Introduction: Navigating the Global Market for chinese leather sewing machine

In the ever-evolving landscape of the global market, sourcing high-quality Chinese leather sewing machines presents both opportunities and challenges for international B2B buyers. As manufacturers and artisans from regions such as Africa, South America, the Middle East, and Europe seek reliable equipment for their leather goods production, understanding the nuances of these machines becomes critical. This guide delves into the diverse types of Chinese leather sewing machines, their specific applications, and the essential factors to consider when evaluating suppliers.

Buyers will gain insights into the intricacies of machine specifications, cost considerations, and the importance of supplier vetting to ensure long-term value and performance. With an emphasis on practical applications, this guide empowers businesses to make informed purchasing decisions, enabling them to select machines that not only meet their production needs but also enhance their operational efficiency. By navigating the complexities of the market, B2B buyers can secure the right equipment, ultimately leading to improved product quality and competitive advantage in their respective sectors.

Whether you are looking to invest in a robust machine for mass production or a specialized model for bespoke leather goods, this comprehensive resource will equip you with the knowledge necessary to thrive in today’s dynamic marketplace.

Table Of Contents

- Top 1 Chinese Leather Sewing Machine Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for chinese leather sewing machine

- Understanding chinese leather sewing machine Types and Variations

- Key Industrial Applications of chinese leather sewing machine

- 3 Common User Pain Points for ‘chinese leather sewing machine’ & Their Solutions

- Strategic Material Selection Guide for chinese leather sewing machine

- In-depth Look: Manufacturing Processes and Quality Assurance for chinese leather sewing machine

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘chinese leather sewing machine’

- Comprehensive Cost and Pricing Analysis for chinese leather sewing machine Sourcing

- Alternatives Analysis: Comparing chinese leather sewing machine With Other Solutions

- Essential Technical Properties and Trade Terminology for chinese leather sewing machine

- Navigating Market Dynamics and Sourcing Trends in the chinese leather sewing machine Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of chinese leather sewing machine

- Strategic Sourcing Conclusion and Outlook for chinese leather sewing machine

- Important Disclaimer & Terms of Use

Understanding chinese leather sewing machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Patcher Sewing Machine | Compact design, free-arm capability, manual or servo motor options | Leather repairs, crafting patches | Pros: Affordable, versatile for small projects. Cons: Requires tuning and assembly, may need upgrades for durability. |

| Walking Foot Sewing Machine | Dual feed mechanism, heavy-duty build, adjustable presser foot | Upholstery, heavy leather goods | Pros: Excellent for thick materials, consistent stitch quality. Cons: Higher initial investment, may be bulky for small spaces. |

| Flatbed Leather Sewing Machine | Large flat surface, suited for various materials, automated options | Mass production, garment manufacturing | Pros: Efficient for high-volume projects, versatile. Cons: Limited maneuverability for intricate designs, requires larger workspace. |

| Cylinder Arm Sewing Machine | Cylindrical arm design, ideal for tubular items | Shoe manufacturing, bags, and belts | Pros: Great for hard-to-reach areas, precise stitching. Cons: More complex setup, may not be suitable for flat items. |

| Overlock Sewing Machine | Multiple threads, clean edges, high-speed operation | Apparel production, finishing seams | Pros: Fast and efficient for seam finishing, reduces fraying. Cons: Limited to specific stitching types, requires skill to operate effectively. |

What Are the Key Features of Patcher Sewing Machines for B2B Buyers?

The patcher sewing machine is characterized by its compact design and free-arm capability, making it particularly suitable for sewing patches and performing leather repairs. Often available at a lower price point, these machines are ideal for small-scale projects or for businesses just starting in leatherwork. However, potential buyers should be aware that they may require some initial tuning and assembly to function optimally, and upgrading components can enhance performance and longevity.

How Do Walking Foot Sewing Machines Benefit Businesses?

Walking foot sewing machines feature a dual feed mechanism that allows for even feeding of thick materials, making them a preferred choice for upholstery and heavy leather goods. Their robust build ensures consistent stitch quality, which is crucial for businesses focusing on high-quality leather products. While they represent a higher initial investment, the efficiency and durability they offer can lead to significant returns in production quality and speed.

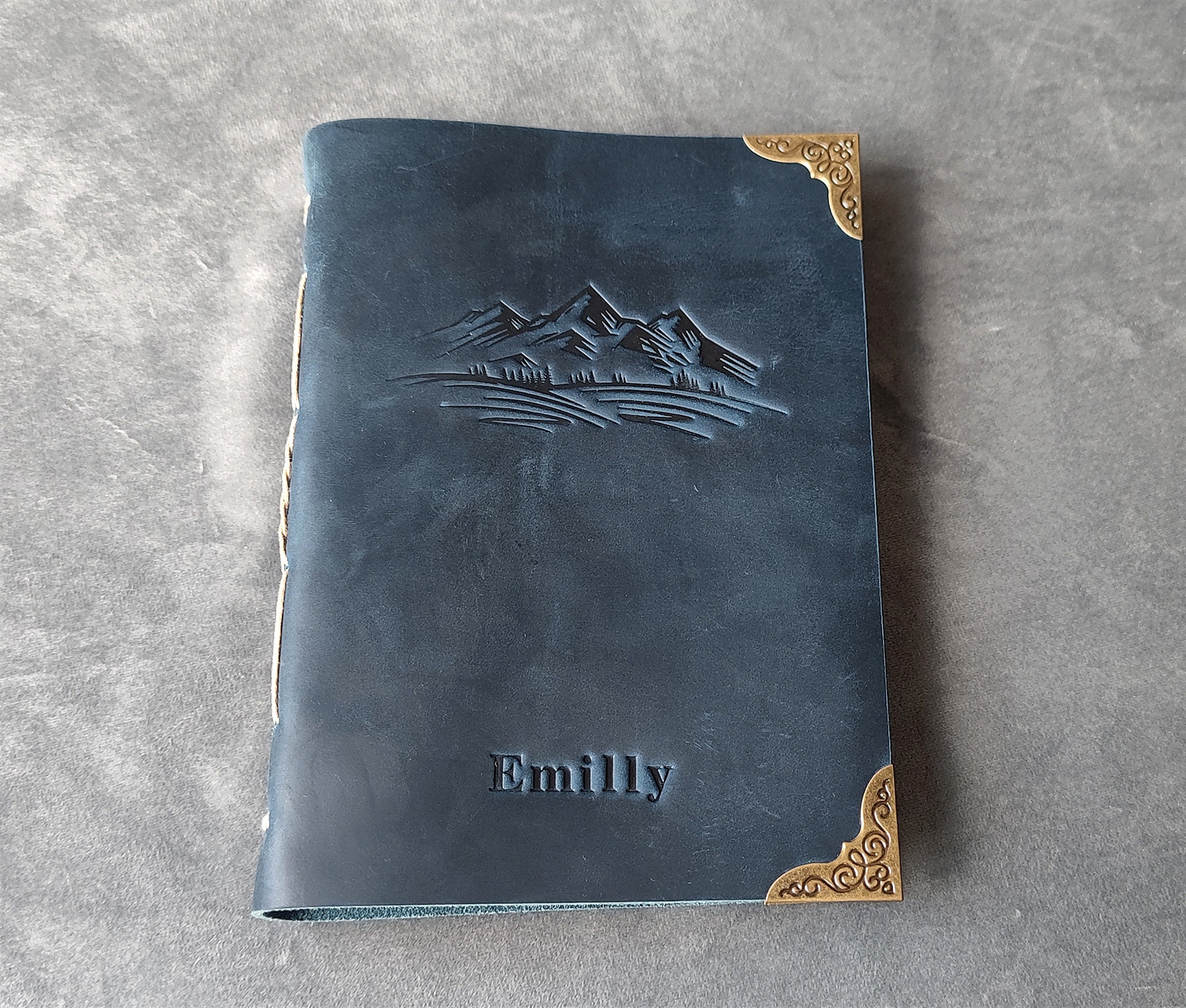

Illustrative image related to chinese leather sewing machine

In What Situations Are Flatbed Leather Sewing Machines Most Effective?

Flatbed leather sewing machines provide a large, flat surface that accommodates various materials, making them ideal for mass production and garment manufacturing. Their automated options enhance efficiency, allowing businesses to produce high volumes of products quickly. However, the limited maneuverability for intricate designs may be a drawback for companies focusing on detailed leatherwork, necessitating a larger workspace for optimal use.

What Are the Advantages of Cylinder Arm Sewing Machines?

Cylinder arm sewing machines are designed with a unique cylindrical arm that facilitates sewing on tubular items, such as shoes and bags. This design allows for precise stitching in hard-to-reach areas, making it a valuable tool for specialized leather manufacturers. While the complexity of setup may deter some buyers, the benefits in terms of accuracy and finish quality can justify the investment for businesses focused on intricate leather products.

Why Choose Overlock Sewing Machines for Leather Applications?

Overlock sewing machines utilize multiple threads to create clean edges and are known for their high-speed operation, making them ideal for apparel production and finishing seams. This capability significantly reduces fraying, ensuring a professional finish that is essential for quality leather goods. Despite their advantages, these machines require skilled operators to maximize their potential, which may be a consideration for B2B buyers looking to optimize labor costs.

Key Industrial Applications of chinese leather sewing machine

| Industry/Sector | Specific Application of Chinese Leather Sewing Machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Stitching and repairing shoes and boots | Cost-effective solution for high-volume production | Ensure machine can handle thick materials and has a reliable motor. |

| Fashion and Apparel | Custom leather garments and accessories | Versatile for various leather types, enhancing product offerings | Look for machines with adjustable settings for different fabric weights. |

| Upholstery and Furniture | Leather upholstery for furniture | Durable seams that withstand heavy use | Check for compatibility with different leather thicknesses and types. |

| Leather Goods Production | Crafting bags, wallets, and belts | Streamlined production for bespoke items | Assess ease of operation and maintenance for long-term reliability. |

| Industrial Equipment Repair | Repairing industrial leather equipment components | Reduces downtime and extends equipment life | Prioritize machines with robust construction and service support. |

How Are Chinese Leather Sewing Machines Used in Footwear Manufacturing?

In the footwear manufacturing sector, Chinese leather sewing machines are integral for stitching and repairing shoes and boots. They offer a cost-effective solution, enabling manufacturers to produce high volumes while maintaining quality. These machines are designed to handle thick materials, making them suitable for various types of leather used in footwear. Buyers should consider sourcing machines that feature a reliable motor to ensure consistent performance during high-demand periods.

What Role Do Chinese Leather Sewing Machines Play in Fashion and Apparel?

In the fashion and apparel industry, Chinese leather sewing machines are utilized for creating custom leather garments and accessories. Their versatility allows designers to work with various leather types, enhancing their product offerings. International buyers must look for machines with adjustable settings to accommodate different fabric weights, ensuring that they can handle everything from lightweight leather to heavy-duty materials.

How Are Chinese Leather Sewing Machines Essential for Upholstery and Furniture?

Chinese leather sewing machines are crucial in the upholstery and furniture industry for crafting durable leather upholstery. These machines provide strong seams that can withstand the rigors of everyday use in furniture settings. When sourcing, it is vital for buyers to ensure that the machines can accommodate various leather thicknesses and types, as this will significantly impact the final product’s quality and durability.

Why Are Chinese Leather Sewing Machines Important for Leather Goods Production?

In the leather goods production sector, these machines are employed for crafting items such as bags, wallets, and belts. They streamline production processes, especially for bespoke items that require precision stitching. Businesses should assess the ease of operation and maintenance of the machines to ensure long-term reliability and minimal downtime, which is critical for maintaining competitive production timelines.

How Do Chinese Leather Sewing Machines Benefit Industrial Equipment Repair?

Chinese leather sewing machines also find applications in the repair of industrial leather equipment components. They play a vital role in reducing downtime and extending the life of expensive machinery. Buyers in this sector should prioritize machines with robust construction and adequate service support, as these features are essential for handling the demanding repairs typically associated with industrial applications.

3 Common User Pain Points for ‘chinese leather sewing machine’ & Their Solutions

Scenario 1: Quality Control Concerns with Chinese Leather Sewing Machines

The Problem: B2B buyers often face significant challenges regarding the quality of Chinese leather sewing machines. Many machines are delivered with subpar components, such as poorly fitted parts, lack of bearings, and general assembly issues. This can lead to operational inefficiencies, increased downtime for repairs, and ultimately affect the quality of the final product. Buyers are particularly concerned about the reliability of machines when they are purchased in bulk for manufacturing purposes, as even a single faulty machine can disrupt production schedules and impact profitability.

The Solution: To mitigate quality control concerns, B2B buyers should prioritize sourcing machines from reputable manufacturers with established track records. Conducting thorough due diligence, including reviewing customer testimonials and seeking references from other businesses in similar industries, can help identify reliable suppliers. Additionally, consider requesting samples or demo units before making bulk purchases. Establishing clear quality specifications in the purchasing agreement can also protect against receiving substandard machines. Furthermore, investing in initial setup and tuning—such as adding necessary bushings or bearings—can enhance the machine’s performance and longevity, making it a more valuable asset in the long run.

Scenario 2: Difficulty in Machine Setup and Tuning

The Problem: Many buyers of Chinese leather sewing machines find the setup process to be daunting. The machines often require significant adjustments and tuning to operate effectively, which can be a barrier for businesses lacking technical expertise. This issue is exacerbated when companies do not have dedicated maintenance personnel, leading to frustration and delays in production as employees struggle to get the machines up and running.

The Solution: To streamline the setup and tuning process, B2B buyers should seek suppliers that provide comprehensive installation guides or video tutorials. These resources can help demystify the setup process and empower staff to handle initial adjustments confidently. Additionally, consider investing in training sessions for employees, either through the supplier or third-party experts, to equip them with the necessary skills to maintain the machines. Creating a maintenance schedule that includes regular checks can also prevent issues from arising, ensuring that the machines remain in optimal working condition and reducing the need for extensive repairs later on.

Scenario 3: Limited Versatility for Diverse Leather Projects

The Problem: A common pain point for businesses using Chinese leather sewing machines is their limited versatility, particularly when it comes to handling different types of leather and project requirements. Some machines are optimized for specific tasks, such as patching or sewing thick leather, but struggle with lighter materials or intricate designs. This can hinder a company’s ability to diversify its product offerings, ultimately affecting competitiveness in the market.

The Solution: To address versatility issues, buyers should carefully assess their operational needs before purchasing. Opting for machines that offer adjustable settings for different materials and stitch types can enhance flexibility. Investing in additional attachments or accessories, such as various presser feet or specialized needles, can expand the machine’s capabilities. Furthermore, consider establishing a modular workflow that allows for the easy interchange of machines or attachments depending on the project. Engaging with suppliers who offer customization options can also lead to acquiring machines that better fit specific production needs, enabling businesses to take on a wider range of leather projects.

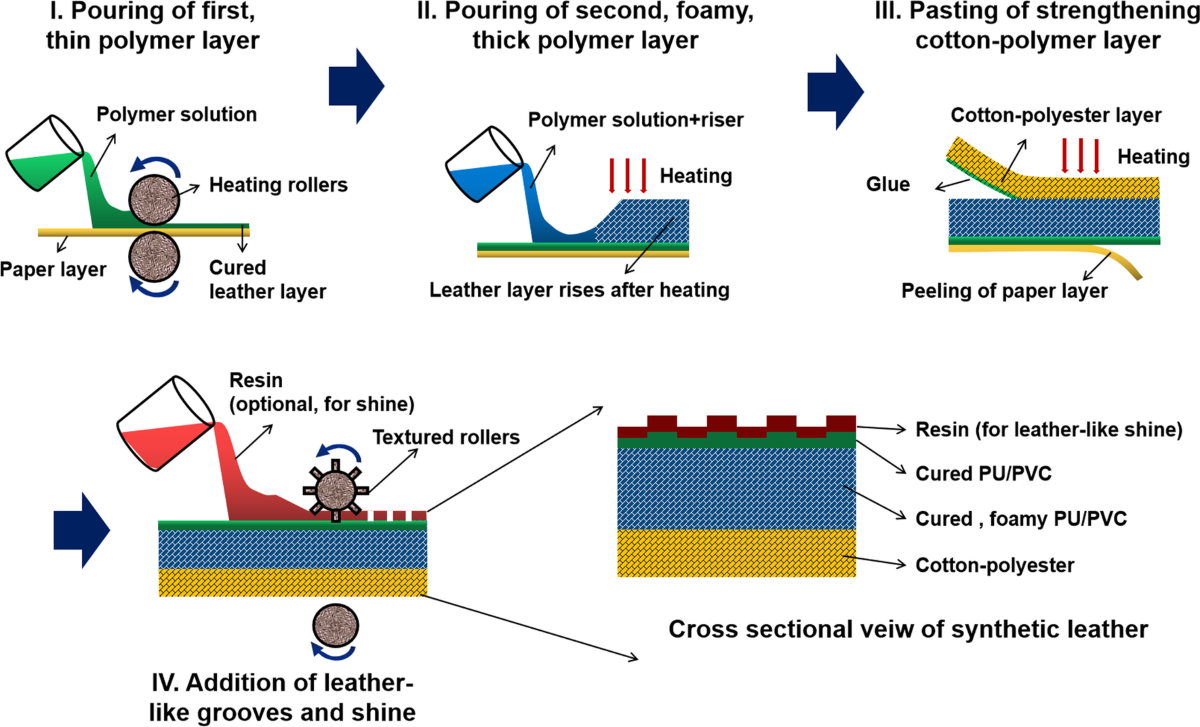

Strategic Material Selection Guide for chinese leather sewing machine

When selecting materials for Chinese leather sewing machines, it is essential to consider various factors that affect performance, durability, and cost. The following analysis covers four common materials used in these machines, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Cast Iron in Leather Sewing Machines?

Cast iron is commonly used in the construction of sewing machine frames due to its excellent rigidity and vibration-damping properties. It can withstand significant mechanical stress and has a high-temperature resistance, making it suitable for prolonged use in various environments. However, cast iron is susceptible to corrosion if not properly maintained, which can be a concern in humid climates.

Pros:

– High durability and strength.

– Excellent stability under operational stress.

– Cost-effective for mass production.

Illustrative image related to chinese leather sewing machine

Cons:

– Heavy, which can complicate shipping and installation.

– Prone to rust without protective coatings.

Impact on Application: Cast iron frames provide stability and longevity, essential for machines operating under high load conditions. However, buyers in humid regions must consider additional protective measures against corrosion.

How Does Aluminum Affect the Performance of Leather Sewing Machines?

Aluminum is increasingly favored for its lightweight nature and resistance to corrosion. This material is often used in components such as the machine arm and housing. Its excellent thermal conductivity helps dissipate heat generated during operation, enhancing machine performance.

Pros:

– Lightweight, facilitating easier handling and transport.

– Corrosion-resistant, reducing maintenance needs.

– Good machinability allows for precise manufacturing.

Cons:

– Lower tensile strength compared to cast iron.

– More expensive than steel alternatives.

Impact on Application: Aluminum’s lightweight nature is advantageous for portable sewing machines. However, its lower strength may not be suitable for heavy-duty applications, which could be a consideration for buyers in industries like leather goods manufacturing.

What Role Does Steel Play in the Durability of Leather Sewing Machines?

Steel is a versatile material that combines strength and durability, making it suitable for various components, including gears and shafts. It can be treated for increased hardness and wear resistance, which is crucial for the longevity of sewing machines.

Pros:

– High strength-to-weight ratio.

– Excellent wear resistance when treated.

– Cost-effective for high-volume production.

Cons:

– Susceptible to rust without proper coatings.

– Heavier than aluminum, which may affect portability.

Impact on Application: Steel components enhance the durability of sewing machines, making them ideal for heavy-duty applications. Buyers must ensure that steel parts are adequately coated to prevent rust, especially in regions with high humidity.

How Does Plastic Impact the Functionality of Leather Sewing Machines?

Plastic is often used in non-structural components, such as knobs and covers, due to its lightweight and cost-effective nature. It can also provide insulation against electrical components, enhancing safety during operation.

Pros:

– Lightweight and easy to mold into complex shapes.

– Resistant to corrosion and many chemicals.

– Low manufacturing costs.

Cons:

– Generally less durable than metal alternatives.

– Can degrade under high temperatures.

Impact on Application: While plastic components can reduce overall machine weight and cost, their limited durability may not be suitable for heavy-duty applications. Buyers should assess the expected wear and tear based on their specific usage scenarios.

Summary Table of Material Selection for Chinese Leather Sewing Machines

| Material | Typical Use Case for chinese leather sewing machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Machine frame and base | High durability and stability | Heavy and prone to rust | Low |

| Aluminum | Machine arm and housing | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Steel | Gears and shafts | High strength and wear resistance | Susceptible to rust | Medium |

| Plastic | Knobs and covers | Lightweight and cost-effective | Less durable under stress | Low |

In conclusion, selecting the right materials for Chinese leather sewing machines involves balancing performance, durability, and cost. International B2B buyers should consider the specific applications and environmental conditions in their regions to make informed decisions that align with their operational needs.

Illustrative image related to chinese leather sewing machine

In-depth Look: Manufacturing Processes and Quality Assurance for chinese leather sewing machine

What Are the Key Stages in the Manufacturing Process of Chinese Leather Sewing Machines?

The manufacturing process for Chinese leather sewing machines involves several critical stages, each designed to ensure efficiency, performance, and durability. Understanding these stages is essential for B2B buyers looking for reliable machinery.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage of manufacturing begins with the selection of raw materials. Steel and aluminum are typically the primary materials used due to their strength and durability. Quality control at this stage is crucial, as the integrity of the materials directly affects the machine’s performance. Suppliers often conduct initial inspections, such as verifying the chemical composition and mechanical properties of metals, to ensure they meet specified standards.

Once materials are selected, they undergo processing, which may include cutting, bending, and shaping. Advanced CNC machines are commonly utilized for precision cutting and forming, ensuring that components fit together seamlessly during assembly. This high level of accuracy reduces waste and enhances the overall quality of the final product.

How Is the Forming Stage Executed to Ensure Precision?

In the forming stage, the various components of the sewing machine—such as the frame, needle, and feed mechanisms—are crafted. This stage may involve techniques like stamping, forging, and casting, with each method chosen based on the component’s design and material properties.

For example, the machine frame is often cast from high-grade aluminum, providing a lightweight yet sturdy foundation. Components like the needle and feed dogs may be stamped from high-carbon steel for added resilience. Quality checks during this stage include dimensional inspections and functionality tests to ensure all parts meet the required specifications.

What Does the Assembly Process Entail?

The assembly process is where all the prepared components come together. Skilled technicians typically oversee this stage, ensuring that each part is installed correctly. This process can be labor-intensive, requiring a blend of manual skill and mechanical assistance.

Illustrative image related to chinese leather sewing machine

During assembly, the machines are often configured in a way that allows for easy maintenance and adjustments. This design consideration is particularly important for users in the field who may need to make quick repairs. Quality checkpoints during assembly include visual inspections and functional tests to verify that the machine operates as intended.

How Is Finishing Handled to Enhance Aesthetic and Functional Qualities?

Finishing processes, such as painting, powder coating, or plating, are applied to enhance both the aesthetic appeal and corrosion resistance of the sewing machines. This stage not only provides a polished look but also contributes to the longevity of the machinery, particularly in environments that may expose them to moisture or chemicals.

Quality assurance during the finishing stage often involves adhesion tests and surface inspections to ensure that coatings are applied uniformly. Any defects identified at this stage can be addressed before the machines are packaged for shipment.

What Quality Assurance Measures Are Implemented in Chinese Leather Sewing Machine Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process, especially for B2B buyers who rely on consistent performance and durability from their machinery.

Which International Standards Are Relevant for Quality Assurance?

Manufacturers of Chinese leather sewing machines often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 indicates that the manufacturer has established processes to ensure product quality and customer satisfaction.

Additionally, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant depending on the machine’s intended use. CE certification, for instance, is crucial for products sold in Europe, ensuring that they meet health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints During Production?

Quality control in the manufacturing of leather sewing machines typically involves several checkpoints:

-

Incoming Quality Control (IQC): This stage assesses the quality of raw materials and components before they enter the production line. Suppliers may provide test reports and certifications for materials used in the manufacturing process.

-

In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to ensure that each stage of manufacturing meets predetermined specifications. This may include dimensional checks and functionality tests.

-

Final Quality Control (FQC): Before the machines are packaged, a comprehensive final inspection is performed. This includes testing the assembled machine to verify its operational capabilities and ensuring it meets all quality standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure product reliability. Here are several approaches:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality assurance measures in place. This provides insights into the supplier’s commitment to quality and compliance with international standards.

-

Quality Reports: Requesting detailed quality assurance reports can offer a snapshot of the supplier’s testing methods, inspection results, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can perform inspections at various stages of the manufacturing process, providing unbiased evaluations of the product quality.

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Regulatory requirements may vary by country, necessitating an understanding of local standards in addition to international certifications.

For example, some regions may have stricter environmental regulations affecting manufacturing processes, while others may prioritize safety certifications. Buyers should also consider the logistical aspects of international shipping, as quality can be impacted during transport. Establishing clear communication with suppliers about packaging and shipping methods can help mitigate these risks.

Illustrative image related to chinese leather sewing machine

In conclusion, understanding the manufacturing processes and quality assurance measures for Chinese leather sewing machines is crucial for B2B buyers. By being informed about material preparation, assembly techniques, and quality control practices, buyers can make educated decisions, ensuring they procure reliable and high-quality machinery.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chinese leather sewing machine’

This guide serves as a practical checklist for international B2B buyers looking to procure Chinese leather sewing machines. The complexity and variety of these machines can pose challenges, especially when considering factors such as quality, functionality, and supplier reliability. Follow these steps to ensure a successful sourcing experience.

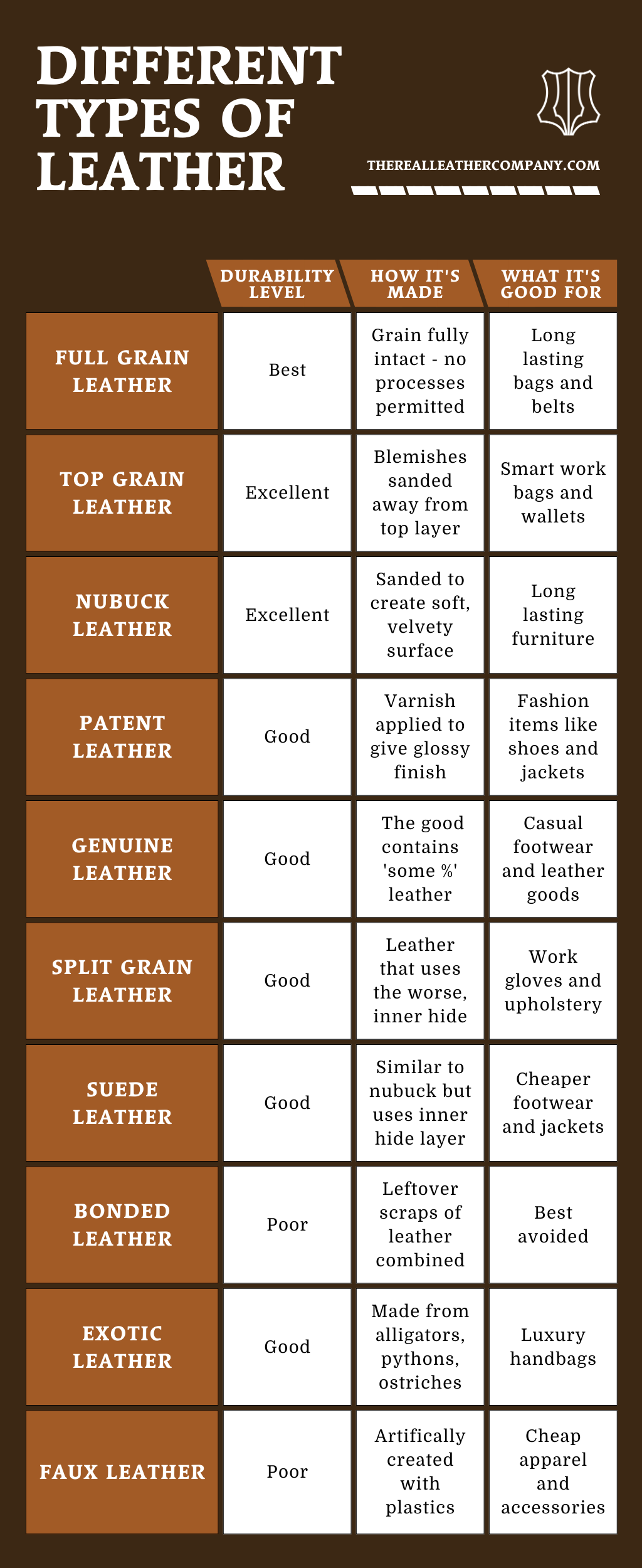

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the leather sewing machines you need. Consider factors such as the types of leather you’ll be working with, the thickness of materials, and the specific sewing techniques required. This clarity will guide your supplier discussions and help you avoid purchasing a machine that doesn’t meet your operational needs.

- Types of leather: Different machines may perform better with specific leather types (e.g., full-grain, suede).

- Sewing techniques: Identify if you need a machine for patching, stitching, or heavy-duty assembly.

Step 2: Research Supplier Credentials

Verify the credentials and reputation of potential suppliers. Look for established manufacturers with a history of supplying leather sewing machines. Check for certifications such as ISO 9001, which indicates adherence to quality management standards.

- Company history: A long-standing supplier is likely to have more experience and reliability.

- Customer reviews: Seek feedback from other businesses that have purchased from the supplier to gauge their reliability and product performance.

Step 3: Evaluate Product Quality and Features

Assess the quality and features of the sewing machines on offer. Given the feedback from users regarding assembly and operational smoothness, look for models that include features such as adjustable speed, durability, and ease of maintenance.

- Build quality: Check for materials used in construction; machines with better build quality tend to last longer.

- User-friendliness: Ensure the machine is designed for ease of use, especially if your team has varying levels of expertise.

Step 4: Request Samples or Demonstrations

Before finalizing your purchase, request samples or arrange demonstrations of the machines. This step allows you to evaluate the machine’s performance and suitability for your specific needs directly.

- Testing: A hands-on demonstration can reveal potential issues that may not be apparent through specifications alone.

- Support: Assess the supplier’s willingness to provide ongoing support and training.

Step 5: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, negotiate the terms and conditions of your purchase. This includes pricing, payment terms, shipping arrangements, and warranty coverage. Ensure that all agreements are documented to protect your interests.

- Payment terms: Discuss options like letters of credit or partial payments to mitigate risk.

- Shipping logistics: Understand delivery timelines and costs, particularly if you are importing from overseas.

Step 6: Confirm After-Sales Support and Warranty

Evaluate the after-sales support offered by the supplier, including warranty terms and availability of spare parts. Reliable after-sales service can be crucial for minimizing downtime and maintaining productivity.

- Warranty coverage: Ensure the warranty covers essential components and provides adequate protection.

- Availability of parts: Confirm that spare parts are readily available, which is critical for long-term maintenance.

Step 7: Establish a Relationship with the Supplier

After completing your purchase, work on establishing a long-term relationship with your supplier. This can lead to better pricing, priority service, and access to new products in the future.

- Feedback loop: Provide feedback on machine performance to help the supplier improve their offerings.

- Future needs: Keep the supplier informed about your future requirements, which can foster collaboration.

By following this checklist, you can navigate the complexities of sourcing Chinese leather sewing machines effectively, ensuring that you make informed decisions that align with your business goals.

Comprehensive Cost and Pricing Analysis for chinese leather sewing machine Sourcing

What Are the Key Cost Components of Sourcing Chinese Leather Sewing Machines?

When sourcing Chinese leather sewing machines, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

Illustrative image related to chinese leather sewing machine

-

Materials: The choice of materials significantly impacts the overall cost. Cheaper, lower-quality materials may reduce the initial purchase price but can lead to higher maintenance costs and shorter lifespans.

-

Labor: Labor costs in China are generally lower than in many Western countries, which contributes to the competitive pricing of these machines. However, the skill level of labor can vary, influencing the quality of assembly and finishing.

-

Manufacturing Overhead: This encompasses factory utilities, rent, and administrative expenses. Efficient production processes can lower overhead, allowing for more competitive pricing.

-

Tooling: Initial tooling costs can be substantial, particularly for custom designs. Buyers should inquire about these costs, as they can be amortized over larger orders, making them more cost-effective.

-

Quality Control (QC): Implementing rigorous QC processes ensures that machines meet international standards, which may increase initial costs but ultimately reduces returns and dissatisfaction.

-

Logistics: Shipping costs can vary based on the destination, chosen shipping method, and current freight rates. It’s essential to consider these factors as they can significantly influence the total cost.

-

Margin: Suppliers typically apply a margin to cover their costs and profit. Understanding the typical margins in this industry can help buyers negotiate better prices.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence the pricing of Chinese leather sewing machines:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs. Negotiating favorable terms regarding MOQs can enhance cost efficiency.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should assess whether customization is necessary for their operations or if standard models will suffice.

-

Materials and Quality Certifications: Machines made from higher-grade materials or those that meet specific certifications (e.g., ISO) typically command higher prices. It’s vital to balance quality with cost.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while lesser-known manufacturers may offer lower prices but come with higher risks.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) can significantly influence costs. Buyers should understand terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) to avoid unexpected charges.

What Are Essential Tips for Negotiating Costs Effectively?

For B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management are key:

-

Research and Benchmarking: Understand the market prices for similar machines. This knowledge will empower you during negotiations and help identify fair pricing.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational efficiency, and potential downtime. A machine that costs more upfront may save money in the long run through reduced repairs and better performance.

-

Build Relationships with Suppliers: Long-term relationships can lead to better pricing, priority service, and improved terms. Investing in rapport can yield benefits beyond the initial purchase.

-

Negotiate Payment Terms: Favorable payment terms can alleviate cash flow issues. Discuss options like staggered payments or extended payment periods to enhance financial flexibility.

What Should Buyers Know About Indicative Prices?

It is essential to note that prices for Chinese leather sewing machines can fluctuate based on market conditions, currency exchange rates, and changes in manufacturing costs. As such, any indicative pricing should be treated as a guideline rather than a fixed amount. Always request updated quotes and be prepared for negotiations that reflect the current market landscape. By understanding these dynamics, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing chinese leather sewing machine With Other Solutions

Introduction

When considering the procurement of sewing machines for leatherwork, particularly for B2B operations, it’s crucial to evaluate various alternatives that can meet specific business needs. The Chinese leather sewing machine, known for its affordability and unique design, presents a viable option, but other solutions may offer advantages in performance, maintenance, or application. This analysis compares the Chinese leather sewing machine with alternative solutions to help buyers make informed decisions.

Comparison Table

| Comparison Aspect | Chinese Leather Sewing Machine | Heavy-Duty Industrial Sewing Machine | Manual Leather Sewing Machine |

|---|---|---|---|

| Performance | Adequate for basic tasks; may require tuning | High-speed, precise stitching; suitable for large volumes | Good for intricate work; slower speed |

| Cost | Low-cost (approx. $150) | High initial investment ($1,000+) | Moderate cost ($300-$600) |

| Ease of Implementation | Requires setup and modification | Plug-and-play; minimal setup needed | Simple operation; requires manual skill |

| Maintenance | High; frequent adjustments needed | Low; robust design minimizes downtime | Moderate; periodic maintenance required |

| Best Use Case | Hobbyists or small businesses needing occasional use | Large-scale production environments | Artisans focusing on detailed, custom work |

Detailed Breakdown

What are the Advantages and Disadvantages of Heavy-Duty Industrial Sewing Machines?

Heavy-duty industrial sewing machines excel in high-performance environments, capable of handling large volumes of leather and complex stitching patterns with precision. They are designed for speed and reliability, making them ideal for manufacturers who require consistent output. However, the significant initial investment can be a barrier for smaller businesses. Moreover, while they are generally easy to operate, they may not be as versatile for intricate tasks compared to manual machines.

How Does a Manual Leather Sewing Machine Compare?

Manual leather sewing machines are favored by artisans and small-scale manufacturers for their ability to perform detailed work, such as custom leather goods. They allow for greater control over stitching and are often used in bespoke tailoring or craft projects. While they are more affordable than industrial machines and offer a tactile sewing experience, their speed and efficiency are lower, which can limit production capabilities for larger orders. Maintenance is also necessary to keep them in optimal condition, but the overall investment remains reasonable for small businesses.

Conclusion

Selecting the right sewing machine for leatherwork depends on various factors, including business size, production needs, and budget constraints. The Chinese leather sewing machine offers an economical solution for smaller operations or hobbyists who may not require extensive performance. In contrast, heavy-duty industrial machines are better suited for high-volume production with minimal downtime, while manual machines excel in craftsmanship and detail. B2B buyers should assess their specific requirements and long-term goals to determine which option aligns best with their operational strategies.

Essential Technical Properties and Trade Terminology for chinese leather sewing machine

What Are the Key Technical Properties of Chinese Leather Sewing Machines?

When considering the purchase of Chinese leather sewing machines, understanding the essential technical specifications is critical for making informed decisions. Here are some important properties to consider:

1. Material Grade

The quality of materials used in the construction of sewing machines significantly impacts their durability and performance. Common materials include cast iron for the body and various grades of steel for the internal components. High-grade materials ensure longevity and reduce the frequency of breakdowns, which is crucial for businesses relying on consistent production.

2. Stitch Type and Length Adjustment

Chinese leather sewing machines typically offer various stitch types, including straight, zigzag, and decorative stitches. The ability to adjust stitch length is also vital, as different leather types require different stitch lengths for optimal results. This flexibility allows businesses to adapt their sewing processes for various products, enhancing versatility in production.

Illustrative image related to chinese leather sewing machine

3. Tolerance and Precision

Tolerance refers to the allowable variation in the dimensions of machine parts. High tolerance levels ensure that the machine operates smoothly and produces high-quality stitches. For B2B buyers, understanding the precision of the machine is essential, as it directly affects the quality of the final product and minimizes waste due to errors.

4. Operating Speed

The operating speed of a sewing machine is measured in stitches per minute (SPM). Machines with higher SPM rates can significantly increase production efficiency, which is essential for businesses aiming to meet large order demands. However, it’s important to balance speed with quality to ensure that the stitching remains consistent and durable.

5. Power Consumption

Power consumption is a critical factor, especially for businesses in regions with high energy costs. Machines that utilize energy-efficient motors can reduce operational costs over time. Buyers should consider the power requirements and the machine’s energy efficiency ratings to ensure cost-effective operations.

6. Weight and Portability

The weight of a sewing machine can affect its portability and ease of use. Heavier machines may provide stability during operation, but lighter models can be more convenient for businesses that require mobility. Understanding the machine’s weight helps buyers make decisions based on their operational needs, whether stationary or mobile.

What Are Common Trade Terms Related to Chinese Leather Sewing Machines?

Familiarity with industry terminology can greatly enhance communication between buyers and suppliers. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of sewing machines, understanding whether a supplier is an OEM can influence pricing and quality expectations, as OEMs often ensure higher standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This is particularly relevant for B2B buyers, as it affects inventory management and pricing. Understanding the MOQ can help businesses plan their purchases according to demand forecasts.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and other details from suppliers. For buyers of sewing machines, submitting an RFQ can lead to better pricing negotiations and ensure that they receive comprehensive information about specifications and terms.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. Understanding these terms helps businesses navigate shipping logistics, costs, and risks associated with transporting sewing machines from manufacturers to their locations.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For businesses that rely on timely production schedules, understanding lead times is crucial for inventory management and ensuring they meet customer demands.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the machine’s performance and lifespan. Understanding warranty terms can help buyers assess the risk associated with their investment and ensure they have support in case of defects or issues.

By grasping these essential technical properties and industry terms, B2B buyers can make more informed decisions when purchasing Chinese leather sewing machines, ultimately leading to improved operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the chinese leather sewing machine Sector

What are the Key Trends Shaping the Chinese Leather Sewing Machine Market?

The global market for leather sewing machines, particularly from China, is witnessing a surge driven by several factors. First, the increasing demand for leather goods in emerging markets such as Africa and South America is prompting manufacturers to invest in efficient sewing technologies. Moreover, the rise of e-commerce platforms is expanding access to diverse supplier options, allowing international buyers to source competitively priced machines directly from manufacturers. This trend is particularly beneficial for businesses in regions like Brazil and Vietnam, where local production of leather goods is gaining momentum.

Technological advancements are also pivotal in shaping market dynamics. Innovations such as automated sewing solutions and smart sewing machines equipped with IoT capabilities are becoming popular. These technologies not only enhance productivity but also reduce operational costs, making them attractive to B2B buyers looking to scale their operations. Furthermore, the trend towards customization in leather goods is pushing manufacturers to offer machines that can handle a variety of materials and sewing techniques, thus broadening their appeal.

In addition to these trends, the growing emphasis on quality assurance and after-sales service is influencing buyer behavior. International buyers are now more inclined to partner with suppliers who offer robust support and maintenance services, ensuring that their investments yield long-term benefits.

How are Sustainability and Ethical Sourcing Influencing the Leather Sewing Machine Industry?

Sustainability has become a cornerstone of modern manufacturing practices, and the leather sewing machine sector is no exception. The environmental impact of leather production, including water usage and chemical waste, necessitates a shift towards more sustainable practices. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and environmentally friendly manufacturing processes. This includes the use of eco-friendly materials and adherence to strict environmental regulations.

In response to this demand, many Chinese manufacturers are adopting “green” certifications and utilizing sustainable materials in their machines. Certifications such as ISO 14001 for environmental management systems are becoming more prevalent, signaling to buyers that a supplier is dedicated to minimizing their environmental footprint. Furthermore, the growing availability of recycled and biodegradable materials in machine components is appealing to buyers focused on sustainability.

Ethical supply chains are also gaining traction as consumers worldwide become more aware of the origins of the products they purchase. For B2B buyers, sourcing from manufacturers who prioritize ethical labor practices and transparency in their supply chains not only enhances brand reputation but also aligns with global sustainability goals. This trend is particularly relevant for buyers in the Middle East and Europe, where consumer expectations for ethical sourcing are high.

What is the Historical Context of Chinese Leather Sewing Machines?

The evolution of Chinese leather sewing machines can be traced back to the early 20th century, when traditional cobbler machines were primarily used for repairing footwear. Over the decades, advancements in technology and manufacturing processes have transformed these machines into sophisticated tools capable of handling various leather goods, including bags, garments, and upholstery.

In the late 20th century, China’s entry into the global market facilitated the mass production of leather sewing machines, enabling manufacturers to offer competitive prices. The rise of globalization further accelerated this trend, as international buyers recognized the potential of Chinese suppliers to meet their demands for quality and affordability.

Today, the landscape of the Chinese leather sewing machine market reflects a blend of traditional craftsmanship and modern technology. As international buyers continue to seek innovative solutions for their manufacturing needs, the sector is poised for further growth, driven by ongoing improvements in machine design and functionality.

Frequently Asked Questions (FAQs) for B2B Buyers of chinese leather sewing machine

-

How do I solve common issues with Chinese leather sewing machines?

To address common issues with Chinese leather sewing machines, first ensure proper setup and calibration. Many machines require adjustments such as aligning the needle, tension, and feed dogs to function optimally. Regular maintenance, including cleaning and lubrication, can prevent performance issues. For more complex problems, refer to video tutorials or user forums, where experienced users share troubleshooting tips. If issues persist, consulting the supplier for technical support or replacement parts is advisable. -

What is the best type of Chinese leather sewing machine for thick leather projects?

The best type of Chinese leather sewing machine for thick leather projects is typically a heavy-duty walking foot machine or a patcher sewing machine. These machines are designed to handle multiple layers of thick materials, ensuring even stitching and preventing skipped stitches. Look for models with adjustable presser feet and strong motors to accommodate various leather thicknesses. Additionally, consider machines that offer customization options to suit specific project requirements. -

How can I ensure the quality of Chinese leather sewing machines before purchase?

To ensure quality, start by vetting suppliers through platforms like Alibaba or Global Sources, checking their ratings and reviews. Request samples to assess machine performance and build quality. Inquire about warranty terms and after-sales support. Also, consider visiting trade shows or factories if possible, as this allows for direct inspection of the machines and discussions with manufacturers about quality control processes. -

What are the minimum order quantities (MOQs) for Chinese leather sewing machines?

Minimum order quantities (MOQs) for Chinese leather sewing machines can vary significantly based on the supplier and machine type. Typically, MOQs range from 1 to 50 units for standard models, while custom machines may have higher MOQs. When negotiating with suppliers, clarify the MOQ and explore options for smaller initial orders, especially if you are testing the market or establishing a new product line. -

What payment terms should I expect when sourcing from Chinese suppliers?

Payment terms with Chinese suppliers often include options like a 30% deposit before production and the remaining 70% before shipping. Some suppliers may offer flexible terms like letter of credit or PayPal for smaller orders. Always negotiate terms that suit your cash flow and ensure the supplier’s legitimacy. Additionally, using escrow services can provide an added layer of security during transactions. -

How can I customize a Chinese leather sewing machine for specific needs?

Customization options for Chinese leather sewing machines typically include modifications to the machine’s features, such as needle size, presser foot type, and motor strength. Discuss your specific needs with the supplier to determine available options. Some manufacturers may offer bespoke solutions based on your production requirements. Additionally, be prepared to meet minimum order quantities for customized machines. -

What logistics considerations should I keep in mind when importing sewing machines from China?

When importing sewing machines from China, consider shipping methods (air vs. sea), lead times, and customs regulations in your country. Work with a reliable freight forwarder who understands international shipping and can handle necessary documentation. Ensure compliance with local import duties and taxes to avoid unexpected costs. It’s also wise to plan for potential delays during transit and customs clearance. -

How can I ensure effective quality assurance (QA) for my imported sewing machines?

To ensure effective quality assurance for imported sewing machines, implement a multi-step process. First, set quality standards and communicate them clearly to your supplier. Conduct inspections during production, and consider hiring a third-party inspection service before shipment to verify compliance with quality specifications. Establish a return policy for defective units, and maintain open communication with the supplier for ongoing quality improvements.

Top 1 Chinese Leather Sewing Machine Manufacturers & Suppliers List

1. Hobby Machinist – Chinese Leather Patcher Sewing Machine

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: Chinese leather patcher sewing machine designed for thick leather projects. Priced at approximately $150. Features a free-arm design suitable for sewing patches and mending bags. Requires setup work including adding bushings and bearings for improved performance. Originally designed for cobblers, capable of sewing woven materials like straps and canvas. Users have noted the need for tuning and ref…

Strategic Sourcing Conclusion and Outlook for chinese leather sewing machine

The landscape of sourcing Chinese leather sewing machines presents a wealth of opportunities for international B2B buyers. As highlighted throughout this guide, these machines offer a competitive edge due to their affordability and versatility, particularly for businesses engaged in leather goods manufacturing. However, potential buyers should be prepared for the inherent challenges associated with quality control and assembly, which may require additional effort and investment to optimize performance.

Strategic sourcing is essential in navigating these complexities. By establishing strong relationships with reliable suppliers, buyers can ensure access to high-quality machines and support services. This approach not only mitigates risks but also enhances the overall value derived from these products. Engaging in thorough due diligence, including understanding the specifications and potential customization options, will empower businesses to make informed purchasing decisions.

Looking ahead, the demand for leather products continues to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As such, now is the opportune time for buyers to leverage the advantages offered by Chinese manufacturers. By taking proactive steps in sourcing, businesses can secure the tools necessary for growth and innovation in their respective markets. Embrace the opportunity to enhance your production capabilities and stay ahead in this competitive industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.