Introduction: Navigating the Global Market for faux leather maintenance

In today’s competitive landscape, sourcing high-quality faux leather maintenance solutions presents a unique challenge for international B2B buyers. With growing demand across various industries—from furniture to automotive—understanding the intricacies of maintaining faux leather products is crucial. This guide offers a comprehensive overview of faux leather types, their applications, and best maintenance practices. It also addresses key considerations such as supplier vetting, cost analysis, and environmental impacts, ensuring that businesses can make informed purchasing decisions.

As businesses expand into diverse markets in Africa, South America, the Middle East, and Europe, the need for reliable faux leather maintenance solutions becomes even more critical. This guide empowers B2B buyers by providing actionable insights and expert tips that enhance product longevity and performance. From understanding the differences between polyurethane and PVC to exploring effective cleaning techniques, readers will gain the knowledge needed to navigate the complexities of faux leather care. By investing in proper maintenance, companies can not only uphold the aesthetic appeal of their products but also improve customer satisfaction and reduce long-term costs.

Join us as we delve into the essential aspects of faux leather maintenance, ensuring your business is equipped to thrive in the global market.

Table Of Contents

- Top 6 Faux Leather Maintenance Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for faux leather maintenance

- Understanding faux leather maintenance Types and Variations

- Key Industrial Applications of faux leather maintenance

- 3 Common User Pain Points for ‘faux leather maintenance’ & Their Solutions

- Strategic Material Selection Guide for faux leather maintenance

- In-depth Look: Manufacturing Processes and Quality Assurance for faux leather maintenance

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather maintenance’

- Comprehensive Cost and Pricing Analysis for faux leather maintenance Sourcing

- Alternatives Analysis: Comparing faux leather maintenance With Other Solutions

- Essential Technical Properties and Trade Terminology for faux leather maintenance

- Navigating Market Dynamics and Sourcing Trends in the faux leather maintenance Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of faux leather maintenance

- Strategic Sourcing Conclusion and Outlook for faux leather maintenance

- Important Disclaimer & Terms of Use

Understanding faux leather maintenance Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Faux Leather | Cost-effective, less breathable, durable | Budget furniture, automotive upholstery | Pros: Affordable, widely available. Cons: Less breathable, prone to cracking over time. |

| PU Faux Leather | More breathable, environmentally friendly, softer | High-end furniture, luxury goods | Pros: Durable, aesthetically pleasing. Cons: Higher cost compared to PVC. |

| Faux cuir microfibre | Ultra-soft texture, stain-resistant, easy to clean | Upholstery, clothing, accessories | Pros: Soft feel, resistant to stains. Cons: May require specific cleaning methods. |

| Biodegradable Faux Leather | Made from sustainable materials, eco-friendly | Eco-conscious brands, high-end markets | Pros: Environmentally friendly, innovative. Cons: Limited availability, potentially higher costs. |

| Coated Fabric | Fabric base with a faux leather coating, versatile | Fashion, upholstery, promotional items | Pros: Versatile, can mimic various textures. Cons: Durability can vary based on coating quality. |

What Are the Key Characteristics of PVC Faux Leather?

PVC (Polyvinyl Chloride) faux leather is known for its cost-effectiveness and durability, making it a popular choice for budget-conscious B2B buyers. Its non-breathable nature means it can withstand wear but is prone to cracking over time, particularly in environments with fluctuating temperatures. Companies in the automotive and budget furniture sectors often opt for PVC due to its affordability. However, buyers must consider the long-term implications of using PVC, as it may require more frequent replacements compared to higher-quality materials.

How Does PU Faux Leather Stand Out in the Market?

Polyurethane (PU) faux leather is favored for its breathability and softer texture compared to PVC, making it suitable for high-end furniture and luxury goods. Its environmental impact is also less severe, appealing to brands focused on sustainability. PU is more resistant to cracking and has a longer lifespan, making it a wise investment for businesses looking to maintain a premium appearance. However, the higher cost may deter some buyers, necessitating a careful evaluation of budget versus quality.

What Makes Microfiber Faux Leather an Attractive Option?

Microfiber faux leather is characterized by its ultra-soft texture and excellent stain resistance, making it a preferred choice for upholstery and clothing. Its ease of cleaning is a significant advantage, particularly for businesses in the hospitality and retail sectors. However, specific cleaning methods may be required to maintain its integrity, which can be a consideration for B2B buyers. Overall, microfiber offers a blend of comfort and practicality that is hard to match.

Why Choose Biodegradable Faux Leather for Sustainable Brands?

Biodegradable faux leather is gaining traction among eco-conscious brands seeking sustainable alternatives to traditional materials. Made from plant-based or recycled materials, it appeals to businesses prioritizing environmental responsibility. While its innovative nature can command higher prices and limited availability, the long-term benefits of aligning with sustainable practices can outweigh these drawbacks. Companies aiming to enhance their corporate social responsibility will find biodegradable faux leather a compelling option.

How Does Coated Fabric Compare to Other Faux Leather Options?

Coated fabric offers versatility, combining a fabric base with a faux leather coating. This type can mimic various textures and styles, making it suitable for a wide range of applications, including fashion and promotional items. However, durability can vary significantly based on the quality of the coating. B2B buyers should assess the intended use and longevity requirements when considering coated fabric, as its performance may not always match that of more robust faux leather options.

Key Industrial Applications of faux leather maintenance

| Industry/Sector | Specific Application of faux leather maintenance | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Maintenance of faux leather furniture in hotels | Enhances guest experience through well-maintained aesthetics | Ensure availability of eco-friendly cleaning products |

| Automotive | Care for faux leather interiors in vehicles | Improves resale value and customer satisfaction | Source durable cleaning agents that prevent cracking |

| Retail | Upkeep of faux leather merchandise displays | Attracts customers with visually appealing displays | Look for suppliers with a range of protective treatments |

| Healthcare | Maintenance of faux leather upholstery in clinics | Ensures hygiene and comfort for patients | Prioritize suppliers with non-toxic and hypoallergenic products |

| Event Management | Care for faux leather seating at events and exhibitions | Provides a polished look, enhancing brand image | Seek cleaning solutions that are quick-drying and non-abrasive |

How is Faux Leather Maintenance Used in the Hospitality Industry?

In the hospitality sector, maintaining faux leather furniture is crucial for creating a welcoming atmosphere in hotels and restaurants. Regular cleaning and protective treatments help prevent stains and cracking, enhancing the overall aesthetic appeal. Buyers in this industry should prioritize eco-friendly cleaning products that align with sustainable practices, as this can further enhance their brand reputation among environmentally conscious travelers.

What are the Specific Needs for Faux Leather Maintenance in Automotive?

Automotive interiors often feature faux leather due to its durability and cost-effectiveness. Regular maintenance ensures these surfaces remain in pristine condition, which is essential for customer satisfaction and vehicle resale value. International buyers should consider sourcing cleaning agents that are specifically formulated for automotive applications, focusing on products that prevent cracking and maintain the material’s integrity over time.

How Does Faux Leather Maintenance Benefit Retail Businesses?

In the retail sector, faux leather is commonly used for merchandise displays and seating areas. Regular maintenance not only keeps these surfaces looking fresh but also attracts customers by presenting a well-maintained shopping environment. Retail buyers should look for suppliers offering a variety of protective treatments that are compatible with different faux leather types to ensure versatility and effectiveness in their maintenance routines.

What are the Key Considerations for Healthcare Faux Leather Maintenance?

In healthcare settings, faux leather is often used for upholstery in patient rooms and waiting areas. Its maintenance is critical for ensuring hygiene and patient comfort. Buyers in this sector should prioritize sourcing non-toxic and hypoallergenic cleaning products that effectively remove stains without compromising patient safety. Regular upkeep also helps maintain a professional appearance, which is vital in healthcare environments.

How is Faux Leather Maintenance Applied in Event Management?

In event management, faux leather seating is frequently used for its stylish appearance and comfort. Maintenance is essential to keep these furnishings looking clean and presentable for guests. Event planners should seek out quick-drying, non-abrasive cleaning solutions that can be applied easily between events, ensuring that the seating remains in top condition while minimizing downtime. This attention to detail enhances the overall experience and reflects positively on the brand hosting the event.

3 Common User Pain Points for ‘faux leather maintenance’ & Their Solutions

Scenario 1: Struggling with Stains on Faux Leather Surfaces

The Problem: B2B buyers often face the challenge of managing stains on faux leather products, especially in high-traffic environments like restaurants or hotels. Food spills, ink marks, and dirt can quickly accumulate, leading to unsightly surfaces that detract from the overall aesthetics of the establishment. The pressure to maintain a clean and appealing environment can be overwhelming, especially when buyers are uncertain about the right cleaning products to use without damaging the material.

The Solution: To effectively manage stains on faux leather, B2B buyers should prioritize preventive measures and establish a routine maintenance schedule. First, invest in a high-quality protective spray specifically designed for faux leather, which creates a barrier against stains. Regularly apply this treatment every few months to maintain its effectiveness. For immediate cleaning, use a solution of mild soap and warm water with a soft, non-abrasive cloth. It’s essential to act quickly on stains—dab, don’t rub, to avoid pushing the stain deeper into the material. For tough stains, consider using specialized faux leather cleaners that are pH-balanced and free from harsh chemicals. Always test any product on a hidden area before application to ensure compatibility with the faux leather.

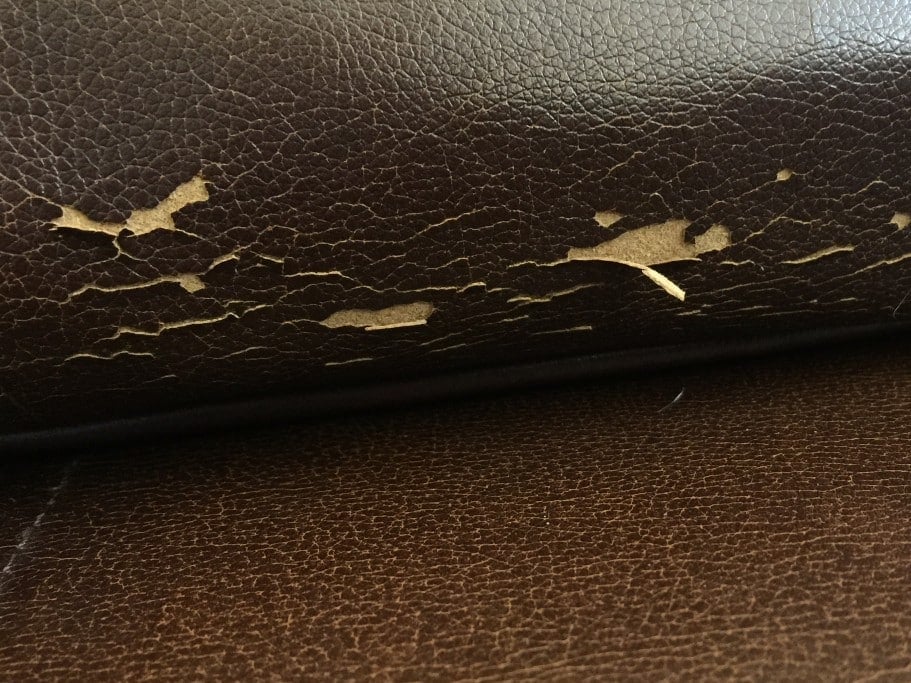

Scenario 2: Dealing with Dryness and Cracking in Faux Leather

The Problem: Buyers often encounter the issue of faux leather drying out and cracking, especially in regions with extreme weather conditions, such as high temperatures or low humidity. This not only affects the aesthetic appeal of the products but also shortens their lifespan, leading to additional costs for replacements or repairs. The challenge lies in finding the right balance between maintaining the material’s flexibility and preventing it from becoming too dry.

The Solution: To combat dryness, B2B buyers should implement a proactive approach to faux leather care. Regular conditioning is key; utilize a specialized faux leather conditioner that replenishes moisture without leaving a greasy residue. Apply the conditioner with a soft cloth, following the manufacturer’s instructions for frequency—generally, every 4 to 6 weeks is advisable. Additionally, buyers should monitor the environment where faux leather items are stored or used. Consider using humidifiers in dry climates to maintain optimal humidity levels, which helps preserve the material’s suppleness. Educate staff on proper faux leather care practices, emphasizing the importance of avoiding direct sunlight and heat sources that can accelerate drying.

Scenario 3: Preventing Color Transfer and Fading on Faux Leather

The Problem: Color transfer from clothing, particularly from denim, can be a significant concern for B2B buyers in the fashion or hospitality sectors. This issue is compounded when light-colored faux leather is involved, leading to permanent discoloration that can mar the appearance of furniture or accessories. Buyers often feel frustrated when they realize that color transfer has occurred, especially if they were unaware of how to prevent it.

The Solution: To prevent color transfer and fading, B2B buyers should adopt a multi-faceted strategy. First, ensure that all staff members are aware of the potential for color transfer and the importance of immediate action. Encourage the implementation of a routine inspection process for all faux leather items, allowing for quick identification of any transfer marks. When a stain is detected, use a baby wipe or a damp cloth to gently clean the area before the stain sets. Additionally, buyers should consider investing in darker or more colorfast faux leather options for high-risk areas. If possible, rotate furniture regularly to minimize prolonged exposure to potential color transfer sources. Finally, educate customers on the importance of wearing non-dyed clothing, particularly in settings where they may come into contact with light-colored faux leather.

Strategic Material Selection Guide for faux leather maintenance

What are the Key Materials Used in Faux Leather Maintenance?

Faux leather, a popular alternative to genuine leather, is often made from various synthetic materials, each with unique properties and maintenance requirements. Understanding these materials can help B2B buyers make informed decisions regarding their faux leather products, especially in international markets like Africa, South America, the Middle East, and Europe.

What are the Properties and Considerations of Polyurethane (PU)?

Polyurethane (PU) is one of the most commonly used materials for faux leather. It is known for its durability and flexibility, making it suitable for various applications, from furniture upholstery to automotive interiors. PU is breathable, which helps prevent moisture buildup, and it can withstand moderate temperatures and pressures.

Pros: PU is easier to clean and maintain compared to other materials. It is also more environmentally friendly than PVC, as it does not release harmful chemicals during production. The cost of PU is generally moderate, making it accessible for a wide range of applications.

Cons: While PU is durable, it can be prone to cracking if it becomes excessively dry. It also may not perform well in extremely high temperatures, which can lead to degradation over time.

Impact on Application: PU is compatible with various cleaning agents, but harsh chemicals can damage its surface. Buyers should consider the local climate, as regions with high humidity may require additional protective treatments to maintain PU’s integrity.

Illustrative image related to faux leather maintenance

How Does Polyvinyl Chloride (PVC) Compare for Faux Leather Maintenance?

Polyvinyl chloride (PVC) is another prevalent material used in faux leather production. It is known for its resistance to moisture and UV light, making it suitable for outdoor furniture and marine applications.

Pros: PVC is highly durable and resistant to wear and tear, making it a cost-effective option for high-traffic areas. Its low manufacturing complexity allows for mass production, which can lower costs for B2B buyers.

Cons: However, PVC is less breathable than PU, which can lead to moisture buildup and eventual deterioration. Additionally, it is less environmentally friendly, as the production process can release harmful chemicals.

Illustrative image related to faux leather maintenance

Impact on Application: PVC’s compatibility with cleaning products is limited. Buyers should avoid using harsh solvents, as they can degrade the material. Compliance with international standards, such as ASTM and DIN, is crucial for buyers in various regions to ensure product safety and performance.

What Role Does Microfiber Play in Faux Leather Maintenance?

Microfiber, often used as a backing material for faux leather, is composed of ultra-fine synthetic fibers. This material is known for its softness and ability to mimic the texture of genuine leather.

Pros: Microfiber is highly absorbent and can effectively trap dust and dirt, making it easier to clean. It is also resistant to staining and fading, which is beneficial for maintaining the aesthetic appeal of faux leather products.

Cons: While microfiber is durable, it can be sensitive to high temperatures, which may lead to melting or deformation. Its production can also be more complex, potentially increasing costs.

Impact on Application: Microfiber is compatible with a wide range of cleaning agents, but buyers should ensure that the products used do not contain harsh chemicals that could damage the fibers. In regions with varying climate conditions, microfiber’s moisture-wicking properties can help maintain the integrity of faux leather.

Summary Table of Materials for Faux Leather Maintenance

| Matériau | Typical Use Case for faux leather maintenance | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Furniture upholstery, automotive interiors | Durable and environmentally friendly | Prone to cracking if too dry | Medium |

| Polyvinyl Chloride (PVC) | Outdoor furniture, marine applications | Highly durable and cost-effective | Less breathable, potential moisture issues | Low |

| Microfibre | Backing material for faux leather products | Soft, absorbent, and stain-resistant | Sensitive to high temperatures | Medium |

By understanding the properties, advantages, and limitations of these materials, B2B buyers can make more informed decisions when selecting faux leather products and maintenance solutions tailored to their specific market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for faux leather maintenance

What Are the Main Stages of Faux Leather Manufacturing?

Faux leather, a popular alternative to genuine leather, undergoes several critical manufacturing stages. Understanding these processes is essential for B2B buyers looking to maintain quality in their faux leather products.

Material Preparation: What Goes Into Faux Leather?

The manufacturing process begins with material preparation, where various synthetic substrates, primarily polyurethane (PU) and polyvinyl chloride (PVC), are selected. PU is favored for its breathability and environmental advantages over PVC. Once the base material is chosen, it is treated to enhance its properties. This may involve adding colorants, plasticizers, and stabilizers to ensure durability and aesthetic appeal.

How Is Faux Leather Formed?

The next step is forming, where the prepared materials are processed into sheets that mimic the texture and appearance of real leather. This can be achieved through techniques such as calendaring, where the material is passed through rollers to achieve the desired thickness and texture. Additionally, embossing may be employed to create a leather-like grain on the surface, enhancing its visual appeal.

Illustrative image related to faux leather maintenance

What Happens During Assembly?

Once the faux leather sheets are formed, they move to the assembly stage. This involves cutting the sheets into specific shapes and sizes for various applications, such as upholstery, fashion items, or automotive interiors. Skilled workers or automated machines will stitch or bond these pieces together, ensuring that the seams are strong and the final product meets design specifications.

What Finishing Techniques Are Used?

The final stage in the manufacturing process is finishing, which includes applying protective coatings to enhance the faux leather’s durability. These coatings can provide water resistance, UV protection, and additional abrasion resistance. The finishing process is crucial as it directly impacts the faux leather’s longevity and ease of maintenance.

What Are the Key Quality Assurance Processes for Faux Leather?

Quality assurance is integral to the production of faux leather, ensuring that the final products meet international standards and customer expectations. Here are the key components of quality control in faux leather manufacturing.

What Are the Relevant International Standards for Faux Leather?

B2B buyers should be aware of various international standards that govern the quality of faux leather products. ISO 9001 is one of the most recognized quality management standards, focusing on consistent quality and customer satisfaction. Additionally, industry-specific certifications like CE mark (indicating compliance with EU regulations) and American Petroleum Institute (API) standards for specific applications may also be relevant.

Illustrative image related to faux leather maintenance

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials for defects before they are used in production. Ensuring high-quality inputs is critical for achieving the desired output quality.

-

In-Process Quality Control (IPQC): During the manufacturing process, IPQC checks are implemented to monitor production parameters, ensuring that the faux leather meets specific quality benchmarks at various stages.

-

Final Quality Control (FQC): Once the product is finished, FQC involves a thorough inspection of the final product to ensure it meets all specifications, including visual appearance, texture, and durability.

What Common Testing Methods Are Used for Faux Leather Quality Assurance?

Several testing methods are employed to assess the quality of faux leather. These include:

-

Physical Testing: This involves assessing tensile strength, tear resistance, and abrasion resistance. Such tests help determine how well the faux leather will perform under typical usage conditions.

-

Chemical Testing: This checks for harmful substances, such as heavy metals or phthalates, to ensure compliance with safety regulations.

-

Environmental Testing: Assessing the material’s resistance to UV light, water, and temperature changes ensures that the faux leather can withstand various environmental conditions.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing faux leather, B2B buyers should take proactive steps to verify supplier quality control processes. Here are some effective strategies:

What Role Do Audits and Reports Play in Supplier Verification?

Conducting regular audits is crucial for understanding a supplier’s quality assurance processes. Buyers should request access to quality control reports and audit results, which provide insights into the supplier’s compliance with international standards and internal quality benchmarks.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can add an additional layer of assurance. Independent inspectors can evaluate the manufacturing processes and quality control measures, providing an unbiased assessment of the supplier’s capabilities.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification can be challenging but essential. Variations in regulations and standards across countries can affect the quality and safety of faux leather products.

How Do Regional Regulations Impact Quality Standards?

It’s important for buyers to familiarize themselves with the specific regulations governing faux leather in their target markets. For example, European buyers must comply with REACH regulations, which restrict the use of certain hazardous substances. Understanding these local regulations will help ensure compliance and enhance marketability.

What Should Buyers Consider About Cultural Preferences and Expectations?

Cultural preferences may also influence expectations regarding faux leather quality. Buyers should consider regional trends in aesthetics and functionality when selecting suppliers. Engaging in dialogue with suppliers about these preferences can lead to better alignment and ultimately more successful partnerships.

In conclusion, understanding the manufacturing processes and quality assurance measures for faux leather is crucial for B2B buyers. By paying close attention to the production stages, quality checkpoints, testing methods, and regional nuances, buyers can ensure they source high-quality faux leather products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘faux leather maintenance’

The purpose of this guide is to provide B2B buyers with a comprehensive checklist for sourcing effective faux leather maintenance solutions. Proper maintenance is critical for ensuring the longevity and aesthetic appeal of faux leather products, making this guide essential for businesses looking to enhance their offerings in furniture, fashion, or automotive industries.

Step 1: Understand Material Specifications

Before sourcing faux leather maintenance products, it’s vital to have a clear understanding of the specific materials you are dealing with. Faux leather can vary significantly in terms of composition, such as PVC, polyurethane (PU), or polyamide microfibre. Knowing the type of faux leather will help you select the right cleaning and maintenance solutions that are compatible and effective.

Step 2: Identify Maintenance Needs

Different faux leather products may have unique maintenance requirements based on their usage and exposure to elements. Consider factors such as:

– Usage Environment: Is it for indoor or outdoor use?

– Exposure to Sunlight: Will the products be placed in direct sunlight, which can cause drying and cracking?

Understanding these needs will help you choose appropriate maintenance products that offer protective qualities against wear and tear.

Step 3: Research Cleaning Solutions

When evaluating cleaning solutions, prioritize those that are mild and non-abrasive. Harsh chemicals can degrade faux leather over time. Look for:

– Eco-Friendly Options: Products that are environmentally safe are increasingly important in global markets.

– Versatility: Choose cleaners suitable for various faux leather colors and finishes to streamline your inventory.

Step 4: Verify Supplier Certifications

Before finalizing any purchase, ensure that suppliers have the necessary certifications and quality assurances. This step is crucial for maintaining compliance with international standards, especially in regions like Europe and the Middle East. Look for:

– ISO Certifications: These indicate adherence to quality management systems.

– Sustainability Certifications: Important for buyers focused on eco-friendly practices.

Step 5: Request Samples

Always request samples of the maintenance products before making a bulk order. Testing samples allows you to assess compatibility with your faux leather products. Pay attention to:

– Effectiveness: Evaluate how well the product cleans and protects the material.

– Ease of Use: Consider whether the application process is straightforward for your staff.

Step 6: Evaluate Pricing and Terms

Conduct a thorough price comparison among potential suppliers. While price is important, also consider:

– Bulk Discounts: Many suppliers offer discounts for larger orders, which can be beneficial for B2B buyers.

– Return Policies: Ensure that the supplier has a flexible return policy in case the products do not meet your expectations.

Illustrative image related to faux leather maintenance

Step 7: Establish a Maintenance Schedule

Once you have sourced the appropriate maintenance solutions, develop a maintenance schedule that outlines regular cleaning and treatment intervals. This proactive approach will help prolong the life of your faux leather products and maintain their appearance, thus enhancing customer satisfaction.

By following this checklist, B2B buyers can make informed decisions regarding faux leather maintenance, ensuring their products remain in excellent condition and meet market demands.

Comprehensive Cost and Pricing Analysis for faux leather maintenance Sourcing

Understanding the cost structure and pricing dynamics of faux leather maintenance sourcing is critical for international B2B buyers aiming to optimize their procurement strategies. This analysis delves into the various components that influence costs and pricing, along with actionable insights for effective negotiation and decision-making.

What Are the Key Cost Components in Faux Leather Maintenance?

-

Materials: The primary material for faux leather maintenance products includes cleaning agents, protective treatments, and tools such as microfiber cloths. The choice between different types of cleaning solutions (e.g., biodegradable vs. traditional) can significantly impact costs. High-quality, eco-friendly materials often come at a premium but can enhance the longevity of faux leather.

-

Labor: Labor costs encompass the workforce required for manufacturing, packaging, and logistics. Depending on the region, labor costs can vary widely. Countries with lower labor costs may provide more competitive pricing, but this could impact quality if not managed properly.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Efficient manufacturing processes can lower overhead, allowing suppliers to offer more competitive pricing.

-

Tooling: For customized maintenance products, tooling costs can be significant. Buyers should consider whether they require standard products or bespoke solutions, as the latter will require higher initial investments.

-

Quality Control (QC): Implementing stringent QC processes ensures that maintenance products meet specified standards, which can add to costs. However, investing in quality control is essential for reducing return rates and enhancing customer satisfaction.

-

Logistics: Transportation and warehousing costs also play a critical role in the total cost structure. These costs can be influenced by the distance from the supplier to the buyer, shipping methods, and any tariffs or import duties applicable to international shipments.

-

Margin: Supplier margins will vary based on their market positioning and pricing strategies. Understanding a supplier’s margin expectations can provide insight into potential negotiation leeway.

What Factors Influence Pricing for Faux Leather Maintenance?

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders typically qualify for bulk discounts, which can lead to substantial savings.

-

Specifications and Customization: Custom solutions often come at a higher price due to additional development and production costs. Buyers should weigh the benefits of customization against the increased costs.

-

Materials: The quality and type of materials used in maintenance products will directly affect pricing. High-quality, environmentally friendly options may be more expensive but could provide better long-term value.

-

Quality and Certifications: Products that meet industry standards or possess certifications often command higher prices. Buyers should consider these factors when evaluating total cost versus perceived value.

-

Supplier Factors: The reputation, reliability, and experience of the supplier can influence pricing. Established suppliers may charge higher prices but offer proven quality and service reliability.

-

Incoterms: Understanding the terms of delivery (e.g., FOB, CIF) is crucial for international buyers. These terms can impact not only the base price but also the total cost of ownership, including shipping, insurance, and customs duties.

How Can Buyers Optimize Costs and Pricing?

-

Negotiation Tips: Engage suppliers early in discussions to explore pricing flexibility. Presenting data on expected order volumes and payment terms can provide leverage in negotiations.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just upfront costs. Consider factors such as product longevity, maintenance frequency, and potential disposal costs.

-

Understand Pricing Nuances for International Sourcing: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions and currency fluctuations, which can affect pricing.

-

Disclaimer on Indicative Prices: Prices for faux leather maintenance products can vary widely based on the aforementioned factors. Buyers should seek multiple quotes and conduct thorough market research to establish a realistic budget.

By understanding these cost components and pricing influencers, B2B buyers can make informed decisions that enhance the value derived from their faux leather maintenance sourcing.

Alternatives Analysis: Comparing faux leather maintenance With Other Solutions

In the realm of material maintenance, faux leather stands as a popular choice due to its durability and aesthetic appeal. However, it is essential for B2B buyers to consider alternative solutions that may offer similar benefits, potentially at a lower cost or with simpler maintenance requirements. This analysis will compare faux leather maintenance with two viable alternatives: genuine leather maintenance and synthetic upholstery care.

Illustrative image related to faux leather maintenance

| Comparison Aspect | Faux Leather Maintenance | Genuine Leather Maintenance | Synthetic Upholstery Care |

|---|---|---|---|

| Performance | High durability and stain resistance | Excellent durability, can develop patina | Good durability, varies by material |

| Cost | Generally lower initial cost | Higher initial investment | Moderate cost, often similar to faux leather |

| Ease of Implementation | Simple care routine, requires specific cleaners | Requires specialized products and techniques | Easy, general cleaning methods suffice |

| Maintenance | Regular mild cleaning and protection needed | Requires conditioning and professional care | Minimal maintenance, occasional vacuuming |

| Best Use Case | Affordable furnishings for high-traffic areas | Luxury items, long-term investment | Versatile for various applications |

What Are the Pros and Cons of Genuine Leather Maintenance?

Genuine leather is a traditional alternative known for its timeless appeal and longevity. One of the primary advantages is its ability to develop a unique patina over time, enhancing its character. However, it requires more meticulous care, including conditioning to prevent drying and cracking. This maintenance often necessitates specialized products, which can increase the overall cost. For businesses looking to invest in high-end furniture or products that can stand the test of time, genuine leather may be a superior choice despite the higher maintenance demands.

How Does Synthetic Upholstery Care Compare?

Synthetic upholstery encompasses a variety of materials, including polyester and nylon blends, which can offer good durability and ease of cleaning. The maintenance routine is typically minimal, often requiring only routine vacuuming and occasional spot cleaning with mild detergents. While synthetic options may provide versatility for different applications, their performance in terms of stain resistance and long-term wear can vary significantly based on the specific fabric used. This makes synthetic upholstery a practical option for businesses needing low-maintenance solutions in diverse environments.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate maintenance approach for their products, B2B buyers must consider several factors including cost, ease of maintenance, and the intended use case. Faux leather offers a balance of affordability and durability, making it suitable for high-traffic areas, while genuine leather presents a luxurious option for those willing to invest in long-term quality. Synthetic upholstery can serve as a versatile alternative for various applications with minimal upkeep. Ultimately, the right choice will depend on the specific needs of the business, including budget constraints and aesthetic preferences. By evaluating these alternatives, buyers can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for faux leather maintenance

What Are the Key Technical Properties of Faux Leather Maintenance?

When considering faux leather products, understanding their technical properties is essential for ensuring quality and longevity. Here are some critical specifications that B2B buyers should be aware of:

1. Material Grade

Material grade refers to the classification of faux leather based on its composition and manufacturing quality. Common grades include PVC (Polyvinyl Chloride) and PU (Polyurethane). PU is often preferred due to its breathability, durability, and environmental benefits. Understanding material grade is vital for buyers to select products that meet their quality standards and end-user expectations.

Illustrative image related to faux leather maintenance

2. Thickness

The thickness of faux leather can significantly impact its durability and appearance. Typically measured in millimeters, thicker materials tend to be more robust and resistant to wear and tear. For B2B buyers, selecting the right thickness ensures that the products can withstand daily usage while maintaining their aesthetic appeal.

3. Abrasion Resistance

This property measures the faux leather’s ability to withstand surface wear from friction. It is typically assessed using the Martindale test, which simulates wear over time. High abrasion resistance is crucial for products such as furniture and automotive upholstery, as it directly affects the lifespan of the material. Buyers should prioritize materials with high abrasion resistance to minimize future maintenance costs.

4. Colorfastness

Colorfastness refers to the ability of faux leather to retain its color when exposed to light, water, and other environmental conditions. This property is critical for products that will be used in bright or humid environments. Understanding colorfastness ratings helps B2B buyers choose materials that maintain their visual appeal over time, reducing the need for replacements.

Illustrative image related to faux leather maintenance

5. Cleanability

Cleanability is a measure of how easily stains and dirt can be removed from faux leather. Non-porous surfaces generally allow for easier cleaning, but the choice of cleaning agents can affect the material’s longevity. Buyers should look for faux leather that is easy to clean with mild detergents to ensure that maintenance remains manageable and cost-effective.

What Are Common Trade Terms in Faux Leather Maintenance?

Familiarity with industry terminology can streamline communication and transactions between buyers and suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of faux leather, an OEM might supply upholstery materials for furniture manufacturers. Understanding OEM relationships can aid buyers in sourcing high-quality materials tailored to their specific needs.

Illustrative image related to faux leather maintenance

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is critical for B2B buyers as it helps determine the initial investment required when sourcing faux leather products. Knowing the MOQ allows buyers to assess budget constraints and inventory needs effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. This term is essential for negotiating costs and terms when sourcing faux leather. A well-prepared RFQ can lead to better pricing and service conditions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers in managing logistics, shipping costs, and risk associated with faux leather procurement.

5. Lead Time

Lead time refers to the time taken from placing an order to its delivery. This term is significant for B2B buyers who need to plan their inventory levels and meet customer demands. Understanding lead times can help businesses maintain a smooth supply chain and avoid stockouts.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions about faux leather products, ensuring they meet their operational and aesthetic requirements.

Navigating Market Dynamics and Sourcing Trends in the faux leather maintenance Sector

What Are the Current Market Dynamics and Key Trends in Faux Leather Maintenance?

The faux leather maintenance market is experiencing significant growth driven by several global factors. Increasing consumer preference for sustainable and cruelty-free products has shifted demand towards faux leather options, which are perceived as more ethical compared to traditional leather. Regions such as Africa, South America, the Middle East, and Europe are witnessing a surge in the adoption of faux leather in various applications, including furniture, automotive interiors, and fashion accessories. Notably, markets in countries like Saudi Arabia and Vietnam are expanding rapidly, driven by urbanization and a growing middle class that favors stylish yet affordable options.

Emerging B2B technologies are transforming sourcing strategies in this sector. Innovations such as blockchain are enhancing supply chain transparency, allowing buyers to trace the origins of faux leather materials, ensuring they meet ethical standards. Additionally, the use of advanced cleaning and maintenance products is gaining traction, with suppliers offering eco-friendly solutions that align with the sustainability ethos prevalent in today’s market. Furthermore, online sourcing platforms are simplifying the procurement process, enabling international buyers to connect with manufacturers and suppliers more efficiently.

In terms of market dynamics, competition is intensifying as new entrants innovate with high-quality alternatives to traditional materials. As a result, international B2B buyers must stay informed about product specifications and maintenance requirements, ensuring they choose solutions that meet both aesthetic and functional criteria.

How Is Sustainability and Ethical Sourcing Influencing Faux Leather Maintenance?

Sustainability is a critical consideration for B2B buyers in the faux leather maintenance sector. The environmental impact of faux leather production, primarily derived from synthetic materials, raises concerns about pollution and resource usage. As a response, manufacturers are increasingly investing in sustainable practices, such as using recycled materials and reducing waste in production processes. For buyers, selecting faux leather products that incorporate these sustainable practices is essential for aligning with corporate social responsibility objectives.

Ethical sourcing is also becoming increasingly important. Buyers are urged to verify that their suppliers adhere to fair labor practices and maintain environmentally friendly production processes. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX® can serve as benchmarks for quality and sustainability, providing assurance that the materials used in faux leather maintenance are safe and responsibly sourced. By prioritizing these certifications, businesses can enhance their brand reputation and appeal to eco-conscious consumers.

Moreover, the demand for “green” cleaning and maintenance products is on the rise. Buyers are now seeking solutions that not only maintain faux leather’s aesthetic appeal but also minimize environmental impact. This shift towards greener alternatives positions companies that prioritize sustainability as leaders in the market.

What Is the Evolution of Faux Leather Maintenance and Its Implications for B2B Buyers?

The evolution of faux leather maintenance can be traced back to the development of synthetic materials in the mid-20th century, which offered a more affordable alternative to genuine leather. Initially, the focus was primarily on cost and aesthetic appeal. However, as environmental concerns and ethical considerations gained traction, the industry began to adapt.

Today, B2B buyers are not only looking for high-quality faux leather products but also for maintenance solutions that reflect their commitment to sustainability. The shift towards eco-friendly materials and cleaning products has reshaped the market landscape, pushing suppliers to innovate continuously. As a result, buyers are presented with a broader range of options that meet their quality standards while supporting their sustainability goals. This ongoing evolution highlights the importance of staying informed about the latest trends and technologies in faux leather maintenance, ensuring that businesses can make informed decisions that align with both market demands and ethical considerations.

Illustrative image related to faux leather maintenance

Frequently Asked Questions (FAQs) for B2B Buyers of faux leather maintenance

-

How do I solve common stains on faux leather?

To effectively address stains on faux leather, begin by identifying the type of stain. For non-greasy stains, use a mixture of warm water and mild soap applied with a soft, non-abrasive cloth. Gently wipe the area and follow up by drying it with a microfiber cloth. For tougher stains, consider using specialized faux leather cleaners, but always test them on a hidden area first to ensure no adverse reactions. Avoid bleach and harsh chemicals, as they can damage the material. -

What is the best cleaning product for maintaining faux leather?

The best cleaning products for faux leather are those that are mild and non-abrasive. Opt for pH-balanced cleaners specifically designed for synthetic materials, as these will help maintain the integrity of the faux leather without causing drying or cracking. Always check the ingredient list; if you wouldn’t apply it to your skin, it’s likely too harsh for your faux leather. Regular cleaning with warm water and a gentle soap can also prevent buildup and maintain its appearance. -

How do I choose a reliable supplier for faux leather products?

When selecting a supplier for faux leather products, consider their experience and reputation in the industry. Request samples to evaluate the quality of their faux leather and inquire about their manufacturing processes. It’s beneficial to check references or reviews from other businesses in your region. Additionally, ensure that the supplier complies with international quality standards and has a transparent supply chain to guarantee product consistency and reliability. -

What are the minimum order quantities (MOQs) for faux leather maintenance products?

Minimum order quantities can vary widely among suppliers, often depending on the type of product and the supplier’s production capabilities. Typically, MOQs range from 100 to 1,000 units. It’s essential to discuss your needs directly with potential suppliers to negotiate terms that align with your business model. Some suppliers may offer flexibility in MOQs for new clients or bulk orders, so it’s worth exploring these options. -

What payment terms are common in international trade for faux leather products?

Common payment terms in international trade for faux leather products include options like Letter of Credit (LC), Telegraphic Transfer (TT), and PayPal for smaller transactions. Many suppliers may require a deposit upfront, usually between 30-50%, with the balance due before shipment. Be sure to clarify payment terms during negotiations to avoid any misunderstandings and to ensure a smooth transaction process. -

How can I customize faux leather products for my business?

Customization options for faux leather products often include variations in color, texture, and design. Discuss your specific needs with potential suppliers, as many offer bespoke services tailored to client specifications. Provide detailed design requirements and request samples to ensure that the final product meets your standards. Be aware that customized orders may come with higher MOQs and longer lead times. -

What quality assurance measures should I expect from faux leather suppliers?

Reputable faux leather suppliers should have established quality assurance processes that include material testing, regular inspections during production, and final product evaluations. Ask about their certifications and compliance with international quality standards, such as ISO 9001. It’s also beneficial to conduct your own inspections or audits, especially for larger orders, to ensure the products meet your specifications. -

What logistics considerations should I be aware of when importing faux leather products?

When importing faux leather products, consider logistics factors such as shipping methods, customs regulations, and tariffs that may apply to your region. Work with a logistics partner experienced in international shipping to navigate potential challenges and ensure timely delivery. Additionally, discuss lead times with your supplier to account for production and shipping durations, and plan your inventory accordingly to avoid disruptions in your supply chain.

Top 6 Faux Leather Maintenance Manufacturers & Suppliers List

1. Danetti – Faux Leather Care Guide

Domain: danetti.com

Registered: 2006 (19 years)

Introduction: This company, Danetti – Faux Leather Care Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Angel Jackets – Faux Leather Apparel

Domain: angeljackets.com

Registered: 2010 (15 years)

Introduction: Faux leather is a synthetic alternative to real leather, made from materials like polyurethane (PU) and polyvinyl chloride (PVC). It is commonly used in apparel such as jackets, gloves, bags, and shoes, as well as furniture. Faux leather is cost-effective, low-priced, and easy to maintain, but it can crack due to low quality, dryness, and exposure to sun or heat. To maintain faux leather, it is re…

3. Lndry – Faux Leather Care Guide

Domain: lndry.com

Registered: 2012 (13 years)

Introduction: Faux leather, also known as synthetic leather, is a popular alternative to genuine leather due to its affordability, ease of cleaning, and cruelty-free nature. Key care instructions include: 1. Pre-Cleaning: Remove dirt with a soft brush or cloth, check care labels, and test cleaning solutions on inconspicuous areas. 2. Cleaning: For spot cleaning, blot stains with a damp cloth, apply mild deterge…

4. Facebook – Dust Cleaning Tips

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Dust Cleaning Tips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Wear Commando – Faux Leather Essentials

Domain: wearcommando.com

Registered: 2012 (13 years)

Introduction: Faux Leather is an affordable, cruelty-free alternative to genuine leather, made by layering a fabric base (such as polyester or cotton) with a polyurethane or PVC coating. It offers low-maintenance care, requiring no specialized leather conditioners. Faux leather is designed with firming fabric that provides light compression, four-way stretch, and high recovery. Care tips include cool machine wa…

6. Meurice – Faux Leather Solutions

Domain: meurice.nyc

Registered: 2015 (10 years)

Introduction: Faux leather, or “Pleather”, is a popular alternative to real leather, favored for its affordability, similar appearance and feel, and ethical sourcing. It is easier to clean and care for than natural leather. Types of faux leather include: 1. Poromeric Imitation Leather – made from plastic coating (usually polyurethane) on a fibrous base layer (typically polyester). 2. Koskin – commonly used for …

Strategic Sourcing Conclusion and Outlook for faux leather maintenance

What Are the Key Takeaways for B2B Buyers in Faux Leather Maintenance?

In summary, effective faux leather maintenance hinges on understanding the material’s unique properties and implementing strategic care practices. Buyers should prioritize sourcing high-quality faux leather, preferably made from polyurethane, which offers better durability and environmental benefits compared to PVC. Regular mild cleaning, protective treatments, and careful handling can significantly extend the lifespan of faux leather products, thus enhancing their value proposition in various applications.

How Can Strategic Sourcing Enhance Faux Leather Maintenance?

Strategic sourcing plays a vital role in ensuring that businesses procure not only aesthetically pleasing but also sustainable faux leather products. By partnering with reputable suppliers who emphasize quality and provide comprehensive maintenance guidelines, international buyers can ensure their investments remain in optimal condition. This proactive approach minimizes costs associated with repairs and replacements, thereby improving overall profitability.

What’s Next for International Buyers in Faux Leather?

As the demand for eco-friendly and cost-effective materials continues to rise globally, now is the time for businesses in Africa, South America, the Middle East, and Europe to reassess their faux leather sourcing strategies. Engaging with suppliers who offer innovative maintenance solutions can provide a competitive edge. Embrace this opportunity to enhance your product offerings and customer satisfaction by prioritizing quality faux leather maintenance today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to faux leather maintenance

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.