Introduction: Navigating the Global Market for custom leather imprinting

In today’s competitive landscape, sourcing custom leather imprinting solutions can be a daunting task for international B2B buyers. With a plethora of options available, from personalized branding stamps to intricate embossing techniques, the challenge lies in identifying reliable suppliers that meet specific requirements. This guide serves as a comprehensive resource, addressing various aspects of custom leather imprinting, including types of stamps, their applications across different leather types, and essential supplier vetting criteria.

Understanding the nuances of the market is crucial for businesses operating in diverse regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Germany. This guide empowers buyers by providing insights into cost considerations, quality benchmarks, and lead times, enabling them to make informed purchasing decisions.

By equipping B2B buyers with actionable knowledge about the intricacies of custom leather imprinting, this resource aims to streamline the sourcing process, ensuring that companies can effectively enhance their brand identity through high-quality leather goods. Whether you’re seeking to create bespoke products or add value to existing lines, navigating the global market for custom leather imprinting has never been more accessible.

Table Of Contents

- Top 8 Custom Leather Imprinting Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather imprinting

- Understanding custom leather imprinting Types and Variations

- Key Industrial Applications of custom leather imprinting

- 3 Common User Pain Points for ‘custom leather imprinting’ & Their Solutions

- Strategic Material Selection Guide for custom leather imprinting

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather imprinting

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather imprinting’

- Comprehensive Cost and Pricing Analysis for custom leather imprinting Sourcing

- Alternatives Analysis: Comparing custom leather imprinting With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather imprinting

- Navigating Market Dynamics and Sourcing Trends in the custom leather imprinting Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather imprinting

- Strategic Sourcing Conclusion and Outlook for custom leather imprinting

- Important Disclaimer & Terms of Use

Understanding custom leather imprinting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Leather Stamps | Made from brass or aluminum; deep relief cuts | Leather goods branding, personalization | Pros: High detail, customizable designs. Cons: Initial setup cost for custom designs. |

| Electric Branding Irons | Heated, quick imprinting, adjustable temperature | High-volume production, uniform branding | Pros: Consistent results, efficient for large batches. Cons: Higher upfront investment, requires power source. |

| Heat Embossing | Uses heat to imprint designs, ideal for fine details | Luxury leather goods, customized gifts | Pros: Creates elegant finishes, suitable for delicate designs. Cons: Slower process, requires more skill. |

| Handheld Mallet Stamps | Manual application, requires physical effort | Small-scale production, artisan crafts | Pros: Cost-effective, portable. Cons: Labor-intensive, may yield inconsistent results. |

| Custom Dies | Metal dies for stamping, suited for high volume | Mass production of leather items | Pros: Durable, suitable for repetitive designs. Cons: Higher initial cost, longer lead times. |

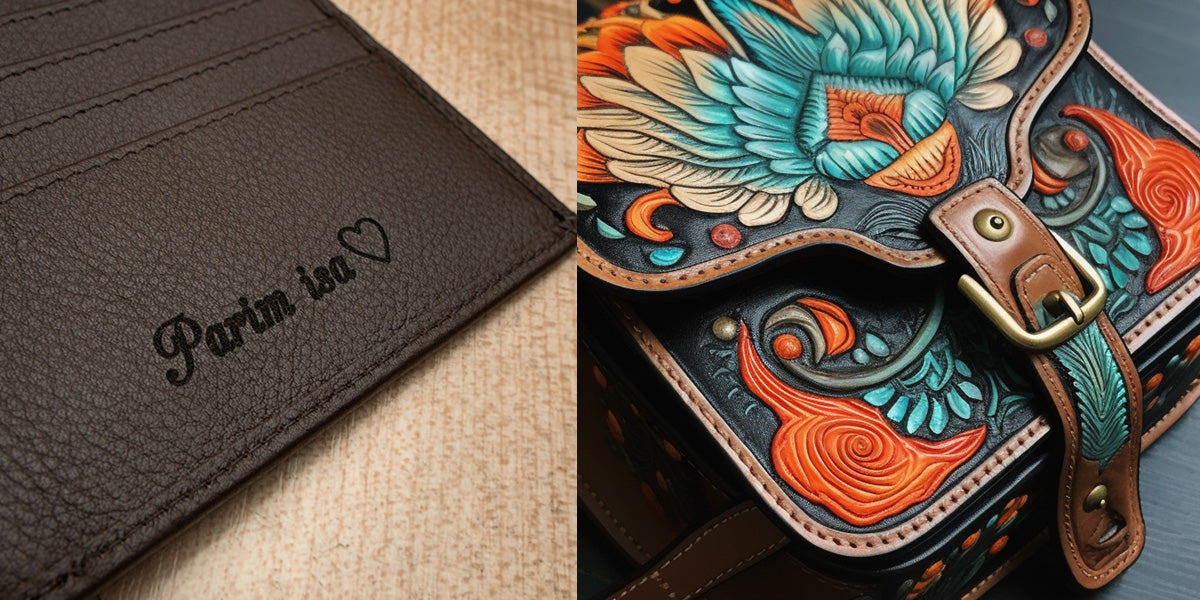

What Are the Key Characteristics of Custom Leather Stamps?

Custom leather stamps are typically made from brass or aluminum and feature deep relief cuts for maximum clarity. They are ideal for branding leather goods and personalizing items such as wallets, belts, and bags. B2B buyers should consider the material’s durability and the detail of the design when purchasing. While they offer high customization, the initial setup cost may be a barrier for smaller businesses.

How Do Electric Branding Irons Enhance Production Efficiency?

Electric branding irons provide a heated method for imprinting, making them suitable for high-volume production where uniform branding is essential. The adjustable temperature settings allow for versatility across different leather types, ensuring optimal results. While they require a higher upfront investment, their efficiency in producing consistent results can significantly reduce labor costs in the long run.

Why Choose Heat Embossing for Luxury Leather Goods?

Heat embossing is a technique that combines heat and pressure to imprint designs, making it perfect for luxury leather goods and customized gifts. This method allows for intricate designs and provides an elegant finish that enhances the product’s perceived value. However, it can be slower and requires skilled operators, making it less suitable for high-volume production environments.

What Advantages Do Handheld Mallet Stamps Offer to Artisans?

Handheld mallet stamps are a cost-effective solution for artisans and small-scale producers. They are portable and easy to use, making them ideal for craft shows or on-site personalization. However, the manual application can be labor-intensive and may result in inconsistent imprints if not applied with care. Buyers should weigh the benefits of low investment against the potential for variability in quality.

How Do Custom Dies Support Mass Production?

Custom dies are essential for businesses looking to mass-produce leather items with consistent branding. Made from durable materials, these dies can withstand repeated use, making them a worthwhile investment for high-volume production. While the initial costs and longer lead times can be challenges, the ability to produce repetitive designs efficiently can lead to significant cost savings over time.

Illustrative image related to custom leather imprinting

Key Industrial Applications of custom leather imprinting

| Industry/Sector | Specific Application of custom leather imprinting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom branding on leather goods like bags and jackets | Enhances brand recognition and adds a luxury feel to products | Quality of materials, precision in imprinting, turnaround time |

| Automotive | Embossing logos on leather interiors and seat covers | Creates a personalized experience for customers and adds value | Durability of the stamp, compatibility with various leather types |

| Furniture | Custom stamps for leather upholstery in furniture | Differentiates products in a competitive market | Custom design capabilities, production lead time, and cost-effectiveness |

| Promotional Products | Creating personalized leather gifts or corporate giveaways | Strengthens brand loyalty and recognition among clients | Design flexibility, minimum order quantities, and shipping options |

| Craft & Hobby | Custom stamps for artisanal leather goods | Enables small businesses to create unique, marketable products | Support for small batch production, ease of use, and availability of design assistance |

How is Custom Leather Imprinting Used in the Fashion & Apparel Industry?

In the fashion sector, custom leather imprinting is widely utilized for branding leather goods such as handbags, jackets, and shoes. This technique not only enhances brand recognition but also adds a touch of luxury and personalization to products. For international B2B buyers, especially those from Africa and Europe, sourcing high-quality materials and precise imprinting techniques is crucial. Fast turnaround times are also essential to meet seasonal demands and market trends.

What Role Does Custom Leather Imprinting Play in the Automotive Sector?

The automotive industry leverages custom leather imprinting to emboss logos and designs on leather interiors and seat covers. This application creates a personalized customer experience, elevating the perceived value of vehicles. Buyers in this sector must consider the durability of the stamping process, ensuring that the imprint can withstand wear and tear. Compatibility with various leather types is also vital, as different vehicles may use diverse materials.

How is Custom Leather Imprinting Beneficial for Furniture Manufacturers?

In the furniture sector, custom leather stamps are employed to brand leather upholstery, helping manufacturers distinguish their products in a crowded market. This adds an element of authenticity and quality assurance to the furniture. For B2B buyers, key considerations include the ability to produce custom designs and the lead time for manufacturing. Cost-effectiveness also plays a significant role, especially for businesses aiming to maintain competitive pricing.

How Can Promotional Products Companies Utilize Custom Leather Imprinting?

Companies in the promotional products industry often use custom leather imprinting to create personalized gifts or corporate giveaways. This practice strengthens brand loyalty and recognition among clients, making the products memorable. Buyers should look for suppliers that offer design flexibility and competitive minimum order quantities, as well as reliable shipping options to ensure timely delivery for events or campaigns.

What Benefits Does Custom Leather Imprinting Offer to Craft & Hobby Businesses?

For artisans and small businesses in the craft and hobby sector, custom leather imprinting enables the creation of unique, marketable leather goods. This application allows for personalization that can attract niche markets. Buyers should seek suppliers that support small batch production and provide ease of use in their stamping tools, along with design assistance to help bring their creative visions to life.

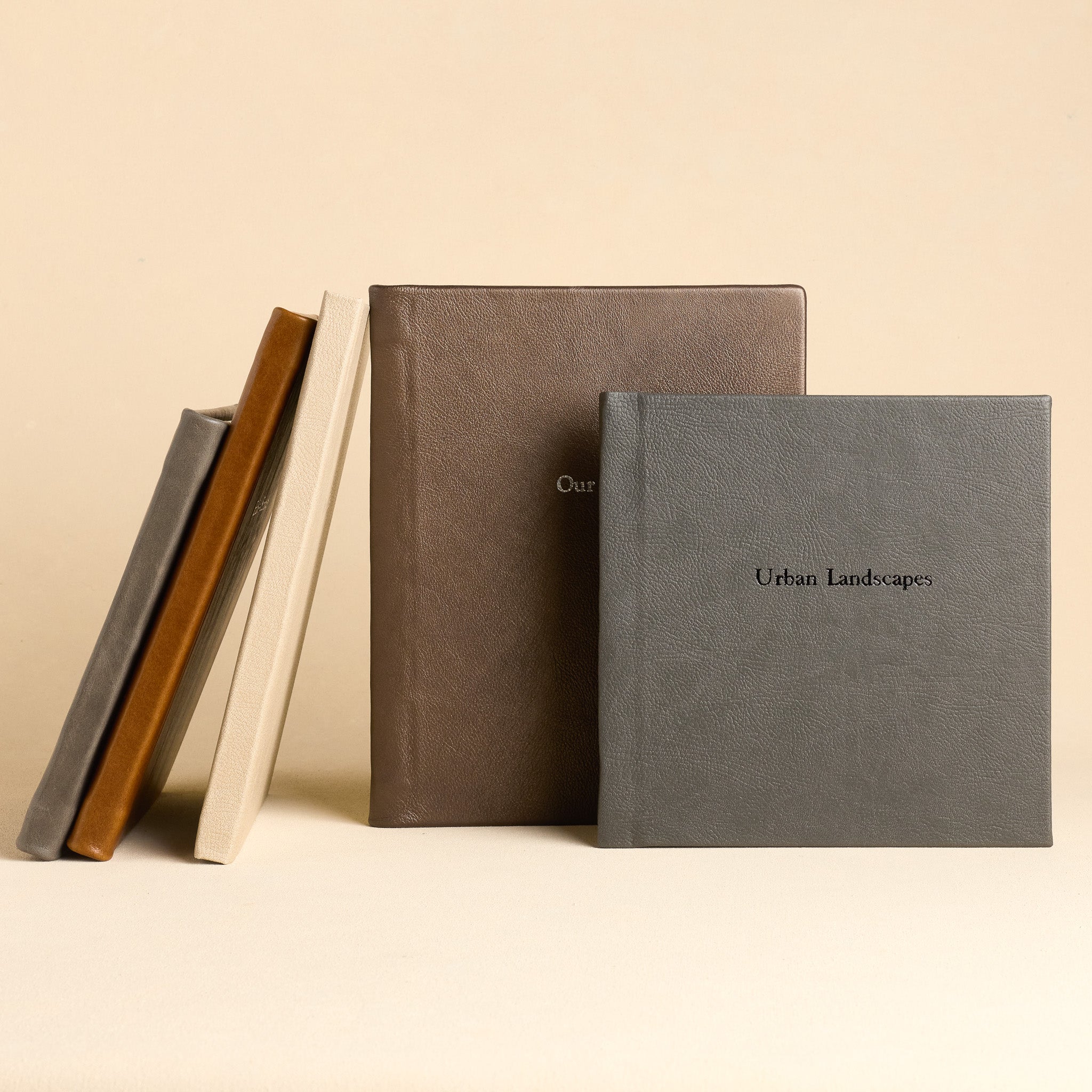

Illustrative image related to custom leather imprinting

3 Common User Pain Points for ‘custom leather imprinting’ & Their Solutions

Scenario 1: Inconsistent Quality of Leather Imprints

The Problem: B2B buyers often face challenges with inconsistent quality in leather imprints, which can lead to dissatisfaction among end customers. Variability in the depth of the imprint, clarity of the design, and even damage to the leather can occur if the stamping process is not executed correctly. This inconsistency can be particularly problematic when producing large batches, as it risks wasting both materials and time, ultimately affecting the bottom line.

The Solution: To ensure consistent quality in custom leather imprinting, buyers should prioritize sourcing high-quality custom stamps and branding tools from reputable manufacturers. When specifying your needs, consider opting for stamps made from durable materials like brass or stainless steel, as they maintain their quality over time. It’s also advisable to work with suppliers who offer a trial run or samples before bulk orders, allowing you to assess the imprint quality firsthand. Additionally, providing clear and precise artwork files, preferably in vector format, can significantly enhance the quality of the final product. Finally, implement a standardized stamping process in your production line, training staff on the optimal techniques for achieving uniformity across all products.

Scenario 2: Long Lead Times Affecting Production Schedules

The Problem: Many B2B buyers encounter long lead times for custom leather imprints, which can disrupt production schedules and delay product launches. When companies rely on external vendors for their stamping needs, unexpected delays in production can result in missed deadlines and lost business opportunities. This issue is especially critical for companies operating in fast-paced markets where timing is crucial.

The Solution: To mitigate the risk of long lead times, buyers should establish strong relationships with suppliers who prioritize quick turnaround times and offer expedited services. When discussing your needs, inquire about their production capabilities and average lead times for custom stamps. Look for vendors that provide assurances for rapid processing, such as 24-48 hour shipping options for rush orders. Furthermore, consider maintaining a small inventory of essential stamp designs to ensure you can meet immediate demands without waiting for new orders. Implementing a proactive communication strategy with your supplier can also help keep you informed about any potential delays, allowing you to adjust your production timelines accordingly.

Scenario 3: Lack of Customization Options Leading to Generic Products

The Problem: B2B buyers frequently struggle with limited customization options for leather imprints, leading to generic and less appealing products. In competitive markets, the ability to differentiate offerings through unique branding is essential. When suppliers only provide standard designs or lack flexibility in customization, it can diminish a company’s brand identity and impact customer engagement.

Illustrative image related to custom leather imprinting

The Solution: To enhance customization capabilities, buyers should seek suppliers who specialize in bespoke solutions and understand the importance of brand identity. When placing an order, clearly communicate your vision and requirements, including specific design elements, sizes, and desired materials. Opt for manufacturers that offer a variety of stamping options, such as different depths, sizes, and finishes, to better align with your branding strategy. Additionally, consider collaborating with suppliers that can assist in the design process, providing expert insights into how to best achieve your desired imprint. This partnership not only ensures a more personalized product but also fosters innovation, allowing your brand to stand out in the marketplace.

Strategic Material Selection Guide for custom leather imprinting

What Are the Key Materials for Custom Leather Imprinting?

When selecting materials for custom leather imprinting, it is crucial to consider their properties, advantages, and limitations. This guide analyzes four common materials used in the industry: brass, aluminum, stainless steel, and copper. Each material presents unique characteristics that influence their suitability for various applications in leather imprinting.

How Does Brass Perform in Custom Leather Imprinting?

Brass is a popular choice for custom leather stamps due to its excellent durability and corrosion resistance. It can withstand high temperatures and pressures, making it suitable for both heat and cold stamping processes. Brass stamps also provide a crisp, clear imprint on leather, which is essential for branding and personalization.

Pros: Brass offers a long lifespan and maintains its integrity under repeated use. It is also relatively easy to engrave, allowing for intricate designs.

Illustrative image related to custom leather imprinting

Cons: The primary drawback of brass is its higher cost compared to aluminum. Additionally, it can tarnish over time if not properly maintained, requiring periodic cleaning to preserve its appearance.

Impact on Application: Brass is compatible with various leather types, including vegetable-tanned and chrome-tanned leather. Its ability to create detailed impressions makes it ideal for high-quality branding.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East may prefer brass due to its durability and aesthetic appeal. Compliance with local standards such as ASTM or DIN may also be necessary, particularly for high-end leather goods.

What Are the Advantages of Aluminum for Leather Stamps?

Aluminum is a cost-effective alternative to brass and is often chosen for its lightweight properties. It is suitable for producing custom leather stamps that require less intricate designs.

Pros: Aluminum is significantly cheaper than brass and offers good corrosion resistance. It is also lightweight, making it easier to handle during the stamping process.

Illustrative image related to custom leather imprinting

Cons: However, aluminum is less durable than brass and may not withstand high temperatures as effectively. This could limit its use in heat stamping applications.

Impact on Application: Aluminum stamps work well for simpler designs and are often used for promotional items or lower-cost leather goods. They may not provide the same level of detail as brass.

Considerations for International Buyers: Buyers in Africa or South America might favor aluminum for its affordability, especially for bulk orders. However, they should ensure that the aluminum used meets relevant quality standards.

How Does Stainless Steel Compare in Custom Leather Imprinting?

Stainless steel is known for its strength and resistance to corrosion, making it an excellent choice for custom leather stamps that require longevity and durability.

Pros: Stainless steel provides a robust option that can endure rigorous use without degrading. Its resistance to rust and tarnishing ensures a consistent quality of imprint over time.

Illustrative image related to custom leather imprinting

Cons: The main limitation of stainless steel is its higher cost compared to aluminum, which may deter budget-conscious buyers. Additionally, it can be more challenging to engrave intricate designs compared to brass.

Impact on Application: Stainless steel is suitable for both cold and heat stamping, providing versatility for various leather types. It performs well in high-volume production settings.

Considerations for International Buyers: Buyers from regions with stringent quality regulations, such as Germany, may prefer stainless steel due to its durability and compliance with industry standards.

What Role Does Copper Play in Leather Imprinting?

Copper is less commonly used but offers unique benefits for specific applications. It is known for its excellent thermal conductivity, making it suitable for heat stamping.

Pros: Copper can create very detailed impressions and is easy to engrave. It also has a distinctive aesthetic that can enhance the visual appeal of stamped products.

Illustrative image related to custom leather imprinting

Cons: However, copper is prone to oxidation, which can affect the quality of the imprint over time. It is also less durable than brass and stainless steel.

Impact on Application: Copper is ideal for custom designs that require high detail and can be effectively used in limited production runs.

Considerations for International Buyers: Buyers in regions with a focus on artisanal products may appreciate the unique qualities of copper. However, they should be aware of the maintenance required to prevent oxidation.

Summary of Material Selection for Custom Leather Imprinting

| Matériau | Typical Use Case for custom leather imprinting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-quality branding and personalization | Durable and provides clear imprints | Higher cost, may tarnish over time | Haut |

| Aluminum | Budget-friendly promotional items | Cost-effective and lightweight | Less durable, limited high-temp use | Low |

| Stainless Steel | High-volume production, versatile applications | Strong and corrosion-resistant | Higher cost, harder to engrave | Medium |

| Copper | Detailed, artisanal designs | Excellent thermal conductivity | Prone to oxidation, less durable | Medium |

This guide aims to assist international B2B buyers in making informed decisions about material selection for custom leather imprinting, ensuring that they choose the best option for their specific needs and market requirements.

Illustrative image related to custom leather imprinting

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather imprinting

What Are the Main Stages of the Manufacturing Process for Custom Leather Imprinting?

The manufacturing process for custom leather imprinting involves several critical stages that ensure high-quality results. Understanding these stages can help B2B buyers appreciate the craftsmanship and quality assurance that goes into each product.

Material Preparation: How Is Leather Selected and Treated?

The first stage in the custom leather imprinting process is material preparation. This involves selecting the appropriate type of leather based on the intended application. Common choices include vegetable-tanned leather, cowhide, and chrome-tanned leather. Each type has unique characteristics that influence the imprinting quality and durability.

Once selected, the leather undergoes a treatment process that may include conditioning and soaking to enhance its pliability. This step is crucial as it ensures the leather can effectively receive and retain the imprint. Additionally, any imperfections in the leather are identified and addressed at this stage to maintain the overall quality of the final product.

Illustrative image related to custom leather imprinting

What Techniques Are Used in Forming Custom Leather Imprints?

The forming stage encompasses the actual imprinting process, which can be accomplished through several techniques:

-

Heat Embossing: This method utilizes a heated stamp to create impressions in the leather. It’s ideal for achieving crisp, detailed designs and is particularly effective for larger logos and intricate patterns.

-

Cold Stamping: This technique employs a mallet to strike the stamp against the leather, leaving an impression without heat. It’s suitable for simpler designs and is often used in conjunction with deep relief stamps to enhance clarity.

-

Laser Engraving: Increasingly popular, this method uses laser technology to etch designs into the leather. It allows for high precision and can accommodate complex graphics that may be difficult to achieve with traditional stamping techniques.

How Is the Assembly Process Handled for Custom Leather Goods?

After the imprinting, the assembly process begins. This involves cutting and stitching the leather pieces into the desired product, whether it be wallets, belts, or bags. Skilled artisans often perform this stage, ensuring that all components align correctly and that the stitching is both durable and aesthetically pleasing.

Quality assurance continues during assembly, as workers inspect the alignment of the imprinted designs and the overall craftsmanship of the product. Any defects detected during this phase can be corrected before the products move on to finishing.

Illustrative image related to custom leather imprinting

What Finishing Techniques Enhance the Quality of Custom Leather Imprinting?

Finishing is the final stage in the manufacturing process. This includes applying treatments such as dyes, oils, and protective coatings to enhance the leather’s appearance and longevity. Finishing techniques may also involve buffing or polishing the leather to give it a refined look.

Moreover, this stage is crucial for ensuring that the imprints are clear and resistant to wear and tear. By applying appropriate sealants, manufacturers can protect the imprinted designs from fading or scratching, particularly important for items that will see frequent use.

What Quality Control Measures Are Implemented in Custom Leather Imprinting?

Quality assurance is a fundamental aspect of the custom leather imprinting process. Various international standards and industry-specific regulations guide manufacturers to maintain high-quality outputs.

Illustrative image related to custom leather imprinting

What International Standards Should B2B Buyers Be Aware Of?

Many manufacturers adhere to international quality standards such as ISO 9001, which sets criteria for a quality management system. Compliance with ISO standards ensures that a company consistently meets customer and regulatory requirements, enhancing buyer confidence.

Additionally, industry-specific certifications such as CE marking for products sold in the European market may be relevant, particularly for leather goods intended for consumer use. This certification indicates compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control is implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials, including leather and stamping tools, to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections ensure that every stage meets quality benchmarks. This could involve checking the precision of the imprinting process or the integrity of stitched seams.

-

Final Quality Control (FQC): Once the products are assembled and finished, a final inspection assesses the overall quality, including the clarity of the imprints and the durability of the finished goods. Any products that do not meet standards are either reworked or discarded.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take an active role in verifying the quality control practices of potential suppliers. Here are several effective strategies:

Illustrative image related to custom leather imprinting

-

Supplier Audits: Conducting on-site audits can provide insights into a manufacturer’s quality control processes and overall operational practices. This helps buyers gauge the supplier’s commitment to quality and compliance with international standards.

-

Quality Reports: Requesting detailed quality reports can help buyers understand how a supplier monitors and maintains quality throughout the manufacturing process. These reports often include data on defect rates, inspection results, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures. These inspections can be conducted at various stages of production, providing assurance that products meet the required standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Cultural differences, regulatory standards, and market expectations can vary significantly across regions.

Buyers should familiarize themselves with local regulations and standards that may affect product compliance. Additionally, clear communication regarding quality expectations and specifications is vital to ensure that suppliers understand and meet these requirements.

In conclusion, understanding the manufacturing processes and quality assurance measures for custom leather imprinting is essential for B2B buyers. By being informed about these aspects, buyers can make better decisions and establish partnerships with manufacturers who prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather imprinting’

To successfully procure custom leather imprinting services, international B2B buyers must navigate a variety of considerations to ensure quality and reliability. This practical sourcing guide offers a clear checklist for making informed decisions, particularly for buyers from regions such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Begin by outlining your specific requirements for the custom leather imprinting project. This includes the type of leather, the desired size and complexity of the design, and the printing method (e.g., stamping, embossing). Clear specifications help suppliers understand your needs and provide accurate quotes.

Illustrative image related to custom leather imprinting

- Leather Type: Identify whether you will use vegetable-tanned, chrome-tanned, or synthetic leather.

- Design Complexity: Consider the intricacy of the design and ensure that it aligns with the supplier’s capabilities.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in custom leather imprinting. Look for companies with a strong track record and positive customer reviews. Reliable suppliers will often have a portfolio showcasing previous work.

- Supplier Location: Consider suppliers that have experience exporting to your region to mitigate potential shipping challenges.

- Expertise: Assess their expertise in handling various types of leather and imprinting techniques.

Step 3: Evaluate Supplier Certifications and Standards

Before making a commitment, verify that potential suppliers adhere to industry standards and certifications. This is crucial for ensuring product quality and ethical manufacturing practices.

- ISO Certifications: Look for suppliers with ISO certifications that indicate adherence to quality management systems.

- Sustainability Practices: Consider suppliers who follow sustainable practices, which can enhance your brand reputation.

Step 4: Request Samples and Prototypes

Once you’ve narrowed down your options, request samples or prototypes of the custom leather imprinting. This step allows you to assess the quality of the imprint, the clarity of the design, and the overall craftsmanship.

- Material Samples: Ask for samples of the leather that will be used in your project.

- Test Imprints: Review the quality of the imprint to ensure it meets your expectations.

Step 5: Discuss Lead Times and Production Capacity

It’s essential to have a clear understanding of the supplier’s production capacity and lead times. This ensures that you can meet your deadlines without compromising quality.

Illustrative image related to custom leather imprinting

- Production Timeline: Inquire about the time required for design approval, production, and shipping.

- Rush Orders: Ask if they offer expedited services for urgent projects, along with any additional costs.

Step 6: Negotiate Pricing and Payment Terms

Once you’ve found a suitable supplier, engage in negotiations regarding pricing and payment terms. Ensure that the pricing reflects the quality and service provided.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

- Payment Flexibility: Discuss payment options, including deposits and payment upon delivery, to manage cash flow effectively.

Step 7: Establish Clear Communication Channels

Finally, establish clear lines of communication with your chosen supplier. This will facilitate smoother project management and ensure that any issues are promptly addressed.

- Point of Contact: Designate a specific contact person for all communications to avoid confusion.

- Regular Updates: Agree on a schedule for updates during the production process to stay informed about progress.

By following this step-by-step checklist, B2B buyers can confidently navigate the procurement process for custom leather imprinting, ensuring a successful partnership that meets their business needs.

Comprehensive Cost and Pricing Analysis for custom leather imprinting Sourcing

What Are the Key Cost Components in Custom Leather Imprinting?

When sourcing custom leather imprinting solutions, several cost components must be considered to ensure an accurate budget and pricing analysis. The primary components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

-

Materials: The type of leather and other materials used significantly affect costs. Vegetable-tanned leather, for instance, is often more expensive due to its eco-friendly processing, while chrome-tanned leather is cheaper but may not provide the same aesthetic quality. Additionally, the choice between aluminum, brass, or steel for stamps can influence material costs.

-

Labor: Labor costs vary based on the complexity of the stamping process and the expertise of the workforce. Skilled artisans who handcraft stamps may command higher wages, impacting overall pricing.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory space. Efficient production lines can reduce overhead costs, allowing suppliers to offer competitive pricing.

-

Tooling: Initial tooling costs, such as the creation of dies or molds for custom designs, can be significant. Buyers should inquire about these costs upfront, particularly if they plan on placing large orders.

-

Quality Control (QC): Ensuring that the finished product meets quality standards incurs additional costs. This may involve testing materials, inspecting finished products, and implementing corrective actions when necessary.

-

Logistics: Shipping costs, including packaging and transportation, can vary based on the distance from the manufacturer to the buyer. International shipping may also involve customs duties and taxes, which should be factored into the total cost.

-

Margin: Suppliers will add a profit margin to cover their risks and ensure profitability. Understanding typical margins in the industry can help buyers negotiate better prices.

What Factors Influence Pricing for Custom Leather Imprinting?

Several factors can influence the pricing of custom leather imprinting, particularly for B2B buyers operating in different regions such as Africa, South America, the Middle East, and Europe.

-

Volume and Minimum Order Quantity (MOQ): Bulk orders usually result in lower per-unit costs. Suppliers often have a minimum order quantity, which can affect overall pricing. Buyers should assess their needs and discuss potential discounts for larger orders.

-

Specifications and Customization: Highly customized products often come with additional costs. Buyers should clearly communicate their design specifications to avoid unexpected charges.

-

Materials and Quality Certifications: The choice of materials impacts pricing. Buyers should consider whether they need certifications for eco-friendliness or compliance with local regulations, which can also affect costs.

-

Supplier Factors: The supplier’s location, production capacity, and reputation can influence pricing. Well-established suppliers may charge more due to their reliability and quality assurance processes.

-

Incoterms: Understanding the terms of sale (Incoterms) is crucial for international buyers. These terms define responsibilities for shipping, insurance, and tariffs, which can significantly impact total costs.

What Are Some Buyer Tips for Cost-Efficiency in Custom Leather Imprinting?

To navigate the complexities of pricing and sourcing, B2B buyers can leverage several strategies:

-

Negotiate Effectively: Establishing strong relationships with suppliers can facilitate better negotiations. Discussing volume discounts and long-term partnerships can yield more favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial costs, consider long-term expenses, including maintenance and replacement. Selecting durable materials may incur higher upfront costs but save money over time.

-

Research Pricing Nuances for International Sourcing: Understand the economic factors affecting pricing in different regions. Currency fluctuations, local labor costs, and supply chain dynamics can all impact final prices.

-

Request Quotes from Multiple Suppliers: Comparing quotes from various suppliers can provide insights into market pricing and help identify the best deal.

-

Stay Informed About Market Trends: Being aware of trends in leather production and stamping technology can help buyers make informed decisions regarding their sourcing strategy.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain current quotes to ensure accurate budgeting.

Alternatives Analysis: Comparing custom leather imprinting With Other Solutions

When evaluating solutions for branding and personalizing leather products, businesses often explore various methods beyond custom leather imprinting. Understanding the strengths and weaknesses of these alternatives can help B2B buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | Custom Leather Imprinting | Heat Branding | Laser Engraving |

|---|---|---|---|

| Performance | High-quality, deep imprints with clear detail | Durable marks, but can vary in depth | Precise, intricate designs with high detail |

| Cost | Moderate, starting around $68 for basic stamps | Higher initial investment due to equipment costs | Higher per unit cost, but cost-effective for large volumes |

| Ease of Implementation | Simple, requires manual operation or basic equipment | Requires training for proper operation | Requires specialized equipment and training |

| Maintenance | Low maintenance, occasional re-sharpening | Moderate, equipment needs regular checks | High, laser machines require calibration and maintenance |

| Best Use Case | Ideal for small to medium runs of personalized items | Best for larger batches where durability is key | Excellent for detailed designs or logos on various materials |

What Are the Advantages and Disadvantages of Heat Branding as an Alternative to Custom Leather Imprinting?

Heat branding employs a heated metal stamp to create an imprint on leather. This method is known for producing durable marks that resist fading over time. However, it may require a significant upfront investment in equipment, and users must undergo training to ensure consistent quality. While it can be efficient for larger production runs, it may not achieve the same level of detail as custom leather imprinting, making it less suitable for intricate designs.

How Does Laser Engraving Compare to Custom Leather Imprinting?

Laser engraving utilizes high-powered lasers to etch designs into leather surfaces. This method offers exceptional precision and can create highly detailed images, making it ideal for logos and complex patterns. Despite its advantages, laser engraving comes with a higher operational cost per unit and requires specialized machinery and training. Additionally, the equipment maintenance can be more demanding, which may not be feasible for smaller operations focused on cost efficiency.

Illustrative image related to custom leather imprinting

Conclusion: Which Leather Branding Solution Should B2B Buyers Choose?

When selecting a branding solution, B2B buyers should consider their specific project requirements, including the desired quality, production volume, and budget. Custom leather imprinting is an excellent choice for businesses looking for a balance between quality and cost, especially for personalized items. Heat branding serves well for larger batches where durability is a priority, while laser engraving is best suited for intricate designs. By weighing these factors, buyers can make a strategic decision that aligns with their branding goals and operational capabilities.

Essential Technical Properties and Trade Terminology for custom leather imprinting

What Are the Key Technical Properties of Custom Leather Imprinting?

When considering custom leather imprinting, understanding the technical specifications is crucial for making informed purchasing decisions. Here are the essential properties that define quality and functionality in this industry.

1. Material Composition: Why Does It Matter?

The most common materials used for custom leather stamps include brass, aluminum, and stainless steel. Brass is favored for its durability and ability to retain fine details during the stamping process, making it ideal for high-quality branding. Aluminum, while more cost-effective, may not provide the same longevity or detail retention. Choosing the right material impacts the lifespan of the stamp and the clarity of the imprint, directly influencing customer satisfaction and brand reputation.

2. Engraving Depth: How Deep Should It Be?

Engraving depth typically ranges from 2mm to 3mm for effective stamping. A deeper engraving allows for better clarity and visibility of the design, especially on thicker leather types. This depth is crucial for ensuring that the imprint is not only aesthetically pleasing but also durable against wear and tear. In a B2B context, this affects the product’s perceived value and can lead to repeat business if the quality meets customer expectations.

Illustrative image related to custom leather imprinting

3. Tolerance Levels: What Are They?

Tolerance refers to the allowable deviation from the specified dimensions of the stamp. For custom leather stamps, a tolerance of ±0.1mm is common. Maintaining tight tolerances is essential for ensuring that the stamps fit precisely in the stamping equipment, leading to consistent and accurate imprints. For B2B buyers, this means reduced waste and increased efficiency in production processes.

4. Stamp Size and Design Limitations: What Should You Know?

Custom stamps can vary in size, but it’s recommended to keep the longest dimension between 3cm to 10cm. Larger designs may require special handling or equipment. Adhering to size limitations is vital for achieving the best imprint quality and ensuring compatibility with various leather types. Understanding these limitations can help buyers make better design choices that align with their production capabilities.

5. Heat Resistance: Why Is It Important?

For heat embossing techniques, the material used must withstand high temperatures without degrading. Stamps designed for heat application typically feature materials that can endure temperatures up to 200°C (392°F). This property is important for buyers who plan to use their stamps for heat branding, as it directly affects the effectiveness of the imprint and the longevity of the stamp itself.

What Are Common Trade Terms in Custom Leather Imprinting?

Understanding industry jargon is essential for effective communication and negotiation in the B2B landscape of custom leather imprinting. Here are some common terms you may encounter:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then branded by another company. In the context of leather imprinting, an OEM might produce custom stamps or branding irons that are sold under a different brand name. Understanding this term helps buyers identify potential partnerships and manufacturing options.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This is particularly important in the custom leather imprinting industry, where set-up costs can be high. Knowing the MOQ can help buyers plan their budgets and production schedules effectively.

Illustrative image related to custom leather imprinting

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. In custom leather imprinting, submitting an RFQ allows buyers to compare prices and terms from different suppliers, facilitating informed purchasing decisions.

4. Incoterms

Incoterms are international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers negotiate better shipping agreements and understand the logistics involved in their orders.

5. Customization Options

This term refers to the variety of ways a product can be tailored to meet specific needs. In leather imprinting, customization can involve design, size, and material choices. Understanding available customization options enables buyers to maximize the value of their orders and enhance their product offerings.

By grasping these technical properties and trade terms, B2B buyers can navigate the custom leather imprinting landscape more effectively, ensuring that they make informed decisions that meet their business needs.

Illustrative image related to custom leather imprinting

Navigating Market Dynamics and Sourcing Trends in the custom leather imprinting Sector

What Are the Current Market Dynamics and Key Trends in Custom Leather Imprinting?

The custom leather imprinting sector is experiencing robust growth driven by several global factors. Increased demand for personalized products across various industries, such as fashion, automotive, and home decor, is reshaping the landscape. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, are seeking unique branding solutions that resonate with their customer base. The rise of e-commerce and digital marketing has also enabled small and medium-sized enterprises (SMEs) to enter the market, increasing competition and innovation.

Emerging technologies, such as CNC machining and laser engraving, are revolutionizing the customization process. These advancements allow manufacturers to produce high-precision, intricate designs with reduced turnaround times. For instance, suppliers are now capable of delivering custom leather stamps within 2-3 working days, catering to the fast-paced demands of international buyers. Furthermore, the shift towards online sourcing platforms has streamlined procurement, making it easier for buyers to compare options, prices, and service levels from global suppliers.

As businesses increasingly prioritize quality and uniqueness, there is a noticeable trend towards using premium materials such as solid brass and stainless steel for branding stamps. This shift not only enhances the durability of products but also aligns with consumer preferences for high-quality, long-lasting goods. For buyers in regions like Germany and Nigeria, understanding these dynamics is critical for making informed purchasing decisions that align with market demands.

How Are Sustainability and Ethical Sourcing Shaping the Custom Leather Imprinting Industry?

Sustainability is becoming a pivotal consideration in the custom leather imprinting sector. The environmental impact of leather production, particularly concerning water usage and chemical processing, has prompted buyers to prioritize ethical sourcing practices. Many international buyers are now actively seeking suppliers who adhere to sustainable practices, such as using vegetable-tanned leather or sourcing from certified suppliers.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly aware of the implications of their sourcing decisions on communities and ecosystems. This awareness has led to a growing preference for suppliers who can provide transparency regarding their materials and processes. Certifications like the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are gaining traction as benchmarks for sustainable practices in leather production.

Illustrative image related to custom leather imprinting

Moreover, the demand for “green” materials is influencing product development within the sector. Suppliers who can offer eco-friendly options are likely to attract B2B buyers looking to enhance their brand reputation and appeal to environmentally conscious consumers. By aligning with sustainability goals, businesses can not only mitigate risks associated with supply chain disruptions but also position themselves as leaders in an increasingly competitive market.

What Is the Brief Evolution and History of Custom Leather Imprinting in B2B?

The history of custom leather imprinting dates back centuries, originally rooted in the craftsmanship of artisans who manually stamped designs onto leather goods. Traditional methods involved rudimentary tools and techniques, which limited the complexity and precision of designs. However, with the advent of industrialization in the 19th century, leatherworking began to evolve with the introduction of mechanized tools, allowing for more consistent and intricate designs.

In recent decades, the rise of digital technology has further transformed the industry. CNC machines and laser engravers have enabled unprecedented levels of customization, allowing businesses to offer tailored solutions to clients. Today, custom leather imprinting is not just about functionality; it has become an art form that combines creativity with technology, catering to diverse markets across the globe. As the industry continues to evolve, B2B buyers must stay informed about innovations and trends to effectively leverage opportunities in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather imprinting

-

How do I choose the right supplier for custom leather imprinting?

When selecting a supplier for custom leather imprinting, consider their experience, product quality, and customer reviews. Look for suppliers with a portfolio showcasing their previous work, particularly in your industry. Verify their manufacturing capabilities and whether they can handle your specific customization needs, such as materials and design intricacies. Additionally, check their responsiveness to inquiries and willingness to collaborate on design adjustments, as effective communication is essential for a successful partnership. -

What is the typical lead time for custom leather stamps?

Lead times for custom leather stamps can vary significantly based on the supplier and the complexity of the design. Generally, expect a turnaround of 2-3 working days for standard orders, with rush options available for an additional fee. It’s advisable to confirm lead times upfront and factor in shipping durations, especially for international orders. Establishing clear timelines with your supplier can help manage expectations and ensure timely delivery for your projects. -

What customization options are available for leather stamps?

Custom leather stamps can be tailored in various ways, including size, shape, and engraving depth. Most suppliers allow you to submit your design in various formats, such as vector files or high-resolution images, to ensure clarity. Additionally, you can choose from different materials, such as brass, aluminum, or steel, each offering varying durability and cost. Discuss your specific needs with the supplier to determine the best options for your branding requirements. -

What is the minimum order quantity (MOQ) for custom leather imprinting?

Minimum order quantities for custom leather imprinting can vary by supplier and may depend on the complexity of the design or materials used. Some suppliers may have no MOQ for individual stamps, while others might require a minimum of 10-50 units for bulk orders. It’s essential to clarify these details before placing an order to ensure that it aligns with your production needs and budget. -

What payment terms should I expect when sourcing custom leather stamps?

Payment terms for custom leather stamps typically include options such as upfront payment, partial deposits, or payment upon delivery. Suppliers may accept various payment methods, including credit cards, bank transfers, or PayPal. It’s crucial to discuss and agree on payment terms before finalizing your order to avoid any misunderstandings. Additionally, be aware of any currency exchange considerations if dealing with international suppliers. -

How can I ensure quality assurance for custom leather stamps?

To ensure quality assurance, request samples or prototypes before committing to a larger order. Many reputable suppliers are willing to provide a sample of your custom stamp to verify the quality and accuracy of the design. Additionally, inquire about their quality control processes, including materials used and production standards. Establishing clear specifications and maintaining open communication with the supplier can further enhance the quality assurance process. -

What logistics considerations should I keep in mind for international shipping?

When sourcing custom leather stamps internationally, consider shipping methods, costs, and delivery times. Choose a reliable shipping partner that offers tracking and insurance for your order. Be aware of customs regulations in your country, including any duties or taxes that may apply. It’s also advisable to factor in potential delays due to customs processing, especially if the shipment contains multiple items or high-value products. -

How do I handle design revisions during the custom stamp creation process?

Handling design revisions effectively involves clear communication with your supplier. Provide detailed feedback on any proposed designs, including specific elements you want to modify or enhance. Most suppliers welcome revisions and may have a set number of design iterations included in the initial cost. Ensure you understand any additional charges that may apply for extensive revisions or changes to the original design to avoid unexpected costs.

Top 8 Custom Leather Imprinting Manufacturers & Suppliers List

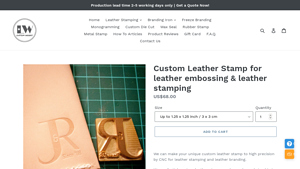

1. LW Leathers – Custom Leather Stamp

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Custom Leather Stamp”, “regular_price”: “US$68.00”, “size_options”: [“Up to 1.25 x 1.25 inch / 3 x 3 cm”, “Up to 1.5 x 1.5 inch / 4 x 4 cm”, “Up to 2 x 2 inch / 5 x 5 cm”, “Up to 3 x 3 inch / 7.5 x 7.5 cm”, “Up to 4 x 4 inch / 10 x 10 cm”], “production_lead_time”: “2-5 working days”, “material”: “Solid Brass”, “stamp_thickness”: “8mm”, “engraving_depth”: “3mm”, “applications”: [“…

2. Gearheart Industry – Custom Leather Stamp

Domain: gearheartindustry.com

Registered: 2013 (12 years)

Introduction: {“product_name”: “Custom Leather Stamp”, “price”: “$119.00”, “dimensions”: [“1″ x 1″”, “1” x 1.5″”, “1.5” x 1.5″”], “production_time”: [“Standard (5 Business Days)”, “RUSH (1 Business Day)”], “file_types”: [“bmp”, “gif”, “jpg”, “jpeg”, “jpe”, “jif”, “jfif”, “jfi”, “png”, “wbmp”, “xbm”, “tiff”, “ai”, “eps”, “pdf”], “max_file_size”: “524288KB”, “features”: [“Custom made per your specifications”, “Cu…

3. Custom Leather Stamps – High-Detail Dies & Brands

Domain: buckeyeengraving.com

Registered: 2015 (10 years)

Introduction: Custom leather stamps, dies, and brands for leather stamping and embossing needs. Made from aluminum, steel, or brass. Aluminum offers a lower price point; brass is popular for its durability and resistance to rust. Customization options available for artwork, signatures, and sketches. High detail engraving with heavy-duty removable steel handles for hand stamping. Custom branding irons available …

4. Custom Brand – Leather Embossing Stamp

5. Infinity Stamps – Custom Leather Steel Plate Stamp

Domain: infinitystamps.com

Registered: 2001 (24 years)

Introduction: Custom Leather Steel Plate Stamp from Infinity Stamps, Inc. Made in the USA. Family owned for over 25 years. Contact available via phone (818-576-1188) or contact form. Suitable for various stamping applications including leather, metal, wood, and more.

6. Steel Stamps Inc. – Custom Leather Stamps

Domain: steelstampsinc.com

Registered: 2009 (16 years)

Introduction: Custom Leather Stamps from Steel Stamps Inc. include various categories such as Custom Jewelry Stamps, Custom Steel Stamps for Knife Makers, Blacksmiths, Farriers, and Custom Locksmith Stamps. The collection features Leather Design Stamps, including Sheridan Flowers/Leaves, Leather State Stamps, and various Pro Series Designs. Specialized stamps like Do Not Duplicate and Made in U.S.A. stamps for …

7. Leather Stamp Maker – Custom Brass Stamps

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Leather & Custom Brass Stamps by Leather Stamp Maker. All custom stamps ship next business day. Made in the USA. Custom brass stamps, cutting dies, lettersets, and more available. Custom stamps are CNC milled from solid brass, thickness up to 1″, and can be used with branding irons or standard presses. Custom leather cutting dies made from solid steel, compatible with mechanical, hydraulic, or cli…

8. Custom Leather Stamps – Quality & Options

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom leather stamps, good price point, quality stamp, options include Leatherstampstools on Etsy, Springfield Leather (makes stamps from PDF designs), leatherstampmaker (US-based, free quotes and proof, quick turnaround).

Strategic Sourcing Conclusion and Outlook for custom leather imprinting

In the realm of custom leather imprinting, strategic sourcing is essential for B2B buyers looking to enhance their product offerings. By investing in high-quality custom leather stamps, embossing tools, and branding irons, businesses can create unique, personalized leather goods that resonate with their clientele. The choice between materials such as brass, aluminum, and steel plays a pivotal role in determining the longevity and clarity of imprints, impacting customer satisfaction and brand perception.

Leveraging suppliers who can deliver precision-engineered products quickly—often within just a few days—ensures that businesses remain agile and responsive to market demands. Additionally, the ability to customize designs, whether from original artwork or existing logos, allows for greater brand differentiation and storytelling through products.

Illustrative image related to custom leather imprinting

As the demand for personalized leather goods continues to rise globally, particularly in Africa, South America, the Middle East, and Europe, now is the time to explore partnerships with trusted manufacturers. By prioritizing quality and innovation in sourcing strategies, international buyers can position themselves at the forefront of this thriving market. Embrace the opportunity to elevate your brand—connect with suppliers today to discover how custom leather imprinting can transform your product line.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to custom leather imprinting

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.