Catalog

Material Insight: Swaid Material

B2B Product Guide: SWAID Material – Sustainable Performance with WINIW Faux Leather

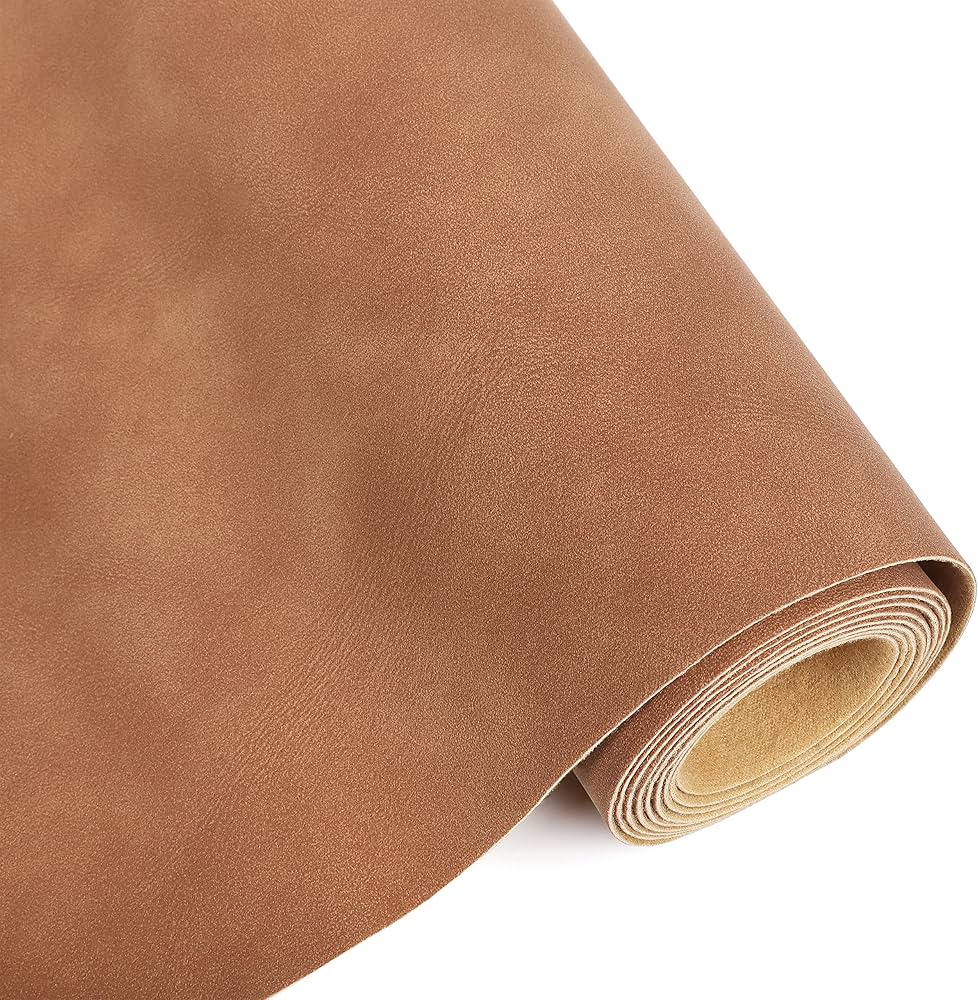

SWAID material represents a new benchmark in performance-driven, eco-conscious synthetic materials designed for demanding industrial and commercial applications. Engineered to deliver durability, consistency, and sustainability, SWAID is ideal for sectors such as automotive interiors, furniture manufacturing, footwear, and specialty protective gear. At the core of SWAID’s innovation is its integration with high-performance faux leather—specifically developed by WINIW, a global leader in synthetic leather solutions.

Faux leather is the optimal choice for SWAID material due to its balanced combination of functional superiority and environmental responsibility. Unlike traditional animal leather, faux leather offers consistent texture, reduced production lead times, and greater design flexibility. It is also inherently more sustainable—requiring fewer natural resources and generating lower carbon emissions during production. For SWAID applications, where performance under stress, resistance to wear, and long-term aesthetics are critical, WINIW’s advanced faux leather delivers:

- Superior abrasion and UV resistance

- Excellent breathability and flexibility

- Customizable thickness, texture, and color

- Compliance with global environmental standards (REACH, RoHS, OEKO-TEX)

- Vegan and cruelty-free certification

With over 20 years of expertise in synthetic leather innovation, WINIW has established itself as a trusted B2B partner for manufacturers seeking high-performance, sustainable materials. Our R&D-driven approach, vertically integrated production, and commitment to eco-friendly practices ensure that every meter of faux leather meets the rigorous demands of modern industrial applications. By integrating WINIW’s faux leather into SWAID material, businesses gain access to a durable, scalable, and responsible solution that aligns with evolving market and regulatory requirements.

Technical Performance & Standards

WINIW SWADE™ Material: Technical Product Guide for B2B Applications

WINIW SWADE™ (Sustainable Water-based Artificial Leather) represents a strategic advancement in high-performance synthetic leather solutions, engineered for manufacturers prioritizing operational efficiency, environmental responsibility, and uncompromised quality. Leveraging proprietary water-based polyurethane (PU) technology, SWADE™ delivers measurable technical and economic advantages across diverse industrial applications—from automotive interiors and furniture upholstery to footwear and technical textiles.

Key Technical Advantages

- Cost-Effectiveness: Achieves 15–20% lower total cost of ownership versus conventional PU leathers through reduced waste (optimized roll yields >95%), energy-efficient water-based processing (30% lower VOC emissions vs. solvent-based alternatives), and extended product lifecycle minimizing replacement costs.

- Enhanced Durability: Features a reinforced polyester backing and cross-linked PU matrix, delivering exceptional resistance to abrasion (50,000+ double-rub cycles per Martindale), tearing (≥45 N), and hydrolysis (passes 14-day 70°C/95% RH testing). Maintains structural integrity under UV exposure (500+ hrs Q-SUN testing).

- Precision Color Customization: Supports full Pantone® matching with zero minimum order quantities (MOQs). Utilizes eco-friendly pigments stable across 10,000+ production meters, ensuring batch-to-batch consistency (ΔE <1.0) without color migration or fading.

- REACH Compliance: Fully adheres to EU REACH Annex XVII, with certified absence of SVHCs (Substances of Very High Concern), phthalates (DEHP, BBP, DBP), and CMRs. All components undergo quarterly 3rd-party testing (SGS/TÜV reports available).

- ISO 9001-Certified Manufacturing: Integrated quality management system ensures <0.5% defect rates. Traceability from raw material sourcing (via blockchain-enabled logs) to finished rolls, with real-time process controls for thickness, bond strength, and surface uniformity.

SWADE™ Technical Specifications

| Paramètres | Spécifications | Test Standard |

|---|---|---|

| Thickness | 0.6–1.2 mm (customizable) | ISO 2417 |

| Weight | 280–450 g/m² | ISO 2417 |

| Abrasion Resistance | ≥50,000 cycles (Martindale) | ISO 12947-2 |

| Tensile Strength | ≥35 N/5cm (warp), ≥30 N/5cm (weft) | ISO 13934-1 |

| Tear Strength | ≥45 N | ISO 13937-3 |

| Color Fastness (Light) | Grade 7–8 (1–8 scale) | ISO 105-B02 |

| Hydrolysis Resistance | Pass (14 days @ 70°C/95% RH) | ISO 1419 |

| REACH Status | Compliant (SVHC-free) | EC 1907/2006 |

| Formaldehyde Content | <20 ppm | ISO 17226-1 |

SWADE™ aligns with circular economy principles through recyclable components (compatible with PU recovery streams) and a 40% lower carbon footprint versus industry averages (verified via LCA). Backed by WINIW’s global technical support team, it offers seamless integration into existing production lines with lead times averaging 15–20 days. Partner with WINIW to deploy a synthetic leather solution that optimizes total cost, ensures regulatory safety, and elevates product longevity—without compromising environmental stewardship.

Why Choose Synthetic over Real Leather

B2B Product Guide: SWAID Material vs. Real Leather

In the evolving landscape of sustainable materials for fashion, automotive, and furniture industries, synthetic alternatives are gaining traction. One such innovation is SWAID material—a high-performance synthetic leather developed with sustainability and functionality in mind. This guide provides a comparative analysis between SWAID material and traditional real leather, focusing on key decision-making factors for B2B procurement and product development.

SWAID material is engineered to replicate the aesthetic and tactile qualities of real leather while addressing environmental and ethical concerns associated with animal-derived hides. It is typically composed of polyurethane (PU) or bio-based polymers, combined with advanced texturing techniques to achieve a leather-like finish. Real leather, by contrast, is tanned animal hide, prized for its natural grain, breathability, and long-term aging characteristics.

Below is a comparative overview based on cost, durability, and eco-friendliness:

| Factor | SWAID Material | Real Leather |

|---|---|---|

| Cost | Lower upfront cost | Higher cost due to sourcing and processing |

| Durabilité | Resistant to cracking and fading; consistent performance in varied climates | Prone to drying, cracking, and staining if not maintained; ages naturally |

| Eco-friendliness | Reduced carbon footprint; no animal sourcing; often uses recycled or bio-based content | High environmental impact from livestock farming, tanning chemicals, and water usage |

Key advantages of SWAID material in a B2B context include:

- Cost Efficiency: Lower material and processing costs make SWAID ideal for scalable production without compromising on visual quality.

- Consistency: Uniform texture and thickness across batches support precision manufacturing in automated production lines.

- Sustainability Compliance: Aligns with ESG goals and supports brands seeking cruelty-free, low-impact materials.

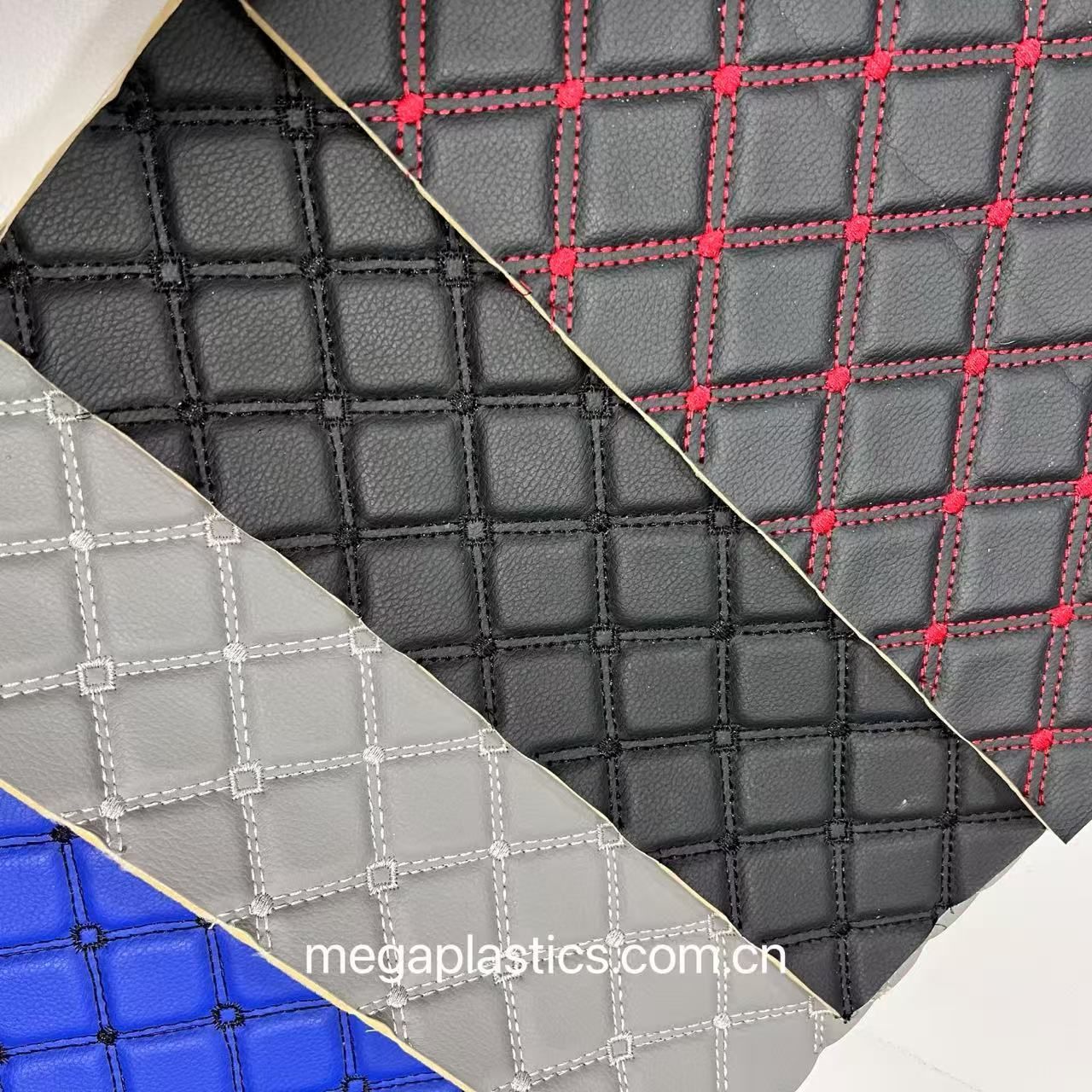

- Customization: Available in a wide range of colors, textures, and finishes, reducing lead times for design iterations.

Real leather remains preferred in premium segments where natural variation, breathability, and legacy craftsmanship are valued. However, its supply chain volatility, ethical concerns, and environmental costs are driving many brands to explore high-end synthetics like SWAID.

For forward-thinking manufacturers, SWAID material represents a responsible, economically viable alternative that meets modern performance standards without sacrificing aesthetics. As regulations tighten around material sourcing and carbon reporting, synthetic leathers with verifiable eco-credentials are positioned to lead the next generation of durable goods.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global Partners

WINIW stands as a premier B2B synthetic leather manufacturer, engineered to meet the stringent demands of international markets. Our vertically integrated production ecosystem combines scale, innovation, and uncompromising quality control to deliver consistent, high-performance materials for automotive, furniture, fashion, and technical applications.

Core Manufacturing Capabilities

- Scale & Infrastructure: Operates a 100,000 sqm state-of-the-art manufacturing complex in China, featuring automated production lines and resource-efficient processes designed for high-volume output without sacrificing precision.

- Dedicated R&D Leadership: Employs a 50+ member technical team specializing in polymer science and material engineering, driving continuous innovation in eco-friendly formulations, texture development, and functional properties (e.g., abrasion resistance, UV stability).

- Certified Quality Assurance: Implements a multi-stage QC protocol aligned with ISO 9001 and IATF 16949 standards, including:

- Raw material traceability from certified suppliers

- In-line spectrophotometric color matching (ΔE ≤ 0.5)

- Batch-level physical testing (tensile strength, seam slippage, Martindale rubs)

- Final product compliance validation against EU REACH, US CPSIA, and OEKO-TEX® STANDARD 100

Global Supply Chain Reliability

WINIW serves Tier-1 brands and manufacturers across regulated markets through:

– Established Export Channels: 70% of annual production shipped to Europe and North America, with dedicated logistics partnerships ensuring on-time delivery (OTD rate > 98.5%).

– Compliance-First Approach: All materials undergo region-specific regulatory screening (e.g., EU Ecolabel criteria, California Prop 65) prior to shipment.

– Sustainability Integration: 40% of product lines utilize bio-based polyols and water-based coatings, reducing carbon footprint while maintaining performance benchmarks for global clients.

Our facility’s scale, technical agility, and adherence to international standards position WINIW as a resilient partner for brands requiring ethically produced synthetic leather with zero compromise on quality or compliance. Partner with us to integrate future-proof materials into your supply chain.

Contact Us for Samples

B2B Product Guide: SWAID Sustainable Microfiber Leather by WINIW

WINIW is a leading innovator in high-performance, eco-conscious synthetic leather solutions for global manufacturers and design-forward brands. Our SWAID material represents the next generation of sustainable microfiber leather—engineered to deliver premium aesthetics, exceptional durability, and a significantly reduced environmental footprint.

Designed for industries including automotive interiors, furniture, footwear, and luxury accessories, SWAID combines advanced material science with ethical production practices. As businesses accelerate their sustainability goals, SWAID offers a scalable, cruelty-free alternative to traditional leather without compromising on quality or performance.

Key Features of SWAID Microfiber Leather

- Made from 100% solvent-free, eco-friendly raw materials

- Contains recycled polyester content, reducing reliance on virgin plastics

- Low-carbon production process with water-based PU technology

- Superior breathability, abrasion resistance, and tear strength

- Comparable hand feel, drape, and appearance to premium genuine leather

- Available in custom colors, textures, and thicknesses (0.6mm to 1.2mm)

- Compliant with REACH, RoHS, and OEKO-TEX® standards

Performance Comparison (Typical Values)

| Property | SWAID Microfiber Leather | Genuine Cowhide (Average) |

|---|---|---|

| Tensile Strength | ≥ 25 MPa | 18–22 MPa |

| Tear Strength | ≥ 75 N | 50–65 N |

| Color Fastness (Rubbing) | Grade 4–5 (Dry/Wet) | Grade 3–4 |

| VOC Emissions | < 10 µg/g (Ultra-low) | Varies (often higher) |

| Durability (Martindale) | 50,000+ cycles | 30,000–40,000 cycles |

Industry Applications

- Automotive: Seat covers, door panels, steering wheels

- Furniture: Upholstery for residential and commercial seating

- Footwear: Sneakers, boots, and formal shoes

- Accessories: Handbags, wallets, watch straps

- Electronics: Protective cases and smart device covers

SWAID is part of WINIW’s commitment to sustainable innovation—supporting brands in achieving ESG targets while maintaining design integrity and functional excellence.

Why Choose SWAID?

- Consistent roll-to-roll quality for seamless manufacturing

- Reduced waste due to high yield and uniform surface

- Custom development support from WINIW’s R&D team

- Scalable production with short lead times

Free samples are available for qualified B2B partners to evaluate performance and aesthetics in real-world applications.

Request SWAID Material Samples Today

Elevate your product line with a sustainable, high-performance alternative to leather. Contact our materials team to begin collaboration.

- Product Name: SWAID Sustainable Microfiber Leather

- Contact: WINIW Marketing Department

- Courriel : MKT88@MicrofiberLeather.com

- Sample Policy: Free samples available for verified business inquiries

Make the sustainable switch with SWAID—where innovation meets responsibility.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.