Introduction: Navigating the Global Market for alcantara fabric roll

In an increasingly competitive global market, sourcing high-quality Alcantara fabric rolls poses significant challenges for B2B buyers. This versatile material, known for its luxury appeal and superior performance in automotive and upholstery applications, is sought after across diverse industries. However, navigating the complexities of supplier selection, pricing, and material specifications can be daunting, especially for international buyers from regions such as Africa, South America, the Middle East, and Europe.

This comprehensive guide aims to demystify the Alcantara fabric roll market by providing an in-depth exploration of its various types, including unbacked panels, foam-backed options, and specialized outdoor fabrics. Each type’s specific applications will be discussed, offering insights into how best to leverage Alcantara’s unique properties to meet your business needs. Additionally, we will cover essential criteria for vetting suppliers to ensure quality and reliability, as well as cost considerations to help you make informed purchasing decisions.

By empowering B2B buyers with actionable insights and expert knowledge, this guide serves as a vital resource for those looking to enhance their product offerings with Alcantara fabric. Whether you are in the automotive sector, luxury goods, or interior design, understanding the nuances of Alcantara will facilitate strategic sourcing and ultimately drive your business success in the global marketplace.

Table Of Contents

- Top 7 Alcantara Fabric Roll Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alcantara fabric roll

- Understanding alcantara fabric roll Types and Variations

- Key Industrial Applications of alcantara fabric roll

- 3 Common User Pain Points for ‘alcantara fabric roll’ & Their Solutions

- Strategic Material Selection Guide for alcantara fabric roll

- In-depth Look: Manufacturing Processes and Quality Assurance for alcantara fabric roll

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara fabric roll’

- Comprehensive Cost and Pricing Analysis for alcantara fabric roll Sourcing

- Alternatives Analysis: Comparing alcantara fabric roll With Other Solutions

- Essential Technical Properties and Trade Terminology for alcantara fabric roll

- Navigating Market Dynamics and Sourcing Trends in the alcantara fabric roll Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alcantara fabric roll

- Strategic Sourcing Conclusion and Outlook for alcantara fabric roll

- Important Disclaimer & Terms of Use

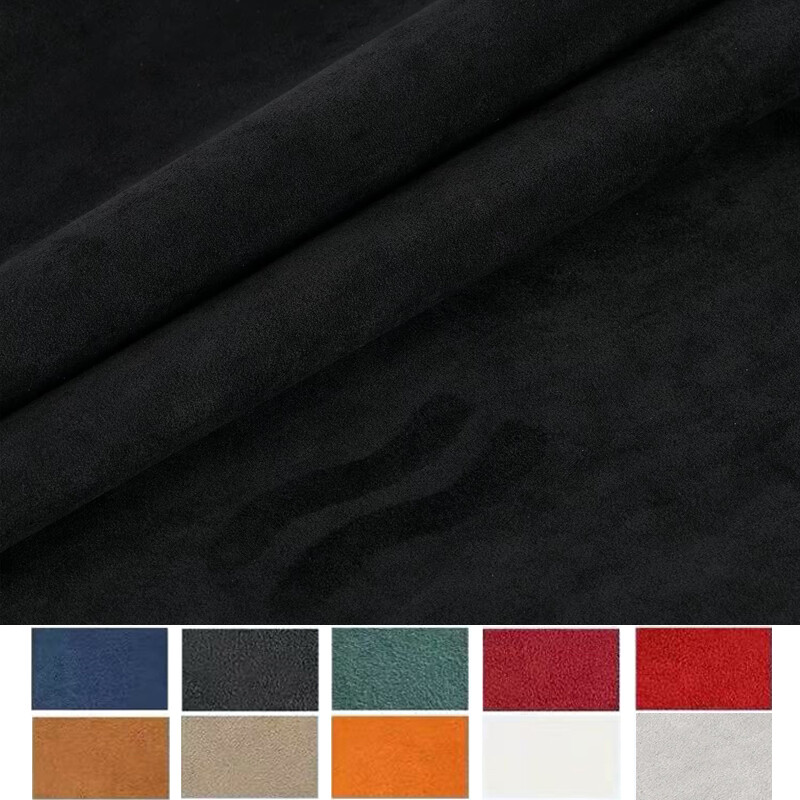

Understanding alcantara fabric roll Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alcantara Panel | Unbacked, lightweight, high stretch | Vehicle headliners, door panels, dashboards | Pros: Flexible, easy to work with; Cons: Less durable than backed options. |

| Alcantara Cover | Backed with a laminated scrim, high durability | Automotive seats, high-wear surfaces | Pros: Stronger, minimizes stretch; Cons: Heavier and less flexible. |

| Alcantara Soft | Foam-backed for added softness and cushioning | Headliners, luxury interiors | Pros: Comfortable, reduces noise; Cons: May not be as durable under heavy use. |

| Alcantara EXO | Water-resistant and UV-protected for outdoor applications | Marine upholstery, outdoor furniture | Pros: High durability against elements; Cons: Limited color options available. |

| Alcantara Multilayer | Soft lamination for added thickness, one-way stretch | Steering wheels, specialized automotive seats | Pros: Enhanced grip, tailored for performance; Cons: More expensive than standard options. |

What are the Characteristics of Alcantara Panel Fabric?

Alcantara Panel is an unbacked fabric known for its lightweight and high stretch capabilities. This makes it particularly suitable for automotive applications where flexibility is crucial, such as vehicle headliners and door panels. B2B buyers should consider its ease of use and ability to conform to complex shapes, but keep in mind that it may not offer the same durability as backed variations, making it less ideal for high-wear surfaces.

How Does Alcantara Cover Stand Out for Automotive Applications?

Alcantara Cover features a laminated backing that enhances its durability and strength, making it the preferred choice for automotive seats and other high-wear surfaces. Its robust construction minimizes stretch, ensuring that it maintains its shape and appearance over time. B2B buyers should focus on its longevity and performance in demanding environments, although its heavier weight might limit applications where flexibility is a priority.

Why Choose Alcantara Soft for Luxury Interiors?

Alcantara Soft includes a layer of foam backing, providing a plush feel and additional sound insulation. This fabric is commonly used in luxury automotive interiors, particularly for headliners where comfort and aesthetics are paramount. For B2B buyers, the softness enhances the overall luxury experience, but it’s essential to consider its potential limitations in terms of durability under extreme conditions.

What Makes Alcantara EXO Ideal for Outdoor Use?

Alcantara EXO is designed specifically for outdoor applications, featuring water resistance and UV protection. This makes it an excellent choice for marine upholstery and outdoor furniture, where exposure to the elements can be a concern. B2B buyers should appreciate its resilience and versatility, although they may find a more limited selection of colors compared to other Alcantara types.

How Does Alcantara Multilayer Enhance Performance?

Alcantara Multilayer incorporates a soft lamination that adds thickness and is designed for applications requiring one-way stretch, such as steering wheels and specialized automotive seats. This fabric offers enhanced grip, making it suitable for performance vehicles. B2B buyers should weigh its benefits in terms of functionality against its higher cost, as it caters to niche applications that demand superior performance.

Key Industrial Applications of alcantara fabric roll

| Industry/Sector | Specific Application of alcantara fabric roll | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for luxury vehicle interiors | Enhances aesthetics and luxury feel, improves grip and comfort | Ensure compliance with automotive standards and certifications; verify color and texture consistency |

| Aviation | Aircraft interiors and seating | Lightweight, durable, and resistant to wear; provides a premium passenger experience | Consider fire safety ratings and certifications for materials; evaluate supply chain reliability for timely delivery |

| Furniture & Décor | Upholstery for high-end furniture | Offers a luxurious look and feel; easy to clean and maintain | Assess fabric durability and maintenance requirements; confirm availability of desired colors and textures |

| Fashion & Accessories | High-fashion clothing and accessories | Provides unique textures and styles, appealing to luxury markets | Look for custom design capabilities; ensure sustainable sourcing and ethical production practices |

| Outdoor Equipment | Upholstery for boats and outdoor furniture | Weather-resistant and durable; maintains aesthetics in harsh conditions | Verify UV and water resistance; consider sourcing from suppliers with outdoor-specific product lines |

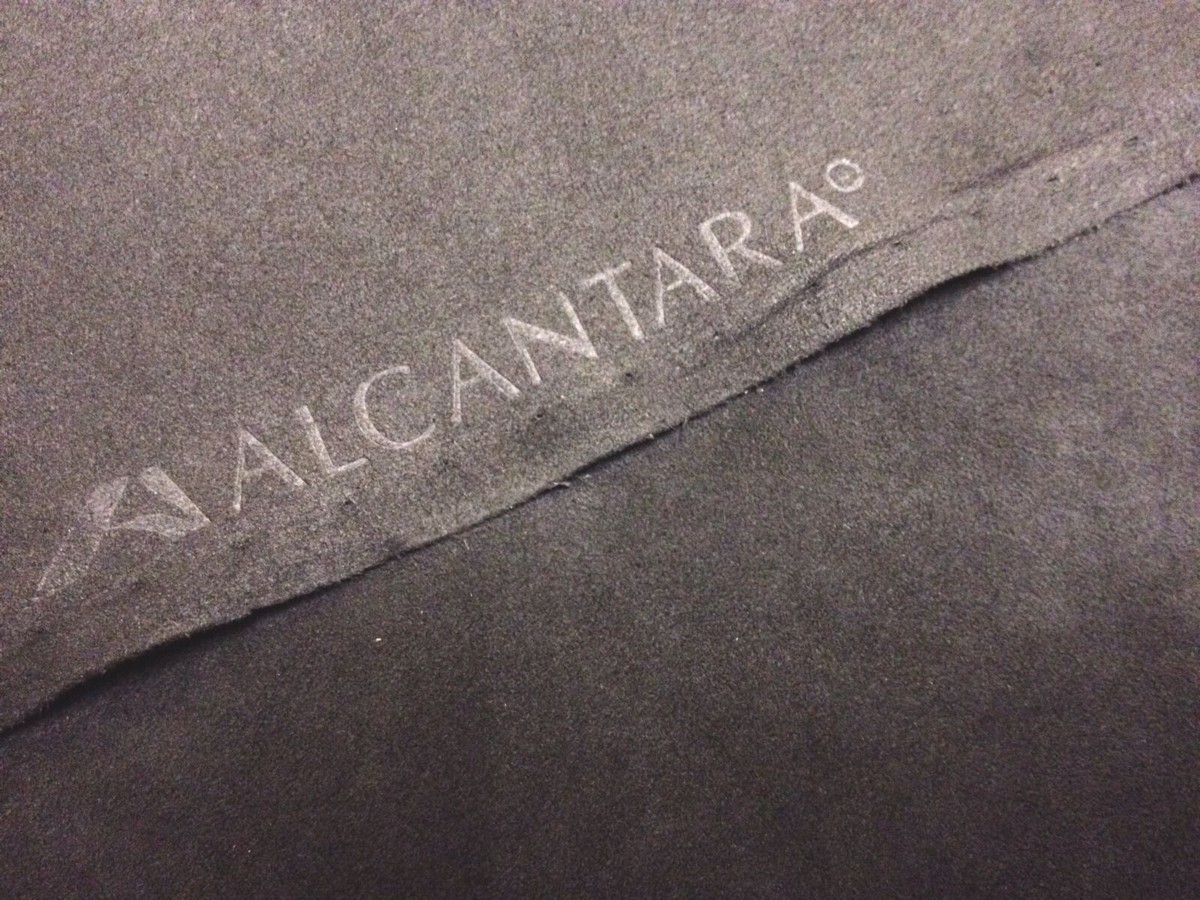

How is Alcantara Fabric Roll Used in the Automotive Industry?

In the automotive sector, Alcantara fabric roll is extensively used for upholstery in luxury vehicle interiors, including seats, dashboards, and door panels. Its suede-like texture enhances the aesthetic appeal while providing superior grip and durability, essential for high-performance vehicles. International buyers, particularly from regions like the Middle East and Europe, must ensure that the material meets stringent automotive standards and certifications, as well as color and texture consistency, to maintain brand integrity.

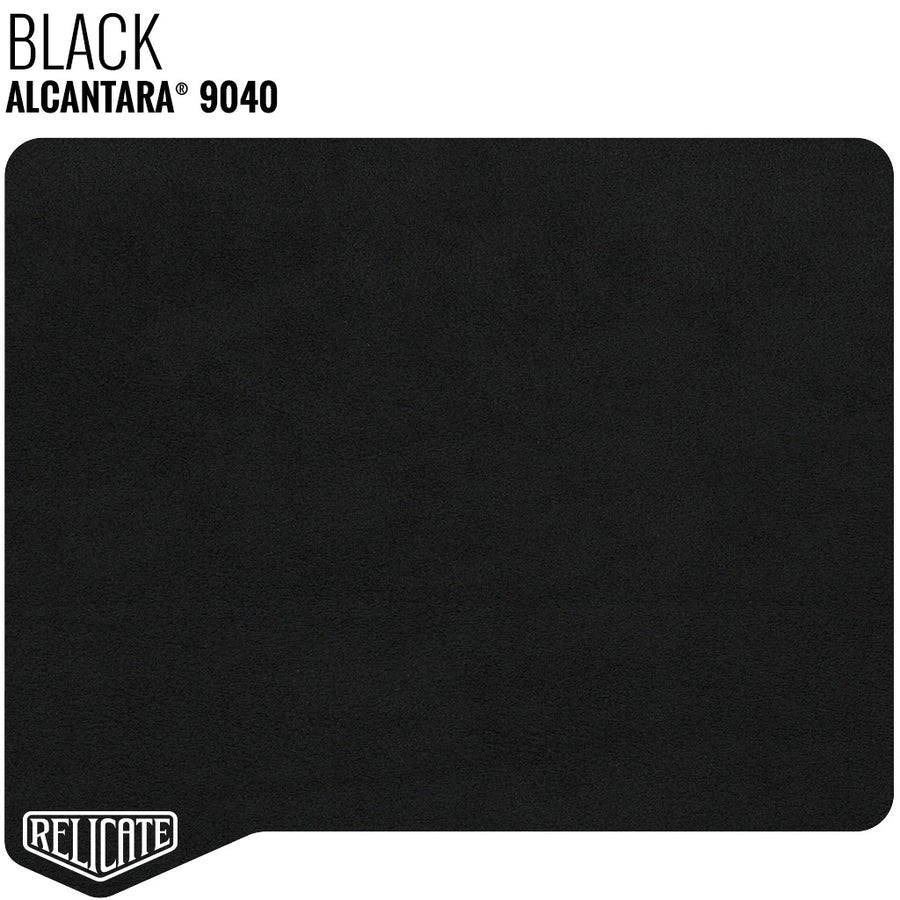

Illustrative image related to alcantara fabric roll

What Role Does Alcantara Play in Aviation Interiors?

Alcantara is increasingly utilized in aviation for aircraft interiors and seating. Its lightweight nature contributes to fuel efficiency, while its durability ensures it withstands the rigors of frequent use. The fabric’s luxurious feel enhances the passenger experience, making it a preferred choice for premium airlines. Buyers in this sector should prioritize sourcing materials with fire safety ratings and certifications, as well as reliability in supply chains to meet production schedules.

How is Alcantara Fabric Beneficial in Furniture and Décor?

In the furniture and décor industry, Alcantara fabric roll is favored for high-end upholstery applications. Its luxurious appearance combined with ease of cleaning makes it ideal for upscale furniture pieces, enhancing both aesthetics and functionality. For B2B buyers, it is crucial to assess the fabric’s durability, maintenance requirements, and the availability of specific colors and textures to meet design specifications.

In What Ways Does Alcantara Enhance Fashion and Accessories?

Alcantara fabric roll is also popular in the fashion industry for creating high-end clothing and accessories. Its unique textures and styles appeal to luxury markets, allowing designers to innovate while maintaining a sustainable approach. When sourcing for fashion applications, buyers should look for suppliers offering custom design capabilities and ensure that the materials are sourced ethically to align with modern consumer values.

How is Alcantara Fabric Used in Outdoor Equipment?

For outdoor equipment, Alcantara is a top choice for upholstering boats and outdoor furniture due to its weather-resistant properties. The fabric’s durability ensures it can maintain its aesthetic appeal even in harsh conditions, making it suitable for various outdoor applications. Buyers should verify the fabric’s UV and water resistance and consider sourcing from suppliers that specialize in outdoor-specific product lines to ensure performance and longevity.

3 Common User Pain Points for ‘alcantara fabric roll’ & Their Solutions

Scenario 1: Difficulty in Color Matching Alcantara Fabric for Custom Projects

The Problem: B2B buyers often face challenges in achieving the perfect color match for Alcantara fabric rolls, especially when working on custom projects for high-end automotive interiors or luxury furnishings. Variations in screen displays and lighting conditions can lead to discrepancies between the ordered samples and the actual material received. This misalignment can cause delays in production schedules and dissatisfaction from clients who expect a specific aesthetic.

The Solution: To mitigate this issue, buyers should prioritize sourcing physical samples before committing to larger orders. Utilizing tools like the EZMatch Swatch Scanner can provide accurate color matching by allowing buyers to compare their project colors directly with Alcantara samples. Additionally, it’s advisable to establish a relationship with suppliers who offer consistent and reliable color matching services, ensuring that all orders reflect the desired hues. When ordering, consider requesting a range of samples that reflect different lighting conditions, as this will help visualize how the fabric will look in various environments, ultimately enhancing client satisfaction and minimizing costly reorders.

Scenario 2: Concerns Over Durability and Maintenance of Alcantara Fabric Rolls

The Problem: Durability is a primary concern for B2B buyers, particularly in industries like automotive or furniture, where wear and tear can significantly affect the product’s lifespan. Buyers may worry that Alcantara fabric, despite its luxurious appearance, may not hold up under the demands of daily use or may require excessive maintenance, leading to additional costs and operational challenges.

The Solution: To address these concerns, buyers should educate themselves about the various types of Alcantara available and their respective maintenance requirements. For instance, Alcantara Soft, which features a foam backing, is designed for applications that require durability without sacrificing comfort. Understanding the specific characteristics of each type—such as water resistance in the EXO range or the ease of cleaning Alcantara Cover—can guide buyers in selecting the right fabric for their needs. Furthermore, suppliers often provide care instructions; leveraging these guidelines can help maintain the fabric’s integrity over time. Regular cleaning with appropriate products will enhance longevity and reduce replacement costs, making Alcantara a cost-effective choice in the long run.

Scenario 3: Sizing and Roll Length Issues When Ordering Alcantara Fabric

The Problem: Sizing discrepancies and confusion over roll lengths can pose significant challenges for B2B buyers, particularly when dealing with large-scale projects. Buyers may find themselves in situations where the fabric roll sizes do not align with their production needs, leading to wasted material, increased costs, and potential project delays.

Illustrative image related to alcantara fabric roll

The Solution: To overcome sizing issues, it is crucial for buyers to accurately assess their project requirements before placing an order. This includes calculating the total yardage needed and understanding the standard roll sizes offered by suppliers. Engaging directly with suppliers to clarify the specifics of roll lengths—typically sold in standard increments—can prevent miscalculations. Additionally, buyers should inquire about the possibility of ordering custom lengths or smaller increments if necessary. By establishing clear communication with suppliers regarding sizing needs and exploring flexible ordering options, buyers can ensure that they receive the right amount of Alcantara fabric, reducing waste and enhancing project efficiency. Implementing a systematic approach to inventory management will also allow for better forecasting and ordering practices in the future.

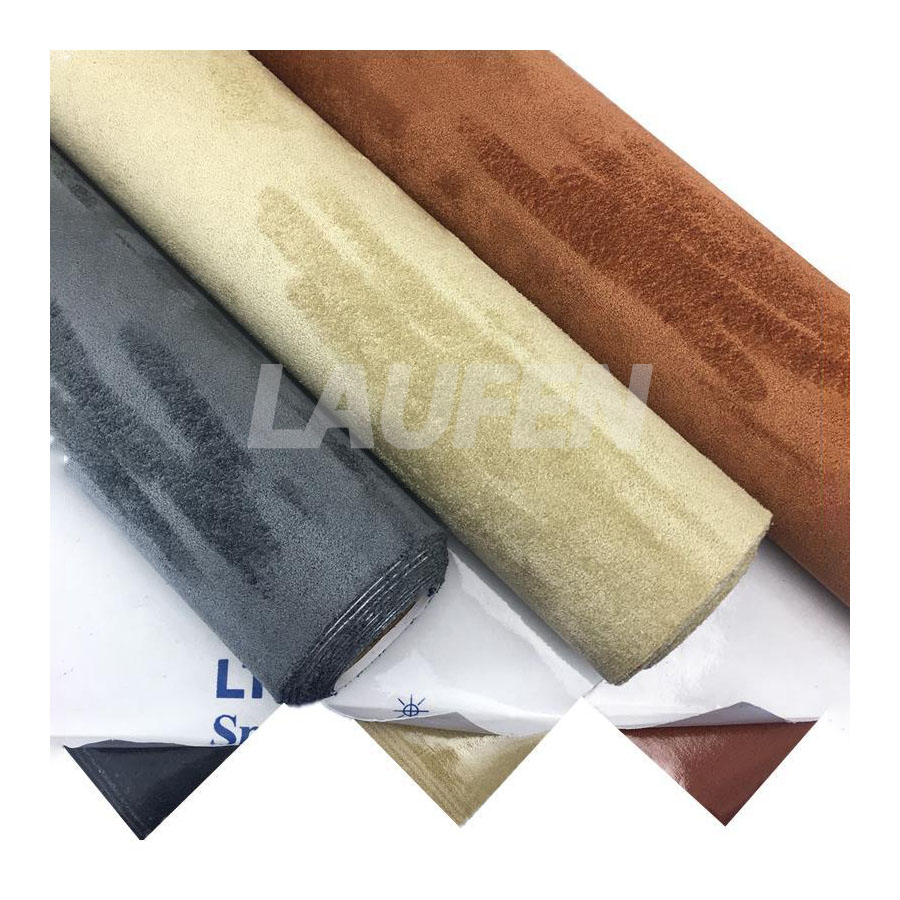

Strategic Material Selection Guide for alcantara fabric roll

What Are the Key Materials Used in Alcantara Fabric Rolls?

When selecting Alcantara fabric rolls for various applications, understanding the different materials and their properties is crucial for B2B buyers. Here, we analyze four common materials used in Alcantara fabric rolls, focusing on their performance, advantages, limitations, and specific considerations for international buyers.

What Are the Properties of Alcantara Soft Foam-Backed Fabric?

Alcantara Soft is composed of 68% Polyester and 32% Polyurethane, featuring a foam backing that enhances comfort and usability. This material is particularly effective in applications requiring a soft touch, such as automotive headliners and seating. The foam backing provides additional cushioning, making it suitable for high-contact areas.

Illustrative image related to alcantara fabric roll

Pros: The fabric is easy to clean, offers excellent grip, and maintains a cool touch, enhancing user comfort. Its durability makes it ideal for high-wear environments.

Cons: The foam backing may limit its use in applications requiring extreme flexibility or where weight is a critical factor. Additionally, the cost may be higher than traditional fabrics.

For international buyers, especially those in regions with high humidity or temperature fluctuations, Alcantara Soft’s properties can help mitigate issues related to moisture retention and heat absorption.

Illustrative image related to alcantara fabric roll

How Does Alcantara Cover Compare to Other Materials?

Alcantara Cover is a backed fabric that combines a laminated 65/35 Poly Cotton scrim with Alcantara, making it robust for applications like seating and automotive interiors.

Pros: This material offers superior strength and durability, making it less prone to tearing or stretching. It is specifically designed for high-stress applications, providing a long-lasting solution.

Cons: The added backing can make it less breathable compared to unbacked alternatives, which may not be suitable for all applications. Additionally, it may require more complex manufacturing processes, impacting production timelines.

International buyers should consider compliance with local automotive standards, as Alcantara Cover is often used in luxury vehicles, which may have specific requirements based on regional regulations.

Illustrative image related to alcantara fabric roll

What Makes Alcantara Multilayer Suitable for Automotive Applications?

Alcantara Multilayer features a soft lamination that provides added thickness and is primarily used for steering wheels and automotive seating.

Pros: Its unique construction allows for stretching in one direction, making it ideal for applications requiring flexibility and resilience. The multilayer design enhances durability while maintaining a premium aesthetic.

Cons: The complexity of manufacturing multilayer fabrics can lead to higher costs and longer lead times. It may also be less suitable for applications that require uniform thickness.

For international B2B buyers, especially in automotive markets, understanding the specific performance metrics and certifications (such as fire ratings) is essential for compliance with safety standards.

Why Choose Alcantara EXO for Outdoor Applications?

Alcantara EXO is specifically designed for outdoor use, featuring additional water repellency and UV protection. This makes it suitable for a variety of applications, including marine upholstery and outdoor furniture.

Pros: The EXO range excels in environments exposed to harsh weather conditions, providing longevity and maintaining aesthetic appeal. Its water-resistant properties make it easy to clean and maintain.

Cons: While it offers excellent outdoor performance, it may not be as soft or luxurious as other Alcantara options, which could be a consideration for high-end applications.

International buyers in regions with extreme weather conditions should prioritize materials like Alcantara EXO to ensure product longevity and customer satisfaction.

Summary Table of Alcantara Fabric Roll Materials

| Matériau | Typical Use Case for alcantara fabric roll | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alcantara Soft | Automotive headliners, seating | Easy to clean, durable, cool to touch | Limited flexibility due to foam backing | Medium |

| Alcantara Cover | Automotive seating, interior trim | Superior strength and durability | Less breathable, complex manufacturing | Haut |

| Alcantara Multilayer | Automotive steering wheels, seating | Flexible, premium aesthetic | Higher cost, longer lead times | Haut |

| Alcantara EXO | Marine upholstery, outdoor furniture | Excellent weather resistance | Less luxurious feel compared to others | Medium |

This guide aims to equip international B2B buyers with the necessary insights to make informed decisions regarding the selection of Alcantara fabric rolls, ensuring compatibility with their specific applications and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for alcantara fabric roll

What Are the Key Stages in the Manufacturing Process of Alcantara Fabric Rolls?

The manufacturing process of Alcantara fabric rolls involves several critical stages that ensure both quality and performance. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: Sourcing and Composition

The first step in the manufacturing process is sourcing high-quality raw materials. Alcantara is primarily composed of 68% polyester and 32% polyurethane, which are carefully selected for their durability and aesthetic qualities. These materials undergo rigorous testing to ensure they meet the required specifications before moving on to the next stage. This phase is crucial as the quality of the raw materials directly impacts the final product.

Forming: Creating the Alcantara Fabric

In the forming stage, the prepared materials are processed to create the Alcantara fabric. This involves weaving or knitting the polyester and polyurethane fibers to form a soft, suede-like texture. Advanced techniques such as non-woven fabric technology may also be employed to enhance the fabric’s characteristics, such as breathability and moisture resistance. The fabric is then coated with a foam backing if required, particularly for specific applications like automotive interiors where added softness and comfort are essential.

Assembly: Cutting and Shaping

Once the fabric is formed, it is cut and shaped according to the specifications of the end product. This assembly stage may involve various techniques, including die-cutting for precision shapes and sizes. Depending on the intended application—whether for automotive seats, headliners, or luxury upholstery—different grades and finishes of Alcantara may be utilized. This stage is crucial for ensuring that the fabric meets the unique demands of various industries.

Finishing: Quality Enhancement and Treatment

The finishing stage is where Alcantara fabric is treated to enhance its properties. This can include dyeing to achieve the desired color and applying protective coatings to improve durability and stain resistance. The finishing process is vital for creating a product that not only looks appealing but also performs well in various environments, including automotive and furniture applications.

Illustrative image related to alcantara fabric roll

How Is Quality Assurance Implemented in Alcantara Fabric Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for Alcantara fabric rolls. It encompasses various international standards and industry-specific protocols to ensure the final product meets customer expectations.

What International Standards Guide Alcantara Fabric Quality?

The manufacturing of Alcantara fabric is guided by several international quality standards, including ISO 9001, which focuses on quality management systems. Compliance with ISO standards ensures that manufacturers adopt a systematic approach to quality management, enhancing customer satisfaction through effective processes. Additionally, industry-specific certifications such as CE (Conformité Européenne) indicate compliance with European health, safety, and environmental protection standards, making the product suitable for the European market.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically integrated throughout the manufacturing process of Alcantara fabric. These checkpoints include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon receipt to ensure they meet predetermined quality standards. Any subpar materials are rejected, preventing defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing stages, periodic checks are conducted to monitor the quality of the fabric as it is formed and assembled. This includes checking for consistency in texture, color, and overall appearance.

-

Final Quality Control (FQC): Once the fabric is completed, a final inspection is performed to ensure it meets all specifications and standards before being packaged and shipped. This may include physical tests for durability, colorfastness, and resistance to wear.

How Can B2B Buyers Verify the Quality Assurance Processes of Their Suppliers?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying the quality assurance processes of suppliers is crucial. Here are several methods to ensure that suppliers maintain high-quality standards:

Conducting Audits: What Should Buyers Look For?

Buyers should consider conducting regular audits of their suppliers’ manufacturing facilities. These audits should assess compliance with international quality standards, inspection procedures, and overall manufacturing capabilities. A comprehensive audit can reveal the supplier’s commitment to quality and adherence to industry standards.

Requesting Quality Reports: What Information Should Be Included?

Requesting detailed quality assurance reports from suppliers can provide valuable insights into their QC processes. These reports should include data on testing methods, results from IQC, IPQC, and FQC stages, and any corrective actions taken for defects. This transparency is essential for establishing trust and ensuring product reliability.

Engaging Third-Party Inspection Services: How Can They Add Value?

Third-party inspection services can be invaluable for B2B buyers looking to verify supplier quality. These independent organizations can conduct inspections and testing on behalf of the buyer, providing an unbiased assessment of the supplier’s quality assurance practices. This can be particularly useful for buyers in regions with less stringent regulatory oversight.

What Are the Unique Quality Assurance Considerations for International B2B Buyers?

International B2B buyers must navigate various nuances in quality assurance when sourcing Alcantara fabric rolls. Factors such as local regulations, cultural differences in quality expectations, and varying standards can complicate the sourcing process. Buyers should be aware of the following:

Illustrative image related to alcantara fabric roll

-

Regional Compliance: Different regions may have specific regulations that affect the quality and safety of fabric products. It is essential for buyers to understand and comply with these regulations to avoid legal issues and ensure product acceptance in their markets.

-

Communication and Language Barriers: Clear communication is vital for establishing quality expectations. Buyers should ensure that suppliers understand their specific requirements, which may involve translating quality standards and specifications.

-

Supply Chain Transparency: Ensuring transparency in the supply chain can help mitigate risks associated with quality. Buyers should seek suppliers who are willing to share information about their sourcing, manufacturing processes, and quality assurance practices.

By understanding these manufacturing processes and quality assurance protocols, international B2B buyers can make informed decisions when sourcing Alcantara fabric rolls, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara fabric roll’

When it comes to procuring Alcantara fabric rolls for various applications, a systematic approach is essential to ensure you secure the best quality and value. This guide outlines crucial steps for B2B buyers looking to make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the foundation of a successful procurement process. Define the type of Alcantara fabric you need, such as foam-backed, unbacked, or multilayer. Consider factors like thickness, width (typically around 54-56 inches), and intended use—be it automotive interiors, upholstery, or fashion applications.

- Key Considerations:

- What is the desired texture and finish?

- Will the fabric be subjected to high wear and tear?

Step 2: Research Potential Suppliers

Identifying reputable suppliers is critical. Look for manufacturers or distributors with a proven track record in supplying Alcantara fabric. Seek recommendations from industry peers and consult online reviews to gauge supplier reliability.

- What to Look For:

- Supplier certifications (e.g., quality standards).

- Geographic proximity to reduce shipping times and costs.

Step 3: Evaluate Product Quality

Quality assurance is paramount when sourcing Alcantara fabric. Request physical samples to assess color, texture, and durability. Be wary of suppliers who provide only digital images, as color discrepancies can occur between monitors and actual materials.

- Important Actions:

- Compare samples from different suppliers.

- Inquire about the fabric’s care instructions and lifespan.

Step 4: Check Compliance and Certifications

Ensure that the Alcantara fabric meets relevant industry standards, especially if used in regulated sectors like automotive or aerospace. Verify that the fabric is made in compliance with environmental and safety regulations, such as fire resistance.

Illustrative image related to alcantara fabric roll

- Compliance Aspects to Consider:

- Certifications for fire ratings (FAR 25.853 for aviation).

- Environmental sustainability certifications.

Step 5: Negotiate Terms and Pricing

Once you’ve identified potential suppliers, it’s time to discuss pricing and terms. Understand the pricing structure, including bulk discounts and shipping costs. Don’t hesitate to negotiate for better terms, especially if you plan to make repeat orders.

- Negotiation Tips:

- Ask about minimum order quantities and lead times.

- Clarify return policies for defective materials.

Step 6: Finalize Your Order

Before placing a significant order, ensure that all details are confirmed in writing. This includes pricing, delivery timelines, and payment terms. A clear purchase order reduces the risk of misunderstandings and ensures accountability.

- Final Checks:

- Review the order for accuracy.

- Confirm delivery timelines and tracking methods.

Step 7: Establish a Relationship for Future Orders

Building a long-term relationship with your supplier can yield benefits such as priority service and better pricing in the future. Keep communication channels open for feedback and potential improvements.

- Long-term Relationship Strategies:

- Schedule regular check-ins to discuss future needs.

- Share feedback on product performance to enhance collaboration.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing Alcantara fabric rolls, ensuring they make informed decisions that align with their business needs.

Illustrative image related to alcantara fabric roll

Comprehensive Cost and Pricing Analysis for alcantara fabric roll Sourcing

What Are the Key Cost Components in Alcantara Fabric Roll Sourcing?

When sourcing Alcantara fabric rolls, understanding the cost structure is essential for B2B buyers. The primary components influencing the total cost include:

-

Materials: Alcantara is a composite material made primarily of polyester and polyurethane. The raw material costs can fluctuate based on market demand and availability. High-quality Alcantara typically commands higher prices due to its durability and aesthetic appeal.

-

Labor: The production of Alcantara involves skilled labor for weaving, dyeing, and finishing processes. Labor costs can vary significantly depending on the region, with European manufacturers generally facing higher labor costs than those in Asia or South America.

-

Manufacturing Overhead: This includes the costs associated with the facility operations where Alcantara is produced, including utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help lower these overhead costs.

-

Tooling: Custom tooling for specific designs or applications can add to the upfront costs. However, investing in quality tooling may lead to better long-term cost efficiencies.

-

Quality Control (QC): Ensuring that the fabric meets industry standards and customer specifications involves QC measures, which add to the overall cost. Rigorous testing and certification processes may be necessary, especially for applications in luxury automotive interiors.

-

Logistics: Shipping costs can be significant, especially when sourcing Alcantara from Italy or other regions. Factors like shipping distance, mode of transport, and customs duties must be factored into the total cost.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on competition, market demand, and the buyer’s negotiation capabilities.

What Factors Influence Pricing for Alcantara Fabric Rolls?

Several elements impact the pricing structure for Alcantara fabric rolls:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts. Buyers should consider their needs and negotiate for better pricing based on volume.

-

Specifications and Customization: Custom colors or finishes may incur additional costs. Standardized products usually offer better pricing due to lower production complexity.

-

Quality and Certifications: Alcantara fabric used in luxury applications may need certifications for fire resistance or environmental sustainability, which can increase costs.

-

Supplier Factors: Relationships with suppliers can lead to better pricing. Established suppliers may offer more competitive rates due to economies of scale.

-

Incoterms: Understanding shipping terms can significantly affect total costs. Buyers should clarify responsibilities for shipping, customs duties, and insurance.

How Can Buyers Optimize Cost-Efficiency in Sourcing Alcantara Fabric Rolls?

To ensure cost efficiency when sourcing Alcantara fabric rolls, buyers should consider the following strategies:

-

Negotiate Effectively: Leverage volume discounts and long-term contracts to negotiate favorable terms. Building a strong relationship with suppliers can lead to better pricing and service.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the longevity, maintenance, and potential waste associated with the fabric. Higher-quality Alcantara may have a higher upfront cost but can result in savings over time due to reduced replacement and maintenance needs.

-

Understand Pricing Nuances for International Transactions: When sourcing from regions like Europe, Africa, or South America, be aware of currency fluctuations, trade tariffs, and regional market dynamics. This knowledge can influence negotiation strategies and overall budgeting.

-

Request Samples and Test Quality: Before making large purchases, request samples to assess the quality and ensure it meets project specifications. This can prevent costly mistakes in the long run.

Disclaimer for Indicative Prices

While indicative prices for Alcantara fabric rolls generally range from $1.99 to $135.00 per yard depending on specifications, these figures can vary based on numerous factors including supplier, order volume, and market conditions. Always confirm current prices directly with suppliers for the most accurate and up-to-date information.

Illustrative image related to alcantara fabric roll

Alternatives Analysis: Comparing alcantara fabric roll With Other Solutions

Exploring Viable Alternatives to Alcantara Fabric Roll

In the competitive landscape of upholstery and automotive interiors, Alcantara fabric roll stands out for its blend of aesthetics, performance, and sustainability. However, buyers may also consider alternative materials that could meet specific project requirements or budget constraints. This analysis compares Alcantara fabric roll with two notable alternatives: synthetic leather and natural leather, examining performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Alcantara Fabric Roll | Synthetic Leather | Natural Leather |

|---|---|---|---|

| Performance | High durability, soft touch, excellent grip, reduces glare | Good durability, less breathable, varied grip | Superior durability, breathability, and luxurious feel |

| Cost | Moderate ($1.99 – $4.99 per yard) | Lower ($5 – $15 per yard) | Higher ($20 – $100+ per hide) |

| Ease of Implementation | Requires specific sewing techniques; easy to cut and sew | Simple to handle; can be glued or sewn easily | Requires skilled labor for cutting and stitching |

| Maintenance | Easy to clean; stain-resistant; machine washable | Varies by quality; generally wipeable | Requires conditioning and special cleaners |

| Best Use Case | Automotive interiors, luxury items, fashion accessories | Budget-conscious projects, furniture, casual wear | High-end furniture, luxury automotive, bespoke items |

Detailed Breakdown of Alternatives

Synthetic Leather

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is a popular alternative due to its affordability and ease of maintenance. It offers a reasonable level of durability and is often designed to mimic the look and feel of real leather. However, it generally lacks the breathability and luxurious texture that Alcantara provides. Synthetic leather is ideal for budget-conscious projects where a leather-like appearance is desired without the associated costs.

Natural Leather

Natural leather is renowned for its durability, breathability, and classic aesthetic appeal. It ages well, developing a unique patina over time, which adds character to products. However, natural leather can be expensive and requires regular maintenance to preserve its quality. Unlike Alcantara, which is easy to clean, natural leather is susceptible to stains and requires specific care products. This material is best suited for high-end applications where luxury and longevity are paramount, such as bespoke furniture and premium automotive interiors.

Conclusion: How to Choose the Right Solution

When selecting between Alcantara fabric roll and its alternatives, B2B buyers should assess their specific needs based on performance, budget, and application. Alcantara is an excellent choice for projects requiring a balance of luxury and functionality, particularly in automotive and fashion industries. If cost is a primary concern, synthetic leather may suffice for less demanding applications. Conversely, for projects where luxury and durability are non-negotiable, investing in natural leather could be the best option. Ultimately, understanding the unique characteristics and benefits of each material will enable buyers to make informed decisions that align with their business objectives.

Essential Technical Properties and Trade Terminology for alcantara fabric roll

What Are the Key Technical Properties of Alcantara Fabric Rolls?

Understanding the essential technical properties of Alcantara fabric is crucial for B2B buyers, especially when sourcing for automotive, interior design, or fashion applications. Here are some critical specifications to consider:

-

Material Composition

Alcantara is primarily composed of 68% polyester and 32% polyurethane. This unique blend gives it the suede-like texture while ensuring durability and ease of maintenance. For buyers, knowing the material composition helps in assessing the fabric’s performance characteristics, such as breathability and resistance to wear, which are vital for high-traffic applications. -

Roll Width and Length

Typical Alcantara fabric rolls have a width of 54 to 56 inches and can be purchased in various lengths, often up to 55 yards. The standardization of roll size is important for manufacturers and designers, as it allows for efficient material planning and minimizes waste during production. Understanding roll dimensions aids in calculating material needs for specific projects. -

Thickness

Alcantara fabric thickness generally ranges from 1.0 mm to 3.0 mm, depending on the type (e.g., unbacked, foam-backed). Thickness affects the fabric’s application; thicker materials are often preferred for areas requiring more cushioning, such as seating, while thinner options are suitable for detailed upholstery. Buyers must consider thickness relative to their specific application to ensure optimal performance. -

Durability Ratings

Alcantara fabrics are known for their high durability and resistance to tearing and abrasion. Many variants are tested for performance against standards like Martindale abrasion tests, which measure fabric wear over time. For B2B buyers, durability ratings are critical in selecting materials that can withstand rigorous use without compromising aesthetics. -

Care and Maintenance Requirements

Alcantara is relatively easy to clean, often requiring only a damp cloth for maintenance. However, specific care instructions can vary by product type. Understanding these requirements ensures that buyers can maintain the fabric’s appearance and longevity, which is especially relevant for high-end applications in automotive interiors and luxury furnishings. -

Fire Resistance Certifications

Certain Alcantara products, such as those used in aviation or automotive applications, may require fire resistance certifications. Awareness of these certifications is essential for compliance with industry regulations, ensuring safety and protecting brands from liability issues.

What Are Common Trade Terms Associated with Alcantara Fabric?

Navigating the terminology of the Alcantara fabric market can streamline procurement processes and enhance communication with suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

In the context of Alcantara, OEM refers to manufacturers who use Alcantara fabric in their products, such as luxury car brands. Understanding OEM relationships is vital for buyers aiming to source materials that meet specific quality and branding standards. -

MOQ (Minimum Order Quantity)

MOQ defines the smallest order size that a supplier is willing to accept. Knowing the MOQ helps buyers plan their purchasing strategy, ensuring they meet supplier requirements while optimizing inventory levels. -

RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specific quantities of Alcantara fabric. Utilizing RFQs can lead to better pricing negotiations and ensure that buyers receive competitive offers from multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that clarify the responsibilities of buyers and sellers in international shipping. Understanding these terms helps B2B buyers manage logistics and shipping costs effectively, ensuring smooth transactions across borders. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to delivery. Knowledge of lead times is crucial for project planning, particularly in industries where timing is essential, such as automotive manufacturing or event planning. -

Color Matching Standards

Color matching is critical in industries that require uniformity in appearance, such as automotive interiors. Familiarity with color matching standards ensures that buyers can achieve consistency across different batches of Alcantara fabric, which is essential for maintaining brand identity.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing Alcantara fabric rolls, ensuring they meet their project requirements efficiently and effectively.

Illustrative image related to alcantara fabric roll

Navigating Market Dynamics and Sourcing Trends in the alcantara fabric roll Sector

What Are the Current Market Dynamics and Key Trends for Alcantara Fabric Rolls?

The Alcantara fabric roll market is experiencing dynamic growth driven by several global factors. The increasing demand for premium materials in automotive and luxury goods sectors is at the forefront. Alcantara, known for its durability, aesthetic appeal, and versatility, has become a preferred choice for high-end vehicle interiors, furniture, and fashion. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to enhance their product offerings, the market is witnessing a shift towards customization and innovative designs.

Emerging technologies are also influencing sourcing trends. Digital platforms are making it easier for buyers to access a diverse range of Alcantara products, allowing for more efficient procurement processes. Moreover, advancements in fabric technology, such as improved water resistance and UV protection, are expanding Alcantara’s application beyond automotive to include outdoor furniture and upholstery. This trend is particularly relevant in regions with varied climates, where durability and maintenance are critical.

Additionally, sustainability is becoming a significant factor in sourcing decisions. B2B buyers are increasingly prioritizing suppliers that adhere to ethical practices and offer eco-friendly products. This shift is not only a response to consumer demand but also a proactive measure to comply with evolving regulations across different markets.

How Does Sustainability and Ethical Sourcing Impact the Alcantara Fabric Roll Market?

The environmental impact of the Alcantara fabric roll sector cannot be overlooked. As a synthetic suede made primarily from polyester and polyurethane, Alcantara production involves considerations of resource consumption and waste management. However, Alcantara S.p.A. emphasizes sustainability through its commitment to responsible manufacturing processes. This includes utilizing recycled materials and minimizing water usage during production.

Illustrative image related to alcantara fabric roll

For B2B buyers, understanding the importance of ethical supply chains is critical. Sourcing Alcantara from manufacturers that prioritize sustainable practices not only aligns with corporate social responsibility goals but also enhances brand value. Certifications such as OEKO-TEX® and Global Recycled Standard (GRS) are increasingly becoming prerequisites for buyers looking to verify the sustainability claims of their suppliers.

Furthermore, the demand for ‘green’ materials is reshaping the competitive landscape. Suppliers who can demonstrate compliance with environmental standards and offer transparent sourcing practices are likely to gain a competitive edge. This trend is particularly prominent among buyers in Europe and North America, where consumer awareness regarding sustainability is at an all-time high.

What Is the Historical Context Behind Alcantara Fabric’s Popularity in B2B Markets?

Alcantara was first introduced in the 1970s as a high-quality alternative to leather, quickly gaining traction in luxury automotive interiors. Its unique combination of softness, durability, and ease of maintenance made it an appealing choice for manufacturers of premium vehicles. Over the decades, Alcantara has expanded its application beyond automotive to include furniture, fashion, and interior design.

The fabric’s evolution reflects changing consumer preferences and technological advancements. Initially celebrated for its aesthetic qualities, Alcantara has now positioned itself as a sustainable option, appealing to modern buyers who value environmental consciousness alongside luxury. As a result, Alcantara fabric rolls have become synonymous with high-end design and ethical sourcing, making them a sought-after material in various B2B sectors globally.

Illustrative image related to alcantara fabric roll

In conclusion, navigating the Alcantara fabric roll market requires an understanding of current trends, sustainability practices, and the historical context that has shaped its evolution. B2B buyers who prioritize these factors will be better equipped to make informed purchasing decisions that align with market demands and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of alcantara fabric roll

-

How do I select the right Alcantara fabric roll for my project?

Choosing the right Alcantara fabric depends on your specific application. Consider the type of backing you need, such as unbacked for flexibility or foam-backed for added comfort. Assess the fabric’s intended use—automotive interiors, furniture, or fashion—as different variants offer unique properties like durability, grip, and ease of cleaning. Always request samples to evaluate color and texture before making a bulk purchase, ensuring that the fabric meets your quality standards. -

What are the typical applications for Alcantara fabric rolls?

Alcantara fabric is highly versatile and commonly used in automotive interiors, including seats, dashboards, and headliners. It’s also suitable for luxury furniture, fashion accessories, and even aviation interiors. The fabric’s unique properties, such as its soft touch, durability, and ability to reduce glare, make it ideal for high-end applications where aesthetics and functionality are paramount. -

What customization options are available for Alcantara fabric rolls?

Many suppliers offer customization options, including color matching, pattern design, and different backing types. You can request specific lengths, widths, and even perforation for ventilation in automotive applications. It’s essential to discuss your requirements with the supplier, as some may have minimum order quantities (MOQs) for custom orders. Always confirm lead times for custom products to align with your project schedule. -

What are the minimum order quantities (MOQs) for Alcantara fabric rolls?

MOQs for Alcantara fabric rolls vary by supplier and can depend on factors like the type of fabric and customization options. Generally, you may find MOQs ranging from a few yards to full rolls, typically around 55 yards. When sourcing internationally, consider bulk purchasing to negotiate better pricing and ensure you have enough material for your projects. -

What payment terms should I expect when ordering Alcantara fabric rolls?

Payment terms can differ among suppliers and regions. Common practices include upfront payments, partial deposits, or net terms (e.g., 30 or 60 days). When dealing with international transactions, be prepared for additional considerations such as currency exchange rates and potential banking fees. Always clarify payment terms in advance to avoid misunderstandings and ensure a smooth transaction process. -

How can I ensure quality assurance when sourcing Alcantara fabric?

To ensure quality, work with reputable suppliers who provide certifications or documentation for their products, confirming that they meet industry standards. Request samples before placing large orders to verify the fabric’s quality and performance. Additionally, consider conducting factory visits or third-party inspections to assess the manufacturing process and quality control measures in place, especially for overseas suppliers. -

What logistics considerations should I keep in mind when importing Alcantara fabric rolls?

When importing Alcantara fabric, consider shipping methods, lead times, and customs regulations. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders but may take longer. Ensure you are familiar with import duties and taxes in your country. Collaborating with a logistics provider can help streamline the process, ensuring timely delivery and compliance with international trade regulations. -

How can I effectively communicate with suppliers for Alcantara fabric sourcing?

Effective communication is key to successful sourcing. Clearly outline your specifications, including fabric type, colors, and quantities. Use professional language and provide visual references when possible. Establish a timeline for responses and updates, and don’t hesitate to ask questions about their production capabilities, lead times, and shipping options. Building a solid relationship with your supplier can lead to better service and more favorable terms in the long run.

Top 7 Alcantara Fabric Roll Manufacturers & Suppliers List

1. Alcantara – Automotive Fabric Solutions

Domain: keystonbros.com

Registered: 1997 (28 years)

Introduction: Alcantara Suede – Automotive Fabric. Product options include Alcantara Cover, Alcantara Soft, Alcantara Pannel, Alcantara EXO, Alcantara Pannel MB-4 Perf, and Alcantara Pannel S-2000 Perf. Prices are available upon login. Additional details such as roll size, cleaning code, abrasion, and UFAC class are mentioned but not specified in the provided text.

2. DLT Corporation – Alcantara Soft

Domain: dltcorporation.com

Registered: 2009 (16 years)

Introduction: Alcantara Soft (Foam-backed) is an Italian synthetic suede composed of 68% Polyester and 32% Polyurethane. It is easy to clean, offers more grip and durability, reduces glare on the windshield, and remains cool to the touch. Pricing starts at $134.99 for various colors, including Pearl White, Silver Grey, Orion Grey, Sand Grey, Mouse Grey, Basalt, Slate Grey, Dark Grey, Charcoal Black, Deep Black,…

3. Relicate – Alcantara Fabric

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: Alcantara fabric available in various types including: Pannel (Unbacked), Cover (Backed), EXO Outdoor, Foam Backed, Multilayer, Perforated, and Starlite. Product offerings include solid color leather, Nappa Italia leather, Napali leather, and various OEM auto colors for brands like BMW, Ferrari, Lamborghini, Porsche, Rolls Royce, and American cars. Specialty leather options include distressed and …

4. Hydes Leather – Alcantara Products

Domain: hydesleather.com

Registered: 2006 (19 years)

Introduction: Hydes Leather is the official distributor of Alcantara in North America, offering a complete range of Alcantara products used by luxury auto brands in Europe. Alcantara is 100% made in Italy and is known for its style, elegance, and functionality while respecting ethics and the environment. The types of Alcantara available include: 1. Alcantara Panel: Unbacked and unlined, used for vehicle headlin…

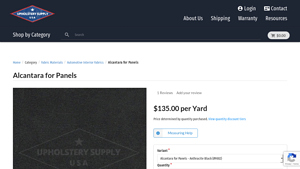

5. Upholstery Supply USA – Alcantara for Panels

Domain: upholsterysupplyusa.com

Registered: 2016 (9 years)

Introduction: {“product_name”: “Alcantara for Panels”, “color_options”: [“Anthracite Black (#9002)”, “Black (#9040)”, “Amber Glow (#1110)”, “Dark Brown (#9500)”, “Red (#4996)”, “Silver Grey (#4978)”, “Orion Grey (#2934)”, “Slate Grey (#2957)”], “price_per_yard”: {“1_to_9”: “$135.00”, “10_to_24”: “$130.00”, “25_plus”: “$125.00”}, “material_type”: “Genuine Alcantara Textile”, “origin”: “Made in Italy”, “product_d…

6. Alcantara – Craft Fabric

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Alcantara Craft Fabric available in various sizes and colors, including Black (9040), Charcoal (9002), Dark Grey (9052), and Deep Black. Prices range from $8.00 to $1,800.00 depending on size and type. Common dimensions include 12″ x 12″, 1.4m x 1.6m, and 36″ x 56″. Some products feature backing while others are bare. Shipping options vary, with some items offering free shipping. Products are suit…

7. Big in Fabric – MicroSuede Alcantara

Domain: big-in-fabric.com

Registered: 2019 (6 years)

Introduction: MicroSuede / Alcantara

– Price: €29.95 per meter (originally €34.95)

– Width: 1.38m

– Composition: 100% PES (polyester)

– Weight per m2: 435g

– Available in 24 variations: Army, Bronze, Burgundy, Cabernet, Cinnamon, Coffee, Darkblue, Desert, Forest, Graphite, Grey, Hazel, Light grey, Liver, Mustard, Natural, Onyx, Scarlet, Shell, Steel, Taupe, Teal, Thyme, Zinc

– Washing instructions:

– Wash at…

Strategic Sourcing Conclusion and Outlook for alcantara fabric roll

In the competitive landscape of B2B sourcing, understanding the value of Alcantara fabric rolls is paramount for international buyers, particularly in emerging markets like Africa and South America, as well as established markets in Europe and the Middle East. Alcantara fabric offers a unique blend of luxury, functionality, and sustainability, making it an ideal choice for a wide range of applications from automotive interiors to high-end upholstery.

Strategic sourcing of Alcantara allows businesses to tap into premium quality while ensuring compliance with ethical production standards. Buyers should prioritize suppliers that offer genuine Alcantara products, as these not only enhance product quality but also align with brand values focused on sustainability and innovation. Understanding the diverse types of Alcantara—such as foam-backed, multilayer, and outdoor variants—enables buyers to make informed decisions that suit specific project requirements.

As the global demand for high-performance fabrics continues to rise, now is the time for B2B buyers to forge partnerships with reputable suppliers. Investing in Alcantara fabric rolls will not only elevate product offerings but also position businesses at the forefront of market trends. Take the next step: explore your sourcing options today and unlock the potential of Alcantara for your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to alcantara fabric roll

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.