Catalog

Material Insight: Leatherette Fabric For Upholstery

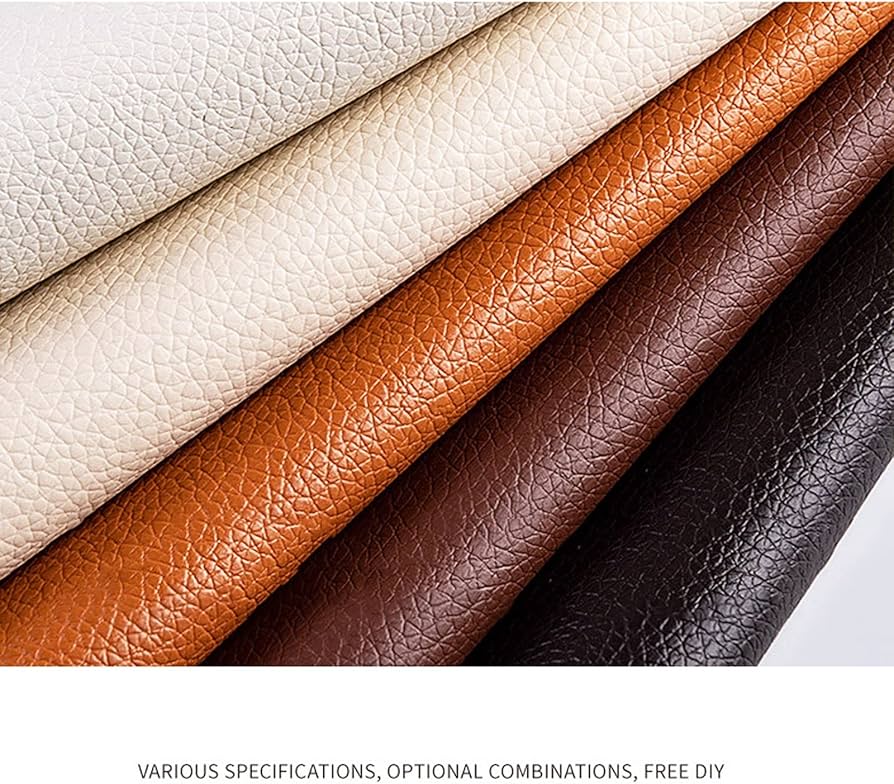

Introducing Premium Leatherette Fabric for Upholstery: The Smart Choice for Modern Furnishings

In today’s competitive furniture and interior design markets, selecting the right upholstery material directly impacts product longevity, sustainability compliance, and end-user satisfaction. Leatherette fabric—specifically high-performance synthetic leather—has become the preferred solution for commercial and residential upholstery applications where genuine leather’s limitations (cost volatility, ethical concerns, and environmental footprint) create significant business challenges. Engineered for resilience and aesthetics, modern leatherette delivers exceptional value without compromising on luxury or responsibility.

Why Leatherette Outperforms Alternatives in Upholstery

- Durability & Performance: Resists scratches, stains, and fading in high-traffic environments (hospitality, office, healthcare), maintaining appearance longer than fabric or untreated leather.

- Eco-Efficiency: Eliminates the water-intensive, chemical-heavy tanning processes of genuine leather; WINIW’s PU-based leatherette uses 80% less water and is free from PVC, phthalates, and heavy metals.

- Design Flexibility: Consistent color and texture across batches enable seamless large-scale production, with customizable finishes (matte, textured, embossed) to match brand-specific aesthetics.

- Cost Predictability: Stabilizes supply chain costs by avoiding livestock market fluctuations, while reducing waste through precise cutting and yield optimization.

- Ethical Assurance: Fully traceable production with certified eco-standards (OEKO-TEX®, ISO 14001), addressing growing corporate ESG mandates and consumer demand for cruelty-free materials.

WINIW: Your Trusted Partner in Sustainable Synthetics

With over 20 years of specialized expertise in advanced synthetic leather innovation, WINIW empowers global B2B clients—from contract furniture manufacturers to automotive OEMs—to elevate product quality while advancing sustainability goals. We engineer leatherette solutions that balance uncompromising performance with planet-positive practices, leveraging proprietary coating technologies and recycled content (up to 30% pre-consumer waste) without sacrificing tactile luxury. Our ISO-certified facilities and collaborative R&D approach ensure materials meet rigorous global fire safety (CAL 117, BS 5852), abrasion (Martindale >50,000 cycles), and VOC emission standards. When you choose WINIW, you invest in a future-proof partnership built on reliability, innovation, and shared environmental stewardship.

Elevate your upholstery projects with material intelligence—where responsibility and refinement converge.

Technical Performance & Standards

WINIW Leatherette Fabric for Upholstery – Technical Product Guide

WINIW’s leatherette fabric for upholstery is engineered for high-performance applications across commercial, residential, and contract furniture markets. Designed with a focus on safety, durability, and environmental responsibility, our PU and PVC-based synthetic leather solutions meet stringent international standards while delivering premium aesthetics and tactile comfort. The material is widely adopted in seating, paneling, and decorative surfaces where consistent quality, ease of maintenance, and regulatory compliance are essential.

Key technical advantages include compliance with fire retardant standards in both the UK and US, exceptional cleanability, a soft-touch surface for enhanced user comfort, full REACH compliance, and manufacturing under ISO9001-certified quality management systems.

-

Fire Retardant Performance (UK & US Standards):

WINIW’s leatherette fabric is formulated to meet and exceed critical fire safety regulations. It complies with UK Furniture and Furnishings (Fire) (Safety) Regulations 1988, including Crib 5 and Crib 5 + Cigarette testing for public space use. In the US, it meets CAL 117, NFPA 260, and ASTM E84 Class B for flame spread and smoke development, making it suitable for healthcare, hospitality, and transportation interiors. -

Easy to Clean and Maintain:

The tightly bonded surface structure resists stains, spills, and microbial growth. Routine cleaning requires only mild soap and water, with no need for waxing or conditioning. The material is resistant to alcohol, UV degradation, and common household chemicals, ensuring long-term appearance retention in high-traffic environments. -

Soft Touch and Premium Hand Feel:

Utilizing advanced coating and embossing technologies, WINIW’s leatherette delivers a tactile experience comparable to premium genuine leather. The micro-foamed back layer enhances flexibility and comfort, reducing surface hardness while maintaining dimensional stability. -

REACH Compliance:

All formulations are fully compliant with EU REACH regulations (EC 1907/2006), including SVHC (Substances of Very High Concern) restrictions. WINIW ensures the absence of phthalates, heavy metals, and other hazardous substances, supporting safer indoor environments and sustainable product lifecycles. -

ISO9001-Certified Manufacturing:

Production processes adhere to ISO9001 quality management standards, ensuring consistent batch-to-batch performance, rigorous in-process inspections, and traceable raw material sourcing. This certification reflects WINIW’s commitment to operational excellence and customer satisfaction.

Technical Specifications Table

| Property | Spécifications |

|---|---|

| Base Material | High-density polyester knit or non-woven fabric |

| Coating | Polyurethane (PU) or Polyvinyl Chloride (PVC) |

| Thickness | 0.6 mm – 1.2 mm (customizable) |

| Weight | 300 – 550 g/m² |

| Fire Retardancy (UK) | BS 5852: Crib 5, Crib 5 + Cigarette |

| Fire Retardancy (US) | CAL 117, NFPA 260, ASTM E84 Class B |

| Color Fastness (ISO 105-B02) | ≥ Grade 4 (after 40 hrs UV exposure) |

| Martindale Abrasion Resistance | 30,000 – 100,000 cycles (depending on grade) |

| Cold Crack Resistance | Passes -20°C (ISO 17233) |

| REACH Compliance | Fully compliant, SVHC-free |

| ISO Certification | ISO9001:2015 (Manufacturing) |

| Cleanability | Wipeable with water, mild detergent, or 70% alcohol |

| Surface Finish | Soft-touch, matte/satin/gloss options |

WINIW’s leatherette fabric combines technical innovation with environmental stewardship, offering B2B clients a reliable, safe, and sustainable alternative to natural leather in upholstery applications.

Why Choose Synthetic over Real Leather

B2B Material Selection Guide: Leatherette vs. Real Leather for Upholstery

Selecting the right upholstery material is a strategic decision impacting product cost, longevity, brand sustainability, and end-user satisfaction. WINIW provides this objective comparison to support informed procurement choices for commercial furniture, automotive, and hospitality applications. Key considerations include total cost of ownership, performance under high-traffic conditions, and alignment with environmental commitments.

Critical Comparison Factors

- Cost Efficiency: Initial price, maintenance, and replacement cycles directly affect project budgets and client ROI.

- Durability Requirements: Resistance to abrasion, stains, UV exposure, and structural stress determines lifespan in commercial settings.

- Eco-Profile: Resource consumption, chemical processing, biodegradability, and regulatory compliance increasingly influence brand reputation and ESG goals.

Performance & Sustainability Comparison

| Criteria | Leatherette Fabric (WINIW-Grade) | Real Leather |

|---|---|---|

| Cost | 30-60% lower initial cost per sqm. Minimal maintenance (clean with mild soap). No conditioning required. Predictable replacement cycle. | High initial cost (premium hides 2-4x leatherette). Ongoing costs for conditioning, stain protection, and repair. Variable lifespan based on hide quality. |

| Durabilité | High abrasion resistance (50,000+ double-rubs). Uniform surface resists stains, moisture, and UV fading. Consistent performance across batches. Vulnerable to sharp punctures; may stiffen in extreme cold. | Develops patina but susceptible to scratches, burns, and liquid absorption. Requires climate control to prevent drying/cracking. High-end full-grain lasts decades; lower grades degrade faster in high-use areas. |

| Eco-Friendliness | WINIW leatherette: 70% lower water use vs. tanned leather. Zero animal byproducts. Recyclable via closed-loop systems (e.g., WINIW ReGen™). PVC-free options available (TPU/PU-based). Microplastic shedding mitigated via advanced coatings. | Resource-intensive: 1 cowhide = ~16,000L water, significant land use. Tanning uses chromium/hazardous chemicals (unless veg-tanned). Biodegradable but slow (decades). Carbon footprint 3-5x higher than synthetic alternatives. |

Strategic Recommendations

- Choose Leatherette When: Budget constraints, high-moisture environments (hospitals, transit), strict sustainability targets (LEED, ISO 14001), or need for color/texture consistency across large orders. Ideal for contract furniture, public transport, and eco-conscious hospitality projects.

- Choose Real Leather When: Heritage branding, luxury automotive interiors, or applications where natural aging adds value. Requires commitment to ethical sourcing (e.g., LWG-certified tanneries) and lifecycle maintenance.

WINIW’s eco-engineered leatherettes deliver commercial-grade performance while addressing critical ESG metrics—reducing water stress, eliminating animal agriculture dependencies, and enabling circular material flows. Partner with us to specify solutions aligned with your sustainability roadmap and total cost objectives.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative and sustainable materials for global B2B clients. Our vertically integrated production capabilities and unwavering commitment to quality have positioned us as a trusted partner in diverse industries, including automotive, furniture, apparel, and accessories.

Our manufacturing excellence is anchored in a state-of-the-art facility spanning over 100,000 square meters. This expansive campus enables us to maintain full control over every stage of production—from raw material processing to finished goods—ensuring efficiency, consistency, and scalability to meet large-volume demands.

Key factory strengths include:

- Advanced production lines equipped with automated systems for precision coating, embossing, and laminating.

- A dedicated R&D team of over 100 engineers and material scientists focused on developing eco-friendly, durable, and high-functionality synthetic leathers.

- Continuous innovation in water-based, solvent-free, and recycled raw material formulations to support sustainable manufacturing goals.

- Strict quality control protocols implemented throughout the production cycle, including raw material inspection, in-process testing, and final product validation.

- Compliance with international standards such as REACH, RoHS, OEKO-TEX, and California Proposition 65.

- In-house testing laboratory capable of evaluating physical properties, color fastness, abrasion resistance, and environmental safety.

WINIW proudly exports to key global markets, with established distribution and partnerships across Europe and the USA. Our logistics network ensures timely delivery and regulatory compliance, supporting OEMs and brands in meeting their sustainability and performance requirements.

With decades of industry experience and a forward-thinking approach to material science, WINIW delivers reliable, high-quality synthetic leather solutions tailored to the evolving needs of international B2B clients.

Contact Us for Samples

WINIW Premium Leatherette Fabric: Sustainable Upholstery Solutions for Commercial Excellence

WINIW delivers high-performance synthetic leather engineered specifically for demanding upholstery applications across furniture, transportation, hospitality, and healthcare sectors. Our eco-conscious manufacturing process eliminates PVC and heavy metals while maintaining superior durability, aesthetics, and compliance—providing brands with a responsible alternative that meets rigorous commercial standards without compromising on luxury or longevity.

Key Advantages for B2B Upholstery Partners

- Eco-Intelligent Composition: 100% PVC-free, phthalate-free, and REACH/OEKO-TEX® Standard 100 certified. Utilizes water-based polyurethane (PU) and recycled polyester backings to reduce environmental impact.

- Commercial-Grade Durability: Exceeds 50,000+ double rubs (Martindale), resists abrasion, staining, and UV fading—ideal for high-traffic environments like airports, offices, and public transit.

- Design Flexibility: Customizable in 1,000+ colorways, textures (suede, pebble, smooth), and thicknesses (0.6mm–1.2mm). Rapid prototyping support for brand-exclusive finishes.

- Cost Efficiency: Eliminates leather’s natural inconsistencies and waste; 30% lighter than genuine leather for reduced shipping costs and easier fabrication.

- Ethical Compliance: Full traceability from raw material to finished roll; supports LEED and BREEAM certification goals for sustainable interiors.

Performance Comparison: WINIW vs. Traditional Upholstery Materials

| Property | WINIW Leatherette | Genuine Leather | PVC-Based Vinyl |

|---|---|---|---|

| Eco-Certifications | OEKO-TEX®, REACH | Limited | Rare |

| Abrasion Resistance | 50,000+ double rubs | 25,000–35,000 | 15,000–20,000 |

| Weight (g/m²) | 380–520 | 800–1,200 | 450–600 |

| Recycled Content | Up to 40% | 0% | 0% |

| VOC Emissions | <10 µg/m³ | Moderate | Haut |

Why Global Brands Partner with WINIW

Our closed-loop water treatment system and solar-powered facilities ensure every meter of leatherette aligns with ESG mandates while delivering tactile richness indistinguishable from premium hides. We collaborate with designers to solve complex challenges—from flame-retardant seating for aviation to antimicrobial surfaces for healthcare—backed by ISO 9001/14001 quality management.

Request Technical Specifications & Free Samples

Elevate your upholstery projects with WINIW’s sustainable innovation. Contact our B2B Solutions Team to receive:

– Custom swatch book (including fire-rated & marine-grade options)

– Full technical datasheets and compliance documentation

– Sample rolls for immediate prototyping

Email MKT88@MicrofiberLeather.com with “Upholstery Sample Request” in the subject line.

Free samples available for qualified commercial partners. Lead time: 3 business days.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.