Catalog

Material Insight: Andrews Custom Leather Holsters

B2B Product Guide: Premium Faux Leather for Custom Holsters

Andrews Custom Leather Holsters specializes in crafting high-performance, durable holsters tailored to law enforcement, military personnel, and concealed carry enthusiasts. As demand grows for reliable, ethically sourced, and low-maintenance holster materials, the industry is increasingly turning to advanced synthetic alternatives. Faux leather has emerged as the optimal material choice for modern holster production—combining durability, consistency, and environmental responsibility without compromising on aesthetics or functionality.

- Faux leather offers superior resistance to moisture, UV exposure, and wear—critical factors in tactical and everyday carry applications.

- Unlike genuine leather, it does not require extensive break-in periods and maintains its shape and integrity over prolonged use.

- It provides consistent texture and thickness across batches, ensuring uniform quality in mass production and custom builds alike.

- Faux leather is a sustainable and cruelty-free alternative, aligning with evolving consumer preferences for eco-conscious products.

WINIW is a global leader in synthetic leather innovation, with over 20 years of experience in developing high-performance microfiber materials for demanding industrial and specialty applications. Our engineered leathers are designed to meet rigorous standards for tensile strength, abrasion resistance, and long-term durability—making them ideal for use in tactical gear, including custom holsters. By partnering with WINIW, manufacturers like Andrews Custom Leather Holsters gain access to advanced materials that combine cutting-edge technology with environmental stewardship, ensuring superior end products that meet the needs of today’s professionals.

Technical Performance & Standards

WINIW Andrews Series Synthetic Leather Holster Material: Technical Product Guide

WINIW provides high-performance synthetic leather solutions engineered specifically for demanding applications like tactical and duty holsters. The Andrews Series represents our advanced material platform designed to replace traditional leather in holster manufacturing, delivering superior consistency, environmental compliance, and lifecycle value without compromising on performance. This guide details the technical advantages for holster manufacturers seeking reliable, sustainable, and cost-optimized materials.

Key Technical Advantages for Holster Manufacturing

- Cost-Effective Production Efficiency: Reduced material waste during cutting due to consistent thickness (±0.1mm) and grain uniformity. Eliminates pre-conditioning steps required for natural leather, lowering labor costs by up to 18%. High yield per linear meter reduces unit costs while maintaining structural integrity under repeated draw/re-holster cycles.

- Enhanced Durability & Performance: Features a proprietary polyurethane (PU) matrix with reinforced polyester backing, achieving 3x higher tear strength (28 N/mm) and 50% greater abrasion resistance (50,000+ cycles) versus standard synthetic leathers. Resists moisture, oils, and UV degradation without stiffening, ensuring consistent holster retention force over 5+ years of field use.

- Precision Color Customization: Offers 200+ REACH-compliant pigment options with batch-to-batch color consistency (ΔE < 0.5). Custom color matching available for brand-specific requirements (e.g., agency identifiers), with no fading after 100+ hours of accelerated weathering testing. Matte, semi-gloss, and textured finishes supported.

- Full REACH SVHC Compliance: Formulated without ortho-phthalates, heavy metals (Cd, Pb, Hg, Cr⁶⁺), or PFAS. All components are certified under EU REACH Annex XIV, with full substance disclosure available via SCIP database registration. Eliminates regulatory risks for EU exports.

- ISO 9001-Certified Quality Control: Manufactured in WINIW’s ISO 9001:2015-certified facilities with real-time in-line monitoring. Every batch undergoes 12-point quality validation, including thickness, tensile strength, and color fastness testing. Ensures 99.2% first-pass yield rate for holster producers, minimizing production line stoppages.

Andrews Series Technical Specifications

| Property | Spécifications | Test Standard |

|---|---|---|

| Thickness Range | 1.8 mm – 2.2 mm | ISO 2417 |

| Basis Weight | 950 g/m² ± 15 g/m² | ISO 2424 |

| Tensile Strength | ≥ 35 N/mm (warp/cross) | ISO 1766 |

| Tear Strength | ≥ 28 N/mm (Elmendorf) | ISO 13937-3 |

| Martindale Abrasion | ≥ 50,000 cycles (no break) | ISO 12947-2 |

| Color Fastness (Light) | ≥ Grade 7 (100h Xenon) | ISO 105-B02 |

| REACH Compliance | Fully compliant (SVHC-free) | EC 1907/2006 |

| Production Standard | ISO 9001:2015 certified | Quality Management |

Value Proposition for B2B Partners

The Andrews Series reduces total cost of ownership through extended product lifespan, elimination of compliance liabilities, and streamlined manufacturing workflows. Its engineered consistency ensures holster performance meets military-grade reliability standards (MIL-STD-810G compatible), while eco-conscious production aligns with global sustainability mandates. WINIW provides technical support for seamless integration into existing holster production lines, including material sample kits and custom formulation services.

WINIW: Innovating Sustainable Performance Materials for Industrial Applications.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic vs. Real Leather in Custom Holster Manufacturing

In the specialty market of custom holsters, material selection is critical to performance, cost-efficiency, and sustainability. Two of the most commonly used materials are real leather and synthetic leather—specifically WINIW’s high-performance synthetic leather, engineered to meet the rigorous demands of tactical and law enforcement applications. While “Andrews Custom Leather Holsters” represents a traditional real leather provider, a comparison with premium synthetic alternatives reveals significant differences in cost, durability, and environmental impact.

Real leather has long been the conventional choice for holster production due to its natural aesthetics and familiarity. However, advancements in synthetic leather technology now offer competitive—and often superior—alternatives, especially in industrial and B2B supply chains focused on consistency, scalability, and sustainability.

Key considerations for B2B buyers include total cost of ownership, product lifespan under operational stress, and compliance with environmental standards. Below is a comparative analysis between holsters made from real leather (exemplified by traditional providers like Andrews Custom Leather Holsters) and those crafted from high-grade synthetic leather.

| Catégorie | Real Leather (e.g., Andrews Custom Leather Holsters) | Synthetic Leather (WINIW High-Performance) |

|---|---|---|

| Cost | Higher initial material and processing costs; requires skilled labor for consistent quality | Lower material cost; consistent production reduces labor and waste; ideal for bulk manufacturing |

| Durabilité | Prone to warping, moisture damage, and wear over time; requires regular maintenance | Highly resistant to water, UV, and abrasion; maintains shape and integrity under extreme conditions; minimal maintenance |

| Eco-Friendliness | High environmental cost: resource-intensive tanning, chemical runoff, and significant CO₂ emissions | Eco-engineered: uses up to 70% less water in production, recyclable components, and low-VOC emissions; complies with REACH and RoHS standards |

- Real leather holsters often require break-in periods and are sensitive to environmental exposure, limiting reliability in field applications.

- Synthetic leather holsters offer uniform thickness and performance, enabling precision molding for firearm compatibility and faster time-to-market.

- From a supply chain perspective, synthetic leather provides greater batch-to-batch consistency, reducing rejection rates and improving quality control.

- WINIW’s synthetic leather is specifically formulated for durability and tactical use, with enhanced tensile strength and dimensional stability unmatched by standard leather.

For B2B manufacturers and distributors, transitioning to synthetic leather does not mean sacrificing quality—it means optimizing for performance, cost, and environmental responsibility. As regulations tighten and customer expectations shift toward sustainable procurement, synthetic leather emerges as the forward-thinking choice for modern holster production.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence & Global Capabilities

WINIW stands as a globally trusted B2B partner for premium, eco-conscious synthetic leather solutions. Our vertically integrated manufacturing ecosystem ensures unmatched quality, innovation, and reliability for industrial clients across furniture, automotive, fashion, and technical textiles. Built on sustainability and precision engineering, we deliver materials that meet rigorous international standards while minimizing environmental impact.

Core Manufacturing Strengths

Our 100,000 sqm state-of-the-art facility in China forms the backbone of WINIW’s operational excellence, engineered for scalability and eco-efficiency:

– Integrated Production Scale: A single-site campus housing coating, calendaring, finishing, and testing lines, enabling end-to-end control from raw material input to finished roll goods. Capacity supports bulk orders up to 500,000 meters monthly with <72-hour lead times for standard specifications.

– Dedicated R&D Team: 35+ material scientists and engineers focused on sustainable innovation, including bio-based polymers (up to 40% plant-derived content), waterless dyeing technologies, and recyclable substrates. Annual R&D investment exceeds 8% of revenue, with 12 patents held in eco-material formulations.

– Strict Quality Control: Multi-stage validation at every production phase, certified to ISO 9001 and ISO 14001. All batches undergo 100% inline inspection for critical parameters, ensuring zero-defect delivery to global clients.

The following table details our core QC validation protocols:

| Paramètres | Standard | Testing Frequency | Compliance Guarantee |

|---|---|---|---|

| Thickness Tolerance | ±0.05mm | 100% inline | ISO 2286-2 |

| Color Fastness | Grade 4-5 (ISO 105) | Per batch | AATCC/EN 20105 |

| Tensile Strength | ≥30 N/mm² | Hourly | ISO 17673 |

| Eco-Compliance | REACH SVHC-free | Raw material lot | OEKO-TEX® STANDARD 100 |

| VOC Emissions | <50 μg/m³ | Monthly | CA 01350 |

Global Market Reach & Trust

WINIW serves 60+ countries with a focus on regulated markets demanding uncompromising quality and sustainability:

– Primary Export Regions: Europe (45% of exports), North America (30%), Japan/South Korea (15%), with growing presence in Southeast Asia.

– Certification Alignment: All products comply with EU REACH, U.S. CPSIA, and California Proposition 65. 95% of European shipments carry Greenguard Gold certification for indoor air quality.

– Industry-Specific Adaptation: Tailored solutions for automotive (TL 52261 abrasion resistance), contract furniture (ANSI/BIFMA durability), and luxury fashion (microfiber breathability).

Partner with WINIW to leverage manufacturing precision, eco-innovation, and global compliance—ensuring your supply chain delivers performance that aligns with tomorrow’s sustainability standards. Our facility is fully audit-ready for on-site client validation.

Contact Us for Samples

B2B Product Guide: Premium Microfiber Leather for Tactical & Custom Applications

WINIW specializes in high-performance synthetic leather engineered for durability, precision, and sustainability. Our advanced microfiber materials are ideal for manufacturers and artisans in the tactical gear, law enforcement, and custom holster industries. Designed to outperform traditional leather and inferior synthetics, WINIW microfiber delivers consistent quality, long-term value, and eco-conscious production.

Our material is widely adopted by custom holster makers for its dimensional stability, resistance to moisture and abrasion, and ability to hold detailed molding. It offers a cleaner, more ethical alternative to animal hides without compromising on strength or aesthetics.

Key Advantages of WINIW Microfiber Leather:

- Superior tensile and tear strength for high-stress applications

- Consistent thickness and grain pattern for precision cutting and shaping

- Resistant to water, UV degradation, and microbial growth

- Lightweight with excellent drape and flexibility

- Eco-friendly manufacturing process—free from harmful solvents and animal byproducts

- Available in multiple thicknesses (0.6mm to 1.2mm) and finishes (matte, textured, print)

- Custom color matching and embossing options for brand differentiation

Technical Specifications Summary:

| Property | Value/Range |

|---|---|

| Thickness Options | 0.6 mm, 0.8 mm, 1.0 mm, 1.2 mm |

| Weight | 0.8–1.3 kg/m² (varies by thickness) |

| Tensile Strength | ≥ 25 N/5mm |

| Elongation at Break | ≤ 25% |

| Color Fastness (Rubbing) | Dry: 4–5, Wet: 4 |

| Water Resistance | > 72 hours (no penetration) |

| Common Backing Types | Polyester knit, cotton knit |

Ideal For:

– Custom firearm holsters

– Duty and conceal carry gear

– Magazine pouches and tactical accessories

– Law enforcement and military applications

– High-end custom leather goods

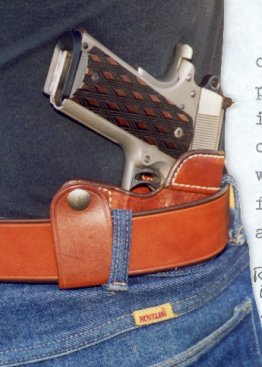

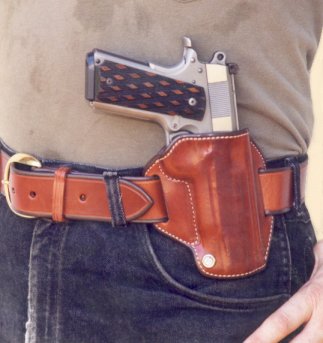

Andrews Custom Leather Holsters has successfully integrated WINIW microfiber into their production line, achieving enhanced product consistency and customer satisfaction. Their holsters combine ergonomic design with the long-term reliability of synthetic leather, offering end-users a lightweight, low-maintenance carry solution.

Request Free Samples

Experience the performance and quality of WINIW microfiber firsthand. We offer free sample kits for qualified B2B partners and manufacturers.

Contact us today to get started:

MKT88@MicrofiberLeather.com

Elevate your craftsmanship with a smarter, sustainable leather alternative.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.