Catalog

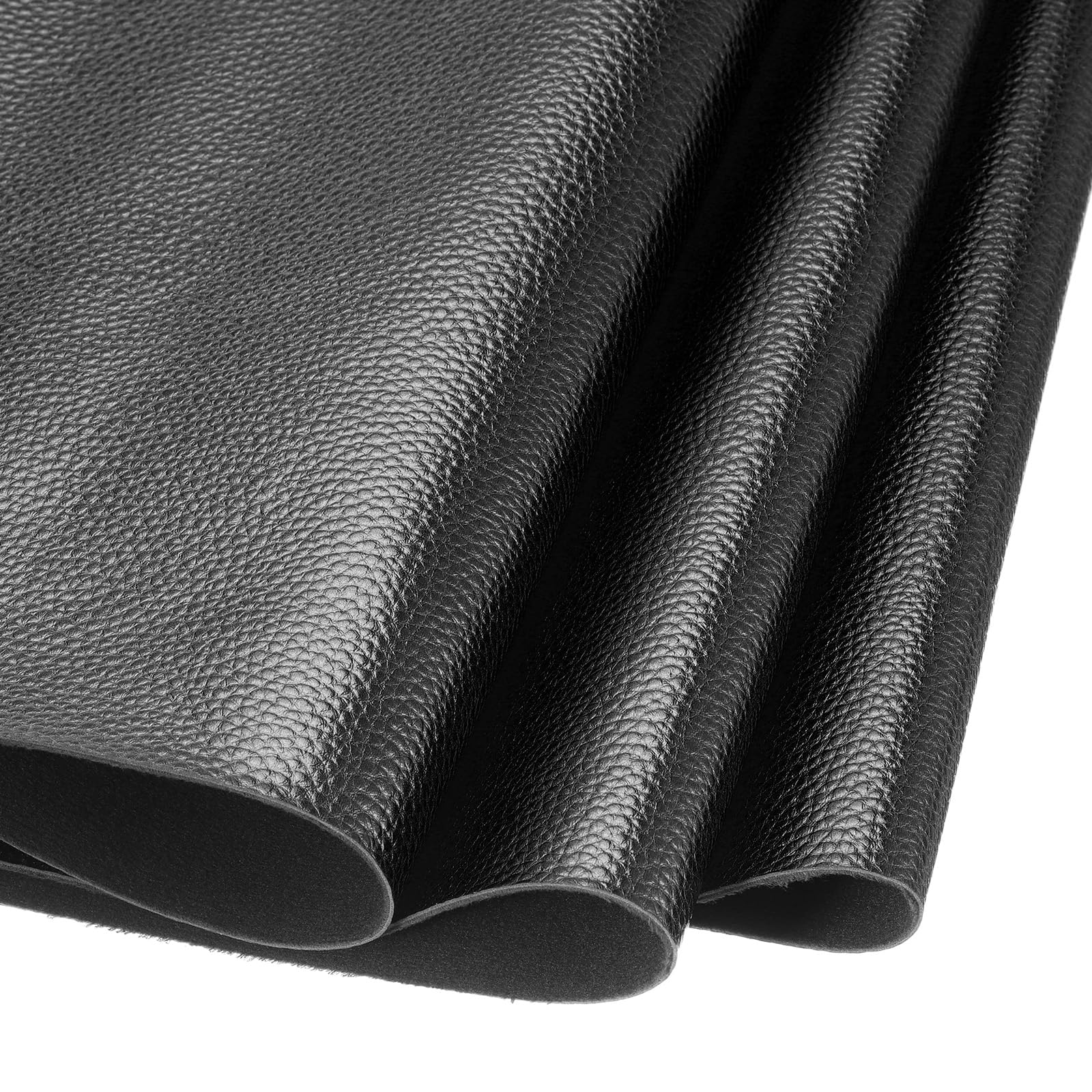

Material Insight: Car Vinyl Fabric

Car vinyl fabric is a high-performance synthetic material engineered to meet the demanding requirements of the automotive industry. Widely used in interior upholstery for seats, door panels, dashboards, and consoles, car vinyl fabric combines durability, aesthetic appeal, and cost-efficiency. As vehicle manufacturers and aftermarket suppliers seek sustainable, low-maintenance, and premium-feel materials, automotive leather has emerged as the preferred alternative to traditional animal leather.

Automotive leather is the best choice for car vinyl fabric applications due to its superior characteristics:

- Exceptional durability and resistance to abrasion, ensuring long-term performance under daily use.

- Excellent UV and colorfastness properties, minimizing fading and degradation from sunlight exposure.

- Enhanced breathability and softness compared to standard PVC-based vinyls, improving passenger comfort.

- Eco-friendly production processes with reduced environmental impact, aligning with global sustainability standards.

- Customizable textures, colors, and finishes to match luxury, sport, or commercial vehicle design aesthetics.

WINIW is a leading innovator in synthetic leather solutions with over 20 years of industry expertise. Specializing in high-quality automotive leather, WINIW serves global B2B clients with advanced materials that combine technical performance and environmental responsibility. Our state-of-the-art manufacturing processes, rigorous quality control, and commitment to R&D enable us to deliver car vinyl fabric that exceeds OEM specifications. Trusted by automotive designers and manufacturers worldwide, WINIW continues to drive the evolution of interior surfaces with smarter, greener, and more luxurious synthetic leather solutions.

Technical Performance & Standards

WINIW Car Vinyl Fabric: Technical Performance Guide for Automotive Manufacturers

WINIW Car Vinyl Fabric represents the pinnacle of engineered synthetic leather for demanding automotive interior applications. Designed specifically for OEMs and Tier-1 suppliers, our solution integrates rigorous material science with uncompromising environmental stewardship. Below are the core technical advantages validated through independent laboratory testing and real-world application performance.

Key Technical Advantages

-

Superior Abrasion Resistance

Engineered with high-density polyurethane (PU) and reinforced backing, WINIW Car Vinyl Fabric achieves >100,000 cycles in Martindale testing (ISO 12947-2), significantly exceeding industry standards for seat upholstery and high-contact surfaces. This translates to extended product lifespan, reduced warranty claims, and consistent aesthetic integrity under daily mechanical stress. -

Exceptional UV Resistance

Stabilized with advanced HALS (Hindered Amine Light Stabilizers) and UV absorbers, the fabric maintains >90% colorfastness (AATCC 16-2014, 1,200 hours xenon arc) and retains >85% tensile strength after 2,000 hours of accelerated weathering (ISO 4892-2). Prevents fading, cracking, and embrittlement in sun-exposed vehicle interiors. -

Zero VOC Emissions

Formulated without solvents, phthalates, or heavy metals, WINIW Car Vinyl Fabric emits undetectable VOC levels (<10 µg/m³ for formaldehyde, <50 µg/m³ for total VOCs) per ISO 12219-3. Ensures cabin air purity and compliance with stringent global automotive air quality standards (e.g., VDA 270, GS-BAU-01). -

Full REACH Compliance

Proactively screened against all SVHC (Substances of Very High Concern) under REACH Annex XIV/XVII. Documentation includes full substance disclosure reports (SDS) and third-party verification (SGS, TÜV), eliminating regulatory risk and supporting sustainable supply chain requirements. -

ISO 9001-Certified Quality Assurance

Manufactured under WINIW’s ISO 9001-certified quality management system, ensuring batch-to-batch consistency, traceability, and defect rates <0.5%. Rigorous in-line testing covers thickness tolerance, color deviation (ΔE <0.5), and seam strength.

Technical Specifications Overview

| Property | Spécifications | Test Method |

|---|---|---|

| Material Composition | 100% Solvent-Free PU Layer on Polyester Knit Backing | – |

| Thickness | 0.80 ± 0.05 mm | ISO 2424 |

| Weight | 320 ± 10 g/m² | ISO 9073-3 |

| Abrasion Resistance | >100,000 cycles (no wear-through) | ISO 12947-2 (Martindale) |

| Colorfastness (UV) | Grade 4-5 (1,200 hrs) | AATCC 16-2014 |

| Tensile Strength | Warp: ≥80 kPa; Weft: ≥75 kPa | ISO 13934-1 |

| VOC Emissions | Formaldehyde: ND; Total VOCs: <50 µg/m³ | ISO 12219-3 |

| REACH Status | Compliant with Annex XVII; No SVHCs >0.1% | EC 1907/2006 |

| Flame Resistance | FMVSS 302 Compliant | ISO 3795 |

WINIW Car Vinyl Fabric delivers measurable performance advantages that directly address automotive manufacturers’ dual imperatives: durability under extreme use conditions and adherence to evolving global sustainability regulations. Our material reduces lifecycle costs through longevity while supporting ESG commitments via VOC-free chemistry and full regulatory transparency. Request technical datasheets or samples for validation in your specific application protocols.

Why Choose Synthetic over Real Leather

B2B Product Guide: Car Vinyl Fabric vs Real Leather

When selecting materials for automotive interiors, manufacturers and suppliers must balance performance, cost, sustainability, and aesthetics. Two of the most widely used materials are car vinyl fabric (synthetic leather) and real leather. While both offer distinct advantages, their differences in cost, durability, and environmental impact significantly influence purchasing decisions in the B2B sector.

Car vinyl fabric, particularly advanced polyurethane (PU) or polyvinyl chloride (PVC)-based synthetics, has evolved to closely mimic the look and feel of real leather while offering enhanced customization and consistency. Real leather, derived from animal hides, remains a premium choice valued for its natural texture and long-term aging properties. However, it comes with higher variability and environmental considerations.

Below is a comparative overview based on key performance metrics relevant to commercial and industrial buyers.

| Criteria | Car Vinyl Fabric | Real Leather |

|---|---|---|

| Cost | Lower initial cost; cost-effective for large-scale production | Higher cost due to raw material scarcity and processing complexity |

| Durabilité | Resistant to fading, cracking, and staining; consistent performance across batches | Prone to drying, cracking over time; requires maintenance; natural variations affect longevity |

| Eco-Friendliness | Modern PU-based vinyls are increasingly eco-friendly, with recyclable content and low-VOC emissions | High environmental footprint due to land use, water consumption, and chemical tanning processes |

Key Advantages of Car Vinyl Fabric:

– Uniform texture and color across production runs, ensuring brand consistency

– Lightweight, contributing to fuel efficiency in vehicles

– Easier to clean and maintain—ideal for high-usage commercial fleets

– Customizable in color, texture, and performance (e.g., UV resistance, breathability)

– Cruelty-free and compliant with animal welfare standards

Key Advantages of Real Leather:

– Premium tactile experience and natural aesthetic appreciated in luxury segments

– Develops a unique patina over time, enhancing perceived value

– Biodegradable at end-of-life under proper conditions (though tanning chemicals may inhibit this)

For B2B clients focused on scalability, sustainability, and cost-efficiency—especially in mass transit, ride-sharing, and electric vehicle markets—car vinyl fabric presents a compelling alternative to real leather. At WINIW, our advanced synthetic leather solutions are engineered for durability, low environmental impact, and superior performance, aligning with global trends toward sustainable mobility.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands as a trusted partner for premium synthetic leather solutions, engineered to meet the rigorous demands of international markets. Our vertically integrated manufacturing ecosystem combines scale, innovation, and uncompromising quality control to deliver consistent, sustainable performance for discerning B2B clients.

Core Manufacturing Capabilities

- 100,000 sqm Advanced Production Facility: One of Asia’s largest dedicated synthetic leather campuses, enabling high-volume output with agile scalability for global supply chains.

- Dedicated R&D Team of 50+ Specialists: Focused on material science innovation, including bio-based polymers, waterless dyeing, and recyclable substrate development to advance circular economy goals.

- Triple-Layer Quality Assurance System:

- Raw material screening via ISO 17025-accredited lab testing

- Real-time production monitoring with AI-driven defect detection

- Pre-shipment compliance validation against EU REACH, US CPSIA, and OEKO-TEX® standards

Global Market Validation

WINIW’s commitment to excellence is proven through sustained partnerships across regulated markets:

– Europe: Certified supplier for 12+ automotive OEMs and luxury fashion houses under strict EU Ecolabel requirements

– USA: Trusted by top 5 furniture brands for CPSIA-compliant, phthalate-free upholstery solutions

– Supply Chain Resilience: 98.7% on-time delivery rate across 60+ countries with LEED-certified warehousing in Rotterdam, Los Angeles, and Singapore

Our facility’s scale and eco-engineered processes eliminate production bottlenecks while reducing water consumption by 65% versus industry averages. This operational excellence ensures your brand receives traceable, high-performance materials that align with evolving sustainability mandates – without compromising on aesthetics or durability. WINIW transforms synthetic leather from a commodity into a strategic asset for global growth.

Contact Us for Samples

B2B Product Guide: WINIW Car Vinyl Fabric

WINIW is a leading innovator in synthetic leather solutions, specializing in high-performance car vinyl fabric for automotive interior applications. Engineered for durability, aesthetics, and sustainability, our car vinyl fabrics meet the rigorous demands of modern vehicle manufacturing and aftermarket customization.

Our advanced production process combines eco-conscious materials with cutting-edge technology, resulting in a product line that delivers superior wear resistance, UV stability, and ease of cleaning—ideal for seating, door panels, dash trims, and more.

- Made from environmentally responsible synthetic materials

- REACH and RoHS compliant for global safety standards

- Excellent resistance to abrasion, fading, and extreme temperatures

- Available in a wide range of textures, including grain patterns that mimic premium leather

- Customizable thickness, color, and finish to meet OEM and aftermarket specifications

- Designed for easy cutting, sewing, and laminating in production environments

Product Specifications Overview

| Property | Spécifications |

|---|---|

| Thickness Range | 0.6 mm – 1.2 mm |

| Weight | 280 – 450 g/m² |

| Base Material | Polyester knitted backing + PU/PVC coating |

| Color Fastness (UV) | ≥ Grade 4 (after 500 hrs Xenon exposure) |

| Martindale Abrasion | ≥ 30,000 cycles |

| Cold Crack Resistance | ≤ -20°C |

| Fire Resistance | Meets FMVSS 302, ISO 3795 |

WINIW car vinyl fabric is trusted by automotive designers, trim suppliers, and aftermarket brands seeking a sustainable, high-quality alternative to genuine leather—without compromising on performance or luxury.

We offer volume-based pricing for manufacturers and distributors, with fast turnaround on custom orders and global shipping support.

Request a Free Sample Today

Experience the quality and versatility of WINIW car vinyl fabric firsthand. Free samples are available for qualified B2B partners.

For product inquiries, technical data sheets, or sample requests:

Contact: MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.