Introduction: Navigating the Global Market for who makes the best quality leather furniture

In the competitive landscape of B2B furniture procurement, identifying who makes the best quality leather furniture can be a daunting task. With myriad brands claiming superiority, international buyers—especially those from regions like Africa, South America, the Middle East, and Europe—often face challenges in sourcing products that meet their standards for durability, comfort, and aesthetic appeal. This guide aims to demystify the complexities of the leather furniture market, providing a comprehensive overview that includes types of leather, applications across various settings, and key factors to consider when vetting suppliers.

Our thorough analysis covers everything from the quality of materials used and manufacturing processes to warranties and price-to-value ratios. By equipping B2B buyers with insights into the rankings of major leather furniture brands and emerging contenders, this guide empowers them to make informed purchasing decisions that align with their specific needs and budget constraints. Whether you’re sourcing for high-end residential projects or large-scale commercial applications, understanding the nuances of leather furniture quality is crucial for ensuring customer satisfaction and long-term investment value.

Dive into this essential resource to navigate the global market effectively, streamline your procurement process, and ultimately elevate your product offerings with the best leather furniture available.

Table Of Contents

- Top 9 Who Makes The Best Quality Leather Furniture Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for who makes the best quality leather furniture

- Understanding who makes the best quality leather furniture Types and Variations

- Key Industrial Applications of who makes the best quality leather furniture

- 3 Common User Pain Points for ‘who makes the best quality leather furniture’ & Their Solutions

- Strategic Material Selection Guide for who makes the best quality leather furniture

- In-depth Look: Manufacturing Processes and Quality Assurance for who makes the best quality leather furniture

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘who makes the best quality leather furniture’

- Comprehensive Cost and Pricing Analysis for who makes the best quality leather furniture Sourcing

- Alternatives Analysis: Comparing who makes the best quality leather furniture With Other Solutions

- Essential Technical Properties and Trade Terminology for who makes the best quality leather furniture

- Navigating Market Dynamics and Sourcing Trends in the who makes the best quality leather furniture Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of who makes the best quality leather furniture

- Strategic Sourcing Conclusion and Outlook for who makes the best quality leather furniture

- Important Disclaimer & Terms of Use

Understanding who makes the best quality leather furniture Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather Furniture | Made from the top layer of the hide, retaining natural grain and imperfections. | High-end residential and commercial spaces. | Pros: Exceptional durability, luxurious appearance. Cons: Higher price point. |

| Top Grain Leather Furniture | Sanded and treated to remove imperfections, offering a more uniform look. | Retail environments, offices, and showrooms. | Pros: More affordable than full grain, still durable. Cons: Less natural character. |

| Bonded Leather Furniture | Made from leftover leather scraps bonded together with a polyurethane layer. | Budget-conscious businesses, temporary setups. | Pros: Cost-effective, lightweight. Cons: Less durable, may not age well. |

| Aniline Leather Furniture | Dyed with transparent dyes, showcasing natural textures and colors. | Luxury hotels and upscale restaurants. | Pros: Unique aesthetic, breathability. Cons: Susceptible to staining and fading. |

| Nubuck Leather Furniture | Sanded to create a soft, velvety surface, offering a unique texture. | Boutique stores, high-end residential. | Pros: Soft feel, stylish appearance. Cons: Requires special care, less durable than other types. |

What are the Characteristics of Full Grain Leather Furniture?

Full grain leather furniture is crafted from the top layer of the hide, which retains the natural grain and imperfections. This type of leather is known for its exceptional durability and luxurious appearance, making it ideal for high-end residential and commercial applications. B2B buyers should consider the long-term investment value, as full grain leather can last for decades when properly maintained. However, it comes at a higher price point, which may require careful budgeting for businesses aiming to furnish upscale environments.

How Does Top Grain Leather Furniture Compare to Other Options?

Top grain leather furniture is sanded and treated to create a more uniform appearance, making it a popular choice for retail environments and offices. It strikes a balance between quality and affordability, providing durability without the premium cost associated with full grain leather. B2B buyers should evaluate the aesthetic needs of their space against the budget, as top grain leather offers a sophisticated look while being more accessible for larger purchases.

What Should Buyers Know About Bonded Leather Furniture?

Bonded leather furniture is made from leftover leather scraps that are bonded together with a polyurethane layer. This type is particularly appealing for budget-conscious businesses or temporary setups, as it offers a cost-effective alternative to genuine leather. While bonded leather is lightweight and easier to clean, B2B buyers must consider its lower durability and potential for wear over time, which may not be suitable for high-traffic environments.

Why Choose Aniline Leather Furniture for Luxury Settings?

Aniline leather furniture is dyed with transparent dyes, allowing the natural textures and colors of the hide to shine through. This makes it an excellent choice for luxury hotels and upscale restaurants that prioritize aesthetic appeal. B2B buyers should be aware that while aniline leather offers a unique and breathable experience, it is also more susceptible to staining and fading, necessitating careful maintenance in commercial settings.

What Are the Benefits and Drawbacks of Nubuck Leather Furniture?

Nubuck leather furniture features a soft, velvety surface created by sanding the hide, giving it a distinctive texture. This type is often used in boutique stores and high-end residential environments. While nubuck offers a stylish appearance and luxurious feel, B2B buyers must consider its care requirements and lower durability compared to other leather types. Proper maintenance is essential to preserve its aesthetic appeal, which may impact operational costs for businesses.

Key Industrial Applications of who makes the best quality leather furniture

| Industry/Sector | Specific Application of who makes the best quality leather furniture | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel Lobby and Lounge Furniture | Enhances guest experience, creating a luxurious atmosphere | Durability, ease of maintenance, warranty, and design aesthetics |

| Corporate Offices | Executive Desks and Conference Room Seating | Projects professionalism and comfort, improving employee morale | Ergonomic design, quality of materials, and brand reputation |

| Retail | High-End Showroom Displays | Attracts customers and promotes brand image | Customization options, quality craftsmanship, and delivery timelines |

| Residential Interior Design | Custom Living Room Furniture | Adds value to homes, appealing to affluent buyers | Sourcing from reputable brands, material quality, and design options |

| Healthcare | Patient Waiting Area Seating | Provides comfort and durability, enhancing patient experience | Hygiene standards, easy-to-clean materials, and warranty coverage |

How is Leather Furniture Used in the Hospitality Industry?

In the hospitality sector, high-quality leather furniture is crucial for hotel lobbies and lounges. It not only enhances the aesthetic appeal but also contributes to a luxurious experience for guests. The durability of leather ensures that furniture withstands heavy use while maintaining its visual integrity. International buyers, especially from regions like Africa and Europe, should focus on sourcing from manufacturers known for their robust warranty policies and maintenance support, ensuring long-term value.

What Role Does Leather Furniture Play in Corporate Offices?

In corporate environments, executive desks and conference room seating made from premium leather serve to project professionalism and sophistication. Such furniture can significantly improve employee morale and productivity by providing comfort during long meetings. Buyers in South America and the Middle East should prioritize ergonomic designs and high-quality materials to ensure durability and comfort, along with sourcing from brands with a strong reputation in the market.

How Can Retailers Benefit from Quality Leather Furniture?

High-end retailers utilize leather furniture for showroom displays to attract customers and enhance their brand image. Quality leather pieces can create an inviting atmosphere, encouraging customers to engage with the products. Retailers should consider customization options and the craftsmanship of the furniture to ensure it aligns with their brand identity. Timely delivery and the ability to meet design specifications are key factors for successful sourcing.

Why is Custom Living Room Furniture Important for Residential Design?

In residential interior design, custom leather furniture adds significant value to homes, appealing especially to affluent buyers seeking unique and high-quality pieces. It enhances the overall aesthetic and comfort of living spaces. For international buyers, particularly in Europe, sourcing from reputable brands that offer a range of design options and material quality is essential to ensure satisfaction and longevity in their investments.

How Does Leather Furniture Enhance Patient Waiting Areas in Healthcare?

In healthcare settings, leather seating in patient waiting areas is vital for providing comfort and durability. High-quality leather is not only aesthetically pleasing but also easy to clean, which is crucial for maintaining hygiene standards. Buyers in the healthcare sector must ensure that the furniture meets specific hygiene requirements and comes with strong warranty coverage, thereby enhancing the overall patient experience while ensuring long-term investment value.

3 Common User Pain Points for ‘who makes the best quality leather furniture’ & Their Solutions

Scenario 1: Navigating Brand Credibility in Leather Furniture Manufacturing

The Problem:

B2B buyers often face significant challenges when trying to determine which manufacturers produce the best quality leather furniture. With numerous brands claiming superior craftsmanship, it can be overwhelming to differentiate between them, especially for international buyers who may not have direct experience with specific brands. Misjudging quality can lead to costly purchases that fail to meet expectations, resulting in financial losses and damaged reputations.

Illustrative image related to who makes the best quality leather furniture

The Solution:

To navigate this complexity, buyers should invest time in researching manufacturer rankings and reviews from credible sources. Utilize platforms that aggregate consumer feedback and expert opinions, focusing on specific metrics such as frame quality, leather type, and warranty responsiveness. When evaluating potential suppliers, request samples or detailed specifications of their products to assess quality firsthand. Engaging with industry experts or attending trade shows can also provide invaluable insights into reputable brands. Establishing a robust supplier evaluation process will ensure that you select manufacturers with a proven track record for quality and reliability.

Scenario 2: Understanding Leather Types and Their Impact on Quality

The Problem:

Another common pain point for B2B buyers is the lack of clarity regarding different types of leather and how they affect the quality and longevity of furniture. For instance, buyers may struggle to understand the distinctions between full-grain, top-grain, and bonded leather, leading to misinformed purchasing decisions. This confusion can result in selecting furniture that does not meet durability requirements for commercial settings or fails to align with the aesthetic vision of a project.

The Solution:

To overcome this challenge, B2B buyers should prioritize educational resources that detail the various types of leather, including their pros and cons. Manufacturers should be required to provide comprehensive information about the leather used in their products. Furthermore, establishing relationships with knowledgeable suppliers who can offer guidance on material selection based on specific use cases—such as high-traffic areas versus luxury showrooms—will enhance decision-making. Consider developing a detailed leather specification guide that aligns with your business needs, ensuring that all stakeholders understand the implications of their choices.

Scenario 3: Managing Warranty and Service Expectations

The Problem:

B2B buyers frequently experience frustration regarding warranty terms and post-purchase service from leather furniture manufacturers. Some brands may offer extensive warranties that create an illusion of quality, but when issues arise, the response time and service quality can be disappointing. This inconsistency can lead to operational disruptions, especially in commercial environments where furniture plays a critical role in client interactions.

The Solution:

To mitigate this risk, it is essential for buyers to conduct thorough due diligence on warranty policies before making purchases. Inquire specifically about the claims process, service responsiveness, and the extent of coverage. It is beneficial to request case studies or testimonials from other businesses that have utilized the warranty service of potential suppliers. Additionally, consider negotiating warranty terms as part of the purchase agreement to ensure that service expectations are clearly defined. Building a strong relationship with the supplier from the outset can facilitate smoother communications when issues arise, ensuring that support is readily available when needed.

Illustrative image related to who makes the best quality leather furniture

Strategic Material Selection Guide for who makes the best quality leather furniture

When selecting materials for high-quality leather furniture, it’s essential to understand the properties and implications of different leather types and their components. This analysis focuses on four common materials used in leather furniture production: Full Grain Leather, Top Grain Leather, Bonded Leather, and Synthetic Leather. Each material has unique characteristics that can significantly impact the durability, aesthetic appeal, and overall performance of the furniture.

What Are the Key Properties of Full Grain Leather?

Full grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain, which contributes to its strength and durability. Key properties include excellent breathability, resistance to wear and tear, and a natural ability to develop a rich patina over time.

Pros: Full grain leather is highly durable and ages beautifully, making it suitable for high-end furniture. It is also resistant to moisture and stains when treated properly.

Cons: The cost is significantly higher than other types of leather, and it may require more maintenance to preserve its appearance.

Illustrative image related to who makes the best quality leather furniture

Impact on Application: Full grain leather is ideal for luxury residential and commercial applications where aesthetics and longevity are paramount. It is compatible with various upholstery styles, enhancing the overall design.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards regarding leather sourcing and treatment. Understanding the environmental impact and sustainability practices of suppliers is also crucial.

How Does Top Grain Leather Compare?

Top grain leather is the second-highest quality, made from the upper layer of the hide but sanded to remove imperfections. This process makes it thinner and more pliable than full grain leather.

Pros: It offers a balance between quality and affordability, providing a more uniform appearance while still being durable. It is also easier to clean and maintain.

Cons: While top grain leather is durable, it does not develop the same rich patina as full grain leather and can be less resistant to scratches.

Illustrative image related to who makes the best quality leather furniture

Impact on Application: This leather type is suitable for both residential and commercial furniture, particularly in settings that require a more polished look without the premium price tag.

Considerations for International Buyers: Buyers should verify the tanning processes used, as some may not comply with environmental regulations. Understanding the local market preferences for leather finishes is also essential.

What Are the Characteristics of Bonded Leather?

Bonded leather is made from leftover leather scraps that are bonded together with polyurethane. It is often marketed as a more affordable alternative to genuine leather.

Pros: The primary advantage is cost; it is significantly cheaper than full or top grain leather. It can also be produced in a variety of colors and finishes.

Cons: Bonded leather is less durable and may not withstand heavy use. It can peel and wear out more quickly than genuine leather.

Impact on Application: Best suited for budget-conscious projects or temporary installations, bonded leather is commonly used in furniture for offices or casual settings.

Considerations for International Buyers: Buyers should be aware of the quality variations in bonded leather products. Compliance with local standards for synthetic materials is also important.

How Does Synthetic Leather Fit into the Market?

Synthetic leather, often made from PVC or polyurethane, mimics the look and feel of real leather without using animal hides.

Illustrative image related to who makes the best quality leather furniture

Pros: It is highly versatile, resistant to stains and water, and typically easier to clean. It is also available at a lower price point.

Cons: Synthetic leather may not offer the same durability or aesthetic appeal as genuine leather and can be less breathable.

Impact on Application: Ideal for high-traffic areas and environments where moisture resistance is critical, synthetic leather is commonly used in commercial settings, such as restaurants and waiting areas.

Illustrative image related to who makes the best quality leather furniture

Considerations for International Buyers: Buyers should evaluate the environmental impact of synthetic materials and ensure compliance with international regulations regarding chemical content.

Summary Table of Material Selection for Leather Furniture

| Matériau | Typical Use Case for who makes the best quality leather furniture | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | Luxury residential and commercial furniture | Exceptional durability and patina | High cost and maintenance required | Haut |

| Top Grain Leather | Mid to high-end residential and commercial furniture | Good balance of quality and price | Less resistant to scratches | Medium |

| Bonded Leather | Budget-conscious projects, casual furniture | Low cost | Less durable, may peel | Low |

| Synthetic Leather | High-traffic commercial settings | Easy to clean and maintain | Less breathable and durable | Low |

This comprehensive guide provides insights into material selection for leather furniture, helping international B2B buyers make informed decisions tailored to their specific market needs and preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for who makes the best quality leather furniture

What Are the Main Stages of Manufacturing High-Quality Leather Furniture?

The manufacturing process for high-quality leather furniture involves several critical stages that ensure the final product meets rigorous standards of durability and aesthetics. Understanding these stages is essential for B2B buyers looking to source premium leather furniture.

Material Preparation: Sourcing and Selecting Quality Hides

The first step in the manufacturing process is the careful selection of leather hides. High-quality leather typically comes from full-grain or top-grain sources, offering superior durability and texture. Manufacturers often establish long-term relationships with reputable tanneries to ensure consistent quality.

Illustrative image related to who makes the best quality leather furniture

During this stage, hides undergo rigorous inspection to identify any defects, such as scars or blemishes. The preparation process may also include soaking, cleaning, and conditioning the leather to enhance its properties. For B2B buyers, verifying the origin and quality of the leather used is crucial. Requesting documentation or certifications from suppliers can help ensure that the materials meet international standards.

Forming: Cutting and Shaping the Leather

Once the leather is prepared, it is cut into panels that will be used to construct various furniture components. Precision cutting is vital to minimize waste and ensure that each piece fits together seamlessly. Advanced cutting technologies, such as laser cutting, are increasingly used for their accuracy.

In addition to leather, manufacturers often select solid hardwoods or engineered woods for frames, as these materials provide strength and longevity. The forming stage may also involve creating cushioning with high-density foams or innerspring systems, which contribute to comfort and durability.

Assembly: Craftsmanship in Construction

The assembly stage is where the real craftsmanship comes into play. Skilled artisans sew the leather panels together, ensuring that seams are strong and aesthetically pleasing. Techniques such as double-stitching or using reinforced seams are common in high-quality furniture to enhance durability.

Furniture frames are constructed using robust joinery methods, such as mortise and tenon, which are essential for stability. Additionally, manufacturers may employ techniques like eight-way hand-tied suspension systems for seating, which provide superior support and comfort.

Finishing: Enhancing Aesthetics and Longevity

The final stage of manufacturing involves applying finishes that enhance the leather’s natural beauty while providing protection against wear and tear. This may include dyeing, waxing, or applying protective coatings that resist stains and moisture.

Quality assurance during this stage is crucial, as it directly impacts the furniture’s longevity and appearance. B2B buyers should inquire about the types of finishes used and their expected durability.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is a vital component of the manufacturing process, ensuring that the final product meets specific standards of performance and safety. For B2B buyers, understanding these standards can inform purchasing decisions and foster confidence in supplier capabilities.

International Standards: ISO 9001 and Beyond

ISO 9001 is one of the most recognized international quality management standards, providing a framework for consistent product quality and customer satisfaction. Manufacturers that adhere to ISO 9001 demonstrate their commitment to quality processes and continuous improvement.

Additionally, industry-specific standards such as CE (Conformité Européenne) for safety and environmental considerations may apply, particularly for buyers in Europe. In regions like Africa and South America, local standards may also influence manufacturing processes and quality assurance practices.

Quality Control Checkpoints: IQC, IPQC, and FQC

Quality control (QC) checkpoints are integrated throughout the manufacturing process. The main checkpoints include:

Illustrative image related to who makes the best quality leather furniture

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process to catch defects or inconsistencies in real-time.

- Final Quality Control (FQC): Conducting a thorough inspection of finished products before shipment, ensuring they meet quality standards.

For B2B buyers, understanding these checkpoints can provide insight into the manufacturer’s commitment to quality. Requesting QC reports or audits can help verify compliance with these practices.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are some strategies to consider:

Conducting Supplier Audits

One of the most effective ways to assess a supplier’s quality control practices is through on-site audits. During these audits, buyers can evaluate manufacturing processes, inspect facilities, and review QC documentation. This hands-on approach allows buyers to gain a deeper understanding of the supplier’s capabilities.

Requesting Detailed QC Reports

B2B buyers should request comprehensive QC reports that outline the manufacturer’s quality assurance processes, including results from IQC, IPQC, and FQC. These reports can offer valuable insights into the supplier’s commitment to quality.

Utilizing Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturer’s quality control processes. These services often include detailed reports and recommendations, which can enhance buyer confidence in the supplier’s capabilities.

What Nuances Should International Buyers Consider in QC and Certifications?

International buyers must navigate various nuances regarding quality control and certifications. Understanding local regulations and international standards is critical for successful procurement.

Variability in Standards by Region

Quality standards can vary significantly by region. For example, European buyers may prioritize CE certifications, while those in the Middle East might focus on local compliance standards. Buyers should familiarize themselves with the regulatory landscape in their target markets to ensure that suppliers meet necessary requirements.

Language and Documentation Barriers

Language barriers can pose challenges when verifying quality control practices. Buyers should ensure that all documentation, including QC reports and certifications, is available in a language they understand. This may involve requesting translated documents or working with suppliers who can provide bilingual support.

Building Long-Term Relationships with Suppliers

Establishing long-term relationships with suppliers can enhance trust and transparency in quality control practices. Regular communication and collaboration can lead to improved quality assurance and a better understanding of each other’s expectations.

By understanding the manufacturing processes and quality assurance practices associated with high-quality leather furniture, B2B buyers can make informed decisions that align with their business objectives. Prioritizing quality not only enhances customer satisfaction but also contributes to the longevity and value of the furniture investment.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘who makes the best quality leather furniture’

To successfully navigate the procurement of high-quality leather furniture, B2B buyers must adopt a structured approach. This guide will outline essential steps to ensure that your sourcing process is efficient and effective, leading to a successful purchase that meets your business needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the first step in sourcing leather furniture. This includes determining the type of leather (e.g., full grain, top grain), the desired durability, and the specific functionalities required for your target market. For instance, commercial applications may necessitate more robust materials than residential setups.

Illustrative image related to who makes the best quality leather furniture

- Consider the environmental factors: Assess the climate of your target market, as this can affect leather durability and maintenance needs.

- Identify user demographics: Different user profiles (e.g., families with children vs. luxury buyers) will have different requirements for wear and tear.

Step 2: Research Reputable Manufacturers

Invest time in researching reputable manufacturers known for their quality leather furniture. Look for brands with a long-standing history and positive reviews from verified sources. This is crucial because not all manufacturers uphold the same standards.

- Utilize industry rankings: Refer to manufacturer rankings that assess quality based on material, construction, and warranty responsiveness.

- Consider geographical factors: Some regions may specialize in specific types of leather or furniture styles, which can influence your choice.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request company profiles, case studies, and references from buyers in a similar industry or region. This provides insight into their reliability and product quality.

- Assess their portfolio: Look for examples of past projects that align with your specifications.

- Verify production capacity: Ensure that the supplier can meet your volume needs without compromising quality.

Step 4: Request Samples and Conduct Quality Inspections

Request samples of the leather and furniture pieces to assess quality firsthand. This step is crucial in verifying the manufacturer’s claims regarding leather type, comfort, and craftsmanship.

- Inspect for defects: Check for consistency in color, texture, and overall finishing.

- Test durability: If possible, conduct stress tests on materials to gauge their performance under typical usage conditions.

Step 5: Understand Pricing Structures and Value Propositions

It’s important to analyze the pricing structures of potential suppliers. While lower prices can be appealing, they may not reflect the true value of the product.

Illustrative image related to who makes the best quality leather furniture

- Compare warranties: A robust warranty can indicate a manufacturer’s confidence in their product quality.

- Evaluate total cost of ownership: Consider factors like maintenance, longevity, and potential resale value.

Step 6: Negotiate Terms and Conditions

Once you have shortlisted suppliers, enter negotiations with a clear understanding of your requirements and budget. This includes discussing payment terms, delivery schedules, and after-sales service.

- Be transparent: Clearly communicate your expectations to avoid misunderstandings later.

- Incorporate flexibility: Allow for adjustments based on supplier capabilities and market conditions.

Step 7: Finalize Contracts and Monitor Delivery

After agreeing on terms, finalize contracts that protect your interests and specify all agreed-upon details. Post-contract, monitor the delivery process to ensure compliance with the agreed specifications.

- Establish communication channels: Maintain ongoing communication with the supplier to address any issues that arise during production and delivery.

- Perform a final inspection upon delivery: Ensure that the products received match the samples and contractual specifications.

By following these structured steps, B2B buyers can effectively navigate the sourcing process for high-quality leather furniture, ensuring a successful procurement that meets both business and customer needs.

Comprehensive Cost and Pricing Analysis for who makes the best quality leather furniture Sourcing

What Are the Key Cost Components in Leather Furniture Manufacturing?

Understanding the cost structure of leather furniture manufacturing is essential for B2B buyers seeking quality products. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type of leather used significantly impacts costs. Full-grain leather, known for its durability and quality, typically commands a higher price than top-grain or corrected-grain leather. Additionally, the quality of hardwoods used for frames, springs, and cushions is crucial; solid hardwood frames tend to have higher upfront costs but provide longer-lasting durability.

-

Labor: Skilled craftsmanship is vital in producing high-quality leather furniture. Labor costs can vary significantly based on the region and the skill level required. Countries with a strong tradition of furniture making, such as Italy or Germany, may have higher labor costs, but they often yield superior craftsmanship.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient production processes can help keep these costs down, impacting the final price.

-

Tooling: The initial investment in tools and machinery necessary for leather furniture production can be substantial. Advanced technology, such as automated cutting machines, can enhance precision and reduce waste, though they may increase initial costs.

-

Quality Control: Rigorous QC processes ensure that the final products meet industry standards. While this adds to production costs, it helps mitigate risks associated with returns and warranty claims.

-

Logistics: Transporting leather furniture can be costly, especially for international shipments. Factors such as distance, mode of transportation, and customs duties play a significant role in overall logistics costs.

-

Margin: Manufacturers typically apply a markup on their costs to achieve a profit margin. Understanding this can help buyers gauge the fairness of pricing.

How Do Price Influencers Affect Leather Furniture Costs?

Several factors influence the pricing of leather furniture, particularly for international B2B buyers.

Illustrative image related to who makes the best quality leather furniture

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to discounts due to economies of scale. Buyers should negotiate MOQs to leverage better pricing.

-

Specifications and Customization: Custom designs or specifications can increase costs. Understanding the trade-off between customization and standard offerings is crucial for cost management.

-

Material Quality and Certifications: Premium materials and certifications (e.g., eco-friendly practices) can drive up costs. Buyers should assess the value of these features against their budget.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established brands may charge more due to their quality assurance and customer service, while lesser-known suppliers might offer lower prices but come with higher risks.

-

Incoterms: The agreed terms of delivery (e.g., FOB, CIF) affect the final price. Buyers should clarify these terms to avoid unexpected costs related to shipping and customs.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Leather Furniture?

-

Negotiation Strategies: Establishing strong relationships with suppliers can lead to better negotiation outcomes. Be prepared to discuss pricing openly and explore options for discounts based on volume or long-term contracts.

-

Total Cost of Ownership: Consider not just the purchase price but the total cost of ownership, which includes maintenance and potential replacement costs. Investing in higher-quality furniture may save money in the long run.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, and the Middle East should account for currency fluctuations and import duties. Understanding local market conditions can inform better purchasing decisions.

-

Requesting Samples: Before finalizing orders, request samples to assess quality firsthand. This can prevent costly mistakes and ensure that the furniture meets your specifications.

In conclusion, navigating the cost and pricing landscape of leather furniture requires an understanding of various components and influencers. By leveraging these insights, international B2B buyers can make informed decisions that align quality with budgetary constraints.

Alternatives Analysis: Comparing who makes the best quality leather furniture With Other Solutions

Understanding Alternatives to Quality Leather Furniture

When considering investments in leather furniture, B2B buyers must explore various options to ensure they choose the best fit for their needs. While high-quality leather furniture is a popular choice, alternative solutions can provide comparable value and functionality. This section analyzes the pros and cons of different options, helping international buyers make informed decisions.

| Comparison Aspect | Who Makes The Best Quality Leather Furniture | Alternative 1: Synthetic Leather Furniture | Alternative 2: Fabric Upholstered Furniture |

|---|---|---|---|

| Performance | Superior durability and comfort; ages well | Good durability, but may not age as well | Moderate durability; varies by fabric type |

| Cost | Higher investment; long-term value | Generally lower cost than leather | Wide range of prices; can be budget-friendly |

| Ease of Implementation | Requires careful selection and sourcing | Easy to source and often readily available | Easy to source; variety of designs available |

| Maintenance | Requires regular conditioning; easy to clean | Low maintenance; easy to clean | Varies; some fabrics require special care |

| Best Use Case | High-end commercial spaces, luxury residences | Budget-friendly options, family spaces | Versatile for both residential and commercial use |

In-Depth Analysis of Alternatives to Quality Leather Furniture

What are the benefits of synthetic leather furniture?

Synthetic leather, often made from polyurethane or PVC, offers a cost-effective alternative to high-quality leather. Its primary advantage lies in its affordability and ease of maintenance. Unlike natural leather, synthetic options are generally more resistant to stains and easier to clean, making them suitable for environments with high foot traffic or families with children. However, synthetic leather may not possess the same aesthetic appeal or longevity as genuine leather, leading to potential replacements sooner.

How does fabric upholstered furniture compare?

Fabric upholstered furniture presents a versatile option with a wide range of designs, colors, and patterns. This alternative can cater to various tastes and interior designs, making it suitable for both residential and commercial applications. The cost can vary significantly, allowing buyers to find budget-friendly options. However, the durability of fabric can be inconsistent, with some types being more susceptible to wear and tear, stains, and fading over time. Regular maintenance is essential to extend the lifespan of fabric upholstery.

How Should B2B Buyers Decide on the Right Solution?

In selecting the right solution for leather furniture, B2B buyers should assess their specific needs, including budget, intended use, and desired longevity. Quality leather furniture may be the best choice for high-end applications where durability and aesthetics are paramount. Conversely, synthetic leather is ideal for budget-conscious projects where ease of maintenance is crucial. Fabric upholstery provides versatility and style but may require more frequent replacements. By carefully weighing these factors, buyers can make informed decisions that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for who makes the best quality leather furniture

What Are the Key Technical Properties of Quality Leather Furniture?

When evaluating the best quality leather furniture, several technical properties are paramount. Understanding these specifications will enable B2B buyers to make informed decisions that align with their market needs and customer expectations.

Illustrative image related to who makes the best quality leather furniture

1. Leather Grade

The grade of leather is one of the most critical factors in determining quality. The three main categories are full-grain, top-grain, and corrected grain. Full-grain leather retains the entire thickness of the hide, showcasing natural imperfections, which enhances durability and breathability. Top-grain leather is sanded and finished for a more uniform appearance but sacrifices some durability. Understanding leather grades helps buyers assess product longevity and suitability for various applications.

2. Frame Construction

The quality of the frame is vital for the durability and stability of leather furniture. Solid hardwood frames are the gold standard, providing strength and resilience. In contrast, softer woods or particle board may lead to sagging or structural failure over time. Buyers should prioritize manufacturers who utilize solid wood and advanced construction techniques, such as mortise and tenon joints, to ensure a long-lasting product.

3. Suspension System

The suspension system affects both comfort and longevity. High-quality leather furniture typically features an 8-way hand-tied system, where springs are tied together in multiple directions for optimal support. This system provides even weight distribution and reduces wear over time. Understanding suspension types allows buyers to evaluate comfort levels and durability effectively.

4. Upholstery Detailing

Attention to detail in upholstery, such as stitching quality and finish, can greatly influence the aesthetic and functional value of leather furniture. Double-stitched seams and reinforced corners enhance durability and visual appeal. Buyers should look for manufacturers who prioritize craftsmanship, as this often reflects a commitment to quality.

5. Warranty and Service Responsiveness

A robust warranty indicates a manufacturer’s confidence in their product. Warranties should cover both materials and workmanship for a reasonable period. Additionally, the responsiveness to warranty claims is crucial; prompt service can significantly impact customer satisfaction. Buyers should inquire about warranty details to assess the manufacturer’s reliability.

What Common Trade Terms Should B2B Buyers Know?

Navigating the leather furniture industry involves familiarizing oneself with essential jargon. Understanding these terms can streamline procurement processes and enhance negotiation efficiency.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces products or components that are used in another company’s end product. In the context of leather furniture, an OEM might manufacture leather upholstery for a brand that sells finished furniture. Understanding OEM relationships can help buyers identify quality sources and establish partnerships with reputable manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it can influence inventory decisions and cash flow management. Knowing the MOQ helps businesses plan their purchases effectively to meet demand without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers. It typically outlines specifications, quantities, and delivery requirements. Issuing an RFQ can lead to competitive pricing and favorable terms, making it an essential tool for B2B negotiations.

Illustrative image related to who makes the best quality leather furniture

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms ensures that B2B buyers understand their obligations and can negotiate better shipping agreements.

5. Lead Time

Lead time refers to the time it takes for a supplier to fulfill an order from the moment it is placed until it is delivered. Understanding lead times is essential for inventory management and meeting customer demands. Buyers should factor lead times into their procurement strategies to avoid stockouts.

By grasping these essential technical properties and trade terminologies, B2B buyers can enhance their procurement strategies and make informed decisions when sourcing high-quality leather furniture.

Navigating Market Dynamics and Sourcing Trends in the who makes the best quality leather furniture Sector

What Are the Global Drivers Shaping the Leather Furniture Market?

The leather furniture market is influenced by several key global drivers, including rising disposable incomes and an increasing demand for luxury home furnishings. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking high-quality leather products that combine durability with aesthetic appeal. The growing urbanization trend also plays a significant role, as more people transition to urban living and seek stylish yet functional furniture options.

Current sourcing trends highlight the integration of advanced technologies, such as AI and blockchain, to enhance supply chain transparency and efficiency. AI-driven analytics allow manufacturers to optimize production processes and predict consumer preferences, which is critical for meeting the diverse demands of international markets. Furthermore, the rise of e-commerce platforms has made it easier for B2B buyers to access a wider range of products and compare quality and prices, streamlining the sourcing process.

Emerging markets in Africa and South America are experiencing a surge in demand for quality leather furniture due to an expanding middle class. This demographic shift is creating opportunities for manufacturers to cater to the unique tastes and preferences of these markets. Additionally, the Middle East’s luxury sector is thriving, with buyers looking for premium leather offerings that reflect their lifestyle aspirations.

How Is Sustainability and Ethical Sourcing Reshaping the Leather Furniture Industry?

Sustainability is becoming a critical consideration for B2B buyers in the leather furniture sector. The environmental impact of leather production, including water usage and chemical treatments, has prompted manufacturers to adopt more sustainable practices. Ethical sourcing is now at the forefront, with buyers increasingly prioritizing suppliers who demonstrate a commitment to environmentally friendly methods and responsible animal welfare practices.

Incorporating ‘green’ certifications and materials is essential for brands aiming to appeal to conscious consumers. Certifications such as the Forest Stewardship Council (FSC) for wood and the Global Organic Textile Standard (GOTS) for organic materials are gaining traction in the leather furniture sector. Manufacturers that utilize eco-friendly tanning processes, such as vegetable tanning, can distinguish themselves in a crowded marketplace.

For international B2B buyers, understanding a supplier’s sustainability practices is crucial not only for compliance with regional regulations but also for enhancing their brand’s reputation. As consumers become more environmentally conscious, the demand for sustainably sourced leather furniture will continue to grow, making it imperative for manufacturers to align with these values.

What Is the Historical Context of Leather Furniture Production and Sourcing?

The evolution of leather furniture production dates back to ancient civilizations, where leather was primarily used for functional purposes. Over the centuries, craftsmanship evolved, and leather began to be recognized as a luxury material for furniture, particularly in Europe and North America. The industrial revolution marked a significant turning point, introducing mass production techniques that made leather furniture more accessible to a broader audience.

In the late 20th century, the market saw a rise in consumer demand for high-quality, artisan-crafted leather products. This shift was driven by a growing appreciation for bespoke furniture and an understanding of the value of craftsmanship. Today, international B2B buyers are not only interested in the quality of the leather but also in the story behind the product, including the sourcing practices and the artisans involved in the production process.

As the market continues to evolve, the integration of modern technology and a renewed focus on sustainability will shape the future of leather furniture sourcing, ensuring that it meets the demands of an increasingly discerning global clientele.

Frequently Asked Questions (FAQs) for B2B Buyers of who makes the best quality leather furniture

-

How do I determine the quality of leather furniture before purchasing?

To assess the quality of leather furniture, examine several key factors: the type of leather used (full-grain vs. top-grain), the frame construction (solid hardwood is preferable), and the quality of suspension systems (look for 8-way hand-tied springs for durability). Additionally, check the upholstery details and stitching, as these are indicators of craftsmanship. Review warranty terms and responsiveness from the manufacturer as well, since a reliable warranty can signify confidence in product quality. -

What is the best type of leather furniture for commercial use?

For commercial environments, such as hotels or offices, choose leather furniture that combines durability and style. Full-grain leather is recommended for its resilience and aging quality, while bonded or faux leather may offer a cost-effective alternative. Brands like Bradington-Young and Hancock & Moore are known for their high-quality commercial-grade offerings. Always verify warranty options and maintenance requirements to ensure the longevity of your investment. -

How can I vet a leather furniture supplier internationally?

To effectively vet an international leather furniture supplier, start by researching their reputation through online reviews and industry forums. Request samples of their products to evaluate material quality and craftsmanship firsthand. Additionally, assess their production capabilities, compliance with international standards, and responsiveness to inquiries. It’s also beneficial to visit their manufacturing facilities if possible, or seek third-party audits to confirm their reliability and ethical practices. -

What are the common minimum order quantities (MOQs) for leather furniture?

Minimum order quantities (MOQs) for leather furniture can vary significantly by supplier and type of product. Typically, MOQs range from 10 to 50 units for standard items, while custom orders may have higher requirements. It’s crucial to discuss MOQs upfront with potential suppliers to ensure they align with your purchasing needs. Understanding these terms will help you manage inventory effectively and optimize your supply chain. -

What payment terms should I expect when sourcing leather furniture internationally?

When sourcing leather furniture internationally, payment terms can vary widely. Common terms include a deposit (usually 30-50%) upfront, with the balance due before shipment or upon delivery. Some suppliers may offer letters of credit or payment via escrow services for added security. It’s advisable to negotiate terms that suit your cash flow while ensuring protection against potential risks associated with international transactions. -

How do I ensure quality assurance (QA) for my leather furniture orders?

To ensure quality assurance for your leather furniture orders, establish clear specifications and standards before production begins. Implement a quality control process that includes inspections at various stages of manufacturing and prior to shipping. Consider hiring third-party inspection services to conduct thorough checks on materials, craftsmanship, and compliance with your specifications. Document all findings and maintain open communication with your supplier to address any issues promptly. -

What logistics considerations should I keep in mind when importing leather furniture?

When importing leather furniture, logistics considerations include shipping methods, customs clearance, and potential tariffs. Choose a reliable freight forwarder familiar with furniture shipments to manage logistics efficiently. Ensure all documentation, such as invoices and packing lists, is accurate to facilitate smooth customs processing. Additionally, consider shipping insurance to protect your investment against loss or damage during transit. -

Can I customize leather furniture to meet specific design requirements?

Yes, many suppliers offer customization options for leather furniture, including choices in leather type, color, dimensions, and design features. Discuss your specific requirements with potential manufacturers to determine their capabilities. Custom orders typically involve longer lead times and may have higher MOQs, so it’s essential to factor these into your planning. Collaborating closely with the supplier during the design phase will help ensure the final product meets your expectations.

Top 9 Who Makes The Best Quality Leather Furniture Manufacturers & Suppliers List

1. Leather Shoppes – Top Leather Furniture Brands

Domain: leathershoppes.com

Registered: 1996 (29 years)

Introduction: Manufacturer Rankings of Leather Furniture Brands, Reviews of Best Made Leather Sofas, Sectionals, and Recliners. Key factors for ranking include: Quality and thickness of framing materials, Seating and Back Suspension, Quality of Leather hides, Quality of upholstery detail, Responsiveness to Warranty issues, Price to Value relationship. Brands ranked from 1 (poor) to 10 (excellent). Notable brand…

2. BHG – Best Overall: Pottery Barn Turner Sofa

Domain: bhg.com

Registered: 1999 (26 years)

Introduction: Best Overall: Pottery Barn Turner Sofa – Dimensions: From 64.5 x 38.5 x 35 in. | Weight Capacity: Not listed | Care Instructions: Vacuum and spot-clean. Best Design: Crate & Barrel Gather Leather 2-Piece Sectional Sofa – 45 different leather finishes available. Best for Pets: Ashley Furniture Leather Modular Sectional – Price: $5,800, Sale Price: $3,700. Best Faux: Better Homes & Gardens Nola Mode…

3. Facebook – Best Leather Couches Recommendations

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: I need recommendations for the best (real) leather couches

4. Article – Sven Couch

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: User is looking for a leather couch, specifically a 3-seater/88″ in a modern style. They have considered the following options: 1. Article Sven – praised for its look and being a Wirecutter top pick, but has bad reviews about cushions flattening and poor customer service. 2. Flexsteel Endurance – recommended in couch threads but visually least favorite; concerns about quality decline after 2010 an…

5. Fine Leather Furniture – Premium Leather Sofas

Domain: fineleatherfurniture.com

Registered: 1997 (28 years)

Introduction: Best Leather Sofas, Couches, Loveseats and Sectional Sofas. Huge Savings: Up To 50% Off Retail. Rated 4.9/5 Based on Customer Reviews. Made in USA. Available in Hundreds of Leather, Wood & Nail Finishes. Types include Leather Stationary Sofas, Reclining Leather Sofas, Leather Chaise Sofas, Leather Chesterfield Sofas, Leather Conversation Sofas, and Leather Sleeper Sofas. Warranty options include E…

6. Smith Brothers – Custom Handcrafted Leather Sofas

Domain: sunsgoods.com

Registered: 2017 (8 years)

Introduction: Top 11 Leather Sofa Manufacturers in USA: Quality & Comfort. Key manufacturers include: 1. Smith Brothers – Established 1926, Old Mission, Michigan, custom handcrafted sofas, solid wood frames, wide range of leather options. 2. Craftmaster – Established 1972, Hickory, North Carolina, customizable designs, soft aging leather, made in the USA. 3. BenchMade Modern – Established 2012, Atlanta, Georgia…

7. Bassett – Ellery Leather Roll Arm L-Shaped Sectional

Domain: bassettfurniture.com

Registered: 1996 (29 years)

Introduction: Custom Leather Furniture including Sofas, Sectionals, Chairs, and Recliners. Key products include: 1. Ellery Leather Roll Arm L-Shaped Sectional – Price: $9,059 (reduced from $11,339) 2. Garner Leather Barrel Swivel Chair – Price: $1,869 (reduced from $2,339) 3. Carolina Leather Roll Arm Sofa – Price: $4,269 (reduced from $5,339) 4. Everett Leather Reclining Sofa – Price: $3,839 (reduced from $4,8…

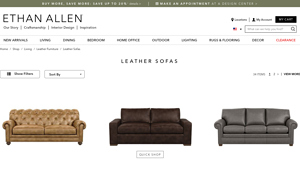

8. Ethan Allen – Leather Sofas & Loveseats

Domain: ethanallen.com

Registered: 1995 (30 years)

Introduction: Leather Sofas & Loveseats | Leather Couches | Ethan Allen. Save up to 20% with purchase options: Spend $3,000 or more to save 20%, or spend up to $2,999 to save 15%. Custom made options available. Categories include Leather Sofas, Leather Sectionals, Leather Chairs, Leather Recliners, Leather Ottomans & Benches, and Leather Upholstered Beds. Sizes range from Loveseats (50″ – 68″), Small Sofas (70″…

9. Pottery Barn – Leather Sofa

Domain: thespruce.com

Registered: 2009 (16 years)

Introduction: Best Overall: Pottery Barn Leather Sofa – Comes in various styles and sizes, waterproof cushion covers, durable frame and leather. Dimensions: 5 sizes available, Weight: 120-200 pounds, Seat Capacity: 2-3, Seat Fill: Springs, foam, down blend, Frame Material: Hardwood, Assembly Required: No, Type of Leather: Top-grain aniline dyed. Best Value: Simpli Home Morrison Sectional in Genuine Leather – Co…

Strategic Sourcing Conclusion and Outlook for who makes the best quality leather furniture

In the competitive landscape of leather furniture manufacturing, strategic sourcing plays a pivotal role in ensuring the procurement of high-quality products that meet both durability and aesthetic standards. By understanding the varying quality levels among manufacturers, buyers can make informed decisions that align with their specific needs, whether for residential or commercial applications. Key factors such as the quality of leather hides, framing materials, and warranty responsiveness are essential in evaluating potential suppliers.

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, leveraging this knowledge can significantly enhance sourcing strategies. Brands such as Bradington-Young and Hancock & Moore stand out for their exceptional craftsmanship, while options like Natuzzi and Restoration Hardware offer a balance of quality and value.

As you consider your next procurement, prioritize partnerships with manufacturers known for transparency and commitment to quality. This approach not only secures superior products but also fosters long-term relationships that are vital in today’s dynamic market. Embrace the opportunity to elevate your offerings by investing in high-quality leather furniture that resonates with your clientele’s expectations and preferences.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.