Introduction: Navigating the Global Market for andrews custom leather holsters

In today’s competitive landscape, sourcing high-quality Andrews custom leather holsters presents a unique set of challenges for international B2B buyers. With varying standards of craftsmanship, delivery timelines, and pricing strategies, buyers from regions such as Africa, South America, the Middle East, and Europe—specifically Nigeria and Germany—must navigate a complex market. This guide aims to simplify that process by providing a comprehensive overview of Andrews custom leather holsters, including the diverse types available, their applications across different industries, and key considerations for supplier vetting.

Buyers will gain insights into the characteristics that differentiate quality leather holsters, such as material selection and craftsmanship, which are crucial for ensuring durability and functionality. Additionally, this guide will outline effective strategies for assessing supplier reliability and managing expectations regarding lead times and pricing—an area where many buyers have encountered challenges in the past.

By equipping B2B purchasers with actionable insights and a structured approach to sourcing, this guide empowers them to make informed decisions that align with their operational needs and budgetary constraints. Whether you are looking to enhance your product offerings or meet specific customer demands, understanding the nuances of the Andrews custom leather holster market is essential for securing the best possible outcomes.

Table Of Contents

- Top 2 Andrews Custom Leather Holsters Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for andrews custom leather holsters

- Understanding andrews custom leather holsters Types and Variations

- Key Industrial Applications of andrews custom leather holsters

- 3 Common User Pain Points for ‘andrews custom leather holsters’ & Their Solutions

- Strategic Material Selection Guide for andrews custom leather holsters

- In-depth Look: Manufacturing Processes and Quality Assurance for andrews custom leather holsters

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘andrews custom leather holsters’

- Comprehensive Cost and Pricing Analysis for andrews custom leather holsters Sourcing

- Alternatives Analysis: Comparing andrews custom leather holsters With Other Solutions

- Essential Technical Properties and Trade Terminology for andrews custom leather holsters

- Navigating Market Dynamics and Sourcing Trends in the andrews custom leather holsters Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of andrews custom leather holsters

- Strategic Sourcing Conclusion and Outlook for andrews custom leather holsters

- Important Disclaimer & Terms of Use

Understanding andrews custom leather holsters Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Monarch Shoulder Rig | Designed for comfort and accessibility; distributes weight evenly across shoulders. | Law enforcement, tactical training, concealed carry. | Pros: Comfortable for prolonged wear; allows quick access. Cons: Longer lead times; may require custom fitting. |

| Cowboy Rig | Classic Western styling; typically made from premium leather with a rugged finish. | Cowboy action shooting, reenactments, collectors. | Pros: Unique aesthetic appeal; high-quality craftsmanship. Cons: Often has extended delivery times; may be costlier than alternatives. |

| Inside Waistband (IWB) | Concealed carry design; fits snugly against the body for discretion. | Personal defense, everyday carry, law enforcement. | Pros: Excellent concealment; comfortable for daily use. Cons: Can be less accessible compared to outside options; limited customization. |

| Outside Waistband (OWB) | Sits outside the waistband; offers quick draw capability. | Competitive shooting, law enforcement, open carry. | Pros: Fast access; comfortable for open carry. Cons: Less concealment; may require a cover garment. |

| Exotic Skin Holsters | Made from unique materials like alligator or ostrich; high-end luxury appeal. | Luxury markets, fashion-forward consumers, collectors. | Pros: Distinctive look; premium quality. Cons: Higher price point; limited availability. |

What are the Characteristics of the Monarch Shoulder Rig?

The Monarch Shoulder Rig is designed for optimal comfort and accessibility, making it ideal for law enforcement and tactical training scenarios. Its ergonomic design distributes the weight evenly across the shoulders, allowing for extended wear without discomfort. When considering this option, B2B buyers should note the importance of fit, as a custom fitting can enhance usability. The lead time for these holsters can be longer due to their handcrafted nature, which may impact procurement timelines for businesses.

Why Choose a Cowboy Rig?

The Cowboy Rig showcases classic Western styling, often crafted from premium leather that offers both durability and aesthetic appeal. It is particularly suitable for cowboy action shooting events, reenactments, or for collectors seeking unique items. B2B buyers should be aware that while these holsters are highly sought after for their craftsmanship, they may come with extended delivery times and a higher price point. This makes them a niche investment but one that can yield high returns in specialized markets.

What Makes Inside Waistband (IWB) Holsters Ideal for Concealed Carry?

Inside Waistband (IWB) holsters are specifically designed for concealed carry, fitting snugly against the body for optimal discretion. They are frequently used in personal defense scenarios and by law enforcement officers. B2B buyers should consider the balance between concealment and accessibility, as IWB options may be less accessible than outside alternatives. Additionally, while they offer comfort for daily use, some may require specific sizing for optimal performance.

How Do Outside Waistband (OWB) Holsters Enhance Accessibility?

Outside Waistband (OWB) holsters are favored for their fast access capabilities, making them popular among competitive shooters and law enforcement personnel. Their design allows for quick drawing of the firearm, which is critical in high-pressure situations. However, B2B buyers should be mindful of the trade-off between accessibility and concealment, as OWB holsters may require additional cover garments for discreet carry. The comfort of these holsters makes them a practical choice for open carry scenarios.

What are the Benefits of Exotic Skin Holsters?

Exotic Skin Holsters, made from unique materials such as alligator or ostrich, cater to high-end markets and fashion-forward consumers. These holsters offer a distinctive look that appeals to collectors and luxury buyers. While they boast premium quality and craftsmanship, the higher price point and limited availability can pose challenges for bulk purchasing. B2B buyers should assess the target market’s demand for luxury items to ensure that these investments align with their sales strategies.

Key Industrial Applications of andrews custom leather holsters

| Industry/Sector | Specific Application of andrews custom leather holsters | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Duty holsters for police officers | Enhanced safety and accessibility for quick firearm access | Durability, comfort during long shifts, and retention features |

| Military | Tactical holsters for soldiers | Improved weapon retention and ease of access in combat | Compatibility with military gear, weather resistance, and fit |

| Outdoor Recreation | Holsters for hunting and fishing | Secure carrying of firearms while engaging in outdoor activities | Customization options for different firearms and styles |

| Security Services | Holsters for private security personnel | Professional appearance and secure firearm handling | Bulk purchasing options, custom branding, and expedited delivery |

| Retail & Wholesale | Retail display and sales of custom leather holsters | Attract customers with high-quality, aesthetically pleasing products | Wholesale pricing, delivery timelines, and product variety |

How Are Andrews Custom Leather Holsters Used in Law Enforcement?

In the law enforcement sector, Andrews custom leather holsters serve as essential tools for police officers. These holsters are designed for optimal safety and accessibility, allowing officers to draw their firearms quickly when necessary. The durability and comfort of these holsters are crucial for officers who spend long hours on duty, ensuring that their equipment remains reliable and functional. For international buyers, particularly in regions like Nigeria or Germany, it’s vital to consider local regulations regarding firearm carry and holster specifications.

What Are the Benefits of Tactical Holsters in Military Applications?

Military personnel utilize tactical holsters from Andrews for their operational effectiveness. These holsters offer improved weapon retention and quick access, which are vital during combat situations. Customization to fit various firearms and compatibility with military gear are key considerations for sourcing. Additionally, the holsters must withstand harsh environmental conditions, making weather resistance an important factor for buyers in regions such as the Middle East.

How Do Outdoor Recreationists Benefit from Custom Leather Holsters?

In the outdoor recreation industry, hunters and anglers benefit from Andrews custom leather holsters that provide secure firearm carry while engaging in their activities. These holsters ensure that firearms are easily accessible yet safely secured, addressing the unique challenges posed by outdoor environments. Buyers should consider customization options based on specific firearm models and styles, as well as the aesthetic appeal of the holsters, which can influence purchasing decisions in markets across South America and Europe.

What Role Do Holsters Play in Private Security Services?

For private security personnel, Andrews custom leather holsters enhance professional appearance and ensure secure handling of firearms. These holsters are designed for both functionality and style, making them suitable for various security contexts. When sourcing for this application, businesses should focus on bulk purchasing options and consider the potential for custom branding to promote their services effectively. Quick delivery times can also be a significant factor for security firms needing to equip personnel promptly.

How Can Retailers Leverage Andrews Holsters in Their Offerings?

Retailers and wholesalers can capitalize on the appeal of Andrews custom leather holsters by offering them as part of their product line. High-quality, aesthetically pleasing holsters attract customers looking for premium firearm accessories. Key sourcing considerations include negotiating wholesale pricing, ensuring timely delivery, and providing a diverse product range to meet various customer needs. This approach can be particularly effective in markets where consumers value craftsmanship and quality, such as in Europe and affluent regions of South America.

3 Common User Pain Points for ‘andrews custom leather holsters’ & Their Solutions

Scenario 1: Long Wait Times for Custom Orders

The Problem: One of the most significant challenges B2B buyers face when ordering from Andrews Custom Leather is the lengthy lead time for custom holster production. Reports indicate that buyers have experienced wait times extending beyond 18 months, significantly longer than initially quoted. This can severely impact inventory planning and customer satisfaction, especially for businesses that depend on timely delivery of products for their operations or clients.

The Solution: To mitigate the issue of long wait times, B2B buyers should establish clear communication with Andrews Custom Leather prior to placing an order. It’s advisable to inquire about current lead times, production schedules, and any potential delays. Additionally, buyers should consider placing orders well in advance of their intended need, allowing for unexpected delays. Implementing a robust inventory management system can also help maintain stock levels while waiting for custom orders. Lastly, exploring bulk order options may provide a faster turnaround, as larger orders could be prioritized in the production queue.

Scenario 2: Price Increases After Order Placement

The Problem: Another pain point that has emerged among B2B buyers is the sudden increase in prices after orders have been placed. Instances where customers were quoted a specific price only to be charged more upon delivery can lead to dissatisfaction and mistrust. This unpredictability can create budgeting challenges for businesses that rely on fixed costs for planning and pricing their own offerings.

The Solution: To prevent issues related to price increases, B2B buyers should secure a written agreement that outlines the pricing terms at the time of order placement. It is also beneficial to ask for a clear explanation of the pricing structure and any factors that might lead to increases. Maintaining open lines of communication with Andrews Custom Leather can provide insights into market trends that may affect pricing. Furthermore, buyers should keep a close eye on the market for similar products, as this knowledge can empower them to negotiate better terms or switch suppliers if necessary.

Scenario 3: Quality Concerns with Leather Holsters

The Problem: Quality concerns have been voiced regarding the durability and functionality of Andrews Custom Leather holsters. Some users have noted that the holsters can become soft over time or do not meet their expectations for performance. For B2B buyers, this can lead to issues with product reliability, resulting in potential returns or dissatisfied end customers.

The Solution: To address quality concerns, B2B buyers should conduct thorough due diligence before placing orders. This includes requesting samples of the leather holsters to evaluate their craftsmanship and durability firsthand. Engaging with other businesses that have previously purchased from Andrews can provide valuable insights into product performance. Additionally, buyers should consider establishing a warranty or return policy in their agreements to ensure recourse in the event of subpar products. Lastly, providing feedback to Andrews Custom Leather regarding quality can help the manufacturer improve their offerings and align better with customer expectations.

Strategic Material Selection Guide for andrews custom leather holsters

What are the Key Materials Used in Andrews Custom Leather Holsters?

When selecting materials for Andrews Custom Leather Holsters, various factors come into play, including durability, cost, and suitability for specific applications. Below, we analyze four common materials used in the production of these holsters, providing insights that are particularly relevant for international B2B buyers.

How Does Traditional Cowhide Leather Perform in Holster Manufacturing?

Cowhide leather is one of the most commonly used materials for holsters due to its excellent durability and flexibility. It can withstand various environmental conditions, making it suitable for diverse climates, from the humid regions of Africa to the cooler climates of Europe.

Key Properties: Cowhide offers a temperature rating that can handle moderate heat and pressure, making it ideal for everyday use. It also has a natural resistance to wear and tear.

Illustrative image related to andrews custom leather holsters

Pros & Cons: The primary advantage of cowhide is its strength and ability to mold to the user’s firearm over time, providing a custom fit. However, it can be more expensive than synthetic alternatives and may require regular conditioning to maintain its appearance and functionality.

Impact on Application: Cowhide is compatible with a range of firearm types and is often favored for its aesthetic appeal. However, it may not perform as well in extreme conditions, such as prolonged exposure to moisture.

Considerations for International Buyers: Buyers from regions like Nigeria or Germany should ensure that the cowhide used complies with local regulations regarding animal products. Familiarity with standards such as ASTM can also aid in selecting high-quality leather.

Illustrative image related to andrews custom leather holsters

What Role Does Exotic Leather Play in Holster Design?

Exotic leathers, such as alligator or ostrich, are often used for high-end holsters. These materials offer unique aesthetics and are highly sought after for their distinctive patterns and textures.

Key Properties: Exotic leathers are generally more resistant to wear and tear than standard leathers, providing an upscale option for discerning customers.

Pros & Cons: The key advantage of exotic leather is its luxurious appearance, which can elevate the perceived value of the holster. However, these materials come at a significantly higher cost and may require specialized care to maintain their quality.

Impact on Application: Exotic leathers are often used in holsters designed for formal occasions or as fashion accessories, rather than for everyday carry. Their unique properties can make them less suitable for rugged use.

Considerations for International Buyers: Buyers should be aware of import regulations regarding exotic leathers, which can vary significantly by country. Compliance with CITES (Convention on International Trade in Endangered Species) is essential for certain types of exotic leather.

How Does Kydex Compare as a Material for Holsters?

Kydex is a thermoplastic material that has gained popularity in holster manufacturing due to its durability and versatility. It is particularly favored for tactical applications.

Key Properties: Kydex can withstand high temperatures and is resistant to moisture, making it ideal for various environmental conditions.

Illustrative image related to andrews custom leather holsters

Pros & Cons: The main advantage of Kydex is its lightweight nature and ability to retain shape, ensuring a consistent fit. However, it lacks the traditional aesthetic appeal of leather, which may deter some buyers.

Impact on Application: Kydex holsters are often used in law enforcement and military applications due to their quick-draw capabilities and durability. They are less suited for formal or aesthetic purposes.

Considerations for International Buyers: Buyers should ensure that Kydex products meet local safety and quality standards, such as DIN in Germany. Understanding the material’s properties can help buyers make informed decisions.

What Are the Benefits of Synthetic Leather in Holster Manufacturing?

Synthetic leather, often made from polyurethane or PVC, is a cost-effective alternative to traditional leather. It is increasingly used in holster production due to its affordability and ease of maintenance.

Key Properties: Synthetic leather can mimic the look and feel of real leather while offering good resistance to water and stains.

Illustrative image related to andrews custom leather holsters

Pros & Cons: The primary advantage of synthetic leather is its lower cost and ease of cleaning. However, it may not offer the same level of durability or aesthetic appeal as genuine leather.

Impact on Application: Synthetic leather is suitable for casual use and is often preferred by budget-conscious buyers. However, it may not provide the same level of comfort and fit as traditional leather.

Considerations for International Buyers: Buyers should check for compliance with local regulations regarding synthetic materials, particularly in regions with strict environmental standards.

Summary Table of Material Selection for Andrews Custom Leather Holsters

| Matériau | Typical Use Case for andrews custom leather holsters | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide Leather | Everyday carry holsters | Excellent durability and flexibility | Requires maintenance and conditioning | Medium |

| Exotic Leather | High-end, luxury holsters | Unique aesthetic appeal | High cost and requires special care | Haut |

| Kydex | Tactical and law enforcement holsters | Lightweight and moisture-resistant | Lacks traditional aesthetic appeal | Medium |

| Synthetic Leather | Budget-friendly, casual use holsters | Cost-effective and easy to clean | May not be as durable as real leather | Low |

This analysis provides a comprehensive overview of the materials used in Andrews Custom Leather Holsters, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for andrews custom leather holsters

What Are the Main Stages of Manufacturing Andrews Custom Leather Holsters?

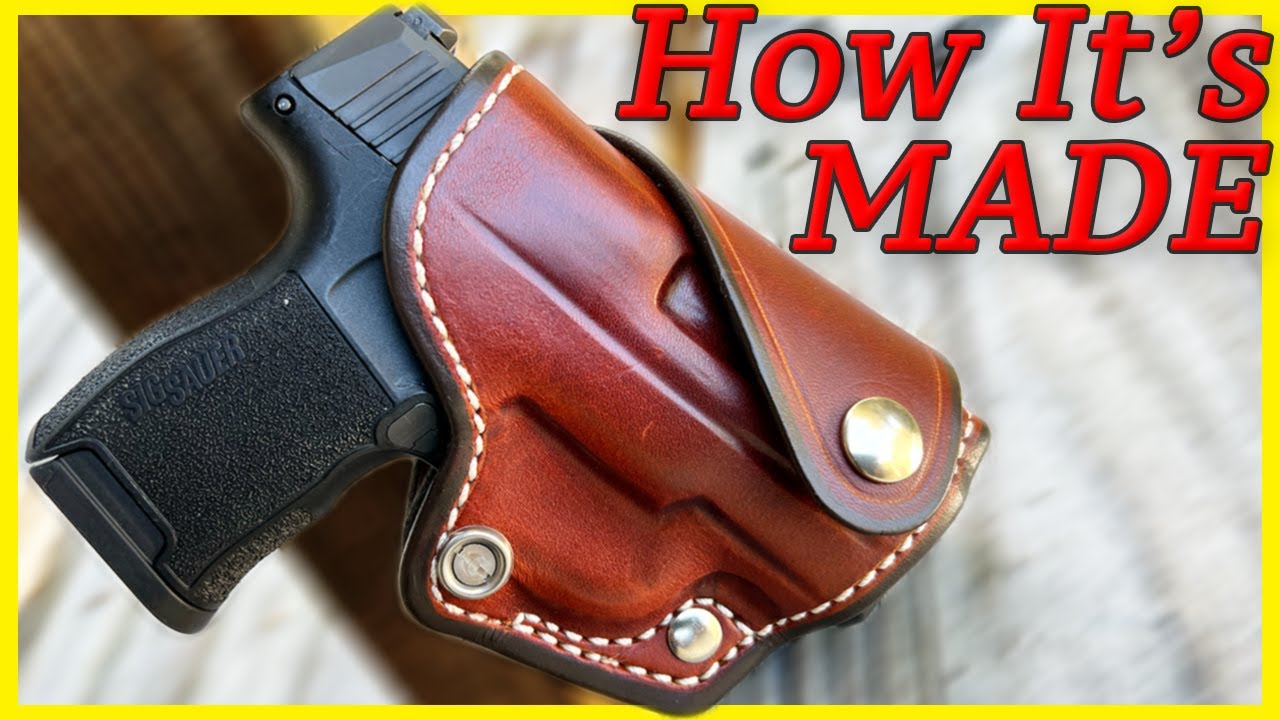

The manufacturing process for Andrews Custom Leather holsters is both intricate and methodical, ensuring that each product meets the high standards expected by discerning buyers. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Custom Leather Holsters?

The journey begins with the selection of high-quality leather, which is often sourced from reputable tanneries. Andrews Custom Leather emphasizes the use of full-grain leather, known for its durability and natural aesthetics. The leather undergoes a rigorous inspection process to ensure that it is free from defects, such as scars or irregularities.

Once selected, the leather is conditioned to enhance its pliability and strength. This process may include oiling or waxing, which helps preserve the leather while adding a layer of protection. The prepared leather is then cut into patterns based on the specific holster design required, ensuring that each piece is accurately measured for a perfect fit.

What Techniques Are Used in the Forming Stage?

Forming is a critical stage in the production of leather holsters. It involves shaping the cut leather pieces to fit the intended firearm securely. Andrews Custom Leather employs a combination of traditional handcrafting techniques and modern machinery to achieve precise shapes.

One common technique is wet forming, where the leather is dampened and then molded around a specific firearm. This method allows for a tight fit that conforms to the contours of the gun, ensuring optimal retention and accessibility. The use of molds and jigs further enhances the accuracy of the forming process, ensuring that each holster meets design specifications.

How Are Custom Leather Holsters Assembled?

The assembly stage involves stitching together the formed leather pieces. Andrews Custom Leather uses heavy-duty thread and robust stitching techniques to ensure durability. This might include saddle stitching, a method that provides strength and longevity due to its double-threaded nature.

Once stitched, additional components such as rivets, snaps, or belt loops are added. Each component is carefully selected for quality, as they play a significant role in the overall performance and aesthetic of the holster. Quality control checkpoints are established throughout this stage to ensure that each holster meets the company’s high standards.

What Finishing Techniques Are Applied to Enhance Quality?

Finishing is the final stage in the manufacturing process. This stage not only enhances the visual appeal of the holster but also adds protective elements. The leather is typically treated with dyes, conditioners, and finishes that improve its resistance to moisture and wear.

Andrews Custom Leather may also apply edge finishing techniques to prevent fraying and enhance the overall appearance of the holster. This attention to detail is crucial, as it contributes to the product’s longevity and customer satisfaction.

Illustrative image related to andrews custom leather holsters

How Does Quality Assurance Ensure the Excellence of Andrews Custom Leather Holsters?

Quality assurance is an integral part of the manufacturing process at Andrews Custom Leather. The company adheres to international standards such as ISO 9001, which outlines the criteria for a quality management system. This commitment to quality ensures that every holster produced meets the expectations of B2B buyers.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process, which includes Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This initial checkpoint ensures that all raw materials meet specified quality standards before they enter the production line. It may involve visual inspections and material testing.

-

In-Process Quality Control (IPQC): During the manufacturing process, periodic checks are performed to ensure that the holsters are being assembled according to specifications. This includes monitoring stitching quality and component alignment.

-

Final Quality Control (FQC): Before the holsters are shipped, a thorough final inspection is conducted. This includes checking for any defects, ensuring that all components are secure, and verifying that the holster meets the design specifications.

What Testing Methods Are Commonly Used for Quality Assurance?

Various testing methods are employed to evaluate the durability and functionality of the holsters. These may include:

Illustrative image related to andrews custom leather holsters

- Stress Testing: Assessing the holster’s ability to withstand wear and tear.

- Retention Testing: Ensuring that the holster securely holds the firearm under various conditions.

- Water Resistance Testing: Evaluating how well the leather repels moisture.

These tests are crucial for ensuring that the holsters not only meet aesthetic standards but also function effectively in real-world scenarios.

How Can B2B Buyers Verify the Quality Control of Their Suppliers?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers like Andrews Custom Leather is essential. Buyers can take several steps to ensure they are partnering with a reputable manufacturer.

What Are Effective Methods for Conducting Supplier Audits?

Conducting audits is a practical approach for buyers to assess a supplier’s manufacturing and quality assurance processes. This can include:

- On-Site Visits: Arranging visits to the manufacturing facility allows buyers to observe the production process, materials used, and quality control measures in place.

- Requesting Documentation: Suppliers should be able to provide documentation of their quality management system, including ISO certifications and internal QC reports.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures.

What Nuances Should International Buyers Consider Regarding QC?

International buyers must also consider specific nuances related to quality assurance that may vary by region. For instance, buyers from Europe may have stricter regulations regarding product safety and environmental standards compared to those in other regions. Understanding these differences can help buyers make informed decisions and establish clear expectations with their suppliers.

Furthermore, recognizing the supply chain logistics that may impact delivery timelines, such as customs delays or shipping constraints, is essential for maintaining strong supplier relationships.

By understanding the manufacturing processes and quality assurance measures employed by Andrews Custom Leather, B2B buyers can make informed purchasing decisions, ensuring they receive products that meet their quality expectations and operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘andrews custom leather holsters’

Introduction

This guide aims to provide international B2B buyers with a comprehensive checklist for sourcing Andrews Custom Leather Holsters. Understanding the nuances of this procurement process will help ensure that your purchase meets quality standards and aligns with your business needs.

Step 1: Identify Your Specific Requirements

Before initiating contact with suppliers, clearly define the specifications of the leather holsters you need. Consider factors such as the type of firearm, intended use, and any specific design features or materials (e.g., traditional vs. exotic leather). This clarity will facilitate more effective communication with potential suppliers and help you evaluate their offerings accurately.

Step 2: Research Andrews Custom Leather’s Product Range

Familiarize yourself with the variety of products offered by Andrews Custom Leather. Visit their online catalog to understand their traditional and exotic skin options. Pay attention to unique features and customization possibilities that could enhance your offering in your target market.

Step 3: Evaluate Supplier Reliability and Reputation

Assess the reliability of Andrews Custom Leather by reviewing customer feedback and testimonials. Look for consistent patterns in reviews regarding quality, delivery times, and customer service. This step is crucial, as a supplier’s reputation can significantly impact your business’s credibility.

- Check Online Reviews: Platforms like forums or industry-specific websites can provide insights from other buyers.

- Ask for References: Contact previous clients to gain firsthand information about their experience.

Step 4: Verify Production and Delivery Timelines

Inquire about the expected production and delivery timelines for your order. Given the reports of extended wait times for custom orders, it’s essential to understand the current lead times. This knowledge will help you manage your inventory and customer expectations effectively.

- Request Written Timelines: Ensure that the supplier provides a written commitment to avoid misunderstandings.

- Consider Buffer Time: Factor in additional time for potential delays, especially for international shipping.

Step 5: Discuss Payment Terms and Pricing

Clarify the payment structure and pricing before finalizing your order. Understand what deposit is required and whether prices may change during the production period. Transparency in financial dealings is vital to avoid any future disputes.

- Negotiate Terms: Don’t hesitate to discuss bulk order discounts or favorable payment terms.

- Document Everything: Keep a record of all agreements to safeguard your interests.

Step 6: Assess Quality Assurance Processes

Inquire about the quality control measures Andrews Custom Leather employs. Knowing how they ensure the durability and craftsmanship of their holsters is essential for maintaining product standards in your business.

- Request Quality Certifications: Ask for documentation that demonstrates adherence to industry quality standards.

- Understand Return Policies: Familiarize yourself with their return policy in case the products do not meet your expectations.

Step 7: Establish a Communication Plan

Create a communication plan for ongoing dialogue with your supplier. Regular check-ins can prevent misunderstandings and keep you informed about the production status. This proactive approach fosters a better working relationship and enhances transparency.

- Set Regular Updates: Agree on a schedule for updates regarding your order status.

- Utilize Multiple Channels: Ensure you have access to various communication channels (email, phone, etc.) to facilitate timely interactions.

By following this checklist, you can streamline the procurement process for Andrews Custom Leather Holsters, ensuring that your business receives high-quality products that meet your specific needs.

Comprehensive Cost and Pricing Analysis for andrews custom leather holsters Sourcing

What Are the Key Cost Components for Sourcing Andrews Custom Leather Holsters?

When considering sourcing from Andrews Custom Leather, it’s essential to understand the various cost components involved in their pricing structure. The primary elements include:

-

Materials: The quality of leather used is a significant factor. Andrews Custom Leather offers traditional and exotic skins, which can vary widely in cost. Higher quality materials typically command a premium, impacting the overall price.

-

Labor: Skilled craftsmanship is a hallmark of Andrews Custom Leather products. Labor costs will reflect the artisans’ expertise and the time required to create custom pieces.

-

Manufacturing Overhead: This encompasses operational costs, including rent, utilities, and administrative expenses. For artisanal businesses, these costs can be relatively high due to the low volume of production.

-

Tooling: Specialized tools and equipment for leatherworking contribute to initial setup costs. The investment in quality tools can affect the pricing of the final product.

-

Quality Control (QC): Ensuring each holster meets specific quality standards involves additional time and resources. The cost of QC is a necessary component that ensures customer satisfaction and product longevity.

-

Logistics: Shipping costs, especially for international orders, can vary significantly based on destination and shipping method. Buyers should consider these expenses when calculating the total cost.

-

Margin: The profit margin that Andrews Custom Leather applies will also influence the final price. Given the bespoke nature of their products, margins may be higher than mass-produced alternatives.

What Influences Pricing for Custom Leather Holsters?

Several factors can influence the pricing of Andrews Custom Leather holsters:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders may qualify for discounts, making it advantageous for B2B buyers to negotiate larger quantities.

-

Specifications and Customization: Custom designs or unique specifications can lead to increased costs. Buyers should communicate their needs clearly to understand any pricing implications.

-

Quality and Certifications: The reputation of the brand and any quality certifications may justify higher prices. Buyers should weigh the benefits of investing in a recognized quality brand versus lower-cost alternatives.

-

Supplier Factors: The reliability and reputation of Andrews Custom Leather as a supplier can impact pricing. Established brands may charge more due to perceived value and trustworthiness.

-

Incoterms: Understanding the shipping terms (Incoterms) is crucial for pricing. Different terms can affect who bears the cost of shipping, insurance, and duties, impacting the overall cost to the buyer.

How Can International B2B Buyers Optimize Their Sourcing Costs?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can benefit from specific strategies to optimize their sourcing costs:

-

Negotiation: Engaging in open discussions about pricing can yield favorable terms. Buyers should be prepared to negotiate based on volume and long-term partnership potential.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also shipping, tariffs, and potential returns or exchanges. A lower upfront price may lead to higher costs over time if quality issues arise.

-

Pricing Nuances: Be aware of fluctuations in material costs, exchange rates, and shipping fees, which can affect the final price. Engaging in forward contracts for currencies or securing fixed pricing agreements can mitigate these risks.

-

Research Alternatives: While Andrews Custom Leather offers quality products, exploring alternative suppliers may provide insights into competitive pricing and product offerings.

In conclusion, understanding the comprehensive cost structure and pricing influences of Andrews Custom Leather holsters is vital for B2B buyers. By considering these factors and employing strategic sourcing techniques, businesses can effectively manage their budgets and ensure they receive quality products that meet their needs.

Alternatives Analysis: Comparing andrews custom leather holsters With Other Solutions

Understanding Alternative Solutions in Leather Holsters

When considering leather holsters for firearms, it’s essential to evaluate various options to determine the best fit for specific needs. This section compares Andrews Custom Leather Holsters with alternative solutions, providing insights on performance, cost, and usability. This analysis aims to equip international B2B buyers with the necessary information to make informed purchasing decisions.

| Comparison Aspect | Andrews Custom Leather Holsters | R Grizzle Leather | Palmetto Leather Works |

|---|---|---|---|

| Performance | Custom fit, high durability | Excellent retention, comfort | Reliable performance, good fit |

| Cost | Higher-end, around $450-$600 | Moderate, typically $300-$450 | Affordable, typically $200-$350 |

| Ease of Implementation | Longer lead times, often over 12 months | Moderate lead times, generally 4-6 months | Fast delivery, usually within 2-4 weeks |

| Maintenance | Minimal, depends on care | Low maintenance required | Low maintenance required |

| Best Use Case | Custom, specialized needs | Everyday carry, law enforcement | General use, casual carry |

R Grizzle Leather: A Reliable Alternative

R Grizzle Leather stands out as a strong contender in the custom holster market. Known for their excellent craftsmanship and attention to detail, R Grizzle products offer a balance of performance and affordability. They are particularly praised for their comfort during extended wear, making them a preferred choice for everyday carry and law enforcement professionals. However, potential buyers should be aware of their moderate lead times, which can range from four to six months, and the variability in custom options compared to Andrews.

Palmetto Leather Works: The Affordable Option

For those seeking a more budget-friendly solution, Palmetto Leather Works presents a compelling alternative. Their holsters are known for reliable performance and ease of use, making them suitable for casual carry and general purposes. The key advantage of Palmetto is their faster delivery times, typically within two to four weeks, which appeals to B2B buyers requiring prompt service. While they may not offer the same level of customization as Andrews or R Grizzle, their affordability and solid construction make them a valuable option for businesses looking to stock holsters without a significant investment.

Illustrative image related to andrews custom leather holsters

Conclusion: Selecting the Right Leather Holster Solution

When choosing between Andrews Custom Leather Holsters and alternative solutions like R Grizzle Leather or Palmetto Leather Works, B2B buyers should consider their specific needs, including budget, customization requirements, and lead times. Andrews offers unparalleled customization and quality for specialized applications, while R Grizzle provides a balance of quality and comfort, and Palmetto offers affordability and quick turnaround times. By assessing these factors, businesses can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for andrews custom leather holsters

What Are the Key Technical Properties of Andrews Custom Leather Holsters?

When considering Andrews Custom Leather holsters, several technical specifications are critical for B2B buyers. Understanding these properties can aid in making informed purchasing decisions that align with business needs.

1. Material Grade

Andrews holsters are crafted from high-quality leather, often sourced from premium tanneries. The grade of leather affects durability, aesthetics, and functionality. Top-grain leather is typically used, known for its strength and resistance to wear, while exotic skins may also be available for specialized applications. For B2B buyers, selecting the right material grade ensures the product meets both performance requirements and customer expectations.

2. Construction Method

The construction method, whether hand-stitched or machine-stitched, significantly impacts the holster’s durability and usability. Hand-stitched options often offer superior strength and a unique aesthetic appeal, making them preferable for high-end markets. B2B buyers should consider the construction method as it relates to the end-use of the holster, especially in high-demand environments.

3. Tolerance Levels

Tolerance refers to the permissible limit of variation in dimensions. For holsters, tight tolerances ensure a secure fit for the firearm, which is essential for safety and ease of use. A holster that does not fit properly can lead to operational issues and customer dissatisfaction. Understanding tolerance levels helps B2B buyers assess product quality and compatibility with specific firearm models.

4. Weight Capacity

The weight capacity of a holster indicates the maximum load it can safely carry without compromising performance. This is particularly important for tactical applications where the user may carry additional equipment. B2B buyers should consider the weight capacity in relation to the intended use, ensuring that the holster can accommodate the necessary gear without risk of failure.

5. Finish and Treatment

The finish on a leather holster affects both its appearance and its resistance to environmental factors such as moisture and UV light. Various treatments can enhance durability, including waterproofing and abrasion resistance. For B2B buyers, understanding the finish options can help in selecting holsters that perform well under specific conditions, particularly in diverse climates found in regions like Africa and South America.

What Are Common Trade Terms Related to Andrews Custom Leather Holsters?

Familiarity with industry jargon and trade terms is essential for effective communication and negotiation in B2B transactions.

Illustrative image related to andrews custom leather holsters

1. OEM (Original Equipment Manufacturer)

In the context of leather holsters, OEM refers to companies that manufacture products that are sold under another company’s brand name. B2B buyers may seek OEM partnerships to offer custom-branded holsters, enhancing their product line while leveraging established manufacturing expertise.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. For holster manufacturers, MOQs can vary widely based on the type of leather and customization options. Understanding MOQs is crucial for B2B buyers to manage inventory costs and ensure they can meet market demand without overcommitting.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products. B2B buyers often use RFQs to compare costs and terms from multiple suppliers, ensuring they receive competitive pricing for their orders of Andrews holsters.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. For B2B transactions involving Andrews Custom Leather holsters, understanding Incoterms is essential for determining shipping responsibilities, costs, and risk transfer points.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Given the custom nature of Andrews holsters, lead times can vary significantly. B2B buyers should factor lead times into their planning to ensure timely fulfillment of customer orders.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing Andrews Custom Leather holsters, ultimately enhancing their product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the andrews custom leather holsters Sector

What Are the Key Market Dynamics and Trends Affecting the Andrews Custom Leather Holsters Sector?

The global leather holster market is shaped by various dynamics that are critical for international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe. A notable driver is the increasing demand for personalized and high-quality leather products. Buyers are gravitating towards custom solutions that cater to specific needs, including ergonomic designs and unique aesthetic preferences. As consumers become more discerning, the emphasis on craftsmanship and the quality of materials used in holsters has intensified.

Emerging technologies are also influencing sourcing trends. For instance, advancements in e-commerce platforms have made it easier for buyers to access niche markets, allowing them to explore a variety of custom leather products without geographical constraints. Additionally, the rise of social media has facilitated greater brand visibility, enabling companies like Andrews Custom Leather to showcase their craftsmanship and engage with potential buyers directly. However, international buyers must remain vigilant about lead times and communication, as feedback from customers indicates significant delays in order fulfillment, which can affect overall satisfaction and brand loyalty.

Moreover, the market is witnessing a shift towards sustainable practices. As environmental awareness grows, buyers are increasingly prioritizing suppliers who adopt ethical sourcing methods and sustainable materials. This shift not only aligns with consumer expectations but also enhances brand reputation, making it a crucial consideration for B2B buyers.

How Are Sustainability and Ethical Sourcing Addressed in the Andrews Custom Leather Holsters Sector?

Sustainability has become a pivotal concern in the leather industry, and B2B buyers should evaluate suppliers based on their environmental impact and ethical sourcing practices. For Andrews Custom Leather, adopting sustainable practices can involve sourcing leather from suppliers who adhere to responsible grazing and tanning processes. This is increasingly important for buyers in regions where environmental regulations are stringent and consumer demand for sustainable products is rising.

Illustrative image related to andrews custom leather holsters

Ethical sourcing also extends to ensuring fair labor practices throughout the supply chain. Buyers should inquire about the working conditions of artisans and workers involved in the production of leather holsters. Certifications for sustainable and ethical practices, such as the Leather Working Group (LWG) certification, can serve as indicators of a supplier’s commitment to these principles.

Furthermore, integrating eco-friendly materials, such as vegetable-tanned leather or recycled components, can enhance the attractiveness of products for environmentally conscious buyers. By prioritizing sustainability, suppliers not only meet regulatory demands but also tap into a growing market segment that values ethical consumption, thereby strengthening their competitive position.

What Is the Historical Context of Andrews Custom Leather Holsters That Influences Current B2B Dynamics?

Andrews Custom Leather has a storied history rooted in craftsmanship and tradition, which continues to influence its current market position. Established in the early days of the leather goods sector, the brand has built a reputation for producing high-quality, custom leather holsters that cater to a discerning clientele. This legacy of craftsmanship is a significant selling point for B2B buyers who seek products that embody both quality and heritage.

Over the years, the brand has faced challenges typical of artisanal businesses, including fluctuations in demand and the complexities of scaling production while maintaining quality. As the market evolves, Andrews Custom Leather has adapted by embracing new technologies and marketing strategies, including an online store that allows for direct sales and customer engagement. However, issues surrounding order fulfillment and communication have surfaced, highlighting the importance of operational efficiency in maintaining customer satisfaction.

For international buyers, understanding this historical context is crucial. It provides insight into the brand’s commitment to quality and customer service, while also shedding light on potential challenges in sourcing. As buyers navigate their purchasing decisions, recognizing the balance between tradition and modern market dynamics will be essential for fostering successful B2B relationships in the leather holster sector.

Frequently Asked Questions (FAQs) for B2B Buyers of andrews custom leather holsters

-

How do I address long lead times for custom holster orders?

Long lead times can be a common issue with custom leather holsters, including those from Andrews Custom Leather. To mitigate this, establish clear communication with the supplier before placing an order. Request a detailed timeline that outlines the production process and expected delivery dates. Consider placing smaller initial orders to gauge the supplier’s reliability and production speed before committing to larger quantities. Additionally, inquire about their current workload and any potential delays that may affect your order. -

What are the customization options available for Andrews custom leather holsters?

Andrews Custom Leather offers a variety of customization options, including holster type, leather quality, color, and stitching. B2B buyers can request specific features tailored to their needs, such as fit for particular firearm models or additional design elements like embossed logos. It’s essential to discuss these options upfront to ensure the final product meets your specifications. Documentation of your requirements can also help avoid misunderstandings during the production process. -

What is the minimum order quantity (MOQ) for wholesale purchases?

The minimum order quantity (MOQ) for Andrews Custom Leather holsters may vary based on the specific product and customization required. For B2B transactions, it is advisable to directly contact the supplier to discuss your needs and negotiate an appropriate MOQ. If your order is below the MOQ, consider collaborating with other buyers to meet the required quantity or explore alternative products that fit your business model. -

How can I ensure quality assurance (QA) for my holster orders?

To ensure quality assurance for your orders from Andrews Custom Leather, request samples before placing a bulk order. This will allow you to assess the craftsmanship, materials, and overall quality of the holsters. Additionally, establish a clear QA process with the supplier, including inspection criteria and potential return policies for defective items. Regular communication during the production phase can also help address any concerns promptly. -

What payment terms are typically offered for international buyers?

Payment terms for international buyers can vary significantly based on the supplier’s policies and the buyer’s location. Common options include upfront payment, partial payment before shipment, or payment upon delivery. It is crucial to discuss and agree upon the payment terms in advance to avoid misunderstandings. Furthermore, consider using secure payment methods that offer buyer protection, especially when dealing with larger transactions. -

How should I vet Andrews Custom Leather as a supplier?

When vetting Andrews Custom Leather or any supplier, consider factors such as their reputation, customer reviews, and production capabilities. Look for testimonials from other B2B buyers, especially those in your region, to gauge reliability and product quality. Engaging in direct communication with the supplier can also provide insights into their responsiveness and willingness to accommodate your specific needs. Additionally, researching their history and experience in the industry can further inform your decision. -

What logistics options are available for shipping orders internationally?

International logistics for shipping holster orders can include various options such as air freight, sea freight, or courier services. Discuss shipping preferences with Andrews Custom Leather to determine the best option based on your delivery timeline and budget. Ensure that the supplier provides tracking information and understands customs regulations for your destination country. Familiarize yourself with import duties and taxes to avoid unexpected costs upon arrival. -

How can I manage expectations regarding order fulfillment timelines?

To manage expectations regarding order fulfillment timelines, maintain open lines of communication with Andrews Custom Leather throughout the order process. Request regular updates on production status and notify them of any critical deadlines you may have. Understanding their workload and production capacity can help set realistic timelines. Additionally, factor in potential delays caused by shipping or customs when planning your order fulfillment strategy.

Top 2 Andrews Custom Leather Holsters Manufacturers & Suppliers List

1. Andrews Leather – Custom Holster

Domain: andrewsleather.com

Registered: 1999 (26 years)

Introduction: Andrews Custom Leather Catalogs, Traditional Leather Catalog, Exotic Skins Catalog, Professional Accessories, Online Store with items available for immediate shipment, only ONE item in stock for each image, Monarch Shoulder Rig, Custom Leather Holster.

2. Andrews Custom Leather – Small Revolver Holster

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”: “Small Revolver Holster Made By Andrews Custom Leather ( Must See )”, “condition”: “Used”, “price”: “$40.00”, “quantity”: “1 available”, “item_number”: “266716349532”, “brand”: “Andrews Custom Leather”, “handedness”: “Left”, “description”: “This little holster could maybe hold a NAA 22 LR with a 1-1/8″ barrel ?. The loop should fit on a 1-1/2” belt. This may have been used but not sure.”…

Strategic Sourcing Conclusion and Outlook for andrews custom leather holsters

In conclusion, strategic sourcing for Andrews Custom Leather Holsters involves understanding both the craftsmanship and the challenges inherent in bespoke leather goods production. Buyers should be aware of the extended lead times reported by some customers, emphasizing the importance of clear communication and realistic expectations regarding delivery timelines. This insight highlights the necessity for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, to establish robust relationships with suppliers.

Investing in high-quality leather holsters can significantly enhance the value proposition for end-users, particularly in markets that prioritize durability and craftsmanship. As demand for premium leather goods continues to rise, buyers are encouraged to engage in proactive sourcing strategies, ensuring they partner with reputable manufacturers who prioritize customer satisfaction and product integrity.

Looking ahead, international buyers should leverage this knowledge to foster partnerships that not only meet their immediate needs but also support long-term growth in the leather goods sector. By aligning with manufacturers like Andrews Custom Leather, buyers can capitalize on the unique offerings of high-quality, custom leather products tailored to their specific market demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.