Introduction: Navigating the Global Market for fake leather fabric by the yard

In today’s competitive landscape, international B2B buyers face the challenge of sourcing high-quality fake leather fabric by the yard that meets diverse project requirements while balancing cost and durability. As the demand for sustainable and versatile materials grows, faux leather emerges as a compelling alternative to traditional leather, offering benefits such as affordability, ease of maintenance, and a wide array of design options. This guide aims to equip buyers from regions like Africa, South America, the Middle East, and Europe—including markets in Saudi Arabia and Vietnam—with the essential knowledge needed to navigate the complexities of sourcing faux leather.

From understanding the various types of faux leather available, including PU and PVC options, to exploring their applications in upholstery, fashion, and automotive industries, this comprehensive resource provides a deep dive into the market. Buyers will learn how to effectively vet suppliers, assess quality standards, and make informed decisions based on cost considerations. By leveraging the insights presented in this guide, you can streamline your purchasing process, ensuring that you select materials that not only meet your aesthetic and functional requirements but also align with your sustainability goals. Embrace the opportunity to enhance your projects with faux leather fabric that combines style, durability, and ethical considerations.

Table Of Contents

- Top 8 Fake Leather Fabric By The Yard Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fake leather fabric by the yard

- Understanding fake leather fabric by the yard Types and Variations

- Key Industrial Applications of fake leather fabric by the yard

- 3 Common User Pain Points for ‘fake leather fabric by the yard’ & Their Solutions

- Strategic Material Selection Guide for fake leather fabric by the yard

- In-depth Look: Manufacturing Processes and Quality Assurance for fake leather fabric by the yard

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fake leather fabric by the yard’

- Comprehensive Cost and Pricing Analysis for fake leather fabric by the yard Sourcing

- Alternatives Analysis: Comparing fake leather fabric by the yard With Other Solutions

- Essential Technical Properties and Trade Terminology for fake leather fabric by the yard

- Navigating Market Dynamics and Sourcing Trends in the fake leather fabric by the yard Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fake leather fabric by the yard

- Strategic Sourcing Conclusion and Outlook for fake leather fabric by the yard

- Important Disclaimer & Terms of Use

Understanding fake leather fabric by the yard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cuir PU | Soft, supple texture; resembles genuine leather; water-resistant | Upholstery, apparel, automotive interiors | Pros: Cost-effective, easy to clean; Cons: May not be as durable as genuine leather. |

| Vinyle Faux cuir | Durable, flexible, and often waterproof; easy to clean | Furniture, marine applications, automotive seats | Pros: Affordable, wide range of designs; Cons: Can be less breathable than leather. |

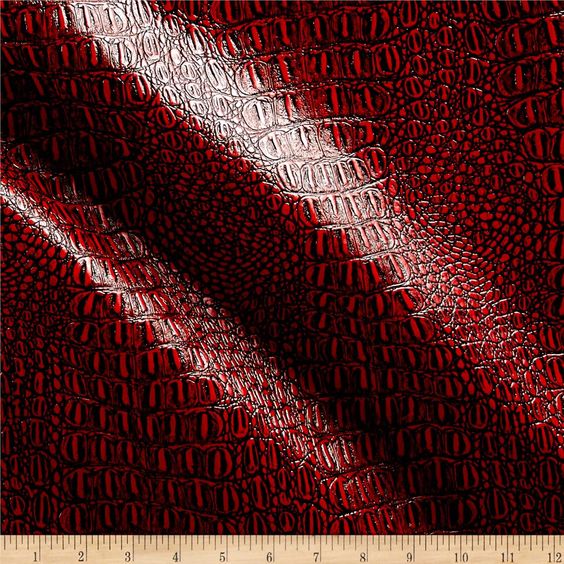

| Embossed Faux Leather | Textured surface mimicking various animal skins; decorative | Fashion, upholstery, accessories | Pros: Aesthetic appeal, variety in designs; Cons: May require specific care to maintain appearance. |

| Faux cuir microfibre | Soft, suede-like feel; excellent durability; stain-resistant | High-end furniture, automotive, fashion accessories | Pros: Soft texture, easy maintenance; Cons: Higher cost compared to other faux options. |

| Eco-Friendly Faux Leather | Made from sustainable materials; animal-friendly | Eco-conscious brands, furniture, fashion | Pros: Sustainable, appealing to ethical consumers; Cons: Often higher price point. |

What are the Key Characteristics and Suitability of PU Leather for B2B Buyers?

PU leather, or polyurethane leather, is a popular choice due to its soft, supple texture that closely resembles genuine leather. Its water-resistant properties make it ideal for upholstery in various sectors, including furniture and automotive interiors. For B2B buyers, sourcing PU leather can be cost-effective, as it is typically priced 75% lower than genuine leather. However, while it offers good durability, it may not withstand heavy wear as well as authentic leather, necessitating careful consideration of the intended application.

How Does Vinyl Faux Leather Stand Out in B2B Applications?

Vinyl faux leather is recognized for its durability and flexibility, making it suitable for a range of applications from furniture to marine environments. Its easy-to-clean surface is a significant advantage, particularly in sectors where hygiene is paramount. B2B buyers appreciate the affordability and the vast array of colors and designs available. However, a potential downside is its reduced breathability compared to natural leather, which might be a concern for certain applications, especially in clothing.

What Advantages Do Embossed Faux Leather Fabrics Offer?

Embossed faux leather features a textured surface that mimics the look of various animal skins, enhancing its aesthetic appeal. This type of material is frequently used in fashion and upholstery, providing a unique decorative element. B2B buyers should consider that while embossed faux leather offers a wide variety of designs, it may require specific maintenance to keep its appearance intact. Overall, it is an excellent option for businesses looking to create stylish products without the ethical concerns associated with real leather.

Why Choose Microfiber Faux Leather for High-End Applications?

Microfiber faux leather is known for its luxurious, soft feel and exceptional durability. It is often used in high-end furniture and automotive applications due to its stain-resistant properties. For B2B buyers, this material can justify a higher price point due to its quality and longevity. However, it is essential to weigh the increased cost against the benefits, particularly if the product’s target market values luxury and durability.

How Does Eco-Friendly Faux Leather Meet Modern Sustainability Goals?

Eco-friendly faux leather is crafted from sustainable materials, appealing to brands that prioritize environmental responsibility. It is suitable for various applications, including furniture and fashion, particularly for companies targeting eco-conscious consumers. While the sustainable aspect is a significant selling point, B2B buyers should be prepared for a higher price point compared to traditional faux leather options. This investment can enhance brand reputation and align with contemporary consumer values, making it a worthwhile consideration.

Key Industrial Applications of fake leather fabric by the yard

| Industry/Sector | Specific Application of fake leather fabric by the yard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas, chairs, and other furniture | Cost-effective, durable, and aesthetically pleasing | Assess color options, durability standards, and fire ratings |

| Automotive Industry | Interior car upholstery and trim | Lightweight, easy to clean, and customizable | Compliance with automotive regulations and availability of samples |

| Fashion and Apparel | Clothing and accessories | Versatile styles, textures, and lower production costs | Consider fabric weight, stretchability, and finish options |

| Marine and Outdoor Applications | Boat upholstery and outdoor furniture covers | Water-resistant, mildew-resistant, and easy maintenance | Evaluate UV resistance, colorfastness, and environmental impact |

| Health and Hospitality | Medical furniture and hotel decor | Hygienic, easy to clean, and durable | Ensure compliance with health regulations and antimicrobial treatments |

How is fake leather fabric by the yard used in furniture manufacturing?

In the furniture manufacturing sector, fake leather fabric is predominantly utilized for upholstery on sofas, chairs, and other furniture items. Its cost-effectiveness compared to genuine leather allows manufacturers to offer high-quality products at competitive prices. Additionally, the durability of faux leather ensures longevity, making it ideal for both residential and commercial settings. Buyers should consider color options, durability standards, and fire ratings to meet consumer demands and regulatory requirements.

What role does fake leather play in the automotive industry?

The automotive industry employs fake leather fabric for interior car upholstery and trim, providing a lightweight and easy-to-clean alternative to traditional leather. This material allows for customization in design and texture, appealing to a diverse consumer base. International buyers must ensure compliance with local automotive regulations and may require samples to evaluate the fabric’s performance under different conditions, such as heat and wear.

Illustrative image related to fake leather fabric by the yard

How is fake leather integrated into the fashion and apparel industry?

In the fashion and apparel industry, fake leather fabric is extensively used for creating clothing and accessories, from jackets to handbags. Its versatility in styles and textures, combined with lower production costs, makes it an attractive option for designers. B2B buyers should consider the fabric’s weight, stretchability, and finish options to align with current fashion trends and consumer preferences.

Why is fake leather important for marine and outdoor applications?

Fake leather fabric is crucial in marine and outdoor applications, particularly for boat upholstery and outdoor furniture covers. Its water-resistant and mildew-resistant properties make it suitable for environments exposed to moisture and harsh weather conditions. Buyers should evaluate UV resistance, colorfastness, and the environmental impact of the materials used to ensure longevity and sustainability in their products.

How does fake leather benefit the health and hospitality sectors?

In the health and hospitality sectors, fake leather fabric is used for medical furniture and hotel decor due to its hygienic properties and ease of cleaning. This material is durable and can withstand heavy use, making it ideal for environments requiring high standards of cleanliness. B2B buyers must ensure that the fabric complies with health regulations and is treated with antimicrobial coatings to enhance safety and hygiene.

3 Common User Pain Points for ‘fake leather fabric by the yard’ & Their Solutions

Scenario 1: Quality Assurance in Bulk Orders of Fake Leather Fabric

The Problem: B2B buyers often face significant challenges in ensuring the quality of fake leather fabric when ordering in bulk. This is particularly true when sourcing from international suppliers, where inconsistencies in material quality, texture, and color can lead to product mismatches and customer dissatisfaction. Buyers may receive fabric that does not meet their specifications, resulting in wasted resources and potential loss of business reputation.

Illustrative image related to fake leather fabric by the yard

The Solution: To mitigate this risk, it is crucial for buyers to implement a thorough supplier vetting process. Start by requesting samples of the fabric before placing large orders. This allows you to assess the quality, texture, and color firsthand. Additionally, establish clear specifications in your purchase agreements, including details on durability, colorfastness, and any certifications that the material must meet. Consider partnering with suppliers who have a proven track record of quality assurance and are willing to provide references. Utilizing third-party inspection services before shipment can further ensure that the product matches your quality standards.

Scenario 2: Navigating the Diverse Range of Faux Leather Options

The Problem: The variety of faux leather options available can overwhelm B2B buyers, especially those new to sourcing this material. With different types such as PU leather, PVC leather, and various finishes, selecting the right fabric for specific applications can be a daunting task. Misunderstanding the differences may lead to choosing a fabric that is not suitable for the intended use, causing performance issues in end products like furniture or apparel.

The Solution: To effectively navigate the diverse range of faux leather options, buyers should invest time in understanding the specific requirements of their projects. Create a detailed list of the intended applications, environmental conditions, and aesthetic preferences. Research the properties of different types of faux leather, focusing on attributes such as durability, flexibility, and ease of maintenance. Engage in conversations with suppliers who can provide insights and recommendations based on their expertise. Additionally, consider utilizing a fabric library or sample swatches that can help visualize how different options will perform in real-world applications.

Illustrative image related to fake leather fabric by the yard

Scenario 3: Overcoming Supply Chain and Delivery Challenges

The Problem: International B2B buyers often encounter delays and uncertainties in the supply chain when ordering fake leather fabric by the yard. Factors such as customs regulations, shipping logistics, and supplier reliability can lead to missed deadlines, which is particularly problematic for businesses that operate on tight production schedules. These delays can result in lost sales opportunities and damaged client relationships.

The Solution: To address supply chain challenges, buyers should establish strong communication channels with suppliers and logistics partners. Discuss lead times and shipping options upfront to set realistic expectations. Consider implementing a just-in-time inventory strategy, which allows for smaller, more frequent orders that align with production schedules and reduce the risk of overstock. Additionally, explore multiple sourcing options or backup suppliers to ensure that you have alternatives in case of unforeseen delays. Leveraging technology, such as supply chain management software, can also enhance visibility and tracking of orders, helping you anticipate potential issues before they escalate.

Strategic Material Selection Guide for fake leather fabric by the yard

What Are the Key Materials for Fake Leather Fabric by the Yard?

When sourcing fake leather fabric by the yard, international B2B buyers should consider several common materials, each with distinct properties and applications. The following analysis highlights the key materials, their advantages and disadvantages, and specific considerations for buyers from diverse regions.

Illustrative image related to fake leather fabric by the yard

What Are the Properties of PVC Faux Leather?

Polyvinyl Chloride (PVC) is one of the most widely used materials for faux leather. It is known for its durability and resistance to water and stains, making it suitable for a variety of applications, including upholstery and automotive interiors. PVC faux leather can withstand a temperature range of -10°C to 60°C, making it versatile for both indoor and outdoor use.

Pros: PVC is cost-effective, typically 50-75% cheaper than genuine leather. It is easy to clean and maintain, and its waterproof nature prevents issues related to moisture absorption.

Cons: However, PVC can be less breathable than other materials, which may lead to discomfort in applications like clothing. Additionally, its production process raises environmental concerns, particularly regarding the release of harmful chemicals.

International Considerations: Buyers from regions like Europe may need to ensure compliance with REACH regulations, which govern the use of chemicals in manufacturing. In contrast, buyers from Africa and South America may prioritize cost-effectiveness and durability over environmental concerns.

How Does PU Leather Compare to Other Options?

Polyurethane (PU) leather is another popular choice among faux leather materials. It offers a more supple feel and is often indistinguishable from genuine leather in appearance. PU leather typically performs well in various temperatures, withstanding conditions from -20°C to 50°C.

Pros: PU leather is lightweight, flexible, and available in a wide range of colors and textures. It is also more environmentally friendly compared to PVC, as it does not contain harmful chlorine.

Illustrative image related to fake leather fabric by the yard

Cons: Despite its advantages, PU leather can be more expensive than PVC and may have a shorter lifespan under heavy use conditions. It is also less resistant to abrasion, which may limit its applications in high-wear environments.

International Considerations: B2B buyers in the Middle East might prefer PU leather for its aesthetic appeal and comfort, while European buyers may focus on its compliance with sustainability standards.

What Are the Benefits of Using Microfiber Leather?

Microfiber leather, made from ultra-fine synthetic fibers, is gaining traction as a high-quality alternative to traditional leather. It is known for its softness, durability, and breathability, making it an excellent choice for upholstery and fashion applications.

Pros: Microfiber leather is stain-resistant, easy to clean, and often machine washable. Its lightweight nature and flexibility make it suitable for a variety of products, from bags to furniture.

Cons: The primary drawback is its cost, which can be higher than PVC and PU options. Additionally, its production process may require more complex manufacturing techniques, which could affect lead times.

International Considerations: Buyers from Europe and North America may favor microfiber leather for its premium feel and performance, while buyers in developing regions might be more sensitive to cost.

How Does Eco-Friendly Leather Compare?

Eco-friendly leather, often made from recycled materials or plant-based sources, is becoming increasingly popular among environmentally conscious consumers. This material is designed to mimic the look and feel of traditional leather while reducing environmental impact.

Illustrative image related to fake leather fabric by the yard

Pros: Eco-friendly leather is sustainable, often biodegradable, and free from harmful chemicals. It offers a unique selling point for brands looking to appeal to eco-conscious consumers.

Cons: However, it can be more expensive than conventional faux leather options, and its durability may not match that of PVC or PU leathers, particularly in demanding applications.

International Considerations: In Europe, eco-friendly certifications can enhance marketability, while buyers in regions like Africa may prioritize affordability over sustainability.

Summary Table of Material Selection

| Matériau | Typical Use Case for fake leather fabric by the yard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC Faux Leather | Upholstery, automotive interiors | Cost-effective and waterproof | Less breathable, environmental concerns | Low |

| Cuir PU | Fashion, upholstery, automotive | Soft feel, environmentally friendlier | Higher cost, shorter lifespan | Medium |

| Cuir microfibre | Bags, furniture, high-end apparel | Soft, durable, and easy to clean | Higher cost, complex manufacturing | Haut |

| Eco-Friendly Leather | Sustainable fashion, eco-conscious products | Sustainable and biodegradable | Higher cost, potentially lower durability | Medium to High |

This strategic material selection guide provides a comprehensive overview of the key materials available for faux leather fabric by the yard, helping B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for fake leather fabric by the yard

The manufacturing of fake leather fabric involves several critical stages, each contributing to the final product’s quality and performance. Understanding these processes is vital for international B2B buyers who are looking to source high-quality materials for their projects.

Illustrative image related to fake leather fabric by the yard

What Are the Key Stages in the Manufacturing Process of Fake Leather Fabric?

-

Material Preparation

The first step in manufacturing faux leather involves sourcing and preparing the raw materials. Typically, a base fabric, such as polyester or cotton, is chosen for its strength and flexibility. This base is then coated with a polymer, commonly polyurethane (PU) or polyvinyl chloride (PVC), which provides the leather-like appearance. During this stage, additives may be included to enhance properties such as water resistance and durability. -

Forming

In the forming stage, the coated fabric undergoes a process called calendaring. This involves passing the material through rollers to achieve the desired thickness and smoothness. The surface may also be embossed with a grain pattern to mimic the look of real leather. This step is crucial, as it not only determines the aesthetic qualities of the fabric but also influences its tactile feel. -

Assembly

After forming, the faux leather is cut and assembled into various products. This could include upholstery for furniture, automotive interiors, or fashion items. Precision in cutting and sewing is vital to ensure that the finished product meets design specifications. Manufacturers may use specialized stitching techniques to enhance durability, especially in high-wear applications like automotive upholstery. -

Finishing

The final stage in the manufacturing process involves applying additional treatments to enhance performance. This could include chemical treatments for stain resistance, UV protection, or antimicrobial properties. The finishing process may also involve dyeing to achieve specific colors or patterns. Quality checks are performed at this stage to ensure that the product meets the required standards before it is shipped to buyers.

How Is Quality Assurance Implemented in the Production of Fake Leather Fabric?

Quality assurance is a critical component in the manufacturing of fake leather, ensuring that the final product adheres to international standards and meets customer expectations. Below are the main elements of quality control within this sector:

-

What International Standards Are Relevant for Quality Assurance?

Compliance with international standards such as ISO 9001 is essential for manufacturers of faux leather. ISO 9001 outlines a framework for quality management systems that can enhance operational efficiency and customer satisfaction. Additionally, industry-specific standards such as CE marking may apply, particularly for products used in automotive and furniture sectors, ensuring they meet European safety and environmental regulations. -

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified criteria.

– In-Process Quality Control (IPQC): During production, samples are taken at various stages to monitor quality and adherence to standards.

– Final Quality Control (FQC): Before shipping, the finished products undergo rigorous testing to verify that they meet both internal specifications and external standards. -

What Common Testing Methods Are Used for Fake Leather Fabric?

Various testing methods are employed to assess the quality of faux leather, including:

– Tensile Strength Testing: To evaluate the fabric’s durability under stress.

– Water Resistance Testing: To determine how well the material repels water.

– Colorfastness Testing: To ensure that dyes do not bleed or fade when exposed to light or washing.

– Flexural Testing: To assess how the material behaves under repeated bending, which is crucial for applications like upholstery.

How Can B2B Buyers Verify Supplier Quality Control Practices?

International B2B buyers must ensure that their suppliers adhere to stringent quality control measures. Here are some actionable steps to verify supplier practices:

-

Conduct Audits

Regular audits of suppliers can provide insights into their manufacturing and quality control processes. Buyers should consider scheduling on-site visits to observe operations, check documentation, and assess compliance with relevant standards. -

Request Quality Assurance Reports

Suppliers should be able to provide detailed quality assurance reports that outline their processes, testing methods, and results. This documentation can help buyers gauge the reliability and quality of the materials they are sourcing. -

Engage Third-Party Inspection Services

Utilizing third-party inspection services can add an additional layer of assurance. These independent entities can conduct thorough evaluations of the manufacturing process and final products, providing unbiased assessments of quality.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing fake leather fabric from international suppliers, particularly from regions such as Africa, South America, the Middle East, and Europe, buyers should be aware of several nuances:

-

Cultural and Regulatory Differences

Different regions may have varying standards and regulations for quality assurance. Buyers should familiarize themselves with local compliance requirements and ensure that their suppliers meet both local and international standards. -

Supply Chain Transparency

Ensuring transparency throughout the supply chain is vital. Buyers should seek suppliers who are willing to share information about their sourcing of raw materials, manufacturing processes, and quality control measures. -

Sustainability Considerations

With increasing focus on sustainability, buyers should also evaluate the environmental impact of faux leather production. Suppliers who adhere to sustainable practices may be more appealing to conscientious consumers and businesses.

In conclusion, understanding the manufacturing processes and quality assurance protocols for fake leather fabric is essential for B2B buyers looking to make informed purchasing decisions. By focusing on quality control measures, international standards, and supplier verification practices, businesses can ensure they are sourcing high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fake leather fabric by the yard’

In the competitive landscape of sourcing fake leather fabric by the yard, B2B buyers must navigate various considerations to ensure they secure the best quality products at competitive prices. This guide provides a structured checklist to streamline your procurement process, ensuring you make informed decisions.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your requirements. Consider factors such as the intended use (e.g., upholstery, apparel), desired thickness, texture, and color. This specificity not only helps in narrowing down options but also aids suppliers in providing you with relevant samples and quotes.

Step 2: Research and Identify Potential Suppliers

Conduct thorough market research to identify suppliers who specialize in faux leather fabric. Utilize industry directories, trade shows, and online platforms to compile a list of reputable vendors. Focus on suppliers with a proven track record and positive reviews from other international buyers.

Illustrative image related to fake leather fabric by the yard

Step 3: Evaluate Supplier Certifications and Quality Standards

It’s essential to verify that potential suppliers meet industry standards and certifications. Look for ISO certifications, compliance with safety regulations, and quality assurance protocols. These certifications can indicate a supplier’s commitment to quality and reliability, reducing the risk of future issues.

Step 4: Request Samples Before Committing

Always request samples of the fabric you intend to purchase. This step allows you to assess the material’s texture, durability, and color accuracy firsthand. Evaluate the samples against your defined specifications to ensure they meet your expectations before placing a bulk order.

Step 5: Understand Pricing Structures and Terms

Before finalizing any agreements, clarify the pricing structure, including unit costs, shipping fees, and potential discounts for bulk orders. Be aware of any hidden costs that may arise during the procurement process. Understanding these financial aspects upfront helps in budgeting and financial planning.

Step 6: Negotiate Terms and Conditions

Engage in discussions with suppliers regarding payment terms, delivery schedules, and return policies. Clear communication on these aspects can prevent misunderstandings later on. Negotiating favorable terms can lead to better cash flow management and mitigate risks associated with supply chain disruptions.

Step 7: Establish a Communication Plan

Once you’ve selected a supplier, set up a clear communication plan. Regular updates on production timelines, shipping schedules, and any potential issues are vital for maintaining transparency and trust. Effective communication can significantly enhance the relationship between you and the supplier, ensuring a smoother procurement process.

By following this step-by-step checklist, B2B buyers can approach the procurement of fake leather fabric by the yard with confidence, ensuring they meet their project requirements while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for fake leather fabric by the yard Sourcing

What Are the Key Cost Components in Sourcing Fake Leather Fabric by the Yard?

When sourcing fake leather fabric by the yard, understanding the cost structure is essential for B2B buyers. The primary cost components include:

Illustrative image related to fake leather fabric by the yard

-

Materials: The base cost of faux leather varies significantly based on the type (e.g., PU leather, PVC vinyl). High-quality materials often come at a premium but offer better durability and aesthetic appeal.

-

Labor: This includes the costs associated with cutting, sewing, and finishing the fabric. Labor costs can fluctuate based on the region, with countries in Asia generally having lower labor rates compared to Europe or North America.

-

Manufacturing Overhead: This encompasses utilities, rent, and other expenses related to operating a production facility. Efficient factories may pass savings onto buyers, making it crucial to assess suppliers’ operational efficiencies.

-

Tooling: Custom tooling for unique designs or specifications can add to initial costs. However, these expenses may be amortized over larger orders, making them less significant per unit.

-

Quality Control (QC): Ensuring the faux leather meets specified standards is critical. QC processes can add to costs but are essential for maintaining quality and minimizing returns.

-

Logistics: Shipping costs vary based on location, order size, and chosen Incoterms. International shipments may incur additional fees such as customs duties and taxes.

-

Margin: Suppliers typically mark up costs to ensure profitability. Understanding typical margins in the industry can help buyers negotiate better prices.

How Do Price Influencers Impact the Cost of Fake Leather Fabric?

Several factors can influence the pricing of faux leather fabric:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs that balance their needs with cost-efficiency.

-

Specifications and Customization: Customized designs or specific requirements can increase costs. Buyers should assess the necessity of these customizations versus standard options.

-

Material Quality and Certifications: Fabrics with specific certifications (e.g., eco-friendly) may command higher prices. Buyers should evaluate whether such certifications align with their brand values and market demands.

-

Supplier Factors: The reliability and reputation of suppliers can affect pricing. Established suppliers may offer better quality assurance but at a higher cost.

-

Incoterms: These terms define the responsibilities of buyers and sellers in shipping agreements. Understanding Incoterms can help buyers avoid unexpected costs related to shipping and customs.

What Negotiation Strategies Can B2B Buyers Use to Optimize Costs?

To achieve cost-efficiency in sourcing faux leather fabric, buyers should consider the following strategies:

-

Volume Negotiation: Buyers can leverage larger orders to negotiate better pricing. Establishing a long-term relationship with suppliers can also lead to discounts over time.

-

Benchmarking Prices: Researching prices from multiple suppliers helps establish a fair market rate. This information can empower buyers during negotiations.

-

Evaluating Total Cost of Ownership (TCO): Beyond initial purchase prices, consider the long-term costs associated with maintenance, durability, and potential waste. A higher upfront cost for quality materials may result in lower TCO over time.

-

Understanding Regional Pricing Nuances: International buyers should be aware of local market conditions, including currency fluctuations and regional demand, which can impact pricing.

-

Flexible Payment Terms: Discussing payment terms can create mutual benefits. Early payment discounts or extended payment schedules can ease cash flow for buyers while providing suppliers with more predictable revenue.

What Should International B2B Buyers Consider When Sourcing?

For international buyers, particularly from Africa, South America, the Middle East, and Europe, several considerations are critical:

-

Cultural and Market Differences: Understanding local preferences and trends can influence the type of faux leather that is in demand.

-

Logistics and Supply Chain Challenges: Be aware of potential delays in shipping and customs that can impact delivery timelines.

-

Regulatory Compliance: Ensure that the faux leather fabric complies with local regulations, especially concerning environmental standards and safety.

-

Negotiation Practices: Different cultures have varying negotiation styles. Being aware of these can facilitate smoother interactions and better outcomes.

In conclusion, while sourcing faux leather fabric by the yard involves multiple cost components and influencing factors, informed negotiation and strategic planning can lead to successful procurement outcomes. Buyers should continuously seek to balance quality, cost, and supplier relationships to maximize their investments.

Alternatives Analysis: Comparing fake leather fabric by the yard With Other Solutions

In the world of upholstery and fashion, the demand for materials that combine aesthetics with practicality has led to the rise of various alternatives to traditional materials. Fake leather fabric by the yard, commonly known as faux leather or synthetic leather, presents a cost-effective and versatile option. However, B2B buyers should explore other alternatives to determine the best fit for their specific needs. This analysis compares fake leather fabric with two notable alternatives: genuine leather and textile-based solutions.

| Comparison Aspect | Fake Leather Fabric By The Yard | Genuine Leather | Textile-Based Solutions |

|---|---|---|---|

| Performance | Durable, waterproof, and stain-resistant. Mimics leather appearance well. | Highly durable and long-lasting; develops a unique patina. | Varies by fabric; typically less durable than leather. |

| Cost | Approximately 75% less than genuine leather, making it budget-friendly. | Generally expensive due to sourcing and processing. | Typically lower cost, but can vary based on material. |

| Ease of Implementation | Easy to cut and sew; widely available in various colors and patterns. | Requires specialized tools for cutting and sewing; limited color choices. | Generally easy to work with, depending on the fabric type. |

| Maintenance | Low maintenance; easy to clean and resistant to mold and mildew. | Requires regular conditioning and careful cleaning. | Maintenance varies; some fabrics may require special care. |

| Best Use Case | Ideal for upholstery, fashion, and accessories; great for projects needing varied designs. | Best for high-end products where longevity and quality are critical. | Suitable for casual wear, soft furnishings, and budget-conscious projects. |

What Are the Advantages and Disadvantages of Genuine Leather as an Alternative?

Genuine leather is revered for its durability and luxurious feel. It ages gracefully, developing a unique character over time. However, the high cost and environmental concerns related to animal sourcing can be significant drawbacks. Additionally, genuine leather requires regular maintenance to prevent cracking and drying, making it less suitable for projects that demand low upkeep.

How Do Textile-Based Solutions Compare?

Textile-based solutions, such as cotton or polyester blends, offer a wide range of colors and patterns, making them appealing for creative projects. They are typically more affordable and easier to handle than both faux and genuine leather. However, their durability is often inferior, particularly in high-wear environments. This makes them less ideal for applications like upholstery where longevity is crucial.

Conclusion: How Can B2B Buyers Select the Right Material?

When choosing the right material, B2B buyers should consider the specific needs of their projects. If cost-effectiveness, ease of maintenance, and design versatility are priorities, fake leather fabric by the yard is a compelling choice. For high-end applications where durability and luxury are paramount, genuine leather may be more suitable, albeit at a higher cost. Conversely, textile-based solutions may serve well for budget-conscious projects with less demanding durability requirements. Ultimately, evaluating these factors will guide buyers in selecting the ideal material that aligns with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for fake leather fabric by the yard

What Are the Key Technical Properties of Fake Leather Fabric by the Yard?

When sourcing fake leather fabric by the yard, understanding its technical properties is essential for making informed purchasing decisions. Here are the critical specifications to consider:

-

Material Composition

Fake leather is primarily made from materials like polyurethane (PU) or polyvinyl chloride (PVC). PU leather is known for its softness and durability, making it a popular choice for high-end applications. PVC, on the other hand, is more economical and offers excellent resistance to water and stains. Understanding the material composition helps buyers evaluate the fabric’s performance and suitability for specific applications, such as upholstery or fashion. -

Weight and Thickness

The weight of faux leather is typically measured in grams per square meter (gsm), while thickness is measured in millimeters (mm). A heavier and thicker fabric often indicates greater durability and better performance in high-stress environments. For B2B buyers, selecting the right weight and thickness is crucial for ensuring that the fabric can withstand the intended use, whether for furniture, automotive, or marine applications. -

Abrasion Resistance

Abrasion resistance is a measure of how well the fabric can withstand wear and tear. This property is especially important for applications that involve heavy use, such as upholstery in commercial settings. Fabrics are often tested using the Martindale test, which simulates rubbing. A higher rub count indicates better durability. Understanding this property helps buyers assess the longevity and value of the fabric over time. -

Water Resistance

Water resistance is a vital property for fake leather, particularly for outdoor or marine applications. Fabrics treated to be water-resistant prevent moisture absorption, making them easier to clean and maintain. This feature is crucial for buyers in regions with high humidity or for applications like boat upholstery. Knowing the level of water resistance can help businesses avoid costly repairs or replacements. -

Solidité des couleurs

Colorfastness refers to the fabric’s ability to retain its color when exposed to light, washing, and abrasion. This property is essential for maintaining the aesthetic appeal of products made from faux leather. Buyers should look for fabrics that have been tested for colorfastness to ensure that their products will remain vibrant over time, particularly in outdoor or high-traffic environments.

What Are Common Trade Terms Related to Fake Leather Fabric?

Familiarity with industry jargon can streamline communication and negotiations. Here are several key trade terms relevant to fake leather fabric:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products based on the specifications provided by another company. In the context of fake leather, an OEM might produce custom-designed fabrics for specific brands or applications. Understanding OEM relationships can help buyers identify potential suppliers capable of meeting unique requirements. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. For B2B buyers, knowing the MOQ is crucial for budgeting and inventory planning. Some suppliers may offer lower MOQs for new customers or sample orders, which can be beneficial for businesses testing new products. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for a specific quantity of goods. When sourcing fake leather fabric, submitting an RFQ can help buyers compare prices, delivery times, and payment terms from various suppliers, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps buyers clarify shipping responsibilities, risk management, and cost allocation. For instance, “CIF” (Cost, Insurance, and Freight) means the seller covers shipping costs and insurance up to the destination port. -

Lead Time

Lead time is the period from placing an order to receiving the goods. Knowing the lead time for faux leather fabric is vital for supply chain management, especially for businesses with tight deadlines. Buyers should inquire about lead times when negotiating with suppliers to ensure timely delivery for their projects.

By understanding these essential technical properties and industry terms, B2B buyers can make more informed decisions, ensuring they select the right fake leather fabric for their needs while optimizing their procurement process.

Navigating Market Dynamics and Sourcing Trends in the fake leather fabric by the yard Sector

What Are the Key Market Dynamics and Trends Influencing Fake Leather Fabric by the Yard?

The global market for fake leather fabric by the yard is experiencing robust growth, driven by increasing demand for cost-effective, versatile, and durable materials in various sectors, including fashion, automotive, and home decor. Key trends shaping this market include the rise of e-commerce, which has made sourcing and purchasing more accessible for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Additionally, the growing preference for synthetic materials over genuine leather, due to ethical considerations and lower costs, is propelling market expansion.

Emerging technologies such as digital printing and advanced manufacturing techniques are enhancing the customization options for faux leather, allowing businesses to offer unique designs and textures that cater to specific consumer preferences. The integration of artificial intelligence in supply chain management is also streamlining sourcing processes, enabling buyers to make data-driven decisions regarding inventory management and supplier selection.

Moreover, as sustainability becomes a focal point for consumers and businesses alike, there is a notable shift towards eco-friendly faux leather options that utilize recycled materials or sustainable production practices. This trend is particularly relevant for buyers in environmentally conscious markets, as they seek to align their sourcing strategies with consumer values.

How Can Sustainability and Ethical Sourcing Impact the Fake Leather Fabric Market?

Sustainability and ethical sourcing are becoming increasingly important in the fake leather fabric market. The environmental impact of traditional leather production, which involves significant water usage and chemical treatments, has led many businesses to seek alternatives that are less harmful to the planet. Faux leather, particularly options made from recycled materials or biodegradable compounds, provides a viable solution that meets the growing demand for sustainable textiles.

Ethical supply chains are paramount for B2B buyers looking to enhance their brand reputation and meet regulatory requirements. By sourcing faux leather from manufacturers that adhere to sustainable practices, businesses can ensure that their materials are produced without exploiting labor or contributing to environmental degradation. Certifications such as Global Recycle Standard (GRS) or OEKO-TEX® can serve as valuable indicators of a supplier’s commitment to sustainability.

Illustrative image related to fake leather fabric by the yard

Additionally, eco-conscious consumers are increasingly favoring brands that prioritize ethical sourcing, influencing purchasing decisions across various markets. For international B2B buyers, aligning sourcing strategies with sustainability goals not only mitigates risks but also enhances market competitiveness in a rapidly evolving landscape.

What is the Evolution of Fake Leather Fabric in the B2B Sector?

The evolution of fake leather fabric, also known as synthetic leather or faux leather, can be traced back to the early 20th century. Initially developed as a cost-effective alternative to genuine leather, these materials gained traction due to their versatility and ease of maintenance. Over the decades, advancements in manufacturing processes, particularly the introduction of polyurethane (PU) and polyvinyl chloride (PVC), have significantly improved the quality and aesthetic appeal of faux leather.

By the 1980s and 1990s, faux leather became a staple in various industries, including fashion, automotive, and upholstery, thanks to its durability and wide range of design options. Today, the market has expanded further with the introduction of eco-friendly materials and innovative production techniques, catering to a global audience that values both style and sustainability.

As B2B buyers navigate this evolving landscape, understanding the historical context of fake leather fabric can provide valuable insights into current trends and future opportunities in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of fake leather fabric by the yard

1. How do I choose the right faux leather fabric for my project?

Selecting the right faux leather fabric depends on your specific application, such as upholstery, fashion, or automotive use. Consider factors like durability, texture, and color. For upholstery, look for heavy-duty options that resist wear and tear, while for fashion, lighter, more flexible fabrics may be ideal. Always request samples to evaluate the feel and appearance before making a bulk purchase. Additionally, consider the environmental impact and seek materials that are sustainable and compliant with international standards.

2. What are the advantages of sourcing faux leather fabric by the yard?

Purchasing faux leather fabric by the yard offers flexibility and cost savings, especially for smaller projects. It allows buyers to select the exact amount needed, reducing waste and inventory costs. This approach is particularly beneficial for businesses that require customization or have varying project sizes. Furthermore, sourcing by the yard can provide access to a wider range of colors and textures that may not be available in full rolls.

3. What should I consider when vetting suppliers for faux leather fabric?

When vetting suppliers, assess their reputation, reliability, and quality of products. Request certifications that indicate compliance with international standards, such as ISO or OEKO-TEX. Look for suppliers who provide transparent information about their manufacturing processes and sourcing practices. Additionally, check customer reviews and testimonials, and consider visiting their facilities if possible. Establishing a good relationship with suppliers can lead to better pricing and terms.

Illustrative image related to fake leather fabric by the yard

4. Are there minimum order quantities (MOQ) when purchasing faux leather?

Many suppliers impose minimum order quantities, which can vary significantly depending on the manufacturer and the specific fabric. Typically, MOQs can range from a few yards to several hundred yards. It’s crucial to clarify these requirements upfront to avoid unexpected costs. Some suppliers may offer flexible MOQs for new customers or smaller businesses, so it’s worth negotiating based on your needs.

5. What payment terms are standard for international faux leather fabric transactions?

Payment terms can vary by supplier and region, but common practices include upfront payments, partial deposits, or payment upon delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services, which can protect both parties. Always clarify payment terms before finalizing orders, and ensure that currency exchange rates are accounted for, particularly when dealing with suppliers in different countries.

6. How can I ensure the quality of faux leather fabric before purchase?

To ensure quality, request samples of the faux leather fabric before making a bulk order. This allows you to assess the texture, durability, and color accuracy. Additionally, inquire about the supplier’s quality assurance processes, including any testing for wear, tear, and environmental resistance. If possible, visit the supplier’s facility to observe their production methods and quality control measures firsthand.

7. What logistics considerations should I keep in mind when importing faux leather fabric?

Logistics plays a crucial role in the timely and cost-effective delivery of faux leather. Consider shipping methods (air vs. sea), as air freight is faster but more expensive. Evaluate customs regulations in your country to ensure compliance and avoid delays. Additionally, factor in warehousing costs and the potential need for local distribution. Partnering with a reliable logistics provider can streamline the process and mitigate risks associated with international shipping.

8. Can I customize faux leather fabric to meet my specific design needs?

Yes, many suppliers offer customization options for faux leather fabric, including color, texture, and pattern modifications. This is particularly beneficial for businesses looking to create unique products that stand out in the market. Discuss your requirements with the supplier, including any minimum order quantities for custom designs. Keep in mind that customization may increase lead times and costs, so plan accordingly.

Illustrative image related to fake leather fabric by the yard

Top 8 Fake Leather Fabric By The Yard Manufacturers & Suppliers List

1. Decorative Fabrics Direct – PU Leather & Faux Leather

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: PU Leather & Faux Leather | Vinyl Upholstery Fabric, Free Shipping Coupon Code: SHIPFREE for Most $199 Orders, Available in various colors including Black, Gray, Blue, Turquoise, Aqua, Brown, Beige, Green, Orange, Coral, Purple, Red, Pink, White, Yellow, Gold. Types include Vinyl (PVC), Urethane, Polycarbonate. Brands include Naugahyde, Omnova Boltaflex, Nassimi, Spradling. Suitable for Automotive…

2. Folio Fabrics – Vinyl & Faux Leather Upholstery

Domain: foliofabrics.com

Registered: 2013 (12 years)

Introduction: Shop Vinyl & Faux Leather For Upholstery By The Yard – Folio Fabrics. Features: 4-Way Stretch, Ink Resistant, Bacteria & Mildew Resistant, Performance, Breathable, Pet Friendly, Eco-Friendly, Stain Resistant, Fade Resistant, Weather Resistant. Applications: Upholstery, Home Contract, Outdoor, Marine, Auto, Healthcare. Patterns: Exotics, Distressed, Pebbled, Metallic, Leather Grain. Prices range fr…

3. Kovi Fabrics – Faux Leather Solutions

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Faux leather fabric is an alternative to genuine leather, made from synthetic materials like polyester, polyurethane (PU), and polyvinyl chloride (PVC). It is soft, easy to clean, and resistant to water and marks. There are two main types: PVC leather, which is waterproof and stain-resistant but less sustainable, and PU leather, which is more eco-friendly and breathable. Faux leather is ethical, p…

4. Sallie Tomato – Faux Leather Collection

Domain: sallietomato.com

Registered: 2015 (10 years)

Introduction: Faux Leather collection by Sallie Tomato includes 66 products available in various colors and textures. Key colors include Beige, Black, Blue, Brown, Green, Grey, Navy, Orange, Pink, Purple, Red, Teal, White, and Yellow. Textures available are Alligator, Basket Weave, Crocodile, Legacy, Limited Edition, Lite, Ostrich, Pebble, Rugged, and Shimmer. The fabric is sold by quarter yard and is a vegan a…

5. Fabric Wholesale Direct – Faux Leather

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: This company, Fabric Wholesale Direct – Faux Leather, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Big Z Fabric – Faux Leather Vinyl

Domain: bigzfabric.com

Registered: 2010 (15 years)

Introduction: Faux Leather Vinyl Fabric – Durable & Stylish for Upholstery. Huge selection of prints and patterns available. Sold by the yard. Regular updates on new arrivals and special pricing through the blog. Featured products include Storm Shield Marine Vinyl, Alligator Embossed Vinyl, DuroLast® Marine Vinyl, AquaGuard® Crocodile Marine Vinyl, and various embossed and patterned faux leather options. Catego…

7. Fabric Warehouse – Faux Leather Fabric By The Yard

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: Faux Leather Fabric By The Yard Vinyl for Upholstery & Craft; SHIPS FREE OVER $100; Various colors available including Beige, Black, Blue, Bronze, Brown, Gold, Gray, Green, Ivory, Khaki; Discounts available: 10% OFF (5), 20% OFF (17), 30% OFF (65), 40% OFF (97), 50% OFF (4), 60% OFF (7), 70% OFF (16); Fabric weights: Extra Heavy Weight (243), Heavy Weight (623), Lightweight (2), Medium/Heavyweight…

8. Kiki Textiles – Faux Leather Fabric

Domain: kikitextiles.com

Registered: 2021 (4 years)

Introduction: Faux leather (pleather) fabric by the yard available in various colors and styles. Key features include:

– Ethical and animal-friendly alternative to genuine leather.

– Advanced technology for realistic texture, sheen, and durability.

– Suitable for fashion (jackets, handbags, clothing), upholstery (furniture), and accessories (wallets, belts, shoes).

– Easy to clean and resistant to wear and tear…

Strategic Sourcing Conclusion and Outlook for fake leather fabric by the yard

In navigating the evolving landscape of faux leather fabric sourcing, international B2B buyers are positioned to capitalize on the myriad benefits this versatile material offers. Key takeaways include the significant cost savings—up to 75% compared to genuine leather—along with its durability, water resistance, and ease of maintenance. The ability to source faux leather by the yard allows for flexible inventory management, catering to diverse project needs without the constraints of minimum order quantities typical of traditional leather.

Strategic sourcing remains essential for optimizing supply chains, particularly for buyers in Africa, South America, the Middle East, and Europe. By fostering relationships with reputable suppliers, businesses can ensure access to high-quality materials that meet stringent industry standards while also aligning with sustainable practices.

Looking ahead, the demand for faux leather is expected to grow, driven by consumer preference for sustainable and cruelty-free options. B2B buyers are encouraged to explore this dynamic market, leveraging online platforms for a wider selection and competitive pricing. Embrace the opportunity to enhance your product offerings and meet evolving consumer expectations by integrating faux leather fabrics into your supply chain today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to fake leather fabric by the yard

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.