Catalog

Material Insight: Patent Leather Fabric

B2B Product Guide: Patent Faux Leather Fabric

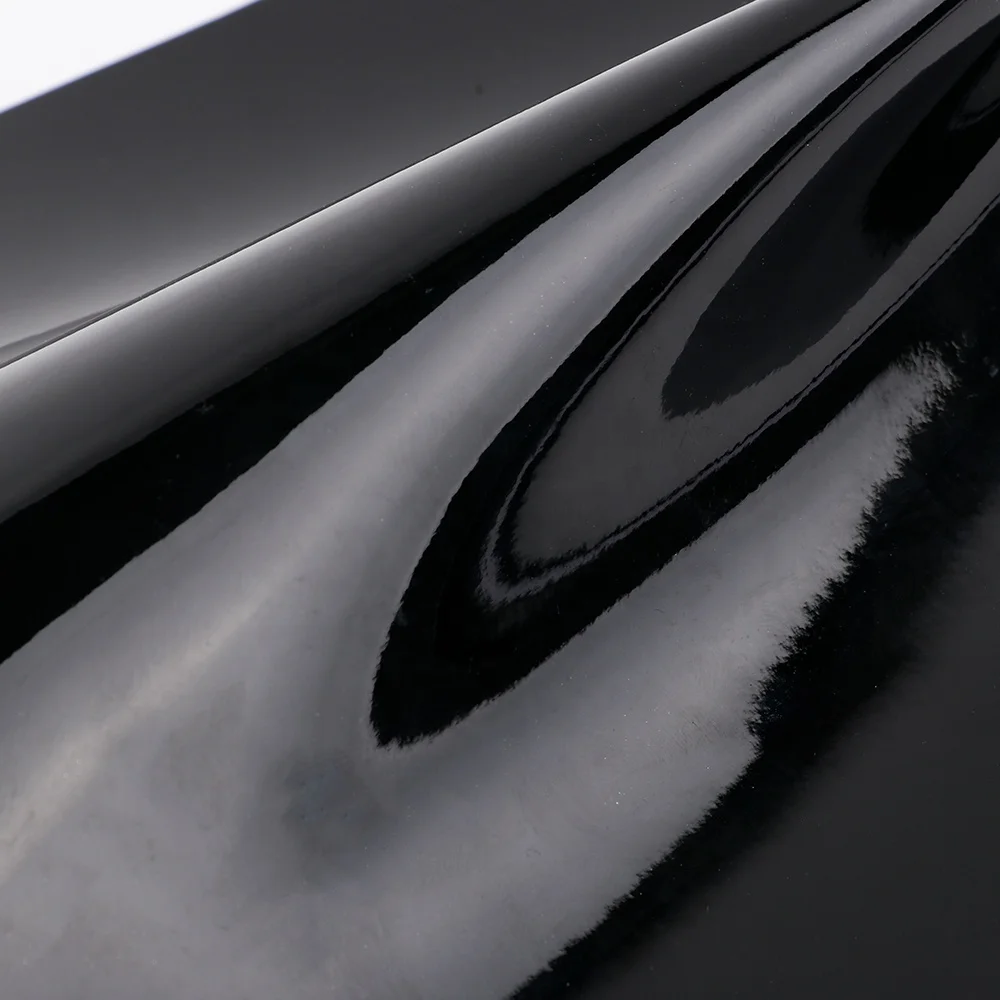

Patent leather fabric is a high-gloss, durable material widely used in fashion, footwear, accessories, automotive interiors, and upholstery applications. Known for its reflective finish and sleek appearance, traditional patent leather is made by applying a plastic coating—typically PVC—onto a leather or fabric backing. However, due to environmental concerns, animal welfare considerations, and the need for consistent quality and scalability, faux (synthetic) patent leather has become the preferred choice across industries.

Faux leather is the optimal solution for patent leather applications due to its ability to deliver a uniform, mirror-like finish while offering superior control over thickness, texture, and performance characteristics. Unlike genuine leather, which can vary in grain and durability, synthetic patent leather ensures batch-to-batch consistency, making it ideal for large-scale manufacturing. Additionally, faux patent leather is more cost-effective, easier to maintain, and can be engineered to be waterproof, abrasion-resistant, and UV-stable—critical factors for both indoor and outdoor use.

As a responsible alternative, modern faux patent leather reduces reliance on animal products and lowers the environmental footprint associated with tanning processes. With advancements in polyurethane (PU) and polyvinyl chloride (PVC) technologies, synthetic patent leathers now offer enhanced breathability, flexibility, and eco-compliance—aligning with global sustainability standards.

Why Choose WINIW for Patent Faux Leather?

WINIW has been a trusted name in the synthetic leather industry for over 20 years, specializing in high-performance, eco-conscious faux leather solutions for global B2B clients. Our expertise lies in developing custom-engineered patent leather fabrics that meet rigorous aesthetic and functional demands across diverse markets.

- Over two decades of R&D-driven innovation in synthetic leather technology

- ISO-certified manufacturing with strict environmental and quality controls

- Customization capabilities in gloss level, color, thickness, and coating type (PU, PVC, or hybrid)

- Commitment to sustainability through low-VOC emissions, recyclable substrates, and compliance with REACH, RoHS, and OEKO-TEX® standards

- Trusted partner to leading brands in fashion, automotive, and luxury goods sectors

With WINIW, businesses gain access to premium patent faux leather that combines visual appeal, durability, and environmental responsibility—delivering value at every stage of the supply chain.

Technical Performance & Standards

WINIW Patent Leather Fabric: Technical Product Guide for B2B Applications

WINIW’s advanced Patent Leather Fabric delivers superior performance for demanding industrial applications across fashion accessories, furniture upholstery, and automotive interiors. Engineered with precision manufacturing and sustainable chemistry, our solution eliminates traditional leather’s inconsistencies while exceeding cost, durability, and regulatory requirements. Ideal for brands prioritizing operational efficiency and environmental responsibility, WINIW provides a future-proof material foundation for high-volume production.

Key Technical Advantages

-

Cost-Effective Production

Optimized thickness tolerance (±0.05mm) reduces material waste by up to 15% versus conventional synthetics. High yield rates (98.5%+) and compatibility with standard cutting/molding equipment lower operational costs without compromising output speed. -

Exceptional Durability

Reinforced 0.8mm–1.2mm polyurethane (PU) coating resists cracking, peeling, and UV degradation. Withstands 100,000+ cycles in Martindale abrasion testing (ISO 12947) and maintains structural integrity under -20°C to +70°C conditions. -

Precision Color Customization

Proprietary digital color-matching system supports 50,000+ Pantone®/RAL shades with ΔE <0.5 tolerance. Batch-to-batch consistency is guaranteed via spectrophotometer validation, eliminating rework in multi-unit production runs. -

Full REACH Compliance

Zero content of SVHCs (Substances of Very High Concern) per REACH Annex XVII. Independent lab reports verify absence of phthalates, heavy metals (Cd, Pb, Hg), and AZO dyes—ensuring seamless EU market access. -

ISO 9001-Certified Quality Control

End-to-end traceability from raw material sourcing to finished roll. Each batch undergoes 12+ in-process inspections, with digital quality passports documenting tensile strength, elongation, and color fastness.

Technical Specifications Overview

| Property | WINIW Standard Spec | Test Method |

|---|---|---|

| Thickness | 0.80mm – 1.20mm (±0.05mm) | ISO 2417 |

| Weight | 280 – 350 g/m² | ISO 9073-3 |

| Abrasion Resistance | ≥100,000 cycles | ISO 12947 (Martindale) |

| Color Fastness (Rubbing) | Grade 4–5 (Dry/Wet) | ISO 105-X12 |

| Tensile Strength | ≥80 N/5cm | ISO 13934-1 |

| Elongation at Break | ≥15% | ISO 13934-1 |

| VOC Emissions | <10 μg/g (Total) | ISO 12219-3 |

| Base Fabric | Recycled PET Knit (≥30%) | GRS Certified |

WINIW Patent Leather Fabric integrates closed-loop water-based PU coating technology, reducing process emissions by 40% versus solvent-based alternatives. All products include full chemical disclosure documentation (SCIP database compliant) and are backed by a 3-year performance warranty. Request our technical dossier for batch-specific test reports or sustainability metrics.

WINIW: Engineering Sustainable Performance for Industry

Why Choose Synthetic over Real Leather

B2B Product Guide: Patent Leather Fabric vs. Real Leather

In the modern marketplace, selecting the right material for luxury goods, footwear, automotive interiors, and fashion accessories requires a balance of aesthetics, performance, and sustainability. Two widely used materials—patent leather fabric and real leather—offer distinct advantages and trade-offs. This guide provides a clear comparison to support informed B2B decision-making.

Overview of Materials

-

Patent Leather Fabric

Patent leather fabric typically refers to a synthetic or semi-synthetic material with a high-gloss finish, often made from polyurethane (PU) or polyvinyl chloride (PVC) coated textiles. At WINIW, our patent leather offerings are premium PU-based synthetic leathers engineered for durability, consistent texture, and reduced environmental impact. These materials are ideal for brands seeking a cruelty-free, cost-effective alternative with a luxurious shine. -

Real Leather

Real leather is derived from animal hides, usually bovine, and undergoes tanning and finishing processes to achieve desired characteristics. It is valued for its natural grain, breathability, and long-term patina development. However, its production involves significant environmental and ethical considerations, including high water usage and chemical processing.

Key Comparative Attributes

| Attribute | Patent Leather Fabric (PU-based) | Real Leather |

|---|---|---|

| Cost | Lower to moderate | Haut |

| Durabilité | High resistance to cracking and fading (especially premium PU); less breathable | Excellent long-term durability; prone to drying and cracking if untreated; develops patina |

| Eco-friendliness | Higher (especially water-based PU); lower carbon footprint, no animal sourcing, reduced water use | Lower; resource-intensive, chemical tanning (especially chrome), higher greenhouse gas emissions |

Advantages of Patent Leather Fabric for B2B Applications

- Cost-efficient for large-scale production without compromising visual appeal

- Consistent texture and color batch-to-batch, improving manufacturing precision

- Available in a wide range of colors and finishes, including high-gloss patent

- Cruelty-free and suitable for vegan product lines

- Reduced environmental impact when using eco-conscious production methods (e.g., WINIW’s water-based PU technology)

Advantages of Real Leather

- Natural breathability and comfort in long-term use

- Unique grain patterns add authenticity and premium perception

- Ages gracefully, developing a desirable patina over time

- Preferred in traditional luxury markets and heritage brands

Sustainability Considerations

As global brands shift toward circular and sustainable supply chains, synthetic alternatives like high-performance patent leather fabric are gaining favor. WINIW’s eco-engineered patent leathers are produced with solvent-free, water-based systems, aligning with REACH and OEKO-TEX® standards. These innovations support ESG goals while maintaining the high-gloss aesthetic associated with luxury.

Conclusion

While real leather retains a niche in premium, traditional markets, patent leather fabric offers a competitive, sustainable, and economically viable alternative for forward-thinking B2B clients. By leveraging advanced synthetic technologies, brands can achieve luxury aesthetics, batch consistency, and environmental responsibility—without compromise.

WINIW Factory Capabilities

WINIW Premium Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands as a trusted global manufacturer of high-performance synthetic leather, engineered to meet the rigorous demands of discerning B2B partners. Our vertically integrated operations combine scale, innovation, and uncompromising quality control to deliver sustainable materials that excel across automotive, furniture, fashion, and technical applications.

Core Manufacturing Strength

Our 100,000 sqm state-of-the-art manufacturing facility in China forms the backbone of reliable, large-scale production:

– Full vertical integration from polymer formulation to finishing, ensuring end-to-end process control and supply chain resilience.

– Advanced automation lines dedicated to PU, PVC, and next-generation bio-based synthetic leathers, minimizing waste and energy consumption.

– Dedicated eco-production zones with closed-loop water systems and VOC recovery technology, aligning with global environmental standards.

– Capacity to support high-volume orders (MOQs scalable from 1,000 to 500,000+ meters monthly) with consistent on-time delivery.

Innovation-Driven R&D Capabilities

WINIW’s 50+ member R&D team continuously advances material science for sustainability and performance:

– Proprietary development of low-carbon footprint materials, including 30%+ bio-content PU and water-based coating systems.

– Custom formulation expertise for flame resistance (FMVSS 302, CAL 117), abrasion durability (>50,000 cycles), and eco-certified finishes.

– Collaborative co-engineering with global brands to meet specific aesthetic, tactile, and functional requirements.

Rigorous Quality Assurance Framework

Every meter of WINIW synthetic leather undergoes multi-stage validation to exceed international benchmarks:

| Quality Control Stage | Key Parameters Verified | Compliance Standards Met |

|---|---|---|

| Raw Material Inspection | Polymer purity, solvent content, color fastness | REACH, OEKO-TEX® STANDARD 100 |

| In-Process Monitoring | Thickness consistency, coating uniformity, tensile strength | ISO 9001, IATF 16949 |

| Final Product Testing | Colorfastness, seam strength, VOC emissions, eco-toxicity | CA Prop 65, EN 71-3, EU Ecolabel |

| Batch Certification | Full traceability documentation, sustainability metrics | GRS, ISO 14001 |

Global Market Readiness

WINIW products are trusted by leading manufacturers across regulated markets:

– Direct export infrastructure serving 30+ countries, with established logistics partners for seamless EU/US customs clearance.

– Full compliance with EU REACH, US CPSIA, and California Proposition 65 regulations, including comprehensive chemical disclosure.

– Dedicated regional technical support teams providing material certifications, sample validation, and production troubleshooting.

WINIW delivers more than synthetic leather—we provide a sustainable, quality-assured material partnership built on industrial scale and scientific precision. Partner with us to elevate your product performance while advancing shared environmental goals.

Contact Us for Samples

B2B Product Guide: Premium Patent Leather Fabric by WINIW

WINIW is a leading innovator in high-performance synthetic leather solutions, specializing in eco-friendly, durable, and aesthetically superior microfiber materials for global B2B clients. Our patent leather fabric combines glossy elegance with industrial-grade resilience, making it ideal for fashion, automotive interiors, furniture, and specialty accessories.

Engineered for brands committed to sustainability and quality, WINIW’s patent leather is free from harmful solvents, phthalates, and heavy metals. It meets international environmental standards, including REACH, RoHS, and OEKO-TEX®. With a focus on low environmental impact and high production efficiency, our material supports eco-conscious manufacturing without compromising on visual appeal or performance.

Key Features of WINIW Patent Leather Fabric

- High-gloss surface with a mirror-like finish for premium aesthetics

- Exceptional abrasion and scratch resistance for long-term durability

- Flexible and soft hand feel, suitable for complex designs and stitching

- UV and colorfast rated—maintains luster and hue under prolonged exposure

- Water-resistant and easy to clean, ideal for high-traffic applications

- PVC-free and solvent-free formulation supports sustainable production

- Consistent thickness and width for optimized cutting and yield

- Customizable in a wide range of colors, textures, and backing fabrics (e.g., knit, woven, or non-woven)

Technical Specifications

| Property | Spécifications |

|---|---|

| Thickness | 0.6 mm – 1.2 mm (customizable) |

| Weight | 180 – 320 g/m² |

| Base Material | Ultra-fine microfiber PU or water-based coating |

| Width | 137 cm (standard), up to 150 cm available |

| Roll Length | 30 m, 50 m (custom options available) |

| Certifications | REACH, RoHS, OEKO-TEX®, ISO 9001 |

| Temperature Resistance | -20°C to +60°C |

Ideal Applications

- Luxury handbags, footwear, and apparel

- Automotive trim, dashboards, and seating surfaces

- Upholstered furniture and decorative panels

- Electronics accessories and smart device covers

- Retail displays and point-of-sale fixtures

WINIW’s patent leather fabric is developed for manufacturers seeking a sustainable alternative to traditional PVC-based patent leathers—without sacrificing shine, strength, or scalability.

Why Partner with WINIW?

- In-house R&D team for custom formulation and design support

- Low MOQs for flexible production planning

- Global logistics network with fast lead times

- Dedicated technical service for seamless integration into existing lines

Request Free Samples

Experience the quality and versatility of WINIW patent leather firsthand. Free samples are available for qualified B2B partners.

For product inquiries, technical data sheets, or sample requests, contact:

MKT88@MicrofiberLeather.com

Elevate your product line with sustainable shine—choose WINIW.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.