Introduction: Navigating the Global Market for polyurethane bags

In today’s competitive landscape, sourcing high-quality polyurethane bags that meet both functionality and aesthetic demands poses a significant challenge for international B2B buyers. Whether you’re a retailer in Brazil looking to stock durable, cost-effective alternatives to traditional leather or a distributor in the Middle East aiming to cater to a growing eco-conscious market, understanding the nuances of polyurethane bags is crucial. This guide delves deep into the diverse types and applications of polyurethane bags, providing insights into the benefits and limitations of various materials, as well as practical advice on supplier vetting and pricing strategies.

International buyers from regions such as Africa, South America, and Europe will find this comprehensive resource invaluable for making informed purchasing decisions. We will explore not only the market trends and consumer preferences shaping the polyurethane bag industry but also the critical factors to consider when evaluating potential suppliers. This includes assessing quality standards, understanding production processes, and recognizing the importance of sustainability in procurement practices.

By the end of this guide, you’ll be equipped with the knowledge to navigate the global market effectively, ensuring that your sourcing decisions align with both your business goals and the expectations of your clientele. Join us as we unlock the potential of polyurethane bags, a versatile and increasingly popular choice in the B2B landscape.

Table Of Contents

- Top 5 Polyurethane Bags Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for polyurethane bags

- Understanding polyurethane bags Types and Variations

- Key Industrial Applications of polyurethane bags

- 3 Common User Pain Points for ‘polyurethane bags’ & Their Solutions

- Strategic Material Selection Guide for polyurethane bags

- In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane bags

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane bags’

- Comprehensive Cost and Pricing Analysis for polyurethane bags Sourcing

- Alternatives Analysis: Comparing polyurethane bags With Other Solutions

- Essential Technical Properties and Trade Terminology for polyurethane bags

- Navigating Market Dynamics and Sourcing Trends in the polyurethane bags Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane bags

- Strategic Sourcing Conclusion and Outlook for polyurethane bags

- Important Disclaimer & Terms of Use

Understanding polyurethane bags Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PU Leather Bags | Synthetic leather with a high-quality finish | Fashion retail, corporate gifting | Pros: Affordable, easy to clean; Cons: Less durable than genuine leather, may crack over time. |

| Polyurethane Tote Bags | Spacious, versatile design with durable handles | Retail, promotional giveaways | Pros: Lightweight, customizable; Cons: Limited protection for fragile items. |

| Polyurethane Backpacks | Ergonomic design, often with waterproof features | Education, corporate travel | Pros: Comfortable, practical for daily use; Cons: Can be bulkier than other types. |

| Polyurethane Duffle Bags | Large capacity, ideal for travel and storage | Travel, sports equipment, logistics | Pros: Versatile and spacious; Cons: May lack structure and durability over time. |

| Polyurethane Messenger Bags | Sleek design, suitable for laptops and documents | Business professionals, students | Pros: Stylish, functional for tech users; Cons: May not offer enough padding for heavy items. |

What Are the Characteristics of PU Leather Bags for B2B Buyers?

PU leather bags are distinguished by their synthetic leather construction, offering a cost-effective alternative to genuine leather. These bags are often used in fashion retail and corporate gifting due to their aesthetic appeal and affordability. When purchasing, B2B buyers should consider the quality of the materials used, as lower-quality PU leather can lead to issues like cracking and peeling over time. Furthermore, understanding the target market’s preferences for durability versus cost can guide purchasing decisions.

How Do Polyurethane Tote Bags Serve B2B Applications?

Polyurethane tote bags are characterized by their spacious and versatile designs, making them ideal for retail and promotional giveaways. These bags are lightweight and can be easily customized with branding, enhancing visibility for businesses. However, buyers should be aware that while tote bags are excellent for carrying items, they may not offer sufficient protection for fragile goods. Evaluating the intended use and the types of items to be carried is crucial when selecting tote bags.

Illustrative image related to polyurethane bags

What Makes Polyurethane Backpacks Suitable for Corporate Use?

Polyurethane backpacks are designed with ergonomics in mind, often featuring waterproof materials that appeal to both students and corporate travelers. Their practicality and comfort make them suitable for daily use, particularly in educational and professional settings. B2B buyers should assess the balance between style and functionality, ensuring that the backpacks meet the needs of the end-users. Additionally, considering the weight and size can help in determining the best fit for the target audience.

Why Choose Polyurethane Duffle Bags for Travel and Logistics?

Polyurethane duffle bags provide ample space and versatility, making them popular choices for travel, sports, and logistics applications. Their large capacity allows for easy storage of various items, but buyers should note that they may lack structural integrity compared to other bag types. When sourcing duffle bags, businesses should weigh the benefits of size and convenience against potential long-term durability concerns. This consideration is essential for ensuring customer satisfaction and repeat purchases.

How Do Polyurethane Messenger Bags Cater to Business Professionals?

Polyurethane messenger bags are designed with a sleek, modern aesthetic that appeals to business professionals and students alike. They often feature compartments for laptops and documents, making them practical for daily commuting. While these bags provide style and functionality, B2B buyers should consider the level of padding available to protect valuable tech items. Ensuring that the messenger bags meet the specific needs of the target market can enhance their appeal and usability.

Key Industrial Applications of polyurethane bags

| Industry/Sector | Specific Application of Polyurethane Bags | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Packaging for perishable goods | Enhances shelf life and maintains product integrity | Compliance with food safety regulations and certifications |

| Pharmaceutical | Containment for medications | Ensures safe transport and storage of sensitive products | Quality assurance and adherence to health regulations |

| Agriculture | Fertilizer and seed packaging | Protects contents from moisture and contamination | Durability and resistance to environmental factors |

| Fashion and Retail | Custom bags for retail display | Attracts customers and enhances brand visibility | Customization options and material quality |

| Electronics | Protective packaging for components | Reduces damage during transit and storage | Anti-static properties and compliance with industry standards |

How are Polyurethane Bags Used in the Food and Beverage Industry?

In the food and beverage sector, polyurethane bags are extensively utilized for packaging perishable items such as fruits, vegetables, and dairy products. These bags provide excellent moisture resistance and barrier properties, which help extend the shelf life of food products. For B2B buyers, ensuring that the bags meet local and international food safety regulations is crucial. Additionally, sourcing bags that are environmentally friendly can align with sustainability goals, especially in regions like Europe where consumers increasingly prefer eco-conscious products.

Illustrative image related to polyurethane bags

What Role Do Polyurethane Bags Play in the Pharmaceutical Industry?

Polyurethane bags are vital in the pharmaceutical industry for the safe containment and transport of medications. They help prevent contamination and maintain the integrity of sensitive products, such as vaccines and biologics. B2B buyers must prioritize quality assurance and compliance with stringent health regulations when sourcing these bags. This is particularly important in regions like Africa and South America, where regulatory frameworks may vary, necessitating thorough due diligence on suppliers.

How Are Polyurethane Bags Beneficial in Agriculture?

In agriculture, polyurethane bags are commonly used for packaging fertilizers and seeds. Their resistance to moisture and environmental contaminants ensures that the products remain effective during storage and transport. For international buyers, especially in developing regions, the durability of these bags is a key consideration, as they must withstand varying climatic conditions. Additionally, sourcing from manufacturers that offer bags with UV protection can further enhance the longevity of agricultural inputs.

Why Are Polyurethane Bags Essential for Fashion and Retail?

In the fashion and retail industries, polyurethane bags serve as custom packaging solutions that not only protect products but also enhance brand visibility. These bags can be designed with unique prints and styles, making them an attractive option for retailers looking to create a memorable customer experience. B2B buyers should consider the customization options available and the quality of materials used, as these factors can significantly impact brand perception and customer satisfaction.

How Do Polyurethane Bags Protect Electronics?

Polyurethane bags are crucial in the electronics industry for protective packaging of components such as circuit boards and devices. Their anti-static properties help prevent electrostatic discharge, which can damage sensitive electronic parts. For buyers in this sector, ensuring compliance with industry standards and sourcing from reputable manufacturers is essential to minimize risks during transportation and storage. This is particularly relevant for buyers in markets like Brazil and Vietnam, where electronic manufacturing is rapidly growing.

3 Common User Pain Points for ‘polyurethane bags’ & Their Solutions

Scenario 1: Concerns About Durability and Longevity of Polyurethane Bags

The Problem: Many B2B buyers are apprehensive about the durability of polyurethane (PU) bags, especially when considering them for long-term use in rigorous environments. Industries such as construction, logistics, and manufacturing often require bags that can withstand wear and tear. Buyers may have experienced issues with PU bags cracking or peeling over time, leading to concerns about product life cycles and return on investment.

The Solution: To ensure the durability of PU bags, buyers should prioritize sourcing from reputable manufacturers that adhere to strict quality control standards. It’s advisable to request samples to assess the material’s thickness, flexibility, and resistance to common stressors in your industry. Additionally, understanding the manufacturing process can help; look for bags made from high-quality polyurethane with reinforced stitching and heat-sealed seams. For extended use, consider bags that are specifically designed for your industry’s demands, as these often incorporate advanced materials that enhance longevity. Regular maintenance, such as cleaning with appropriate non-abrasive solutions, can also prolong the life of PU bags.

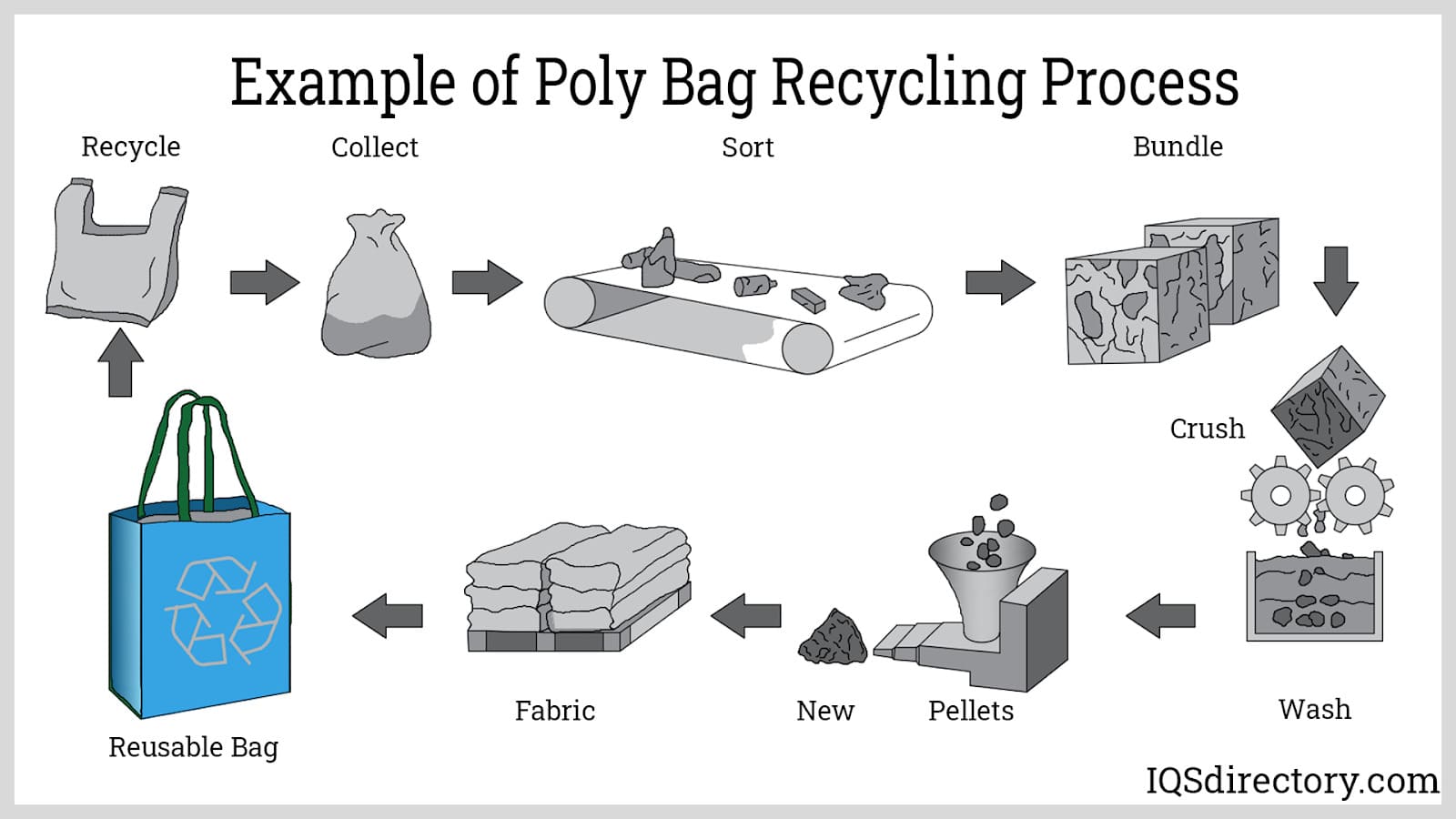

Scenario 2: Environmental Concerns Surrounding Polyurethane Materials

The Problem: With increasing scrutiny on environmental impacts, B2B buyers often face pressure to select sustainable products. Polyurethane bags, being synthetic, can raise concerns about their ecological footprint, particularly in regions where environmental regulations are stringent. Buyers may struggle to justify the use of PU bags over eco-friendly alternatives, fearing backlash from environmentally conscious stakeholders or customers.

The Solution: To navigate environmental concerns, buyers should seek suppliers that provide transparency regarding their manufacturing processes and the environmental impact of their products. Look for certifications that indicate compliance with environmental standards, such as the Global Recycling Standard (GRS) or OEKO-TEX certification. Additionally, consider sourcing PU bags that incorporate recycled materials or are designed for recyclability at the end of their life cycle. Communicating these sustainable practices to stakeholders can enhance your company’s reputation and align with broader corporate social responsibility goals.

Scenario 3: Difficulty in Sourcing the Right Specifications for Polyurethane Bags

The Problem: B2B buyers often encounter challenges when trying to find polyurethane bags that meet specific size, capacity, and functionality requirements. Different applications demand unique bag designs, and failure to procure the right specifications can lead to operational inefficiencies, increased costs, and dissatisfaction among end-users.

The Solution: To effectively source the right polyurethane bags, it’s essential to conduct a thorough needs assessment before engaging suppliers. Clearly define your requirements, including dimensions, weight capacity, and any special features like waterproofing or additional compartments. Engaging with manufacturers directly during the design phase can facilitate customization options that align with your operational needs. Furthermore, leveraging online platforms and trade shows to explore various suppliers can provide insights into innovative designs and materials that may better serve your requirements. Establishing a close relationship with a trusted supplier can also ensure that they are responsive to your evolving needs and can quickly adapt to changes in specifications.

Illustrative image related to polyurethane bags

Strategic Material Selection Guide for polyurethane bags

What Are the Key Materials for Polyurethane Bags?

When selecting materials for polyurethane bags, it is essential to consider various options that cater to specific application needs, performance requirements, and regional compliance standards. Below is an analysis of several common materials used in the production of polyurethane bags, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Polyurethane Foam?

Polyurethane foam is a versatile material known for its lightweight and cushioning properties. It exhibits excellent thermal insulation and can withstand a range of temperatures, making it suitable for various environments.

Pros and Cons: The primary advantage of polyurethane foam is its durability and resistance to wear and tear, which enhances the longevity of the bags. However, it can be more expensive compared to other materials, and its manufacturing process may involve complex techniques such as molding and cutting.

Impact on Application: This material is ideal for applications requiring impact resistance, such as travel bags and protective cases. It is less suitable for heavy-duty applications due to its compressibility under high pressure.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local regulations regarding material safety and environmental impact. Standards such as ASTM and ISO can guide material selection.

How Does Polyurethane Coating Enhance Bag Performance?

Polyurethane coatings are often applied to fabrics to enhance water resistance and durability. This coating provides a protective layer that can withstand exposure to moisture and UV light.

Pros and Cons: The key advantage of polyurethane-coated fabrics is their enhanced resistance to environmental factors, making them suitable for outdoor applications. However, the coating can add to the overall cost and may affect the breathability of the material.

Impact on Application: These coated materials are ideal for bags used in humid or wet conditions, such as outdoor gear or marine applications. However, they may not be suitable for applications requiring high breathability.

Illustrative image related to polyurethane bags

Considerations for International Buyers: Buyers should check for compliance with international standards regarding water resistance and UV protection, particularly in regions with varying climates like the Middle East and Europe.

What Role Does Polyurethane Film Play in Bag Design?

Polyurethane films are thin, flexible sheets that can be used as the primary material for bags or as a lining. They offer excellent clarity and can be made to be biodegradable, appealing to environmentally conscious consumers.

Pros and Cons: The primary advantage of polyurethane film is its lightweight nature and ability to provide a moisture barrier, making it suitable for food packaging and medical applications. However, it may lack the structural integrity required for heavy-duty bags.

Impact on Application: This material is particularly effective for applications requiring visibility and moisture protection, such as packaging for perishable goods. Its limited durability makes it less suitable for heavy-duty uses.

Considerations for International Buyers: Compliance with food safety standards is crucial for buyers in the food industry. Regulations such as FDA and EU food safety standards should be adhered to, especially in regions like Europe and South America.

How Do Recycled Polyurethane Materials Impact Sustainability?

Recycled polyurethane materials are gaining traction in the market due to their environmental benefits. These materials are derived from post-consumer products and can help reduce waste.

Pros and Cons: The key advantage of using recycled polyurethane is its positive impact on sustainability and reduced environmental footprint. However, the availability of high-quality recycled materials can be inconsistent, potentially affecting product quality.

Impact on Application: Recycled materials are suitable for eco-friendly product lines, appealing to consumers in markets increasingly focused on sustainability. However, they may not perform as well under extreme conditions compared to virgin materials.

Considerations for International Buyers: Buyers should ensure that recycled materials meet local environmental regulations and standards, especially in regions like Europe, where sustainability is a significant purchasing factor.

Summary Table of Material Selection for Polyurethane Bags

| Matériau | Typical Use Case for Polyurethane Bags | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Foam | Travel bags, protective cases | Durable and impact-resistant | Higher cost, complex manufacturing | Medium |

| Polyurethane Coating | Outdoor gear, marine applications | Water and UV resistant | Affects breathability, higher cost | Medium |

| Polyurethane Film | Food packaging, medical applications | Lightweight and moisture barrier | Limited durability for heavy-duty use | Low |

| Recycled Polyurethane | Eco-friendly product lines | Positive environmental impact | Inconsistent quality | Medium |

This strategic material selection guide aims to provide B2B buyers with the insights necessary to make informed decisions when sourcing polyurethane bags. By understanding the properties, advantages, and limitations of various materials, buyers can align their choices with both application needs and compliance standards in their respective regions.

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane bags

What Are the Key Stages in the Manufacturing Process of Polyurethane Bags?

The manufacturing of polyurethane (PU) bags involves a series of carefully orchestrated stages that ensure quality, durability, and aesthetic appeal. Understanding these stages can help B2B buyers make informed decisions when sourcing products.

1. Material Preparation: What Materials Are Used and How Are They Processed?

The first stage in manufacturing PU bags is the preparation of raw materials. The primary material is polyurethane, which is available in various forms, including sheets, foams, and coatings. The selection of high-quality PU is crucial, as it influences the bag’s overall durability and performance.

In addition to PU, manufacturers may use other materials such as fabric linings, zippers, and hardware. These components are sourced from reputable suppliers to ensure compatibility with the PU. The materials undergo cleaning and cutting processes to prepare them for the subsequent stages.

2. Forming: How Are PU Bags Shaped and Constructed?

Forming is a critical stage where the prepared materials are shaped into the desired bag designs. This can be achieved through various techniques:

- Die-Cutting: Using precision dies, manufacturers cut PU sheets into specific shapes that will form the bag’s panels.

- Molding: For certain designs, PU can be molded into shape using heat and pressure, allowing for more complex structures.

- Sewing: After cutting, the panels are stitched together using industrial sewing machines. This process requires skilled labor to ensure strong seams that can withstand stress.

The forming stage is where the design elements, such as pockets and straps, are integrated, requiring attention to detail to ensure functionality and aesthetics.

3. Assembly: What Steps Are Involved in Finalizing the Product?

Once the individual components are formed, they move to the assembly stage. Here, all parts are brought together to create the final product. Key steps include:

- Zipper and Hardware Attachment: Zippers, clasps, and other hardware are securely attached to the bag. This is a critical quality control point, as improper attachment can lead to product failure.

- Quality Checks: Before moving on to finishing, bags undergo initial quality checks to identify any defects from the forming and assembly processes.

Attention to detail during assembly ensures that the final product meets design specifications and quality standards.

4. Finishing: How Is the Bag Prepared for Market?

The finishing stage involves several processes that enhance the bag’s appearance and functionality:

- Surface Treatment: PU bags may receive treatments such as UV protection, waterproofing, or additional coatings to enhance durability and resistance to environmental factors.

- Final Quality Inspection: Each bag undergoes a thorough inspection to check for defects in stitching, material integrity, and overall appearance. Defective items are either repaired or discarded.

After passing the final inspection, the bags are packaged and prepared for shipment.

What Quality Assurance Practices Should B2B Buyers Consider?

Quality assurance (QA) is paramount in the manufacturing of PU bags, as it directly affects product reliability and customer satisfaction. B2B buyers should be aware of the following QA practices:

1. Which International Standards Are Relevant for PU Bag Manufacturing?

Manufacturers should comply with international quality standards, such as:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS), ensuring that organizations consistently produce products that meet customer and regulatory requirements.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: In certain industries, adherence to American Petroleum Institute (API) standards may be necessary, particularly if the bags are used in specific applications like oil and gas.

These certifications provide assurance of the manufacturer’s commitment to quality.

2. What Are the Key Quality Control Checkpoints in PU Bag Manufacturing?

The manufacturing process typically includes multiple quality control (QC) checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify issues early, preventing defective products from proceeding to the next stage.

- Final Quality Control (FQC): The final inspection ensures that the completed products meet all quality standards before they are shipped.

Implementing these checkpoints can significantly reduce the risk of defects.

3. How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers can take several steps to verify the quality control measures of potential suppliers:

- Conduct Audits: Regular audits of the manufacturing facilities can provide insight into the supplier’s processes and adherence to quality standards.

- Request Quality Reports: Suppliers should be willing to share their quality control reports, including details of inspections and compliance with international standards.

- Engage Third-Party Inspectors: Utilizing independent inspection services can offer an unbiased assessment of the manufacturer’s quality practices.

These actions help build trust and ensure that suppliers meet the required quality benchmarks.

What Testing Methods Are Commonly Used in the Quality Assurance of PU Bags?

Testing methods for PU bags typically include:

- Physical Testing: Assessing the strength and durability of seams and materials through tensile strength tests.

- Environmental Testing: Evaluating how the bags perform under various environmental conditions, such as exposure to UV light or moisture.

- Chemical Testing: Ensuring that the materials used do not contain harmful substances and comply with safety regulations.

These tests help ensure that the products are safe, durable, and suitable for their intended use.

How Do Quality Control Nuances Affect International B2B Transactions?

For international B2B buyers, understanding the nuances of quality control is essential. Different regions may have varying standards and regulations, influencing product acceptance in local markets. Buyers from Africa, South America, the Middle East, and Europe should:

- Be Aware of Regional Standards: Familiarize themselves with local regulations regarding product safety and quality.

- Consider Logistics: Quality issues can arise during shipping, so it’s important to ensure that the supplier uses appropriate packaging and handling methods.

- Negotiate Clear Terms: Establish clear quality expectations and terms in contracts to avoid disputes and ensure that suppliers are held accountable for quality.

By paying close attention to these factors, B2B buyers can mitigate risks and ensure a successful partnership with PU bag manufacturers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane bags’

In the competitive landscape of B2B procurement, sourcing polyurethane bags requires a strategic approach. This guide provides actionable steps for international buyers, particularly those from Africa, South America, the Middle East, and Europe, to ensure they make informed decisions when procuring these versatile products.

Illustrative image related to polyurethane bags

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your requirements for polyurethane bags. Consider the intended use, size, weight capacity, and any specific features such as waterproofing or UV resistance. Establishing these specifications will help you communicate your needs effectively and filter potential suppliers who can meet your criteria.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in polyurethane bags. Utilize platforms like Alibaba, Global Sources, and trade directories to compile a list of potential manufacturers. Pay attention to their product range, manufacturing capabilities, and industry reputation. Consider reaching out to industry contacts or using LinkedIn to gather insights on supplier reliability.

Step 3: Evaluate Supplier Certifications

Quality assurance is critical in sourcing. Verify that potential suppliers hold relevant certifications such as ISO 9001 for quality management or other industry-specific certifications. These certifications ensure that the supplier adheres to international standards, which is essential for maintaining product quality and consistency.

Illustrative image related to polyurethane bags

Step 4: Request Samples for Evaluation

Once you have narrowed down your list, request samples of the polyurethane bags. This step allows you to assess the quality, durability, and functionality of the products firsthand. Evaluate the samples based on your defined specifications and consider conducting stress tests to determine their suitability for your intended use.

Step 5: Assess Production Capacity and Lead Times

Understanding a supplier’s production capacity is crucial for timely procurement. Inquire about their manufacturing processes, lead times, and ability to scale production based on your order volume. Ensure they can meet your demand without compromising quality, especially if you require bulk orders or have tight deadlines.

Step 6: Negotiate Pricing and Terms

Once you are satisfied with the supplier’s capabilities, engage in pricing discussions. Be prepared to negotiate terms, including payment methods, delivery timelines, and bulk order discounts. Ensure that the final agreement is detailed and includes all terms to avoid misunderstandings later.

Illustrative image related to polyurethane bags

Step 7: Establish Quality Control Procedures

Before finalizing your order, set up quality control measures to monitor the production process. Discuss with your supplier how quality checks will be conducted and consider arranging third-party inspections if necessary. This proactive approach can help identify potential issues early and ensure that the final products meet your standards.

By following this comprehensive checklist, you can effectively source high-quality polyurethane bags that meet your business needs while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for polyurethane bags Sourcing

What Are the Key Cost Components in Sourcing Polyurethane Bags?

When sourcing polyurethane bags, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The primary material for polyurethane bags is polyurethane itself, which can vary in quality and price based on the supplier. Additional materials, such as zippers, linings, and reinforcement fabrics, also contribute to the overall material cost. Buyers should inquire about the source and quality of materials to ensure durability and compliance with relevant standards.

-

Labor: Labor costs can fluctuate based on the manufacturing location. Countries with lower labor costs may offer competitive pricing, but it’s essential to assess the skill level and efficiency of the workforce, as this affects the quality of the final product.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturers will have optimized overhead costs, which can be passed on to buyers in the form of lower prices.

-

Tooling: Custom molds and tooling for specific designs can represent a significant upfront cost. Buyers should consider whether they need unique shapes or sizes, as this can influence the overall pricing.

-

Quality Control (QC): Implementing stringent QC processes incurs additional costs but is vital for ensuring that the bags meet quality standards. Buyers should look for suppliers that prioritize QC to minimize defects and returns.

-

Logistics: Shipping and handling costs are especially pertinent for international buyers. Factors such as distance, shipping method, and import duties can significantly impact the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding industry standards for margins can help buyers assess whether they are receiving competitive quotes.

What Factors Influence the Pricing of Polyurethane Bags?

Several factors can influence the pricing of polyurethane bags:

-

Volume/MOQ: Larger order volumes often qualify for bulk pricing discounts. Buyers should negotiate minimum order quantities (MOQs) to reduce costs effectively.

-

Specifications and Customization: Custom designs or specifications can increase costs due to the need for specialized materials or tooling. Clear communication of requirements will aid suppliers in providing accurate quotes.

-

Materials and Quality: The choice of materials significantly affects pricing. Higher-quality polyurethane or eco-friendly alternatives may come at a premium but can enhance the product’s marketability.

-

Certifications: Compliance with international quality certifications (such as ISO or REACH) may add costs but can be a selling point in competitive markets.

-

Supplier Factors: The supplier’s reputation, reliability, and location will influence pricing. Established suppliers with proven track records may charge more but often deliver better quality and service.

-

Incoterms: Understanding the shipping terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for budgeting. Different terms can shift costs and responsibilities between buyers and suppliers.

What Are the Best Tips for Negotiating Prices on Polyurethane Bags?

For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Conduct Market Research: Familiarize yourself with prevailing market prices and supplier options in your target region. Knowledge is power in negotiations.

-

Focus on Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as longevity, maintenance, and potential resale value of the bags.

-

Leverage Long-Term Relationships: Building a rapport with suppliers can lead to better pricing and terms. Suppliers are often more willing to negotiate with repeat customers.

-

Be Transparent About Your Needs: Clearly communicate your requirements and constraints. This transparency helps suppliers tailor their offers and may lead to cost-saving recommendations.

-

Evaluate Multiple Quotes: Request quotes from multiple suppliers to compare pricing and terms. This strategy not only helps in finding the best deal but also provides leverage in negotiations.

Disclaimer on Pricing

Pricing for polyurethane bags can vary significantly based on the aforementioned factors. The prices mentioned in discussions should be regarded as indicative and subject to change based on market conditions, supplier agreements, and other variables. Always request detailed quotes and terms before finalizing any contracts.

Alternatives Analysis: Comparing polyurethane bags With Other Solutions

Understanding the Importance of Alternatives in Polyurethane Bags

In the competitive landscape of B2B packaging and product solutions, it’s crucial for businesses to explore various alternatives to polyurethane bags. While polyurethane (PU) bags offer numerous advantages, such as affordability and ease of maintenance, other options may better suit specific applications or sustainability goals. Evaluating these alternatives enables buyers to make informed decisions that align with their operational requirements and values.

Comparison Table of Polyurethane Bags and Alternatives

| Comparison Aspect | Polyurethane Bags | Reusable Cloth Bags | Biodegradable Bags |

|---|---|---|---|

| Performance | Durable, water-resistant | Moderate durability | Varies; typically less durable |

| Cost | Cost-effective | Generally higher initial cost | Comparable to PU bags |

| Ease of Implementation | Simple manufacturing process | Requires sourcing of materials | May require special sourcing |

| Maintenance | Easy to clean with a damp cloth | Machine washable | Limited lifespan; compostable |

| Best Use Case | Everyday consumer goods | Retail and groceries | Environmentally conscious brands |

In-Depth Analysis of Alternatives

Reusable Cloth Bags: Are They a Sustainable Choice?

Reusable cloth bags, typically made from cotton or other natural fibers, offer an eco-friendly alternative to PU bags. Their durability allows for multiple uses, making them a preferred choice for retailers aiming to reduce waste. However, they often come with a higher initial cost and require specific care to maintain their longevity. While they are machine washable, over time, they may not withstand the same rigorous use as PU bags, leading to potential replacement costs. Their best use case is in retail environments where sustainability is a core value.

Illustrative image related to polyurethane bags

Biodegradable Bags: A Step Towards Environmental Responsibility

Biodegradable bags are designed to decompose more quickly than traditional plastics, making them an appealing option for environmentally conscious businesses. They can be made from materials like cornstarch or other plant-based substances. While they represent a progressive approach to reducing plastic waste, their performance can vary, and they may not be as durable as PU bags. This option is ideal for companies looking to enhance their sustainability profile but may require careful consideration regarding sourcing and cost.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right packaging solution depends on various factors, including budget, intended use, and sustainability goals. Polyurethane bags are a cost-effective and durable option, particularly for everyday consumer goods. However, businesses should weigh the advantages of alternatives like reusable cloth and biodegradable bags. By considering the performance, cost implications, and environmental impact, B2B buyers can make strategic decisions that align with their operational requirements and brand values. Prioritizing both functionality and sustainability will ultimately lead to more informed purchasing choices that benefit both the business and the planet.

Essential Technical Properties and Trade Terminology for polyurethane bags

What Are the Key Technical Properties of Polyurethane Bags?

When considering polyurethane (PU) bags for your business needs, understanding their technical properties is crucial. Here are some essential specifications that impact performance, durability, and cost-effectiveness:

1. Material Grade

Material grade refers to the quality and type of polyurethane used in manufacturing bags. Higher-grade materials offer enhanced durability, resistance to wear and tear, and improved aesthetic appeal. For B2B buyers, investing in higher-grade PU bags can lead to lower replacement costs and increased customer satisfaction due to better product longevity.

2. Tolerance Levels

Tolerance levels indicate the acceptable variations in size and shape during the manufacturing process. This specification is vital for ensuring that bags fit specific applications or machinery correctly. Inconsistent tolerances can lead to product failures or operational inefficiencies. For international buyers, understanding tolerance levels helps in quality assurance and compliance with local standards.

3. Thickness

The thickness of the polyurethane material plays a significant role in the bag’s strength and flexibility. Thicker bags generally offer better protection against punctures and abrasions, making them ideal for heavy-duty applications. Buyers should assess the required thickness based on the intended use, as this can significantly affect the overall performance and cost.

4. Waterproofing

Polyurethane bags often possess inherent waterproof properties, but the extent can vary based on the manufacturing process. A bag’s waterproof rating is critical for applications in environments where moisture exposure is a concern. For industries like logistics and outdoor equipment, understanding the waterproof capabilities can prevent product damage and enhance reliability.

5. UV Resistance

UV resistance indicates a bag’s ability to withstand exposure to sunlight without degrading. This property is particularly important for outdoor applications where prolonged sun exposure is expected. For buyers in regions with high UV levels, investing in UV-resistant bags can ensure longevity and maintain the bag’s appearance over time.

What Are the Common Trade Terms Used in the Polyurethane Bag Industry?

Familiarity with industry terminology can streamline communication and negotiations. Here are several key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. In the context of polyurethane bags, an OEM may manufacture bags that are branded and sold by another company. Understanding OEM relationships can help buyers identify potential suppliers and negotiate better pricing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for B2B buyers, as it affects inventory management and cash flow. Knowing the MOQ helps businesses assess whether a supplier’s offerings align with their purchasing needs.

3. RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to request pricing and terms from suppliers. It typically includes specific details about the products needed, such as material specifications and quantities. Using RFQs allows buyers to compare offers from multiple suppliers, ensuring they receive competitive pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs during the transportation of goods. Understanding Incoterms is crucial for B2B buyers engaged in global transactions, as they can significantly affect total costs and liabilities.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. In the context of polyurethane bags, understanding lead times is essential for planning inventory and meeting customer demand. Buyers should always clarify lead times with suppliers to ensure timely delivery.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing polyurethane bags, ultimately enhancing their supply chain efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the polyurethane bags Sector

What are the Current Market Dynamics and Key Trends in the Polyurethane Bags Sector?

The polyurethane (PU) bags market is experiencing significant growth, driven by factors such as increasing demand for lightweight, durable, and cost-effective alternatives to traditional leather bags. International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly turning to PU bags due to their affordability and ease of maintenance. Notably, the rise of e-commerce has facilitated access to a broader range of products, allowing buyers to source PU bags from global manufacturers with greater efficiency.

Illustrative image related to polyurethane bags

Emerging trends in B2B sourcing include the integration of technology in supply chain management, which enhances transparency and traceability. Digital platforms are enabling buyers to connect directly with manufacturers, streamlining procurement processes. Furthermore, the demand for customization is on the rise, with buyers seeking unique designs and features to differentiate their offerings in competitive markets. As consumers become more fashion-conscious, manufacturers are responding by innovating designs, colors, and functionalities, thus expanding the appeal of PU bags across diverse demographics.

How is Sustainability and Ethical Sourcing Impacting the Polyurethane Bags Market?

Sustainability is increasingly becoming a focal point for international buyers in the PU bags sector. The environmental impact of synthetic materials, including PU, has raised concerns, prompting buyers to prioritize suppliers who adopt sustainable practices. Ethical sourcing is crucial, as buyers seek to align with manufacturers who demonstrate responsible environmental stewardship and fair labor practices.

To address these concerns, many manufacturers are investing in eco-friendly production methods and materials. Green certifications, such as Global Recycle Standard (GRS) and OEKO-TEX, are becoming essential for buyers looking to verify the sustainability of their suppliers. Additionally, innovations in biodegradable polyurethane and recycled materials are gaining traction, offering buyers a way to meet consumer demands for environmentally friendly products. By emphasizing ethical sourcing and sustainability, businesses can enhance their brand image and appeal to a growing segment of environmentally conscious consumers.

What is the Brief Evolution and History of Polyurethane Bags?

The evolution of polyurethane bags traces back to the development of polyurethane as a synthetic material in the mid-20th century. Initially used in various applications, its versatility led to the creation of PU leather, which gained popularity for its resemblance to genuine leather at a fraction of the cost. Over the years, the technology behind PU manufacturing has improved, enhancing the durability and aesthetic appeal of PU bags.

By the early 2000s, the global market for PU bags expanded significantly, fueled by rising consumer demand for affordable and stylish alternatives to traditional leather products. As manufacturers began to innovate with designs and functionalities, PU bags became a staple in both fashion and practical applications. Today, the market continues to evolve, with an increasing focus on sustainability, ethical sourcing, and technological advancements, positioning polyurethane bags as a viable option for discerning international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane bags

1. How do I choose the right supplier for polyurethane bags?

When selecting a supplier for polyurethane bags, consider their experience and reputation in the industry. Look for suppliers with positive reviews and testimonials from previous clients, particularly in your region. It’s crucial to assess their manufacturing capabilities, quality assurance processes, and compliance with international standards. Request samples to evaluate the quality of their products firsthand. Additionally, ensure they have a clear communication process and are responsive to inquiries, as this will facilitate smoother transactions throughout your partnership.

2. What are the key customization options available for polyurethane bags?

Customization options for polyurethane bags can vary significantly between suppliers. Common choices include size, color, design features, and branding elements such as logos or labels. Some suppliers may also offer custom materials or additional functionalities, such as waterproofing or reinforced seams. When discussing customization, provide detailed specifications and quantities to get accurate quotes. It’s advisable to ask for prototypes before mass production to ensure the final product meets your expectations.

3. What are the typical minimum order quantities (MOQ) for polyurethane bags?

Minimum order quantities (MOQ) can vary widely among manufacturers, often influenced by the complexity of the design and the materials used. Generally, MOQs for polyurethane bags range from 100 to 1,000 units. It’s essential to clarify these details upfront with potential suppliers, as lower MOQs might be available for standard designs. Be aware that higher MOQs often lead to better pricing per unit, so balancing your budget and needs is crucial when placing an order.

4. What payment terms should I expect when sourcing polyurethane bags?

Payment terms can differ from supplier to supplier, but common arrangements include a deposit (typically 30% to 50%) upfront, with the balance due before shipment or upon delivery. Some suppliers might offer credit terms for established businesses, allowing for payment after receipt of goods. Always discuss payment options and conditions before finalizing your order to avoid misunderstandings. It’s advisable to use secure payment methods to protect your transactions.

5. How can I ensure quality assurance when sourcing polyurethane bags?

To ensure quality assurance, select suppliers who adhere to recognized international quality standards, such as ISO certifications. Request detailed information on their quality control processes, including inspection protocols and testing methods. Consider implementing a third-party inspection service to evaluate the products before shipment, especially for large orders. Establishing clear quality expectations in your contract and maintaining open communication with your supplier can also help mitigate quality issues.

6. What logistics considerations should I keep in mind for shipping polyurethane bags?

When planning logistics for shipping polyurethane bags, consider factors such as shipping methods (air, sea, or land), costs, and delivery times. Assess whether the supplier can handle shipping logistics or if you need to arrange them independently. Be aware of customs regulations and import duties in your country, as these can impact overall costs and delivery schedules. It’s also prudent to discuss insurance options for your shipment to protect against loss or damage during transit.

7. Are polyurethane bags environmentally friendly?

Polyurethane bags are generally considered less environmentally friendly than natural materials due to the chemical processes involved in their production. However, some manufacturers are increasingly adopting sustainable practices, such as using recycled materials or eco-friendly production methods. If environmental impact is a concern for your business, inquire about the supplier’s sustainability initiatives and certifications. Opting for suppliers committed to environmentally responsible practices can enhance your brand’s image and appeal to eco-conscious consumers.

8. How do I handle disputes with suppliers when sourcing polyurethane bags?

Disputes can arise in any B2B transaction, so having a clear contract that outlines terms, conditions, and responsibilities is essential. In the event of a dispute, maintain open communication with the supplier to resolve issues amicably. If direct communication fails, refer to your contract for any dispute resolution clauses, which may include mediation or arbitration. Keeping thorough records of all communications and transactions can also support your case if formal action becomes necessary.

Illustrative image related to polyurethane bags

Top 5 Polyurethane Bags Manufacturers & Suppliers List

1. Vacupress – Industrial Extruded Polyurethane Bags

Domain: vacupress.com

Registered: 1998 (27 years)

Introduction: 30 Mil Industrial Extruded Polyurethane VacuPress® Bags

Price Range: $204.00 – $811.00

Custom Bags Available – Call for Quote

Caractéristiques :

– Patch Kit

– Heat Welded Nipple

– C Channel Closures

– 4 Platen Sleeves

– Heat-welded seams and clamp-less air-tight vacuum hose attachments

– C channel closures for an air-tight seal

– Single end entry for bags 4×4 and smaller

– Double end entry for bags 4×8 and…

2. Zappos – Handbags

Domain: zappos.com

Registered: 1999 (26 years)

Introduction: This company, Zappos – Handbags, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. MarkRyden – Polyurethane Bags

Domain: markrydenglobal.com

Registered: 2017 (8 years)

Introduction: Polyurethane (PU) is a versatile material used in MarkRyden bags, offering benefits such as durability, water resistance, and flexibility. The bags include various types such as anti-theft, business, laptop, travel, weatherproof, messenger, slings, and accessories. MarkRyden provides a one-year warranty, free shipping, and a 10% discount for new sign-ups.

4. The Store Bags – Best Women’s PU Leather Bags

Domain: thestorebags.com

Registered: 2019 (6 years)

Introduction: Best Women’s PU Leather Bags | The Store Bags

– Collection: PU Bags

– Customer Rating: 4.2/5 based on 1338 reviews

1. PU Tote Bag

– Regular Price: $51.00 USD

– Sale Price: $51.00 USD

2. PU Leather Tote

– Regular Price: $56.00 USD

– Sale Price: $56.00 USD

3. Beaded Leather Crossbody Bag

– Regular Price: $52.00 USD

– Sale Price: $52.00 USD

4. Leather Flap Over Shoulder Bag

…

5. Szoneier – PU Leather Bags

Domain: szoneier.com

Registered: 2024 (1 years)

Introduction: PU leather is a synthetic leather made from polyurethane, popular for its stylish look and affordability. It mimics genuine leather without the high cost and special care requirements. PU leather bags come in various shapes, sizes, and colors, appealing to diverse tastes. Key components include a base material (usually polyester or cotton) and a polyurethane coating. Types of PU leather include re…

Strategic Sourcing Conclusion and Outlook for polyurethane bags

As the global demand for polyurethane bags continues to rise, strategic sourcing emerges as a crucial factor for B2B buyers aiming to leverage this trend. The versatility, affordability, and durability of PU bags make them an attractive choice across various industries, from retail to logistics. By partnering with reputable manufacturers who prioritize quality materials and sustainable practices, buyers can ensure they receive products that meet both market standards and consumer expectations.

Moreover, understanding regional preferences and environmental concerns is essential for successful sourcing, especially in diverse markets like Africa, South America, the Middle East, and Europe. By aligning sourcing strategies with these regional insights, businesses can enhance their competitive edge and foster long-term relationships with suppliers.

Looking ahead, the polyurethane bag market presents significant opportunities for growth and innovation. B2B buyers should remain proactive in exploring new suppliers, materials, and technologies that can elevate their product offerings. Embrace this dynamic landscape to not only meet current demands but also to anticipate future trends. Engage with your suppliers today to secure a sustainable, high-quality supply chain that positions your business for success in the evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to polyurethane bags

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.