Introduction: Navigating the Global Market for leather jacket customization

In the dynamic landscape of fashion, the demand for leather jacket customization has surged, presenting a unique challenge for international B2B buyers looking to source high-quality, bespoke products. With an increasing number of consumers seeking individuality and personalized style, businesses must navigate a complex market filled with diverse suppliers, varying quality standards, and fluctuating costs. This comprehensive guide aims to demystify the intricacies of leather jacket customization, offering valuable insights into different types of jackets, applications for various markets, and essential strategies for vetting suppliers effectively.

From understanding the nuances of material selection to evaluating production capabilities and pricing structures, this guide equips B2B buyers from regions such as Africa, South America, the Middle East, and Europe—specifically Brazil and Nigeria—with the knowledge necessary for making informed purchasing decisions. Whether you’re a retailer aiming to expand your product line or a fashion designer looking to create unique pieces for your clientele, our guide provides actionable advice tailored to meet your specific needs.

By the end of this resource, you’ll be empowered to engage with suppliers confidently, negotiate favorable terms, and ultimately deliver high-quality, customized leather jackets that resonate with your target audience. This is not just about sourcing; it’s about crafting a unique brand identity in a competitive global marketplace.

Table Of Contents

- Top 6 Leather Jacket Customization Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather jacket customization

- Understanding leather jacket customization Types and Variations

- Key Industrial Applications of leather jacket customization

- 3 Common User Pain Points for ‘leather jacket customization’ & Their Solutions

- Strategic Material Selection Guide for leather jacket customization

- In-depth Look: Manufacturing Processes and Quality Assurance for leather jacket customization

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather jacket customization’

- Comprehensive Cost and Pricing Analysis for leather jacket customization Sourcing

- Alternatives Analysis: Comparing leather jacket customization With Other Solutions

- Essential Technical Properties and Trade Terminology for leather jacket customization

- Navigating Market Dynamics and Sourcing Trends in the leather jacket customization Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather jacket customization

- Strategic Sourcing Conclusion and Outlook for leather jacket customization

- Important Disclaimer & Terms of Use

Understanding leather jacket customization Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Fit | Tailored to individual body measurements | Fashion retailers, costume designers | Pros: Perfect fit; Cons: Longer production time |

| Design Customization | Options for colors, fabrics, and unique design elements | Fashion brands, promotional items | Pros: Unique branding; Cons: Higher costs |

| Embellishment | Addition of logos, graphics, embroidery, or monograms | Corporate gifts, team uniforms | Pros: Brand visibility; Cons: May require more time |

| Functional Customization | Features like additional pockets, linings, or insulation | Outdoor brands, specialty retailers | Pros: Enhanced usability; Cons: Complexity in design |

| Replica Customization | Exact replicas of iconic jackets from films or designs | Film production, cosplay, fashion shows | Pros: High demand; Cons: Intellectual property issues |

What are the Characteristics of Custom Fit Leather Jackets?

Custom fit leather jackets are designed specifically for individual body measurements, ensuring a perfect fit. This type of customization is particularly suitable for B2B buyers in the fashion retail sector, where fit is crucial for customer satisfaction. When purchasing, businesses should consider the accuracy of measurement processes, as well as the potential for returns if the fit is not as expected. Custom fit options can enhance brand loyalty by providing customers with a personalized experience.

How Does Design Customization Enhance Brand Identity?

Design customization allows businesses to choose from a variety of colors, fabrics, and design elements, creating jackets that align with their brand identity. This is particularly valuable for fashion brands and companies looking to create promotional items. Buyers should assess the range of options available and the flexibility in design changes to ensure that the final product meets their branding requirements. While this type of customization can elevate brand visibility, it often comes at a higher price point.

What are the Benefits of Embellishment in Leather Jacket Customization?

Embellishment involves adding logos, graphics, or personalized embroidery to leather jackets. This customization is commonly used for corporate gifts or team uniforms, as it enhances brand visibility. B2B buyers should evaluate the quality of the embellishment process and the materials used to ensure durability. While embellishments can significantly enhance the perceived value of a product, they may also increase lead times and costs, which are important considerations for budget-conscious buyers.

How Does Functional Customization Improve Usability?

Functional customization focuses on adding practical features like extra pockets, specialized linings, or insulation. This type of customization is ideal for outdoor brands and specialty retailers aiming to enhance the usability of their products. Buyers should consider the specific needs of their target market when selecting functional features, as these can greatly influence customer satisfaction. While functional customization can set products apart in a competitive market, it may complicate the design process and increase production times.

What is the Market Demand for Replica Customization?

Replica customization involves creating exact replicas of iconic jackets from films or unique designs. This type of customization is particularly relevant for film production companies, cosplayers, and fashion shows. Buyers should be aware of potential intellectual property issues when commissioning replicas, as these can affect production timelines and costs. Despite these challenges, the high demand for replicas can provide significant market opportunities for businesses willing to navigate the complexities involved.

Key Industrial Applications of leather jacket customization

| Industry/Sector | Specific Application of leather jacket customization | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Custom fashion lines for exclusive collections | Differentiation in a competitive market; enhanced customer loyalty | Sourcing high-quality leather; ethical production practices; lead times for custom orders |

| Film & Entertainment | Replication of iconic jackets for film productions | Authenticity in costume design; potential for merchandising | Access to skilled artisans; ability to match original designs; material sourcing for durability |

| Corporate Branding | Customized jackets for team uniforms or promotional events | Enhanced brand visibility and employee morale | Custom branding options; bulk order discounts; quick turnaround times |

| Motorcycle Industry | Bespoke jackets for motorcycle clubs or events | Community building; unique identity for members | Compliance with safety standards; durability of materials; size customization for various body types |

| Sports Teams | Personalized jackets for fans and athletes | Fostering team spirit; creating unique merchandise | Licensing agreements; high-quality embroidery options; scalability for large orders |

How Is Leather Jacket Customization Utilized in the Fashion Retail Sector?

In the fashion retail sector, leather jacket customization is crucial for creating exclusive collections that cater to niche markets. Retailers can offer bespoke designs that reflect current trends or customer preferences, allowing for a unique selling proposition. This approach not only enhances customer loyalty but also helps brands stand out in a crowded marketplace. Buyers in this sector should prioritize sourcing high-quality leather and ensure ethical production practices, as well as consider lead times for custom orders to manage inventory effectively.

What Role Does Leather Jacket Customization Play in Film and Entertainment?

In the film and entertainment industry, leather jacket customization is often used to replicate iconic jackets worn by characters in films or television shows. This authenticity is vital for costume designers aiming to create a believable representation of a character. Additionally, these custom jackets can become merchandise for fans, providing an additional revenue stream. Buyers need access to skilled artisans who can match original designs accurately and ensure that materials used are durable enough to withstand the rigors of production.

Why Is Leather Jacket Customization Important for Corporate Branding?

Corporate branding benefits significantly from leather jacket customization, particularly for creating team uniforms or promotional items. Customized jackets can enhance brand visibility at events and foster a sense of belonging among employees. For businesses looking to implement this, it’s essential to consider custom branding options, potential bulk order discounts, and quick turnaround times to meet event deadlines. Sourcing should focus on quality materials that reflect the company’s image while ensuring employee comfort.

How Does Leather Jacket Customization Enhance Community in the Motorcycle Industry?

In the motorcycle industry, bespoke jackets serve as a means of identity for motorcycle clubs and events. Customized jackets foster a sense of community among members while providing a unique identity that distinguishes them from other clubs. Compliance with safety standards is crucial, as these jackets must be durable and suitable for riding. Buyers should focus on the durability of materials and the ability to customize sizes to accommodate various body types, ensuring comfort and safety.

What Benefits Does Leather Jacket Customization Offer to Sports Teams?

For sports teams, personalized leather jackets are an effective way to foster team spirit and create unique merchandise for fans. Customized jackets can feature team logos, player names, and other branding elements, enhancing the emotional connection fans have with their teams. Buyers need to navigate licensing agreements for branding, ensuring high-quality embroidery options are available. Scalability for large orders is also crucial, particularly during peak seasons or when launching new merchandise.

3 Common User Pain Points for ‘leather jacket customization’ & Their Solutions

Scenario 1: Navigating Sizing Challenges for Custom Leather Jackets

The Problem: One of the most significant challenges B2B buyers face when ordering custom leather jackets is ensuring proper sizing. Many businesses often cater to a diverse clientele, which includes a wide range of body types. This can lead to frustrations if the jackets do not fit as intended, resulting in costly returns and alterations. Buyers may also encounter difficulties in accurately communicating sizing requirements to manufacturers, especially if they lack experience in measuring for custom fits.

The Solution: To mitigate sizing challenges, buyers should consider partnering with manufacturers that offer a comprehensive measurement guide and virtual sizing tools. Before placing an order, they can request detailed instructions on how to take accurate measurements for various body shapes. Additionally, leveraging technology like 3D fitting apps or virtual consultations can enhance the accuracy of sizing. Establishing a clear communication channel with the manufacturer regarding sizing specifications will ensure that all parties are aligned, reducing the likelihood of fit-related issues and enhancing customer satisfaction.

Illustrative image related to leather jacket customization

Scenario 2: Overcoming Design Limitations in Customization

The Problem: B2B buyers often struggle with the limitations imposed by manufacturers on the customization options available for leather jackets. Buyers may wish to incorporate unique design elements, such as specific logos, colors, or patterns, but find that manufacturers either lack the capability or the willingness to accommodate these requests. This can lead to dissatisfaction and a feeling of compromise on the buyer’s part, which is particularly detrimental when aiming to establish a strong brand identity through customized apparel.

The Solution: To address design limitations, buyers should conduct thorough research on potential manufacturers before committing to a partnership. They should seek out suppliers known for their flexibility in customization and inquire about their capabilities regarding unique design requests. Additionally, establishing a collaborative relationship with the manufacturer can foster creativity and innovation. By sharing inspiration, sketches, or samples, buyers can work closely with manufacturers to push the boundaries of what is possible, ensuring that the final product truly reflects their brand’s vision.

Scenario 3: Managing International Shipping and Customs Issues

The Problem: For international B2B buyers, shipping and customs can present significant obstacles when ordering custom leather jackets. Complications may arise from varying regulations, unexpected duties, and long lead times, which can disrupt inventory management and affect customer satisfaction. Buyers may also find it challenging to navigate the complexities of shipping logistics, particularly when dealing with suppliers located in different countries.

Illustrative image related to leather jacket customization

The Solution: To streamline the shipping process, buyers should prioritize working with manufacturers who have established logistics systems and clear shipping policies. It’s essential to discuss shipping options upfront, including the possibility of expedited services and the handling of customs documentation. Buyers should also familiarize themselves with their local customs regulations to anticipate any potential duties or taxes. By maintaining open communication with the supplier regarding shipping timelines and requirements, buyers can better manage expectations and ensure a smoother delivery process, ultimately enhancing their operational efficiency.

Strategic Material Selection Guide for leather jacket customization

What Are the Key Materials for Leather Jacket Customization?

When considering leather jacket customization, the choice of material is critical for ensuring the final product meets performance expectations and customer satisfaction. Here, we analyze four common materials used in leather jacket customization, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Full Grain Leather Perform in Custom Jackets?

Full grain leather is often regarded as the highest quality leather available. It retains the natural grain and imperfections of the hide, which contribute to its unique character. Key properties include excellent durability, breathability, and resistance to wear and tear. It can withstand various temperatures, making it suitable for both warm and cold climates.

Pros: Full grain leather is incredibly durable and ages beautifully, developing a rich patina over time. It is also water-resistant to a degree, which adds to its longevity.

Cons: The cost of full grain leather is typically high, which may deter some buyers. Additionally, its manufacturing process can be complex, requiring skilled artisans to handle the material properly.

Illustrative image related to leather jacket customization

For international buyers, particularly those in regions like Africa and South America, full grain leather’s appeal lies in its premium quality. However, compliance with local regulations regarding leather sourcing and environmental standards should be considered.

What Are the Benefits of Top Grain Leather for Custom Jackets?

Top grain leather is a step below full grain but still offers a high-quality finish. It is sanded and treated to remove imperfections, resulting in a more uniform appearance. This material is also known for its flexibility and softness, making it comfortable for wear.

Pros: Top grain leather is generally more affordable than full grain while still providing a luxurious look and feel. Its flexibility makes it suitable for various jacket styles.

Cons: While durable, top grain leather is less resistant to scratches and wear compared to full grain. It may not develop the same rich patina over time, which could be a downside for some customers.

For buyers in Europe and the Middle East, top grain leather is often preferred for its balance of quality and cost. Understanding local market preferences for leather types can help in making informed purchasing decisions.

How Does Suede Compare as a Material for Leather Jacket Customization?

Suede is made from the underside of the animal hide, giving it a soft texture and a unique aesthetic appeal. It is less durable than other leather types but offers a distinct look that many consumers find attractive.

Pros: Suede is lightweight and comfortable, making it ideal for casual jackets. It is also available in a variety of colors, allowing for creative customization options.

Cons: The primary drawback of suede is its susceptibility to stains and water damage, which can limit its usability in certain environments. Additionally, it requires more maintenance to keep it looking good.

Illustrative image related to leather jacket customization

For international buyers, especially in humid climates like Nigeria, the practicality of suede should be carefully evaluated. Buyers should also be aware of any local care standards for suede materials.

What Role Does Synthetic Leather Play in Custom Jacket Production?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is an alternative to traditional leather. It mimics the look and feel of leather while being more affordable.

Pros: Synthetic leather is generally more cost-effective and easier to clean than natural leather. It is also available in a wide range of colors and finishes.

Cons: However, synthetic leather lacks the durability and breathability of genuine leather. It may not age as well, leading to a shorter lifespan for the product.

Illustrative image related to leather jacket customization

For buyers in regions like South America and Africa, synthetic leather can be an appealing option due to its lower cost and ethical considerations. However, understanding local preferences for leather materials is essential for successful marketing.

Summary Table of Material Selection for Leather Jacket Customization

| Matériau | Typical Use Case for leather jacket customization | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | High-end jackets, luxury markets | Exceptional durability and character | High cost and complex manufacturing | Haut |

| Top Grain Leather | Fashion-forward jackets, versatile styles | Affordable luxury and flexibility | Less durable than full grain | Medium |

| Daim | Casual jackets, fashion statements | Soft texture and variety of colors | Susceptible to stains and damage | Medium |

| Synthetic Leather | Budget-friendly options, ethical markets | Cost-effective and easy to maintain | Less durable and breathability issues | Low |

This guide provides a comprehensive overview of materials for leather jacket customization, helping B2B buyers make informed decisions based on their specific market needs and customer preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for leather jacket customization

What Are the Main Stages of Leather Jacket Manufacturing?

The manufacturing process of custom leather jackets involves several critical stages, each essential for ensuring high-quality final products that meet specific buyer requirements. Understanding these stages will help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: How Is Leather Selected and Processed?

The first stage in manufacturing custom leather jackets is material preparation. This involves selecting the appropriate type of leather, which can vary significantly in quality, texture, and finish. High-quality full-grain leather is often preferred due to its durability and natural appearance.

Once the leather is selected, it undergoes a tanning process to preserve its qualities and enhance its aesthetics. Tanning methods can include vegetable tanning, which is eco-friendly and enhances the leather’s natural characteristics, and chrome tanning, which allows for faster processing and a wider array of colors.

Additionally, suppliers may offer different types of leather sourced from various regions, which can affect pricing and quality. B2B buyers should inquire about the origin of the leather and the tanning methods used to ensure they align with their quality expectations.

Forming: What Techniques Are Used to Shape the Leather?

The forming stage involves cutting the leather into specific patterns that will be assembled into the final jacket. Advanced cutting techniques, such as laser cutting or precision die-cutting, are often employed to ensure accuracy and reduce waste.

After cutting, leather pieces are often subjected to a conditioning process to make them more pliable for sewing. This step is crucial, especially for custom designs that may feature unique shapes or intricate details.

Illustrative image related to leather jacket customization

B2B buyers should assess the supplier’s capabilities in cutting and forming techniques, as this directly impacts the jacket’s fit and finish.

Assembly: How Are the Pieces Brought Together?

The assembly stage is where the individual leather pieces are sewn together. This process requires skilled craftsmanship to ensure that seams are strong and aligned correctly. Techniques such as double stitching may be used in high-stress areas to enhance durability.

Quality hardware, such as zippers and buttons, is also integrated during this stage. The choice of hardware can affect both the functionality and aesthetics of the jacket, so suppliers should offer a variety of options for customization.

For B2B buyers, understanding the assembly techniques and the level of craftsmanship involved can provide insights into the jacket’s longevity and overall quality.

Finishing: What Final Touches Are Applied?

Finishing is the final stage in the manufacturing process, where jackets are treated to enhance their appearance and functionality. This may include polishing, dyeing, or applying protective coatings.

Illustrative image related to leather jacket customization

Additionally, quality control checks are conducted during this stage to ensure that the jackets meet the established quality standards. This includes checking for defects, ensuring the correct fit, and verifying that all customizations have been implemented accurately.

Buyers should confirm that suppliers adhere to high finishing standards, as this stage greatly affects the end-user experience.

What Are the Key Quality Control Measures in Leather Jacket Manufacturing?

Quality control (QC) is a critical aspect of leather jacket manufacturing, ensuring that products meet international standards and buyer specifications. Understanding the QC measures can help B2B buyers assess the reliability of potential suppliers.

Which International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 are crucial for ensuring quality management systems are in place. This certification indicates that a supplier has established processes for maintaining product quality throughout the manufacturing cycle.

Additionally, industry-specific certifications like CE (for safety) and API (for quality assurance in specific sectors) may also be relevant, particularly for buyers in regulated markets. B2B buyers should request documentation of these certifications to verify compliance.

What Are the Key QC Checkpoints During Production?

Quality control is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet the required standards. This is crucial for leather, as defects can affect the entire production process.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to ensure that all processes adhere to quality standards. This helps catch issues early, minimizing waste and rework.

-

Final Quality Control (FQC): Before the jackets are shipped, a comprehensive inspection is conducted to check for defects, fit, and adherence to customization specifications. This stage is vital for ensuring customer satisfaction.

B2B buyers should inquire about the frequency and methods of these QC checkpoints to ensure that their suppliers maintain rigorous quality standards.

How Can Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of potential suppliers:

-

Audits: Conducting regular audits of the supplier’s manufacturing facilities can provide insights into their QC processes and adherence to standards. Buyers may consider hiring third-party inspection services for an unbiased review.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the supplier’s performance metrics, defect rates, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services before shipment can provide additional assurance of product quality. This is particularly important for international transactions where buyers cannot physically inspect the goods.

What Are the QC and Certification Nuances for International Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certifications is essential. Different regions may have varying standards and regulations, impacting what certifications are necessary for importation.

Buyers should familiarize themselves with local regulations regarding leather goods, including any tariffs, duties, and compliance requirements. Additionally, establishing clear communication with suppliers about these regulations can help mitigate risks associated with international trade.

Illustrative image related to leather jacket customization

Conclusion: What Should B2B Buyers Look for in Supplier Quality Assurance?

In summary, the manufacturing processes and quality assurance measures for leather jacket customization are complex and multifaceted. B2B buyers should prioritize suppliers who demonstrate transparency in their manufacturing practices, adhere to international quality standards, and provide comprehensive documentation of their QC processes. By focusing on these aspects, buyers can ensure they receive high-quality, customized leather jackets that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather jacket customization’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring customized leather jackets. Whether you are a fashion retailer, a brand owner, or a designer, understanding the steps involved in sourcing customized leather jackets will help you make informed decisions, ensuring quality and satisfaction in your purchases.

Step 1: Define Your Customization Requirements

Before engaging suppliers, clearly outline your customization needs. Identify specific elements such as style, color, material, and any unique features such as embroidery or lining. This clarity will facilitate smoother communication with potential suppliers and ensure they understand your vision.

- Key Considerations:

- What styles resonate with your target market?

- Are there specific materials or colors that align with your brand identity?

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers specializing in leather jacket customization. Evaluate their experience, product offerings, and reputation in the market. Shortlist suppliers who align with your requirements and have positive reviews from other buyers.

Illustrative image related to leather jacket customization

- Actionable Tips:

- Look for suppliers with a portfolio showcasing past customizations.

- Read testimonials or case studies from businesses similar to yours.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of your shortlisted suppliers. Inquire about their production processes, customization options, and the technology they use. Understanding their capabilities will help you gauge whether they can meet your specific requirements.

- Important Aspects to Review:

- Do they offer a variety of leather types and colors?

- What are their minimum order quantities, and can they accommodate smaller runs?

Step 4: Request Samples and Prototypes

Before finalizing your order, request samples or prototypes of the jackets. This step is crucial to evaluate the quality of materials, craftsmanship, and overall fit. Having a physical sample allows you to make necessary adjustments before committing to a larger order.

- Sample Evaluation Criteria:

- Check for stitching quality and overall finish.

- Ensure the fit aligns with your specifications.

Step 5: Verify Compliance and Certifications

Ensure that the suppliers comply with relevant industry standards and regulations, particularly concerning ethical sourcing and environmental practices. Certifications such as ISO or Fair Trade can indicate a supplier’s commitment to quality and ethical manufacturing.

- What to Look For:

- Are the materials sourced responsibly?

- Does the supplier have certifications that align with your brand values?

Step 6: Negotiate Terms and Conditions

Once you select a supplier, engage in negotiations regarding pricing, lead times, payment terms, and return policies. Clear agreements on these aspects will prevent misunderstandings and facilitate a smooth transaction.

- Negotiation Points:

- What is the expected delivery timeline for custom orders?

- Are there provisions for alterations or returns if the product does not meet expectations?

Step 7: Establish Ongoing Communication

After placing your order, maintain open lines of communication with your supplier. Regular updates on production status and any potential issues will help build a strong partnership and ensure timely delivery of your customized jackets.

Illustrative image related to leather jacket customization

- Best Practices:

- Schedule regular check-ins or updates.

- Be proactive in addressing any concerns or changes in your order.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing customized leather jackets, ensuring that they receive high-quality products tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for leather jacket customization Sourcing

When sourcing leather jacket customization, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This section delves into the various cost components, price influencers, and offers strategic buyer tips tailored to regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Leather Jacket Customization?

Materials: The choice of leather significantly impacts costs. Full-grain leather is often the most expensive due to its quality and durability, while lower-grade options may reduce costs but compromise longevity and style. Additionally, custom features such as embroidery, lining fabrics, and hardware selections can further influence material costs.

Labor: Skilled craftsmanship is essential in leather jacket production. Labor costs vary based on the complexity of the design and the skill level required. Customization typically necessitates more labor-intensive processes, which can increase overall costs.

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Efficient operations can help minimize overhead, allowing suppliers to offer competitive pricing.

Illustrative image related to leather jacket customization

Tooling: Custom designs may require specific tools or molds, which can add to initial costs. However, once these tools are in place, the cost per unit may decrease with higher production volumes.

Quality Control (QC): Ensuring the final product meets quality standards is paramount, especially for customized items. Investing in rigorous QC processes can lead to higher upfront costs but reduces the risk of returns and dissatisfaction.

Logistics: Shipping costs can vary widely based on the destination and chosen Incoterms. International buyers should consider potential customs duties and taxes, which can add to the total cost.

Margin: The profit margin for suppliers typically reflects the perceived value of the product, market demand, and competition. Understanding the margin expectations of suppliers can aid in effective negotiation.

How Do Price Influencers Affect Leather Jacket Customization Costs?

Volume and Minimum Order Quantity (MOQ): Higher order volumes usually lead to cost savings. Suppliers may offer lower per-unit prices for bulk orders, making it advantageous for businesses aiming to stock inventory.

Illustrative image related to leather jacket customization

Specifications and Customization Levels: The more complex the customization (e.g., unique designs, special features), the higher the costs. Simplifying design requests can lead to more competitive pricing.

Material Quality and Certifications: Suppliers that provide certified materials (e.g., sustainable sourcing) may charge a premium. However, these investments can enhance brand reputation and appeal to eco-conscious consumers.

Supplier Factors: The supplier’s location, operational efficiency, and reputation can influence pricing. Engaging with suppliers who have established a strong market presence can ensure better quality and service.

Incoterms: Understanding shipping terms is critical. Different Incoterms can shift responsibilities and costs between buyers and sellers, affecting total expenses.

What Are the Best Negotiation Tips for International Buyers?

Research and Benchmarking: Before negotiations, research market prices and competitors to establish a fair baseline for discussions. This knowledge empowers buyers to negotiate effectively.

Leverage Long-Term Relationships: Building strong relationships with suppliers can lead to better terms, including pricing, payment terms, and priority in production.

Focus on Total Cost of Ownership (TCO): Instead of just looking at upfront costs, consider long-term expenses related to quality, durability, and maintenance. This perspective can justify higher initial investments in better-quality products.

Understand Regional Nuances: Buyers from Africa, South America, and the Middle East should be aware of regional pricing trends and buyer behavior. Tailoring discussions based on local market conditions can yield better results.

Illustrative image related to leather jacket customization

Flexibility in Order Specifications: Being open to adjusting order specifications or accepting slightly longer lead times can sometimes secure more favorable pricing.

Conclusion

The cost structure and pricing dynamics of leather jacket customization sourcing are multifaceted. By understanding the various cost components, price influencers, and leveraging effective negotiation strategies, international B2B buyers can make informed decisions that align with their business goals. Always remember that indicative prices are subject to change based on market conditions, and thorough due diligence is essential for achieving the best outcomes.

Alternatives Analysis: Comparing leather jacket customization With Other Solutions

Exploring Alternatives to Leather Jacket Customization

In the realm of fashion, particularly in the leather jacket market, businesses often seek tailored solutions that align with their unique branding and customer needs. While leather jacket customization offers a distinct way to express individuality and meet specific requirements, several alternatives exist that can also fulfill similar objectives. This section compares leather jacket customization against other viable options, helping B2B buyers make informed decisions.

| Comparison Aspect | Leather Jacket Customization | Alternative 1: Off-the-Rack Jackets | Alternative 2: Mass Production Leather Jackets |

|---|---|---|---|

| Performance | High quality, tailored fit | Variable quality, may not fit well | Generally consistent quality, standard sizing |

| Cost | Moderate ($398-$502) | Low to moderate ($100-$300) | Low to moderate ($150-$400) |

| Ease of Implementation | Requires detailed input and measurements | Quick purchase, immediate availability | Streamlined process, bulk orders available |

| Maintenance | Requires careful handling and care | Standard care required | Similar care as custom jackets |

| Best Use Case | Unique branding, individual expression | Quick, cost-effective options | Large-scale distribution, uniform branding |

What Are the Pros and Cons of Off-the-Rack Jackets?

Off-the-rack jackets are readily available in retail environments, offering a quick solution for businesses that need immediate inventory. The primary advantage is the lower cost, making them accessible for budget-conscious buyers. However, the major drawback is the fit and quality variability; these jackets may not cater to specific body types or branding needs. This option is best for businesses looking for a fast and economical solution without the emphasis on customization.

How Do Mass Production Leather Jackets Compare?

Mass production leather jackets are manufactured in large quantities, providing consistency in quality and style. This alternative is appealing for companies that prioritize uniformity and a streamlined purchasing process. While the price point is competitive, the downside is the lack of individuality and the potential for lower craftsmanship compared to custom options. Businesses that focus on large-scale distribution or uniform branding may find this approach beneficial, but it may not resonate with consumers seeking uniqueness.

Illustrative image related to leather jacket customization

How Can B2B Buyers Choose the Right Solution?

When considering the right solution for leather jackets, B2B buyers should evaluate their specific needs, including budget constraints, desired level of customization, and target market preferences. Leather jacket customization stands out for its quality and individuality, making it ideal for brands aiming to offer unique, bespoke items that resonate with customers. In contrast, off-the-rack and mass production options may serve as suitable alternatives for businesses focused on quick turnaround and lower costs. Ultimately, the choice hinges on the balance between quality, cost, and the brand’s vision.

Essential Technical Properties and Trade Terminology for leather jacket customization

What Are the Key Technical Properties in Leather Jacket Customization?

When engaging in leather jacket customization, understanding the essential technical properties is crucial for B2B buyers. Here are some key specifications to consider:

1. Material Grade

The grade of leather significantly impacts the jacket’s quality, durability, and appearance. Full grain leather, the highest quality available, retains the natural texture and grain, providing longevity and a luxurious feel. In contrast, corrected grain leather, while less expensive, undergoes more processing and may not be as durable. For B2B buyers, selecting the right material grade is vital to ensure customer satisfaction and brand reputation.

2. Tolerance Levels

Tolerance levels refer to the permissible variations in measurements during the manufacturing process. For custom jackets, precise tolerances are critical to achieving a perfect fit. Deviations can lead to customer dissatisfaction or increased return rates. Establishing clear tolerance specifications helps maintain quality control and reduces operational inefficiencies.

3. Customization Options

Customization encompasses a variety of features such as color, lining, hardware, and additional embellishments like embroidery or patches. Offering diverse customization options allows businesses to meet the unique demands of their clients, enhancing the perceived value of the product. This flexibility can be a significant differentiator in a competitive market.

4. Construction Techniques

The method of construction affects the jacket’s fit, durability, and aesthetic appeal. Techniques such as double stitching or reinforced seams enhance structural integrity, while traditional handcrafting adds a level of artistry. Understanding these techniques enables buyers to make informed decisions that align with their brand’s quality standards.

5. Sizing and Fit Specifications

Accurate sizing is crucial for customer satisfaction. Custom jackets often require precise measurements, including chest, waist, and sleeve lengths. Providing a detailed sizing guide and consulting with clients can mitigate fit issues, ensuring that the final product meets their expectations.

Which Trade Terms Should B2B Buyers Know in Leather Jacket Customization?

Familiarity with industry jargon is essential for effective communication in the leather jacket customization market. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another company’s brand name. In leather customization, businesses may collaborate with OEMs to manufacture unique designs, allowing them to leverage specialized expertise while maintaining brand identity.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to produce or sell. Understanding MOQ helps buyers plan their purchasing strategies effectively. A higher MOQ might lower costs per unit but can lead to excess inventory if demand fluctuates.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It is vital for B2B buyers to clearly outline their customization requirements in an RFQ to receive accurate pricing and lead time estimates. This process fosters competitive bidding and helps secure the best deal.

Illustrative image related to leather jacket customization

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms is essential for B2B transactions, especially when dealing with international shipments. This knowledge helps in negotiating terms that minimize costs and risks.

5. Lead Time

Lead time refers to the period from order placement to delivery. Understanding lead times is crucial for inventory management and meeting customer demands. Clear communication with suppliers about expected lead times can enhance operational efficiency and customer satisfaction.

By grasping these technical properties and trade terms, B2B buyers can navigate the leather jacket customization landscape more effectively, ensuring high-quality products that meet market demands.

Navigating Market Dynamics and Sourcing Trends in the leather jacket customization Sector

What Are the Key Drivers Influencing the Leather Jacket Customization Market?

The leather jacket customization sector is experiencing significant growth, driven by a global increase in demand for personalized fashion. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where consumers are increasingly seeking unique, high-quality products that reflect their individual styles. Technological advancements in design software and e-commerce platforms have made it easier for international B2B buyers to source custom leather jackets directly from manufacturers, reducing lead times and costs. Additionally, the rise of social media has amplified the influence of fashion trends, driving consumers to seek customized options that allow for personal expression.

Emerging technologies such as 3D modeling and virtual fitting solutions are reshaping the customization process. These tools not only enhance the consumer experience but also streamline operations for manufacturers. Moreover, as buyers become more discerning, there is a growing emphasis on quality craftsmanship and materials, with buyers increasingly favoring suppliers who can guarantee premium leather and meticulous attention to detail.

How Is Sustainability Shaping the Leather Jacket Customization Sector?

Sustainability and ethical sourcing are becoming pivotal in the leather jacket customization market. The environmental impact of leather production has prompted many buyers to seek suppliers who prioritize sustainable practices. This includes sourcing leather as a byproduct of the meat industry, ensuring that no resources go to waste. Furthermore, ethical supply chains are critical for international buyers, especially in regions where consumers are more environmentally conscious.

Manufacturers are increasingly adopting ‘green’ certifications and using eco-friendly materials in their processes. This not only helps in reducing the carbon footprint but also appeals to a demographic that values sustainability in their purchasing decisions. Certifications such as the Leather Working Group (LWG) ensure that the leather sourced is produced in compliance with environmental standards, thereby providing buyers with the assurance they need. By aligning with suppliers who uphold these values, B2B buyers can enhance their brand reputation while meeting the growing demand for responsible fashion.

What Is the Historical Context of Leather Jacket Customization?

The leather jacket has a rich history that dates back to the early 20th century, originally worn by pilots and military personnel for its durability and warmth. Over the decades, it has evolved into a symbol of rebellion and style, embraced by various subcultures. The customization aspect began gaining traction in the late 20th century as consumers sought to personalize their jackets to reflect their unique identities. Today, the blending of traditional craftsmanship with modern technology has paved the way for an expansive customization market. This evolution not only caters to individual preferences but also allows for the incorporation of sustainable practices, making it a compelling choice for B2B buyers.

How Can B2B Buyers Leverage Market Trends in Leather Jacket Customization?

As the leather jacket customization sector continues to evolve, B2B buyers should stay informed about key trends and consumer preferences. Engaging with suppliers who utilize advanced technologies and uphold ethical standards can provide a competitive edge. Additionally, understanding regional market dynamics and cultural preferences will enable buyers to tailor their offerings effectively, ensuring they meet the diverse needs of their clientele across different markets. By adopting a proactive approach to sourcing and customization, B2B buyers can capitalize on the growing demand for unique, high-quality leather jackets that resonate with consumers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of leather jacket customization

-

How do I ensure the quality of leather jackets from a supplier?

To ensure quality when sourcing leather jackets, it is crucial to conduct thorough supplier vetting. Start by requesting samples to assess the leather quality, craftsmanship, and stitching. Look for suppliers who provide transparency regarding their materials, such as the type of leather used and its sourcing. Additionally, check for certifications related to ethical practices and quality assurance. Consider visiting the supplier’s production facility if possible, or leveraging third-party inspection services to validate quality standards before placing larger orders. -

What customization options are available for leather jackets?

Customization options for leather jackets can vary widely among suppliers. Common choices include selecting leather types (e.g., full-grain, top-grain), colors, lining materials, and hardware finishes. Many suppliers also offer personalized embroidery, logos, and unique design elements tailored to your brand’s identity. To maximize your options, inquire about the design process, including how to submit designs or specifications, and whether there are any limitations on custom features based on the jacket style or production capabilities. -

What are the minimum order quantities (MOQs) for custom leather jackets?

Minimum order quantities (MOQs) for custom leather jackets depend on the supplier and the complexity of the customization. Typically, MOQs can range from 50 to 200 units per style, but some suppliers may offer lower MOQs for initial orders or samples. It’s essential to discuss your requirements upfront with potential suppliers to understand their policies and negotiate terms that align with your business needs, especially if you are a smaller retailer or startup. -

What payment terms should I expect when ordering custom jackets?

Payment terms for custom leather jackets can vary widely. Most suppliers require a deposit, typically ranging from 30% to 50% of the total order value, with the balance due before shipment. It’s advisable to clarify payment methods accepted (e.g., wire transfer, credit card, PayPal) and any additional fees for international transactions. Establishing a clear agreement regarding payment terms in the contract can help prevent misunderstandings and ensure a smooth transaction. -

How can I manage logistics and shipping for international orders?

Managing logistics for international orders of custom leather jackets involves understanding shipping options, costs, and delivery timelines. Suppliers may offer different shipping methods, such as air freight for faster delivery or sea freight for cost-effectiveness. It’s important to discuss who will bear the shipping costs and any customs duties or taxes that may apply upon import. Collaborating with a logistics partner experienced in international trade can streamline the process and ensure compliance with local regulations. -

What quality assurance measures should I implement for custom leather jackets?

Implementing quality assurance measures for custom leather jackets involves several steps. First, establish clear quality standards in your contract with the supplier, specifying acceptable material grades, craftsmanship, and finishing details. Consider conducting pre-shipment inspections to verify that products meet your specifications. Additionally, developing a feedback loop with customers post-purchase can help you identify any issues and continuously improve the quality of future orders. -

What are the best practices for communicating with suppliers about customization?

Effective communication with suppliers about customization starts with clarity. Provide detailed specifications and visual references to ensure your vision is understood. Utilize tools like design software or sketches to illustrate your ideas. Regular check-ins during the production process can help address any questions or concerns promptly. Establishing a dedicated point of contact on both sides can facilitate smoother communication and foster a strong working relationship. -

How do trade regulations impact my ability to import custom leather jackets?

Trade regulations can significantly impact the import of custom leather jackets, especially regarding tariffs, duties, and compliance with safety standards. Research the specific regulations for your target market, including any trade agreements that may affect costs. It’s advisable to consult with a customs broker to navigate the complexities of international trade laws and ensure that all necessary documentation is in place to avoid delays or penalties during importation.

Top 6 Leather Jacket Customization Manufacturers & Suppliers List

1. Lusso Leather – Custom Leather Jackets

Domain: lussoleather.com

Registered: 2016 (9 years)

Introduction: Custom Leather Jackets – Design Your Own Leather Jacket

Regular price: $502.00

Sale price: $398.00 (Free Shipping and 30 days for Returns/Alterations)

Available Sizes: XSmall, Small, Medium, Large, Xlarge, XXL, Custom Size, Custom Plus Size

Custom Plus Size Price: $481.00

Customization Options: Select from a variety of fabrics and leathers, custom embroidery, sublimation printing, logos, graphics,…

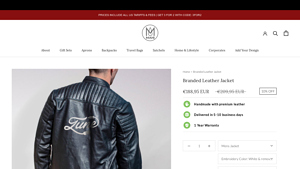

2. Mahileather – Branded Leather Jacket

Domain: mahileather.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “Branded Leather Jacket”, “price”: “$215.46”, “original_price”: “$239.40”, “discount”: “10% OFF”, “material”: “premium leather”, “shipping”: “Free Worldwide Shipping”, “warranty”: “1 Year Warranty”, “return_policy”: “30 day returns”, “availability”: “Delivered to most destinations in 5 business days”, “sizes”: [“Small”, “Medium”, “Large”], “colors”: [“White”, “Grey”, “Black”, “Nav…

3. Aero Leather Clothing – Custom Leather Jackets

Domain: aeroleatherclothing.com

Registered: 1997 (28 years)

Introduction: Custom leather jackets made to order, expertly hand-crafted by Aero Leather Jackets since 1981. Specializing in vintage designs from the 1920s to 1960s, offering over 100 classic coats. Customization options include various leather and lining combinations, stitch color, and more. Known for high-quality craftsmanship and unique personalization. Available for order through the website or by contacti…

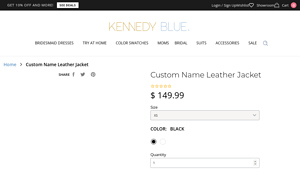

4. Kennedy Blue – Custom Name Leather Jacket

Domain: kennedyblue.com

Registered: 2011 (14 years)

Introduction: {“product_name”: “Custom Name Leather Jacket”, “brand”: “Kennedy Blue”, “price”: “$149.99”, “sizes_available”: [“XS”, “S”, “M”, “L”, “XL”, “2XL”, “3XL”, “4XL”, “5XL”, “6XL”], “colors_available”: [“Black”, “White”], “material”: “Vegan Leather”, “customization_options”: [“Last name”, “Date on collar”, “Words on inner panel”], “shipping_time”: “4-6 weeks”, “return_policy”: “No returns or exchanges on…

5. Travis Austin Customs – Custom Leather Jacket

Domain: travisaustincustoms.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Custom Leather Jacket”, “brand”: “Travis Austin Customs”, “price”: “$1,500.00”, “consultation”: “Includes a one-on-one consultation to assure fit and representation”, “custom_lining”: “Custom lining on the interior of the jacket”, “warranty”: “Lifetime warranty for any repairs or edits”, “availability”: “Sold out”}

6. Reddit – Leather Jacket Customization

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: First-time customization of leather jackets, planning to pick up two secondhand jackets from a charity store. One jacket will be painted as a gift, and the second will be recolored dark red. Recommendations for paints/materials are sought, particularly for detailing and the feasibility of painting a black jacket red. Suggestions include using saddle soap and Fiebings for cleaning, and acrylic leat…

Strategic Sourcing Conclusion and Outlook for leather jacket customization

What Are the Key Takeaways for B2B Buyers in Leather Jacket Customization?

In the competitive landscape of leather jacket customization, strategic sourcing stands as a critical pillar for success. By leveraging high-quality materials from reliable suppliers and maintaining transparent pricing structures, businesses can offer exceptional value to their customers. The bespoke nature of leather jackets allows for unique expressions of individuality, aligning well with current consumer trends emphasizing personalization. Additionally, ethical manufacturing practices not only enhance brand reputation but also resonate with increasingly conscious consumers globally.

How Can International Buyers Benefit from Customized Leather Jackets?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, the opportunity to source customized leather jackets presents a lucrative avenue. By collaborating with manufacturers that prioritize craftsmanship and customer satisfaction, businesses can tap into diverse markets eager for distinctive products.

What Steps Should You Take Moving Forward?

As you consider entering or expanding in the leather jacket customization market, focus on building relationships with suppliers that prioritize quality and sustainability. Engage in discussions to tailor offerings that meet the unique demands of your target demographics. Embrace this opportunity to differentiate your brand and drive growth. The future of leather jacket customization is bright—make your mark today!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.