Catalog

Material Insight: Leather Factory Firenze

B2B Product Guide: Premium Synthetic Leather Solutions for the Florence Craftsmanship Market

Florence, Italy, represents the global epicenter of artisanal leather craftsmanship, renowned for its heritage of luxury bags, footwear, and accessories. However, modern luxury brands and manufacturers in this historic region face evolving challenges: stringent EU environmental regulations, volatile raw material costs, ethical sourcing demands, and the need for consistent, high-performance materials that withstand Mediterranean climates. Genuine leather, while traditional, introduces supply chain vulnerabilities and sustainability gaps incompatible with contemporary luxury standards.

Why Faux Leather is the Strategic Choice for Florence Applications

For Florence-based manufacturers targeting discerning global consumers, premium faux leather outperforms genuine leather in critical operational and market-driven areas:

- Climate Resilience: Florence’s humid summers and seasonal rains demand materials with inherent water resistance and mold prevention—features engineered into WINIW’s synthetic hides, unlike untreated genuine leather.

- Color & Texture Consistency: Eliminates costly production delays caused by natural hide variations, ensuring batch-to-batch uniformity essential for luxury brand compliance.

- Ethical & Regulatory Alignment: Meets EU REACH and upcoming Ecodesign for Sustainable Products Regulation (ESPR) requirements without traceability complexities of animal hides.

- Cost Predictability: Shields manufacturers from leather market volatility (e.g., 2023 rawhide price swings exceeding 30%), stabilizing production budgets.

- Design Flexibility: Enables custom textures (e.g., velluto finishes) and vibrant, fade-resistant colors unachievable with traditional tanning.

Introducing WINIW: Your Trusted Synthetic Leather Partner Since 2002

WINIW has empowered B2B manufacturers across Europe’s luxury sector for over 20 years, specializing in eco-engineered synthetic leather that merges Italian aesthetic rigor with uncompromising sustainability. Our Florence-focused solutions are:

- Certified Responsible: OEKO-TEX® STANDARD 100, ISO 14001, and GRS-certified production using 40%+ recycled content.

- Performance-Optimized: Proprietary microfiber technology delivers breathability, tear strength (>35 N), and abrasion resistance (50,000+ Martindale cycles) rivaling top-grain leather.

- Florence-Ready: Formulated for high-humidity environments with anti-microbial treatments and UV-stable pigments.

- B2B Focused: End-to-end collaboration from R&D to bulk production (MOQs from 500m), with dedicated technical support for seamless integration into artisan workflows.

WINIW transcends conventional faux leather—delivering materials that honor Florence’s legacy of excellence while future-proofing production against ecological and economic uncertainties. Our next-generation synthetics empower your botteghe to create heirloom-quality pieces with a conscience.

Proceed to Section 2: WINIW’s Florence-Optimized Product Portfolio & Technical Specifications

Technical Performance & Standards

WINIW B2B Product Guide: Leather Factory Firenze

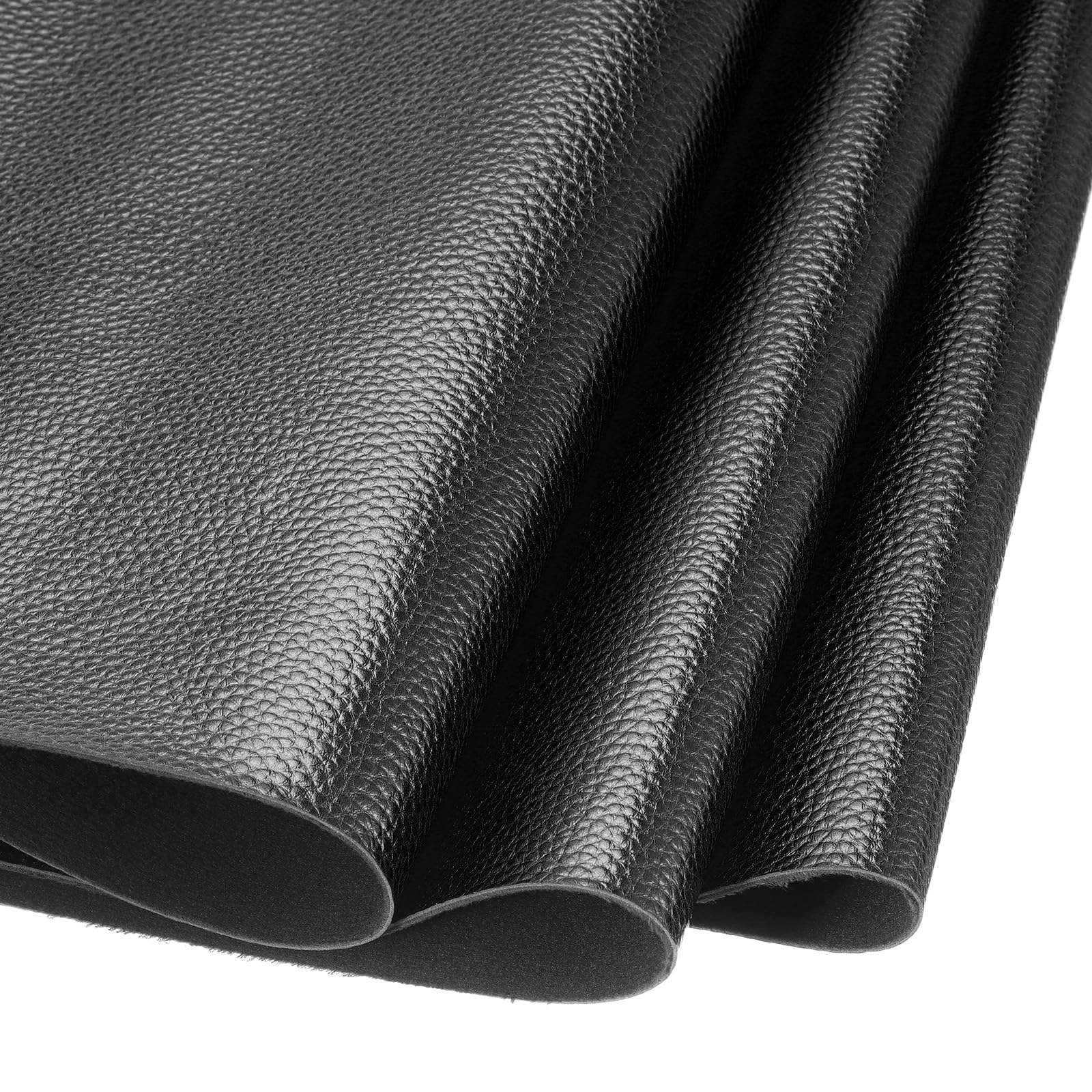

WINIW’s Leather Factory Firenze is a premium synthetic leather solution engineered for industrial and commercial applications across fashion, upholstery, automotive, and accessories sectors. Designed with performance, sustainability, and cost-efficiency in mind, this product line delivers consistent quality without compromising on aesthetics or environmental responsibility.

Built on advanced manufacturing standards, Leather Factory Firenze combines durability with design flexibility, offering businesses a reliable alternative to natural leather. The material is ideal for B2B clients seeking scalable production, reduced lead times, and compliance with international safety and quality benchmarks.

Key Technical Advantages

-

Cost-effective Production: Lower total cost of ownership compared to natural leather due to reduced waste, consistent roll yields, and minimal post-processing requirements. Enables high-volume manufacturing with predictable budgeting.

-

Exceptional Durability: Engineered with high-tensile strength polyurethane and reinforced backing for superior abrasion resistance, tear strength, and dimensional stability. Suitable for high-traffic applications including automotive interiors and contract furniture.

-

Customizable Colors & Finishes: Offers full color-matching capabilities (Pantone, RAL, or custom swatches) and a wide range of textures (suede, grain, smooth, embossed). Supports batch-specific customization without minimum order penalties.

-

REACH Compliance: Fully compliant with EU REACH regulations (EC 1907/2006), ensuring absence of SVHCs (Substances of Very High Concern) and restricted hazardous substances. Safe for consumer and industrial use across European markets.

-

ISO9001-Certified Manufacturing: Produced in facilities audited and certified under ISO9001 quality management standards, guaranteeing consistent product performance, traceability, and process control across all production batches.

Technical Specifications

| Paramètres | Spécifications |

|---|---|

| Base Material | High-performance polyurethane (PU) |

| Backing Fabric | Polyester knitted or woven scrim |

| Thickness Range | 0.6 mm – 1.8 mm (customizable) |

| Width (Roll) | 137 cm, 140 cm, or 150 cm (standard) |

| Weight | 280 – 420 g/m² (depending on thickness) |

| Abrasion Resistance | >50,000 cycles (Martindale, 500g load) |

| Color Fastness (Light) | Grade 6–7 (ISO 105-B02) |

| Color Fastness (Rubbing) | Dry: 4–5, Wet: 3–4 (ISO 105-X12) |

| Tensile Strength | >80 N (warp and weft) |

| Tear Strength | >35 N |

| REACH SVHC Status | Compliant (no substances above threshold) |

| ISO Certification | ISO9001:2015 (manufacturing process) |

| Eco-Profile | Phthalate-free, heavy metal-free, low VOC |

| Customization Lead Time | 7–10 days (color/finish development) |

Leather Factory Firenze supports sustainable supply chains by reducing reliance on animal-derived materials and minimizing environmental impact through low-emission production and recyclable components. WINIW’s commitment to quality and innovation ensures B2B partners receive a scalable, reliable, and future-ready material solution.

Why Choose Synthetic over Real Leather

B2B Material Comparison Guide: Premium Synthetic Leather vs. Genuine Leather

As a leader in sustainable material innovation, WINIW provides this objective comparison to support informed procurement decisions for upholstery, automotive, and luxury goods manufacturing. “Leather Factory Firenze” represents a category of premium, performance-engineered synthetic leather (like WINIW’s collections), distinct from traditional bovine leather.

Key Differentiators for B2B Applications

- Supply Chain Stability: Synthetic leather offers consistent batch-to-batch color, texture, and width, eliminating natural hide variations that disrupt production scheduling and increase waste in genuine leather.

- Design Flexibility: Achieve precise, repeatable aesthetics (e.g., uniform grain, custom colors/metrics) impossible with inherently variable animal hides, accelerating time-to-market for new product lines.

- Ethical & Traceability Compliance: Fully documented, cruelty-free production aligns with evolving ESG mandates and consumer demands, avoiding complex livestock supply chain audits required for certified genuine leather.

- Processing Efficiency: Synthetic materials cut faster with standard tools, require no tanning, and generate less scrap, reducing labor costs and energy use in manufacturing.

Comparative Analysis: Premium Synthetic Leather vs. Genuine Leather

| Criteria | Premium Synthetic Leather (e.g., WINIW Collections) | Genuine Leather (Full-Grain/Bovine) |

|---|---|---|

| Cost (B2B) | – Lower total landed cost (consistent yield, no grading waste) – Predictable pricing unaffected by livestock markets – Reduced processing/tooling expenses |

– Higher base cost (hide scarcity, grading) – Significant waste (25-40% unusable) – Volatile pricing tied to agriculture |

| Durabilité | – Superior abrasion resistance (50,000+ Martindale) – Consistent tensile strength across batches – Resists stains, UV fading, and moisture damage – No risk of cracking or peeling with proper formulation |

– Variable durability (hide quality dependent) – Prone to scratches, water staining, and drying/cracking – Requires ongoing maintenance – Lower UV resistance (fades over time) |

| Eco-Friendliness | – WINIW Standard: OEKO-TEX® certified, PVC-free, >30% bio-based content options – Zero hazardous waste (water-based PU) – 70% lower carbon footprint vs. tanned leather (Higg Index) – Fully recyclable at end-of-life |

– Resource-intensive (15,000L water/hide, high CO2) – Toxic tanning chemicals (chromium) – Significant landfill waste (trimmings) – Limited recyclability |

Strategic Recommendation for Manufacturers

Premium synthetic leather delivers superior cost control, performance reliability, and verifiable sustainability for volume-driven B2B applications. While genuine leather retains heritage appeal for niche luxury segments, WINIW’s engineered alternatives meet rigorous technical specifications while future-proofing supply chains against ethical, environmental, and volatility risks. For projects demanding consistency, scalability, and ESG compliance, synthetic leather is the strategic material of choice.

WINIW collaborates with partners to tailor specifications (thickness, weight, abrasion resistance) for automotive seating, contract furniture, and fashion accessories—ensuring optimal performance without compromise. Request our technical datasheets for ISO-tested performance metrics.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, operating from a state-of-the-art production facility spanning 100,000 square meters. Our large-scale factory integrates advanced manufacturing technologies with sustainable practices, enabling us to deliver consistent quality and high-volume output to meet global B2B demands.

Our competitive advantage lies in our vertically integrated production system, which allows precise control over every stage—from raw material selection to final product packaging. This integration is supported by a dedicated R&D team comprising material scientists and technical specialists who continuously innovate to enhance product functionality, durability, and environmental sustainability.

Key Factory Strengths:

– 100,000 sqm manufacturing facility equipped with automated production lines for efficiency and precision

– In-house R&D team focused on developing eco-friendly materials, including water-based and recycled content leathers

– Strict quality control (QC) protocols implemented at every production stage, ensuring compliance with international standards such as REACH, RoHS, and ASTM

– Capacity for customized development and rapid prototyping to meet specific client requirements

– Environmentally responsible operations with reduced emissions and waste through advanced filtration and recycling systems

WINIW products are trusted by international clients across Europe and the USA, where demand for sustainable, high-quality synthetic leather is growing. Our global export network ensures reliable logistics and on-time delivery, backed by rigorous documentation and certification support for seamless customs clearance.

We are committed to advancing sustainable materials without compromising performance—making WINIW a preferred B2B partner in the global synthetic leather market.

Contact Us for Samples

WINIW Premium Synthetic Leather: Sustainable Performance for Luxury Manufacturing

WINIW delivers globally certified eco-friendly microfiber leather engineered for high-end furniture, automotive, and fashion applications. Our closed-loop production process achieves ISO 14001 certification with 30% lower carbon footprint versus conventional synthetics, meeting stringent EU Ecolabel and OEKO-TEX® standards. Partner with us to future-proof your supply chain while exceeding consumer sustainability expectations.

Core Product Advantages

- Resource Efficiency: 60% less water consumption and zero heavy metal discharge in production

- Performance Parity: Tensile strength (25-35 N/mm²) and abrasion resistance (50,000+ cycles) matching top-grain leather

- Traceability: Blockchain-enabled material journey from recycled PET bottles to finished roll

- Customization: 1,200+ color/matte/gloss finish options with 2-week lead time for samples

Key Product Lines for Luxury Applications

| Product Series | Composition | Primary Applications | Key Eco-Features |

|---|---|---|---|

| WINIW ECO LUXE™ | 40% recycled PET + plant-based PU | High-end automotive seating | GRS-certified, 100% solvent-free coating |

| WINIW AURA™ | 30% bio-based PU + recycled fibers | Designer handbags & footwear | Cradle to Cradle™ Silver certified |

| WINIW FLAMEGUARD® | Inherently fire-retardant fibers | Aviation/contract furniture | Meets FAR 25.853, no halogen additives |

Why Global Luxury Manufacturers Choose WINIW

- Regulatory Assurance: Compliant with REACH, CA Proposition 65, and EU Circular Economy Action Plan

- Waste Reduction: 95% production scrap recycled into new material batches

- Durabilité: 5-year warranty against delamination and color fading under ISO 105-B02 testing

- Technical Partnership: Dedicated engineering support for custom substrate development

Join Leather Factory Firenze and other leading European ateliers who reduced material waste by 22% while achieving carbon-neutral certification using WINIW FLAMEGUARD® for their certified fire-resistant collections.

Request Technical Specifications & Free Samples

Contact WINIW’s B2B Solutions Team:

MKT88@MicrofiberLeather.com

Specify “Leather Factory Firenze Reference” for priority sample processing. Free 30cm x 30cm samples available for qualified manufacturers.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.