Catalog

Material Insight: Fabric For Motorcycle Seat

B2B Product Guide: Premium Fabric Solutions for Motorcycle Seats

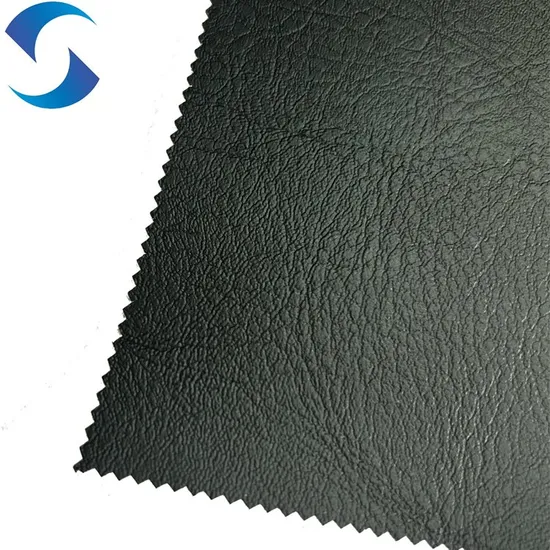

Motorcycle seats endure extreme conditions – relentless UV exposure, torrential rain, abrasive friction, and wide temperature fluctuations. Selecting the right upholstery fabric is critical for rider comfort, product longevity, and brand reputation. Traditional materials like genuine leather or basic vinyl often fail to deliver the consistent performance, sustainability, and cost-efficiency demanded by modern motorcycle OEMs and aftermarket manufacturers.

Faux leather (synthetic leather) has emerged as the superior choice for motorcycle seating applications, offering unparalleled advantages over conventional options:

- Exceptional Weather & Abrasion Resistance: Engineered to withstand prolonged UV exposure without fading or cracking, repel water effectively, and resist tearing from rider movement or road debris, ensuring seats maintain integrity and aesthetics throughout the product lifecycle.

- Consistent Quality & Design Flexibility: Eliminates the natural imperfections and variability of genuine leather, providing uniform texture, color, and thickness across every batch. Enables precise customization of grain patterns, colors, and textures to match specific brand aesthetics.

- Enhanced Rider Comfort & Breathability: Advanced formulations incorporate micro-porous structures and specialized backing fabrics that significantly improve airflow compared to traditional vinyl, reducing heat buildup and moisture retention during long rides.

- Simplified Maintenance & Hygiene: Features non-porous, wipe-clean surfaces that resist staining from oils, fuels, and everyday grime. Inhibits microbial growth, crucial for seats exposed to sweat and varying climates.

- Sustainable Performance: Modern eco-conscious faux leathers drastically reduce environmental impact versus leather tanning (which involves heavy metals and high water usage) while offering comparable or superior durability.

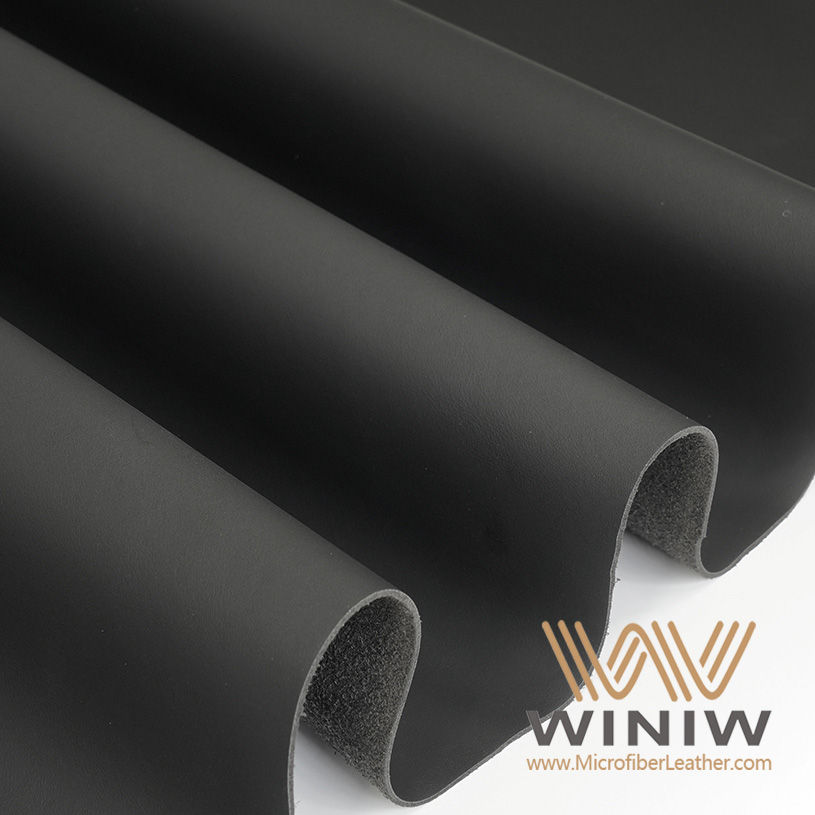

Introducing WINIW: Your Trusted Partner in Advanced Synthetic Leather

For over 20 years, WINIW has been a global leader in developing high-performance, eco-responsible synthetic leather solutions specifically engineered for demanding transportation applications. We understand the rigorous requirements of the motorcycle industry – from the need for extreme durability on long-distance touring bikes to the premium tactile experience demanded by luxury cruiser manufacturers. WINIW leverages cutting-edge material science, rigorous testing protocols, and a deep commitment to sustainable manufacturing to deliver faux leather that consistently exceeds OEM specifications. Our dedicated R&D team works collaboratively with clients to create tailored solutions that enhance product value, reduce total cost of ownership, and support evolving environmental regulations. Partner with WINIW to elevate your motorcycle seat performance with innovation you can rely on.

Technical Performance & Standards

WINIW B2B Product Guide: Synthetic Leather for Motorcycle Seats

WINIW specializes in high-performance synthetic leather engineered specifically for motorcycle seat applications. Our material combines advanced manufacturing techniques with stringent quality control to deliver a cost-effective, durable, and eco-conscious solution for OEMs and aftermarket manufacturers. Designed to meet the rigorous demands of the motorcycle industry, WINIW’s fabric offers superior performance across mechanical strength, weather resistance, and aesthetic flexibility.

Technical Advantages

-

Cost-Effective Production

WINIW’s synthetic leather reduces overall manufacturing costs through optimized material yield and simplified processing. The fabric requires no pre-treatment and is compatible with standard cutting, sewing, and molding equipment, minimizing downtime and labor costs. -

Exceptional Durability

Engineered with high-density polyurethane and reinforced backing, the material exhibits outstanding abrasion resistance, tensile strength, and tear resistance. It maintains integrity under prolonged exposure to vibration, UV radiation, and extreme temperatures (-30°C to +80°C). -

Customizable Color Options

WINIW offers full color customization with precise Pantone matching and batch-to-batch consistency. Our digital color management system ensures accurate replication across large production runs, supporting brand-specific design requirements. -

REACH Compliance

Our synthetic leather is fully compliant with EU REACH regulations (EC 1907/2006), including SVHC (Substances of Very High Concern) screening. Free from harmful phthalates, heavy metals, and AZO dyes, it supports sustainable and safe product development. -

ISO9001-Certified Manufacturing

WINIW operates under an ISO9001-certified quality management system, ensuring consistent product quality, traceability, and process efficiency. Every batch undergoes rigorous in-line and final inspection to meet defined performance criteria.

Application Benefits

- Ideal for both sport and cruiser motorcycle seat designs

- Resistant to oil, sweat, and common cleaning agents

- Lightweight construction contributes to overall vehicle efficiency

- Excellent adhesion to foam substrates without delamination

- Low VOC emissions, supporting indoor air quality standards

Technical Specifications

| Property | Spécifications | Test Standard |

|---|---|---|

| Material Type | Polyurethane Synthetic Leather | – |

| Thickness | 0.8 mm – 1.2 mm (customizable) | ISO 2589 |

| Tensile Strength (Warp) | ≥ 90 N/50mm | ISO 1421 |

| Tensile Strength (Weft) | ≥ 85 N/50mm | ISO 1421 |

| Elongation at Break | ≤ 30% | ISO 1421 |

| Tear Strength | ≥ 45 N | ISO 1781 |

| Abrasion Resistance | ≥ 50,000 cycles (Martindale) | ISO 12947-2 |

| Color Fastness to Rubbing | Dry: Class 4–5; Wet: Class 4 | ISO 105-X12 |

| Light Fastness | ≥ 6 (on Blue Wool Scale) | ISO 105-B02 |

| Cold Crack Resistance | Pass (-30°C) | ISO 4675 |

| Heat Aging Resistance | Pass (80°C, 168h) | ISO 1789 |

| REACH Compliance | Fully compliant | EC 1907/2006 |

| ISO Certification | ISO9001:2015 | – |

WINIW’s motorcycle seat fabric delivers a balanced combination of performance, compliance, and value—making it a trusted choice for global two-wheeler manufacturers seeking reliable, scalable, and environmentally responsible materials.

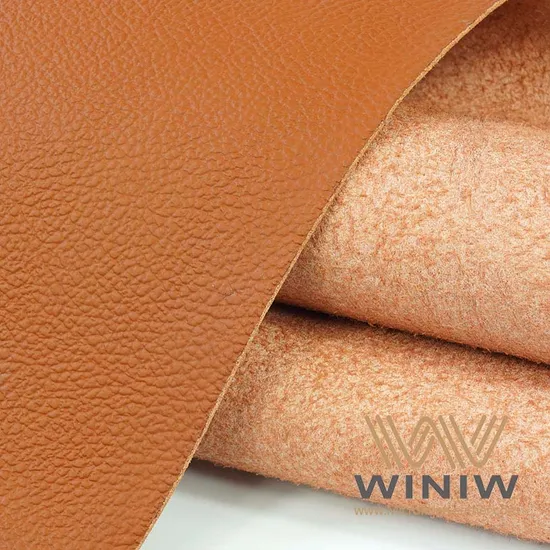

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Material Selection for Premium Motorcycle Seats

Selecting the optimal material for motorcycle seats is a strategic decision impacting performance, sustainability, and total cost of ownership. As OEMs prioritize rider comfort, durability, and ESG compliance, synthetic leather (specifically high-performance PU alternatives) increasingly outperforms traditional leather in critical operational areas. Below we detail key considerations for manufacturers evaluating these materials.

Key Considerations for Motorcycle Seat Fabric Selection

- Weight Reduction: Lightweight synthetic fabrics enhance vehicle agility and fuel efficiency, critical for modern performance and electric motorcycles.

- Consistency & Yield: Engineered synthetics offer uniform texture, color, and thickness, minimizing production waste versus variable natural hides.

- Weather Resistance: Superior resistance to UV degradation, rain, and temperature extremes ensures long-term aesthetic and functional integrity.

- Design Flexibility: Customizable textures, colors, and embossing support brand differentiation without lead-time penalties.

- Ethical Sourcing: Eliminates supply chain complexities tied to animal agriculture, aligning with global sustainability mandates.

Comparative Analysis: WINIW Synthetic Leather vs. Real Leather

| Criteria | WINIW High-Performance Synthetic Leather | Real Leather |

|---|---|---|

| Cost | 30-50% lower material cost; reduced waste during cutting (95%+ yield) | High raw material cost; significant waste (40-60% hide unusable for seating) |

| Durabilité | 500+ hrs UV resistance; waterproof; abrasion-tested to 100,000+ cycles; no cracking/drying in extreme climates | Fades/cracks under UV exposure; absorbs moisture (requires frequent conditioning); susceptible to abrasion damage |

| Eco-Friendliness | Zero animal byproducts; water-based PU production; 70% lower CO2e vs. leather; OEKO-TEX® certified; fully recyclable | High water consumption (15,000L+/hide); toxic tanning chemicals (chromium); methane emissions from livestock; non-recyclable |

Strategic Advantages of WINIW Synthetic Leather for OEMs

- Accelerated Time-to-Market: Consistent roll goods enable immediate production scaling without hide sourcing delays.

- Total Cost Leadership: Lower material costs combined with near-zero waste deliver 22-35% savings in seated component production.

- Regulatory Future-Proofing: Compliant with EU REACH, California Proposition 65, and emerging circular economy directives.

- Brand Alignment: Supports ESG reporting with verifiable LCAs (Life Cycle Assessments) and carbon footprint data.

For motorcycle manufacturers committed to high-performance engineering and sustainable innovation, WINIW’s synthetic leather delivers uncompromised rider experience while advancing core business objectives. Request our technical dossier for full test reports, color libraries, and OEM case studies.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global B2B clients with premium, eco-friendly materials engineered for durability and sustainability. Our vertically integrated production capabilities and commitment to innovation position us as a trusted partner across industries including automotive, furniture, fashion, and technical textiles.

Our state-of-the-art manufacturing facility spans 100,000 square meters, making it one of the largest synthetic leather production bases in Asia. This expansive infrastructure supports high-volume output while maintaining flexibility for customized solutions and rapid scaling to meet client demands.

Key strengths of the WINIW factory include:

- Advanced R&D team with over 15 years of industry expertise, focused on developing sustainable, high-functionality materials using cutting-edge technology.

- In-house innovation capabilities covering formulation, coating, lamination, and finishing processes, ensuring full control over product performance and quality.

- Strict quality control (QC) protocols implemented at every stage of production, from raw material inspection to final product testing, in compliance with international standards (REACH, RoHS, OEKO-TEX®).

- Environmentally responsible manufacturing with low-VOC emissions, water-based PU systems, and recyclable material options to support clients’ ESG goals.

- Certified production processes aligned with ISO 9001 and ISO 14001 standards, ensuring consistent quality and environmental management.

WINIW exports to key markets worldwide, with established distribution and quality assurance in Europe and the USA. Our products are trusted by leading brands for their consistency, aesthetic precision, and long-term performance. With robust logistics partnerships and localized customer support, we ensure seamless integration into global supply chains.

| Feature | WINIW Factory Capability |

|---|---|

| Facility Size | 100,000 sqm |

| R&D Team | 50+ engineers and material scientists |

| QC Standards | ISO 9001, REACH, RoHS, OEKO-TEX® compliant |

| Key Export Regions | Europe, USA, Japan, Southeast Asia |

| Sustainable Technologies | Water-based PU, microfiber, recyclable bases |

By combining scale, innovation, and rigorous quality management, WINIW delivers synthetic leather solutions that meet the evolving needs of global B2B partners—driving performance, sustainability, and competitive advantage.

Contact Us for Samples

WINIW Premium Synthetic Leather: Engineered for Motorcycle Seat Excellence

WINIW delivers high-performance, eco-conscious synthetic leather solutions designed specifically for demanding automotive applications. Our motorcycle seat fabrics combine superior durability with sustainable manufacturing, meeting the rigorous requirements of OEMs and aftermarket manufacturers. As a certified eco-friendly supplier, we prioritize reduced environmental impact without compromising on the mechanical properties essential for rider safety and comfort.

Why WINIW for Motorcycle Seat Fabric?

- Extreme Durability: Engineered to withstand 100,000+ double-rub cycles (Martindale test), resisting abrasion from gear, friction, and long-term use.

- Weather & UV Resistance: Maintains integrity under prolonged sun exposure, rain, and temperature extremes (-30°C to +80°C) without cracking or fading.

- Enhanced Grip & Comfort: Micro-textured surfaces provide secure rider positioning while optimizing breathability for extended journeys.

- Eco-Certified Production: OEKO-TEX® Standard 100 and REACH compliant; 30% lower carbon footprint vs. conventional synthetics via waterless dyeing technology.

- Customization Flexibility: Tailored thickness (0.8–1.5mm), color matching (Pantone®), and embossing for brand-specific aesthetics.

Technical Specifications Comparison

| Property | WINIW Motorcycle Grade | Standard PU Leather | Genuine Leather |

|---|---|---|---|

| Abrasion Resistance | 100,000+ cycles | 15,000–25,000 cycles | Varies (ages) |

| Tensile Strength | 35–45 N/mm² | 20–30 N/mm² | 25–35 N/mm² |

| Water Absorption | <5% (24h) | 15–25% | Haut |

| Eco-Certifications | OEKO-TEX®, REACH | Limited | None |

| Production Lead Time | 15–20 days | 30+ days | 45+ days |

Sustainable Value for Your Production Line

WINIW’s closed-loop manufacturing minimizes waste and energy use, aligning with global emissions regulations. Our fabrics eliminate the ethical and consistency challenges of animal hides while offering:

– Consistent batch-to-batch quality for seamless integration into automated cutting systems.

– 20% lighter weight than genuine leather, contributing to vehicle efficiency.

– Resistance to oils, fuels, and cleaning chemicals—critical for maintenance longevity.

Elevate your motorcycle seating with WINIW’s performance-driven, planet-responsible innovation.

→ Request free samples to validate quality against your specifications.

→ Contact WINIW’s B2B Team: MKT88@MicrofiberLeather.com for technical datasheets, MOQ details, and custom prototyping.

WINIW: Where Engineering Meets Ecology in Every Yard.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.