Introduction: Navigating the Global Market for leather work gloves bulk

In the ever-evolving landscape of global commerce, sourcing leather work gloves in bulk presents unique challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With a myriad of options available, discerning the right supplier and product that meets both quality standards and budgetary constraints can be daunting. This guide aims to demystify the procurement process, providing a comprehensive overview of leather work gloves in bulk, including various types, their applications across industries, and key considerations for supplier vetting.

From cowhide to deerskin, the diversity of leather materials offers choices tailored to specific tasks, whether it’s construction, agriculture, or logistics. Understanding the distinct features—such as abrasion resistance and grip strength—can significantly impact operational efficiency and worker safety. Additionally, we delve into bulk pricing strategies, allowing buyers to maximize their investment by capitalizing on volume discounts.

By equipping international B2B buyers with actionable insights, this guide empowers informed purchasing decisions, ensuring that your workforce is equipped with the right tools to enhance productivity and safety. Whether you’re based in Nigeria, Vietnam, or elsewhere, navigating the complexities of sourcing leather work gloves has never been more accessible. With the right knowledge at your fingertips, you can streamline your procurement process and forge valuable partnerships with reliable suppliers.

Table Of Contents

- Top 6 Leather Work Gloves Bulk Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather work gloves bulk

- Understanding leather work gloves bulk Types and Variations

- Key Industrial Applications of leather work gloves bulk

- 3 Common User Pain Points for ‘leather work gloves bulk’ & Their Solutions

- Strategic Material Selection Guide for leather work gloves bulk

- In-depth Look: Manufacturing Processes and Quality Assurance for leather work gloves bulk

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather work gloves bulk’

- Comprehensive Cost and Pricing Analysis for leather work gloves bulk Sourcing

- Alternatives Analysis: Comparing leather work gloves bulk With Other Solutions

- Essential Technical Properties and Trade Terminology for leather work gloves bulk

- Navigating Market Dynamics and Sourcing Trends in the leather work gloves bulk Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather work gloves bulk

- Strategic Sourcing Conclusion and Outlook for leather work gloves bulk

- Important Disclaimer & Terms of Use

Understanding leather work gloves bulk Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cowhide Leather Gloves | Durable, abrasion-resistant, often with reinforced palms | Construction, warehousing, outdoor work | Pros: Long-lasting, versatile. Cons: May be heavier than alternatives. |

| Deerskin Leather Gloves | Soft, flexible, excellent dexterity | Automotive, light assembly, maintenance | Pros: Comfortable, great grip. Cons: Less durable than cowhide. |

| Goatskin Leather Gloves | Lightweight, breathable, good for precision tasks | Electronics, agriculture, landscaping | Pros: Flexible, moisture-wicking. Cons: Not ideal for heavy-duty tasks. |

| Pigskin Leather Gloves | Good grip, resistant to oil and water | Oil and gas industries, mechanics | Pros: Excellent grip, durable. Cons: Can be less breathable. |

| Insulated Leather Gloves | Lined for warmth, often with Thinsulate or fleece | Cold weather work, outdoor activities | Pros: Warmth without bulk. Cons: May restrict dexterity. |

What Are the Key Characteristics of Cowhide Leather Gloves?

Cowhide leather gloves are renowned for their durability and resistance to abrasion, making them ideal for heavy-duty applications such as construction and warehousing. They often feature reinforced palms for added protection during rough handling. B2B buyers should consider the weight of these gloves, as they can be bulkier than other types, which may affect comfort during prolonged use. However, their longevity and versatility make them a popular choice across various sectors.

How Do Deerskin Leather Gloves Compare in Terms of Flexibility?

Deerskin leather gloves stand out for their softness and flexibility, providing excellent dexterity. This makes them suitable for tasks requiring precision, such as automotive work or light assembly. Buyers should note that while deerskin offers superior comfort and grip, it tends to be less durable than cowhide, which may affect long-term cost-effectiveness. Overall, they are an excellent choice for applications where tactile sensitivity is paramount.

Why Choose Goatskin Leather Gloves for Precision Work?

Goatskin leather gloves are lightweight and breathable, making them ideal for precision tasks in industries like electronics and landscaping. Their moisture-wicking properties also enhance comfort during extended wear. B2B buyers should consider the specific requirements of their tasks, as goatskin may not be suitable for heavy-duty applications. However, for jobs requiring flexibility and breathability, they are an excellent option.

What Advantages Do Pigskin Leather Gloves Offer?

Pigskin leather gloves are known for their excellent grip and resistance to oil and water, making them particularly useful in the oil and gas industries and for mechanics. Their durability is a strong selling point, but buyers should be aware that they may lack breathability compared to other materials. For businesses that prioritize grip and protection in oily environments, pigskin gloves provide a valuable solution.

When Are Insulated Leather Gloves the Best Choice?

Insulated leather gloves are designed for cold weather work, often lined with materials like Thinsulate or fleece to provide warmth without excessive bulk. These gloves are ideal for outdoor activities where maintaining dexterity in cold conditions is essential. B2B buyers should weigh the benefits of warmth against potential limitations in dexterity. For businesses operating in colder climates, these gloves are a practical investment for employee safety and comfort.

Key Industrial Applications of leather work gloves bulk

| Industry/Sector | Specific Application of leather work gloves bulk | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Handling heavy materials and tools during construction projects | Enhanced safety and protection for workers | Durability, compliance with safety standards, bulk pricing options |

| Agriculture | Farm work, including planting, pruning, and harvesting | Improved grip and protection against abrasions | Material quality, comfort, and ability to withstand rough conditions |

| Manufacturing | Assembly line work and handling machinery | Increased productivity and reduced hand injuries | Customization options, bulk order discounts, and delivery timelines |

| Logistics/Warehousing | Loading/unloading goods and warehouse management | Increased efficiency and safety in material handling | Bulk availability, shipping logistics, and ergonomic design |

| Mining and Heavy Industry | Operating machinery and handling raw materials | Protection against extreme conditions and hazards | Compliance with industry-specific regulations and durability under stress |

How Do Leather Work Gloves Benefit the Construction Industry?

In the construction sector, leather work gloves are essential for workers handling heavy materials and tools. These gloves provide superior grip and durability, reducing the risk of hand injuries while ensuring that workers can operate machinery safely. For international buyers, sourcing gloves that meet specific safety standards and offer bulk pricing can significantly enhance the overall safety and productivity of construction teams, especially in regions with demanding work conditions, such as Africa and the Middle East.

What Role Do Leather Work Gloves Play in Agriculture?

In agriculture, leather work gloves are used for various tasks, including planting, pruning, and harvesting. They protect hands from cuts, abrasions, and exposure to harsh elements, ensuring that agricultural workers can perform their duties safely and efficiently. Buyers in South America, where agriculture is a major industry, should prioritize gloves made from high-quality leather that can withstand the rigors of outdoor work, while also considering comfort for prolonged use.

Illustrative image related to leather work gloves bulk

Why Are Leather Work Gloves Important in Manufacturing?

In the manufacturing industry, leather work gloves are vital for assembly line workers and those handling machinery. These gloves not only protect against cuts and abrasions but also enhance grip, allowing for more efficient handling of components. International B2B buyers must consider sourcing gloves that comply with safety regulations and provide customization options, ensuring that they meet the specific needs of their workforce while maximizing productivity.

How Do Leather Work Gloves Enhance Safety in Logistics and Warehousing?

In logistics and warehousing, leather work gloves are indispensable for loading and unloading goods. They provide the necessary grip and protection against heavy and sharp objects, which can prevent accidents and injuries. For buyers in Europe and other regions, focusing on sourcing gloves that are ergonomically designed and available in bulk can lead to improved operational efficiency and worker safety.

What Are the Key Considerations for Leather Work Gloves in Mining and Heavy Industry?

In the mining and heavy industry sectors, leather work gloves are crucial for operating machinery and handling raw materials. These gloves must be durable enough to withstand extreme conditions while providing maximum protection against hazards. B2B buyers should prioritize sourcing gloves that comply with industry-specific safety regulations, ensuring that their workforce is equipped with reliable protective gear that meets the challenges of their environment.

3 Common User Pain Points for ‘leather work gloves bulk’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Bulk Orders

The Problem: B2B buyers often face significant challenges when ordering leather work gloves in bulk, particularly concerning quality assurance. Many suppliers may offer competitive prices, but the actual quality of the gloves can vary widely. Buyers might receive gloves that are not durable, fail to meet safety standards, or have inconsistent sizing, leading to dissatisfaction among employees and increased costs for replacements. This issue can be particularly pronounced for international buyers, who may have limited means to inspect products before purchase.

Illustrative image related to leather work gloves bulk

The Solution: To mitigate quality assurance issues, buyers should prioritize suppliers that offer transparent information about their manufacturing processes and material specifications. Requesting samples before placing a bulk order is crucial. This allows buyers to assess the glove’s comfort, durability, and fit firsthand. Additionally, establishing clear quality criteria and communicating these to the supplier can prevent misunderstandings. It’s beneficial to work with suppliers who have established quality certifications, such as ISO or ANSI standards, and to consider customer reviews and testimonials to gauge reliability.

Scenario 2: Managing Shipping and Logistics Complexities

The Problem: International B2B buyers often encounter logistical hurdles when ordering leather work gloves in bulk, including high shipping costs, customs delays, and unpredictable delivery times. These challenges can disrupt operational timelines and lead to stock shortages, which can be detrimental for businesses relying on these gloves for their workforce. Buyers may also struggle with understanding the shipping regulations and duties applicable in their regions.

The Solution: To streamline the shipping and logistics process, buyers should collaborate closely with suppliers who have experience in international shipping. Establishing a clear communication channel regarding shipping timelines and costs is essential. Buyers should inquire about the supplier’s logistics partners and their track record in timely delivery. Utilizing logistics software can help track shipments in real-time and anticipate any delays. Moreover, working with customs brokers can simplify the import process, ensuring compliance with local regulations and minimizing unexpected fees. It’s also wise to consider suppliers who offer freight forwarding services, as they can provide comprehensive shipping solutions tailored to the buyer’s location.

Illustrative image related to leather work gloves bulk

Scenario 3: Ensuring Proper Sizing and Fit for Diverse Workforces

The Problem: A common pain point for B2B buyers is ensuring that the leather work gloves purchased in bulk fit well across a diverse workforce. Inconsistent sizing can lead to discomfort, reduced productivity, and increased risk of accidents. Companies often struggle to find gloves that cater to different hand sizes and shapes, which can be particularly challenging in industries with varied job roles and requirements.

The Solution: To address sizing issues, buyers should first conduct a thorough assessment of the glove sizes needed for their workforce. Utilizing a sizing chart and gathering input from employees can provide valuable insights into the required sizes. When placing a bulk order, opt for suppliers that offer a range of sizes and, ideally, allow for customized orders based on the specific needs of the workforce. It’s also advisable to include a return policy that accommodates size exchanges, ensuring that all employees can find a comfortable fit. Additionally, investing in gloves that feature adjustable elements, such as elastic cuffs or straps, can enhance the fit for different users, thus improving overall satisfaction and safety.

Strategic Material Selection Guide for leather work gloves bulk

When selecting leather work gloves in bulk, understanding the properties and applications of various materials is crucial for making informed purchasing decisions. This guide analyzes four common types of leather used in work gloves: cowhide, deerskin, goatskin, and pigskin. Each material has unique characteristics that can impact performance, durability, and overall suitability for specific tasks.

What Are the Key Properties of Cowhide Leather for Work Gloves?

Cowhide leather is renowned for its strength and durability. It offers excellent abrasion resistance, making it ideal for heavy-duty applications. The temperature and pressure ratings are high, allowing it to withstand rough handling and exposure to various environmental conditions. Cowhide is also relatively resistant to water, though prolonged exposure can lead to damage.

Illustrative image related to leather work gloves bulk

Pros and Cons: The primary advantage of cowhide leather is its durability and cost-effectiveness, making it a popular choice for bulk purchases. However, it can be heavier than other types of leather, which may affect comfort during extended use.

Impact on Application: Cowhide gloves are particularly suitable for construction, automotive, and agricultural tasks, where heavy-duty protection is necessary.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local safety standards. Cowhide gloves often meet ASTM and EN standards, which can be crucial for international trade.

Illustrative image related to leather work gloves bulk

How Does Deerskin Leather Compare for Work Gloves?

Deerskin leather is softer and more flexible than cowhide, providing excellent dexterity and comfort. This material is ideal for tasks requiring precision, such as mechanics or detailed assembly work. Deerskin also has good resistance to moisture, which can be beneficial in humid climates.

Pros and Cons: The key advantage of deerskin is its comfort and dexterity, making it suitable for intricate tasks. However, it is generally more expensive than cowhide and may not offer the same level of abrasion resistance.

Impact on Application: Deerskin gloves are best suited for light to medium-duty tasks where tactile sensitivity is essential, such as in the automotive or electronics industries.

Considerations for International Buyers: Buyers should be aware of the higher price point and ensure that deerskin gloves comply with international safety standards, particularly in Europe and the Middle East.

Illustrative image related to leather work gloves bulk

What Benefits Does Goatskin Leather Provide for Work Gloves?

Goatskin leather is known for its exceptional softness and flexibility, providing a high level of comfort and dexterity. It also offers good abrasion resistance and is less likely to crack than other leathers when exposed to moisture.

Pros and Cons: The main advantage of goatskin is its balance of durability and comfort, making it suitable for a variety of applications. However, it can be more expensive than cowhide, which may be a consideration for bulk orders.

Impact on Application: Goatskin gloves are ideal for industries requiring fine motor skills, such as electronics assembly, landscaping, and light construction.

Considerations for International Buyers: Goatskin gloves should meet relevant international standards, and buyers should consider the cost implications when ordering in bulk.

Illustrative image related to leather work gloves bulk

Why Choose Pigskin Leather for Work Gloves?

Pigskin leather is often overlooked but offers a unique blend of durability and breathability. It is resistant to water and provides good abrasion resistance, making it suitable for various outdoor applications.

Pros and Cons: The key advantage of pigskin is its affordability and durability, making it a cost-effective option for bulk purchases. However, it may not provide the same level of comfort as softer leathers like deerskin or goatskin.

Impact on Application: Pigskin gloves are suitable for outdoor work, including farming and construction, where durability is essential.

Considerations for International Buyers: Buyers should ensure that pigskin gloves comply with local regulations, especially in regions with specific animal welfare standards.

Illustrative image related to leather work gloves bulk

Summary Table of Leather Materials for Work Gloves

| Matériau | Typical Use Case for leather work gloves bulk | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide | Heavy-duty applications in construction | High durability and cost-effectiveness | Heavier than other leathers | Medium |

| Deerskin | Precision tasks in automotive and assembly | Excellent dexterity and comfort | Higher cost and less abrasion resistance | Haut |

| Goatskin | Fine motor skill tasks in electronics | Balance of comfort and durability | More expensive than cowhide | Medium to High |

| Pigskin | Outdoor tasks in farming and construction | Affordability and durability | Less comfort compared to softer leathers | Low |

This strategic material selection guide provides essential insights for international B2B buyers looking to procure leather work gloves in bulk, ensuring that they make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for leather work gloves bulk

Manufacturing leather work gloves in bulk involves several intricate stages, each contributing to the final product’s quality and functionality. Understanding these processes and the associated quality assurance measures is vital for B2B buyers looking to source leather gloves internationally.

What Are the Main Stages in the Manufacturing Process of Leather Work Gloves?

Material Preparation: How Is Leather Selected and Processed?

The journey of leather work gloves begins with the careful selection of raw materials. Manufacturers typically source various types of leather, including cowhide, goatskin, deerskin, and pigskin, each offering unique properties suited for different applications. The leather must undergo a tanning process to preserve its durability and flexibility.

Once tanned, the leather is cut into specific patterns that correspond to the glove design. This cutting process can be manual or automated, depending on the scale of production. For bulk orders, precision cutting machines are often employed to ensure uniformity and minimize waste.

Forming: How Are Leather Gloves Shaped?

In the forming stage, the cut leather pieces are shaped into glove forms. This can involve stitching various components like the palm, fingers, and cuffs together. Key techniques during this phase include the use of reinforced stitching, which enhances durability, especially in high-abrasion areas such as the palms and fingertips.

The gloves may also feature ergonomic designs, such as keystone thumbs, which improve the fit and dexterity for the wearer. Manufacturers may employ techniques like heat sealing or adding elastic components to enhance comfort and ensure a secure fit.

Assembly: What Happens During the Glove Assembly Process?

The assembly stage integrates all the components into a finished glove. This typically involves several quality control checkpoints to ensure that each glove meets the required specifications. Assembly can include adding features like reinforced patches, extra lining for warmth, or waterproofing treatments, depending on the intended use of the gloves.

Illustrative image related to leather work gloves bulk

Heavy-duty stitching is a common technique employed during assembly to ensure that gloves withstand rigorous use. Manufacturers often conduct initial quality checks during this phase to catch any defects early in the production process.

Finishing: How Is the Final Product Prepared for Distribution?

Finishing touches are applied to the gloves to enhance their aesthetic and functional qualities. This may include treatments for water resistance, applying protective coatings, or adding branding elements. Gloves are then packaged, often in bulk quantities, to facilitate shipping and storage.

Before distribution, a final quality inspection is conducted to ensure that the gloves meet both the manufacturer’s and international standards.

What Quality Assurance Measures Are Common in Leather Work Gloves Manufacturing?

What International Standards Should B2B Buyers Be Aware Of?

Quality assurance in the manufacturing of leather work gloves is governed by several international standards. ISO 9001 is one of the most recognized quality management standards, ensuring that organizations meet customer and regulatory requirements consistently. Compliance with ISO standards indicates that a supplier has effective quality management systems in place.

In addition to ISO, industry-specific certifications such as CE marking for personal protective equipment (PPE) are crucial for buyers, especially in Europe. This certification verifies that the gloves meet health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This step verifies the quality of raw materials before production begins. Suppliers should provide documentation of material specifications and certifications.

-

In-Process Quality Control (IPQC): During assembly, periodic checks are performed to ensure adherence to quality standards. This includes inspecting stitching, fit, and functionality.

-

Final Quality Control (FQC): After assembly, gloves undergo a final inspection to check for defects, proper packaging, and compliance with specifications before shipment.

What Common Testing Methods Are Used for Leather Gloves?

Testing methods vary based on the intended use of the gloves but may include:

-

Abrasion Resistance Tests: Measure how well the gloves withstand wear and tear.

-

Tensile Strength Tests: Assess the maximum amount of stress the gloves can handle before failing.

-

Water Resistance Tests: Determine how well the gloves repel moisture.

-

Comfort and Fit Tests: Evaluate how well the gloves conform to the hand and allow for dexterity.

How Can B2B Buyers Verify Supplier Quality Assurance?

What Steps Should Buyers Take to Ensure Quality?

To ensure that suppliers meet quality standards, B2B buyers should consider the following actions:

-

Supplier Audits: Conduct on-site audits to evaluate manufacturing processes, quality control measures, and compliance with international standards.

-

Request Quality Reports: Ask suppliers for detailed quality assurance reports, including test results and compliance certifications.

-

Third-Party Inspections: Engage independent inspection agencies to verify product quality before shipment. This can help mitigate risks associated with sourcing from international suppliers.

What Are the QC Nuances for International Buyers?

Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of regional standards and practices. Different countries may have specific regulations regarding PPE, and understanding these nuances is essential for compliance.

Additionally, cultural factors may influence communication and expectation management during the procurement process. Establishing clear communication channels and expectations upfront can help facilitate smoother transactions.

Conclusion: Why Understanding Manufacturing and QC Is Crucial for B2B Buyers

For B2B buyers, a comprehensive understanding of the manufacturing processes and quality assurance measures for leather work gloves is essential. By being informed about the production stages, international standards, and verification methods, buyers can make better sourcing decisions, ensuring that the gloves they procure are not only high-quality but also compliant with applicable regulations. As the market for leather work gloves continues to grow, leveraging these insights will help buyers maintain a competitive edge in their industries.

Illustrative image related to leather work gloves bulk

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather work gloves bulk’

Introduction

Sourcing leather work gloves in bulk requires careful consideration and strategic planning to ensure you select the best products for your business needs. This guide provides a practical checklist to streamline your procurement process, helping you make informed decisions while optimizing cost and quality.

Step 1: Define Your Technical Specifications

Establish clear specifications for the leather work gloves you need. Consider factors such as material type (cowhide, goatskin, etc.), intended use (construction, gardening, industrial), and any specific features (reinforced palms, waterproofing). Defining these specifications upfront ensures you communicate your needs effectively to suppliers, reducing the likelihood of misalignment.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in leather work gloves. Use industry-specific directories, trade shows, and online marketplaces to compile a list of potential vendors. Pay attention to suppliers with positive reviews and a solid reputation in your target regions, such as Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Focus on their experience with bulk orders and their ability to meet your specific technical requirements, ensuring they are capable of delivering quality products consistently.

- Look for certifications: Verify that suppliers adhere to international quality standards and safety regulations, which can be particularly important in regions with stringent compliance requirements.

Step 4: Request Samples

Always request samples before placing a bulk order. This allows you to assess the quality, durability, and comfort of the gloves firsthand. Pay attention to stitching, fit, and material quality, as these factors can significantly impact user satisfaction and performance in real-world applications.

Step 5: Discuss Pricing and Bulk Discounts

Engage in discussions about pricing structures and available bulk discounts. Many suppliers offer tiered pricing based on order quantities, which can lead to significant savings. Ensure you understand the terms of the pricing and any additional costs associated with shipping, taxes, or customs duties, especially when dealing with international suppliers.

- Negotiate terms: Don’t hesitate to negotiate terms to secure the best possible deal, including payment terms and delivery timelines.

Step 6: Check Logistics and Shipping Options

Evaluate the logistics capabilities of your chosen supplier. Confirm their shipping options, lead times, and any associated costs. Consider the implications of shipping delays on your operations, especially if you require gloves for a specific project or season.

Step 7: Finalize the Order and Monitor Delivery

Once you’ve selected a supplier and agreed on terms, finalize your order with a written contract. Monitor the production and shipping processes closely to ensure timelines are met. Maintain communication with the supplier to address any potential issues proactively, ensuring a smooth delivery experience.

By following this checklist, you will enhance your procurement process for leather work gloves in bulk, ensuring that you make informed decisions that align with your business needs and budget.

Comprehensive Cost and Pricing Analysis for leather work gloves bulk Sourcing

In the competitive landscape of sourcing leather work gloves in bulk, understanding the cost structure and pricing mechanisms is essential for international B2B buyers. This section delves into the various components influencing costs, pricing strategies, and actionable tips to enhance procurement efficiency.

What Are the Key Cost Components in Leather Work Gloves Manufacturing?

The cost structure for leather work gloves comprises several components:

-

Materials: The choice of leather—be it cowhide, goatskin, deerskin, or pigskin—significantly impacts costs. Premium materials like full-grain leather command higher prices due to their durability and comfort.

-

Labor: Skilled labor is essential for crafting high-quality leather gloves. Labor costs can vary widely based on the region and the complexity of the glove design, influencing the overall price.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial tooling costs for molds and cutting machines can be substantial, particularly for custom designs. However, these costs can be amortized over large production runs, making bulk orders more economical.

-

Quality Control (QC): Ensuring that gloves meet safety and quality standards incurs additional costs. Investing in robust QC processes can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping costs, including tariffs and freight, are critical in determining the total cost. Buyers should consider the proximity of suppliers and the efficiency of their logistics networks.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the average margins in the industry can aid in negotiation.

How Do Price Influencers Affect Bulk Leather Work Gloves Costs?

Several factors can influence the pricing of leather work gloves, especially in bulk orders:

-

Volume and Minimum Order Quantities (MOQ): Larger orders often attract significant discounts. Suppliers typically provide tiered pricing structures that reward higher volume purchases.

-

Specifications and Customization: Custom designs or specific material requirements can lead to increased costs. Buyers should clearly define their needs to obtain accurate quotes.

-

Quality Certifications: Gloves that comply with international safety standards (e.g., EN 388) may cost more but provide assurance of quality and safety, which can be critical in certain industries.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge higher prices but offer better quality assurance and customer support.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can affect the final price, as they dictate who bears shipping costs and risks during transport.

What Are Effective Buyer Tips for Negotiating Leather Work Gloves Pricing?

To navigate the complexities of sourcing leather work gloves, international buyers should consider the following strategies:

-

Negotiate Effectively: Leverage bulk purchasing power to negotiate better terms. Be transparent about your needs and express interest in long-term partnerships for better deals.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, shipping, potential duties, and long-term durability. Sometimes, a higher upfront cost can lead to lower lifetime costs.

-

Understand Pricing Nuances for International Purchases: Be aware of currency fluctuations and international trade regulations that might affect pricing. Establishing payment terms in a stable currency can mitigate risks.

-

Prioritize Supplier Relationships: Building strong relationships with suppliers can lead to better service, priority in stock availability, and more favorable terms over time.

-

Request Samples: Before committing to a large order, request samples to assess quality. This practice can help avoid costly mistakes and ensure that the products meet your requirements.

Conclusion

By comprehensively understanding the cost components, price influencers, and effective negotiation strategies, international B2B buyers can make informed decisions when sourcing leather work gloves in bulk. While indicative prices can vary widely based on specific conditions, leveraging these insights will enable buyers to optimize their procurement processes and enhance their supply chain efficiency.

Illustrative image related to leather work gloves bulk

Alternatives Analysis: Comparing leather work gloves bulk With Other Solutions

Introduction

When sourcing protective gear, particularly for manual labor, businesses often encounter various options that can meet their needs. Leather work gloves in bulk offer a durable and reliable solution for many industries. However, it is essential to consider alternative solutions that may provide similar benefits, such as synthetic gloves and specialized safety gear. This analysis aims to compare leather work gloves with these alternatives to guide B2B buyers in making informed purchasing decisions.

Comparison Table

| Comparison Aspect | Leather Work Gloves Bulk | Synthetic Work Gloves | Specialized Safety Gear |

|---|---|---|---|

| Performance | High abrasion resistance; durable | Moderate durability; good grip | High protection; often specialized |

| Cost | Medium to high, depending on material | Generally lower; cost-effective | Higher due to specialized features |

| Ease of Implementation | Simple to procure and distribute | Easy to source; wide availability | May require training or specific sourcing |

| Maintenance | Requires occasional cleaning; durable | Disposable options available; low maintenance | Regular checks needed for integrity |

| Best Use Case | General manual labor, outdoor tasks | Light to medium tasks, assembly work | High-risk environments (construction, industrial) |

Detailed Breakdown

What Are the Pros and Cons of Synthetic Work Gloves?

Synthetic work gloves, often made from materials like nitrile, latex, or polyurethane, are increasingly popular due to their cost-effectiveness. They typically offer excellent dexterity and grip, making them suitable for tasks requiring precision. However, their durability can be a drawback when faced with heavy-duty tasks. While they may be cheaper upfront, they often need to be replaced more frequently than leather gloves, which could lead to higher long-term costs.

How Does Specialized Safety Gear Compare?

Specialized safety gear includes items like cut-resistant gloves, impact-resistant gloves, or gloves designed for specific tasks like welding or electrical work. These products provide targeted protection and are ideal for high-risk environments. However, their specialized nature often comes with a higher price point and may require additional training for effective use. Businesses in sectors like construction or manufacturing might find them indispensable, while less hazardous industries may find them unnecessarily expensive.

Conclusion

Choosing the right protective gloves or gear ultimately depends on the specific needs and operational context of the business. Leather work gloves in bulk offer significant durability and protection for various manual tasks, making them a solid choice for many industries. However, for tasks requiring high dexterity or in specialized environments, synthetic gloves or specialized safety gear may be more appropriate. B2B buyers should evaluate the nature of their work, budget constraints, and the level of protection required to select the optimal solution for their workforce.

Essential Technical Properties and Trade Terminology for leather work gloves bulk

What Are the Key Technical Properties of Leather Work Gloves in Bulk?

When sourcing leather work gloves in bulk, understanding the technical specifications is crucial for ensuring that the products meet industry requirements and operational needs. Here are some essential properties to consider:

-

Material Grade

– Leather work gloves are typically made from various grades of leather, including cowhide, goatskin, deerskin, and pigskin. Each material offers different levels of durability, flexibility, and protection. For example, cowhide is known for its robustness and abrasion resistance, making it ideal for heavy-duty applications. Understanding material grades helps buyers select gloves that align with specific tasks and environments. -

Tensile Strength

– This property measures the maximum amount of tensile (pulling) stress that a material can withstand before failure. High tensile strength in leather gloves indicates superior durability and the ability to resist wear and tear, which is critical for industries requiring rigorous manual labor. Selecting gloves with adequate tensile strength minimizes the risk of injuries and prolongs the lifespan of the product. -

Thickness

– The thickness of the leather is an important specification that affects both comfort and protection. Thicker gloves generally provide better protection against cuts and abrasions but may reduce dexterity. Buyers should consider the balance between thickness and the required tactile sensitivity for specific tasks, especially in environments where precision is necessary. -

Grip and Texture

– The design and texture of the glove palm can significantly impact grip performance. Features such as reinforced palms, textured surfaces, or rubberized grips enhance the ability to handle tools and materials securely. A strong grip reduces the risk of accidents and improves productivity, making this a vital consideration for bulk purchases. -

Sizing and Fit

– Proper sizing ensures that gloves fit securely without being too tight or too loose. A well-fitted glove allows for better control and comfort, which is essential for long-term wear. Bulk orders should consider various sizes to accommodate different hand shapes and sizes within a workforce. -

Abrasion Resistance

– This property refers to the glove’s ability to withstand surface wear from friction. Gloves with high abrasion resistance are essential for tasks involving rough materials or environments. Selecting gloves with robust abrasion resistance can lead to lower replacement costs and increased safety for workers.

What Are Common Trade Terms in the Leather Work Gloves Industry?

Navigating the procurement process for leather work gloves requires familiarity with industry terminology. Here are some key terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce components or products that are marketed by another company. Understanding OEM relationships can help buyers identify reliable suppliers and negotiate better pricing for bulk orders. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and ensuring that order sizes meet suppliers’ requirements, which can affect pricing and availability. -

RFQ (Request for Quotation)

– An RFQ is a document that a buyer sends to suppliers requesting pricing and terms for specific products. It’s a crucial step in the procurement process, allowing buyers to compare costs and terms before making purchasing decisions. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, insurance, and liability, which are vital for budgeting and risk management. -

Lead Time

– This term refers to the amount of time it takes for a supplier to fulfill an order after it has been placed. Understanding lead times is important for planning inventory and ensuring that operational needs are met without delay. -

Certifications

– Certifications such as ISO (International Organization for Standardization) or CE (Conformité Européenne) indicate that products meet specific quality and safety standards. Buyers should look for certifications to ensure compliance with industry regulations and enhance product reliability.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing leather work gloves in bulk, ultimately leading to improved safety, efficiency, and cost-effectiveness in their operations.

Navigating Market Dynamics and Sourcing Trends in the leather work gloves bulk Sector

What Are the Current Market Dynamics and Key Trends in the Leather Work Gloves Bulk Sector?

The leather work gloves bulk sector is experiencing a robust transformation driven by several global factors. Demand is primarily fueled by the construction, agriculture, and manufacturing industries, particularly in emerging markets across Africa, South America, the Middle East, and Europe. These regions are witnessing a surge in infrastructure projects and industrial activities, leading to increased requirements for durable and protective work gear. Key trends include the adoption of advanced materials, like synthetic leather blends, which enhance performance and reduce costs while maintaining durability.

Additionally, there’s a growing interest in bulk purchasing options, as companies seek to optimize their supply chain efficiency and cost-effectiveness. B2B buyers are increasingly leveraging technology for sourcing, with platforms that facilitate bulk orders and provide real-time inventory updates. Notably, international buyers are looking for suppliers who can ensure quick turnaround times and reliable shipping, particularly in regions with logistical challenges. As the market evolves, it’s crucial for buyers to stay informed about pricing trends and product innovations to make strategic sourcing decisions.

How Is Sustainability and Ethical Sourcing Impacting the Leather Work Gloves Bulk Market?

Sustainability has become a pivotal focus in the leather work gloves sector, as environmental concerns and consumer awareness drive demand for ethically sourced products. The leather industry has historically faced criticism for its environmental impact, including deforestation and chemical pollution. Consequently, B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices and offer ‘green’ certifications.

Ethical sourcing not only reduces environmental footprints but also ensures compliance with international labor standards. Buyers should seek manufacturers who utilize eco-friendly tanning processes and sustainable materials, such as vegetable-tanned leather. Certifications like the Global Organic Textile Standard (GOTS) or Leather Working Group (LWG) can serve as indicators of a supplier’s commitment to ethical practices. By choosing responsibly sourced leather work gloves, companies can enhance their brand reputation and appeal to environmentally conscious customers, ultimately driving long-term business growth.

What Is the Evolution of the Leather Work Gloves Industry and Its Significance for B2B Buyers?

The leather work gloves industry has evolved significantly over the years, transitioning from basic protective gear to highly specialized equipment that meets diverse occupational needs. Historically, leather gloves were primarily hand-crafted for specific tasks, but advancements in manufacturing technology have allowed for mass production and the introduction of various leather types, including cowhide, goatskin, and pigskin.

This evolution has been significant for B2B buyers, as the availability of specialized gloves tailored to specific industries has increased. For instance, gloves designed for high abrasion resistance are now common in construction, while insulated options cater to colder climates in the agriculture sector. Understanding this historical context enables buyers to appreciate the range of options available today and make informed decisions based on their specific industry requirements and safety standards. As the market continues to evolve, staying abreast of innovations and trends will be critical for successful sourcing strategies.

Illustrative image related to leather work gloves bulk

Frequently Asked Questions (FAQs) for B2B Buyers of leather work gloves bulk

-

How do I choose the right leather work gloves for my business needs?

Selecting the right leather work gloves involves assessing the specific tasks your workforce will perform. Consider the glove material—options like cowhide, goatskin, and deerskin each offer different levels of durability and flexibility. Evaluate factors such as grip, insulation, and any additional features like reinforced palms or waterproofing. It’s also essential to ensure that the gloves meet safety standards relevant to your industry, which can vary by region. -

What are the benefits of buying leather work gloves in bulk?

Purchasing leather work gloves in bulk can significantly reduce costs, as many suppliers offer tiered pricing discounts based on order volume. This approach also ensures consistent quality across all gloves and simplifies inventory management. Additionally, bulk buying can streamline your supply chain, reducing lead times and ensuring that your workforce is always equipped with the necessary protective gear. -

What is the minimum order quantity (MOQ) for bulk leather work gloves?

Minimum order quantities can vary widely among suppliers, often ranging from as low as 12 pairs to over 100 pairs. It’s crucial to inquire directly with potential suppliers about their MOQ policies, as this can impact your purchasing strategy. Some suppliers may also be flexible with MOQs for repeat customers or larger contracts, so it’s worth discussing your specific needs. -

How can I ensure the quality of leather work gloves when sourcing internationally?

To guarantee quality, work with reputable suppliers who can provide certifications and compliance with international safety standards. Request samples before placing a bulk order to evaluate the gloves’ performance and durability. Conducting background checks on suppliers and reading customer reviews can also provide insights into their reliability and product quality. Additionally, consider third-party quality assurance inspections if you are placing large orders. -

What customization options are available for bulk leather work gloves?

Many suppliers offer customization options such as branding, color choices, and specific design features tailored to your needs. Customization can enhance your brand visibility and ensure the gloves meet the specific requirements of your industry. Be sure to discuss these options with suppliers during the initial negotiations, as this may influence pricing and lead times. -

What payment terms should I expect when sourcing leather work gloves in bulk?

Payment terms can vary significantly based on the supplier and your relationship with them. Common practices include partial upfront payments with the balance due upon delivery, or net 30/60 terms depending on the order size. Always clarify payment methods accepted, including credit terms, wire transfers, or letters of credit, especially in international transactions, to avoid any misunderstandings. -

What logistics considerations should I keep in mind when importing leather work gloves?

Logistics can be complex, especially for international shipments. Be aware of customs regulations in your country and ensure all documentation is accurate to avoid delays. Consider working with logistics partners who specialize in international trade to facilitate shipping and customs clearance. Additionally, discuss shipping timelines with your supplier to align delivery expectations with your operational needs. -

How do I handle returns or exchanges for defective leather work gloves?

When negotiating with suppliers, clarify their return and exchange policies, especially concerning defective products. Most reputable suppliers will have a process in place for handling returns, which typically includes notifying them within a specific timeframe and providing evidence of defects. Understanding these policies upfront will help mitigate risks and ensure you have recourse should issues arise with the gloves you purchase.

Top 6 Leather Work Gloves Bulk Manufacturers & Suppliers List

1. G & F Products – Premium Cowhide Leather Work Gloves

Domain: workglovesdepot.com

Registered: 2005 (20 years)

Introduction: {“name”: “Premium Cowhide Leather Work Gloves, Reinforced Palm Patch, 3 Pairs”, “brand”: “G & F Products”, “MSRP”: “$28.99”, “sale_price”: “$24.99”, “savings”: “$4.00”, “SKU”: “6203”, “UPC”: “899324000809”, “availability”: “Usually ships within 2 business days”, “shipping”: “Calculated at Checkout”, “features”: [“Premium leather gloves with keystone thumb design”, “Washable, durable, with elastic …

2. Safety Smart Gear – Wholesale Work Gloves

Domain: safetysmartgear.com

Registered: 2006 (19 years)

Introduction: Best Wholesale Work Gloves for the Job. Categories include: High Visibility Clothing, Accessories, Bibs/Overalls, Coveralls, Cold Weather Coveralls, Hoodies, Jackets, Kids Hi Vis Pants, Rain Gear, Safety Vests, Shirts, Sweatshirts, T-Shirts, Women’s Hi Vis, Flame Resistant Clothing, PPE, Ergonomic Supports, Hand Protection, Head Protection, Hearing Protection, Industrial Rain Gear, Lighting Safety…

3. MCR Safety – Premium Gold Elkskin Welder

Domain: shop.mcrsafety.com

Registered: 2003 (22 years)

Introduction: {“category”:”Bulk Leather Gloves”,”products”:[{“name”:”Premium Gold Elkskin Welder”,”price”:”$12.00 / Pair”,”size”:”XL”,”ansi_abrasion”:”4″,”ansi_contact_heat”:”5″,”ansi_puncture”:”5″,”leather_type”:”Elk”},{“name”:”Premium Pearl Gray Elkskin Welder”,”price”:”$12.00 / Pair”,”size”:”XL”,”ansi_abrasion”:”4″,”ansi_contact_heat”:”5″,”ansi_puncture”:”5″,”leather_type”:”Elk”},{“name”:”Premium Gold Elkski…

4. Golden Stag – Cowhide Leather Work Gloves

Domain: shopgoldenstagglove.com

Registered: 2020 (5 years)

Introduction: Cowhide Leather Work Gloves from Golden Stag Gloves are crafted from high-quality gold grain cowhide leather, designed for durability and versatility. Ideal for farming, ranching, and construction, these gloves provide protection from abrasions, cuts, and punctures. They are naturally water-resistant and come in sizes XS-XXXL. The collection includes various styles, such as the Iron Fencer glove, …

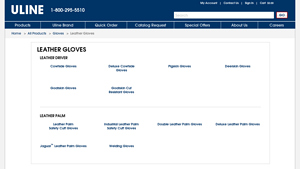

5. ULINE – Leather Gloves

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Leather Gloves, Leather Palm Work Gloves in Stock – ULINE. Types include Leather Driver Cowhide Gloves, Deluxe Cowhide Gloves, Pigskin Gloves, Deerskin Gloves, Goatskin Gloves, Goatskin Cut Resistant Gloves, Leather Palm Safety Cuff Gloves, Industrial Leather Palm Safety Cuff Gloves, Double Leather Palm Gloves, Deluxe Leather Palm Gloves, Jaguar ™ Leather Palm Gloves, Welding Gloves.

6. The Glove Warehouse – Lined Leather Palm Work Gloves

Domain: theglovewarehouse.com

Registered: 2010 (15 years)

Introduction: Lined Leather Palm Work Gloves made from Cowhide, Goathide, and Pigskin leather. Available in insulated and uninsulated options. Free shipping on orders over $99. Various brands including LIBERTY SAFETY, RADIANS, CAIMAN, and MAJESTIC. Multiple SKU options with varying prices.

Strategic Sourcing Conclusion and Outlook for leather work gloves bulk

In the competitive landscape of bulk leather work gloves, strategic sourcing emerges as a pivotal element for international buyers. By prioritizing quality materials like cowhide, deerskin, and goatskin, businesses can ensure their workforce is equipped with gloves that offer durability, comfort, and protection. The insights gained from bulk pricing structures not only facilitate cost savings but also enhance supplier relationships, enabling buyers to secure the best deals while meeting their operational needs.

Moreover, understanding the specific applications of different glove types allows for tailored selections that enhance productivity and safety in various industries, from agriculture to construction. As demand continues to rise across regions such as Africa, South America, the Middle East, and Europe, the ability to navigate supplier networks and leverage economies of scale will be crucial for staying ahead of the competition.

Looking forward, we encourage B2B buyers to actively engage with suppliers to explore bulk options that align with their business goals. By investing in quality leather work gloves, companies can safeguard their workforce while optimizing their operational efficiency. Now is the time to make informed sourcing decisions that will pave the way for future success in an evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.