Introduction: Navigating the Global Market for belt thickness

In the competitive landscape of global sourcing, understanding belt thickness is crucial for B2B buyers seeking high-quality products. Whether you’re sourcing durable leather belts for fashion retail or weightlifting belts for fitness equipment suppliers, the challenge lies in navigating varying thickness standards and material specifications across different markets. This comprehensive guide delves into the intricacies of belt thickness, covering types, applications, and essential factors for vetting suppliers.

Buyers from Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Brazil, will find actionable insights on how to assess quality, gauge performance, and manage costs effectively. By exploring the nuances of thickness measurement—from ounces to millimeters—and understanding how thickness impacts functionality and comfort, this guide empowers you to make informed purchasing decisions.

Additionally, we will provide valuable strategies for evaluating suppliers, ensuring you can secure the best products that meet your specific business needs. With this knowledge, you can confidently navigate the complexities of the global market, ensuring your sourcing efforts yield the highest quality belts tailored to your target audience.

Table Of Contents

- Top 6 Belt Thickness Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for belt thickness

- Understanding belt thickness Types and Variations

- Key Industrial Applications of belt thickness

- 3 Common User Pain Points for ‘belt thickness’ & Their Solutions

- Strategic Material Selection Guide for belt thickness

- In-depth Look: Manufacturing Processes and Quality Assurance for belt thickness

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt thickness’

- Comprehensive Cost and Pricing Analysis for belt thickness Sourcing

- Alternatives Analysis: Comparing belt thickness With Other Solutions

- Essential Technical Properties and Trade Terminology for belt thickness

- Navigating Market Dynamics and Sourcing Trends in the belt thickness Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of belt thickness

- Strategic Sourcing Conclusion and Outlook for belt thickness

- Important Disclaimer & Terms of Use

Understanding belt thickness Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 6.5mm Belt | Thinner design, highly flexible, offers moderate support | General training, casual use | Pros: Comfortable, easy to wear. Cons: Less support, may not be suitable for heavy lifting. |

| 10mm Belt | Balanced thickness providing solid support and comfort | Powerlifting, bodybuilding | Pros: Versatile, widely recommended. Cons: May feel restrictive for some users. |

| 13mm Belt | Maximum thickness for superior support | Competitive powerlifting | Pros: Excellent stability, legal for competitions. Cons: Can be uncomfortable for extended wear. |

| Leather (8-10oz) | Varies in thickness, typically measured in ounces | High-end fashion, formal wear | Pros: Durable, classic aesthetic. Cons: Heavier, may require more maintenance. |

| Suede Overlay | Additional suede layer for aesthetics and grip | Fashion belts, custom designs | Pros: Stylish, customizable. Cons: Suede offers less support than leather. |

What Are the Characteristics of a 6.5mm Belt?

The 6.5mm belt is ideal for general training and casual wear due to its thinner design, which allows for a high degree of flexibility. This thickness is perfect for users who prioritize comfort over maximum support, making it suitable for lighter workouts and everyday use. When purchasing, buyers should consider the intended use and whether the moderate support meets their training needs, especially for those new to weightlifting.

How Does a 10mm Belt Stand Out in Performance?

The 10mm belt strikes a balance between comfort and support, making it a popular choice among athletes in powerlifting and bodybuilding. This thickness offers sufficient rigidity for effective lifting while remaining comfortable for extended use. B2B buyers should look for belts made from high-quality materials, as these will enhance durability and performance, ensuring a reliable investment for their training regimen.

Why Choose a 13mm Belt for Competitive Powerlifting?

Designed for serious lifters, the 13mm belt provides maximum support during heavy lifts, making it a staple for competitive powerlifters. This thickness is often a requirement for various lifting federations, ensuring compliance during competitions. Buyers should consider the potential discomfort associated with this thickness, as well as the need for proper sizing to avoid restrictions during movement.

What Are the Advantages of Using Leather Belts (8-10oz)?

Leather belts, typically ranging from 8 to 10 ounces, offer a classic aesthetic and durability that appeals to both fashion and function. They are commonly used in high-end fashion and formal settings, providing a polished look. However, buyers should be aware that these belts can be heavier and may require more maintenance to preserve their quality, making them a long-term investment.

How Does a Suede Overlay Affect Belt Functionality?

Belts with a suede overlay are popular for their stylish appearance and additional grip, making them an attractive option for custom designs. While they enhance the aesthetic appeal, buyers should note that suede does not provide the same level of support as traditional leather. This makes them more suitable for fashion-centric applications rather than serious lifting, so buyers should align their purchase with their specific needs.

Key Industrial Applications of belt thickness

| Industry/Sector | Specific Application of belt thickness | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor belts for material handling | Enhanced durability and load-bearing capacity | Material quality, thickness specifications, and supplier reliability |

| Fitness & Sports | Weightlifting belts for athletes | Improved support and safety during lifts | Compliance with sport regulations, customization options, and comfort |

| Automotive | V-belt systems in engines | Increased efficiency and reduced wear | Compatibility with vehicle models, thickness tolerance, and temperature resistance |

| Mining & Construction | Heavy-duty belts for machinery | Maximized operational efficiency and reliability | Resistance to environmental conditions, thickness standards, and supplier certifications |

| Fashion & Retail | Leather belts for apparel | Enhanced product quality and consumer satisfaction | Sourcing from reputable tanneries, thickness consistency, and design options |

How is Belt Thickness Utilized in Manufacturing Conveyor Systems?

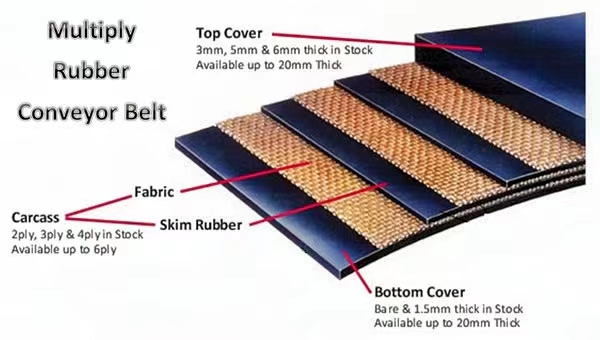

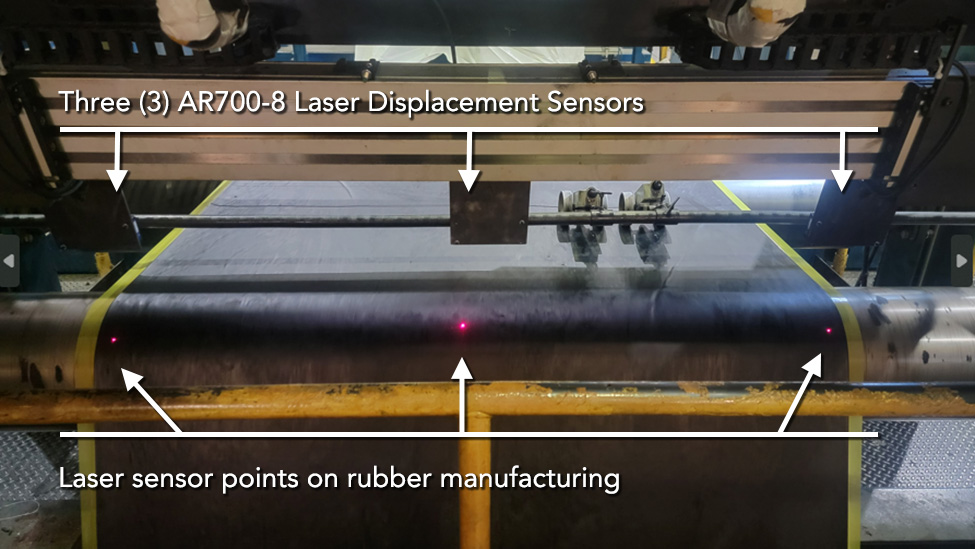

In the manufacturing sector, conveyor belts are integral to material handling processes. The thickness of these belts directly affects their durability and load-bearing capabilities. A thicker belt can withstand heavier loads and resist wear and tear, which is crucial in high-volume production environments. For international buyers, particularly in regions like Africa and South America, sourcing belts that meet specific thickness standards is essential to ensure operational efficiency and minimize downtime.

What Role Does Belt Thickness Play in Fitness and Sports Equipment?

In the fitness industry, weightlifting belts are designed with varying thicknesses to provide different levels of support. Thicker belts, typically around 10mm, offer maximum stability, which is crucial for powerlifting and heavy lifts. Athletes from Europe and the Middle East often seek belts that comply with competition regulations while ensuring comfort during intense training sessions. Buyers should consider customization options and the quality of materials used to ensure optimal performance.

Illustrative image related to belt thickness

Why is Belt Thickness Important in Automotive Applications?

In the automotive industry, V-belts are critical components in engine systems. The thickness of these belts influences their efficiency and longevity, with thicker belts generally offering better performance under high tension and temperature conditions. International buyers, especially in regions like Saudi Arabia and Brazil, must ensure that the belts sourced meet specific thickness tolerances and are compatible with various vehicle models to maintain optimal engine performance.

How Does Belt Thickness Affect Mining and Construction Equipment?

Heavy-duty belts used in mining and construction equipment require significant thickness to withstand harsh operational environments. A thicker belt provides enhanced reliability and efficiency in transporting materials, which is vital in these sectors. Buyers from international markets need to consider the specific environmental conditions and thickness standards required for their applications to ensure that the belts can endure the rigors of heavy-duty use.

What is the Significance of Belt Thickness in Fashion and Retail?

In the fashion industry, leather belts are often crafted with specific thicknesses to enhance their aesthetic appeal and durability. Thicker leather belts are generally more desirable due to their quality and longevity, which can significantly impact consumer satisfaction. For B2B buyers in Europe and beyond, sourcing belts that maintain consistent thickness and quality from reputable tanneries is crucial for ensuring a premium product offering that meets market demands.

3 Common User Pain Points for ‘belt thickness’ & Their Solutions

Scenario 1: Misalignment of Belt Thickness with Application Needs

The Problem: B2B buyers often struggle with selecting the appropriate belt thickness for their specific applications, leading to either over-engineering or under-engineering of their products. For instance, a company sourcing belts for industrial machinery may opt for a thicker belt, assuming it will provide greater durability. However, this can result in increased costs without proportional benefits, while a too-thin belt could fail prematurely, jeopardizing operations. The mismatch between belt thickness and application needs can lead to dissatisfied customers and costly returns.

The Solution: To mitigate this challenge, buyers should conduct thorough needs assessments that involve understanding the operational environment and specific application requirements. Engaging with suppliers who provide detailed specifications on belt performance in various contexts is essential. Implementing a standardized testing protocol that evaluates belt performance under real-world conditions can also be beneficial. By leveraging these insights, companies can make informed decisions that align belt thickness with actual operational demands, ultimately enhancing product reliability and customer satisfaction.

Scenario 2: Inconsistency in Belt Thickness Quality Across Suppliers

The Problem: Another common issue is the inconsistency in belt thickness quality when sourcing from different suppliers. B2B buyers may find that the same nominal thickness can vary in actual measurements, especially when sourcing from regions with different manufacturing standards. This inconsistency can lead to compatibility issues in multi-component systems, resulting in downtime and increased operational costs.

The Solution: To overcome this pain point, buyers should establish clear specifications that include acceptable tolerances for belt thickness. It’s advisable to request samples from multiple suppliers and conduct rigorous quality checks to ensure adherence to these specifications. Building long-term relationships with reputable manufacturers who have a proven track record of quality assurance can also help in minimizing these discrepancies. Additionally, utilizing third-party testing services to verify the thickness before full-scale production can provide an added layer of confidence in the product quality.

Scenario 3: Difficulty in Communicating Belt Thickness Requirements to Suppliers

The Problem: Effective communication of belt thickness requirements can often be a stumbling block for B2B buyers, especially when they lack technical expertise. Buyers may find it challenging to articulate their needs clearly, leading to misunderstandings with suppliers about the required specifications. This can result in receiving products that do not meet the desired thickness, affecting the performance of the final application.

The Solution: To address this communication gap, B2B buyers should invest in creating comprehensive specification documents that outline not only the required thickness but also other critical attributes such as material composition, intended use, and environmental conditions. Providing visual aids, such as diagrams or photographs of desired thickness measurements, can also facilitate better understanding. Regular training sessions for procurement teams on technical aspects of belt specifications can further enhance communication effectiveness. Engaging suppliers in discussions about their capabilities and seeking their input during the specification phase can foster a collaborative approach that ensures alignment on expectations.

By addressing these common pain points with actionable solutions, B2B buyers can enhance their sourcing strategies for belt thickness, ensuring they meet operational needs while maintaining cost efficiency and product quality.

Strategic Material Selection Guide for belt thickness

What Are the Key Materials for Belt Thickness in B2B Applications?

When selecting materials for belt thickness, it is crucial to consider the properties and suitability of various materials based on the intended application. Here, we analyze four common materials used in belt manufacturing—leather, synthetic leather, nylon, and rubber—focusing on their performance, advantages, disadvantages, and implications for international buyers.

How Does Leather Perform as a Material for Belt Thickness?

Leather is a traditional choice for belts, prized for its durability and aesthetic appeal. It typically ranges in thickness from 7 to 10 ounces (approximately 3.2 mm to 4 mm). Key properties include excellent tensile strength and resistance to wear, making it suitable for applications requiring durability. However, leather can be sensitive to moisture and temperature variations, which may lead to degradation over time.

Pros: Leather belts offer superior comfort and flexibility, making them ideal for everyday wear. They also have a high-end appearance, appealing to consumers seeking quality.

Cons: The cost of high-quality leather can be significant, and manufacturing complexity increases with the need for tanning and finishing processes. Additionally, leather may not be suitable for environments with high humidity or extreme temperatures.

For international buyers, compliance with local regulations regarding animal products is essential, particularly in regions with strict animal welfare laws.

What Advantages Does Synthetic Leather Offer for Belt Thickness?

Synthetic leather, or faux leather, is made from polyurethane (PU) or polyvinyl chloride (PVC). It mimics the appearance of natural leather while providing additional benefits. Typically available in various thicknesses, synthetic leather is resistant to moisture and UV light, making it suitable for diverse applications.

Illustrative image related to belt thickness

Pros: Synthetic leather is generally more affordable than genuine leather and offers easier maintenance. It is also available in a wide range of colors and finishes, allowing for customization.

Cons: While durable, synthetic leather may not match the longevity or comfort of genuine leather. Additionally, it may not be as environmentally friendly, depending on the manufacturing process.

International buyers should consider the environmental impact of synthetic materials, especially in regions where sustainability is a growing concern.

How Does Nylon Compare as a Material for Belt Thickness?

Nylon is a versatile synthetic material often used in industrial applications, including belts. It is lightweight, flexible, and resistant to abrasion and chemicals, making it suitable for various environments. Nylon belts can be produced in different thicknesses, providing options for different applications.

Pros: Nylon belts offer excellent strength-to-weight ratios and are resistant to moisture and chemicals, making them ideal for industrial applications. They are also relatively inexpensive compared to leather.

Cons: Nylon may not provide the same aesthetic appeal as leather, and its performance can be affected by high temperatures, which may lead to degradation.

For international buyers, compliance with standards such as ASTM or ISO is crucial, particularly in industries requiring specific material certifications.

What Role Does Rubber Play in Belt Thickness Applications?

Rubber is commonly used in industrial belts, particularly in conveyor systems and heavy machinery. It offers excellent flexibility, durability, and resistance to wear and tear. Rubber belts can be manufactured in various thicknesses, depending on the application requirements.

Pros: Rubber belts are highly resistant to abrasion and can withstand harsh environments, making them suitable for heavy-duty applications. They also provide good grip and traction.

Illustrative image related to belt thickness

Cons: The cost of high-quality rubber can be significant, and rubber belts may degrade over time when exposed to UV light or extreme temperatures.

International buyers should be aware of the specific rubber grades and standards required in their regions, as compliance can vary significantly.

Summary Table of Material Selection for Belt Thickness

| Matériau | Typical Use Case for belt thickness | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Fashion belts, high-end accessories | Superior comfort and aesthetic appeal | Sensitive to moisture and temperature | Haut |

| Synthetic Leather | Fashion belts, casual wear | Affordable and easy to maintain | Less durable than genuine leather | Medium |

| Nylon | Industrial applications, straps | Lightweight and chemical resistant | Aesthetic appeal may be lacking | Low |

| Rubber | Conveyor belts, heavy machinery | Excellent durability and grip | Can degrade under UV exposure | Medium |

This guide provides a comprehensive overview of material selection for belt thickness, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

Illustrative image related to belt thickness

In-depth Look: Manufacturing Processes and Quality Assurance for belt thickness

What Are the Key Stages in the Manufacturing Process for Belt Thickness?

The manufacturing of belts, particularly those used in various industrial applications, involves several critical stages to ensure the product meets the desired specifications and quality standards. Understanding these stages can help B2B buyers assess supplier capabilities and make informed purchasing decisions.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage in the manufacturing process is material preparation. This involves selecting the appropriate materials based on the intended application of the belt. Common materials include leather, synthetic fabrics, and various composites. For leather belts, the hide undergoes a tanning process that preserves and strengthens the material.

Once the raw materials are selected, they are inspected for quality. This includes checking for inconsistencies in thickness, texture, and color. For synthetic materials, manufacturers may conduct tests to assess tensile strength and flexibility. The goal is to ensure that only high-quality materials are used, as this directly impacts the durability and performance of the final product.

Forming: What Techniques Are Used to Shape the Belts?

The forming stage involves shaping the prepared materials into the desired belt configuration. This can be achieved through several methods, including cutting, molding, and stitching. For leather belts, precision cutting tools are used to ensure uniform thickness, typically measured in ounces or millimeters.

Key techniques include:

- Die Cutting: This method uses a die to cut the material into the required shapes and sizes, ensuring consistency across production batches.

- Molding: For synthetic belts, materials may be heated and molded into specific shapes, providing flexibility in design.

- Stitching: This technique is essential for assembling the belt. High-quality stitching not only adds to the aesthetic appeal but also enhances durability.

Assembly: How Are the Components Joined Together?

Once the individual components are shaped, they move to the assembly stage. This process involves joining various parts, such as buckles, straps, and linings. The assembly can be manual or automated, depending on the manufacturer’s capabilities and the complexity of the design.

Attention to detail is crucial during assembly, as improper joining can lead to product failure. Manufacturers often employ specialized machinery to ensure precision and consistency in fastening techniques. After assembly, the belts undergo initial quality checks to identify any defects before moving on to the finishing stage.

Finishing: What Treatments Enhance the Quality of Belts?

The final stage of the manufacturing process is finishing. This includes applying treatments that enhance the belt’s appearance and performance. Common finishing techniques include:

- Dyeing and Coloring: This process adds aesthetic appeal and can also protect the material from environmental factors.

- Coating: Some belts receive a protective coating that enhances water resistance and durability.

- Quality Inspection: Before packaging, each belt undergoes a thorough inspection to ensure it meets all specifications and quality standards.

What Are the Quality Assurance Standards Relevant to Belt Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, particularly for B2B buyers who require consistent quality in their products. Various international and industry-specific standards govern these processes.

How Do International Standards Like ISO 9001 Impact Quality Control?

ISO 9001 is a widely recognized quality management standard that outlines the criteria for a quality management system. Manufacturers certified under ISO 9001 demonstrate their commitment to quality, customer satisfaction, and continuous improvement. This standard emphasizes the importance of processes and documentation, ensuring that manufacturing practices are efficient and effective.

What Industry-Specific Certifications Should Buyers Look For?

In addition to ISO standards, there are industry-specific certifications that may be relevant depending on the application of the belts. For instance:

- CE Marking: Indicates compliance with European safety standards, often required for products sold in the European market.

- API Specification: Relevant for belts used in the oil and gas industry, ensuring they meet specific performance standards.

These certifications provide buyers with confidence in the quality and safety of the products they are purchasing.

What Are the Key QC Checkpoints Throughout the Manufacturing Process?

Quality control (QC) checkpoints are vital for ensuring that belts meet the required specifications. Key checkpoints include:

- Incoming Quality Control (IQC): This initial inspection checks the raw materials for quality and consistency before they enter the production process.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, periodic checks are conducted to identify any issues early in the process, allowing for timely corrections.

- Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is performed to ensure that each belt meets quality standards before packaging and shipment.

How Can B2B Buyers Verify Supplier QC Practices?

For international B2B buyers, verifying a supplier’s QC practices is essential. Here are some effective strategies:

- Supplier Audits: Conducting audits helps buyers assess the supplier’s manufacturing capabilities, quality control processes, and adherence to industry standards.

- Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC practices and any issues encountered during production.

- Third-Party Inspections: Engaging third-party inspection services can offer unbiased evaluations of the supplier’s quality management system and product quality.

What Are the Challenges in QC for International Buyers from Diverse Regions?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe may face unique challenges in quality assurance:

- Cultural Differences: Variations in quality expectations and manufacturing standards can lead to misunderstandings.

- Logistical Issues: Shipping and customs can introduce delays that affect product quality, especially for sensitive materials.

- Regulatory Compliance: Buyers must navigate different regulations and standards across countries, which can complicate the procurement process.

By understanding the manufacturing processes and quality assurance measures involved in belt thickness production, B2B buyers can make informed decisions and select suppliers that align with their quality expectations and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt thickness’

Introduction

In the competitive landscape of B2B sourcing, understanding the specific requirements for belt thickness is essential for making informed purchasing decisions. This guide provides a step-by-step checklist for international buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. By following these steps, you can ensure that your procurement process aligns with both technical specifications and market demands.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications required for the belt thickness you need. This includes understanding the material (e.g., leather, synthetic), the desired thickness range (measured in ounces or millimeters), and the intended use of the belts, whether for fashion, industrial applications, or sports.

- Material Considerations: Different materials have varying durability and flexibility. Leather belts may require specific thickness to ensure longevity, while synthetic options might offer different performance characteristics.

- Use Case: The application will dictate the thickness; for example, weightlifting belts typically range from 6.5mm to 13mm for optimal support.

Step 2: Research Industry Standards

Investigate the industry standards related to belt thickness. This ensures compliance with regulations and quality benchmarks relevant to your region and sector.

- Compliance Requirements: Some industries may require belts to meet specific safety standards, especially in sectors like construction or sports.

- Quality Assurance: Familiarize yourself with certifications that verify the quality of the belts, such as ISO standards or specific regional certifications.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure they meet your specifications and quality standards. Request company profiles, case studies, and references from other buyers in similar industries or regions.

- Supplier Reputation: Look for reviews and testimonials to gauge reliability and customer satisfaction.

- Product Samples: Always request samples to assess the quality of the belts, specifically the thickness and material properties.

Step 4: Verify Material Sourcing

Understand where and how your potential suppliers source their materials. Ethical sourcing and sustainable practices are increasingly important to B2B buyers.

- Sustainability Practices: Inquire about the environmental impact of their material sourcing, especially for leather products, which can have significant ecological implications.

- Traceability: Ensure that the supplier can provide documentation or certifications regarding the origin of their materials.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers, engage in negotiations regarding pricing and terms. This is crucial for securing a deal that aligns with your budget while ensuring quality.

Illustrative image related to belt thickness

- Bulk Discounts: Discuss potential discounts for larger orders, which can significantly impact your overall cost.

- Payment Terms: Clarify payment terms to avoid cash flow issues, and consider options such as letters of credit if dealing with international suppliers.

Step 6: Assess Logistics and Delivery Capabilities

Evaluate the supplier’s logistics and delivery capabilities to ensure they can meet your timelines. This is especially important for international transactions, where shipping times can vary significantly.

- Shipping Options: Discuss available shipping methods and timelines to ensure they meet your operational needs.

- Customs and Duties: Be aware of any potential customs requirements and duties that may affect delivery times and costs.

Step 7: Establish a Quality Control Process

Implement a quality control process to ensure that the belts received meet the agreed-upon specifications and standards. This is vital to maintain product consistency and customer satisfaction.

- Inspection Protocols: Define clear inspection procedures for both incoming goods and ongoing quality checks.

- Feedback Mechanism: Establish a system for providing feedback to suppliers, which can foster long-term relationships and improvements in quality.

By following this checklist, you can navigate the complexities of sourcing belt thickness effectively, ensuring that your procurement aligns with both operational needs and market expectations.

Comprehensive Cost and Pricing Analysis for belt thickness Sourcing

What Are the Key Cost Components in Sourcing Belt Thickness?

When sourcing belts, particularly in international B2B markets, understanding the cost structure is crucial. The primary components include:

-

Materials: The type of material used for belts significantly influences cost. Leather, synthetic materials, or specialized fabrics each carry different price points. For instance, high-quality leather can range from 8 to 10 ounces (approximately 3.2mm to 4mm), affecting both the price and durability of the final product.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Skilled labor for leatherworking is often more expensive in regions with higher living costs, while automated manufacturing can reduce costs but may compromise on quality.

-

Manufacturing Overhead: This encompasses facility costs, utilities, and administrative expenses. In countries with higher operational costs, such as those in Europe, overhead can make up a larger percentage of the total cost.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. Buyers should consider whether the supplier has the necessary tooling for specific belt thicknesses and styles, as this can affect lead times and pricing.

-

Quality Control (QC): Implementing stringent QC processes is essential, especially for products that require specific thickness standards. The cost of testing materials and finished products can add to the overall expense.

-

Logistics: Transportation costs, which can fluctuate based on fuel prices and shipping methods, are another crucial element. Buyers should evaluate local versus international shipping options to optimize costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding the market rates for similar products can help buyers negotiate better deals.

How Do Price Influencers Affect Belt Thickness Sourcing?

Several factors can influence pricing, especially for B2B buyers in diverse markets:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often yield lower per-unit costs. Suppliers may offer tiered pricing based on the volume, making it vital for buyers to assess their needs and negotiate accordingly.

-

Specifications and Customization: Custom designs or specific thickness requirements can lead to increased costs. Buyers should be prepared to invest in higher-quality materials or specialized manufacturing processes for custom belts.

-

Material Quality and Certifications: The quality of materials used directly impacts pricing. Certifications such as ISO or compliance with local regulations (e.g., REACH in Europe) may also add to costs but can enhance product credibility.

-

Supplier Factors: The supplier’s reputation, reliability, and production capabilities can significantly influence pricing. Established suppliers with proven quality may charge a premium but can offer peace of mind.

-

Incoterms: Understanding the terms of sale, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for international transactions. These terms dictate who bears the cost at various stages of shipping, impacting the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency in Belt Thickness Sourcing?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiation: Always engage in negotiations. Suppliers often have flexibility in pricing, especially for larger orders or long-term contracts.

-

Total Cost of Ownership (TCO): Consider the TCO, which includes not only the purchase price but also shipping, customs duties, and potential maintenance costs. A lower initial price may not always equate to lower overall costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import taxes, and tariffs that can affect the final price. Establishing relationships with local agents or distributors can also provide insights into regional pricing trends.

-

Research and Benchmarking: Conduct thorough market research to benchmark prices against competitors. Understanding the average market price for specific belt thicknesses can empower buyers during negotiations.

Disclaimer on Indicative Prices

It is important to note that prices in the belt thickness sourcing market can vary widely based on the factors discussed. Always seek multiple quotes and verify supplier credentials to ensure competitive pricing and quality assurance.

Alternatives Analysis: Comparing belt thickness With Other Solutions

Exploring Alternative Solutions to Belt Thickness

In the quest for optimal performance and durability, understanding the alternatives to traditional belt thickness is essential for B2B buyers. This analysis will compare belt thickness with two viable alternatives: synthetic belting materials and harness systems. Each option offers unique benefits and considerations, enabling businesses to make informed decisions based on their specific requirements.

Comparison Table

| Comparison Aspect | Belt Thickness | Synthetic Belting Materials | Harness Systems |

|---|---|---|---|

| Performance | High durability, varying thickness affects support | Good durability, often lighter, flexible | Excellent load distribution, customizable support |

| Cost | Moderate to high, depending on material | Generally lower, cost-effective | Higher initial investment, potential long-term savings |

| Ease of Implementation | Simple installation, requires minimal tools | Easy to install, often pre-fabricated | More complex, may require training for effective use |

| Maintenance | Moderate, requires regular checks for wear | Low, resistant to environmental factors | Moderate, requires regular adjustments and checks |

| Best Use Case | Weightlifting, general support | Industrial applications, casual wear | Heavy lifting, specialized tasks requiring support |

Detailed Breakdown of Alternatives

What are Synthetic Belting Materials and How Do They Compare to Belt Thickness?

Synthetic belting materials, such as nylon or polyester, are increasingly popular in various industries. They offer good durability and flexibility while being lighter than traditional leather belts. The lower cost of synthetic options makes them appealing for businesses looking to minimize expenditures. However, their performance in high-stress applications may not match that of thicker, leather belts. For tasks requiring significant support and rigidity, synthetic materials may fall short, making them less ideal for industries like weightlifting or heavy machinery.

How Do Harness Systems Provide an Alternative to Belt Thickness?

Harness systems are designed to distribute weight evenly across the body, offering excellent support for heavy lifting tasks. They are particularly effective in environments where workers need to carry substantial loads without compromising their safety. While harness systems typically require a higher initial investment and may necessitate training for proper use, they can lead to long-term savings by reducing the risk of injury. However, the complexity of harness systems might deter some users who prefer the straightforward application of belts.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When choosing between belt thickness and its alternatives, B2B buyers should consider their specific operational needs, budget constraints, and the environment in which the product will be used. For applications that demand maximum support and durability, traditional belt thickness remains a strong contender. Conversely, for lighter, more flexible solutions, synthetic materials or harness systems may provide a better fit. Ultimately, understanding the unique benefits and limitations of each option will empower businesses to make informed decisions that enhance performance and safety in their operations.

Essential Technical Properties and Trade Terminology for belt thickness

What Are the Key Technical Properties of Belt Thickness?

When evaluating belt thickness for various applications, several critical specifications come into play. Understanding these properties is essential for B2B buyers to ensure they select the right product for their needs.

1. Material Grade

The material grade of a belt, typically leather or synthetic, determines its durability, flexibility, and overall performance. For instance, high-grade leather belts often provide superior strength and longevity, while synthetic materials may offer advantages in terms of cost and moisture resistance. Buyers should assess the application requirements—such as load-bearing capacity and environmental conditions—before making a selection.

2. Thickness Measurement

Belt thickness is often measured in ounces or millimeters (mm). For example, a belt that is 8-10 ounces typically translates to approximately 3.2-4 mm in thickness. This measurement is crucial as it impacts the belt’s support, comfort, and flexibility. Thicker belts generally offer more support, making them ideal for heavy-duty applications, while thinner belts may be better suited for casual wear.

3. Tolerance

Tolerance refers to the allowable variation in belt thickness during production. A lower tolerance indicates higher quality, as it ensures consistency in performance and fit. For manufacturers, maintaining tight tolerances can lead to reduced waste and increased customer satisfaction, making it a vital consideration for B2B buyers when sourcing belts.

4. Load Capacity

The load capacity of a belt is a critical factor, especially for industrial and heavy-duty applications. This property defines how much weight the belt can support without compromising its integrity. Buyers must evaluate the specific requirements of their operations to select belts that can withstand the necessary loads without failure.

Illustrative image related to belt thickness

5. Flexibility

Flexibility is another important property that affects the usability of a belt in various applications. A more flexible belt can conform better to body movements, making it suitable for active environments, such as sports or physical labor. Conversely, less flexible belts may provide more support but can limit mobility.

What Are Common Trade Terms Related to Belt Thickness?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some common trade terms that buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another company. In the context of belts, OEMs often provide customized products tailored to the specifications of their clients, which is critical for businesses looking for specialized belt solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is vital for budgeting and inventory management. High MOQs can lead to excess inventory, while low MOQs may increase per-unit costs, influencing purchasing decisions.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for a specific quantity of products. When dealing with belt thickness, submitting an RFQ can help buyers gather competitive pricing and terms from multiple suppliers, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms helps B2B buyers understand their obligations and risks when purchasing belts from international suppliers.

5. Lead Time

Lead time refers to the amount of time it takes for an order to be fulfilled after it has been placed. For B2B buyers, understanding lead times is crucial for inventory planning and ensuring that production schedules are met without delays.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the complexities of selecting the right belt thickness for their specific applications and ensure successful transactions.

Illustrative image related to belt thickness

Navigating Market Dynamics and Sourcing Trends in the belt thickness Sector

What Are the Current Market Dynamics for Belt Thickness?

The global market for belt thickness is driven by several key factors, including the growing demand for high-quality leather products and the increasing prevalence of weightlifting and fitness activities across various regions. In particular, countries in Africa, South America, the Middle East, and Europe, such as Saudi Arabia and Brazil, are witnessing a surge in fitness culture, leading to higher consumption of specialized belts. This trend is further fueled by the rising awareness of health and wellness, which has propelled fitness enthusiasts to invest in quality gear, including belts that provide optimal support and comfort during workouts.

Emerging B2B technology trends are reshaping the sourcing landscape, with advancements in e-commerce platforms allowing international buyers to connect directly with manufacturers. This shift towards digital sourcing is particularly advantageous for buyers in remote regions, enabling them to access a broader range of products and suppliers. Additionally, the integration of data analytics tools in supply chain management is enhancing inventory forecasting and demand planning, allowing businesses to optimize their purchasing strategies for belt thickness.

As the market matures, customization options are becoming increasingly popular, enabling buyers to select specific thicknesses and materials tailored to their needs. This is especially relevant in regions where local preferences may dictate the demand for belts of varying thicknesses, such as 6.5mm for comfort or 13mm for maximum support. Understanding these dynamics will be crucial for international buyers looking to make informed sourcing decisions in the belt thickness sector.

How Is Sustainability and Ethical Sourcing Impacting the Belt Thickness Sector?

Sustainability is becoming a pivotal concern for B2B buyers in the belt thickness sector, with environmental impact and ethical sourcing at the forefront of purchasing decisions. As consumers increasingly demand transparency regarding the origins of their products, businesses must ensure their supply chains are not only efficient but also environmentally responsible. This includes sourcing leather from suppliers that adhere to ethical practices, such as responsible animal husbandry and sustainable tanning processes.

Moreover, the adoption of ‘green’ certifications and materials is gaining traction among manufacturers and buyers alike. Certifications such as the Leather Working Group (LWG) or Global Organic Textile Standard (GOTS) indicate that products meet specific environmental and social criteria. Buyers from regions like Europe and the Middle East, where regulatory frameworks favor sustainable practices, are likely to prioritize suppliers with such certifications.

Investing in sustainable materials, such as vegetable-tanned leather or alternative materials like recycled synthetics, can also appeal to the growing segment of environmentally conscious consumers. As the market evolves, international buyers must consider the ethical implications of their sourcing strategies, recognizing that sustainable practices can enhance brand reputation and customer loyalty.

What Is the Historical Context of Belt Thickness in the B2B Market?

The evolution of belt thickness can be traced back to the early days of leather craftsmanship, where artisans would create belts primarily for utility and durability. Over time, as fashion and fitness trends emerged, the focus shifted towards creating belts that not only served a functional purpose but also provided aesthetic appeal and support for activities like weightlifting and bodybuilding.

In the late 20th century, the introduction of various thickness standards transformed the market. Manufacturers began to offer belts in a range of thicknesses, each designed for specific applications—from casual wear to specialized athletic use. This diversification allowed buyers to select products that catered to their unique needs, paving the way for the customized offerings that dominate the market today.

As consumer preferences continue to evolve, the belt thickness sector remains dynamic, reflecting broader trends in fashion, fitness, and sustainability. Understanding this historical context can help international B2B buyers appreciate the intricacies of sourcing decisions and the importance of aligning product offerings with market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of belt thickness

-

How do I determine the right belt thickness for my business needs?

Selecting the appropriate belt thickness depends on its intended use and the materials involved. For instance, leather belts typically range from 7oz to 10oz (approximately 3mm to 4mm). Consider the function: heavier belts provide more support, ideal for weightlifting or industrial applications, while thinner belts offer flexibility for casual wear. Assess your target market’s preferences and regulatory standards in your region to ensure the selected thickness aligns with customer expectations and safety regulations. -

What is the best leather thickness for durability in belts?

Generally, a thickness of 8oz to 10oz (3.2mm to 4mm) is recommended for durable leather belts, as this range balances strength and flexibility. Thicker belts may resist wear and tear better, making them suitable for heavy-duty applications. Conversely, thinner belts can be more comfortable for everyday use but may wear out faster. Evaluate your market’s needs to determine if durability or comfort is more critical, and consider sourcing samples to assess quality firsthand. -

How can I ensure quality assurance when sourcing belts?

Implement a robust quality assurance (QA) process by establishing clear specifications for materials, thickness, and craftsmanship. Work with suppliers who provide detailed product descriptions and samples to verify quality. Consider visiting manufacturing sites if feasible, or request third-party inspections. Additionally, inquire about warranties or return policies to safeguard your investment. This proactive approach minimizes the risk of receiving subpar products that could harm your brand reputation. -

What customization options are available for belt thickness?

Many manufacturers offer customization options for belt thickness, allowing you to cater to specific market demands. You can choose from various materials, thicknesses, and finishes. Some suppliers may also allow you to specify exact measurements to meet your needs. It’s advisable to discuss these options upfront with your supplier to ensure they can accommodate your requests while maintaining quality and production timelines. -

How do I evaluate potential suppliers for belt thickness?

When vetting suppliers, consider their experience, reputation, and production capabilities. Request references from previous clients and check online reviews. Evaluate their ability to meet your specific thickness requirements and customization options. Also, assess their compliance with international quality standards and regulations. Establishing a clear communication channel is crucial for addressing any concerns promptly and ensuring a smooth collaboration. -

What are the typical minimum order quantities (MOQs) for belts?

Minimum order quantities can vary significantly based on the supplier and the complexity of your order. For standard leather belts, MOQs often range from 100 to 500 units, while custom designs may require higher quantities. Always confirm MOQs with your supplier before placing an order, as lower quantities might incur higher per-unit costs. Understanding MOQs helps in planning your inventory and ensuring you meet market demand without overcommitting resources. -

What payment terms should I expect when sourcing belts internationally?

Payment terms can vary widely among suppliers, often influenced by factors like order size and relationship history. Common terms include upfront deposits (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer net terms (e.g., net 30 or net 60 days) for established clients. Clarifying payment terms upfront helps avoid misunderstandings and ensures a smooth transaction process, particularly in international trade where currency fluctuations can impact costs. -

How does logistics impact the sourcing of belt thickness?

Logistics play a critical role in ensuring timely delivery and cost-effectiveness when sourcing belts. Factors to consider include shipping methods, customs regulations, and potential tariffs, especially when importing from regions like Europe to Africa or South America. Work with logistics providers experienced in international trade to navigate these complexities. Proper planning for lead times and inventory management will help maintain your supply chain’s efficiency and meet customer demands promptly.

Top 6 Belt Thickness Manufacturers & Suppliers List

1. Reddit – Leather Belt Strips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1) 3.2~3.5 mm strip of leather (0.126 ~0.137 inch) 2) Two strips of 2mm each, glued and stitched together to achieve a belt 4mm thick (0.078 inches each).

2. Art of Manliness – Belts

Domain: artofmanliness.com

Registered: 2007 (18 years)

Introduction: Belts are worn for both function and style, impacting the overall impression of an outfit. They consist of two main parts: the buckle and the strap, with some belts also featuring a keeper loop and/or an end tip. Belts should generally be worn with pants that have belt loops, especially in formal settings. There are two main categories of belts: formal and casual. Formal belts typically have a fra…

3. Pioneer Fit – Weightlifting Belts

Domain: pioneerfit.com

Registered: 2019 (6 years)

Introduction: Pioneer Fit offers a variety of weightlifting belts including: Pioneer Lever Lifting Belts, Pioneer Powerlifting Belts, Pioneer Cut Weight Lifting Belts, Pioneer Hybrid Weightlifting Belts, Pioneer Deadlift Belts, Pioneer Bench Belts, Pioneer Dip Belts, Pioneer Training Belts, Pioneer Exclusive Design Belts, Pioneer Nylon Belts, Custom Lifting Belts, Custom Lever Lifting Belts, and Custom Powerlif…

4. Marakesh – Belt Sizing Guide

Domain: marakeshleathergoods.com

Registered: 2010 (15 years)

Introduction: Belt Sizing Details: 1.25″ – Standard width for dress pants, khakis, Dickies, and slacks; 1.5″ – Standard width for jean loops and Theme Buckles; 1.75″ – Widest width for most jean loops. Order belt size to match pant size in inches (e.g., 34″ jeans = size 34 belt). Custom-sized with 5 holes, extra holes can be added. Size chart: Size 28 (31″ middle hole, 29″-33″ range, 37″ length), Size 29 (32″ m…

5. Facebook – High Quality Leather Belts

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Leather thickness for a high quality belt

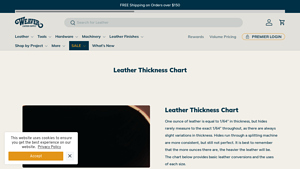

6. Weaver Leather – Thickness & Ounces Chart

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Leather Thicknesses & Ounces Chart – One ounce of leather is equal to 1/64″ in thickness. Hides run through a splitting machine are more consistent, but still not perfect. The more ounces, the heavier the leather. The chart provides basic leather conversions and uses for each size.

Strategic Sourcing Conclusion and Outlook for belt thickness

What Are the Key Insights for Strategic Sourcing of Belt Thickness?

In conclusion, understanding belt thickness is crucial for international B2B buyers seeking to optimize their purchasing strategies. The thickness of belts can significantly influence durability, functionality, and overall value. For instance, while belts around 7-10oz are commonly favored for their balance of strength and flexibility, specialized applications may require thicker options for maximum support. Buyers should prioritize sourcing from reputable suppliers who offer a range of thickness options tailored to their specific needs.

Strategic sourcing allows businesses to not only enhance product quality but also to negotiate better pricing, ensuring a competitive edge in the market. As companies expand their global footprint, especially in regions like Africa, South America, the Middle East, and Europe, it becomes increasingly important to foster relationships with manufacturers who understand local demands and preferences.

Illustrative image related to belt thickness

Looking ahead, the demand for customized belt solutions will continue to rise. We encourage international buyers to engage with suppliers who offer personalized options and insights into the latest trends. By investing in strategic sourcing now, businesses can secure their supply chains and position themselves for success in an evolving marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.