Catalog

Material Insight: Artificial Leather For Sale

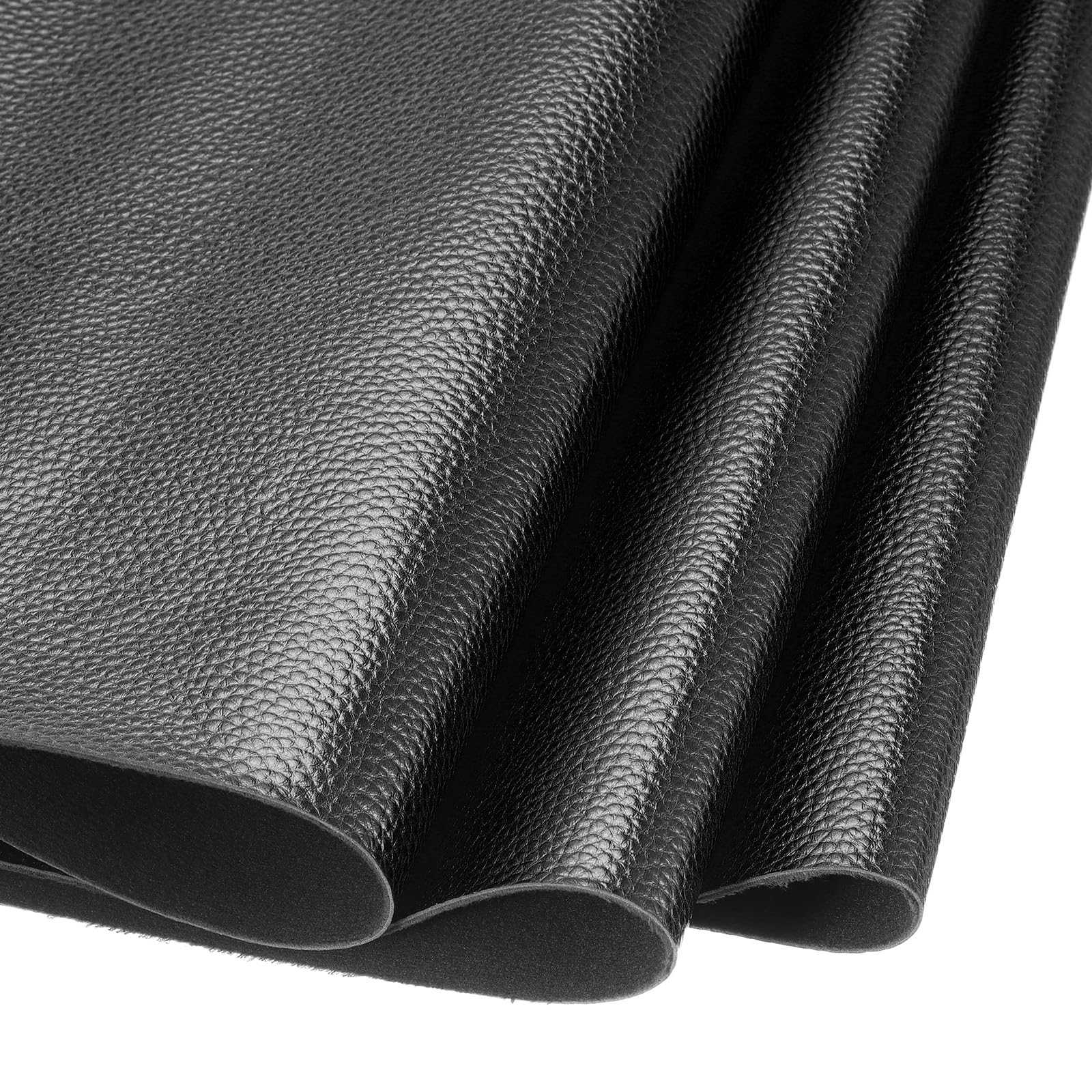

Artificial Leather for Sale – Premium Faux Leather Solutions for Modern Industries

Artificial leather, also known as faux leather, has emerged as a high-performance, sustainable alternative to genuine leather across a broad range of industries. From automotive and furniture manufacturing to fashion accessories and consumer electronics, businesses are increasingly turning to synthetic leather for its consistency, durability, and eco-conscious production. As global demand for ethical and scalable materials grows, artificial leather delivers a compelling combination of aesthetic appeal, functional versatility, and cost-efficiency.

- Faux leather offers superior batch-to-batch consistency, ensuring uniform color, texture, and thickness—critical for large-scale manufacturing.

- It is highly customizable in terms of weight, finish, breathability, and resistance to abrasion, UV light, and chemicals.

- Unlike genuine leather, faux leather does not rely on animal sourcing, making it a more ethical and sustainable choice.

- Advanced manufacturing techniques allow for lower environmental impact, including reduced water usage and fewer harmful emissions.

- With innovations in microfiber and polyurethane (PU) technologies, modern artificial leather closely mimics the softness, drape, and look of natural leather—without the variability or high cost.

For over 20 years, WINIW has been at the forefront of synthetic leather innovation, serving B2B clients worldwide with high-performance, eco-friendly artificial leather solutions. Our expertise spans material science, sustainable production, and industrial application engineering, enabling us to deliver tailored products that meet rigorous industry standards. Whether for seating, upholstery, or protective surfaces, WINIW’s faux leather is engineered for durability, aesthetics, and long-term value—making it the preferred choice for forward-thinking manufacturers.

Technical Performance & Standards

WINIW Premium Synthetic Leather: Technical Product Guide for Industrial Applications

WINIW delivers high-performance synthetic leather engineered for demanding B2B manufacturing environments. Our material combines advanced polymer science with sustainable production, offering a reliable alternative to genuine leather without compromising on technical integrity or environmental responsibility. Designed for automotive, furniture, luggage, and technical textile applications, WINIW provides measurable operational advantages through precision engineering and rigorous quality control.

Core Technical Advantages

- Cost-Effectiveness Through Operational Efficiency: Reduced waste during cutting (up to 15% material savings vs. traditional leathers) and elimination of tanning chemical costs. Consistent roll-to-roll thickness minimizes production downtime for adjustments.

- Enhanced Durability Metrics: Engineered with high-density microfiber backing and wear-resistant polyurethane topcoats. Achieves 50,000+ double-rub cycles (Martindale test), UV stability (ISO 105-B02: Grade 7-8), and cold crack resistance down to -30°C.

- Precision Color Customization: Digital color matching system (ΔE < 0.5 tolerance) supports Pantone, RAL, and custom formulations. Batch consistency guaranteed across 10,000+ meter production runs with lightfastness rating of ≥7 (ISO 105-B02).

- REACH & Regulatory Compliance: Fully documented SVHC-free formulation. Compliant with EU REACH Annex XVII, California Proposition 65, and OEKO-TEX® STANDARD 100 Class II. Full traceability via batch-specific compliance certificates.

- Certified Quality Management: ISO 9001:2015 certified production processes with real-time in-line quality monitoring. 100% roll inspection for defects, ensuring ≤0.5% defect rate.

Technical Specifications Overview

| Property | Test Standard | WINIW Performance | Industry Benchmark |

|---|---|---|---|

| Thickness | ISO 2417 | 0.8 – 2.2 mm (±0.05) | 0.7 – 2.0 mm |

| Tensile Strength | ISO 1767 | ≥ 25 MPa | ≥ 20 MPa |

| Tear Strength | ISO 4674-1 | ≥ 45 N | ≥ 35 N |

| Color Fastness (Rubbing) | ISO 105-X12 | Dry: 4-5 / Wet: 4 | Dry: 4 / Wet: 3 |

| Martindale Abrasion | ISO 12947-2 | ≥ 50,000 cycles | ≥ 30,000 cycles |

| VOC Emissions | ISO 16000-9 | < 10 µg/m³ | < 50 µg/m³ |

| Roll Width | – | 137 cm ± 0.5 cm | 135-137 cm |

| Roll Length | – | 30-50 meters | 25-45 meters |

Sustainable Manufacturing Commitment

All WINIW synthetic leather is produced in ISO 14001-certified facilities using solvent-free coating technology (reducing VOC emissions by 92% vs. conventional PU leather). Our closed-loop water recycling system achieves 85% water reuse, and 100% of production scrap is mechanically recycled into new backing substrates. This ensures compliance with stringent environmental regulations while maintaining cost stability through resource efficiency.

For technical data sheets, compliance documentation, or custom formulation support, contact WINIW’s B2B solutions team to request application-specific performance validation reports. WINIW: Engineered Performance, Verified Responsibility.

Why Choose Synthetic over Real Leather

B2B Product Guide: Artificial Leather vs. Real Leather

When sourcing materials for upholstery, fashion, automotive interiors, or accessories, businesses must weigh performance, cost, and sustainability. Two primary options dominate the market: artificial leather and real leather. Each has distinct advantages and trade-offs in terms of production, application, and environmental impact.

Artificial leather—also known as synthetic leather, faux leather, or engineered leather—includes materials like polyurethane (PU) and polyvinyl chloride (PVC) leather. Real leather is derived from animal hides, predominantly bovine, through a tanning process.

While real leather is often associated with premium aesthetics and longevity, artificial leather offers a cruelty-free, consistent, and increasingly sustainable alternative. Advances in material science have significantly narrowed the performance gap, making artificial leather a competitive choice for B2B applications.

Key considerations include:

- Cost Efficiency: Artificial leather typically has lower production and material costs. It requires no complex curing or grading of raw hides, reducing variability and waste.

- Durabilité: Real leather can last decades with proper care but is susceptible to cracking and fading. High-quality artificial leather (especially PU-based) offers excellent resistance to abrasion, UV light, and moisture.

- Eco-Friendliness: Artificial leather reduces reliance on livestock farming, a major contributor to greenhouse gas emissions. Modern versions, such as those made with bio-based PU or recycled content, further lower environmental impact.

- Consistency & Scalability: Artificial leather provides uniform texture, thickness, and color across batches—critical for mass production. Real leather varies in grain and defects, requiring sorting and grading.

- Customization: Synthetic options allow for greater control over color, texture, and performance features (e.g., water resistance, flame retardancy).

The following table compares key attributes of artificial leather and real leather:

| Attribute | Cuir artificiel | Real Leather |

|---|---|---|

| Cost | Lower upfront cost; cost-stable | Higher cost; fluctuates with hide supply |

| Durabilité | High resistance to wear, stains, and UV; consistent performance | Long lifespan but prone to cracking, fading, and moisture damage |

| Eco-Friendliness | Reduced carbon footprint; no animal sourcing; recyclable options available | High environmental cost from land use, water, and tanning chemicals |

WINIW specializes in high-performance, eco-conscious artificial leather solutions tailored for B2B clients. Our materials are engineered for durability, aesthetic versatility, and sustainability—supporting responsible manufacturing without compromising quality.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global B2B Partners

WINIW operates one of the most advanced and vertically integrated synthetic leather manufacturing facilities in Asia, engineered to deliver consistent, high-performance materials for demanding global markets. Our 100,000 sqm production ecosystem combines scale, innovation, and uncompromising quality control to meet the stringent requirements of leading brands in footwear, furniture, automotive, and accessories.

Core Manufacturing Capabilities

- Strategic Scale: A 100,000 sqm facility enabling end-to-end production control—from polymer formulation to finishing—ensuring supply chain resilience and rapid scalability for large-volume orders.

- Dedicated R&D Leadership: An in-house team of 50+ material scientists and engineers continuously develops eco-innovative solutions, including water-based PU systems, recycled content formulations (up to 30% PCR), and bio-based alternatives, all aligned with global sustainability frameworks.

- Certified Quality Assurance: Rigorous QC protocols exceeding international standards, featuring:

- ISO 9001-certified processes with 12-stage inline inspections

- Full compliance with EU REACH, US CPSIA, and OEKO-TEX® STANDARD 100

- Real-time performance testing for abrasion resistance, colorfastness, and eco-toxicity

- Global Compliance Ready: Pre-qualified for Tier-1 supply chains in Europe and North America, with full traceability documentation (including IMDS for automotive) and carbon footprint reporting.

Global Export Infrastructure

WINIW maintains seamless logistics partnerships facilitating reliable delivery to key markets:

| Region | Key Compliance Adhered To | Typical Lead Time |

|————–|—————————|——————-|

| Europe | REACH, SVHC, Blue Angel | 25-35 days |

| North America| CPSIA, Prop 65, TSCA | 20-30 days |

| Japan/Korea | JIS L 1081, KCLP | 18-28 days |

Our vertically integrated model eliminates third-party dependencies, ensuring every meter of WINIW synthetic leather meets exacting environmental and performance benchmarks while supporting partners’ ESG commitments. This operational excellence has established WINIW as a trusted material source for 200+ global brands seeking durable, eco-responsible alternatives to traditional leather.

Contact Us for Samples

WINIW B2B Product Guide: Premium Synthetic Leather Solutions

WINIW is a leading innovator in high-performance artificial leather, delivering sustainable, durable, and cost-effective microfiber materials for industries worldwide. Our advanced manufacturing processes ensure consistent quality, superior texture, and eco-friendly credentials—making WINIW the preferred choice for forward-thinking B2B partners across furniture, automotive, apparel, and footwear sectors.

Our synthetic leather is engineered to meet rigorous industrial standards while reducing environmental impact. With a focus on customization, scalability, and technical support, WINIW empowers manufacturers to elevate product quality and meet evolving market demands.

Key Advantages of WINIW Artificial Leather

- Eco-Friendly Production: Made from 100% solvent-free, recyclable microfiber materials; low VOC emissions and compliant with global environmental regulations (REACH, RoHS, OEKO-TEX®).

- Superior Durability: High abrasion resistance, excellent tear strength, and long-term color fastness ensure extended product lifecycle.

- Customizable Finishes: Available in a wide range of textures (suede, grain, nubuck), colors, and thicknesses (0.6mm to 2.0mm) to meet specific design and functional requirements.

- Breathable & Soft Hand Feel: Engineered for comfort in seating, apparel, and accessories—ideal for premium consumer products.

- Water & Stain Resistant: Non-porous surface resists moisture, oils, and everyday wear—easy to clean and maintain.

- Consistent Quality: Uniform thickness and performance across large production runs ensure reliability for mass manufacturing.

Applications by Industry

- Furniture & Upholstery: Sofas, office chairs, headboards—offering luxury aesthetics with high wear resistance.

- Automotive Interiors: Seat covers, dashboards, door panels—meets flammability and durability standards (FMVSS 302).

- Footwear & Accessories: Lightweight, flexible microfiber ideal for shoes, handbags, and belts.

- Apparel & Sportswear: Breathable, stretchable options suitable for jackets, gloves, and performance gear.

- Electronics & Cases: Premium protective covers for tablets, laptops, and mobile devices.

Technical Specifications Overview

| Property | Standard Performance |

|---|---|

| Thickness Range | 0.6 mm – 2.0 mm |

| Weight Range | 200 g/m² – 500 g/m² |

| Width per Roll | 137 cm / 54 inches |

| Roll Length | 30 m, 50 m (custom options) |

| Color Fastness (ISO 105) | ≥ Grade 4 |

| Martindale Abrasion | 30,000 – 100,000 cycles |

| Flammability | FMVSS 302, CAL 117 compliant |

Custom technical profiles available upon request.

Why Partner with WINIW?

- Global Supply Reliability: Stable production capacity with export experience to North America, Europe, and Asia.

- R&D-Driven Innovation: Continuous development of bio-based and recycled content materials.

- OEM/ODM Support: Full-service collaboration from design to delivery.

- Fast Lead Times: Streamlined logistics and inventory management for on-time delivery.

Request Free Samples Today

Experience the quality and versatility of WINIW artificial leather firsthand. We offer free samples to qualified B2B partners to support product development and prototyping.

Contact our sales team:

MKT88@MicrofiberLeather.com

Elevate your product line with sustainable, high-performance synthetic leather—engineered for the future.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.