Introduction: Navigating the Global Market for leather fabric store

In today’s competitive landscape, sourcing high-quality leather fabric is a critical challenge for international B2B buyers. From Africa to South America, the Middle East, and Europe, businesses must navigate a complex market characterized by diverse suppliers, varying quality standards, and fluctuating prices. This guide on leather fabric stores offers an in-depth exploration of the myriad options available, empowering buyers to make informed decisions.

We will delve into the different types of leather, including vegetable-tanned and chrome-tanned options, and discuss their applications across various industries such as fashion, automotive, and furniture. Additionally, this guide provides practical insights into supplier vetting processes, ensuring that you select partners who meet your quality and ethical standards. Cost considerations, such as bulk purchasing discounts and shipping logistics, will also be examined to help you maximize your investment.

By the end of this guide, B2B buyers from regions like Vietnam and Nigeria will be equipped with the knowledge and tools needed to confidently navigate the global leather market. Whether you’re looking to create bespoke products or stock your inventory, understanding these key elements will enable you to forge successful partnerships and drive your business forward.

Table Of Contents

- Top 6 Leather Fabric Store Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather fabric store

- Understanding leather fabric store Types and Variations

- Key Industrial Applications of leather fabric store

- 3 Common User Pain Points for ‘leather fabric store’ & Their Solutions

- Strategic Material Selection Guide for leather fabric store

- In-depth Look: Manufacturing Processes and Quality Assurance for leather fabric store

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather fabric store’

- Comprehensive Cost and Pricing Analysis for leather fabric store Sourcing

- Alternatives Analysis: Comparing leather fabric store With Other Solutions

- Essential Technical Properties and Trade Terminology for leather fabric store

- Navigating Market Dynamics and Sourcing Trends in the leather fabric store Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather fabric store

- Strategic Sourcing Conclusion and Outlook for leather fabric store

- Important Disclaimer & Terms of Use

Understanding leather fabric store Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vegetable-Tanned Leather | Eco-friendly, retains natural characteristics, ages well | Footwear, belts, bags, and craft projects | Pros: Sustainable, develops a unique patina. Cons: Longer tanning process, may be more expensive. |

| Chrome-Tanned Leather | Soft, flexible, often more affordable, available in various colors | Apparel, upholstery, and accessories | Pros: Quick production, wide color range. Cons: Environmental concerns, less durable than veg-tanned. |

| Suede | Soft, napped finish, typically lighter weight | Fashion accessories, garments, and upholstery | Pros: Luxurious feel, good for fashion items. Cons: Less durable, requires careful maintenance. |

| Nubuck | Sanded grain, soft texture, durable | High-end footwear, luxury goods | Pros: Durable, elegant appearance. Cons: Stains easily, requires special care. |

| Exotic Leather | Unique textures and patterns, often sourced from reptiles | High-end fashion, luxury goods, and accessories | Pros: Distinctive look, premium quality. Cons: High cost, ethical sourcing concerns. |

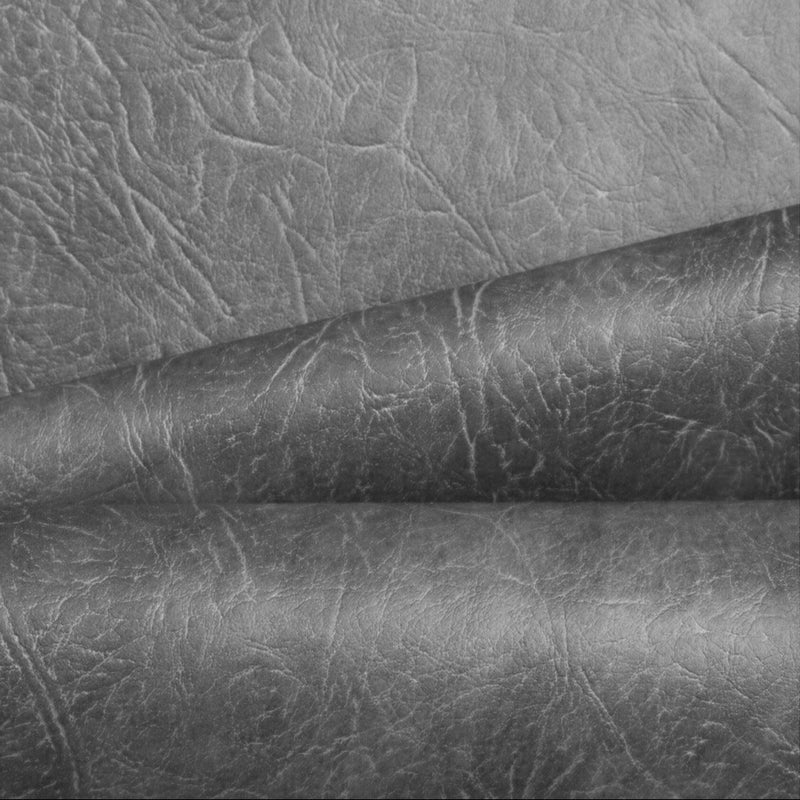

What Are the Key Characteristics of Vegetable-Tanned Leather?

Vegetable-tanned leather is known for its eco-friendly tanning process, using natural tannins from plant sources. This type of leather retains its natural characteristics, resulting in a product that ages beautifully and develops a unique patina over time. It is particularly suitable for items that require durability and a classic aesthetic, such as footwear, belts, and bags. B2B buyers should consider the longer tanning process and potentially higher costs, but the sustainability aspect and long-lasting quality can justify the investment.

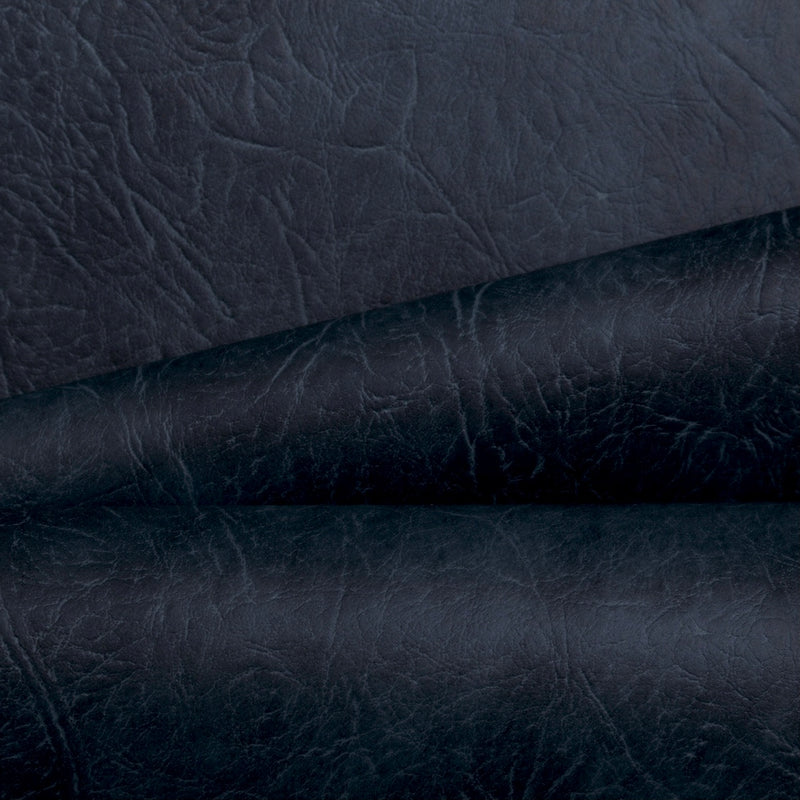

How Does Chrome-Tanned Leather Differ from Other Types?

Chrome-tanned leather is recognized for its softness, flexibility, and vibrant color options, making it a popular choice in various industries. This type of leather is produced through a quicker tanning process that allows for a broader range of colors and textures. It is commonly used in apparel, upholstery, and accessories. B2B buyers should weigh the affordability and quick turnaround against environmental concerns and potential durability issues, as chrome-tanned leather may not age as gracefully as its vegetable-tanned counterpart.

What Makes Suede an Attractive Option for Fashion Applications?

Suede is characterized by its soft, napped finish, providing a luxurious texture that is highly sought after in fashion accessories and garments. It is lighter in weight compared to other leather types, making it ideal for clothing and delicate items. However, B2B buyers need to be cautious about its durability and maintenance requirements, as suede can be prone to stains and wear. The aesthetic appeal of suede can elevate product lines, but careful consideration of care and longevity is essential.

Illustrative image related to leather fabric store

Why Choose Nubuck for High-End Products?

Nubuck leather features a sanded grain that gives it a soft texture and luxurious appearance, making it a favored choice for high-end footwear and luxury goods. Its durability and elegant finish make it suitable for products that demand both style and strength. However, buyers should be aware that nubuck can stain easily and requires special care to maintain its appearance. The balance between its premium qualities and maintenance needs is a crucial consideration for B2B buyers.

What Are the Pros and Cons of Exotic Leather?

Exotic leather, sourced from animals like reptiles, offers unique textures and patterns that can significantly enhance luxury goods. Its premium quality and distinctive look make it a desirable choice for high-end fashion and accessories. However, B2B buyers must consider the high costs associated with exotic leathers and the ethical sourcing concerns that can arise. While the allure of exclusivity and superior craftsmanship can drive demand, responsible purchasing practices are essential in this market.

Key Industrial Applications of leather fabric store

| Industry/Sector | Specific Application of leather fabric store | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Apparel | Manufacturing of leather garments and accessories | High-quality, durable products that enhance brand image | Sourcing sustainable leather, ensuring quality control |

| Footwear | Production of leather shoes and boots | Superior comfort and longevity, appealing to consumers | Weight, flexibility, and wear resistance of leather |

| Furniture & Interiors | Upholstery for leather furniture and decor items | Aesthetic appeal and durability in high-traffic areas | Color, texture, and fire-retardant certifications |

| Automotive | Interior leather for vehicles | Enhances luxury and comfort, increases resale value | Compliance with safety standards and durability tests |

| Craft & DIY | Supplies for leather crafting projects | Encourages creativity and customization for small businesses | Variety of hides, patterns, and tools for crafting |

How is Leather Fabric Store Utilized in the Apparel Industry?

In the apparel industry, leather fabric stores supply high-quality hides used for creating garments such as jackets, skirts, and pants. The durability and unique aesthetic of leather enhance the brand image, making products more appealing to consumers. International B2B buyers, particularly from regions like Africa and South America, require sustainable sourcing options and consistent quality control to meet local market demands. This ensures that the final products not only meet fashion trends but also align with ethical standards.

Illustrative image related to leather fabric store

What Role Does Leather Fabric Store Play in Footwear Production?

Leather fabric stores are crucial for the footwear industry, providing various types of leather suitable for shoes and boots. The materials sourced must offer a balance of weight, flexibility, and wear resistance to ensure comfort and longevity. B2B buyers, especially from Europe and the Middle East, must consider the specific characteristics of the leather, such as breathability and moisture resistance, to cater to diverse climate conditions and consumer preferences.

How is Leather Fabric Used in Furniture and Interior Design?

In the furniture and interiors sector, leather fabric stores supply upholstery materials for sofas, chairs, and decorative items. The aesthetic appeal and durability of leather make it a preferred choice for high-traffic areas, enhancing the overall design of spaces. Buyers from regions like Africa and Europe should focus on sourcing leathers that meet fire-retardant certifications and are available in various textures and colors to match different interior styles.

Why is Leather Essential for Automotive Interiors?

The automotive industry relies on leather fabric stores for high-quality interior materials that enhance the luxury and comfort of vehicles. Leather interiors not only improve the driving experience but also increase the vehicle’s resale value. B2B buyers must ensure that the sourced leather complies with safety standards and undergoes durability tests to withstand wear and tear, especially in varying climates, making it essential for international transactions.

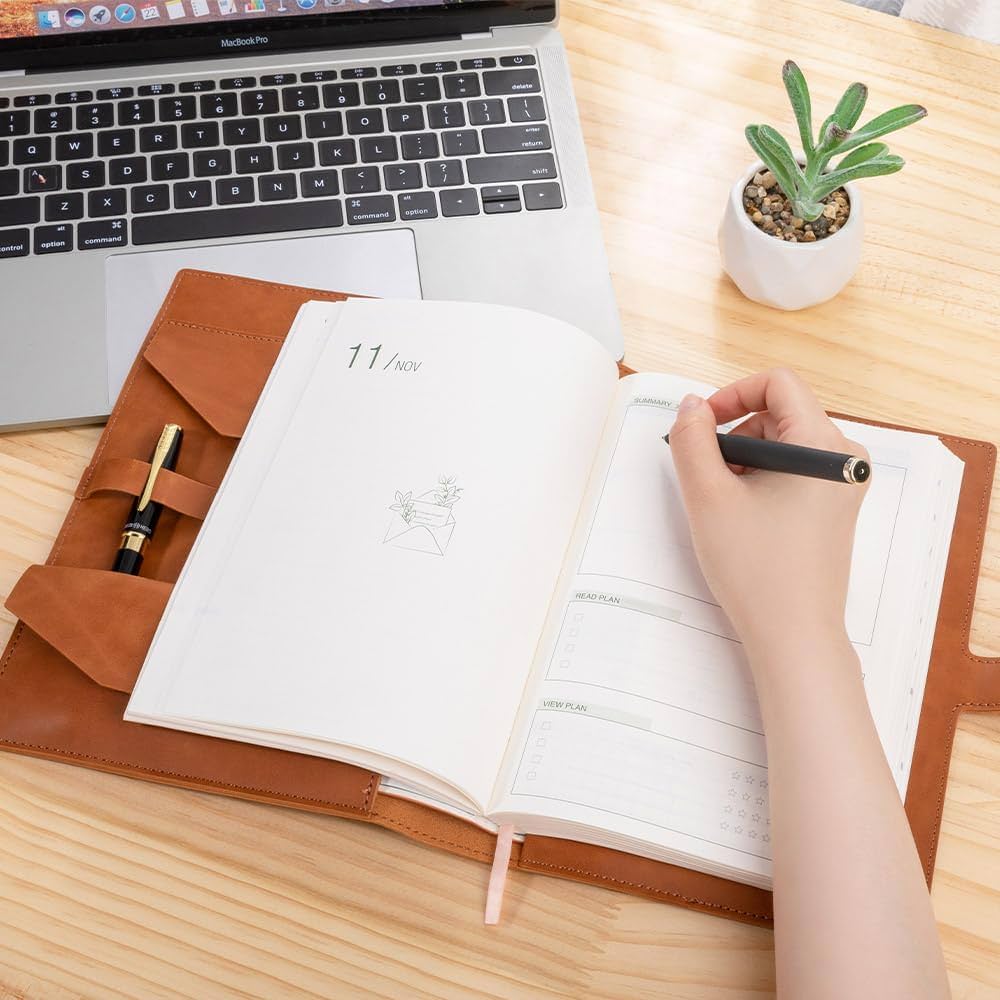

How Can Leather Fabric Stores Support Craft and DIY Projects?

Leather fabric stores play a significant role in the craft and DIY sector by providing a wide range of hides, patterns, and crafting tools. This availability encourages creativity and customization among small businesses and individual artisans. Buyers, particularly from emerging markets, should look for suppliers that offer diverse materials and educational resources to support their crafting endeavors, ensuring they can create unique, market-ready products.

3 Common User Pain Points for ‘leather fabric store’ & Their Solutions

Scenario 1: Navigating Quality Variability in Leather Supplies

The Problem: B2B buyers often face the challenge of inconsistent quality in leather supplies. Different suppliers may have varying standards, leading to discrepancies in texture, color, and durability. This variability can result in production delays, increased costs, and dissatisfied customers, particularly for manufacturers who rely on leather for high-end products. For example, a buyer may receive a shipment that does not meet the expected quality, forcing them to either reject the batch or incur additional expenses to source replacement materials quickly.

The Solution: To mitigate the risks associated with quality variability, buyers should prioritize establishing long-term relationships with reputable leather fabric stores known for their consistent standards. It’s beneficial to request samples before making bulk purchases to assess the quality firsthand. Additionally, implementing a comprehensive quality control process upon receipt of leather shipments can help identify issues early. Buyers should also engage in open communication with suppliers, discussing quality expectations and any previous challenges. By setting clear quality criteria and maintaining regular feedback loops, buyers can improve their sourcing strategy, ensuring they receive reliable materials that meet their production needs.

Scenario 2: Understanding Different Leather Types for Specific Applications

The Problem: Many B2B buyers lack a comprehensive understanding of the various types of leather available and their specific applications. This knowledge gap can lead to inappropriate material choices for projects, resulting in product failures or costly reworks. For instance, a manufacturer might select a heavy-duty leather for a product that requires flexibility, leading to an unsatisfactory final product that could damage their brand reputation.

The Solution: To overcome this challenge, buyers should invest time in educating themselves about the different leather types, including their properties and best uses. Engaging with suppliers that offer educational resources, such as guides or workshops on leather selection, can be invaluable. When sourcing leather, buyers should consider their project’s specific requirements—such as durability, texture, and appearance—and ask suppliers for recommendations based on these criteria. Furthermore, leveraging online resources or attending industry trade shows can provide insights into the latest leather innovations and applications. By enhancing their understanding of leather types, buyers can make informed decisions that align with their product specifications.

Scenario 3: Managing Supply Chain Disruptions in Leather Procurement

The Problem: Global supply chain disruptions can significantly impact the availability and cost of leather supplies, particularly for buyers in regions with limited local sourcing options. Political instability, environmental factors, and transportation challenges can lead to delays in delivery, increased prices, and even stock shortages. For example, a buyer expecting a timely shipment may find themselves scrambling to meet production deadlines due to unforeseen delays.

Illustrative image related to leather fabric store

The Solution: To navigate supply chain disruptions, buyers should adopt a proactive approach to procurement. Diversifying the supplier base by sourcing from multiple regions or countries can reduce dependency on a single supplier and minimize risks associated with localized disruptions. Establishing a robust inventory management system that anticipates demand fluctuations can help maintain adequate stock levels during supply shortages. Additionally, buyers should foster strong relationships with suppliers, enabling them to receive timely updates on potential issues and alternative solutions. Engaging in strategic planning, such as placing orders well in advance and considering bulk purchases during stable periods, can also help mitigate the impacts of supply chain uncertainties. By implementing these strategies, buyers can enhance their resilience against disruptions in the leather supply chain.

Strategic Material Selection Guide for leather fabric store

What Are the Key Properties of Common Leather Materials?

When selecting leather materials for a B2B leather fabric store, understanding the specific properties of various types of leather is crucial. Here, we analyze four common leather materials: Vegetable-Tanned Leather, Chrome-Tanned Leather, Suede, and Nubuck. Each material has unique characteristics that affect its performance, durability, and suitability for different applications.

How Does Vegetable-Tanned Leather Perform?

Vegetable-tanned leather is known for its eco-friendly tanning process, using natural tannins from plant sources. This type of leather is highly durable and develops a rich patina over time, making it ideal for high-quality goods such as belts, wallets, and bags. Its key properties include excellent breathability and the ability to hold dyes well, which enhances its aesthetic appeal.

Pros: It is biodegradable, offers a unique finish with age, and is generally more resistant to heat.

Cons: The tanning process can be time-consuming and costly, leading to higher prices. It may also be less resistant to water compared to other types of leather.

Illustrative image related to leather fabric store

For international buyers, particularly from regions like Africa and South America, compliance with environmental regulations is critical. Buyers should ensure that their suppliers adhere to local and international standards such as ASTM for material safety.

What Are the Benefits of Chrome-Tanned Leather?

Chrome-tanned leather is processed using chromium salts, resulting in a softer and more pliable product. This leather is often used in the automotive and fashion industries due to its versatility and resistance to water and heat.

Pros: It offers a wide range of colors and finishes, is less expensive than vegetable-tanned leather, and has a shorter production time.

Cons: The tanning process can be harmful to the environment if not managed properly, and it may not develop the same desirable patina as vegetable-tanned leather.

International buyers should consider the environmental impact of chrome tanning, particularly in regions with strict regulations. Compliance with local standards, such as those set by the European Union, is essential for market acceptance.

What Makes Suede a Popular Choice?

Suede is a type of leather made from the underside of animal hides, providing a soft and luxurious texture. It is often used in clothing, upholstery, and accessories, appealing to consumers looking for comfort and style.

Pros: Suede is lightweight, offers excellent flexibility, and is available in various colors.

Cons: It is less durable than other leather types and can be more susceptible to stains and water damage.

For B2B buyers in the Middle East and Europe, understanding the end-use application is vital. Suede may require additional treatments for durability in harsh climates, and buyers should ensure they source from reputable suppliers who provide quality assurance.

Why Choose Nubuck Leather?

Nubuck is similar to suede but is made from the outer side of the hide, giving it a more durable finish. It has a velvety texture and is often used in high-end products like shoes and handbags.

Illustrative image related to leather fabric store

Pros: Nubuck is more durable than suede, offers a luxurious feel, and can be treated for water resistance.

Cons: It is prone to staining and requires special care to maintain its appearance.

International buyers should be aware of the maintenance requirements for nubuck, especially in humid climates. Ensuring that products come with care instructions can enhance customer satisfaction and reduce returns.

Summary Table of Leather Materials

| Material | Typical Use Case for leather fabric store | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Belts, wallets, bags | Eco-friendly, develops unique patina | Higher cost, less water-resistant | High |

| Chrome-Tanned Leather | Automotive interiors, fashion accessories | Versatile, wide range of colors | Environmental concerns, less desirable patina | Medium |

| Suede | Clothing, upholstery | Soft, luxurious texture | Less durable, susceptible to stains | Medium |

| Nubuck | High-end shoes, handbags | Durable, luxurious feel | Prone to staining, requires special care | Medium |

This guide provides a comprehensive overview of the strategic material selection process for leather fabric stores, helping B2B buyers make informed decisions based on their specific needs and the unique characteristics of each leather type.

In-depth Look: Manufacturing Processes and Quality Assurance for leather fabric store

What Are the Main Stages of the Leather Manufacturing Process?

The manufacturing process for leather involves several key stages that transform raw hides into finished leather suitable for various applications. Understanding these stages is essential for B2B buyers to ensure they are sourcing high-quality products.

Material Preparation: How Are Raw Hides Processed?

The first stage in leather manufacturing is material preparation, which includes sourcing and selecting raw hides. Quality control begins here, as the condition of the hides can significantly influence the final product. Hides are typically inspected for defects such as scars, brands, or any other imperfections.

After selection, the hides undergo a process known as curing, which preserves them and prevents decomposition. Common curing methods include salting, drying, or using chemicals. This stage is critical as it sets the foundation for the quality of the leather.

Forming: What Techniques Are Used to Shape Leather?

Once the hides are prepared, the next stage is forming. This involves soaking the hides to remove salt and other impurities, followed by liming, which loosens the hair and prepares the hide for tanning. The tanning process is where the transformation occurs, making the hides durable and resistant to decomposition.

Various tanning methods can be employed, including vegetable tanning, chrome tanning, and synthetic tanning. Each method affects the leather’s properties, such as flexibility, color, and texture. B2B buyers should inquire about the tanning processes used by suppliers, as these will impact the end product’s quality and usability.

Assembly: How Is Leather Constructed into Final Products?

In the assembly stage, tanned leather is cut into various shapes and sizes according to product specifications. This can involve techniques such as die-cutting or hand-cutting, depending on the complexity of the design.

Illustrative image related to leather fabric store

After cutting, leather pieces are stitched or bonded together to form the final product. Quality control during this stage is crucial to ensure that seams are secure and that the product meets design specifications. Buyers should verify the assembly techniques used by their suppliers, as these directly affect durability and aesthetics.

Finishing: What Processes Enhance the Leather’s Appearance and Durability?

The final stage in leather manufacturing is finishing, which enhances both the appearance and durability of the leather. This may include processes such as dyeing, coating, and polishing. Finishing techniques can vary widely, from aniline dyeing that allows the natural grain to show through to more opaque finishes that provide additional protection.

Quality control in the finishing stage often involves visual inspections and testing for color consistency, texture, and resistance to wear and tear. B2B buyers should ensure that their suppliers adhere to industry standards for finishing to guarantee the longevity and appeal of the leather products.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is vital in the leather industry, ensuring that products meet both regulatory and customer expectations. International standards such as ISO 9001 provide a framework for quality management systems, promoting consistency and continuous improvement.

How Do International Standards Impact Leather Quality?

ISO 9001 focuses on customer satisfaction and the quality of processes, making it a relevant standard for leather manufacturers. Compliance with this standard can assure buyers that the supplier has established processes for quality control and continuous improvement.

In addition to ISO certifications, industry-specific standards such as CE marking for safety and environmental compliance may also apply. B2B buyers should familiarize themselves with these standards to ensure that their suppliers are compliant, which can affect marketability and legal compliance.

What Are the Key Quality Control Checkpoints in Leather Manufacturing?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the leather manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials as they arrive at the facility. It ensures that only high-quality hides are used for production.

-

In-Process Quality Control (IPQC): This checkpoint occurs during the manufacturing stages, monitoring processes such as tanning and finishing to catch any defects early.

-

Final Quality Control (FQC): This stage involves a thorough inspection of the finished products to ensure they meet all specifications before shipment.

These checkpoints help mitigate risks and ensure that products meet the quality standards expected by B2B buyers.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must adopt a proactive approach to verify their suppliers’ quality control practices. Here are some effective strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. This can be done through on-site visits or third-party audits.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers assess their adherence to standards. These reports should include data on defect rates, compliance with industry standards, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. This is particularly important for international buyers, as it helps bridge the gap in trust and transparency.

What Are the Quality Control Nuances for International Buyers?

B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control.

Illustrative image related to leather fabric store

-

Cultural and Regulatory Differences: Different regions may have varying standards and expectations for leather products. Buyers should understand local regulations and cultural preferences to ensure compliance and acceptance in their target markets.

-

Communication Challenges: Language barriers and differing business practices can complicate quality assurance processes. Establishing clear communication channels and expectations with suppliers is crucial for successful collaboration.

-

Logistical Considerations: International shipping can introduce additional challenges, such as delays or damage during transport. Buyers should work with suppliers to implement quality checks at various stages of the supply chain to mitigate these risks.

By understanding the manufacturing processes and quality assurance practices in the leather industry, B2B buyers can make informed decisions that lead to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather fabric store’

In the competitive landscape of leather fabric procurement, establishing a systematic approach is essential for success. This guide serves as a comprehensive checklist for B2B buyers looking to source from leather fabric stores, ensuring that you make informed and strategic decisions throughout the process.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline your technical requirements. This includes the type of leather (e.g., vegetable-tanned, chrome-tanned), thickness, weight, and color preferences. Understanding these specifications will streamline your search, allowing you to find suppliers that meet your exact needs.

- Consider the application: Different projects may require specific leather characteristics, such as durability for upholstery or softness for garments.

- Identify industry standards: Familiarize yourself with relevant standards in your market to ensure compliance and quality assurance.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for companies with a solid track record in the leather industry, particularly those that cater to your region, such as Africa, South America, the Middle East, and Europe.

Illustrative image related to leather fabric store

- Utilize online directories: Platforms like Alibaba, ThomasNet, or industry-specific directories can provide a wealth of options.

- Read reviews and testimonials: Assess feedback from other buyers to gauge supplier reliability and product quality.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess the necessary certifications and comply with industry regulations. Certifications such as ISO 9001 or environmental standards indicate a commitment to quality and sustainability.

- Request documentation: Ask for copies of certifications and any compliance reports.

- Inspect manufacturing processes: Understanding how leather is sourced and processed can reveal insights into product quality.

Step 4: Request Samples for Evaluation

Always request samples before placing a bulk order. Evaluating physical samples helps you assess the quality, texture, and color of the leather firsthand.

- Specify your requirements: Ensure samples represent the exact specifications you need for your projects.

- Conduct quality tests: Consider conducting tests for durability, flexibility, and colorfastness to ensure they meet your standards.

Step 5: Negotiate Terms and Pricing

Engage in negotiations with your shortlisted suppliers to discuss pricing, minimum order quantities, lead times, and payment terms. A transparent negotiation process can lead to better deals and long-term partnerships.

- Be clear about your budget: Communicate your financial constraints early to avoid misunderstandings later.

- Consider bulk discounts: Many suppliers offer tiered pricing, so inquire about discounts for larger orders.

Step 6: Establish Clear Communication Channels

Effective communication is vital in any business relationship. Ensure that you establish clear channels for ongoing communication with your suppliers.

- Set expectations: Discuss preferred methods of communication and response times.

- Maintain regular updates: Regular check-ins can help address any issues quickly and keep the project on track.

Step 7: Plan for Logistics and Shipping

Finally, consider the logistics of shipping and delivery. Collaborate with your supplier to determine the best shipping methods and ensure timely delivery.

Illustrative image related to leather fabric store

- Evaluate shipping options: Look for suppliers that offer various shipping solutions, including express and standard options.

- Understand import regulations: Familiarize yourself with the import regulations in your country to avoid potential delays and additional costs.

By following this checklist, B2B buyers can navigate the complexities of sourcing leather effectively, ensuring that they find the right suppliers to meet their specific needs and contribute to successful project outcomes.

Comprehensive Cost and Pricing Analysis for leather fabric store Sourcing

Understanding the cost structure and pricing dynamics of sourcing leather fabrics is crucial for B2B buyers aiming to maximize value while minimizing expenses. This analysis delves into the various cost components involved, the key influencers on pricing, and essential tips for buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Leather Fabric Sourcing?

1. Materials:

The primary cost driver in leather sourcing is the raw materials. The type of leather—such as vegetable-tanned, chrome-tanned, or suede—significantly affects pricing. Leather quality and characteristics, such as weight and finish, also play a crucial role. For instance, premium Italian leather often commands higher prices due to its superior quality and craftsmanship.

2. Labor:

Labor costs vary based on the region and skill level required for leather processing. Countries with lower labor costs may offer more competitive pricing, but quality may be compromised. It’s essential to assess the balance between labor cost and the quality of craftsmanship.

Illustrative image related to leather fabric store

3. Manufacturing Overhead:

This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can lower overhead costs, which can be passed on to the buyer in the form of reduced prices.

4. Tooling Costs:

Investment in specialized tools and machinery for leather production can affect pricing. Suppliers with advanced equipment may offer better quality and consistency, but this can also reflect in higher costs.

5. Quality Control (QC):

Robust QC processes ensure that the leather meets the required specifications and standards. While this adds to the overall cost, it is a necessary investment to avoid defects and returns, which can be more costly in the long run.

Illustrative image related to leather fabric store

6. Logistics:

Shipping and handling costs are critical, especially for international buyers. Factors such as distance, shipping mode, and customs duties influence these costs. Understanding Incoterms is vital for clarifying who bears these costs at various stages of the shipping process.

7. Margin:

Suppliers typically add a profit margin to cover their risks and operational costs. This margin can vary widely based on market demand, supplier reputation, and the exclusivity of the leather being offered.

What Influences the Pricing of Leather Fabrics?

1. Volume and Minimum Order Quantity (MOQ):

Prices often decrease with larger orders. Suppliers may offer tiered pricing based on the quantity purchased, incentivizing bulk purchases.

2. Specifications and Customization:

Customized products or specific leather specifications can lead to higher costs. Buyers should weigh the need for customization against potential price increases.

Illustrative image related to leather fabric store

3. Quality Certifications:

Leather that meets specific quality certifications or environmental standards may come at a premium. Buyers should evaluate whether these certifications are necessary for their market.

4. Supplier Factors:

The reputation and reliability of suppliers can influence pricing. Established suppliers with a proven track record may charge more but offer better quality assurance and service.

What Are the Best Negotiation Tips for B2B Leather Buyers?

1. Leverage Volume Discounts:

Negotiate based on the quantity you plan to order. Suppliers are often willing to reduce prices for bulk purchases, making it beneficial to consolidate orders.

Illustrative image related to leather fabric store

2. Consider Total Cost of Ownership (TCO):

When assessing costs, consider not only the purchase price but also shipping, handling, and potential returns. A lower upfront price may not always equate to lower total costs.

3. Understand Pricing Nuances for International Transactions:

Buyers from regions like Africa and South America should be aware of exchange rates, import tariffs, and local regulations that could impact overall costs. Being informed can enhance negotiation leverage.

4. Build Relationships:

Developing strong relationships with suppliers can lead to better pricing and terms. Trust can encourage suppliers to offer better deals or prioritize your orders.

Conclusion

While indicative prices can provide a baseline, variations in costs due to quality, specifications, and supplier factors necessitate careful analysis. By understanding the cost structure and leveraging negotiation strategies, B2B buyers can make informed decisions that align with their business needs and budget constraints.

Alternatives Analysis: Comparing leather fabric store With Other Solutions

In the competitive landscape of leather procurement, B2B buyers often explore various options to meet their needs. While a leather fabric store provides a dedicated platform for sourcing leather materials, several alternative solutions can also fulfill similar requirements. This analysis compares ‘leather fabric store’ with two viable alternatives: direct sourcing from tanneries and online marketplaces specializing in leather products.

| Comparison Aspect | Leather Fabric Store | Direct Sourcing from Tanneries | Online Marketplaces |

|---|---|---|---|

| Performance | High-quality, specialized selection | Custom orders, specific needs met | Varied quality, depends on seller |

| Cost | Moderate to high pricing, often transparent | Potentially lower costs, bulk discounts available | Often competitive, but hidden fees can apply |

| Ease of Implementation | Simple ordering process, user-friendly interface | More complex, requires negotiation and relationship building | Easy to navigate, but quality can vary |

| Maintenance | Regular stock updates, reliable supply chain | Requires ongoing relationship management | Minimal maintenance, but quality assurance needed |

| Best Use Case | Small to medium projects needing specific leathers | Large-scale projects with custom specifications | Diverse projects, quick procurement needs |

What Are the Advantages and Disadvantages of Direct Sourcing from Tanneries?

Direct sourcing from tanneries can provide significant advantages, particularly for businesses seeking large quantities of leather or specialized types. By establishing a relationship with a tannery, buyers may negotiate better pricing and ensure the leather meets specific quality standards. However, this approach often requires more time and effort, as it involves navigating contracts and establishing trust. Additionally, the minimum order quantities can be high, making it less suitable for smaller projects or businesses without the capacity for bulk purchases.

How Do Online Marketplaces Compare in Terms of Leather Sourcing?

Online marketplaces represent a flexible alternative for sourcing leather materials. They offer a wide range of products from various sellers, allowing buyers to compare prices and qualities easily. This option is particularly beneficial for projects requiring quick turnaround times, as products can often be shipped directly to the buyer. However, the quality of leather can be inconsistent, and buyers must exercise caution to avoid hidden fees and unreliable sellers. This route is best suited for smaller projects or when experimenting with different types of leather.

How Should B2B Buyers Decide on the Right Leather Sourcing Solution?

Selecting the appropriate leather sourcing solution hinges on several factors, including project scale, budget, and specific material requirements. For businesses with established production processes and large-scale demands, direct sourcing from tanneries may offer the best cost-effectiveness and customization options. Conversely, if speed and variety are critical, online marketplaces can provide quick access to a diverse range of products. Leather fabric stores serve as a reliable middle ground, offering specialized selections and a straightforward purchasing process that suits small to medium-sized projects. Ultimately, B2B buyers should evaluate their unique needs and consider factors such as budget constraints, project timelines, and the importance of quality assurance when making their decision.

Essential Technical Properties and Trade Terminology for leather fabric store

What Are the Key Technical Properties of Leather That B2B Buyers Should Know?

When sourcing leather for various applications, understanding its technical properties is crucial for B2B buyers. Here are several key specifications that can impact purchasing decisions:

-

Material Grade

Material grade refers to the quality classification of leather. Common grades include full-grain, top-grain, genuine leather, and bonded leather. Full-grain leather, for instance, is the highest quality as it retains the natural grain and has not been sanded or altered. Understanding the grade helps buyers ensure they are getting the right quality for their intended use, whether it’s for high-end fashion, automotive interiors, or durable work gear. -

Thickness (Ounce Weight)

Leather thickness is typically measured in ounces (1 ounce = 1/64 of an inch). For example, 4-5 oz leather is often used for bags, while 8-10 oz leather might be more suitable for belts or heavy-duty products. Knowing the thickness is essential for determining the leather’s strength and flexibility, which directly affects the durability and functionality of the final product. -

Tannage Type

The tanning process affects the leather’s appearance, durability, and resistance to moisture. Common tanning methods include chrome tanning and vegetable tanning. Chrome-tanned leather is typically softer and more water-resistant, making it suitable for garments, while vegetable-tanned leather is more environmentally friendly and preferred for tooling and crafting. B2B buyers should consider the end-use when evaluating tannage types. -

Finish and Texture

The finish of leather can vary widely, from smooth and glossy to rugged and textured. The choice of finish impacts aesthetics and usability; for example, a distressed finish may be ideal for casual wear, while a smooth finish might be preferred for formal applications. Understanding different finishes allows buyers to align their sourcing decisions with market trends and consumer preferences. -

Color Fastness

Color fastness refers to the leather’s ability to retain its color when exposed to light, water, and friction. This property is vital for products that will be used in varying environments. Buyers should inquire about color fastness ratings to ensure the leather will maintain its appearance over time, especially for items like bags and upholstery. -

Flexibility and Drape

Flexibility indicates how easily the leather can bend and conform to shapes, while drape refers to how the leather hangs and flows. These properties are crucial for apparel and accessories. Buyers should test samples to ensure they meet the specific requirements of their projects.

What Are the Common Trade Terms in the Leather Industry That B2B Buyers Should Understand?

Navigating the leather fabric market requires familiarity with industry-specific terminology. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In leather, this could involve manufacturers that create leather goods for brands, often under private labels. Understanding OEM relationships is essential for buyers looking to establish partnerships for custom products. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers to understand as it affects inventory levels and cash flow. Buyers should negotiate MOQ terms to ensure they can meet their demand without overcommitting. -

RFQ (Request for Quotation)

An RFQ is a standard business process to solicit bids for specific products or services. In the leather industry, buyers may issue RFQs to multiple suppliers to compare prices, quality, and delivery times. This process is vital for making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand their obligations and risks in international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This factor is crucial for supply chain management. Buyers should inquire about lead times when negotiating with suppliers to ensure timely delivery aligns with production schedules. -

Batch Production

Batch production refers to the manufacturing of a set number of items at one time. Understanding batch production processes can help buyers plan their orders and manage stock levels effectively, ensuring they meet market demand without excess inventory.

Understanding these technical properties and trade terms will empower B2B buyers in the leather industry to make informed decisions, leading to successful partnerships and profitable ventures.

Navigating Market Dynamics and Sourcing Trends in the leather fabric store Sector

What Are the Current Market Trends in the Leather Fabric Store Sector?

The leather fabric store sector is experiencing significant shifts driven by evolving consumer preferences, technological advancements, and global economic dynamics. International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking diverse product offerings that cater to both traditional and contemporary uses of leather. For instance, the demand for high-quality, sustainable leather products is on the rise, reflecting a broader trend towards eco-conscious purchasing. Technological innovations, such as digital platforms for sourcing and augmented reality (AR) for product visualization, are enhancing the purchasing experience and streamlining supply chains.

Emerging markets are also becoming significant players in the leather industry, with countries like Vietnam and Nigeria ramping up their production capabilities. These regions are leveraging their abundant natural resources and labor force to provide competitive pricing and unique materials. As a result, international buyers are encouraged to explore partnerships with local suppliers who can offer bespoke solutions tailored to specific market needs. Additionally, the rise of e-commerce platforms is making it easier for businesses to access a wider range of leather products globally, driving competition and innovation in the market.

How Is Sustainability Shaping the Leather Fabric Store Sector?

Sustainability is increasingly becoming a critical factor for B2B buyers in the leather fabric sector. As environmental concerns gain traction, buyers are focusing on the ecological impact of their sourcing decisions. This includes a preference for suppliers who adhere to ethical sourcing practices and offer environmentally friendly leather options. Certifications such as the Leather Working Group (LWG) and the Global Organic Textile Standard (GOTS) are gaining importance, as they provide assurance regarding the sustainability of materials and manufacturing processes.

Moreover, the concept of circular economy is taking root, encouraging businesses to consider the lifecycle of leather products. This includes sourcing from tanneries that prioritize waste reduction and recycling, as well as exploring alternative materials, such as plant-based leathers. As consumers become more environmentally conscious, B2B buyers who align their sourcing strategies with sustainability will not only meet market demand but also enhance their brand reputation.

What Is the Historical Context Behind the Leather Fabric Store Sector?

The leather industry has a rich history dating back thousands of years, evolving from basic animal hide processing to a complex global market. Initially, leather was primarily used for functional purposes, such as clothing and shelter. However, over time, it has transformed into a luxury commodity, with various treatments and finishes enhancing its aesthetic appeal and durability.

The industrial revolution marked a significant turning point, introducing mechanized processes that increased production efficiency. Today, the leather fabric store sector is characterized by a blend of traditional craftsmanship and modern technology, catering to a diverse array of applications, from fashion to automotive interiors. Understanding this evolution is crucial for B2B buyers as it highlights the craftsmanship and innovation that can be leveraged in contemporary sourcing strategies.

In summary, the leather fabric store sector is not only about sourcing materials but also about understanding the broader market dynamics, embracing sustainability, and appreciating the historical context that shapes the industry’s future.

Frequently Asked Questions (FAQs) for B2B Buyers of leather fabric store

-

How do I choose the right leather type for my project?

Choosing the right leather type depends on the intended use and desired characteristics of the final product. For apparel, lightweight and supple leathers such as lambskin or cowhide are ideal, while for furniture, you might opt for more durable options like full-grain leather. Consider factors like texture, thickness, and finish, as these can affect both aesthetics and functionality. Researching suppliers’ offerings and consulting product specifications can also help narrow down your choices. -

What are the minimum order quantities (MOQs) for leather purchases?

Minimum order quantities can vary widely among suppliers. Some may have MOQs as low as 10 square feet, while others may require larger orders, especially for custom or specialized leather types. It’s essential to discuss your needs with potential suppliers to understand their policies and whether they can accommodate smaller orders. Negotiating MOQs may also be possible, especially if you establish a strong business relationship. -

What are common payment terms for international leather transactions?

Payment terms often vary by supplier and region but typically include options such as letters of credit, advance payments, or net 30/60 days terms. Ensure you clarify payment expectations upfront to avoid misunderstandings. International buyers should also be aware of currency exchange rates and transaction fees, which can impact overall costs. Establishing clear payment agreements can help foster trust and facilitate smoother transactions. -

How do I vet suppliers before making a purchase?

Vetting suppliers involves assessing their reputation, product quality, and service capabilities. Start by checking references and reading reviews from other buyers. Request samples to evaluate the leather’s quality firsthand and inquire about their production processes and sourcing practices. Additionally, look for certifications that indicate compliance with industry standards, such as environmental sustainability or ethical labor practices. -

What should I know about customs and import regulations for leather?

When importing leather, it’s crucial to familiarize yourself with the customs regulations of your country, as different regions have specific tariffs and restrictions. You may need to provide documentation such as invoices, certificates of origin, and compliance with environmental regulations. Engaging a customs broker can help navigate these complexities and ensure timely clearance of your goods at the border. -

Can I customize my leather order, and what are the options?

Many leather suppliers offer customization options, including color, thickness, and finish. Some may also provide services like embossing, dyeing, or cutting to specific dimensions. Discuss your requirements with suppliers early in the negotiation process to determine their capabilities and any associated costs. Custom orders may have longer lead times, so plan accordingly to align with your production schedules. -

What quality assurance practices should I expect from leather suppliers?

Reputable leather suppliers implement strict quality assurance practices to ensure their products meet industry standards. This may include visual inspections, testing for durability, and compliance with environmental regulations. Inquire about their quality control processes, including any third-party certifications they might hold. A supplier with a solid QA program is likely to deliver consistent, high-quality leather that meets your specifications. -

How can I manage logistics and shipping for my leather orders?

Effective logistics management is essential for international leather purchases. Coordinate with your supplier to understand their shipping capabilities and timelines. Consider factors such as shipping methods (air vs. sea), estimated delivery times, and costs. Utilizing freight forwarders can streamline the shipping process and help manage customs documentation. Additionally, planning for potential delays and having contingency plans in place can mitigate disruptions to your supply chain.

Top 6 Leather Fabric Store Manufacturers & Suppliers List

1. Tandy Leather – Crafting Materials and Supplies

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Crafting Materials and Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Leather Hide Store – Premium Upholstery Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Upholstery Leather Supplier | Leather Hide Store offers a wide range of premium upholstery hides in various colors and prints. All leather is 100% genuine cowhide suitable for furniture, automotive, and leathercraft. The inventory includes leather types such as Aniline, Auto Distress, Full Grain, Embossed, Italian Leather, Nappa, Nubuck, Pebble Leather, Pigmented, Pull Up, Semi Aniline, and Suede….

3. United Leather – Premium Leather Hides

Domain: unitedleather.com

Registered: 2003 (22 years)

Introduction: Best Leather Hides Supplier | Shop Online | LA Headquarters. Categories: Cowhide, Lambskin, Novelty, Vegetable-Tanned, Suede & Nubuck, Shearling & Fur, Hair-On, Vegan. Overstock Sale. Uses: Apparel and Fashion, Handbag and Accessories, Lining, Interior and Upholstery, Entertainment, Footwear, Fetish, Sports, Equestrian. Textures: Pebbled Leather, Smooth Leather, Embossed Leather, Perforated, Metal…

4. Yelp – Best Leather Fabrics

Domain: yelp.com

Registered: 2003 (22 years)

Introduction: This company, Yelp – Best Leather Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Waterhouse Leather – Vegetable Tanned Strap Sides

Domain: waterhouseleather.com

Registered: 2006 (19 years)

Introduction: { “products”: [ { “name”: “Vegetable Tanned Strap Sides”, “price”: “$9.45/sq. ft. – $249.95 per side”, “description”: “Available in multiple thicknesses from 3/4 to 8/9 oz.” }, { “name”: “Highest Quality Italian Upholstery Whole Hides & Sides”, “price”: “$7.75/sq. ft. – $449.95 per whole hide”, “description”: “Sourced directly from Italy. Multiple styles and finishes each available in various colo…

6. Weaver Leather Supply – Leathercrafting Supplies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Weaver Leather Supply offers a wide range of leathercrafting and leatherworking supplies, including various types of leather such as ChahinLeather®, Hermann Oak® Veg Tan, and Chrome Tanned options. The product categories include leather cuts (double shoulders, backs, bends, panels, half sides, fringes, sides, whole hides, bellies, belt blanks, laces, strapping, remnants, and samples), textures (to…

Strategic Sourcing Conclusion and Outlook for leather fabric store

In navigating the complex landscape of the leather fabric industry, international B2B buyers must prioritize strategic sourcing to enhance their competitive edge. Key takeaways include the importance of selecting reliable suppliers who offer diverse leather types, from eco-friendly options to premium grades. Buyers should leverage technology to streamline procurement processes and enhance inventory management, ensuring they meet market demands efficiently.

Additionally, fostering strong relationships with suppliers can lead to better pricing, access to exclusive products, and insights into emerging trends. As the global market continues to evolve, staying informed about innovations in leather production and sustainable practices will be crucial for long-term success.

Looking ahead, the opportunity for growth in regions like Africa, South America, the Middle East, and Europe is significant. By investing in strategic sourcing and building a robust supply chain, businesses can not only meet current demands but also anticipate future market shifts. Now is the time for international buyers to seize these opportunities and forge partnerships that will drive their success in the leather fabric market. Engage with trusted suppliers and enhance your product offerings to thrive in this dynamic industry.

Illustrative image related to leather fabric store

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to leather fabric store