Catalog

Material Insight: Leather Furniture Companies

B2B Product Guide: Upholstery Leather for Furniture Manufacturers

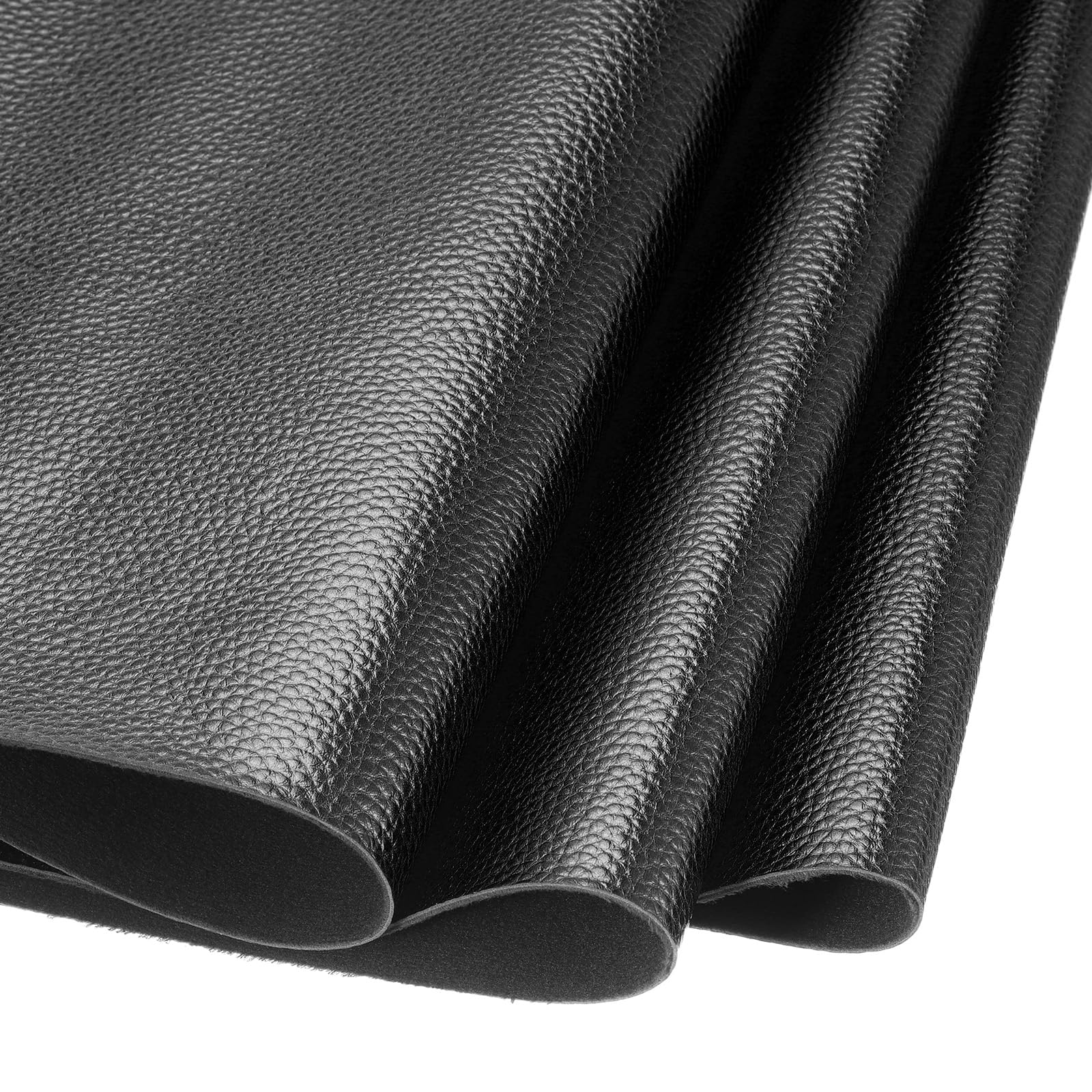

For leather furniture companies, selecting the right material is critical to ensuring product durability, aesthetic appeal, and customer satisfaction. Upholstery leather stands out as the premier choice for high-end furniture production due to its natural beauty, long-term performance, and luxurious tactile experience. Unlike synthetic alternatives, genuine upholstery leather develops a unique patina over time, enhancing its visual character and increasing the perceived value of each furniture piece.

Upholstery leather offers exceptional breathability, making it ideal for seating applications where comfort and temperature regulation are essential. Its natural fibers provide strength and resilience, withstanding daily wear in both residential and commercial environments. Additionally, premium leather is highly customizable in terms of finish, color, and texture, allowing furniture makers to align their designs with evolving market trends and client preferences.

At WINIW, we have been a trusted partner to furniture manufacturers worldwide for over 20 years. Specializing in high-performance upholstery leather, we combine traditional craftsmanship with innovative, eco-conscious production methods. Our leathers are sourced and processed to meet strict environmental and quality standards, ensuring sustainability without compromising on luxury or durability. With a deep understanding of B2B needs, WINIW delivers consistent quality, scalable supply, and technical support tailored to the demands of modern furniture manufacturing.

Technical Performance & Standards

WINIW Synthetic Leather: Technical Advantages for Premium Furniture Manufacturing

WINIW delivers high-performance synthetic leather engineered specifically for the demanding requirements of commercial and residential furniture production. Our solutions prioritize safety, durability, and sustainability without compromising on the luxurious aesthetics and tactile experience end-users expect. Below are the key technical advantages relevant to furniture manufacturers seeking reliable, compliant, and market-differentiating materials.

Core Technical Advantages

- Certified Fire Retardancy (UK & US Standards): WINIW formulations inherently meet stringent flammability regulations critical for public and residential spaces. Our materials pass BS 5852:2015+ Source 5 (UK) for furniture used in contract settings and CAL 117 (US) / CSFM Title 19 for residential and commercial upholstery, ensuring compliance for global markets. Testing is conducted on the complete fabric + foam assembly, not just the surface layer, providing real-world safety assurance and reducing liability risk.

- Superior Easy Clean Performance: Engineered with a dense, non-porous polyurethane surface and advanced topcoat technology, WINIW leather resists deep penetration of common stains (oils, inks, food dyes, cosmetics). Routine maintenance requires only mild soap and water; tougher spills wipe clean effortlessly without留下 residue or discoloration, significantly reducing maintenance costs and extending product lifespan in high-traffic environments.

- Exceptional Soft Touch & Drape: Utilizing proprietary micro-foam backing and surface texturing techniques, WINIW achieves a remarkably soft, supple hand feel comparable to premium PU leathers, yet with enhanced durability. The material offers excellent drape characteristics for complex furniture contours, ensuring a seamless, luxurious appearance on sofas, chairs, and headboards without stiffening or cracking over time.

- Full REACH SVHC Compliance: WINIW proactively monitors and strictly adheres to EU REACH regulations. Our synthetic leather is free from Substances of Very High Concern (SVHC) listed on the REACH Candidate List. Comprehensive chemical documentation (including full material disclosures upon request) ensures your finished furniture meets stringent EU chemical safety requirements for consumer protection.

- ISO 9001 Certified Manufacturing: Every meter of WINIW leather is produced within a rigorously controlled quality management system certified to ISO 9001:2015. This guarantees consistent thickness, color fastness (≥4-5 on Blue Wool Scale), tensile strength, and abrasion resistance batch after batch, minimizing production waste and ensuring predictable performance in your upholstery processes.

Technical Specifications Overview

| Property | WINIW Standard | Test Method Reference | Compliance Target |

|---|---|---|---|

| Fire Retardancy (UK) | Passes BS 5852:2015+ Source 5 | BS 5852:2015 (Cigarette + Match Flame) | UK Furniture & Furnishings (Fire) (Safety) Regulations 1988 |

| Fire Retardancy (US) | Passes CAL 117 / CSFM Title 19 | TB 117-2013 / CA Fire Marshal | California Bureau of Home Furnishings & Thermal Insulation |

| Stain Resistance | >95% Removal of Common Stains | AATCC 174 / ISO 105-E01 | Exceeds Industry Benchmarks |

| Abrasion Resistance | >50,000 cycles (Martindale) | ISO 12947-2 | FAR Exceeds Residential/Commercial Requirements |

| REACH SVHC Status | None detected (>0.1% w/w) | Internal Screening + 3rd Party Lab | Full Compliance with EU REACH Regulation (EC) No 1907/2006 |

| Color Fastness | Grade 4-5 (Light), Grade 4 (Rubbing) | ISO 105-B02, ISO 105-X12 | Meets/Exceeds Furniture Grade Standards |

| Quality Management | ISO 9001:2015 Certified Processes | ISO 9001 Audit | Consistent Batch-to-Batch Quality |

Eco-Conscious Manufacturing Advantage

Beyond compliance, WINIW prioritizes sustainable production. Our processes utilize water-based PU systems, significantly reducing VOC emissions compared to traditional solvent-based methods. This aligns with growing market demand for eco-friendly furniture solutions while maintaining the stringent performance standards required by modern manufacturers.

WINIW synthetic leather provides furniture companies with a technically superior, responsibly manufactured material that directly addresses critical safety, performance, and regulatory challenges. It enables the creation of durable, luxurious, and compliant furniture that meets the highest expectations of discerning commercial and residential clients. Request samples and full technical data sheets to validate performance for your specific applications.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Real Leather in Furniture Manufacturing

In the evolving landscape of furniture production, material selection plays a pivotal role in shaping product performance, sustainability, and market appeal. For B2B manufacturers and suppliers, understanding the key differences between leather furniture companies utilizing real leather and those adopting high-performance synthetic leather—such as WINIW’s advanced solutions—is essential for informed decision-making.

Real leather has long been associated with luxury and durability. However, increasing environmental regulations, cost volatility, and ethical sourcing concerns are prompting a shift toward innovative synthetic alternatives. Modern synthetic leather, engineered with precision, now rivals real leather in aesthetics and tactile quality while offering significant advantages in consistency, customization, and sustainability.

Key considerations for B2B buyers include cost efficiency, long-term durability, and environmental impact. The following comparison evaluates real leather against synthetic leather as used by forward-thinking leather furniture companies.

| Criteria | Real Leather | Synthetic Leather (e.g., WINIW) |

|---|---|---|

| Cost | High (raw material and processing costs fluctuate; premium pricing) | Lower to moderate (stable pricing, scalable production) |

| Durabilité | High tensile strength but prone to cracking, fading, and water damage over time | Excellent resistance to abrasion, UV, and moisture; consistent performance across batches |

| Eco-friendliness | Moderate to low (involves livestock farming, high water/energy use, chemical tanning) | High (reduced carbon footprint, recyclable components, water-based manufacturing options) |

Additional Advantages of Synthetic Leather in B2B Applications:

– – Consistent texture and color across large production runs

– – Greater design flexibility with customizable thickness, finish, and color

– – Reduced lead times and supply chain volatility

– – Compliance with global environmental and animal welfare standards (e.g., REACH, RoHS, cruelty-free)

– – Ideal for urban, contract, and outdoor furniture where maintenance and longevity are critical

WINIW’s synthetic leather solutions are engineered for performance-driven manufacturers seeking sustainable innovation without compromising quality. By partnering with WINIW, furniture companies can meet rising consumer demand for eco-conscious products while optimizing production efficiency and margin control.

For B2B clients, the transition to synthetic leather is not a compromise—it is a strategic upgrade aligned with the future of responsible manufacturing.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands at the forefront of sustainable synthetic leather manufacturing, delivering high-performance materials trusted by leading brands across automotive, furniture, fashion, and technical textiles. Our vertically integrated operations combine scale, innovation, and uncompromising quality to meet the rigorous demands of global supply chains.

Core Manufacturing Capabilities

- 100,000 sqm Advanced Production Facility: One of Asia’s largest dedicated synthetic leather campuses, enabling end-to-end control from resin formulation to finished roll goods. High-capacity production lines ensure scalability for bulk orders while maintaining agility for custom development.

- Vertical Integration Advantage: In-house polymer synthesis, coating, embossing, and finishing processes eliminate third-party dependencies, reducing lead times by 30% and ensuring consistent material integrity.

- Eco-Optimized Infrastructure: Solar-powered production zones, closed-loop water recycling systems, and low-VOC emission protocols minimize environmental impact without sacrificing throughput.

Innovation-Driven R&D Ecosystem

- Dedicated 50+ Specialist Team: Materials scientists, chemical engineers, and application developers collaborate on next-generation solutions, including bio-based PU (up to 40% renewable content) and recycled PET substrates.

- Co-Creation Partnerships: Joint development programs with EU/US research institutes and Tier-1 brands accelerate time-to-market for bespoke textures, performance additives (e.g., antimicrobial, flame-retardant), and circularity-focused innovations.

- Sustainability Lab: Proprietary testing for biodegradability (ASTM D5511), carbon footprint reduction, and recyclability ensures materials align with global ESG mandates.

Uncompromising Quality Assurance Framework

Every meter undergoes 127+ validation checkpoints across production. Our QC protocols exceed international benchmarks:

| Standard | Scope | WINIW Implementation |

|---|---|---|

| ISO 9001:2015 | Quality Management Systems | Real-time IoT monitoring of 200+ process parameters |

| REACH SVHC | Chemical Safety (EU) | Full material disclosure; 0% banned substances |

| OEKO-TEX® STANDARD 100 | Human-ecological Safety | Class I certification (baby-safe) across all product lines |

| ASTM D412/D624 | Physical Durability | 200%+ tensile strength retention after 500hrs UV exposure |

Global Compliance & Market Access

WINIW materials are engineered to navigate complex regulatory landscapes:

– Europe: Full compliance with EU Ecolabel criteria, EN 14372 (chemical safety), and GRS-certified recycled content options.

– USA: Meets CA Prop 65, CPSIA, and stringent VOC limits (≤20g/L) for indoor air quality (GREENGUARD Gold).

– Supply Chain Reliability: 99.2% on-time delivery rate to 47 countries, with dedicated logistics hubs in Rotterdam and Los Angeles ensuring seamless customs clearance.

WINIW transforms sustainability commitments into tangible business value—delivering synthetic leather that performs, protects, and powers progress for forward-thinking brands worldwide. Partner with us to future-proof your material supply chain.

Contact Us for Samples

B2B Product Guide: Premium Microfiber Leather for Furniture Manufacturers

WINIW is a leading global supplier of high-performance, eco-friendly microfiber leather engineered specifically for the furniture industry. Our advanced manufacturing process delivers a sustainable alternative to genuine leather—without compromising on durability, aesthetics, or comfort. Trusted by leading furniture brands, WINIW microfiber leather offers superior consistency, enhanced workability, and long-term cost efficiency.

Designed for B2B partners in the leather furniture sector, our product line supports mass production needs with stable supply chains, customization options, and rigorous quality control. Whether you specialize in luxury sofas, office seating, or modular living systems, WINIW provides the ideal balance of performance and sustainability.

Key Advantages of WINIW Microfiber Leather for Furniture

- Exceptional durability with high tear and abrasion resistance, ideal for daily-use furniture

- Soft, leather-like hand feel with consistent grain and thickness across batches

- Eco-conscious material: free from harmful solvents, heavy metals, and animal byproducts

- Low environmental impact with reduced carbon footprint compared to animal leather

- Excellent color fastness and resistance to fading, staining, and UV exposure

- High breathability and moisture management for enhanced user comfort

- Easy to cut, sew, and upholster—optimized for automated and manual production lines

- Customizable in texture, color, thickness (0.6mm–1.2mm), and roll width (up to 1.4m)

Technical Specifications Overview

| Property | Performance Standard |

|---|---|

| Thickness Range | 0.6 mm – 1.2 mm |

| Width per Roll | Up to 1.4 meters |

| Weight | 280–450 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale test) |

| Color Fastness | Grade 4–5 (light and rub fastness) |

| Cold Crack Resistance | Passes -20°C bend test |

| Environmental Compliance | REACH, RoHS, OEKO-TEX® STANDARD 100 |

All WINIW microfiber leathers are manufactured under ISO 9001 and ISO 14001 certified processes, ensuring consistent quality and responsible production practices.

Why Furniture Brands Choose WINIW

- Reliable large-volume production with short lead times

- Global logistics network for timely delivery

- R&D support for custom development and prototyping

- Competitive pricing with long-term supply stability

- Alignment with ESG and sustainability goals

We invite leather furniture companies seeking premium, scalable, and sustainable upholstery solutions to experience the WINIW difference.

Free samples are available upon request.

Contact our business development team today to discuss your material requirements and receive complimentary swatches for evaluation.

CTA:

For partnerships, technical data sheets, or sample requests:

Courriel MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.