Introduction: Navigating the Global Market for distress fake leather

In the evolving landscape of synthetic materials, sourcing distress fake leather poses a unique challenge for international B2B buyers. This versatile alternative to genuine leather has become increasingly popular across various industries, from fashion to automotive upholstery. However, with a plethora of options available, identifying high-quality materials that meet specific aesthetic and functional requirements can be daunting. This guide aims to demystify the global market for distress fake leather by providing in-depth insights into different types, applications, and sourcing strategies.

We will explore the diverse varieties of distress fake leather, detailing their unique properties and suitability for various applications, such as apparel, furniture, and accessories. Additionally, this guide will offer practical advice on vetting suppliers, ensuring compliance with international standards, and evaluating cost factors to optimize your procurement process. By equipping B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Nigeria—with actionable insights, this comprehensive resource empowers informed purchasing decisions.

Navigating the complexities of sourcing distress fake leather has never been more straightforward, as this guide consolidates essential knowledge to help you make strategic choices that enhance your product offerings while aligning with market demands.

Table Of Contents

- Top 8 Distress Fake Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for distress fake leather

- Understanding distress fake leather Types and Variations

- Key Industrial Applications of distress fake leather

- 3 Common User Pain Points for ‘distress fake leather’ & Their Solutions

- Strategic Material Selection Guide for distress fake leather

- In-depth Look: Manufacturing Processes and Quality Assurance for distress fake leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘distress fake leather’

- Comprehensive Cost and Pricing Analysis for distress fake leather Sourcing

- Alternatives Analysis: Comparing distress fake leather With Other Solutions

- Essential Technical Properties and Trade Terminology for distress fake leather

- Navigating Market Dynamics and Sourcing Trends in the distress fake leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of distress fake leather

- Strategic Sourcing Conclusion and Outlook for distress fake leather

- Important Disclaimer & Terms of Use

Understanding distress fake leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Upholstery Vinyl | Thick, durable, often with a textured finish | Furniture, automotive interiors | Pros: Durable, easy to clean. Cons: Heavier, may not flex well. |

| Stretch Faux Leather | Thin, flexible, mimics the feel of genuine leather | Apparel, bags, and accessories | Pros: Comfortable, versatile. Cons: Less durable, can show wear quickly. |

| Embossed Faux Leather | Patterned surface, offers a variety of textures | Fashion items, upholstery | Pros: Aesthetic appeal, unique designs. Cons: Can be more expensive, may require specialized care. |

| Suede-like Faux Leather | Soft, napped finish resembling genuine suede | Footwear, clothing, and upholstery | Pros: Luxurious feel, visually appealing. Cons: More prone to staining, maintenance needed. |

| Coated Faux Leather | PVC or PU coating for added durability and water resistance | Outdoor furniture, bags | Pros: Water-resistant, robust. Cons: Can feel less breathable, potential for peeling. |

What are the characteristics of Upholstery Vinyl?

Upholstery vinyl is characterized by its thickness and durability, making it suitable for high-wear environments such as furniture and automotive interiors. This type of fake leather often features a textured finish that enhances its aesthetic appeal while providing resistance to wear and tear. B2B buyers should consider the weight and flexibility of upholstery vinyl, as it may not be ideal for applications requiring high flexibility, such as clothing. Its ease of cleaning is a significant advantage for commercial settings.

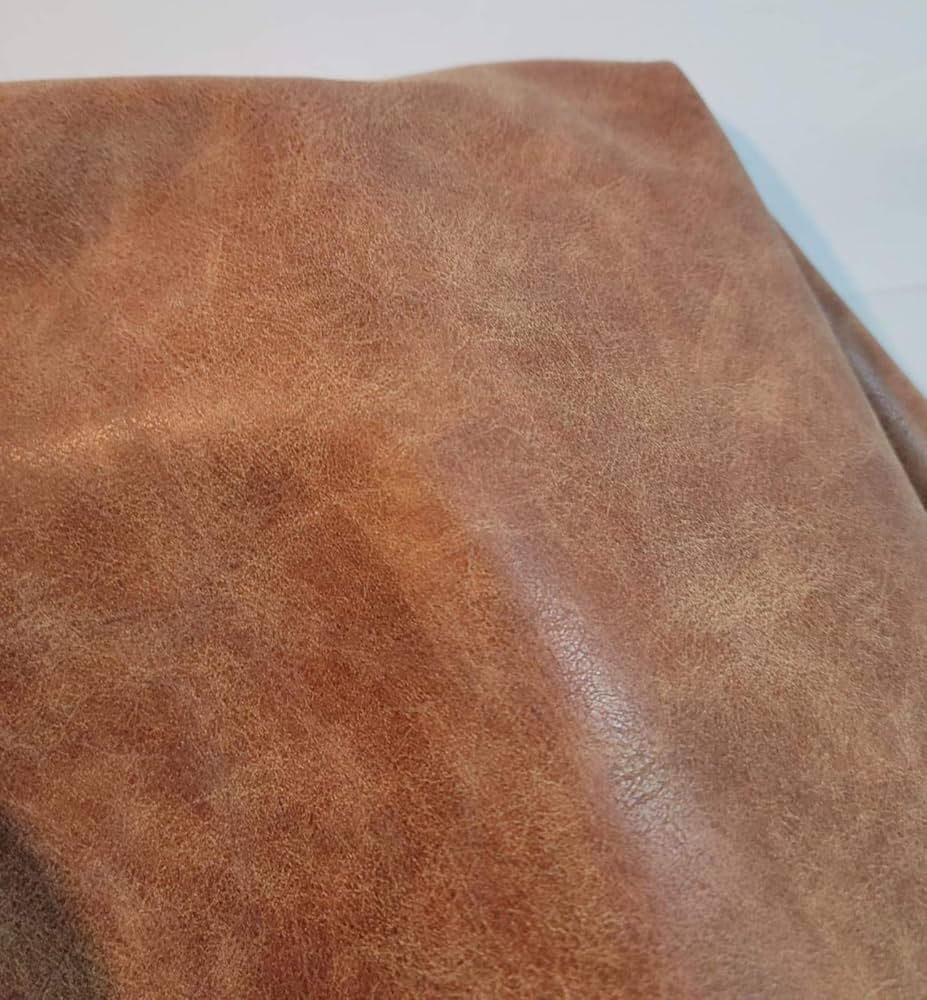

How does Stretch Faux Leather stand out in the market?

Stretch faux leather is designed for flexibility, making it an excellent choice for apparel, bags, and accessories. This type mimics the feel of genuine leather while being lighter and more comfortable for wear. However, B2B buyers should be aware that its thinner nature may lead to quicker wear and tear, making it less suitable for high-durability applications. When purchasing, consider the balance between comfort and durability to meet customer expectations.

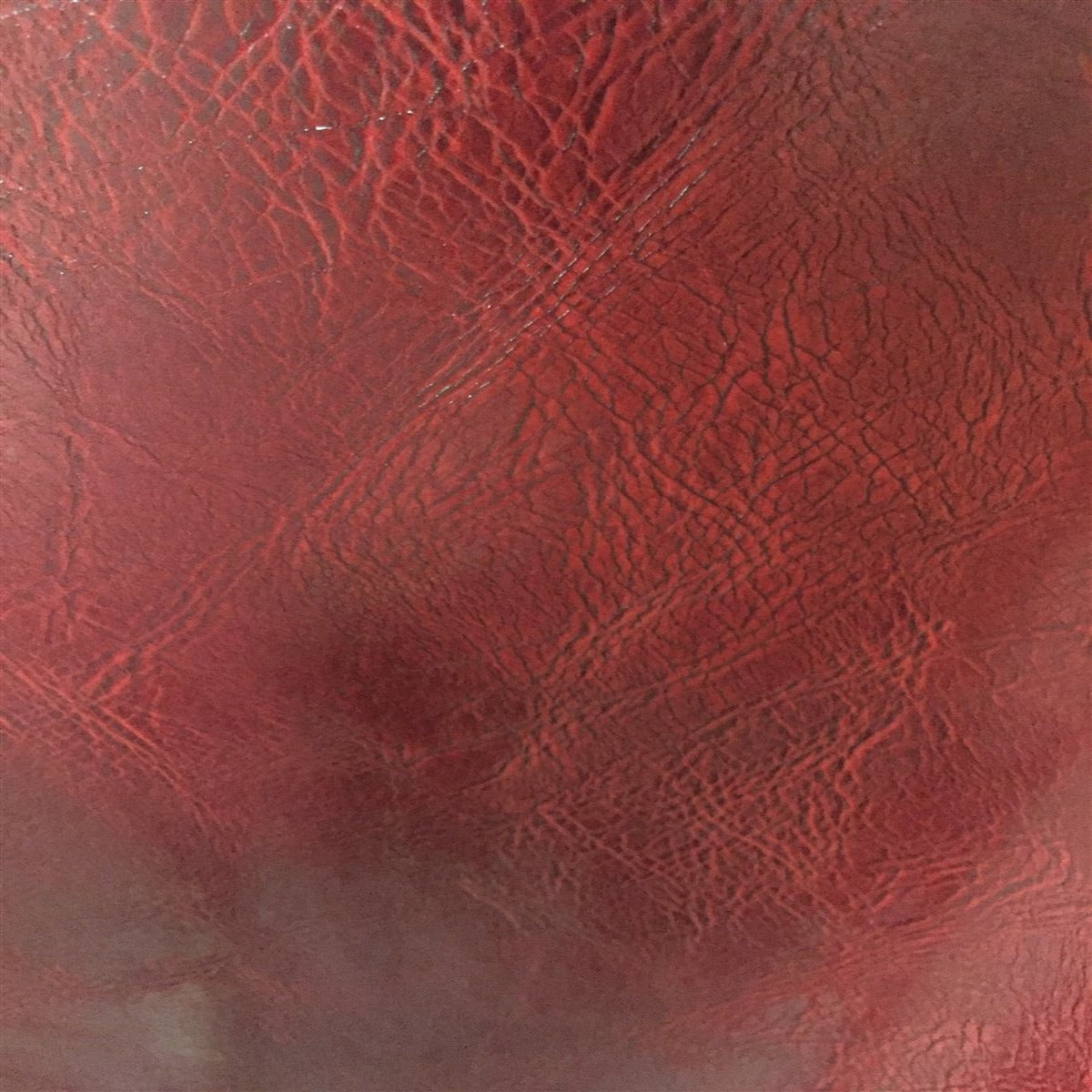

What makes Embossed Faux Leather a unique option?

Embossed faux leather features intricate patterns and textures, providing a unique visual appeal that can enhance fashion items and upholstery. This type allows for creative designs that can differentiate products in a competitive market. B2B buyers should evaluate the cost-effectiveness of embossed options, as they can be pricier than standard faux leather. However, the aesthetic benefits may justify the investment for brands aiming to stand out.

Why choose Suede-like Faux Leather for luxury applications?

Suede-like faux leather offers a soft, napped finish that closely resembles genuine suede, making it ideal for luxury items such as footwear and high-end clothing. Its luxurious feel is appealing to consumers looking for premium products. However, B2B buyers must consider the maintenance requirements, as this type can be more susceptible to stains and may require special cleaning methods. The potential for a higher price point should also be factored into purchasing decisions.

What are the benefits of Coated Faux Leather for outdoor use?

Coated faux leather, often made with PVC or PU, is specifically designed for added durability and water resistance, making it perfect for outdoor furniture and bags. Its robust nature allows it to withstand various environmental conditions, which is crucial for outdoor applications. B2B buyers should assess the breathability of coated options, as they can sometimes feel less comfortable. Additionally, the potential for peeling over time should be considered when evaluating long-term usage.

Key Industrial Applications of distress fake leather

| Industry/Sector | Specific Application of distress fake leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Distressed jackets and accessories | Provides a trendy, vintage look that attracts consumers | Quality, durability, and texture consistency are critical |

| Furniture and Upholstery | Upholstered furniture with a vintage aesthetic | Cost-effective alternative to genuine leather | Fire resistance, stain resistance, and ease of maintenance |

| Automotive | Interior trim and upholstery for vehicles | Enhances aesthetic appeal while being cost-effective | Compliance with safety standards and color matching |

| Footwear | Fashionable shoes and boots | Offers a stylish option while reducing environmental impact | Flexibility, breathability, and wear resistance |

| Home Décor | Decorative items such as cushions and wall art | Adds unique character and style to home interiors | Sourcing for diverse textures and finishes |

How is Distress Fake Leather Used in the Fashion and Apparel Sector?

In the fashion industry, distress fake leather is commonly utilized in the production of jackets, bags, and accessories. This material allows designers to create a vintage, worn-in look that resonates with modern consumer trends. For international buyers, especially from regions like Africa and South America, sourcing quality distress fake leather that meets aesthetic and durability standards is crucial. Buyers should also consider the environmental impact of materials, as sustainable sourcing can enhance brand reputation.

What Role Does Distress Fake Leather Play in Furniture and Upholstery?

In the furniture sector, distressed fake leather is frequently used for upholstered items, providing a stylish yet cost-effective alternative to traditional leather. This material can mimic the appearance of aged leather, appealing to consumers seeking rustic or vintage home décor. Buyers must ensure that the material meets specific requirements such as fire resistance and stain resistance, particularly in markets across the Middle East and Europe, where regulations may be stricter.

How is Distress Fake Leather Applied in Automotive Interiors?

Within the automotive industry, distress fake leather serves as a popular choice for vehicle interiors, including seats and trim. Its ability to deliver a luxurious appearance at a lower cost makes it attractive to manufacturers. International buyers should prioritize sourcing materials that comply with safety regulations and offer color consistency to meet brand specifications. Additionally, durability is a key consideration, as automotive interiors are subject to wear and tear.

Why is Distress Fake Leather Important in Footwear Production?

In the footwear industry, distress fake leather is increasingly used for stylish shoes and boots, providing a fashionable option that aligns with eco-friendly practices. This material allows brands to offer trendy designs without the ethical concerns associated with animal leather. Buyers should focus on sourcing materials that provide flexibility and breathability while maintaining wear resistance, ensuring comfort and longevity in their products.

How Can Distress Fake Leather Enhance Home Décor Items?

Distress fake leather is also gaining traction in home décor applications, such as decorative cushions and wall art. This material adds a unique character and aesthetic appeal, making it popular among consumers looking to personalize their living spaces. For B2B buyers, sourcing a variety of textures and finishes can help meet diverse customer preferences, particularly in regions with a growing interest in home styling and customization.

3 Common User Pain Points for ‘distress fake leather’ & Their Solutions

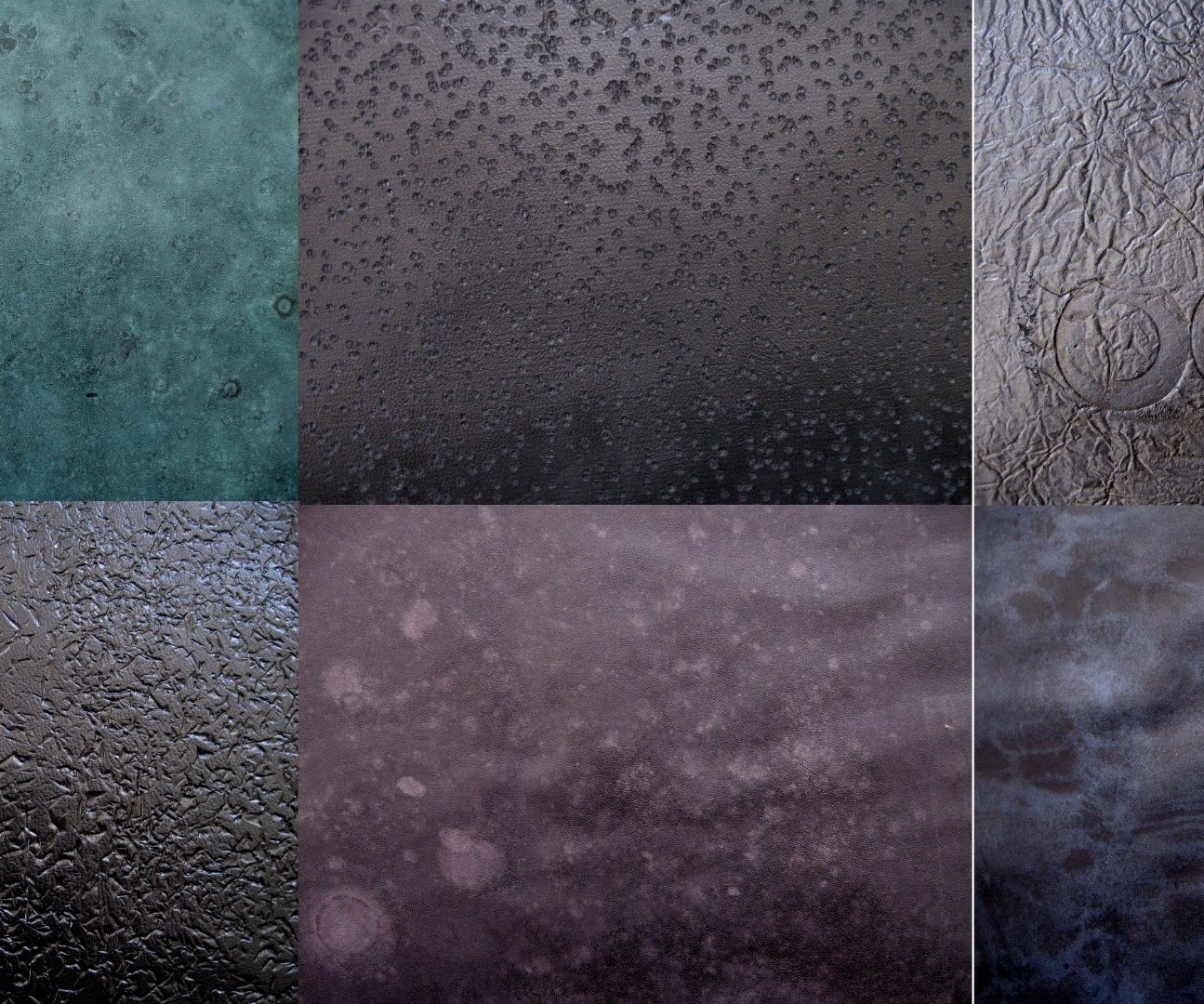

Scenario 1: Difficulty Achieving Authenticity in Appearance

The Problem: B2B buyers often struggle with sourcing distress fake leather that convincingly mimics the look and feel of genuine leather. This is particularly important in industries like fashion and furniture, where aesthetics play a crucial role. Buyers may encounter products that appear too shiny or have a visible knit backing, which detracts from the desired authentic leather look. This can lead to customer dissatisfaction and return issues, ultimately affecting sales and brand reputation.

The Solution: To overcome this challenge, buyers should prioritize sourcing high-quality distress fake leather that is specifically designed to replicate the texture and appearance of real leather. When assessing suppliers, inquire about the material’s composition and texture finish. Look for products that feature a matte finish and a more complex texture to avoid the “plastic” look. Additionally, consider suppliers who provide samples for testing. Conduct a thorough evaluation by testing the material under different lighting conditions and in various applications. This ensures that the chosen fake leather meets aesthetic expectations and can withstand the intended use.

Illustrative image related to distress fake leather

Scenario 2: Limited Customization Options for Unique Designs

The Problem: Many B2B buyers find themselves restricted by the limited customization options available for distress fake leather. Whether for creating bespoke furniture or unique apparel, a lack of variety in colors, textures, and distressing techniques can hinder creativity and product differentiation in the market. Buyers may feel pressured to settle for generic designs that fail to capture their brand’s essence, ultimately impacting their market competitiveness.

The Solution: To address this pain point, B2B buyers should seek partnerships with suppliers that offer customizable distress fake leather options. Engage with manufacturers who allow for color matching, textural alterations, and even bespoke distressing techniques. This can be achieved by collaborating closely with design teams to develop unique patterns or finishes that align with brand identity. Additionally, consider utilizing digital printing technologies to create custom designs on fake leather, providing a unique and personalized product offering that can stand out in the marketplace.

Scenario 3: Challenges in Maintenance and Longevity

The Problem: Another common pain point for B2B buyers is the maintenance and longevity of distress fake leather products. While these materials can be more affordable than genuine leather, they often require specific care to avoid damage, such as peeling or cracking. Buyers may face complaints from end-users regarding the durability of their products, which can lead to increased warranty claims and operational costs.

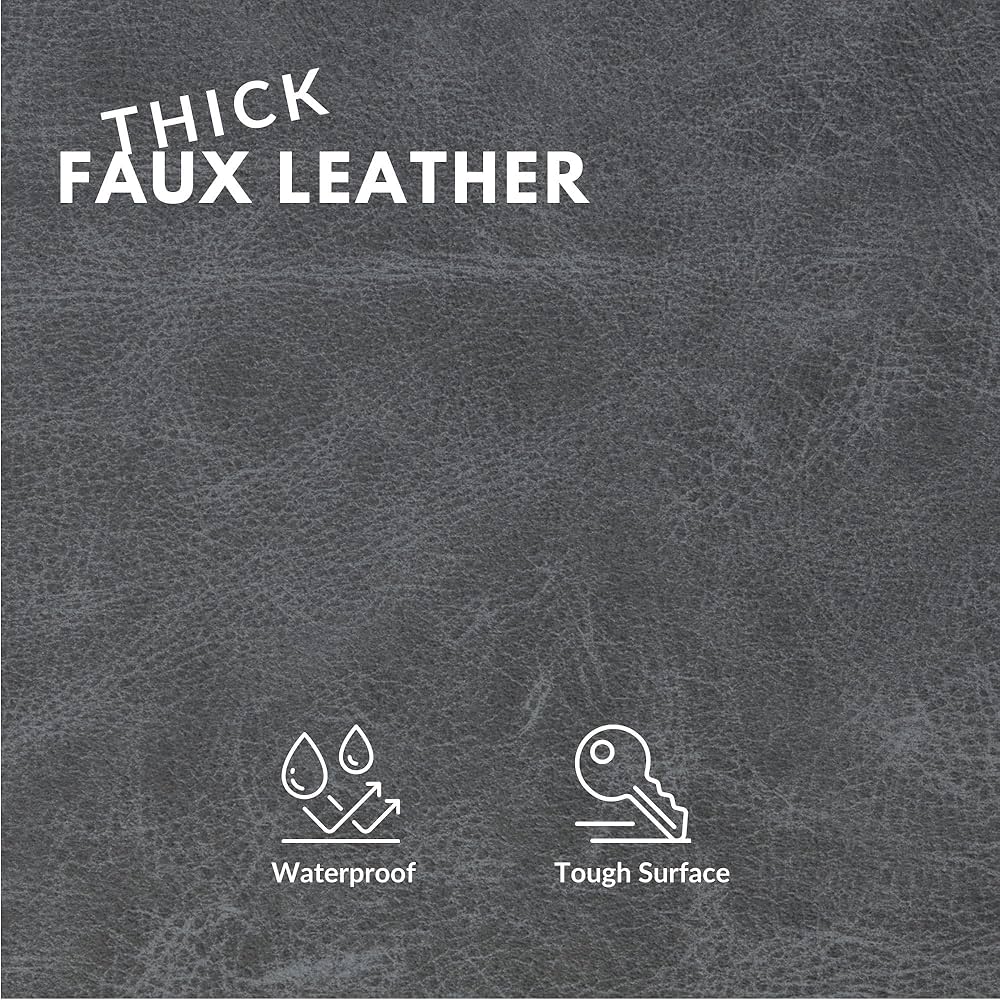

Illustrative image related to distress fake leather

The Solution: To mitigate maintenance issues, buyers should educate themselves about the appropriate care and usage of distress fake leather. This includes sourcing materials that have been treated for enhanced durability and stain resistance. When presenting these products to clients, provide clear maintenance guidelines that outline best practices for cleaning and care. Consider offering protective coatings or finishes that can extend the life of the material. Regular training sessions with staff and end-users can also ensure proper handling and care, thereby reducing the likelihood of product failure and enhancing customer satisfaction.

Strategic Material Selection Guide for distress fake leather

When selecting materials for distress fake leather, it is essential for B2B buyers to understand the properties, advantages, and limitations of each material. This knowledge will aid in making informed decisions that align with their production needs and market demands.

What are the Key Properties of PVC in Distress Fake Leather?

Polyvinyl Chloride (PVC) is one of the most commonly used materials for fake leather. It offers excellent durability and resistance to moisture, making it suitable for various applications, including upholstery and fashion accessories. PVC can withstand a temperature range of -10°C to 70°C, providing flexibility in different climatic conditions.

Pros: PVC is cost-effective and widely available, making it a popular choice for manufacturers. Its ability to be easily colored and textured allows for a wide variety of design options.

Illustrative image related to distress fake leather

Cons: However, PVC is less breathable than other materials, which can lead to discomfort in clothing applications. Additionally, its environmental impact is a concern, as PVC production can release harmful chemicals.

How Does PU Compare to PVC for Distress Fake Leather?

Polyurethane (PU) is another prevalent material used in the production of fake leather. It is known for its soft texture and high flexibility, which closely resembles genuine leather. PU can withstand moderate pressure and is resistant to abrasion, making it suitable for high-wear applications.

Pros: The aesthetic appeal of PU is a significant advantage, as it can mimic the look and feel of real leather more effectively than PVC. It is also more environmentally friendly, as it can be produced without harmful chemicals.

Cons: On the downside, PU can be more expensive than PVC, which may impact cost-sensitive projects. Its durability can vary based on the manufacturing process, and lower-quality PU may not hold up well under extreme conditions.

What Makes TPO a Viable Option for Distress Fake Leather?

Thermoplastic Olefin (TPO) is an emerging material in the fake leather market, known for its excellent weather resistance and UV stability. TPO can endure high temperatures and is resistant to chemicals, making it suitable for outdoor applications.

Pros: TPO is lightweight and flexible, which enhances comfort in clothing and accessories. Its recyclability aligns with growing sustainability trends, appealing to eco-conscious buyers.

Cons: However, TPO may not provide the same level of aesthetic appeal as PU or PVC, as it often lacks the luxurious finish associated with traditional leather. Additionally, its cost can be higher than PVC, which may deter some manufacturers.

What Are the Benefits and Limitations of Microfiber in Distress Fake Leather?

Microfiber is a synthetic material that has gained popularity due to its ultra-soft texture and high durability. It is often used in high-end products, providing a luxurious feel similar to genuine leather.

Pros: Microfiber is highly resistant to stains and easy to clean, making it ideal for applications in automotive and home furnishings. Its lightweight nature also enhances comfort in apparel.

Cons: The primary drawback of microfiber is its cost, which tends to be higher than PVC and PU. Additionally, it may not be as readily available in all markets, particularly in regions with limited access to synthetic textiles.

Summary Table of Material Selection for Distress Fake Leather

| Material | Typical Use Case for distress fake leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Upholstery, fashion accessories | Cost-effective and widely available | Less breathable, environmental concerns | Low |

| PU | Clothing, high-wear applications | Mimics real leather effectively | Higher cost, variable durability | Med |

| TPO | Outdoor applications, automotive | Excellent weather resistance | Less aesthetic appeal, higher cost | Med |

| Microfiber | High-end apparel, furnishings | Luxurious feel, stain-resistant | Higher cost, limited availability | High |

In conclusion, B2B buyers should carefully evaluate each material’s properties and implications for their specific applications. Understanding these factors will enable them to make strategic decisions that align with their brand values and market demands, particularly in diverse regions such as Africa, South America, the Middle East, and Europe.

In-depth Look: Manufacturing Processes and Quality Assurance for distress fake leather

What Are the Main Stages in the Manufacturing Process of Distress Fake Leather?

The manufacturing process of distress fake leather typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring the final product meets quality and aesthetic standards, particularly for B2B buyers looking for reliable suppliers.

Illustrative image related to distress fake leather

How Is Material Prepared for Distress Fake Leather Production?

Material preparation begins with selecting the appropriate synthetic substrates, primarily polyurethane (PU) or polyvinyl chloride (PVC). These materials are chosen for their durability, flexibility, and ease of manipulation. The selection process also involves assessing the texture and thickness of the vinyl, as these factors will affect the final appearance of the distressing techniques used.

After selecting the substrate, the material undergoes processes such as cutting and testing for compatibility with various distressing techniques. Manufacturers often create samples to explore the effectiveness of different distressing methods, such as painting, heat treatment, or texturing. This step is critical in ensuring that the material will respond well to the desired alterations without compromising its integrity.

What Techniques Are Commonly Used in Forming Distress Fake Leather?

Once the materials are prepared, the forming stage begins. This involves shaping the substrate into the desired form through techniques such as embossing, laminating, and coating. For distress fake leather, specific texturing techniques, like crumpling or heat embossing, are commonly employed to create a worn, vintage look.

Illustrative image related to distress fake leather

Heat application is a popular method in distressing processes. By using tools like heat guns or irons, manufacturers can manipulate the vinyl to create unique textures and patterns. Additionally, paint techniques using acrylics and solvents can further enhance the appearance, simulating the natural aging process of real leather. The combination of these techniques allows manufacturers to produce a wide variety of styles that appeal to different market segments.

How Is the Assembly of Distress Fake Leather Products Conducted?

In the assembly stage, the formed pieces of distress fake leather are sewn or bonded together to create finished products such as bags, jackets, or upholstery. This process often involves quality checks at multiple points to ensure that the stitching is consistent and that the seams are durable.

Manufacturers may also incorporate additional elements, like zippers or buckles, which need to be compatible with the distressed aesthetic. This is where attention to detail becomes paramount, as the final product must not only look good but also function well and meet customer expectations.

What Finishing Processes Are Essential for Distress Fake Leather?

The finishing stage is where the distress fake leather is given its final touches. This can include applying protective coatings, further distressing with additional paint or heat techniques, and polishing the surface to achieve the desired sheen. Quality assurance at this stage is crucial, as the final appearance and feel of the material will directly impact customer satisfaction.

Manufacturers often conduct final inspections, checking for color consistency, texture quality, and overall appearance. This ensures that any products sent to B2B buyers meet the established specifications and quality standards.

Illustrative image related to distress fake leather

How Is Quality Assurance Implemented in Distress Fake Leather Production?

Quality assurance (QA) is an integral part of the manufacturing process for distress fake leather. Implementing robust QA measures ensures that the products meet international standards and customer expectations.

What International Standards Apply to Distress Fake Leather Manufacturing?

For international B2B buyers, compliance with standards such as ISO 9001 is essential. This standard emphasizes a quality management system that enhances customer satisfaction through effective processes. Additionally, industry-specific certifications like CE marking (for compliance with European health, safety, and environmental protection standards) or API (American Petroleum Institute) certification may be relevant, particularly for products intended for specific sectors.

What Are the Key Quality Control Checkpoints in the Production Process?

Quality control (QC) is typically divided into several checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins. Buyers should request documentation or reports from suppliers to verify the quality of incoming materials.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor the quality of the product at various stages. This may include testing for texture, color consistency, and adherence to design specifications.

-

Final Quality Control (FQC): Before products are shipped to buyers, final inspections are performed to ensure that they meet all quality standards. This includes checking for defects, ensuring that distressing techniques have been applied correctly, and confirming that the final product aligns with customer requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of their suppliers. Conducting audits is one of the most effective methods. These audits can be performed in-house or by third-party inspection firms specializing in manufacturing quality assessments.

Buyers should also request quality assurance reports that detail the results of IQC, IPQC, and FQC processes. These documents should provide insights into the testing methods used, the frequency of inspections, and any corrective actions taken for non-conformities.

What Are the Common Testing Methods for Distress Fake Leather?

Common testing methods for distress fake leather include:

-

Tensile Strength Testing: This measures the material’s resistance to being pulled apart, ensuring durability.

-

Abrasion Resistance Testing: This assesses how well the material can withstand wear and tear, an essential characteristic for products like upholstery.

-

Colorfastness Testing: This evaluates how well the color of the fake leather holds up against various environmental factors, such as light exposure or washing.

-

Flame Retardancy Testing: Particularly important for products used in commercial settings, this testing ensures that the materials meet safety standards.

What Nuances Should International B2B Buyers Consider Regarding Quality Control and Certification?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality control and certification processes. Regulatory requirements can vary significantly by region, so understanding local standards and certifications is crucial.

Moreover, cultural factors and market expectations can influence the perception of quality. Buyers should engage in open communication with suppliers to clarify expectations and ensure that the products delivered align with their quality standards.

In conclusion, understanding the manufacturing processes and quality assurance practices for distress fake leather is essential for B2B buyers seeking reliable suppliers. By focusing on material preparation, forming, assembly, and finishing, as well as implementing robust quality control measures, manufacturers can produce high-quality products that meet international standards and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘distress fake leather’

Introduction

This practical sourcing guide is designed for B2B buyers looking to procure distress fake leather, a versatile material that simulates the look of aged leather while offering the durability and ease of maintenance of synthetic options. By following this step-by-step checklist, buyers can ensure they select the right suppliers and materials to meet their specific needs, whether for fashion, upholstery, or other applications.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical specifications for distress fake leather. Consider factors such as thickness, texture, color, and finish. This step is vital as it sets the groundwork for your sourcing process, ensuring that suppliers understand your requirements and can provide samples that meet your expectations.

Illustrative image related to distress fake leather

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in distress fake leather. Look for manufacturers with a proven track record in your target regions, such as Africa, South America, the Middle East, and Europe. Utilize platforms like industry trade shows, online directories, and trade associations to compile a list of potential partners.

- Industry Reputation: Review supplier ratings and feedback from previous clients.

- Product Range: Ensure they offer a variety of distressing techniques and finishes.

Step 3: Evaluate Supplier Certifications

Before making any commitments, verify that potential suppliers hold relevant certifications. Certifications such as ISO 9001 for quality management or adherence to environmental standards (e.g., REACH) are essential indicators of reliability. This step is critical in ensuring compliance with international standards, which can affect your product’s marketability.

Step 4: Request Samples for Assessment

Request physical samples of distress fake leather to evaluate quality firsthand. This allows you to assess the texture, color, and durability of the material. Pay attention to how the fabric responds to various distressing techniques, as this can influence your final product offerings.

- Testing Conditions: Consider testing samples under conditions similar to their intended end use.

- Visual Appeal: Look for consistency in color and texture across samples.

Step 5: Discuss Customization Options

Engage in discussions with suppliers about customization options. Many suppliers can modify colors, textures, or patterns to suit your specific needs. This flexibility can be a significant advantage, allowing you to differentiate your products in a competitive market.

Illustrative image related to distress fake leather

Step 6: Analyze Pricing Structures

Once you have shortlisted suppliers, analyze their pricing structures. Request detailed quotes that include pricing per unit, minimum order quantities, and potential discounts for bulk orders. Understanding the cost implications will help you make informed decisions and negotiate better terms.

- Comparative Analysis: Create a comparison chart to evaluate pricing alongside other factors like quality and lead time.

- Total Cost of Ownership: Consider logistics and potential import duties when calculating total costs.

Step 7: Establish Clear Communication Channels

Ensure that clear communication channels are established with your chosen supplier. Discuss lead times, payment terms, and delivery schedules upfront. This step is essential for maintaining a smooth workflow and addressing any potential issues proactively throughout the procurement process.

By adhering to this checklist, B2B buyers can navigate the complexities of sourcing distress fake leather effectively, ensuring they find high-quality materials that meet their business needs.

Comprehensive Cost and Pricing Analysis for distress fake leather Sourcing

Understanding the cost structure and pricing analysis for sourcing distress fake leather is crucial for B2B buyers aiming to optimize their procurement strategies. This section provides an in-depth look at the various cost components, price influencers, and practical tips to navigate the complexities of international sourcing.

What Are the Key Cost Components in Distress Fake Leather Production?

-

Materials: The primary material for distress fake leather is vinyl or polyurethane, which varies in quality and type. Thicker upholstery vinyl generally costs more than thinner stretch vinyl, as it requires more raw materials and offers better durability. Specialty finishes or textures that mimic aged leather can also increase material costs.

-

Labor: Labor costs are influenced by the region of production and the complexity of the manufacturing processes involved in distressing techniques. Skilled labor is required for tasks such as texturing and painting, which may command higher wages, particularly in regions with stringent labor laws.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, maintenance, and administrative expenses. Efficient production processes can help reduce overhead, but initial setup costs for tooling and machinery can be significant, especially for customized products.

-

Tooling: The need for specialized tools and equipment to create specific textures or finishes can add to the initial costs. Buyers should consider the lifespan and amortization of these tools when evaluating overall costs.

-

Quality Control (QC): Ensuring that the distress fake leather meets quality standards is vital. Quality control measures, including inspection and testing, contribute to costs but are necessary to maintain product integrity and minimize returns.

-

Logistics: Shipping and handling costs can significantly impact the total cost, particularly for international transactions. Factors such as distance, mode of transport, and customs duties should be accounted for in the pricing structure.

-

Margin: Suppliers typically add a profit margin on top of their costs. This margin can vary widely based on market competition, demand, and the perceived value of the product.

What Influences Pricing for Distress Fake Leather?

-

Volume/MOQ: Pricing is often tiered based on the minimum order quantity (MOQ). Larger orders typically benefit from lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom orders that require unique textures, colors, or finishes can lead to increased costs. Buyers should clearly communicate their specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials or certifications (e.g., eco-friendly or sustainable sourcing) can raise costs. Buyers should weigh the benefits of certifications against their budget constraints.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge a premium for their experience and quality assurance, while newer suppliers may offer competitive rates to gain market share.

-

Incoterms: Understanding international commercial terms (Incoterms) is crucial. They define the responsibilities of buyers and sellers in shipping, affecting costs associated with shipping, insurance, and customs clearance.

What Are the Best Negotiation Tips for B2B Buyers in Distress Fake Leather Sourcing?

-

Leverage Volume: Buyers should negotiate based on order size. Committing to larger volumes can lead to more favorable pricing and terms.

-

Total Cost of Ownership (TCO): Consider all cost factors, including shipping, handling, and potential returns, rather than just the upfront price. A lower initial cost may not always result in the best value.

-

Build Relationships: Developing a strong relationship with suppliers can lead to better pricing and more favorable terms in the long run. Trust and communication are key.

-

Understand Market Trends: Staying informed about market trends, material availability, and pricing fluctuations can provide leverage during negotiations.

-

Cultural Sensitivity: When dealing with international suppliers, understanding cultural nuances can facilitate smoother negotiations and foster goodwill.

Disclaimer on Indicative Prices

Pricing for distress fake leather can vary significantly based on numerous factors, including market conditions, supplier capabilities, and specific buyer requirements. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing distress fake leather With Other Solutions

Exploring Alternatives to Distress Fake Leather: A Comparative Analysis

In today’s competitive market, B2B buyers are increasingly seeking sustainable and cost-effective materials that replicate the aesthetics and functionality of traditional leather. Distress fake leather, known for its textured and worn appearance, is a popular option. However, several alternative solutions can achieve similar results. This analysis will compare distress fake leather with two viable alternatives: treated natural leather and bio-based synthetic leather, helping buyers make informed decisions.

| Comparison Aspect | Distress Fake Leather | Treated Natural Leather | Bio-Based Synthetic Leather |

|---|---|---|---|

| Performance | Durable, versatile; mimics leather texture well | High durability, luxurious feel; varies in performance based on treatment | Good durability, eco-friendly; performance may vary by manufacturer |

| Cost | Generally lower cost, accessible for bulk purchases | Higher initial cost; may require significant investment | Mid-range cost, potentially less expensive than treated leather |

| Ease of Implementation | Easy to source and work with; minimal processing required | Requires skilled craftsmanship and tools for treatment | Needs specialized manufacturing techniques; may be less accessible |

| Maintenance | Low maintenance; easy to clean | Moderate; requires conditioning and care | Low maintenance; often resistant to stains |

| Best Use Case | Fashion, upholstery, and accessories where a vintage look is desired | High-end fashion, bespoke goods, and luxury products | Eco-conscious brands looking for sustainable options |

What Are the Advantages and Disadvantages of Treated Natural Leather?

Treated natural leather offers a luxurious feel and exceptional durability. It is often used in high-end products, making it a preferred choice for bespoke items. However, the initial investment can be significant, and the craftsmanship required for treatment can limit accessibility for some manufacturers. Additionally, the maintenance involved, such as conditioning and cleaning, can be more demanding compared to synthetic alternatives. Treated leather is best suited for luxury markets where quality and craftsmanship are paramount.

Illustrative image related to distress fake leather

How Does Bio-Based Synthetic Leather Compare?

Bio-based synthetic leather is an innovative alternative that combines the aesthetics of leather with eco-friendly materials. It typically offers good durability and is resistant to stains, making it low maintenance. This option is increasingly popular among brands committed to sustainability. However, the performance of bio-based leather can vary significantly by manufacturer, and it may not always replicate the luxurious feel of natural leather. It is best suited for brands looking to promote their eco-conscious values while still providing quality products.

Conclusion: How Should B2B Buyers Decide on the Right Material?

Selecting the right material hinges on various factors, including budget, intended use, and brand values. For buyers looking for a cost-effective solution with a vintage aesthetic, distress fake leather is an excellent choice. Conversely, if the goal is to convey luxury and quality, treated natural leather remains unmatched despite its higher cost. Lastly, for those prioritizing sustainability, bio-based synthetic leather presents a compelling option that aligns with eco-conscious initiatives. By carefully evaluating these alternatives against their specific needs, B2B buyers can make informed decisions that align with their business objectives and market demands.

Essential Technical Properties and Trade Terminology for distress fake leather

What Are the Key Technical Properties of Distress Fake Leather?

Understanding the technical specifications of distress fake leather is crucial for B2B buyers looking to source materials that meet their quality and performance needs. Here are some essential properties to consider:

1. Material Composition

Distress fake leather is primarily made from synthetic materials such as polyurethane (PU) or polyvinyl chloride (PVC). The choice of material affects the product’s durability, flexibility, and appearance. PU is often preferred for its superior breathability and softer texture, while PVC may offer more resistance to wear but can be less comfortable.

2. Thickness and Weight

The thickness of fake leather is typically measured in millimeters (mm) and can range from 0.5 mm to 2 mm or more. Heavier materials tend to be more durable and suitable for upholstery, while lighter options are better for clothing. Understanding the thickness helps buyers select the right product for their intended application, whether it’s fashion, automotive interiors, or furniture.

3. Abrasion Resistance

Abrasion resistance is a critical property that measures how well the material can withstand wear and tear. It is usually tested using the Martindale method, where the material is rubbed against a standard abrasive surface. High abrasion resistance ensures longevity, making it a key factor for products subjected to frequent use, such as handbags or footwear.

4. Colorfastness

Colorfastness refers to the material’s ability to retain its color when exposed to light, water, and various environmental conditions. This property is essential for maintaining the aesthetic appeal of products made from distress fake leather. Buyers should look for materials with high colorfastness ratings, especially for items that will be used outdoors or in bright lighting.

5. Flexibility and Stretchability

Flexibility and stretchability determine how well the material can conform to different shapes without losing integrity. This is particularly important for applications in clothing and accessories. A good distress fake leather should be able to stretch without cracking or peeling, ensuring comfort and durability.

6. Surface Texture

The surface texture of distress fake leather can vary widely, influencing both appearance and tactile feel. Techniques such as embossing or printing can create patterns that mimic the look of natural leather. Buyers should consider the desired aesthetic and tactile properties when selecting materials, as these will impact consumer perception and satisfaction.

Illustrative image related to distress fake leather

What Are Common Trade Terms Related to Distress Fake Leather?

Navigating the world of B2B procurement involves understanding specific trade terminology. Here are some key terms relevant to distress fake leather:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products that are sold under another company’s brand. In the context of distress fake leather, buyers may work with OEMs to produce customized products that meet specific design requirements or branding needs.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to assess the feasibility of sourcing materials, especially for smaller businesses or new product lines. Suppliers often set MOQs to ensure production efficiency and cost-effectiveness.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When sourcing distress fake leather, an RFQ helps buyers gather competitive quotes and evaluate suppliers based on price, quality, and delivery timelines.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and ensure smooth transactions across borders.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is vital for planning inventory and production schedules, especially in industries with tight timelines.

6. Certification Standards

Certification standards, such as OEKO-TEX or REACH, indicate that materials meet specific safety and environmental criteria. Buyers should prioritize sourcing distress fake leather that complies with relevant certification standards to ensure product safety and sustainability.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions when sourcing distress fake leather, ensuring quality and compliance with market demands.

Navigating Market Dynamics and Sourcing Trends in the distress fake leather Sector

What Are the Key Market Dynamics and Trends Impacting Distress Fake Leather?

The distress fake leather market is witnessing significant growth driven by a combination of sustainability demands, innovative production techniques, and evolving consumer preferences. Globally, the demand for faux leather alternatives is surging due to increasing awareness of animal welfare and environmental concerns. B2B buyers from Africa, South America, the Middle East, and Europe are particularly focused on sourcing materials that align with ethical consumption trends. This shift is prompting manufacturers to innovate, with emerging technologies enabling the production of more authentic-looking and durable distress fake leather.

Illustrative image related to distress fake leather

One notable trend is the adoption of digital printing technologies that allow for intricate designs and textures that mimic natural leather. This technology not only enhances the aesthetic appeal of faux leather products but also reduces waste by enabling on-demand production. Furthermore, the rise of e-commerce platforms is transforming sourcing strategies, allowing international buyers to access a broader range of suppliers and materials, facilitating competitive pricing and diverse product offerings.

Another critical factor is the impact of regulatory frameworks aimed at reducing plastic waste, especially in regions like Europe where legislation is increasingly stringent. Buyers must navigate these regulations while seeking suppliers who comply with sustainability standards. This evolving landscape necessitates that businesses stay informed about market dynamics, enabling them to make strategic sourcing decisions that enhance their brand reputation and meet consumer expectations.

How Is Sustainability Shaping the Sourcing of Distress Fake Leather?

Sustainability is at the forefront of sourcing decisions in the distress fake leather sector. The environmental impact of traditional leather production, which involves significant water usage and chemical treatments, has prompted businesses to seek eco-friendly alternatives. B2B buyers are increasingly prioritizing suppliers that offer sustainable materials, such as those derived from recycled plastics or plant-based sources. This shift not only reduces the carbon footprint associated with sourcing but also appeals to a growing segment of environmentally conscious consumers.

Ethical supply chains are another crucial consideration. Buyers must ensure that their suppliers adhere to fair labor practices and provide transparency in their sourcing processes. Certifications such as Global Recycle Standard (GRS) and OEKO-TEX serve as benchmarks for assessing the sustainability and ethicality of materials. These certifications not only enhance the credibility of products but also provide buyers with assurance that their sourcing aligns with global sustainability goals.

Additionally, the market is seeing a rise in innovative materials that mimic the look and feel of distressed leather without the environmental drawbacks. For instance, bio-based polyurethane (PU) and innovative textile blends are gaining traction, offering durability and aesthetic appeal while minimizing ecological harm. By prioritizing sustainability, international B2B buyers can position themselves as leaders in ethical consumption, appealing to a broad customer base and fostering long-term business relationships.

What Is the Evolution of Distress Fake Leather in the B2B Market?

The evolution of distress fake leather has been shaped by technological advancements and shifting consumer preferences over the past few decades. Initially, faux leather was primarily viewed as a budget-friendly alternative to genuine leather, often lacking in quality and aesthetic appeal. However, as manufacturing technologies advanced, the production of distress fake leather became more sophisticated, allowing for the replication of authentic textures and finishes.

In recent years, the rise of ethical consumerism has further transformed the landscape. Buyers began to demand products that not only look good but are also produced responsibly. This demand has spurred innovation within the industry, leading to the development of high-quality, sustainable materials that meet the expectations of modern consumers. Consequently, the distress fake leather sector has evolved from a simple alternative to a viable, attractive option for a wide range of applications, including fashion, automotive, and furniture industries.

Illustrative image related to distress fake leather

As the market continues to grow, the focus on sustainability and ethical sourcing will likely intensify, shaping the future of distress fake leather and its role within the broader B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of distress fake leather

-

How do I ensure the quality of distress fake leather before making a bulk purchase?

To ensure the quality of distress fake leather, request samples from suppliers before placing a bulk order. Evaluate the material for texture, durability, and visual appeal, focusing on how well it mimics authentic leather. Additionally, inquire about the manufacturing process and the materials used. Establishing clear quality assurance protocols, including third-party inspections, can further mitigate risks associated with defects. -

What are the most popular applications for distress fake leather in various industries?

Distress fake leather is widely used in fashion, upholstery, automotive interiors, and accessories. In the fashion industry, it is popular for jackets, bags, and shoes, offering a vintage look without compromising animal welfare. In furniture, it provides a stylish, cost-effective alternative to real leather. Understanding specific applications helps in sourcing the right type of material suitable for your target market. -

What factors should I consider when selecting a supplier for distress fake leather?

When selecting a supplier, consider their reputation, production capacity, and experience in the industry. Evaluate their compliance with international quality standards and sustainability practices. Request references or case studies from previous clients, and assess their responsiveness to inquiries. Also, consider their logistics capabilities, including shipping times and costs, especially when sourcing from international markets. -

What is the minimum order quantity (MOQ) for distress fake leather, and how does it vary by supplier?

Minimum order quantities for distress fake leather can vary significantly depending on the supplier and the type of material. Generally, MOQs may range from 100 to 1,000 meters. It’s essential to discuss your specific needs with potential suppliers, as many are willing to negotiate MOQs based on your business requirements and the potential for ongoing orders. -

How can I customize distress fake leather for my brand?

Customization options for distress fake leather may include color, texture, and pattern variations. Some suppliers offer digital printing services, allowing you to create unique designs that reflect your brand identity. To initiate the customization process, provide detailed specifications and any design files to the supplier. Be prepared for potential lead times and cost adjustments associated with custom orders. -

What payment terms are commonly used in international B2B transactions for distress fake leather?

Payment terms in international transactions often include options like advance payment, letters of credit, or payment upon delivery. It’s crucial to discuss and agree upon payment terms upfront to avoid misunderstandings. Consider using secure payment methods and escrow services to protect your investment, especially when dealing with new suppliers. -

How do I handle logistics and shipping for distress fake leather orders?

When arranging logistics for distress fake leather orders, consider factors such as shipping methods, freight forwarders, and customs regulations in your country. Collaborate with your supplier to determine the most efficient shipping options and lead times. Additionally, stay informed about import tariffs and duties that may affect your total landed cost. -

What quality assurance processes should I implement when sourcing distress fake leather?

Implementing quality assurance processes involves establishing clear specifications and standards for the material. Conduct regular inspections during production and upon receipt of goods. Consider using third-party inspection services to provide unbiased quality checks. Document all findings and communicate any discrepancies to the supplier immediately to ensure resolution and maintain quality standards.

Top 8 Distress Fake Leather Manufacturers & Suppliers List

1. Instructables – Key Techniques for Texturing Fake Leather

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Key techniques for texturing fake leather include:

1. **Picking Your Vinyl**: Choose between thicker upholstery vinyl and thinner stretch vinyl. Recommended products: [Vinyl 1](http://www.amazon.com/gp/product/B00FVE4VT6?ref_=c…) and [Vinyl 2](http://www.amazon.com/gp/product/B00C7CFP2C?ref_=c…).

2. **Painting Techniques**:

– **Technique 1**: Use acrylic paint, rubbing alcohol, and water t…

2. Vintage Leather Gear – Premium Leather Goods

Domain: vintageleathergear.com

Registered: 2019 (6 years)

Introduction: This company, Vintage Leather Gear – Premium Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Fashion Fabric LA – Distressed Faux Leather Vinyl

Domain: fashionfabricla.com

Registered: 2014 (11 years)

Introduction: Distressed Faux Leather Vinyl Fabric – Sold By The Yard

4. Steam Fashion – Distressed Faux Leather Boots

Domain: steamfashion.livejournal.com

Registered: 1999 (26 years)

Introduction: Distressing Faux Leather boots that are shiny and new, with a desire to make them appear worn and dirty.

5. Big Z Fabric – 2-Tone Distressed Granum Vinyl Faux Leather

Domain: bigzfabric.com

Registered: 2010 (15 years)

Introduction: 2-Tone Distressed Granum Vinyl Faux Leather – Rugged, Stylish & Timeless. Features a rich, dual-tone distressed finish that offers a worn-in, vintage appeal. Ideal for upholstery, fashion accessories, and automotive interiors. Adds depth, texture, and sophistication to projects. Perfect for crafting rustic furniture, vintage-style bags, or bold statement pieces. Enhances rugged charm while ensurin…

6. Etsy – Distressed Vegan Leather by the Yard

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Distressed Vegan Leather by the Yard, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Kovi Fabrics – Faux Leather Fabric

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Faux leather fabric is a synthetic alternative to genuine leather, made from polyester or other fabric bases coated for a leather-like texture. It is soft, easy to clean, water-resistant, and stain-resistant. Common components include wax, polyurethane, polyvinyl chloride (PVC), and dye. There are two main types: PU leather, which is eco-friendly and breathable, and PVC leather, which is waterproo…

8. Vegan Lthr – Faux Leather by the Yard

Domain: veganlthr.com

Registered: 2021 (4 years)

Introduction: This company, Vegan Lthr – Faux Leather by the Yard, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for distress fake leather

How Can Strategic Sourcing Enhance Your Distress Fake Leather Supply Chain?

In summary, the strategic sourcing of distress fake leather presents a compelling opportunity for B2B buyers seeking to enhance product offerings while optimizing costs. By carefully selecting suppliers who can provide high-quality materials with the right textures and finishes, businesses can improve their competitive edge in markets across Africa, South America, the Middle East, and Europe. Leveraging innovative techniques in sourcing can lead to unique product variations that cater to evolving consumer preferences.

Moreover, establishing strong relationships with manufacturers who specialize in the specific nuances of fake leather production can significantly reduce lead times and improve supply chain efficiency. This is particularly vital in regions like Vietnam and Nigeria, where market dynamics can shift rapidly.

As you explore the potential of distress fake leather, consider engaging with suppliers who demonstrate a commitment to sustainability and innovation. The future of the industry hinges on collaboration and adaptability. Embrace these opportunities and position your business for success in a competitive landscape by prioritizing strategic sourcing in your procurement strategy. Take the next step today—evaluate your sourcing options and seize the potential of this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.