Catalog

Material Insight: Embossed Leather Fabric

B2B Product Guide: Embossed Leather Fabric

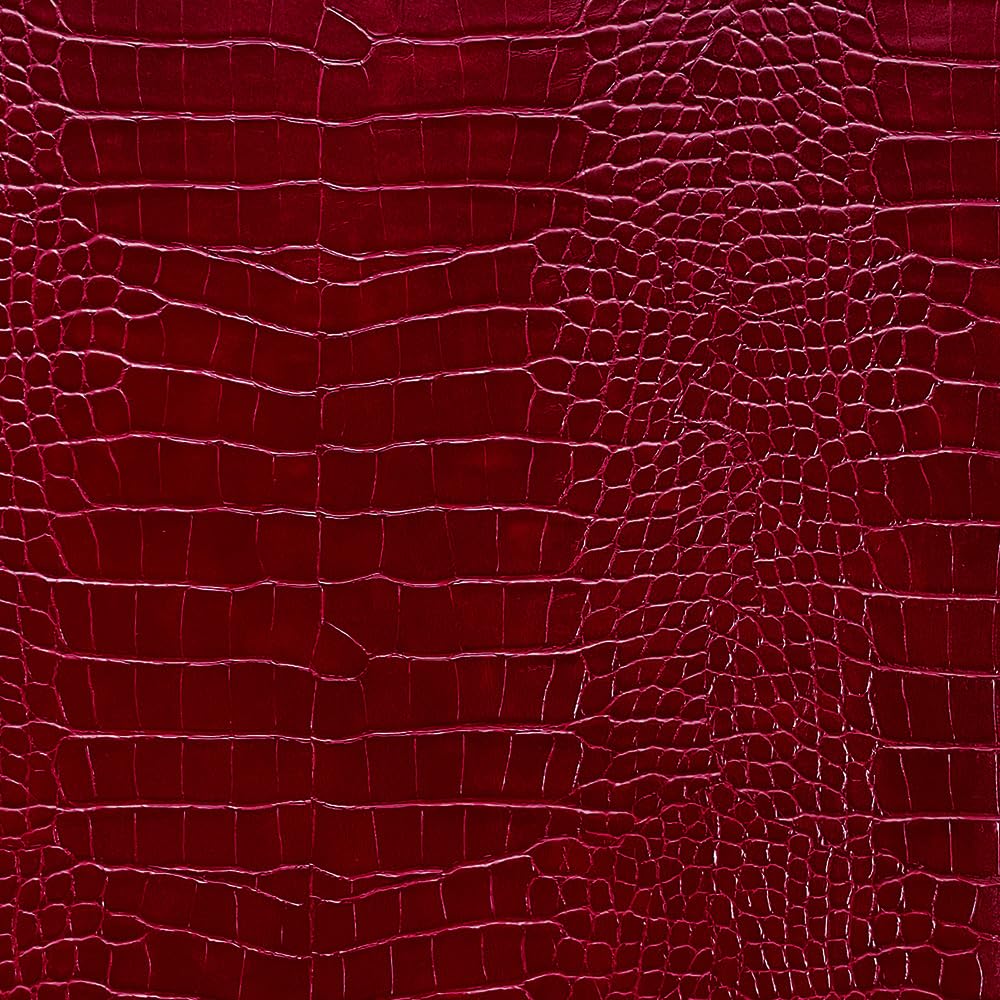

Embossed leather fabric refers to a synthetic material engineered with a textured surface pattern pressed or stamped into its finish. This process replicates the natural grain, exotic skins, or custom-designed patterns of genuine leather, achieving specific aesthetic and tactile qualities required for high-end applications. Widely utilized in premium furniture upholstery, automotive interiors, luggage, and fashion accessories, embossed fabric delivers the sophisticated visual appeal of leather while offering superior consistency and performance characteristics critical for commercial production.

Why Faux Leather is the Strategic Choice for Embossed Applications

Genuine leather presents significant limitations for embossed surface applications in B2B manufacturing. Faux leather (synthetic leather) is the optimal solution for these demanding uses due to:

- Unmatched Consistency & Yield: Natural hide variations (scars, insect bites, uneven grain) make uniform embossing impossible. Faux leather provides a perfectly consistent base substrate, ensuring 100% of the material accepts the embossing pattern identically, minimizing waste and maximizing production efficiency.

- Precision Design Control: Manufacturers can create any embossed pattern—from ultra-realistic calfskin to geometric abstractions—with exact repeatability across global production runs. This level of customization and control is unattainable with natural hides.

- Enhanced Durability & Performance: Embossed faux leather can be engineered with integrated wear layers, making the textured surface highly resistant to abrasion, cracking, and fading in high-traffic environments (e.g., public transport seating, contract furniture), outperforming finished genuine leather.

- Sustainable Production: The embossing process on faux leather avoids the resource-intensive tanning and finishing required for genuine leather. WINIW’s eco-engineered bases significantly reduce water consumption, eliminate harmful chemical runoff, and support circular economy goals—key for ESG-compliant supply chains.

- Cost Efficiency at Scale: Eliminating hide grading, sorting, and the inherent waste of natural leather (up to 30-40%) translates to lower material costs and predictable pricing for large-volume orders, protecting project budgets.

Introducing WINIW: Your Trusted Partner in Advanced Synthetic Leather

WINIW has been a global leader in high-performance, eco-conscious synthetic leather solutions for over 20 years. We specialize in developing and manufacturing premium faux leather materials engineered specifically for the rigorous demands of B2B applications, including precision embossing. Our expertise spans material science, sustainable chemistry, and large-scale production, enabling us to deliver:

- Deep Technical Knowledge: Two decades of R&D focused on optimizing PU/PVC formulations for superior embossing fidelity, durability, and eco-credentials.

- End-to-End Sustainability: Industry-leading closed-loop manufacturing, waterless dyeing technologies, and extensive use of recycled and bio-based content (e.g., WINIW® Eco series) without compromising performance.

- Global Reliability: A robust international supply chain ensuring consistent quality, on-time delivery, and technical support for clients across furniture, automotive, and consumer goods sectors.

- Collaborative Innovation: We work closely with design and procurement teams to develop bespoke embossed solutions that meet exact aesthetic, functional, and sustainability targets.

For manufacturers seeking a premium, consistent, and responsible material foundation for embossed leather applications, WINIW’s engineered faux leather delivers unparalleled value, performance, and environmental stewardship—proven across two decades of global partnership.

Technical Performance & Standards

WINIW Embossed Leather Fabric – Technical Product Guide

WINIW’s embossed leather fabric is a premium synthetic leather solution engineered for B2B applications across furniture, automotive interiors, fashion accessories, and commercial upholstery. Combining advanced manufacturing techniques with stringent quality control, this product delivers superior performance, sustainability, and design flexibility at a competitive price point.

Technical Advantages

-

Cost-Effective Production

WINIW’s embossed leather fabric reduces material and processing costs without compromising quality. Its consistent thickness and surface finish minimize waste during cutting and sewing, improving yield in high-volume manufacturing. The material eliminates the variability and higher procurement costs associated with genuine leather. -

Exceptional Durability

Reinforced with high-tenacity polyester backing and a wear-resistant polyurethane (PU) coating, the fabric withstands abrasion, tearing, and flexing. It maintains structural integrity and appearance under prolonged use, making it ideal for high-traffic environments such as public transport seating and commercial furniture. -

Customizable Color Options

WINIW offers full color customization using eco-friendly, non-toxic dyes. Clients can match specific Pantone codes or develop proprietary shades, ensuring brand consistency. The pigmentation process ensures excellent colorfastness to light, rubbing, and atmospheric exposure. -

REACH Compliant Chemistry

The embossed leather fabric is manufactured in full compliance with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals). It contains no SVHCs (Substances of Very High Concern), phthalates, heavy metals, or AZO dyes, ensuring safety for end-users and environmental responsibility. -

ISO9001-Certified Manufacturing

Produced in ISO9001-certified facilities, WINIW’s embossed leather undergoes rigorous quality assurance at every stage—from raw material sourcing to final inspection. This certification guarantees consistent product performance, traceability, and continuous improvement in manufacturing processes.

Product Specifications

| Property | Spécifications |

|---|---|

| Base Material | High-tenacity polyester non-woven |

| Coating | Thermoplastic polyurethane (PU) |

| Thickness | 0.6 mm – 1.2 mm (customizable) |

| Weight | 200 – 350 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale, dry) |

| Colorfastness to Rubbing | ≥4–5 (wet & dry) |

| Light Fastness | ≥6 (Blue Wool Scale) |

| Tensile Strength | ≥80 N/5cm (warp and weft) |

| Tear Strength | ≥15 N |

| Folding Endurance | >30,000 cycles (Glenroy method) |

| REACH Compliance | Fully compliant, no SVHCs detected |

| ISO Certification | ISO9001:2015 |

| Customization Options | Color, thickness, embossing pattern, width |

| Roll Width | 137 cm, 140 cm, or customized up to 150 cm |

| Roll Length | 30 m, 50 m, or as per client requirement |

WINIW’s embossed leather fabric is engineered to meet the evolving demands of modern manufacturing—offering a sustainable, reliable, and economically viable alternative to traditional leather. With full customization and global compliance, it is the preferred choice for forward-thinking brands committed to quality and environmental stewardship.

Why Choose Synthetic over Real Leather

B2B Product Guide: Embossed Leather Fabric vs. Real Leather

For design, manufacturing, and procurement professionals seeking optimal material solutions, understanding the core differences between embossed leather fabric (high-performance synthetic leather) and real leather is critical. Both serve distinct market segments, but their performance, economic, and sustainability profiles vary significantly. This guide provides a clear, objective comparison to support informed sourcing decisions aligned with business goals and evolving market demands.

Key Definitions:

– Embossed Leather Fabric: A technologically advanced synthetic material, typically polyurethane (PU) or polyvinyl chloride (PVC) based, engineered with a surface texture pressed (“embossed”) to mimic the grain and feel of natural leather. WINIW’s offerings utilize premium, eco-conscious PU formulations and precise embossing techniques for superior aesthetics and performance.

– Real Leather: A natural material derived from the tanned hide or skin of animals (primarily bovine). Its characteristics are inherent to the raw material and tanning process, resulting in natural variations in grain, thickness, and color.

Critical Comparison: Cost, Durability & Eco-Friendliness

The following table outlines the essential comparative metrics for business evaluation:

| Feature | Embossed Leather Fabric (WINIW Premium PU) | Real Leather (Full-Grain) |

|---|---|---|

| Cost | Predictable & Stable: Lower base material cost. Significantly reduced waste during cutting (up to 30% less). Consistent roll goods enable higher automation efficiency. No volatile raw material market fluctuations. | Variable & Higher: Subject to significant price volatility based on hide availability, quality grade, and market demand. Higher waste factors (15-25%+) due to natural defects and irregular shapes. Labor-intensive processing adds cost. |

| Durabilité | Controlled & Consistent: Highly uniform thickness and structure. Excellent resistance to abrasion, tearing (engineered strength), and staining (surface treatments). Consistent performance across batches. Resistant to moisture absorption and mildew. | Variable by Hide & Grade: Natural variations mean performance differs between hides and even within a single hide. Prone to scratches, scuffs, and water damage without frequent conditioning. Susceptible to drying, cracking, and mildew if not meticulously maintained. Requires skilled craftsmanship for longevity. |

| Eco-Friendliness | High Potential for Sustainability: WINIW utilizes water-based PU systems, eliminating DMF and other harmful solvents. Significantly lower water consumption and energy use in production vs. tanning. Zero animal sourcing. Recyclable at end-of-life (check specific product specs). Traceable, consistent supply chain with lower carbon footprint. | Resource-Intensive & Variable: Tanning (especially chrome) is water, chemical, and energy-intensive, generating substantial pollution if not strictly managed. Requires significant land/water for livestock. Generates solid waste (trimmings, sludge). Biodegradability is slow and conditional. Ethical sourcing (animal welfare, deforestation links) is a major concern requiring rigorous auditing. |

Strategic Business Advantages of Premium Embossed Leather Fabric:

- Supply Chain Resilience: Eliminates dependence on volatile hide markets and complex, geographically concentrated tanning infrastructure. Ensures consistent, reliable material flow.

- Design & Production Efficiency: Uniform roll goods with consistent color, thickness, and texture streamline cutting, sewing, and quality control, boosting throughput and reducing labor costs.

- Enhanced Sustainability Credentials: Directly supports ESG goals and circular economy initiatives through reduced resource use, non-toxic production (WINIW standards), and traceable, animal-free materials. Meets growing consumer and regulatory demand for transparent, responsible sourcing.

- Performance Tailoring: Material properties (softness, strength, breathability, fire resistance) can be engineered precisely for specific applications (furniture, automotive, luggage, fashion accessories), offering solutions real leather cannot match.

- Compliance & Risk Mitigation: Avoids ethical controversies and regulatory risks associated with animal agriculture and traditional tanning processes (e.g., REACH, Prop 65).

WINIW’s commitment to eco-innovation ensures our embossed leather fabrics deliver not only superior performance and cost-effectiveness but also represent a responsible, future-proof material choice for forward-thinking B2B partners. We provide comprehensive technical data, sample support, and collaborative development to integrate our sustainable solutions seamlessly into your product lines.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, sustainable materials for global B2B clients. Our vertically integrated production capabilities and commitment to quality have established us as a trusted partner across industries including automotive, furniture, apparel, and luxury goods.

Our manufacturing strength is anchored in a state-of-the-art facility spanning 100,000 square meters. This expansive campus enables large-scale production capacity while maintaining flexibility for customized solutions and rapid turnaround times. The facility integrates advanced coating, embossing, and finishing lines, optimized for both efficiency and environmental responsibility.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 engineers and material scientists focused on developing next-generation synthetic leather with enhanced durability, texture, and eco-performance.

- Proprietary technologies that reduce solvent use and energy consumption, aligning with global sustainability standards.

- Strict quality control protocols enforced at every production stage, from raw material inspection to final product testing. Our QC system complies with ISO 9001 standards and meets the rigorous requirements of European and North American markets.

- In-house testing laboratory equipped to perform abrasion resistance, color fastness, tensile strength, and environmental compliance testing (REACH, RoHS, CPSIA, etc.).

- Scalable production lines capable of handling both high-volume orders and low-MOQ specialty runs.

WINIW proudly exports to key markets worldwide, with a strong presence in Europe and the USA. Our products are trusted by leading brands that demand consistent quality, regulatory compliance, and sustainable innovation. Through continuous investment in technology and talent, WINIW remains at the forefront of synthetic leather manufacturing, delivering reliable, eco-conscious solutions for forward-thinking partners.

Contact Us for Samples

WINIW Premium Embossed Synthetic Leather: Technical Product Guide

WINIW delivers high-performance, eco-conscious synthetic leather solutions engineered for commercial applications. Our embossed microfiber leather combines aesthetic versatility with industrial-grade durability, offering designers and manufacturers a sustainable alternative to traditional leather without compromising on quality or functionality. All products are OEKO-TEX® Standard 100 certified, PVC-free, and incorporate up to 30% recycled content, aligning with global circular economy initiatives.

Key Advantages for B2B Partners

- Superior Customization: 500+ embossing patterns available (or client-specific designs), including lifelike grain structures, geometric textures, and tactile finishes.

- Eco-Efficiency: 60% lower carbon footprint vs. bovine leather; water-based PU coatings eliminate hazardous solvents.

- Performance-Driven: Abrasion resistance >50,000 cycles (Martindale test), tear strength >35 N, and UV stability for 1,000+ hours.

- End-Use Flexibility: Optimized for automotive interiors, luxury furniture, footwear uppers, and technical upholstery.

- Cost Control: Consistent roll-to-roll quality reduces waste; MOQs start at 500 linear meters.

Technical Specifications: Embossed Series Comparison

| Property | WINIW EcoGrain™ | WINIW Luxura™ | WINIW Tactile™ |

|---|---|---|---|

| Base Material | Recycled PET microfiber | Virgin microfiber | Recycled PET + TPU |

| Thickness (mm) | 0.8–1.2 | 1.0–1.5 | 0.7–1.0 |

| Width (cm) | 137 ± 2 | 140 ± 2 | 137 ± 2 |

| Weight (g/m²) | 380–420 | 450–500 | 320–360 |

| Embossing Depth | Medium | Deep | Bien |

| Best For | Furniture, Bags | Automotive, Luxury Interiors | Footwear, Sportswear |

Why Partner with WINIW?

- Sustainability Verified: Cradle-to-gate LCA reports available; compliant with REACH, RoHS, and California Proposition 65.

- Global Scalability: ISO 9001/14001 certified production; 15-day lead time for standard orders; 30+ countries served.

- Design Support: In-house R&D team provides color matching (Pantone®), pattern development, and prototyping.

- Total Cost Reduction: 40% longer lifespan vs. standard synthetics lowers replacement frequency for end products.

Request Free Technical Samples Today

Validate WINIW’s performance for your next project. Contact our Material Science Team at MKT88@MicrofiberLeather.com to specify:

– Target application (e.g., automotive seat covers, designer handbags)

– Preferred embossing pattern or custom design requirements

– Quantity needs for sampling

Free 30cm x 30cm swatches + full technical dossier provided within 48 hours. No obligation.

WINIW: Engineering Sustainable Innovation, One Fiber at a Time.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.