Introduction: Navigating the Global Market for printed leatherette fabric

In today’s fast-paced global marketplace, sourcing high-quality printed leatherette fabric can be a daunting challenge for B2B buyers. With a myriad of options available, it is essential to navigate through the complexities of material types, printing technologies, and supplier reliability to ensure that your projects meet both aesthetic and functional demands. This comprehensive guide aims to simplify the procurement process by offering in-depth insights into the various types of printed leatherette fabrics, their diverse applications across industries, and effective strategies for vetting suppliers.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, including countries such as Saudi Arabia and Brazil, will find this guide invaluable. It not only highlights the latest trends in printed leatherette but also provides actionable advice on cost management and quality assurance. By understanding the nuances of this versatile material—from its durability and design capabilities to ethical sourcing considerations—businesses can make informed purchasing decisions that align with their brand values and customer expectations.

As you explore the sections ahead, you will gain the knowledge needed to select the right printed leatherette fabric for your specific needs, ensuring your products stand out in a competitive market. This guide is designed to empower you with the tools necessary to navigate the global supply chain effectively and to foster successful partnerships with suppliers.

Table Of Contents

- Top 7 Printed Leatherette Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for printed leatherette fabric

- Understanding printed leatherette fabric Types and Variations

- Key Industrial Applications of printed leatherette fabric

- 3 Common User Pain Points for ‘printed leatherette fabric’ & Their Solutions

- Strategic Material Selection Guide for printed leatherette fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for printed leatherette fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘printed leatherette fabric’

- Comprehensive Cost and Pricing Analysis for printed leatherette fabric Sourcing

- Alternatives Analysis: Comparing printed leatherette fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for printed leatherette fabric

- Navigating Market Dynamics and Sourcing Trends in the printed leatherette fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of printed leatherette fabric

- Strategic Sourcing Conclusion and Outlook for printed leatherette fabric

- Important Disclaimer & Terms of Use

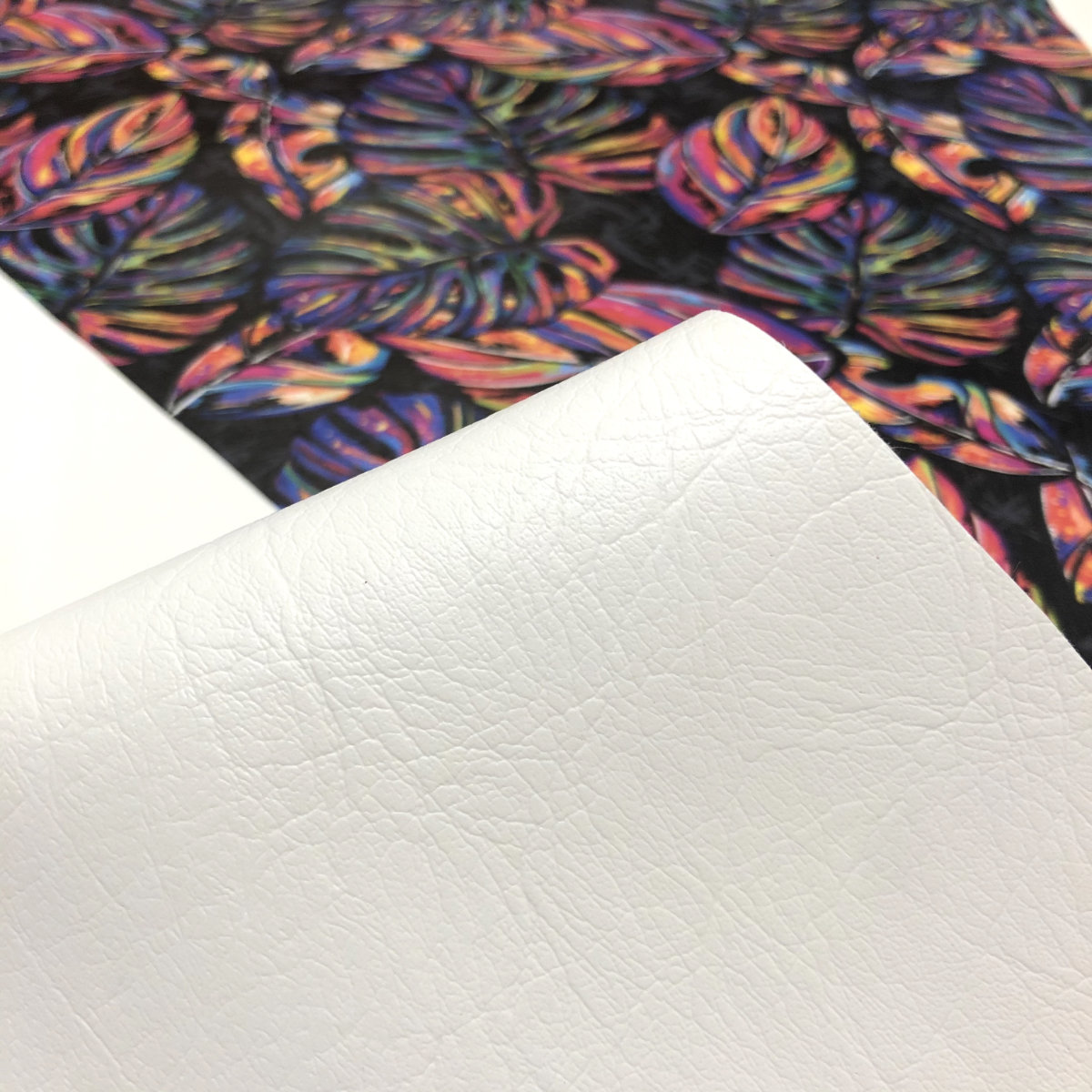

Understanding printed leatherette fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Smooth Nappa Leatherette | Soft, supple texture; high color fidelity | Fashion apparel, upholstery, accessories | Pros: Luxurious feel, excellent print quality. Cons: Higher cost compared to alternatives. |

| Textured Leatherette | Grainy surface texture; adds depth to prints | Home furnishings, automotive interiors | Pros: Unique aesthetic, durable. Cons: May be harder to clean. |

| Vegan Leatherette | Made from synthetic materials; eco-friendly options available | Sustainable fashion, eco-conscious brands | Pros: Animal-friendly, often less expensive. Cons: May lack the premium feel of real leather. |

| Bubble Leatherette | Distinctive bubble-like texture; adds dimension | Novelty items, promotional products | Pros: Eye-catching, fun designs. Cons: Limited applications due to texture. |

| Suede Leatherette | Soft, velvety finish; rich colors | High-end fashion, luxury accessories | Pros: Elegant appearance, luxurious touch. Cons: Susceptible to staining. |

What Are the Key Characteristics of Smooth Nappa Leatherette?

Smooth Nappa leatherette is characterized by its soft, supple texture and high color fidelity, making it an ideal choice for applications where a luxurious feel is paramount. Its smooth surface allows for vibrant, detailed prints, which are particularly appealing in fashion apparel and high-end accessories. B2B buyers should consider the initial investment, as it tends to be pricier than other options, but the quality and aesthetic appeal can justify the cost for premium brands.

How Does Textured Leatherette Enhance Product Design?

Textured leatherette features a grainy surface that adds depth and character to printed designs. This type is especially popular in home furnishings and automotive interiors, where durability and a unique look are essential. For B2B buyers, the key consideration is its durability against wear and tear, although cleaning can be more challenging compared to smoother finishes. Textured leatherette can enhance the perceived value of products, making it a worthwhile investment for brands aiming for a distinctive aesthetic.

Why Should B2B Buyers Consider Vegan Leatherette?

Vegan leatherette is an attractive option for brands focused on sustainability and ethical sourcing. Made from synthetic materials, it offers an eco-friendly alternative to traditional leather without compromising on style. B2B buyers should weigh the benefits of lower costs and animal-friendliness against potential drawbacks, such as a less premium feel. This type is gaining traction in sustainable fashion markets, making it a smart choice for eco-conscious brands looking to appeal to a broader consumer base.

Illustrative image related to printed leatherette fabric

What Are the Unique Advantages of Bubble Leatherette?

Bubble leatherette is defined by its distinctive bubble-like texture, which creates an eye-catching and playful design element. This variation is often used in novelty items and promotional products, where attracting attention is crucial. While it offers unique design opportunities, B2B buyers should consider its limited applications due to the specific texture, which may not suit all product types. However, when used appropriately, bubble leatherette can significantly enhance brand visibility and engagement.

How Does Suede Leatherette Compare to Other Variants?

Suede leatherette boasts a soft, velvety finish that exudes luxury, making it a popular choice for high-end fashion and accessories. Its rich colors and elegant appearance can elevate product lines, appealing to consumers seeking sophistication. However, B2B buyers should be aware of its susceptibility to staining, which may require additional care and maintenance. The investment in suede leatherette can pay off through enhanced customer perception and brand prestige, making it a valuable addition to luxury product offerings.

Key Industrial Applications of printed leatherette fabric

| Industry/Sector | Specific Application of printed leatherette fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom clothing items such as jackets and skirts | Unique branding opportunities and design flexibility | Consider fabric durability and print quality |

| Furniture & Interior Design | Upholstery for furniture and home decor | Enhances aesthetic appeal while being cost-effective | Ensure compliance with fire safety standards |

| Automotive | Custom interiors for vehicles | High durability and easy maintenance | Assess compatibility with automotive standards |

| Accessories | Production of bags, wallets, and belts | Customization options for branding and style | Verify the quality of inks and printing technology |

| Promotional Products | Branded merchandise such as keychains and tags | Increases brand visibility and customer engagement | Check for minimum order quantities and lead times |

How is Printed Leatherette Fabric Used in the Fashion & Apparel Industry?

In the fashion industry, printed leatherette fabric is utilized for creating custom clothing items, such as jackets and skirts. This fabric allows designers to incorporate vibrant prints and patterns that can enhance brand identity. Buyers in this sector must prioritize the durability of the fabric, as well as the quality of the print, to ensure longevity and customer satisfaction. International buyers should also consider regional fashion trends and preferences when selecting designs.

Illustrative image related to printed leatherette fabric

What Role Does Printed Leatherette Fabric Play in Furniture & Interior Design?

In furniture and interior design, printed leatherette is increasingly used for upholstery on chairs, sofas, and decorative items. Its cost-effectiveness and variety of designs enable businesses to offer unique aesthetic choices to consumers. Buyers should ensure that the materials meet fire safety regulations, particularly in commercial settings. Additionally, sourcing from suppliers who provide high-quality prints will ensure that the upholstery remains visually appealing over time.

How is Printed Leatherette Fabric Beneficial for Automotive Customization?

Automotive manufacturers and customizers use printed leatherette fabric for vehicle interiors, including seats and door panels. This application benefits businesses by providing a durable, easy-to-clean option that can withstand wear and tear. Buyers should assess the fabric’s compatibility with automotive industry standards, including resistance to fading and abrasion. Ensuring that the printing technology used is robust will also contribute to a longer-lasting product.

In What Ways Can Printed Leatherette Fabric Enhance Accessories Production?

The accessories sector, including bags, wallets, and belts, makes extensive use of printed leatherette fabric. This material allows brands to offer customizable options that resonate with consumers’ tastes. For B2B buyers, verifying the quality of the inks used in printing is crucial, as it affects both the appearance and longevity of the products. Additionally, businesses should inquire about minimum order quantities to align with their production capabilities.

How is Printed Leatherette Fabric Used in Promotional Products?

Printed leatherette fabric is a popular choice for creating promotional products like branded keychains, tags, and other merchandise. These items enhance brand visibility and foster customer engagement. Buyers must consider the minimum order quantities and lead times when sourcing these products to ensure they meet marketing timelines. Furthermore, understanding the printing process and material quality can help businesses deliver high-impact promotional items.

3 Common User Pain Points for ‘printed leatherette fabric’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Printed Leatherette Fabric

The Problem: B2B buyers often face significant challenges in ensuring the quality of printed leatherette fabric. Inconsistent color reproduction, fading, or poor durability can lead to unsatisfactory final products, resulting in financial losses and damaged reputations. This is especially critical for buyers in competitive markets like fashion or upholstery, where the aesthetic appeal and longevity of materials are paramount. Additionally, sourcing from different suppliers can result in varying quality standards, making it difficult to maintain consistent product offerings.

Illustrative image related to printed leatherette fabric

The Solution: To overcome these quality assurance challenges, it is essential to establish a robust supplier evaluation process. Buyers should request samples from multiple suppliers before placing bulk orders, focusing on aspects like color accuracy and durability through rigorous testing methods. Engaging in clear communication with suppliers about specific requirements, such as print clarity and material composition, can also mitigate discrepancies. Furthermore, consider partnering with suppliers who offer a quality guarantee or have certifications that attest to their manufacturing processes. Regular audits and quality checks throughout the supply chain can help ensure that the printed leatherette fabric meets the expected standards consistently.

Scenario 2: Understanding Design Limitations in Custom Printed Leatherette

The Problem: Many B2B buyers encounter difficulties when trying to create custom designs on printed leatherette fabric. Common issues include misalignment, poor image resolution, or design elements that do not translate well onto the material. Such challenges not only waste time and resources but can also lead to products that do not resonate with the target audience, ultimately affecting sales and brand image.

The Solution: To address these design limitations, it is crucial to collaborate closely with the printing service provider from the outset. Buyers should ensure that their design files meet the required specifications—this includes resolution, color profiles, and file formats. It may be beneficial to invest in professional graphic design services to create high-quality images that are specifically tailored for printing on leatherette. Additionally, using mock-ups or digital proofs can provide valuable insights into how designs will appear on the final product, allowing for adjustments before production begins. Educating the design team about the characteristics of printed leatherette will also facilitate smoother transitions from concept to reality.

Illustrative image related to printed leatherette fabric

Scenario 3: Managing Cost-Effectiveness and Pricing Structures

The Problem: Cost management is a critical concern for B2B buyers, especially when ordering custom printed leatherette fabrics. Buyers often face unexpected costs due to design setup fees, minimum order quantities, or variations in pricing based on material quality. These hidden costs can disrupt budget forecasts and complicate project timelines, leading to delays and financial strain.

The Solution: To navigate these cost challenges effectively, buyers should develop a clear understanding of the pricing structures offered by different suppliers. It is advisable to inquire about all potential fees upfront, including setup charges, shipping costs, and discounts for bulk orders. Establishing long-term relationships with suppliers can also yield better pricing and more favorable terms. Buyers should consider placing larger, consolidated orders to benefit from economies of scale, thus reducing the per-unit cost. Additionally, leveraging technology such as inventory management systems can help track usage and optimize order quantities, ensuring that resources are utilized efficiently and cost-effectively.

Strategic Material Selection Guide for printed leatherette fabric

What Are the Key Materials for Printed Leatherette Fabric?

When selecting printed leatherette fabric for various applications, understanding the properties, advantages, and limitations of different materials is crucial. This guide analyzes four common materials used in printed leatherette, providing actionable insights for international B2B buyers.

How Does PVC Leatherette Perform?

Key Properties: PVC (Polyvinyl Chloride) leatherette is known for its excellent durability and resistance to moisture, making it suitable for a variety of environments. It typically withstands temperatures ranging from -10°C to 60°C and offers good UV resistance.

Illustrative image related to printed leatherette fabric

Pros & Cons: PVC leatherette is cost-effective and easy to manufacture, making it a popular choice for mass production. However, it can be less breathable than other materials, which may affect comfort in applications like upholstery. Additionally, the environmental impact of PVC production is a growing concern among consumers.

Impact on Application: PVC is compatible with various printing methods, including digital and screen printing, allowing for vibrant designs. However, its lower flexibility may limit its use in applications requiring a high degree of stretch, such as fitted clothing.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding PVC usage, particularly in regions like the EU, where stringent standards exist. Understanding the local market’s environmental preferences can also influence purchasing decisions.

What About PU Leatherette?

Key Properties: Polyurethane (PU) leatherette is celebrated for its soft feel and high breathability. It generally performs well in temperatures from -20°C to 50°C and has good abrasion resistance.

Pros & Cons: PU leatherette is more environmentally friendly than PVC, as it is often produced with less harmful chemicals. It offers a premium look and feel, making it suitable for high-end products. However, it can be more expensive and may not be as durable as PVC in high-wear applications.

Impact on Application: PU leatherette is ideal for fashion items, accessories, and upholstery where aesthetics are paramount. Its compatibility with various printing techniques allows for detailed designs, but it may require special inks for optimal results.

Considerations for International Buyers: Buyers in regions like Africa and South America should be aware of the cost implications of PU leatherette, as it may affect pricing strategies. Additionally, understanding local consumer preferences for eco-friendly materials can enhance market positioning.

Why Choose Vegan Leatherette?

Key Properties: Vegan leatherette, often made from materials like recycled plastics or plant-based fibers, is gaining popularity for its sustainability. It typically offers good durability and resistance to moisture and UV light.

Pros & Cons: The key advantage of vegan leatherette is its eco-friendly profile, appealing to a growing segment of environmentally conscious consumers. However, it may not match the durability of traditional leatherette materials, which could limit its use in high-stress applications.

Illustrative image related to printed leatherette fabric

Impact on Application: Vegan leatherette is suitable for various applications, including fashion, accessories, and home décor. Its compatibility with eco-friendly printing methods can enhance brand image, but buyers should ensure that the inks used are also sustainable.

Considerations for International Buyers: Buyers should be aware of the increasing demand for sustainable materials in markets across Europe and the Middle East. Compliance with environmental standards and certifications can be a significant selling point.

What Is the Role of Textile-Based Leatherette?

Key Properties: Textile-based leatherette combines a fabric backing with a synthetic surface, providing a unique blend of flexibility and durability. It typically performs well in a range of temperatures and is resistant to wear and tear.

Pros & Cons: This material offers excellent comfort and breathability, making it suitable for clothing and upholstery. However, it can be more complex to manufacture, potentially increasing costs.

Illustrative image related to printed leatherette fabric

Impact on Application: Textile-based leatherette is ideal for applications requiring both durability and comfort, such as automotive interiors and high-end fashion. Its compatibility with various printing techniques allows for intricate designs.

Considerations for International Buyers: Buyers should consider the manufacturing complexities and costs associated with textile-based leatherette. Understanding regional preferences for comfort and performance can guide product development strategies.

Summary Table

| Material | Typical Use Case for printed leatherette fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC Leatherette | Mass-produced items, upholstery | Cost-effective and durable | Less breathable and environmental concerns | Low |

| PU Leatherette | High-end fashion, accessories | Premium feel and eco-friendliness | Higher cost and lower durability | Medium |

| Vegan Leatherette | Fashion, accessories, eco-friendly products | Sustainable and appealing | May lack durability in high-stress applications | Medium |

| Textile-Based Leatherette | Automotive interiors, high-end fashion | Comfort and breathability | More complex manufacturing | High |

This analysis provides B2B buyers with a comprehensive understanding of the materials available for printed leatherette fabric, enabling informed decision-making tailored to specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for printed leatherette fabric

What Are the Key Stages in the Manufacturing Process of Printed Leatherette Fabric?

The manufacturing process for printed leatherette fabric involves several critical stages that ensure the final product meets the necessary quality and durability standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step in manufacturing printed leatherette is the selection and preparation of raw materials. High-quality synthetic materials, often PVC or polyurethane, are chosen for their durability and aesthetic qualities. These materials are treated to enhance their printability and adhesion properties. During this stage, manufacturers may conduct tests to ensure the materials meet specific standards for tensile strength, flexibility, and resistance to wear and tear. -

Forming

Once the raw materials are prepared, they are formed into sheets or rolls. This process typically involves extrusion, where the material is heated and then forced through a mold to create a uniform thickness. The forming process can also include calendering, where the material is passed through rollers to achieve a smooth surface. This stage is crucial as it determines the final texture and appearance of the leatherette, influencing both its aesthetic appeal and print quality. -

Printing

The printing process is where creativity meets technology. Manufacturers utilize advanced digital printing techniques, such as UV printing or dye-sublimation, to apply designs onto the leatherette surface. These methods ensure that the inks penetrate deeply into the material, resulting in vibrant colors and sharp details. This stage is essential for achieving high-quality prints that are durable and resistant to fading. -

Finishing

After printing, the leatherette undergoes a finishing process, which may include treatments to enhance its tactile properties and longevity. Common finishing techniques include applying protective coatings to improve resistance to stains, scratches, and UV light. The final product is then rolled or cut into specified dimensions, ready for distribution.

How Is Quality Assurance Integrated into the Manufacturing Process?

Quality assurance (QA) is a critical aspect of the manufacturing process for printed leatherette fabric, ensuring that products meet both international and industry-specific standards. Implementing robust QA procedures helps manufacturers minimize defects and enhance customer satisfaction.

-

International Standards for Quality Assurance

Many manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards demonstrates a commitment to quality and continuous improvement. For specific products, certifications like CE (Conformité Européenne) may be required to ensure compliance with European safety and health regulations. -

Key Quality Control Checkpoints

Quality control (QC) is integrated at various stages of the manufacturing process:

– Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet the specified quality standards before production begins. Random sampling and testing of materials help in identifying any non-conforming items early in the process.

– In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to ensure processes are followed correctly. This includes regular inspections of printed outputs for color accuracy and adherence to design specifications.

– Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted to ensure that the finished goods meet all quality standards. This includes checking for print quality, material integrity, and overall appearance. -

Common Testing Methods for Quality Assurance

To ensure durability and performance, manufacturers often employ various testing methods, including:

– Rub Testing: Assesses the abrasion resistance of the printed surface.

– Colorfastness Testing: Evaluates how well the colors hold up against washing and exposure to light.

– Flexibility Testing: Measures the material’s ability to bend without cracking, essential for applications requiring flexibility.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

B2B buyers must conduct due diligence to ensure that their suppliers maintain high-quality standards. Here are several actionable steps to verify quality control processes:

-

Supplier Audits

Conducting on-site audits of potential suppliers provides valuable insights into their manufacturing processes and quality control measures. This allows buyers to assess compliance with international standards and evaluate the effectiveness of the supplier’s QA systems. -

Requesting Quality Reports

Buyers should request documentation of quality control processes, including IQC, IPQC, and FQC reports. These documents outline the testing methods used and results achieved, providing transparency regarding the supplier’s commitment to quality. -

Engaging Third-Party Inspectors

Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices. These inspectors can conduct random checks during production and before shipment, ensuring that the products meet the specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial for successful procurement.

Illustrative image related to printed leatherette fabric

-

Regional Compliance Requirements

Different regions may have specific regulations regarding material safety and environmental impact. For instance, buyers in Europe must ensure compliance with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations, while those in the Middle East may need to adhere to local safety standards. -

Cultural and Operational Differences

Cultural differences can impact communication and operational practices. Buyers should establish clear communication channels and expectations regarding quality standards to avoid misunderstandings. -

Logistical Considerations

Shipping and handling can affect the quality of printed leatherette fabric. Buyers should work closely with suppliers to understand their packaging methods and transportation conditions, ensuring that products arrive in optimal condition.

By understanding the manufacturing processes, quality assurance protocols, and verification methods, B2B buyers can make informed decisions when sourcing printed leatherette fabric, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘printed leatherette fabric’

To assist B2B buyers in sourcing printed leatherette fabric effectively, this guide outlines a step-by-step checklist. Each step is designed to ensure informed decision-making, leading to successful procurement and a fruitful partnership with suppliers.

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for your printed leatherette fabric. This includes considerations such as thickness, texture, and intended use (e.g., upholstery, fashion accessories, etc.). Defining these parameters upfront helps narrow down supplier options and ensures that the materials meet your project needs.

Illustrative image related to printed leatherette fabric

- Key Characteristics: Identify whether you need vegan options, specific colors, or patterns.

- Usage Considerations: Determine if the fabric will be exposed to heavy wear and tear, which may influence your choice of durability.

Step 2: Research Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for manufacturers with a strong reputation in the industry, particularly those who specialize in printed leatherette. Utilizing trade directories, industry associations, and online marketplaces can help you identify reliable options.

- Supplier Reviews: Seek feedback from other businesses that have previously worked with these suppliers.

- Geographical Considerations: Consider suppliers from regions known for high-quality textile production, such as Europe or the Middle East.

Step 3: Evaluate Supplier Certifications

Verify that your potential suppliers hold relevant certifications that demonstrate compliance with industry standards. Certifications can indicate a commitment to quality, sustainability, and ethical manufacturing practices, which are increasingly important in today’s market.

- Quality Assurance: Look for ISO certifications or other quality management systems.

- Sustainability Practices: Consider certifications like OEKO-TEX or GOTS if eco-friendliness is a priority for your brand.

Step 4: Request Samples

Before making a bulk purchase, always request samples of the printed leatherette fabric. This allows you to assess the quality, color accuracy, and texture firsthand, ensuring it aligns with your expectations.

- Test for Durability: Evaluate how the fabric holds up under various conditions, such as abrasion and exposure to light.

- Color Matching: Check that the printed colors match your design specifications and are consistent across different batches.

Step 5: Review Pricing and Minimum Order Quantities

Examine the pricing structure and minimum order quantities (MOQs) set by suppliers. Understanding these financial aspects will help you budget accordingly and avoid unexpected costs.

Illustrative image related to printed leatherette fabric

- Negotiation Opportunities: Don’t hesitate to discuss pricing for larger orders or long-term contracts, which may yield better rates.

- Flexibility on MOQs: Inquire if suppliers are willing to negotiate MOQs, especially for first-time orders or sample runs.

Step 6: Assess Shipping and Delivery Times

Evaluate the logistics involved in sourcing the fabric, including shipping options and estimated delivery times. Efficient shipping is crucial, especially if your project timelines are tight.

- International Shipping: Ensure that suppliers can accommodate international shipping, particularly if you are sourcing from different continents.

- Lead Times: Ask for clear timelines on production and delivery to avoid any disruptions in your supply chain.

Step 7: Establish Clear Communication Channels

Finally, ensure that you have established effective communication channels with your chosen supplier. Clear communication can help resolve issues quickly and foster a positive working relationship.

- Point of Contact: Identify a dedicated account manager or point of contact for your orders.

- Regular Updates: Set expectations for regular updates on order status, especially for large or custom orders.

By following this checklist, B2B buyers can navigate the complexities of sourcing printed leatherette fabric with confidence, ensuring they secure high-quality materials that meet their business needs.

Comprehensive Cost and Pricing Analysis for printed leatherette fabric Sourcing

What Are the Key Cost Components in Sourcing Printed Leatherette Fabric?

When sourcing printed leatherette fabric, understanding the cost structure is essential for B2B buyers. The main cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of leatherette material significantly impacts cost. Options range from basic synthetic leather to high-end, eco-friendly alternatives. The quality of inks used for printing also affects pricing; premium inks yield more vibrant and durable prints but come at a higher cost.

-

Labor: Labor costs encompass the wages of workers involved in both manufacturing and printing processes. Regions with higher labor costs, such as parts of Europe, may result in higher prices compared to manufacturers in countries with lower labor expenses.

-

Manufacturing Overhead: This includes expenses related to the operation of machinery, factory maintenance, and utilities. Efficient production processes can help reduce these costs, making it vital for buyers to assess the operational efficiencies of potential suppliers.

-

Tooling: Custom designs often require specific tooling and setup, which can lead to initial costs. Many suppliers charge a one-time design setup fee that can influence the overall pricing structure, especially for first-time orders.

-

Quality Control (QC): Ensuring high-quality output is crucial, especially for B2B buyers. QC processes may involve additional costs, but they are essential for minimizing defects and ensuring customer satisfaction.

-

Logistics: Shipping costs can vary significantly based on the destination and the chosen Incoterms. Buyers should consider freight costs, duties, and potential delays in their total cost analysis.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market competition and the perceived value of their products.

How Do Price Influencers Affect the Cost of Printed Leatherette Fabric?

Several factors influence the pricing of printed leatherette fabric, particularly for international B2B buyers.

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer price breaks for larger orders. Understanding the MOQ can help buyers negotiate better pricing and manage inventory more effectively.

-

Specifications and Customization: Custom designs, complex patterns, or specific dimensions can increase production costs. Buyers should communicate their requirements clearly to avoid unexpected fees.

-

Material Quality and Certifications: Higher-quality materials or those with eco-certifications typically come at a premium. Buyers should weigh the benefits of quality against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more for their products due to their proven track record, while emerging suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of shipping and delivery can significantly affect total costs. Different Incoterms (like FOB, CIF, etc.) dictate who is responsible for shipping costs and risks, impacting the final price.

What Tips Can Buyers Use to Negotiate Better Prices on Printed Leatherette Fabric?

Negotiating effectively is crucial for achieving cost efficiency when sourcing printed leatherette fabric.

-

Conduct Market Research: Understanding the market rates for different types of leatherette can provide a solid basis for negotiation. Buyers should gather quotes from multiple suppliers to compare pricing structures.

-

Leverage Volume Discounts: If possible, consolidate orders to meet MOQs or establish long-term relationships with suppliers to secure better pricing on future orders.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also the longevity, quality, and maintenance costs associated with the fabric. A slightly higher initial price may result in lower costs over time due to durability.

-

Understand Pricing Nuances: Be aware of pricing variations based on geographical factors, such as tariffs or import duties that may apply when sourcing from different regions.

-

Build Relationships: Establishing a strong rapport with suppliers can lead to better deals and more favorable terms. Regular communication and feedback can enhance collaboration and trust.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and may vary based on market fluctuations, supplier terms, and specific order requirements. B2B buyers should request formal quotes from suppliers to obtain accurate pricing tailored to their unique needs.

Alternatives Analysis: Comparing printed leatherette fabric With Other Solutions

When evaluating printed leatherette fabric, it’s essential to consider various alternatives that may suit different business needs and applications. Each material or method offers distinct advantages and challenges, impacting performance, cost, and usability. This analysis aims to provide a comprehensive comparison to help B2B buyers make informed decisions.

| Comparison Aspect | Printed Leatherette Fabric | Custom Printed Leather | Vinyl Faux Leather |

|---|---|---|---|

| Performance | Durable, flexible, and maintains color vibrancy; suitable for various applications. | High-quality prints with excellent color accuracy; retains leather-like texture. | Generally durable but may not match the aesthetic of leather; colors can fade with time. |

| Cost | Typically moderate pricing; bulk orders may reduce costs significantly. | Higher initial costs due to setup fees; pricing decreases with repeat orders. | Generally lower cost; widely available but may vary by supplier. |

| Ease of Implementation | Requires minimal setup; designs can be submitted easily for printing. | Requires design code for repeat orders; initial setup can be complex. | Simple ordering process; often available in pre-cut pieces or rolls. |

| Maintenance | Easy to clean and maintain; resistant to wear and tear with proper care. | Requires similar care as leather; may be sensitive to harsh cleaning agents. | Easy to maintain but may show wear faster than leatherette. |

| Best Use Case | Ideal for fashion items, upholstery, and accessories; versatile applications. | Best for high-end products where appearance is paramount, such as luxury items. | Suitable for budget-conscious projects, such as promotional items or temporary displays. |

What are the Advantages and Disadvantages of Custom Printed Leather?

Custom printed leather offers a premium alternative to printed leatherette. Its primary advantage lies in the high-quality finish and aesthetic appeal, making it ideal for luxury goods. The printing technology used allows for vibrant colors and intricate designs, often resulting in a product that closely resembles traditional leather. However, the cost can be a significant drawback, especially for small businesses or those requiring large quantities. Additionally, the need for a design setup charge may complicate initial orders.

How Does Vinyl Faux Leather Compare in Terms of Usability?

Vinyl faux leather is a cost-effective alternative that appeals to businesses on a budget. It provides a leather-like appearance at a fraction of the cost, making it suitable for promotional items and temporary applications. Its availability in various colors and patterns adds to its versatility. However, while vinyl is durable, it may not offer the same level of aesthetic appeal or longevity as printed leatherette or custom printed leather. Over time, vinyl can also show signs of wear, affecting its overall presentation.

Conclusion: How Should B2B Buyers Decide on the Right Solution?

Choosing the right fabric solution ultimately depends on specific business needs, including budget, intended use, and aesthetic requirements. Printed leatherette fabric stands out for its balance of quality, cost, and versatility, making it a solid choice for many applications. Custom printed leather is best suited for high-end products where appearance is crucial, while vinyl faux leather is ideal for budget-conscious projects. By carefully weighing these factors, B2B buyers can select the most suitable option to meet their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for printed leatherette fabric

What Are the Key Technical Properties of Printed Leatherette Fabric?

When sourcing printed leatherette fabric, understanding its technical properties is crucial for making informed purchasing decisions. Here are some key specifications:

1. Material Grade

Material grade refers to the quality classification of the leatherette, which is often determined by the type of synthetic material used, such as PVC or polyurethane (PU). Higher-grade materials offer enhanced durability, resistance to wear, and a more realistic leather-like appearance. For B2B buyers, selecting the right material grade ensures that the final product meets quality standards and customer expectations.

2. Print Quality

Print quality is essential in assessing how well designs and colors transfer onto the leatherette surface. This is typically measured in terms of resolution (measured in DPI—dots per inch) and color vibrancy. High-quality prints ensure that branding and designs appear crisp and vivid, which is crucial for products intended for retail. Buyers should prioritize suppliers that utilize advanced printing technologies for optimal results.

3. Durability and Abrasion Resistance

Durability refers to the fabric’s ability to withstand wear and tear over time, while abrasion resistance indicates how well the surface can resist damage from friction. These properties are vital for products like upholstery and fashion items that will undergo frequent use. B2B buyers should consider fabrics that have been rigorously tested for these attributes to ensure longevity and satisfaction.

Illustrative image related to printed leatherette fabric

4. Chemical Resistance

Chemical resistance indicates the fabric’s ability to withstand exposure to various substances, such as oils, solvents, and cleaning agents. This property is particularly important for applications in environments where spills may occur. Buyers should look for printed leatherette that can maintain its integrity and appearance even after exposure to harsh chemicals.

5. Weight and Thickness

The weight and thickness of leatherette can significantly affect its usability for different applications. Thicker materials may be more suitable for heavy-duty applications, while lighter materials are preferable for garments and accessories. Understanding these specifications helps buyers select the right type for their specific needs, ensuring both functionality and aesthetic appeal.

What Are Common Trade Terms Related to Printed Leatherette Fabric?

Familiarity with industry jargon can greatly enhance communication and negotiation with suppliers. Here are some essential terms to know:

Illustrative image related to printed leatherette fabric

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of printed leatherette, an OEM may provide the base material that is then customized with prints by another company. Understanding OEM relationships can help buyers identify potential partners for custom projects.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and cost-effectiveness. Knowing the MOQ allows businesses to plan their orders efficiently and ensure they meet demand without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price bids from suppliers for specific products or services. When considering printed leatherette, submitting an RFQ helps buyers obtain detailed pricing and terms, enabling informed comparisons between different suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers to clarify shipping, insurance, and risk management during the procurement process.

Illustrative image related to printed leatherette fabric

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. In the context of printed leatherette, understanding lead times is essential for inventory planning and ensuring that products are available when needed. Buyers should communicate clearly with suppliers to establish realistic timelines.

By grasping these technical properties and trade terms, B2B buyers can navigate the printed leatherette market more effectively, ensuring they select the right materials and suppliers for their business needs.

Navigating Market Dynamics and Sourcing Trends in the printed leatherette fabric Sector

What Are the Current Market Dynamics and Key Trends in the Printed Leatherette Fabric Sector?

The printed leatherette fabric market is experiencing notable growth, driven by increasing demand across various industries, including fashion, automotive, and furniture. Key trends influencing this sector include the rise of customization, where businesses seek unique designs to differentiate themselves in a competitive landscape. Digital printing technology has emerged as a game-changer, allowing for vibrant, intricate designs that cater to specific consumer preferences. This trend is particularly relevant for international B2B buyers, who can leverage these advancements to meet local market demands, especially in regions like Africa, South America, the Middle East, and Europe.

Moreover, the shift towards online sourcing platforms is reshaping procurement processes. Buyers now have access to a broader range of suppliers and products, facilitating price comparisons and the ability to assess quality through reviews and ratings. In regions such as Brazil and Saudi Arabia, where traditional supply chains may be less established, this digital transition can significantly enhance sourcing efficiency. As competition intensifies, businesses that adopt agile sourcing strategies and invest in technology are likely to gain a competitive edge.

Illustrative image related to printed leatherette fabric

How Is Sustainability Influencing Sourcing Decisions in the Printed Leatherette Fabric Sector?

Sustainability has become a cornerstone of sourcing strategies in the printed leatherette fabric sector. B2B buyers are increasingly aware of the environmental impact of their procurement choices, prompting them to seek out suppliers that prioritize ethical sourcing practices. The demand for eco-friendly materials is on the rise, with businesses looking for printed leatherette fabrics that are produced using sustainable processes and materials.

Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX® Standard 100 are becoming critical benchmarks for buyers aiming to validate the sustainability claims of their suppliers. By prioritizing ethical sourcing, companies not only reduce their environmental footprint but also enhance their brand reputation, appealing to a growing segment of environmentally-conscious consumers. In regions like Europe, where regulatory frameworks around sustainability are becoming stricter, aligning with certified suppliers can also mitigate risks associated with compliance.

What Historical Trends Have Shaped the Printed Leatherette Fabric Market?

The evolution of the printed leatherette fabric market can be traced back to advances in synthetic materials and digital printing technology. Initially, leatherette was primarily used as a cost-effective alternative to genuine leather, appealing to budget-conscious consumers. However, as technology progressed, the quality of leatherette improved significantly, allowing for more realistic textures and finishes that closely mimic natural leather.

The introduction of digital printing techniques in the late 20th century revolutionized the industry, enabling manufacturers to produce custom designs with remarkable precision and speed. This shift not only expanded design possibilities but also catered to the growing consumer demand for personalization. As a result, printed leatherette has transitioned from a mere substitute to a preferred choice for various applications, from fashion to interior design, effectively carving out its niche in the global textile market.

Illustrative image related to printed leatherette fabric

As B2B buyers navigate this dynamic landscape, understanding these historical trends can provide valuable context for making informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of printed leatherette fabric

-

How do I ensure the quality of printed leatherette fabric from suppliers?

To ensure the quality of printed leatherette fabric, start by requesting samples from potential suppliers. Evaluate the texture, durability, and print quality, including color accuracy and resistance to fading. Additionally, check for certifications related to material safety and environmental standards. Establishing a quality assurance process, such as third-party testing or factory visits, can also help maintain consistent product quality. Lastly, review customer testimonials and case studies to gauge previous buyers’ experiences. -

What are the customization options available for printed leatherette fabric?

Customization options for printed leatherette fabric are extensive. Suppliers typically offer various textures, colors, and finishes, allowing you to create unique designs that match your brand. You can upload your artwork or select from existing patterns, ensuring that your product stands out in the market. Additionally, inquire about minimum order quantities (MOQs) for custom prints, as some suppliers may have specific requirements based on the complexity of the design. -

What are the typical minimum order quantities (MOQs) for printed leatherette fabric?

Minimum order quantities (MOQs) for printed leatherette fabric vary by supplier, often ranging from 50 to 200 meters. Some manufacturers may allow smaller orders for sample runs or prototypes, while larger quantities may be required for bulk pricing. Always confirm the MOQ with your supplier before placing an order to ensure it aligns with your production needs. Additionally, consider negotiating terms, especially if you anticipate placing larger orders in the future. -

What payment terms should I expect when sourcing printed leatherette fabric?

Payment terms can differ significantly among suppliers, but common practices include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer credit terms, especially for established relationships. It’s essential to clarify payment methods accepted, such as bank transfers or letters of credit, and ensure that all terms are documented in the purchase agreement to avoid disputes later. -

How can I vet suppliers of printed leatherette fabric effectively?

Vetting suppliers involves several steps. Start by researching their reputation online through reviews and ratings from other B2B buyers. Request references and follow up with those businesses to inquire about their experiences. Check for relevant certifications that demonstrate compliance with international quality and safety standards. Additionally, consider visiting the manufacturing facility if possible or utilizing third-party verification services to assess their operational capabilities. -

What logistics considerations should I keep in mind when importing printed leatherette fabric?

When importing printed leatherette fabric, consider shipping methods, lead times, and customs regulations. Evaluate the total cost of shipping, including freight charges, insurance, and potential duties or tariffs. Collaborate with a logistics provider experienced in international trade to navigate customs documentation and ensure compliance with local regulations. Additionally, factor in the supplier’s ability to meet delivery timelines, as delays can impact your production schedule. -

What are the most common uses for printed leatherette fabric in various industries?

Printed leatherette fabric is versatile and commonly used across various industries, including fashion, furniture, and automotive. In fashion, it serves as a material for clothing, handbags, and accessories. In furniture, it is utilized for upholstery and decorative items, while in automotive applications, it can be found in seat covers and interior trims. Understanding the specific applications within your target market can help tailor your sourcing strategy effectively. -

How can I ensure compliance with international trade regulations when sourcing printed leatherette fabric?

To ensure compliance with international trade regulations, familiarize yourself with the import/export laws of both your country and the supplier’s country. This includes understanding tariffs, trade agreements, and any restrictions on materials. Engage with a customs broker or trade compliance specialist who can provide guidance on required documentation, such as certificates of origin and material safety data sheets (MSDS). Staying informed about changes in regulations can also help mitigate risks associated with international sourcing.

Top 7 Printed Leatherette Fabric Manufacturers & Suppliers List

1. Zipper Valley – Printed Faux Leather

Domain: zippervalley.com

Registered: 2020 (5 years)

Introduction: Printed Faux Leather is pliable, vibrant, and bursting with personality. It is easy to cut and sews beautifully, even on domestic machines. Ideal for bags, wallets, key fobs, embroidery, and other creative projects. Available styles include Witch, Please, Spook-tacular, Fab-boo-lous, Cool Cats, Butterfly Dance, Japanese Arch, Flower Basket, Butterfly Conservatory, Love On The Brain, Travel Time, a…

2. Contrado – Custom Printed Leather

Domain: contrado.com

Registered: 2004 (21 years)

Introduction: Printed Leather allows you to create custom leather prints using your artwork or designs. Options include Smooth Nappa Leather, Textured Nappa Leather, Bubble Nappa Leather, Vegan Leather, Furnishing Leatherette, and Suede. Leather Swing Tags are available in packs of 10. Prices include: Smooth Nappa Leather ($26.25), Textured Nappa Leather ($26.25), Bubble Nappa Leather ($26.25), Vegan Leather, F…

3. Leatherette Lane – Custom Printed Fabrics

Domain: leatherettelane.co.uk

Registered: 2024 (1 years)

Introduction: Custom Printed Leatherette fabric available in various designs and colors. Free UK delivery on orders over £40 and free international delivery on orders over £150. Categories include Artisan Leatherette, Animals & Critters, Floral & Fauna, Special Occasions, and more. Options for bespoke fabrics and sample leatherette sheets are also available.

4. Nature’s Fabrics – Custom Print Faux Leather Vinyl

Domain: naturesfabrics.com

Registered: 2009 (16 years)

Introduction: This company, Nature’s Fabrics – Custom Print Faux Leather Vinyl, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

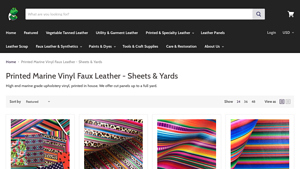

5. Frog Jelly Leather – Printed Marine Vinyl

Domain: frogjellyleather.com

Registered: 2016 (9 years)

Introduction: Printed Marine Vinyl Faux Leather – Sheets & Yards: High-end marine grade upholstery vinyl, printed in-house. Available cut panels up to a full yard. Features UV resistant marine upholstery vinyl with resilient stretching, suitable for bags, jewelry (earrings), crafts (hair bows), and upholstery. Products include various patterns such as Wild Serape, Braided Serape, Classic Serape, and more, all p…

6. Lone Star Adhesive – Textured Printed Leatherette Sheets

Domain: lonestaradhesive.com

Registered: 2023 (2 years)

Introduction: Textured Printed Premium Leatherette™ Sheets

7. Buy Leather Online – Premium Leather Products

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Introduction: {“price_range”:”$10.00 – $330.00″,”colors”:[{“name”:”White”,”count”:16},{“name”:”Ice-White”,”count”:1},{“name”:”Talc”,”count”:2},{“name”:”Platinum”,”count”:3},{“name”:”Ivory – Off-White”,”count”:13},{“name”:”Light Beige”,”count”:2},{“name”:”Beige – Natural”,”count”:17},{“name”:”Dark Beige”,”count”:1},{“name”:”Sand Beige”,”count”:8},{“name”:”Pinky Beige – Powder”,”count”:11},{“name”:”Greenish Beige…

Strategic Sourcing Conclusion and Outlook for printed leatherette fabric

In summary, the strategic sourcing of printed leatherette fabric presents a wealth of opportunities for international B2B buyers. With advancements in digital printing technologies, businesses can now access vibrant, customizable materials that meet diverse market needs—from fashion and upholstery to accessories and promotional items. The ability to create unique designs not only enhances product offerings but also caters to growing consumer demand for personalization.

Moreover, understanding regional market dynamics is crucial. Buyers from Africa, South America, the Middle East, and Europe should leverage local insights to identify trends and consumer preferences that can influence their sourcing strategies. Establishing strong relationships with reliable suppliers who prioritize quality and sustainability will be key to maintaining a competitive edge in this evolving landscape.

Illustrative image related to printed leatherette fabric

Looking ahead, the printed leatherette market is poised for growth, driven by innovation and sustainability. As you consider your sourcing strategies, embrace the potential of this versatile material to elevate your product lines. Engage with suppliers who can provide tailored solutions, and invest in quality designs that resonate with your target audience. The future of printed leatherette fabric is bright—seize the opportunity to lead in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to printed leatherette fabric