Heavier fabrics are often more durable but may be less flexible. Conversely, lighter fabrics may provide greater comfort but could be prone to wear and tear. Buyers need to assess the appropriate weight and thickness based on the intended application, whether for residential or commercial use.

5. Tolerance Levels

Tolerance refers to the allowable variation in fabric dimensions and quality. For example, a tolerance level of ±5% in width means that the fabric could be slightly wider or narrower than specified. This is crucial for manufacturers who need precise measurements for production. Understanding tolerance levels helps buyers ensure that the fabrics will fit correctly in their intended applications.

What Are Common Trade Terms Used in American Leather Fabrics?

Familiarity with industry jargon can facilitate smoother transactions and better communication between buyers and suppliers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of leather fabrics, OEMs create customized solutions that meet specific design and quality requirements. Understanding OEM relationships can help buyers find reliable partners for custom upholstery projects.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers as it affects inventory costs and purchasing decisions. Understanding MOQs can help businesses manage cash flow while ensuring they have enough material for their projects.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. By providing detailed specifications, buyers can receive tailored quotes that help them make informed purchasing decisions. Crafting a precise RFQ can lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with Incoterms helps buyers understand their obligations regarding shipping costs, insurance, and risk during transit, which is crucial for international transactions.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. In the leather fabric industry, lead times can vary based on production schedules and shipping distances. Awareness of lead times is vital for buyers who need to plan their production timelines effectively.

Understanding these properties and trade terms can empower B2B buyers to make informed decisions when sourcing American leather fabrics, ensuring they select the best materials for their needs while navigating the complexities of international procurement.

Navigating Market Dynamics and Sourcing Trends in the american leather fabrics Sector

What Are the Current Market Dynamics and Key Trends in the American Leather Fabrics Sector?

The American leather fabrics market is currently experiencing significant growth, driven by a surge in demand for high-quality, durable materials across various sectors, including furniture, automotive, and fashion. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable suppliers, they must navigate several key trends.

One of the most notable trends is the increasing adoption of advanced technology in sourcing and production processes. Innovations such as digital textile printing and automation in manufacturing are enhancing efficiency and allowing for more customized solutions. Additionally, e-commerce platforms are transforming how buyers source materials, enabling easier access to a wider range of products and suppliers. Buyers are also increasingly interested in performance fabrics that offer stain resistance, durability, and ease of maintenance, making brands that offer such innovations particularly appealing.

Illustrative image related to american leather fabrics

Furthermore, there is a noticeable shift towards personalization, with customers looking for unique textures and colors that reflect their brand identity or lifestyle. This demand is pushing manufacturers to diversify their product ranges, offering an array of finishes and styles. For buyers in diverse markets, understanding these dynamics is crucial for making informed purchasing decisions that align with regional preferences and expectations.

How Is Sustainability Influencing B2B Sourcing in American Leather Fabrics?

Sustainability has become a pivotal factor in the American leather fabrics sector, influencing how businesses source materials. The environmental impact of leather production—often associated with water usage, chemical treatments, and waste—has prompted buyers to prioritize ethical sourcing. International B2B buyers are increasingly seeking suppliers who adhere to sustainable practices and can provide transparency regarding their supply chains.

The importance of ethical supply chains cannot be overstated. Buyers should look for manufacturers that utilize eco-friendly tanning processes and materials, as well as those that have obtained certifications such as the Global Organic Textile Standard (GOTS) or the Leather Working Group (LWG). These certifications not only signify a commitment to reducing environmental impact but also enhance the credibility of suppliers in the eyes of discerning buyers.

Incorporating green materials and practices into sourcing strategies can offer a competitive advantage. As consumers globally become more environmentally conscious, suppliers who can showcase their sustainability credentials are likely to attract more business. Thus, B2B buyers should prioritize partnerships with manufacturers that demonstrate a commitment to sustainable practices, ensuring their supply chains are both ethical and environmentally responsible.

Illustrative image related to american leather fabrics

What Is the Evolution of American Leather Fabrics and Its Significance for B2B Buyers?

The American leather fabrics industry has evolved significantly over the decades, transitioning from traditional tanning methods to modern, innovative techniques that prioritize quality and sustainability. Historically, leather was primarily sourced from local tanneries, but globalization has expanded access to premium materials from around the world. This evolution has allowed American manufacturers to blend artisanal craftsmanship with contemporary design, resulting in products that meet the diverse needs of international markets.

For B2B buyers, understanding this evolution is crucial. The shift towards quality over quantity means that investing in premium leather fabrics can yield long-term benefits in durability and aesthetics. Additionally, as the industry continues to innovate, buyers can expect ongoing advancements in fabric technology, offering even greater options for customization and performance. This historical context not only informs current trends but also helps buyers anticipate future developments in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of american leather fabrics

-

How do I ensure the quality of American leather fabrics before purchasing?

To ensure the quality of American leather fabrics, request samples from suppliers to assess the texture, color, and durability firsthand. Look for certifications or third-party testing reports that confirm the leather meets international quality standards. Additionally, inquire about the sourcing practices and the tanneries used by the manufacturer, as reputable tanneries ensure superior quality. Engaging in discussions with existing clients of the supplier can also provide insights into their product reliability and performance. -

What is the best type of leather fabric for high-traffic areas?

For high-traffic areas, consider heavy protection leathers, which feature a robust finish designed to withstand spills, stains, and wear. Fabrics such as Crypton or Sunbrella are excellent choices due to their durability and stain resistance. These materials not only provide longevity but also maintain aesthetic appeal over time, making them ideal for environments like hotels, restaurants, and busy family homes. -

What customization options are available for American leather fabrics?

American leather fabrics offer various customization options, including color selection, texture variations, and even bespoke designs tailored to specific projects. Many manufacturers allow clients to choose specific grades of leather or fabric, ensuring that the final product aligns with their design vision and functional needs. It’s advisable to communicate your requirements early in the sourcing process to facilitate a smoother customization experience. -

What are the minimum order quantities (MOQs) for American leather fabrics?

Minimum order quantities for American leather fabrics can vary significantly between suppliers. Generally, MOQs can range from a few yards to several hundred yards, depending on the type of fabric and the supplier’s policies. For international buyers, it’s essential to clarify these terms upfront to ensure that your order aligns with your project needs and budget. -

How can I vet suppliers of American leather fabrics effectively?

To vet suppliers of American leather fabrics, start by researching their reputation in the industry. Look for reviews, testimonials, and case studies from previous clients. Verify their certifications and adherence to international standards, and assess their experience in handling export orders to your region. Additionally, consider visiting their manufacturing facilities if possible or requesting a virtual tour to better understand their operations and quality control measures. -

What payment terms should I expect when sourcing American leather fabrics internationally?

Payment terms for international orders of American leather fabrics typically include options such as advance payment, letter of credit, or payment upon delivery. Suppliers may require a deposit upfront, especially for customized orders. It’s crucial to negotiate terms that protect your interests, ensuring clarity on payment schedules, currency, and any potential fees associated with international transactions. -

What logistics considerations should I keep in mind when importing American leather fabrics?

When importing American leather fabrics, consider logistics factors such as shipping methods, costs, and timelines. Engage with freight forwarders who specialize in textile imports to streamline the process. Be aware of customs regulations and tariffs in your country, as these can impact delivery times and overall costs. Additionally, ensure that the supplier provides proper documentation, including invoices and certificates of origin, to facilitate smooth customs clearance. -

What quality assurance processes should be in place for leather fabric orders?

Quality assurance processes for leather fabric orders should include thorough inspections at multiple stages of production. Request detailed reports on material sourcing, production techniques, and final inspections before shipment. Additionally, consider implementing a quality control agreement with your supplier to outline specific standards and metrics for assessing the fabric’s quality. Regular communication and updates throughout the production process can also help ensure that the final product meets your expectations.

Top 2 American Leather Fabrics Manufacturers & Suppliers List

1. American Leather – Fabrics and Upholstery Collections

Domain: americanleather.com

Registered: 1997 (28 years)

Introduction: Fabrics Selection and Swatches available at American Leather B2B Portal. Key features include a variety of collections such as Accent Chairs, Beds and Headboards, Classics, Comfort Recliner, Comfort Sleeper, and more. The fabrics are designed for both contemporary and traditional styles, featuring high-performance materials from brands like Sunbrella, Ultrasuede, and Crypton. Customers can order u…

2. West Avenue – American Leather Swatches

Domain: westave.com

Registered: 1997 (28 years)

Introduction: American Leather Swatches available at West Avenue Furniture include a variety of options such as Amara Sage, Apollo Flint, Apollo Mahogany, and many more. Each swatch is free and showcases top-grain hides, buttery nubuck, and high-performance Crypton® fabrics suitable for Comfort Sleeper® sofas, recliners, and sectional seating. The hides are sustainably tanned in Dallas, TX, and engineered for a…

Strategic Sourcing Conclusion and Outlook for american leather fabrics

As the demand for high-quality and stylish leather fabrics continues to rise globally, international B2B buyers must recognize the strategic importance of sourcing from reputable suppliers like American Leather. The diverse range of textures, colors, and finishes available not only enhances the aesthetic appeal of furniture but also ensures durability and longevity. By investing in premium materials, businesses can meet the evolving preferences of consumers who seek both luxury and functionality.

Sourcing from American Leather offers a unique advantage, as their partnerships with exclusive tanneries guarantee access to the top-tier leather available on the market. Furthermore, their commitment to quality extends to their performance fabrics, which are engineered to withstand the rigors of everyday use while maintaining their beauty over time.

Looking ahead, businesses in regions such as Africa, South America, the Middle East, and Europe stand to benefit significantly from these premium offerings. As consumer trends shift towards sustainable and long-lasting materials, aligning with a trusted supplier can provide a competitive edge. Now is the time to explore the possibilities of American leather fabrics—connect with suppliers today to elevate your product offerings and meet the demands of a discerning market.

Illustrative image related to american leather fabrics

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.