Introduction: Navigating the Global Market for leather goods manufacturers usa

As international B2B buyers seek to source high-quality leather goods manufacturers in the USA, a common challenge arises: how to navigate the diverse landscape of suppliers while ensuring product quality and reliability. With the leather goods market expanding globally, particularly in regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Brazil—understanding the nuances of American leather manufacturing is crucial for making informed purchasing decisions.

This comprehensive guide delves into the various types of leather goods available, from wallets and bags to corporate gifts and custom items. It covers essential aspects such as supplier vetting processes, cost considerations, and application-specific recommendations. By equipping buyers with actionable insights, this guide empowers them to identify reputable manufacturers, assess product quality, and negotiate favorable terms.

Whether you are looking to enhance your product offerings or establish long-term partnerships, understanding the dynamics of the US leather goods manufacturing sector will be invaluable. With this resource at your disposal, you can confidently navigate the complexities of international trade and make strategic decisions that align with your business goals.

Table Of Contents

- Top 8 Leather Goods Manufacturers Usa Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather goods manufacturers usa

- Understanding leather goods manufacturers usa Types and Variations

- Key Industrial Applications of leather goods manufacturers usa

- 3 Common User Pain Points for ‘leather goods manufacturers usa’ & Their Solutions

- Strategic Material Selection Guide for leather goods manufacturers usa

- In-depth Look: Manufacturing Processes and Quality Assurance for leather goods manufacturers usa

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather goods manufacturers usa’

- Comprehensive Cost and Pricing Analysis for leather goods manufacturers usa Sourcing

- Alternatives Analysis: Comparing leather goods manufacturers usa With Other Solutions

- Essential Technical Properties and Trade Terminology for leather goods manufacturers usa

- Navigating Market Dynamics and Sourcing Trends in the leather goods manufacturers usa Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather goods manufacturers usa

- Strategic Sourcing Conclusion and Outlook for leather goods manufacturers usa

- Important Disclaimer & Terms of Use

Understanding leather goods manufacturers usa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Handcrafted Leather Goods | Artisan-made, unique designs, often customizable | Corporate gifts, luxury retail | Pros: Unique, high-quality; Cons: Higher cost |

| Mass-Produced Leather Goods | Standardized designs, produced in large quantities | Retail chains, bulk orders | Pros: Cost-effective, quick turnaround; Cons: Less unique |

| Specialty Leather Goods | Focused on niche markets (e.g., sports, travel) | Specialty shops, online retailers | Pros: Tailored to specific needs; Cons: Limited availability |

| Sustainable Leather Products | Eco-friendly materials, ethical sourcing practices | Green businesses, eco-conscious brands | Pros: Appeals to ethical consumers; Cons: Potentially higher costs |

| Customized Leather Goods | Personalized items, often made to order | Corporate branding, promotional items | Pros: Tailored to client specifications; Cons: Longer lead times |

What Are the Key Characteristics of Handcrafted Leather Goods?

Handcrafted leather goods are often distinguished by their artisan craftsmanship, which results in unique designs and high-quality finishes. These products are typically made using traditional techniques, allowing for customization options that cater to specific client needs. B2B buyers interested in corporate gifts or luxury retail will find these items appealing due to their exclusivity and craftsmanship, although they often come at a higher price point.

Illustrative image related to leather goods manufacturers usa

How Do Mass-Produced Leather Goods Differ from Other Types?

Mass-produced leather goods are manufactured on a larger scale, ensuring consistent quality and uniformity across products. This type is ideal for retail chains and businesses looking to fulfill bulk orders quickly and cost-effectively. While they offer significant savings and faster delivery times, buyers should be aware that these products may lack the uniqueness and artisanal appeal of handcrafted options.

What Are Specialty Leather Goods and Their Market Applications?

Specialty leather goods focus on specific niches, such as sports equipment or travel accessories. These products are designed to meet the unique needs of particular markets and are often marketed through specialty shops and online platforms. B2B buyers can leverage these goods to differentiate their offerings, though they may face challenges related to limited availability and higher pricing.

Why Are Sustainable Leather Products Gaining Popularity?

Sustainable leather products are made from eco-friendly materials and sourced through ethical practices, making them increasingly attractive to environmentally conscious businesses. This type caters to green businesses and brands aiming to align with consumer values around sustainability. While they may carry a higher price tag, the demand for these products is growing, offering significant opportunities for B2B buyers looking to enhance their brand reputation.

What Advantages Do Customized Leather Goods Offer to Businesses?

Customized leather goods are tailored to specific client specifications, making them ideal for corporate branding and promotional items. These products allow businesses to create a unique identity and foster customer loyalty through personalized offerings. However, buyers should consider the potential for longer lead times and higher costs associated with customization, which may impact inventory management and budgeting.

Key Industrial Applications of leather goods manufacturers usa

| Industry/Sector | Specific Application of leather goods manufacturers usa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-end leather garments and accessories | Enhances brand prestige and customer loyalty | Quality of leather, craftsmanship, and customization options |

| Automotive | Leather interiors and upholstery for vehicles | Increases luxury perception and resale value | Durability, color options, and compliance with automotive standards |

| Corporate Gifts and Branding | Customized leather products for corporate gifting | Strengthens brand identity and client relationships | Personalization options, bulk order capabilities, and lead times |

| Sports and Recreation | Leather sports equipment (e.g., gloves, bags) | Improves performance and durability for athletes | Material quality, safety standards, and product customization |

| Home and Lifestyle | Leather home decor and accessories | Adds elegance and functionality to living spaces | Design trends, sustainability practices, and pricing strategies |

How Are Leather Goods Manufacturers in the USA Beneficial for the Fashion and Apparel Industry?

Leather goods manufacturers in the USA provide high-quality leather garments and accessories that cater to the luxury fashion market. By sourcing premium leather, these manufacturers enhance the prestige of brands, allowing companies to attract discerning customers. International buyers, particularly from regions like Europe and the Middle East, often seek unique designs and craftsmanship that reflect their cultural aesthetics. Key considerations include the type of leather used, sustainability practices, and the ability to customize designs to meet specific market demands.

Illustrative image related to leather goods manufacturers usa

What Role Does Leather Play in the Automotive Sector?

In the automotive industry, leather manufacturers supply premium upholstery and interiors that elevate the aesthetic and tactile experience within vehicles. High-quality leather not only enhances the luxury perception of cars but also contributes to higher resale values. For international buyers, especially in regions like Saudi Arabia and Brazil, sourcing durable and stylish leather that meets stringent automotive standards is crucial. Manufacturers must provide a variety of color and texture options to align with diverse consumer preferences.

How Can Leather Goods Enhance Corporate Gifting Strategies?

Leather goods manufacturers in the USA offer a range of customizable products suitable for corporate gifting. Items such as personalized wallets, journals, and keychains can help businesses strengthen their brand identity and improve client relationships. For B2B buyers, particularly from Africa and South America, it’s essential to consider personalization capabilities, bulk order discounts, and delivery timelines when sourcing these products. The quality and craftsmanship of the leather used also play a significant role in making a lasting impression.

Why Are Leather Goods Important in Sports and Recreation?

In the sports and recreation sector, leather goods manufacturers provide essential equipment such as gloves, bags, and protective gear that enhance athlete performance. High-quality leather offers durability and comfort, making it a preferred choice for professional and amateur athletes alike. Buyers from regions with strong sports cultures should prioritize manufacturers that ensure safety standards and offer customization options for team branding. Additionally, understanding the specific needs of different sports can guide sourcing decisions effectively.

How Do Leather Products Add Value to Home and Lifestyle Markets?

Leather goods manufacturers supply elegant home decor items and lifestyle accessories that elevate the ambiance of living spaces. Products like leather furniture, cushions, and wall art not only add functionality but also infuse a sense of luxury into homes. For international buyers, it’s important to consider design trends and sustainability practices, as these factors significantly influence market acceptance. Additionally, competitive pricing strategies and the ability to cater to specific regional tastes can enhance sourcing decisions in this sector.

3 Common User Pain Points for ‘leather goods manufacturers usa’ & Their Solutions

Scenario 1: Sourcing Quality Leather at Competitive Prices

The Problem: Many B2B buyers encounter challenges when it comes to sourcing high-quality leather that meets their specifications while remaining within budget. Manufacturers often find that the cost of premium leather can be prohibitive, especially when working with multiple suppliers who may not guarantee consistency in quality or ethical sourcing practices. This not only affects profit margins but can also lead to delays if the leather does not meet the required standards upon delivery.

Illustrative image related to leather goods manufacturers usa

The Solution: To address this issue, buyers should establish direct relationships with reputable leather goods manufacturers in the USA who specialize in the specific types of leather they need. Research manufacturers known for their commitment to quality and ethical sourcing, such as those using full-grain or vegetable-tanned leather. Request samples to evaluate the leather quality before placing bulk orders. Additionally, consider negotiating long-term contracts with manufacturers for better pricing on larger orders, as this can help stabilize costs and ensure consistent quality over time.

Scenario 2: Navigating Customization and Production Lead Times

The Problem: B2B buyers often face the frustration of long lead times for customized leather goods. This delay can be particularly troublesome for businesses looking to launch new products or fulfill client demands promptly. Many manufacturers have set production timelines that may not align with the buyer’s launch schedule, leading to potential revenue loss and damaged client relationships.

The Solution: To mitigate this challenge, buyers should proactively communicate their timelines and customization needs upfront. It’s crucial to work with manufacturers that offer flexible production capabilities and are open to collaboration on design and materials. Establishing clear timelines and milestones can help keep the project on track. Additionally, consider manufacturers that utilize advanced technologies, such as CAD for design, which can streamline the customization process and reduce lead times significantly. Regular check-ins throughout the production phase can also ensure that any potential delays are addressed swiftly.

Scenario 3: Ensuring Ethical Practices and Sustainability

The Problem: Increasingly, B2B buyers are pressured to ensure that their suppliers adhere to ethical and sustainable practices. This is especially true for leather goods, which often come under scrutiny due to environmental concerns and labor practices in the tanning and manufacturing processes. Buyers may find it challenging to vet manufacturers thoroughly to confirm their compliance with sustainability standards and ethical labor practices.

Illustrative image related to leather goods manufacturers usa

The Solution: To navigate this issue, buyers should prioritize working with leather goods manufacturers that are transparent about their sourcing and production processes. Look for certifications such as the Leather Working Group (LWG) certification, which indicates adherence to environmental standards. Engage in direct dialogues with manufacturers regarding their supply chain practices and request detailed documentation of their sustainability efforts. Additionally, consider forming partnerships with manufacturers that have a proven track record in sustainable production, which not only aligns with ethical standards but also appeals to increasingly eco-conscious consumers. This proactive approach can help mitigate reputational risks and position your business as a leader in sustainability within your market.

Strategic Material Selection Guide for leather goods manufacturers usa

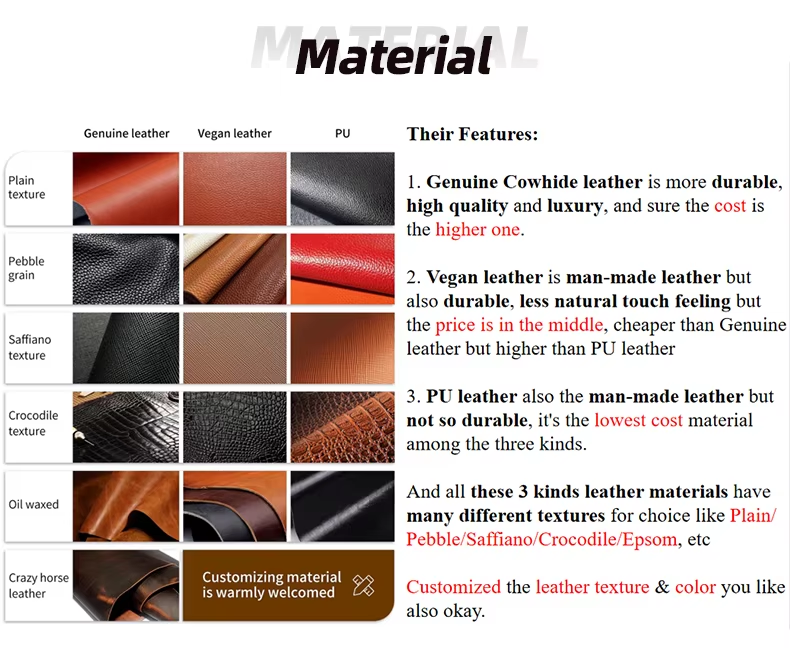

What Are the Key Properties of Common Leather Materials Used by Manufacturers in the USA?

When selecting materials for leather goods, manufacturers in the USA often consider a variety of leather types, each with unique properties that impact product performance and suitability. Here, we analyze four common materials: full-grain leather, top-grain leather, suede, and bonded leather.

How Does Full-Grain Leather Perform in Leather Goods Manufacturing?

Full-grain leather is the highest quality leather available, made from the top layer of the hide, retaining the natural grain. This material is known for its durability, breathability, and ability to develop a unique patina over time. It can withstand significant wear and tear, making it ideal for high-end products such as bags, wallets, and belts.

Pros & Cons: The primary advantage of full-grain leather is its longevity and aesthetic appeal. However, it is relatively expensive and may require more complex manufacturing processes, such as specialized stitching and finishing techniques.

Impact on Application: Full-grain leather is compatible with various media, including dyes and finishes, allowing for customization. Its robustness makes it suitable for products that require high durability.

Illustrative image related to leather goods manufacturers usa

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should be aware of compliance with international standards such as ASTM for leather quality. Additionally, preferences for natural, high-quality materials are prevalent in luxury markets.

What Advantages Does Top-Grain Leather Offer for Leather Goods?

Top-grain leather is the second-highest quality leather, made by sanding down the surface of full-grain leather to remove imperfections. It retains many of the desirable characteristics of full-grain leather, such as durability and a refined look, while being more affordable.

Pros & Cons: The main advantage of top-grain leather is its balance between quality and cost, making it a popular choice for mid-range products. However, it is less durable than full-grain leather and may not develop the same rich patina over time.

Impact on Application: This leather type is suitable for a wide range of products, including handbags and wallets, where a polished appearance is desired without the high cost of full-grain leather.

Illustrative image related to leather goods manufacturers usa

Considerations for International Buyers: Buyers in Europe and South America often seek top-grain leather for its cost-effectiveness. Compliance with local regulations regarding leather sourcing and treatment is essential.

How Does Suede Compare to Other Leather Materials?

Suede is made from the underside of the hide, giving it a soft, velvety texture. While it is less durable than full-grain or top-grain leather, it offers a unique aesthetic and is often used in fashion-forward products.

Pros & Cons: The softness and luxurious feel of suede are significant advantages, making it popular for shoes, jackets, and accessories. However, it is more susceptible to stains and damage from moisture, which can limit its application.

Impact on Application: Suede is often used in products that prioritize style over durability, making it suitable for seasonal fashion items.

Considerations for International Buyers: In regions with humid climates, such as parts of Africa and South America, buyers should consider the maintenance needs of suede products. Understanding local market preferences for texture and style is also crucial.

Illustrative image related to leather goods manufacturers usa

What Is Bonded Leather and Its Role in Manufacturing?

Bonded leather is made from leftover leather scraps that are bonded together with adhesives. It offers a cost-effective alternative to traditional leather, making it appealing for budget-conscious consumers.

Pros & Cons: The primary advantage of bonded leather is its affordability, allowing manufacturers to produce stylish products at lower costs. However, it lacks the durability and longevity of genuine leather, making it less suitable for high-end goods.

Impact on Application: Bonded leather is often used in lower-priced items, such as notebooks and inexpensive bags, where cost is a significant factor.

Considerations for International Buyers: Buyers from Europe and the Middle East may prefer bonded leather for promotional items or gifts. Awareness of the material’s limitations in terms of quality and longevity is essential for making informed purchasing decisions.

Illustrative image related to leather goods manufacturers usa

Summary Table of Material Properties

| Material | Typical Use Case for leather goods manufacturers usa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end bags, wallets, belts | Exceptional durability and aesthetics | High cost and complex manufacturing | High |

| Top-Grain Leather | Mid-range handbags, wallets | Good balance of quality and cost | Less durable than full-grain | Medium |

| Suede | Fashion items, shoes, jackets | Soft texture and luxurious feel | Susceptible to stains and moisture damage | Medium |

| Bonded Leather | Budget-friendly notebooks, promotional items | Cost-effective alternative | Lacks durability and longevity | Low |

This strategic material selection guide offers valuable insights into the properties, advantages, and limitations of various leather types, assisting international B2B buyers in making informed decisions tailored to their market needs.

In-depth Look: Manufacturing Processes and Quality Assurance for leather goods manufacturers usa

What Are the Key Stages of the Manufacturing Process for Leather Goods?

The manufacturing process for leather goods typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential for ensuring that the final product meets the high standards expected by B2B buyers.

Material Preparation

This initial stage focuses on selecting and preparing the leather. High-quality leather, often sourced from reputable tanneries, is inspected for imperfections. The leather is then cut into appropriate patterns based on the product design. Techniques such as vegetable tanning and chrome tanning may be employed, each affecting the leather’s final attributes, such as durability and flexibility.

Forming

During this phase, the cut leather pieces are shaped into the desired form. Techniques such as die-cutting and hand-cutting are common, depending on the complexity of the design. For instance, intricate designs may require skilled artisans to ensure precision. Heat and moisture may be applied to mold the leather, enhancing its fit and appearance.

Illustrative image related to leather goods manufacturers usa

Assembly

Once the leather is formed, the assembly stage begins. This involves stitching, riveting, or otherwise securing the leather pieces together. High-quality leather goods often utilize reinforced stitching techniques, such as double-stitching, to enhance durability. Artisans may also incorporate additional materials, like linings or hardware, during this phase to create a finished product that balances functionality and aesthetics.

Finishing

The final stage includes applying finishes to protect and enhance the leather. Techniques such as dyeing, waxing, and polishing are common. These processes not only improve the product’s appearance but also provide a layer of protection against wear and environmental factors. Quality assurance checks are typically conducted at this stage to ensure that the product meets all specifications before it is packaged for shipment.

How Is Quality Assurance Implemented in Leather Goods Manufacturing?

Quality assurance (QA) is a fundamental aspect of leather goods manufacturing, ensuring that products meet international standards and customer expectations. Various methods and checkpoints are established throughout the manufacturing process to uphold quality.

International Standards and Certifications

Manufacturers often adhere to international quality management standards, such as ISO 9001, which outlines requirements for a quality management system (QMS). These standards ensure that manufacturers have consistent processes in place to produce high-quality products. Industry-specific certifications may also apply, such as CE marking for products sold in the European market, which indicates compliance with health, safety, and environmental protection standards.

Illustrative image related to leather goods manufacturers usa

Quality Control Checkpoints

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon receipt. Suppliers should provide documentation verifying the quality and origin of materials, which is crucial for international buyers.

-

In-Process Quality Control (IPQC): During the manufacturing stages, periodic inspections ensure adherence to specifications. This may include measuring stitching consistency, verifying dye application, and checking for defects in leather pieces.

-

Final Quality Control (FQC): Before products are packaged, a thorough inspection is conducted to ensure that finished goods meet quality standards. This step often includes functionality tests and visual inspections to detect any flaws.

What Testing Methods Are Commonly Used in Leather Goods Manufacturing?

B2B buyers should be aware of the common testing methods employed to verify the quality of leather goods. These methods help ensure that products are durable and perform well in various conditions.

-

Physical Testing: This includes abrasion tests to measure durability, tensile strength tests to assess the leather’s resistance to tearing, and flex tests to evaluate the material’s ability to withstand repeated bending.

-

Chemical Testing: To ensure that leather products are free from harmful substances, manufacturers may conduct tests for heavy metals, phthalates, and other restricted chemicals. This is particularly important for international markets with stringent regulations.

-

Environmental Testing: Leather goods may be subjected to water resistance tests, UV exposure tests, and temperature resistance tests to evaluate their performance in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Here are some actionable steps to take:

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insight into their manufacturing practices and quality control measures. This may involve on-site visits to assess their facilities, processes, and adherence to quality standards.

-

Quality Reports: Request detailed quality assurance reports from suppliers, which outline their QC processes, testing methods, and results. These documents should include information on compliance with international standards and any certifications held by the manufacturer.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices. These services can conduct inspections at various stages of production, providing reports that help buyers make informed decisions.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, must navigate various quality control and certification nuances. Understanding these differences can facilitate smoother transactions and enhance product quality.

-

Regional Standards: Different regions may have specific regulations and standards that must be met. For instance, European markets may require CE marking, while buyers in the Middle East may focus on compliance with local quality standards. Familiarizing oneself with these requirements is crucial for successful market entry.

-

Cultural Considerations: Quality expectations may vary significantly across cultures. For example, European buyers may prioritize sustainability and ethical sourcing, while buyers from the Middle East may focus on luxury and craftsmanship. Tailoring quality assurance practices to align with these expectations can improve supplier relationships.

-

Documentation Requirements: International transactions often require extensive documentation, including certificates of compliance, quality assurance reports, and customs declarations. Ensuring that suppliers can provide these documents will streamline the import process and reduce the risk of delays or disputes.

In conclusion, understanding the intricacies of manufacturing processes and quality assurance in leather goods is vital for B2B buyers. By being aware of the manufacturing stages, quality control checkpoints, testing methods, and regional nuances, buyers can make informed decisions and establish successful partnerships with leather goods manufacturers in the USA.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather goods manufacturers usa’

This guide serves as a practical checklist for B2B buyers interested in sourcing leather goods from manufacturers in the USA. Understanding the specific requirements and quality standards in the leather goods industry is crucial for making informed procurement decisions. Follow these steps to ensure a successful sourcing process.

Step 1: Define Your Product Specifications

Clearly outline what types of leather goods you need, including materials, styles, and functionalities. This step is essential to ensure that suppliers understand your requirements and can meet your quality standards. Consider the following:

– Material Types: Specify if you need full-grain, top-grain, or other leather types.

– Design Features: Include details about size, color, and any custom branding needs.

Step 2: Research Potential Manufacturers

Conduct thorough research to identify reputable leather goods manufacturers in the USA. This can include looking at online directories, trade shows, and industry associations. Focus on:

– Company Background: Investigate their history, production capabilities, and market reputation.

– Product Range: Ensure they offer a diverse range of products that align with your specifications.

Illustrative image related to leather goods manufacturers usa

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; consider:

– Customer Testimonials: Look for reviews or feedback from previous clients to gauge satisfaction.

– Case Studies: Analyze specific projects that demonstrate their capability and reliability.

Step 4: Verify Certifications and Compliance

Ensure that the manufacturers comply with relevant industry standards and certifications. This step is vital for maintaining quality and ethical sourcing practices. Pay attention to:

– Sustainability Certifications: Check if they follow eco-friendly practices and use responsibly sourced materials.

– Quality Assurance Standards: Confirm certifications like ISO or ASTM that ensure quality management.

Step 5: Request Samples

Always request samples before placing a bulk order. This allows you to assess the quality, craftsmanship, and suitability of the products. Consider:

– Material Quality: Examine the leather’s texture, durability, and overall finish.

– Workmanship: Look for attention to detail in stitching, lining, and hardware.

Step 6: Negotiate Terms and Conditions

Discuss pricing, payment terms, and delivery timelines to avoid misunderstandings later. This is crucial for establishing a transparent and mutually beneficial relationship. Focus on:

– Pricing Structure: Ensure you understand the cost breakdown, including any additional fees.

– Delivery Schedules: Agree on timelines that align with your business needs, factoring in potential delays.

Step 7: Establish a Communication Plan

Effective communication is essential throughout the sourcing process. Set up a clear plan for regular updates and feedback. Keep in mind:

– Point of Contact: Designate a representative from your company and the supplier for streamlined communication.

– Regular Check-ins: Schedule periodic meetings to discuss progress and address any issues that arise.

By following this checklist, B2B buyers can streamline their sourcing process and establish successful partnerships with leather goods manufacturers in the USA. This structured approach not only enhances efficiency but also ensures that the final products meet your business’s quality and design standards.

Comprehensive Cost and Pricing Analysis for leather goods manufacturers usa Sourcing

What Are the Key Cost Components in Leather Goods Manufacturing in the USA?

When sourcing leather goods from manufacturers in the USA, understanding the cost structure is essential for international B2B buyers. The major components of the cost include:

-

Materials: The type and quality of leather significantly impact the overall cost. Full-grain leather, for instance, is more expensive than corrected-grain leather due to its durability and premium appearance. Additional materials such as linings, zippers, and hardware also contribute to the cost.

-

Labor: Labor costs in the USA are typically higher than in many other countries, reflecting the skilled craftsmanship required in leather goods production. Manufacturers often employ artisans who specialize in specific techniques, which can drive up labor costs.

-

Manufacturing Overhead: This includes costs related to utilities, rent, equipment maintenance, and administrative expenses. These overheads can vary widely based on the location of the manufacturer and the scale of operations.

-

Tooling: Initial investments in tooling and machinery can be substantial, particularly for custom designs. This upfront cost may be amortized over larger production runs, but smaller orders may face higher per-unit tooling costs.

-

Quality Control (QC): Implementing stringent QC measures ensures that the final product meets the required standards. This process may add to the overall cost but is crucial for maintaining quality, especially when exporting to international markets.

-

Logistics: Shipping costs, including freight and customs duties, can significantly affect the total cost. The choice of shipping method and Incoterms will influence the final price and delivery time.

-

Margin: Manufacturers typically include a profit margin that reflects their operational efficiency and market positioning. This margin can vary based on brand reputation and the uniqueness of the products offered.

How Do Price Influencers Affect Sourcing Decisions for Leather Goods?

Several factors can influence pricing when sourcing leather goods:

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually benefit from economies of scale, resulting in lower per-unit costs. Be mindful of MOQs as they can vary between manufacturers and affect your overall budget.

-

Specifications and Customization: Custom designs or specifications often incur additional costs. Clarifying your requirements upfront can prevent misunderstandings and unexpected expenses later in the process.

-

Materials and Certifications: The choice of materials not only impacts quality but also pricing. Certifications for sustainable or ethically sourced leather can also add to the cost but may be essential for certain markets.

-

Supplier Factors: The reputation, location, and operational capabilities of suppliers can affect pricing. Established manufacturers with a proven track record may charge more but offer reliability and quality assurance.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) applicable to your order is crucial. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact overall costs.

What Tips Should Buyers Consider for Cost-Efficiency in Leather Goods Sourcing?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, navigating the complexities of sourcing leather goods can be challenging. Here are some actionable tips:

-

Negotiate Wisely: Leverage your purchasing power by negotiating terms that suit both parties. Discuss potential discounts for larger orders or long-term agreements.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as durability, maintenance, and potential resale value when evaluating the total cost of ownership.

-

Understand Pricing Nuances: Be aware that prices may fluctuate based on market demand, currency exchange rates, and local economic conditions. Staying informed can help you make timely purchasing decisions.

-

Build Relationships: Developing strong relationships with suppliers can lead to better pricing and service. Regular communication and feedback can foster trust and encourage suppliers to prioritize your needs.

-

Research and Compare Suppliers: Don’t settle for the first manufacturer you find. Conduct thorough research, compare quotes, and assess quality to ensure you make informed decisions.

By understanding the intricate cost components and pricing influencers in the leather goods manufacturing sector, international B2B buyers can make strategic sourcing decisions that align with their business goals while ensuring quality and value.

Illustrative image related to leather goods manufacturers usa

Alternatives Analysis: Comparing leather goods manufacturers usa With Other Solutions

The leather goods market is highly competitive, and international B2B buyers often seek the best solutions that meet their specific needs. While leather goods manufacturers in the USA offer unique craftsmanship and quality, several alternative solutions may also be viable depending on the buyer’s requirements. This analysis compares the offerings of leather goods manufacturers in the USA against two alternatives: synthetic leather producers and overseas manufacturers.

| Comparison Aspect | Leather Goods Manufacturers USA | Synthetic Leather Producers | Overseas Manufacturers |

|---|---|---|---|

| Performance | High durability and quality; unique craftsmanship | Varies; generally lower durability but can mimic leather appearance | Varies widely; can offer quality but often lacks the craftsmanship of US-made goods |

| Cost | Higher price point due to craftsmanship; typically $50-$600 | Generally lower cost, ranging from $20-$300 | Often the lowest cost option; prices can be as low as $10 for basic items |

| Ease of Implementation | May require longer lead times due to custom orders | Typically ready-to-ship products; easy to source | Can be sourced in bulk; often requires navigating import regulations |

| Maintenance | Requires regular care to maintain quality | Low maintenance; often water-resistant and easy to clean | Varies; some may require more care depending on materials used |

| Best Use Case | Ideal for premium markets valuing quality and craftsmanship | Best for budget-conscious buyers needing a leather-like appearance | Suitable for high-volume orders at lower price points, less focus on quality |

What Are the Advantages and Disadvantages of Synthetic Leather Producers?

Synthetic leather, often referred to as faux leather, is made from polyurethane or polyvinyl chloride (PVC). The primary advantage of synthetic leather is its affordability and ease of maintenance. It is resistant to water and stains, making it suitable for products that require durability without the high cost associated with genuine leather. However, synthetic options typically lack the unique aesthetic and feel of real leather, which can be a significant drawback for premium brands looking to convey quality and craftsmanship.

How Do Overseas Manufacturers Compare in Terms of Quality and Cost?

Overseas manufacturers can provide an attractive alternative due to their lower production costs. They often produce in bulk, allowing for significant savings, which is appealing for businesses focused on cost-efficiency. However, the quality can vary greatly, and many overseas manufacturers may not offer the same level of craftsmanship or customization available from US-based manufacturers. Additionally, buyers need to consider shipping times and potential import tariffs, which can complicate the procurement process.

Conclusion: How Should B2B Buyers Choose the Right Leather Goods Solution?

When deciding between leather goods manufacturers in the USA and alternative solutions like synthetic leather or overseas manufacturers, B2B buyers must assess their specific needs. Factors such as budget, desired quality, and target market will heavily influence this decision. For businesses aiming to position themselves in the premium market, investing in high-quality, American-made leather goods may be the best route. Conversely, for those focused on affordability and volume, synthetic leather or overseas options might be more suitable. Ultimately, understanding the trade-offs associated with each alternative will empower buyers to make informed decisions that align with their business goals.

Illustrative image related to leather goods manufacturers usa

Essential Technical Properties and Trade Terminology for leather goods manufacturers usa

What Are the Key Technical Properties of Leather Goods for Manufacturers in the USA?

When sourcing leather goods from manufacturers in the USA, it’s crucial to understand the essential technical properties that define product quality and performance. Here are several critical specifications:

1. Material Grade

Material grade indicates the quality of leather used in production. Common grades include full-grain, top-grain, genuine leather, and bonded leather. Full-grain leather is the highest quality, retaining the natural grain and durability. Understanding material grade helps buyers assess the longevity and aesthetic appeal of the products.

2. Thickness

Leather thickness is typically measured in ounces or millimeters. Thicker leather (e.g., 4-5 oz) is often used for durable goods like bags and belts, while thinner leather (1-2 oz) is suitable for wallets and small accessories. Knowing the thickness is essential for ensuring the product meets specific functional and aesthetic requirements.

3. Finish Type

The finish type affects both the appearance and performance of leather goods. Common finishes include aniline, semi-aniline, and pigmented. Aniline leather retains its natural look but is less resistant to stains, while pigmented leather offers better protection and color consistency. Buyers should consider the intended use of the products when evaluating finish types.

4. Tensile Strength

Tensile strength measures the leather’s ability to withstand pulling forces without breaking. This property is vital for products like bags and belts that undergo regular stress. Manufacturers often conduct tests to ensure their leather meets industry standards, which helps buyers ensure product reliability.

5. Water Resistance

Water resistance is a critical property for leather goods, especially for outdoor or travel-related products. Some manufacturers apply treatments to enhance water resistance without compromising the leather’s breathability. Understanding this property can help buyers choose products that suit their target markets and climates.

What Trade Terminology Should B2B Buyers Know When Sourcing Leather Goods?

Navigating the procurement process requires familiarity with industry-specific terminology. Here are some key terms every buyer should understand:

Illustrative image related to leather goods manufacturers usa

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on another company’s specifications. In the leather goods sector, buyers may engage OEMs to produce custom designs, ensuring brand consistency while leveraging the manufacturer’s expertise.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to determine if a supplier meets their purchasing needs without overcommitting resources. This term is especially relevant for startups or smaller businesses looking to manage costs.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing and terms for specified products. Including detailed specifications in an RFQ helps suppliers provide accurate quotes, streamlining the purchasing process and ensuring that buyers receive competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, thus reducing the risk of misunderstandings. Familiarity with Incoterms is vital for international buyers to ensure compliance and minimize costs.

Illustrative image related to leather goods manufacturers usa

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times helps buyers plan inventory and manage customer expectations. Shorter lead times can enhance competitiveness, especially in fast-paced markets.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing leather goods from manufacturers in the USA, ensuring they receive high-quality products that meet market demands.

Navigating Market Dynamics and Sourcing Trends in the leather goods manufacturers usa Sector

What Are the Current Market Dynamics and Key Trends in the Leather Goods Manufacturing Sector?

The leather goods manufacturing sector in the USA is experiencing a transformative phase, driven by global demand for high-quality, artisanal products. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking unique offerings that blend traditional craftsmanship with modern design. Key trends include the rise of direct-to-consumer models, which allow manufacturers to engage with customers more effectively while reducing reliance on intermediaries. Additionally, advancements in technology, such as digital supply chain management and automated production processes, are streamlining operations and enhancing the efficiency of sourcing and distribution.

Illustrative image related to leather goods manufacturers usa

Emerging markets are particularly focused on luxury leather goods, with buyers in countries like Saudi Arabia and Brazil showing a preference for bespoke items that reflect cultural heritage and personal identity. The demand for customization and personalization is reshaping product offerings, compelling manufacturers to adapt and innovate. As competition increases, businesses that leverage e-commerce platforms and social media for marketing are gaining a significant edge in reaching international clients.

How Is Sustainability and Ethical Sourcing Influencing Leather Goods Manufacturers in the USA?

Sustainability has become a pivotal concern for leather goods manufacturers in the USA, particularly in response to heightened consumer awareness and regulatory pressures. The environmental impact of leather production, including deforestation, water usage, and pollution from tanning processes, has prompted many companies to adopt more responsible practices. Ethical sourcing is no longer just a trend; it’s an expectation. Manufacturers are increasingly exploring alternatives such as vegetable-tanned leather and sourcing hides from sustainable farms that prioritize animal welfare and ecological balance.

Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining traction among B2B buyers who prioritize green credentials. These certifications not only enhance brand reputation but also open doors to new markets that emphasize sustainability. By investing in environmentally friendly materials and processes, manufacturers can differentiate themselves in a competitive landscape while aligning with the values of their international clientele.

What Is the Historical Context of Leather Goods Manufacturing in the USA?

The leather goods manufacturing industry in the USA has a rich history, dating back to the colonial era when leather was a vital resource for clothing and tools. Over the centuries, the industry evolved significantly, with innovations in tanning and crafting techniques that laid the groundwork for modern production. The post-war boom saw a surge in demand for leather products, establishing the USA as a leader in quality craftsmanship.

Illustrative image related to leather goods manufacturers usa

In recent decades, however, the sector has faced challenges from globalization and the rise of synthetic materials. Nevertheless, many manufacturers have successfully pivoted to emphasize quality, heritage, and artisanal production. This shift has not only revitalized interest in American-made leather goods but has also positioned the industry to cater to a global market that increasingly values authenticity and sustainability in product sourcing.

In summary, understanding these market dynamics, trends, and historical contexts is crucial for international B2B buyers looking to navigate the complex landscape of leather goods manufacturing in the USA. By aligning sourcing strategies with these insights, businesses can make informed decisions that resonate with current consumer expectations and market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of leather goods manufacturers usa

-

How do I identify reliable leather goods manufacturers in the USA?

To find trustworthy leather goods manufacturers, start by researching industry directories and trade associations, such as the Leather Industries of America. Look for manufacturers with a solid reputation, verified reviews, and a history of serving international clients. Request samples to assess quality, and consider visiting their facilities if possible. Additionally, check for certifications related to ethical sourcing and sustainability, which can be indicators of reliability and quality. -

What are the key factors to consider when vetting leather goods suppliers?

When vetting suppliers, evaluate their production capabilities, quality control processes, and compliance with industry standards. Assess their experience with international shipping and customs regulations, especially if you are importing from regions like Africa or South America. Request references from other international buyers to gauge their reliability and responsiveness. Lastly, review their communication practices to ensure they can meet your needs efficiently. -

What customization options are typically available for leather goods?

Most manufacturers offer a range of customization options, including material selection (e.g., full-grain leather, suede), color choices, and personalized branding through embossing or engraving. Some may also provide design modifications to suit your specifications. It’s essential to communicate your requirements clearly and inquire about minimum order quantities (MOQs) for customized products, as these can vary significantly among manufacturers. -

What are the standard minimum order quantities (MOQs) for leather goods?

Minimum order quantities vary by manufacturer and product type. Typically, MOQs can range from 50 to 500 units, depending on the complexity of the item and the level of customization required. It’s advisable to discuss your needs with potential suppliers early in the negotiation process to find a manufacturer that can accommodate your order volume without compromising quality. -

What payment terms should I expect when dealing with US leather goods manufacturers?

Payment terms can vary significantly among manufacturers. Common practices include a deposit (often 30-50%) upon order confirmation, with the balance due before shipment. Some suppliers may offer net payment terms (e.g., net 30 or net 60) for established relationships. Always clarify payment methods accepted (e.g., wire transfer, credit card) and ensure that contracts outline all terms to avoid misunderstandings. -

How can I ensure quality assurance in my leather goods order?

To ensure quality assurance, request detailed specifications and quality standards from the manufacturer before placing an order. Consider implementing a quality control inspection process, either through third-party services or by visiting the manufacturing facility. Establish clear communication regarding acceptable quality levels and conduct pre-shipment inspections to verify that products meet your standards before they are dispatched. -

What logistics considerations should I keep in mind when importing leather goods?

Logistics is critical when importing leather goods. Ensure you understand shipping options, lead times, and costs associated with freight forwarding. Be aware of customs regulations and duties that may apply to your imports, especially when shipping to regions like the Middle East or Europe. Collaborate with a logistics provider experienced in handling leather products to streamline the process and mitigate potential delays. -

What are the common challenges faced by international buyers of leather goods?

International buyers often encounter challenges such as language barriers, varying quality standards, and compliance with local regulations. Additionally, navigating customs procedures and managing shipping logistics can be complex. To overcome these issues, establish strong communication channels with your supplier, conduct thorough research on importing regulations in your country, and consider working with a freight forwarder who specializes in international trade for leather goods.

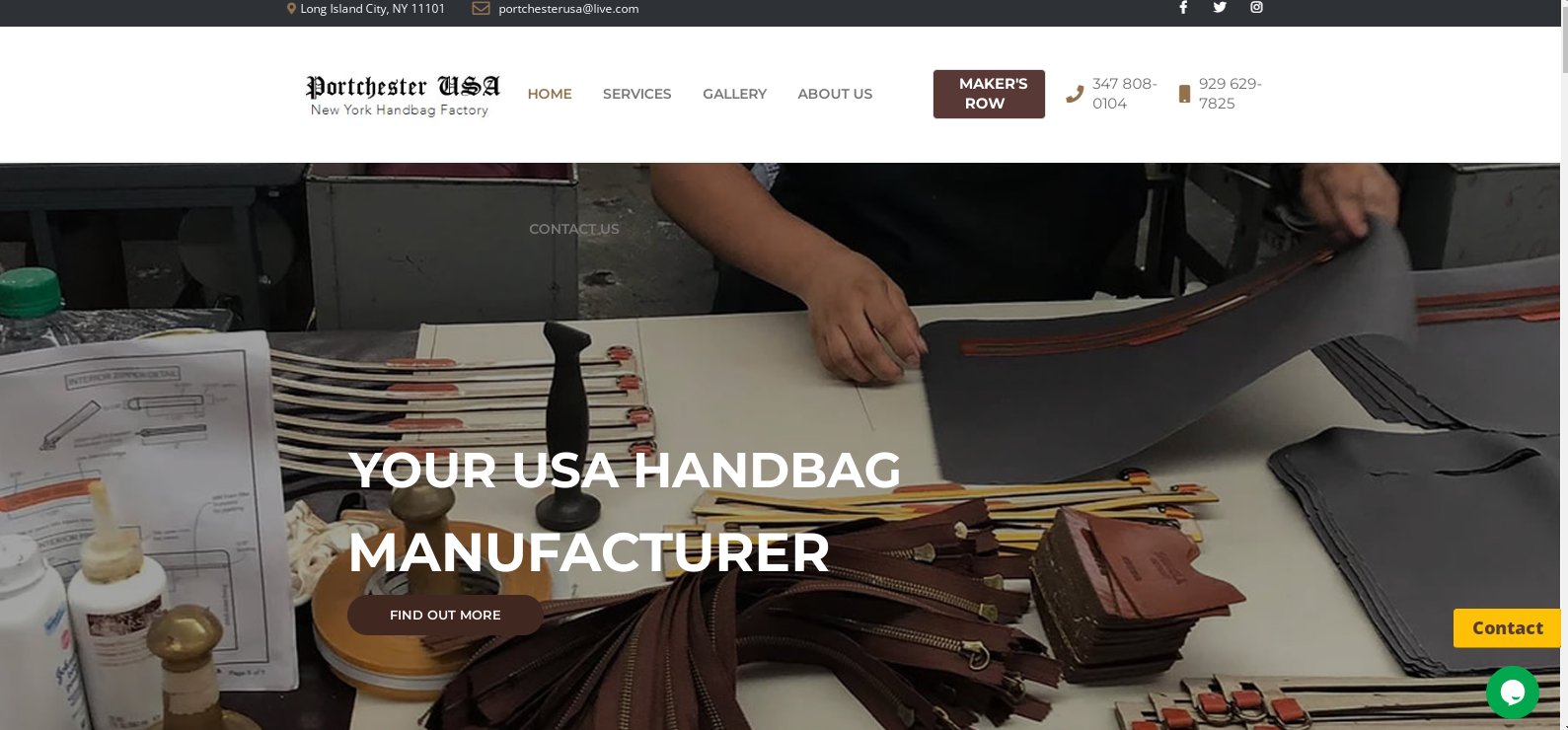

Top 8 Leather Goods Manufacturers Usa Manufacturers & Suppliers List

1. Rogue Industries – Rogue Front Pocket Wallet – Classic

Domain: rogue-industries.com

Registered: 2012 (13 years)

Introduction: American Made Leather Goods collection from Rogue Industries includes a variety of products such as wallets, card cases, bags, and duffles. All items are crafted in Maine using high-quality materials like bison and moose leather. Key products include: Rogue Front Pocket Wallet – Classic ($55), Sheepscot Felt Wool Tote Bag ($198), American Bison Leather Front Pocket Wallet ($65), Fore Street Tote B…

2. Holtz Leather – The Trifecta Personalized Leather Tri-Fold Wallet

Domain: holtzleather.com

Registered: 2015 (10 years)

Introduction: {“products”:[{“name”:”The Trifecta Personalized Leather Tri-Fold Wallet with ID Slot”,”price”:”$109.00″},{“name”:”The Maria Fine Leather Tote Bag”,”price”:”$449.00″},{“name”:”Personalized Bridle Leather Men’s Casual Belt – Square Nickel or Brass Buckle”,”price”:”$105.00″},{“name”:”Tennessee Whiskey Barrel Stave Towel Hanger Wall Hook”,”price”:”$35.00″},{“name”:”The Monticello Fine Leather Personal…

3. Goforth Goods – Handmade Leather Bags and Accessories

Domain: goforthgoods.com

Registered: 2014 (11 years)

Introduction: Handmade Leather Goods, Made in the USA; Free shipping on orders over $150; Product categories include: Bags (Tote Bags, Crossbody Bags, Backpacks, Duffle Bags, Briefcases), Accessories (Leather Wallets, Belts, Key Fobs, Travel Accessories, Home Goods), and Apparel (Shirts and Hats); Best Sellers available; Color options include Smooth Caramel, Natural veg, Oxblood, Pebbled Bermuda, Black, Black B…

4. The Little Leather Factory – Luxury Leather & Vegan Products

Domain: thelittleleatherfactory.com

Registered: 2015 (10 years)

Introduction: The Little Leather Factory is a manufacturer of traditional leather and vegan leather products, specializing in luxury designer items. They offer beautiful hand-made products with low minimum quantities and quick reorder times. The company provides assistance in the design process, helping clients transform sketches into finished prototypes and managing production runs. They use high-quality susta…

5. Corter Leather – Handcrafted Leather Goods

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Independent leather companies in the USA include Corter Leather, Open Sea Leather, Low Tide Leather, The Leather Shop (Seattle, WA), Colonel Littleton (Tennessee), Mascon Leather, Norm Cahn Leatherworks (Etsy), Himel Bros, Schott NYC, Vermilyea Pelle, Urban Southern, Loyal Stricklin, and Lotus Leather Studio. Some users also mentioned Saddleback Leather, although it is manufactured in Mexico and n…

6. Affix Apparel – Custom Leather Goods

Domain: affixapparel.com

Registered: 2020 (5 years)

Introduction: Affix Apparel specializes in crafting custom leather goods tailored for retail brands, including stylish bags, wallets, belts, and accessories. They emphasize high-quality materials, skilled craftsmanship, and attention to detail in stitching and finishing. The manufacturing process includes consultation, design and sampling, production, and quality control. They offer customization options, susta…

7. Will Leather Goods – All-In-One Leather Solution

Domain: willleathergoods.com

Registered: 2009 (16 years)

Introduction: All-In-One Leather Solution – $30.00, The Original Will Utility Tote – $150.00, Rainier Leather Backpack – $498.00, Set Of Eight Coasters – $75.00, Otto Crossbody – Best Seller, Simple Tote – Best Seller, William Collection Continental Briefcase, Italian Collection Rome Tote, Kent Messenger – Better With Age. Will Leather Goods offers a Lifetime Guarantee on all products.

8. Portland Leather Goods – Handmade Leather Bags

Domain: portlandleathergoods.com

Registered: 2015 (10 years)

Introduction: Portland Leather Goods offers handmade leather products from Portland, OR. Key product categories include leather totes, purses, handbags, small goods, and various styles of bags such as crossbody bags, shoulder bags, and backpacks. Featured products include the Koala Sling Bag, Naomi Shoulder Bag, Metro Crossbody, and Circle Crossbody. The site offers a variety of colors for products, including N…

Strategic Sourcing Conclusion and Outlook for leather goods manufacturers usa

As the leather goods market continues to evolve, strategic sourcing remains paramount for international buyers seeking quality, craftsmanship, and sustainability. The unique attributes of U.S. leather manufacturers—such as their commitment to handcrafted excellence and the use of premium materials—offer significant advantages. For buyers from regions like Africa, South America, the Middle East, and Europe, partnering with American manufacturers can provide not only superior products but also the opportunity to align with brands that prioritize ethical sourcing and environmental responsibility.

By understanding the diverse offerings and specializations of U.S. leather goods manufacturers, businesses can effectively navigate their sourcing strategies. With the growing demand for personalized and bespoke products, leveraging the capabilities of these manufacturers can enhance brand value and customer loyalty.

Looking ahead, the landscape of leather goods will likely be shaped by innovations in design and sustainability. International buyers are encouraged to engage with U.S. manufacturers to explore collaborative opportunities that leverage these trends. By investing in strategic partnerships now, businesses can position themselves at the forefront of a dynamic market, ensuring they meet the evolving preferences of consumers worldwide.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.