Introduction: Navigating the Global Market for leather shoe upper

In an increasingly competitive global market, sourcing high-quality leather shoe uppers presents a significant challenge for B2B buyers. With an array of materials, styles, and suppliers worldwide, the decision-making process can be overwhelming. This comprehensive guide aims to streamline your procurement journey by providing in-depth insights into the various types of leather used for shoe uppers, their applications in different footwear categories, and critical factors to consider when vetting suppliers.

From the luxurious feel of full-grain leather to the affordability of corrected grain options, understanding the nuances of each type can empower you to make informed purchasing decisions. Additionally, this guide will explore the intricacies of pricing structures, allowing you to identify cost-effective solutions without compromising on quality.

Designed specifically for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—this resource serves as a strategic tool. By equipping you with actionable insights and best practices, we aim to enhance your sourcing capabilities, ultimately facilitating successful partnerships and driving growth in your business. Navigate the complexities of the leather shoe upper market with confidence, and unlock the potential for superior product offerings in your portfolio.

Table Of Contents

- Top 6 Leather Shoe Upper Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather shoe upper

- Understanding leather shoe upper Types and Variations

- Key Industrial Applications of leather shoe upper

- 3 Common User Pain Points for ‘leather shoe upper’ & Their Solutions

- Strategic Material Selection Guide for leather shoe upper

- In-depth Look: Manufacturing Processes and Quality Assurance for leather shoe upper

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather shoe upper’

- Comprehensive Cost and Pricing Analysis for leather shoe upper Sourcing

- Alternatives Analysis: Comparing leather shoe upper With Other Solutions

- Essential Technical Properties and Trade Terminology for leather shoe upper

- Navigating Market Dynamics and Sourcing Trends in the leather shoe upper Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather shoe upper

- Strategic Sourcing Conclusion and Outlook for leather shoe upper

- Important Disclaimer & Terms of Use

Understanding leather shoe upper Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Retains original grain, high durability, develops a patina | Premium footwear, luxury brands | Pros: Long-lasting, breathable, develops character. Cons: Higher cost, requires maintenance. |

| Corrected Grain Leather | Uniform surface, resistant to wear, easy maintenance | Everyday shoes, work boots | Pros: Cost-effective, durable, low maintenance. Cons: Less breathable, may lack character. |

| Split Leather | Soft, often used for suede, less expensive | Casual and sports footwear | Pros: Affordable, flexible, good for various styles. Cons: Less durable, susceptible to moisture. |

| Cuir verni | Glossy finish, treated for water resistance | Dress shoes, formal wear | Pros: Eye-catching, easy to clean, water-resistant. Cons: Can be less breathable, may scuff easily. |

| Cuir nubuck | Sanded surface, soft and velvety texture | Casual and high-end footwear | Pros: Luxurious feel, good breathability. Cons: Requires careful maintenance, prone to stains. |

What Are the Characteristics of Full Grain Leather Shoe Uppers?

Full grain leather is considered the highest quality leather available. It retains the natural grain of the hide, providing durability and a unique aesthetic that improves with age. This type is ideal for premium footwear and luxury brands, appealing to B2B buyers focused on quality. When purchasing, consider sourcing from suppliers that guarantee authenticity and ethical sourcing, as these factors can enhance brand reputation and customer loyalty.

How Does Corrected Grain Leather Differ in Applications?

Corrected grain leather has a uniform appearance due to surface treatments that enhance durability. This makes it a preferred choice for everyday shoes and work boots, where functionality and cost-effectiveness are paramount. B2B buyers should assess the balance between price and quality, ensuring the leather meets the specific demands of their target market without compromising on durability.

Why Choose Split Leather for Casual Footwear?

Split leather, often associated with suede, is derived from the lower layers of the hide. It offers flexibility and an appealing texture, making it suitable for casual and sports footwear. While its affordability is attractive, B2B buyers should consider its susceptibility to moisture and potential durability issues. Selecting split leather from reputable suppliers can mitigate these concerns and ensure product quality.

What Are the Benefits of Patent Leather in Formal Wear?

Patent leather is characterized by its glossy finish, achieved through a unique treatment process. This type is frequently used in dress shoes and formal wear, appealing to B2B buyers in the fashion industry. While its eye-catching appearance and water resistance are significant advantages, buyers should be aware of its potential lack of breathability and susceptibility to scuffing. Establishing relationships with suppliers who specialize in high-quality patent leather can enhance product offerings.

How Does Nubuck Leather Enhance the Luxury Footwear Market?

Nubuck leather is known for its soft, velvety texture, resulting from sanding the grain side of the hide. This luxurious feel makes it a popular choice for both casual and high-end footwear. B2B buyers must weigh the maintenance requirements and potential stain susceptibility against the premium appeal of nubuck. Sourcing from established suppliers who provide care guidelines can help maintain product quality and customer satisfaction.

Key Industrial Applications of leather shoe upper

| Industry/Sector | Specific Application of leather shoe upper | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | High-end luxury footwear | Enhances brand image and customer loyalty through quality design | Sourcing premium materials, ensuring ethical production practices |

| Sports and Recreation | Athletic shoes for performance | Provides durability and comfort, improving athletic performance | Material flexibility, breathability, and moisture resistance |

| Safety and Workwear | Safety shoes and boots | Ensures worker safety and compliance with industry regulations | Compliance with safety standards, slip-resistance, and durability |

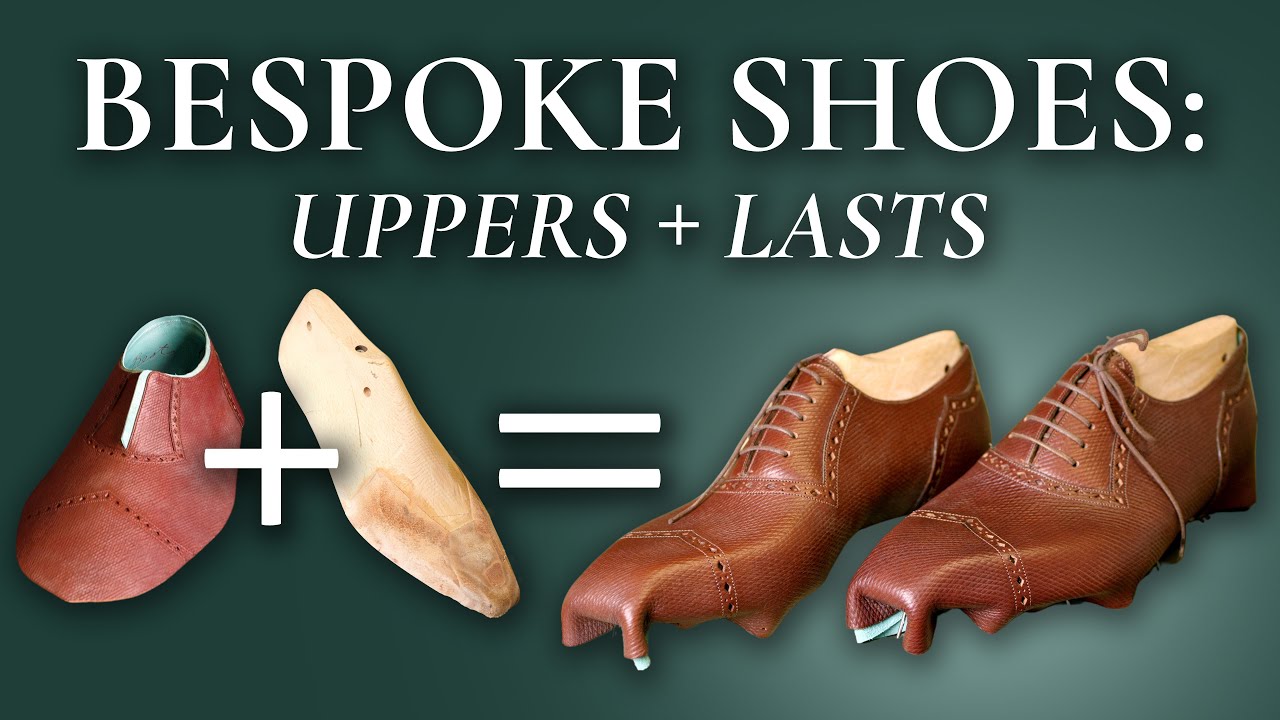

| Footwear Manufacturing | Custom shoe production | Allows for bespoke designs, catering to niche markets | Quality control in leather selection, customization options |

| Outdoor and Adventure | Hiking and outdoor footwear | Offers protection and comfort in rugged terrains | Weather resistance, traction, and support for various climates |

How is Leather Shoe Upper Used in the Fashion Retail Industry?

In the fashion retail sector, leather shoe uppers are essential for creating high-end luxury footwear. These products often feature intricate designs and superior craftsmanship, which enhance brand image and customer loyalty. Buyers in this sector seek premium materials that not only provide aesthetic appeal but also ensure durability and comfort. Sourcing considerations include the ethical production of leather, adherence to environmental standards, and the ability to meet seasonal fashion trends.

What Role Does Leather Shoe Upper Play in Sports and Recreation?

In the sports and recreation industry, leather shoe uppers are commonly used in athletic shoes designed for various sports. The leather provides necessary durability and comfort, which are critical for enhancing athletic performance. International buyers from regions with diverse climates, such as Africa and South America, must consider the flexibility and breathability of the leather to ensure it meets the specific needs of athletes. Additionally, moisture resistance is a significant factor for performance and comfort during rigorous activities.

How is Leather Shoe Upper Integral to Safety and Workwear?

Leather shoe uppers are pivotal in the safety and workwear industry, particularly for safety shoes and boots. These products are designed to protect workers in hazardous environments while ensuring compliance with safety regulations. Buyers in this sector prioritize sourcing leather that meets strict safety standards, including slip-resistance and puncture protection. The durability of leather also contributes to the longevity of the footwear, reducing the need for frequent replacements and thereby lowering overall costs for businesses.

Why is Leather Shoe Upper Important in Footwear Manufacturing?

In footwear manufacturing, leather shoe uppers are crucial for producing custom shoes. This application allows manufacturers to cater to niche markets with bespoke designs that meet specific consumer demands. Buyers must focus on quality control in leather selection to ensure the final product aligns with customer expectations. Additionally, the ability to offer customization options enhances competitiveness in the market, making sourcing strategies vital for maintaining quality while meeting diverse consumer preferences.

How Does Leather Shoe Upper Enhance Outdoor and Adventure Footwear?

Leather shoe uppers are widely used in hiking and outdoor footwear, providing essential protection and comfort for outdoor enthusiasts. The rugged nature of leather allows for durability in harsh environments, while its natural properties offer breathability and moisture management. For international buyers in regions with varying climates, sourcing leather that provides weather resistance and traction is crucial for ensuring customer satisfaction and performance in diverse outdoor conditions.

3 Common User Pain Points for ‘leather shoe upper’ & Their Solutions

Scenario 1: Sourcing High-Quality Leather for Durability

The Problem: B2B buyers often struggle with sourcing high-quality leather that meets durability and performance standards. They may find themselves receiving inferior leather that cracks, fades, or wears out quickly, leading to customer dissatisfaction and increased returns. This is particularly concerning for businesses that aim to establish a strong brand reputation in competitive markets, where the quality of materials directly influences customer loyalty.

The Solution: To ensure the procurement of superior leather, buyers should focus on sourcing from reputable suppliers who provide detailed documentation of their leather’s quality, such as certifications for full grain or corrected grain leather. Conducting site visits to tanneries can also provide insights into their production processes and quality control measures. Additionally, buyers should request samples and perform rigorous testing, including flexibility, colorfastness, and water resistance assessments, before committing to larger orders. By setting clear quality specifications and maintaining open communication with suppliers, businesses can mitigate risks and enhance product longevity.

Scenario 2: Addressing Comfort and Fit Issues in Production

The Problem: Another common challenge faced by B2B buyers is the inconsistency in comfort and fit when using leather uppers across different shoe models. This can lead to sizing discrepancies, resulting in consumer complaints and returns. In markets where customer comfort is paramount, such as in Europe and North America, failing to deliver well-fitting shoes can significantly impact sales and brand reputation.

The Solution: To tackle this issue, buyers should collaborate closely with manufacturers during the design phase to establish standardized fit protocols. Implementing a feedback loop that incorporates customer input on fit and comfort can also help refine the production process. Additionally, using high-quality, supple leathers that conform to the foot can enhance comfort. Providing clear sizing charts and product descriptions, along with offering a range of widths, can also help ensure that customers find the right fit. Regular training for production teams on the nuances of leather handling and fitting techniques will further enhance the overall quality of the footwear.

Scenario 3: Managing Leather Sustainability and Ethical Sourcing

The Problem: With an increasing emphasis on sustainability, B2B buyers are often confronted with the challenge of sourcing leather that aligns with ethical practices. Concerns regarding environmental impact and animal welfare are rising, leading to pressure from consumers and stakeholders to adopt more responsible sourcing strategies. Buyers may find it difficult to navigate certifications and claims regarding sustainability, causing confusion and potential reputational risks.

The Solution: To effectively manage sustainability concerns, buyers should prioritize partnerships with suppliers who are transparent about their sourcing practices and who comply with recognized environmental and ethical standards. Certifications such as the Leather Working Group (LWG) or Global Organic Textile Standard (GOTS) can provide assurance of responsible practices. Conducting thorough research on the supply chain and engaging with suppliers about their sustainability initiatives will also help buyers make informed decisions. Additionally, incorporating recycled or upcycled leather options into product lines can appeal to environmentally conscious consumers while reducing waste. By actively promoting these sustainable practices, businesses can enhance their brand image and cater to a growing market segment focused on ethical consumption.

Strategic Material Selection Guide for leather shoe upper

What Are the Key Properties of Common Leather Upper Materials?

When selecting materials for leather shoe uppers, it is crucial to consider various types of leather, each with distinct properties that influence their performance, durability, and suitability for different applications. This guide will analyze four common materials used in leather shoe uppers: full-grain leather, corrected-grain leather, split leather, and synthetic leather.

Full-Grain Leather: What Makes It Stand Out?

Full-grain leather is known for its superior quality and durability. It retains the original grain of the hide, which provides a unique texture and aesthetic appeal. This material is highly breathable and can withstand significant wear and tear, making it ideal for high-end footwear. However, it can be more expensive and requires careful maintenance to preserve its appearance.

Pros: Exceptional durability, breathability, and aesthetic appeal.

Cons: Higher cost and maintenance requirements.

Impact on Application: Full-grain leather is compatible with various weather conditions and is often preferred for premium shoe lines.

International Considerations: Buyers should ensure compliance with local leather sourcing regulations and standards, such as ASTM for performance and safety.

Corrected-Grain Leather: A Balanced Choice

Corrected-grain leather is processed to remove imperfections, resulting in a uniform surface. This leather type is more resistant to stains and easier to maintain, making it suitable for mass-produced footwear. While it offers a good balance between durability and cost, it may lack the unique character of full-grain leather.

Illustrative image related to leather shoe upper

Pros: Cost-effective, easy to maintain, and durable.

Cons: Less breathable and may not have the same aesthetic appeal as full-grain leather.

Impact on Application: Suitable for casual and everyday footwear, as it can withstand daily wear.

International Considerations: Commonly accepted in various markets, but buyers should verify compliance with specific standards like DIN for quality assurance.

Split Leather: What Are Its Unique Features?

Split leather is derived from the lower layers of the hide and is often used for suede applications. It is softer and more flexible, providing a comfortable fit. However, it is less durable than full-grain and corrected-grain leathers, making it more suitable for fashion-oriented shoes rather than high-performance footwear.

Pros: Soft, flexible, and comfortable.

Cons: Lower durability and less water resistance.

Impact on Application: Ideal for casual and fashion shoes, but not recommended for heavy-duty use.

International Considerations: Buyers should be aware of potential restrictions on split leather imports in certain regions due to durability concerns.

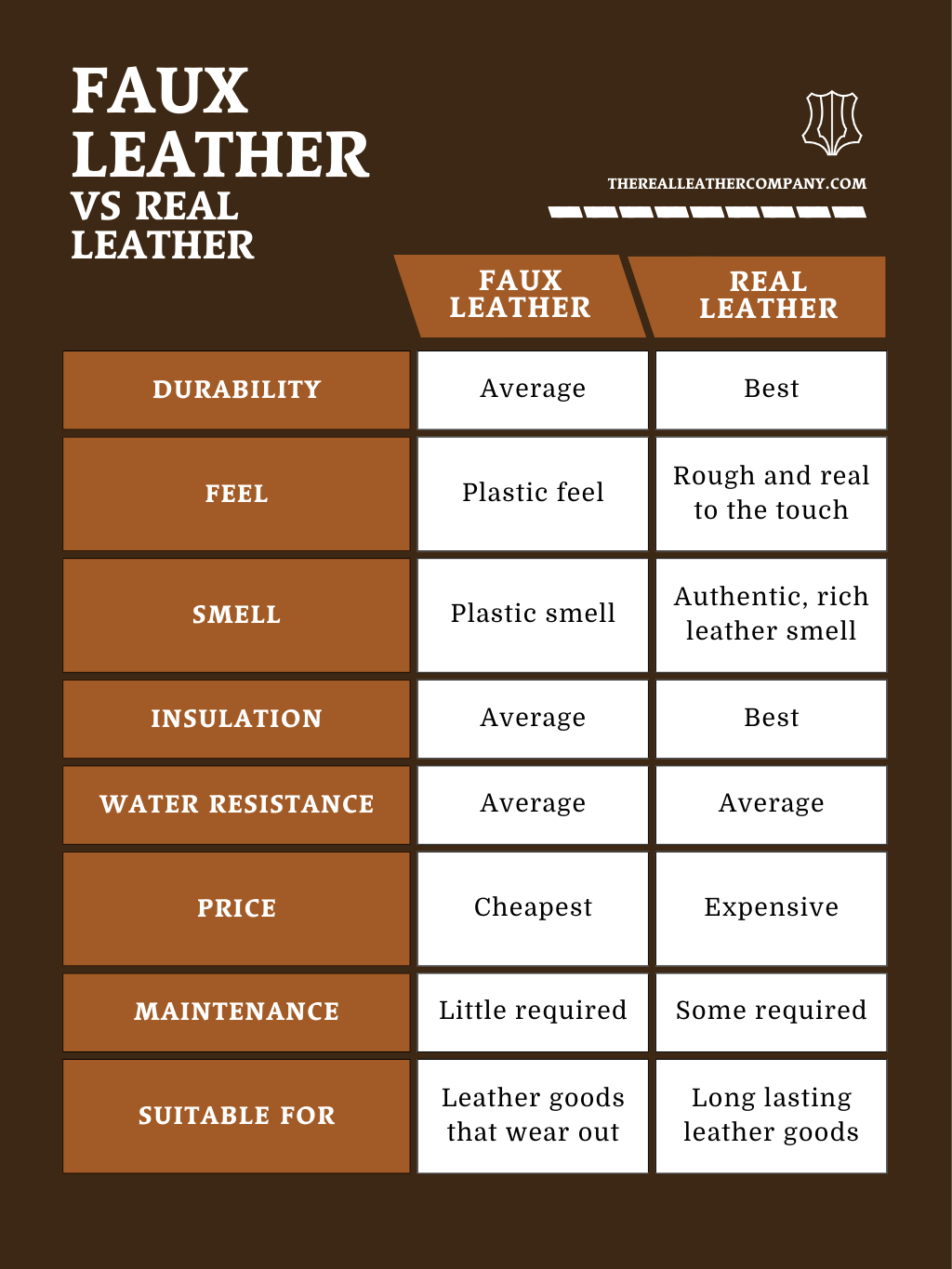

Synthetic Leather: Is It a Viable Alternative?

Synthetic leather, often made from polyurethane or PVC, offers a cost-effective alternative to natural leather. It is easy to clean and maintain, and it can mimic the appearance of real leather. However, it may not offer the same breathability and longevity as natural leather options.

Pros: Cost-effective, easy to maintain, and available in various colors and textures.

Cons: Less breathable and may not be as durable as natural leather.

Impact on Application: Suitable for budget-friendly footwear and fashion items, but may not perform well in extreme conditions.

International Considerations: Compliance with environmental regulations is essential, especially in regions focused on sustainability.

Summary Table of Leather Upper Materials

| Matériau | Typical Use Case for leather shoe upper | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end footwear | Exceptional durability and breathability | Higher cost and maintenance | Haut |

| Corrected-Grain Leather | Casual and everyday footwear | Cost-effective and easy to maintain | Less breathable | Medium |

| Split Leather | Fashion and casual shoes | Soft and comfortable | Lower durability | Medium |

| Synthetic Leather | Budget-friendly footwear | Easy to maintain and versatile | Less breathable and durable | Low |

This guide provides an overview of the key materials for leather shoe uppers, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for leather shoe upper

What Are the Key Stages in the Manufacturing Process of Leather Shoe Uppers?

The manufacturing process of leather shoe uppers involves several critical stages, ensuring that the final product meets high standards of quality and durability. Understanding these stages is essential for B2B buyers looking to source high-quality leather footwear.

1. Material Preparation: How Is Leather Selected and Processed?

The first step in the manufacturing process is the selection and preparation of leather. Various types of leather, such as full grain, corrected grain, and split leather, are commonly used for shoe uppers. Full grain leather is often preferred for its durability and aesthetic appeal, while corrected grain offers easier maintenance.

Once selected, the leather undergoes a tanning process to preserve it and enhance its properties. Vegetable tanning and chrome tanning are the two primary methods. Vegetable tanning uses natural tannins from plant materials, resulting in a more environmentally friendly product, while chrome tanning provides faster processing and a softer finish.

After tanning, the leather is conditioned and dyed to achieve the desired color and texture. This step is crucial as it affects not only the aesthetics but also the performance characteristics of the shoe upper.

2. Forming: What Techniques Are Used to Shape the Leather?

The forming stage involves cutting the leather into specific patterns and shapes that correspond to the shoe design. This is typically done using die-cutting machines for precision.

Once cut, the leather pieces are often prepped through processes such as skiving (thinning the edges) and edge finishing to ensure a smooth and professional appearance. Some manufacturers may also use heat-setting techniques to mold the leather into the desired shape, enhancing its fit and comfort.

3. Assembly: How Are Leather Shoe Uppers Constructed?

In the assembly phase, the prepped leather pieces are stitched together. Various stitching techniques, such as Goodyear welt or Blake stitch, may be employed depending on the shoe style and intended use. These methods not only provide structural integrity but also enhance the comfort and longevity of the shoe.

Additionally, eyelets, linings, and other components are integrated during this stage. The use of high-quality adhesives may also be applied to reinforce joints and seams, ensuring that the shoe upper remains durable under various conditions.

4. Finishing: What Processes Enhance the Appearance and Performance?

The finishing stage is critical for both aesthetics and functionality. This involves applying protective coatings, such as water repellents or anti-scuff treatments, to enhance the shoe’s performance.

Furthermore, polishing and buffing techniques are used to achieve a high-quality finish, giving the leather a refined look. Quality checks are performed at this stage to ensure that the shoe upper meets the desired specifications regarding color, texture, and overall appearance.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance in leather shoe upper manufacturing is paramount for ensuring product reliability and customer satisfaction. Buyers should be familiar with relevant international standards and industry-specific certifications.

1. Which International Standards Are Relevant for Leather Shoe Uppers?

ISO 9001 is a widely recognized international standard for quality management systems. It ensures that manufacturers maintain consistent quality through systematic processes. Compliance with ISO 9001 can significantly enhance a supplier’s credibility in the eyes of B2B buyers.

In addition to ISO 9001, specific certifications such as CE marking (Conformité Européenne) for products sold in the European market are essential. This certification indicates that the product meets health, safety, and environmental protection standards.

2. What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that the leather shoe uppers meet the required standards. These checkpoints typically include:

Illustrative image related to leather shoe upper

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitors the manufacturing process, identifying defects during production.

- Final Quality Control (FQC): Conducts thorough inspections of the finished products to ensure they meet quality standards before shipping.

Common testing methods include physical tests for tensile strength, water resistance, and color fastness, ensuring that the leather can withstand various conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, verifying the quality control practices of potential suppliers is crucial. Here are several methods to ensure that suppliers adhere to high-quality standards:

1. Conducting Supplier Audits

Regular audits can provide insights into a supplier’s quality management systems. Audits should focus on evaluating compliance with international standards, examining production processes, and assessing the effectiveness of QC checkpoints.

Illustrative image related to leather shoe upper

2. Requesting Quality Assurance Reports

Buyers should request detailed quality assurance reports from suppliers, documenting the results of various tests and inspections. This transparency can help buyers make informed decisions about their sourcing.

3. Utilizing Third-Party Inspection Services

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes. These services can conduct pre-shipment inspections to verify that the products meet the agreed-upon specifications and standards.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regulatory Compliance: Different regions may have varying regulations regarding leather products. Buyers should ensure that suppliers comply with local regulations and international standards to avoid potential legal issues.

- Cultural Considerations: Understanding cultural differences in business practices can impact quality control expectations. Building strong relationships with suppliers can facilitate better communication regarding quality standards.

- Sustainability Practices: Increasingly, buyers are looking for suppliers who prioritize sustainable practices in leather sourcing and production. Verifying a supplier’s commitment to sustainability can enhance a brand’s reputation in the global marketplace.

By understanding the manufacturing processes and quality assurance practices associated with leather shoe uppers, B2B buyers can make informed decisions that ensure the acquisition of high-quality products tailored to their market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather shoe upper’

Introduction

This practical sourcing guide aims to provide B2B buyers with a clear and actionable checklist for procuring leather shoe uppers. Understanding the nuances of this material and the procurement process can significantly enhance product quality and supplier relationships, particularly for businesses operating across diverse markets such as Africa, South America, the Middle East, and Europe.

Illustrative image related to leather shoe upper

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to establish clear technical specifications for the leather shoe uppers you intend to purchase. This includes detailing the type of leather—be it full grain, corrected grain, or split leather—along with thickness, color, and finish. By defining these parameters upfront, you can streamline communication with suppliers and ensure that the final product meets your quality standards.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify suppliers who specialize in leather shoe uppers. Utilize online platforms, trade shows, and industry directories to compile a list of potential partners. Pay attention to suppliers’ reputations, customer reviews, and their experience in your specific market segment, as this can influence the reliability of your sourcing efforts.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, certifications, and references from buyers in similar industries. Look for suppliers with a proven track record of delivering high-quality leather products, and consider visiting their facilities if feasible to assess their production capabilities and quality control processes.

Step 4: Request Samples

Always request samples of the leather shoe uppers before placing a large order. This allows you to evaluate the material’s quality, texture, and durability firsthand. Assess the samples against your specifications, and consider running wear tests to ensure they meet performance standards in real-world conditions.

Step 5: Verify Supplier Certifications

Ensure that your chosen suppliers comply with international quality and environmental standards. Certifications such as ISO 9001 for quality management and ISO 14001 for environmental management can indicate a supplier’s commitment to quality and sustainable practices. This not only helps in maintaining product integrity but also enhances your brand’s reputation in the marketplace.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate the terms and conditions of your procurement agreement. Discuss pricing, lead times, payment terms, and delivery schedules to ensure clarity and mutual agreement. Clear communication during this stage can prevent misunderstandings and foster a positive working relationship.

Step 7: Establish a Quality Control Process

After placing your order, establish a quality control process to monitor the production and delivery of your leather shoe uppers. This may involve periodic inspections or third-party quality assessments to ensure that the final products meet your specifications. A robust quality control mechanism can help mitigate risks associated with product defects and ensure customer satisfaction.

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing leather shoe uppers, ensuring that they obtain high-quality products that align with their business needs.

Comprehensive Cost and Pricing Analysis for leather shoe upper Sourcing

Understanding the cost structure and pricing dynamics of leather shoe upper sourcing is essential for B2B buyers aiming to optimize their procurement strategies. The following analysis highlights key cost components, influential pricing factors, and practical buyer tips tailored for international markets.

What Are the Key Cost Components in Leather Shoe Upper Sourcing?

-

Materials: The primary cost driver in leather shoe upper production is the quality of leather. Options include full-grain, corrected grain, and split leather, each varying in price based on durability and aesthetic appeal. For instance, full-grain leather, being the highest quality, commands a premium price, while split leather offers a more budget-friendly option. Other materials, such as linings and reinforcements, also contribute to the overall material costs.

-

Labor: Labor costs vary significantly based on geographic location and the complexity of craftsmanship required. Regions with lower labor costs, such as parts of Southeast Asia, may offer competitive pricing, but this can come at the expense of quality. Skilled labor in Europe, while more expensive, often results in superior craftsmanship and product longevity.

-

Manufacturing Overhead: This encompasses operational costs related to running the manufacturing facility, including utilities, maintenance, and administrative expenses. Buyers should consider suppliers with efficient operations to minimize overhead costs.

-

Tooling: Customization often necessitates specific tooling for production. Initial tooling costs can be significant; however, these costs are amortized over larger production runs. Buyers should inquire about minimum order quantities (MOQs) that can justify these upfront investments.

-

Quality Control (QC): Implementing a robust QC process ensures that the final products meet specified standards. This aspect is crucial, especially for international buyers who may face higher costs if products fail to meet import regulations or customer expectations.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and Incoterms. Buyers should consider logistics as part of the total cost of ownership, factoring in customs duties and potential delays.

-

Margin: Supplier margins typically range from 10% to 30%, influenced by the supplier’s market positioning and the level of service provided. Buyers should evaluate the total value offered by suppliers beyond just price.

What Influences the Pricing of Leather Shoe Uppers?

-

Volume/MOQ: Suppliers often provide tiered pricing based on order volume. Larger orders can significantly reduce the per-unit cost, making it crucial for buyers to assess their purchasing strategy.

-

Specifications and Customization: Custom designs or specific material requests can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Quality and Certifications: Products with recognized quality certifications (e.g., ISO, environmental standards) may come at a premium. However, these certifications often ensure better quality and compliance with international regulations.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality and timely delivery may charge more but provide greater peace of mind.

-

Incoterms: The agreed-upon Incoterms affect the allocation of costs and responsibilities during shipping. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers anticipate additional costs.

What Are Some Effective Buyer Tips for Sourcing Leather Shoe Uppers?

-

Negotiation: Engaging in open dialogue with suppliers can yield better pricing. Leverage volume commitments or long-term partnerships to negotiate favorable terms.

-

Cost-Efficiency: Focus on the total cost of ownership rather than just the upfront price. Consider factors such as durability, maintenance, and potential for returns or defects.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations and geopolitical factors that can affect pricing. Establishing contracts in stable currencies can mitigate risks.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, including reviews and past performance. Attend trade shows or industry events to connect with reputable manufacturers.

-

Disclaimer on Indicative Prices: Prices can fluctuate based on market conditions and supply chain dynamics. Always seek updated quotes and verify current market rates before finalizing orders.

By understanding the intricacies of cost components, price influencers, and strategic buying tips, B2B buyers can enhance their sourcing strategies for leather shoe uppers, ensuring they achieve both quality and cost-effectiveness in their procurement efforts.

Alternatives Analysis: Comparing leather shoe upper With Other Solutions

When considering footwear solutions, particularly for B2B buyers looking to source shoe uppers, it’s essential to evaluate alternatives to leather shoe uppers. While leather is widely recognized for its durability and aesthetic appeal, other materials and technologies can also serve effectively, depending on the specific needs and contexts of use. This analysis compares leather shoe uppers against synthetic leather and textile uppers, providing insights into their respective performance, costs, and maintenance requirements.

| Comparison Aspect | Leather Shoe Upper | Synthetic Leather | Textile Upper |

|---|---|---|---|

| Performance | Excellent durability and breathability; molds to foot shape over time | Good durability but less breathability; can mimic leather appearance | Varies widely; lightweight and breathable, but generally less durable |

| Cost | Higher initial investment; long-term value due to durability | Generally lower cost; price varies with quality | Typically the lowest cost option; wide range of prices |

| Ease of Implementation | Requires skilled craftsmanship for high-quality products | Easier to work with; can be produced at scale | Simple production processes, often machine-made |

| Maintenance | Requires regular conditioning; can be susceptible to water and stains | Easy to clean; resistant to moisture and stains | Generally machine washable; may lose shape over time |

| Best Use Case | Formal and high-end casual footwear; long-lasting products | Fashion-forward styles and budget-friendly options | Athletic and casual footwear; suitable for quick trends |

What Are the Pros and Cons of Synthetic Leather as an Alternative?

Synthetic leather, often made from polyurethane or PVC, offers a compelling alternative to traditional leather. Its main advantages include lower cost and easier maintenance, as it typically resists moisture and stains better than genuine leather. However, synthetic leather may lack the breathability and comfort that leather provides, which can impact long-term wearability. Additionally, while synthetic options can mimic the look of leather, they may not deliver the same level of aesthetic appeal, particularly for formal applications.

How Do Textile Uppers Compare to Leather Shoe Uppers?

Textile uppers, which can be made from various materials such as nylon or canvas, are often the most cost-effective option available. They are lightweight and breathable, making them ideal for athletic footwear or casual applications where comfort is paramount. However, the durability of textile uppers is generally inferior to leather, and they may not offer the same level of support or shape retention over time. For buyers seeking quick turnover in fashion or athletic shoes, textiles can be advantageous, but they may not be suitable for more formal or long-lasting footwear needs.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right shoe upper material, B2B buyers should consider their specific market demands and customer preferences. For high-end or formal footwear, leather remains the gold standard, offering unmatched durability and style. On the other hand, synthetic leather and textiles can provide cost-effective solutions for brands targeting a younger, trend-focused demographic or those prioritizing sustainability. By evaluating performance, cost, and maintenance requirements against their target audience’s expectations, buyers can make informed decisions that align with their business objectives and market positioning.

Essential Technical Properties and Trade Terminology for leather shoe upper

What Are the Key Technical Properties of Leather Shoe Uppers?

When sourcing leather shoe uppers for production, understanding the essential technical properties is crucial for ensuring quality, performance, and durability. Here are some critical specifications that B2B buyers should consider:

-

Material Grade

Material grade refers to the quality of leather used in the shoe upper. Full-grain leather, for example, retains the original grain and is considered the highest quality, offering superior durability and breathability. Corrected grain leather is more uniform and easier to maintain, while split leather, often used for suede, provides a softer finish. Selecting the appropriate grade can impact the shoe’s longevity and marketability. -

Thickness

The thickness of the leather upper is a vital specification, typically measured in millimeters (mm). A thickness of 1.2-2.0 mm is standard for most casual and formal shoes, whereas athletic shoes may require thinner materials for flexibility. Understanding thickness helps in assessing durability and comfort, influencing production costs and consumer satisfaction. -

Tensile Strength

This property measures the leather’s ability to withstand pulling forces without breaking. Tensile strength is critical for shoe uppers, especially in high-performance footwear. Higher tensile strength ensures that the shoe can endure stress during use, prolonging its life and reducing returns due to defects. -

Water Resistance

Water resistance is an essential property for leather shoes, particularly in regions with varied climates. Treatments such as waterproofing or using water-resistant leather can enhance performance. Buyers should evaluate the level of water resistance required based on the target market, as this feature can significantly affect consumer appeal and satisfaction. -

Breathability

Breathability refers to the ability of leather to allow air circulation, which is crucial for comfort. Shoes that trap moisture can lead to discomfort and foot issues. Leather with good breathability properties helps maintain a comfortable foot environment, making it an attractive feature for buyers focused on performance and comfort.

What Are Common Trade Terms in the Leather Shoe Upper Industry?

Understanding industry jargon is crucial for effective communication in B2B transactions. Here are several common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end products. In the leather shoe industry, OEMs typically manufacture shoe uppers for established brands. Buyers should clarify OEM capabilities to ensure alignment with their product specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory and production costs effectively. Suppliers often set MOQs based on production costs, so negotiating favorable terms can lead to better pricing. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For buyers sourcing leather shoe uppers, issuing an RFQ can help in comparing prices, quality, and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international trade. Understanding Incoterms is critical for managing shipping costs, risk, and responsibilities, ensuring smooth transactions across borders. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the leather shoe upper industry, lead times can vary significantly based on factors like material availability and manufacturing processes. Buyers should account for lead time in their planning to avoid production delays. -

Certification Standards

Certification standards, such as ISO or ASTM, ensure that leather products meet specific quality and safety criteria. Buyers should verify that suppliers comply with relevant certifications to guarantee product reliability and compliance with international regulations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing leather shoe uppers, ultimately enhancing their product offerings and market competitiveness.

Illustrative image related to leather shoe upper

Navigating Market Dynamics and Sourcing Trends in the leather shoe upper Sector

What are the Current Market Dynamics and Key Trends in the Leather Shoe Upper Sector?

The leather shoe upper sector is experiencing significant shifts driven by consumer preferences, technological advancements, and global economic factors. As international markets, particularly in Africa, South America, the Middle East, and Europe, evolve, buyers must navigate a landscape marked by increasing demand for high-quality materials and innovative designs. Key trends include the rise of customization and personalization, as brands cater to the unique tastes of diverse markets. Additionally, the integration of e-commerce platforms has made sourcing more accessible, allowing businesses to connect with suppliers worldwide.

Emerging technologies such as 3D printing and artificial intelligence are also influencing the production process, enabling manufacturers to reduce lead times and costs while maintaining quality. The demand for lightweight and breathable materials is on the rise, driven by the growing popularity of athleisure and casual footwear. Furthermore, B2B buyers are increasingly focused on sourcing from suppliers who can provide transparency in their supply chains, ensuring product quality and ethical sourcing practices.

How is Sustainability Influencing Sourcing Trends in the Leather Shoe Upper Sector?

Sustainability and ethical sourcing have become paramount in the leather shoe upper sector. The environmental impact of leather production is significant, with concerns surrounding deforestation, chemical use in tanning processes, and water consumption. Buyers are increasingly prioritizing suppliers who adopt sustainable practices, such as utilizing vegetable-tanned leather or sourcing from farms that adhere to ethical animal husbandry standards.

Green certifications like the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining importance, as they provide credibility to suppliers committed to reducing their environmental footprint. Moreover, the demand for eco-friendly alternatives, such as synthetic leather made from recycled materials, is on the rise. B2B buyers must not only consider the quality and cost of leather shoe uppers but also the ethical implications of their sourcing decisions, as consumers increasingly favor brands that demonstrate a commitment to sustainability.

Illustrative image related to leather shoe upper

How Has the Leather Shoe Upper Sector Evolved Over Time?

The evolution of the leather shoe upper sector is marked by a transition from artisanal craftsmanship to mass production techniques, significantly impacting sourcing strategies. Historically, leather footwear was handmade, utilizing locally sourced materials and traditional techniques. However, the Industrial Revolution introduced mechanization, allowing for greater production volumes and the globalization of supply chains.

In recent decades, there has been a resurgence in interest in high-quality, handcrafted leather products, driven by consumer desire for authenticity and durability. This shift has led to a blending of traditional craftsmanship with modern technologies, enhancing production efficiency while maintaining quality. As the sector continues to evolve, B2B buyers must stay informed about these historical trends to better understand current market dynamics and anticipate future developments.

Frequently Asked Questions (FAQs) for B2B Buyers of leather shoe upper

-

How do I ensure the quality of leather shoe uppers from suppliers?

To ensure quality, establish a stringent vetting process for suppliers. Request samples and conduct thorough inspections for material authenticity, stitching quality, and finish. Verify certifications for leather types, such as full-grain or corrected grain, and assess compliance with international quality standards. Building a strong relationship with suppliers can also facilitate transparency in their production processes, enabling you to monitor quality consistently. -

What types of leather are best for shoe uppers?

The best types of leather for shoe uppers are full-grain, corrected grain, and split leather. Full-grain leather offers durability and breathability, making it ideal for high-end products. Corrected grain leather is more resistant to wear and easier to maintain, suitable for mass production. Split leather, commonly used for a suede finish, provides a softer touch but may not be as durable. Your choice should depend on the intended market and product positioning. -

How can I customize leather shoe uppers to meet specific market demands?

Customization can be achieved by collaborating closely with your supplier to discuss design preferences, colors, textures, and finishes. Many manufacturers offer bespoke services that allow for unique branding elements, such as logos or specific patterns. Ensure you provide detailed specifications and engage in prototypes to refine the product before full-scale production, ensuring it aligns with your market’s expectations. -

What is the typical minimum order quantity (MOQ) for leather shoe uppers?

The MOQ for leather shoe uppers varies significantly by supplier and product type, often ranging from 100 to 1,000 units. Factors influencing MOQ include the complexity of the design, the type of leather used, and the supplier’s production capabilities. Discussing your needs directly with suppliers can sometimes lead to negotiated terms, especially for long-term partnerships or bulk orders. -

What payment terms should I expect when sourcing leather shoe uppers internationally?

Payment terms can vary widely but typically include options like net 30, net 60, or payment in advance, especially for new suppliers. Common practices involve a deposit upfront (often 30-50%) with the balance due before shipment. Consider using secure payment methods such as letters of credit or escrow services to mitigate risk. Establish clear terms in your contract to avoid misunderstandings. -

How do I handle logistics and shipping for leather shoe uppers?

Effective logistics management involves selecting reliable shipping partners and understanding import/export regulations specific to your region. Consider factors like shipping time, costs, and customs clearance processes. Collaborating with a freight forwarder experienced in handling leather products can streamline the process. Always plan for contingencies, such as delays or additional fees, to maintain a smooth supply chain. -

What quality assurance measures should I implement when sourcing leather shoe uppers?

Implementing quality assurance measures involves conducting regular audits of your suppliers and their production facilities. Establish clear quality benchmarks based on international standards and ensure that your suppliers adhere to these guidelines. Incorporate random sampling for inspections during production and prior to shipment. This proactive approach helps mitigate risks of receiving subpar materials. -

How can I ensure compliance with international trade regulations for leather products?

To ensure compliance, familiarize yourself with the regulations governing leather imports in your country and the exporting country. This may include environmental standards, labeling requirements, and certifications for animal welfare. Engage with trade experts or legal advisors who specialize in international trade to navigate complexities. Additionally, maintaining open communication with your suppliers about compliance can prevent potential issues during customs clearance.

Top 6 Leather Shoe Upper Manufacturers & Suppliers List

1. Buy Leather Online – Premium Leather Products

Domain: buyleatheronline.com

Registered: 2015 (10 years)

Introduction: {“price_range”:”$0.00 – $640.00″,”colors”:[{“name”:”White”,”count”:35},{“name”:”Ice-White”,”count”:3},{“name”:”Talc”,”count”:5},{“name”:”Platinum”,”count”:7},{“name”:”Ivory – Off-White”,”count”:37},{“name”:”Light Beige”,”count”:7},{“name”:”Beige – Natural”,”count”:67},{“name”:”Dark Beige”,”count”:3},{“name”:”Sand Beige”,”count”:20},{“name”:”Pinky Beige – Powder”,”count”:28},{“name”:”Greenish Beige…

2. Oliver Sweeney – Anatomy of a Shoe

Domain: oliversweeney.com

Registered: 2000 (25 years)

Introduction: Anatomy of a Shoe: Shoe Upper – covers the foot, consists of vamp, quarters, and linings. Vamp – front section of the upper. Toe (Toecap) – reinforces the toe area. Tongue – flexible material under laces for pressure distribution. Collar – padded top edge of the quarter for comfort. Counter – supports and stiffens the heel area. Quarter – back part of the upper. Heel – raises and supports the back…

3. International Leather Club – Leather Uppers

Domain: internationalleatherclub.com

Registered: 2020 (5 years)

Introduction: Leather upper is the leather material on a shoe that covers the foot and attaches to the sole. Common materials include Suede, Nubuck, full grain, and patent leather. Leather uppers are known for durability, comfort, and style. They are available in various sizes (Children: 0 to youth 3, Men: 6.5–15, Women: 4.5 to 16) and colors (Brown, black, white, red). Popular styles include dress shoes, boots…

4. Shoe Upper Evolution – Craft to Machine

Domain: shoegazing.com

Registered: 2019 (6 years)

Introduction: The article discusses the history of shoe upper making, highlighting its intricate processes and evolution from handcrafting to machine production. Key points include: 1. The oldest known leather shoe, Areni-1, is 5,500 years old, made from a single piece of leather. 2. For most of history, shoe uppers were made entirely by hand, with intricate decorative stitching. 3. The first sewing machine for…

5. LeatherNeo – Footwear Uppers

Domain: leatherneo.com

Registered: 2020 (5 years)

Introduction: Leather uppers are a key component in footwear, providing style, durability, and comfort. There are various types of leather used for uppers, including: 1. Smooth leather – versatile, used in sneakers, boots, and dress shoes. 2. Nubuck – soft, velvety texture, requires care to maintain its look. 3. Suede – soft and fuzzy, made from the bottom layer of animal skin, less water-resistant. 4. Full gra…

6. Noble Shoe – Types of Leather

Domain: thenobleshoe.com

Registered: 2019 (6 years)

Introduction: Types of Shoe Leather: 1. Full Grain Leather – Top layer with grain and pores intact, highest quality. 2. Top Grain Leather – Sanded grain, good quality but lower than full grain. 3. Corrected Grain/Genuine Leather – Lower quality, often appears nice initially. 4. Calfskin – Smooth, durable, ages well, suitable for all shoe types. 5. Grain Leather – Textured, often embossed, hides creasing well. 6…

Strategic Sourcing Conclusion and Outlook for leather shoe upper

In navigating the complex landscape of leather shoe upper sourcing, B2B buyers must prioritize strategic partnerships that enhance product quality and operational efficiency. The diverse range of leather types—such as full grain, corrected grain, and split leather—offers unique advantages for different market segments, ensuring that brands can meet varying consumer preferences. By leveraging quality materials and maintaining sustainable sourcing practices, businesses can not only improve their product offerings but also enhance brand reputation and customer loyalty.

Moreover, understanding regional market dynamics is critical. For buyers in Africa, South America, the Middle East, and Europe, adapting to local trends while also considering global demands can create competitive advantages. Collaborating with reliable suppliers who prioritize innovation and sustainability will be essential in meeting the evolving expectations of consumers.

As we look ahead, the future of leather shoe upper sourcing is poised for growth, driven by advancements in technology and sustainability. B2B buyers are encouraged to engage actively with suppliers, explore new material innovations, and embrace sustainable practices to stay ahead in this competitive market. Your next step could redefine your brand’s success—start building those strategic partnerships today.

Illustrative image related to leather shoe upper

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.