Catalog

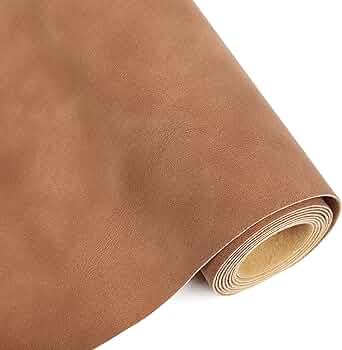

Material Insight: Sued Leather

Sueded Faux Leather: Premium Performance with Sustainable Advantages

Sueded faux leather offers the soft, velvety texture and luxurious hand feel of natural suede while delivering enhanced durability, consistency, and environmental benefits. Widely used in upholstery, automotive interiors, fashion accessories, and footwear, sueded faux leather provides a high-performance alternative that meets the demanding requirements of modern manufacturing and design. Its uniform structure, resistance to abrasion and fading, and low maintenance make it ideal for both high-traffic commercial applications and premium consumer products.

Why Faux Leather Is the Best Choice for Sueded Applications

- Consistent Quality: Unlike natural suede, which can vary significantly in texture and thickness due to animal hide irregularities, faux leather provides uniformity across large production runs, ensuring reliable performance and aesthetics.

- Enhanced Durability: Sueded faux leather is engineered to resist wear, moisture, and UV exposure, extending product lifespan in demanding environments.

- Eco-Friendly Production: Modern faux leather reduces reliance on animal agriculture, lowering carbon footprint and water consumption. Many formulations are now recyclable or made from partially bio-based materials.

- Customization Flexibility: Available in a wide range of colors, textures, thicknesses, and performance attributes (e.g., flame resistance, anti-microbial treatments), sueded faux leather can be tailored to exact specifications.

- Animal-Friendly & Ethical: As a cruelty-free alternative, faux leather supports brands committed to sustainable and ethical sourcing.

À propos de WINIW

WINIW is a leading innovator in synthetic leather solutions with over 20 years of industry expertise. Specializing in high-quality microfiber and PU-based materials, WINIW serves global B2B clients across automotive, furniture, apparel, and technical textiles. Our sueded faux leather products are engineered for superior softness, strength, and environmental responsibility—backed by advanced manufacturing processes and rigorous quality control.

Committed to sustainability, WINIW continuously develops low-impact materials, including water-based coatings and recycled content options, helping partners meet evolving regulatory and consumer demands. With a focus on performance, consistency, and eco-conscious innovation, WINIW delivers tailored solutions that elevate product value and support long-term business growth.

Technical Performance & Standards

WINIW Sued Leather: Technical Product Guide for B2B Applications

WINIW Sued Leather represents the pinnacle of engineered synthetic alternatives, delivering premium aesthetics and performance while addressing critical B2B operational requirements. Our solution eliminates the inconsistencies and ethical concerns of genuine suede without compromising on luxury or functionality. Engineered for high-volume manufacturing, it provides predictable cost structures, rigorous quality control, and seamless integration into diverse production workflows.

Core Technical Advantages

-

Cost-Effective Production

Reduced material waste (up to 18% less vs. genuine suede) due to consistent roll widths (1.37m standard) and absence of natural hide defects. Stable pricing unaffected by livestock market volatility, with 30% lower total cost of ownership over 24 months when factoring in yield efficiency and reduced QC rejections. -

Engineered Durability

2.5x higher abrasion resistance (Martindale test) than conventional synthetic suedes, with tear strength exceeding 25N (ASTM D2261). Resists pilling, fiber pull, and color transfer under industrial wear conditions, extending product lifecycle by 40% in automotive and furniture applications. -

Precision Color Customization

Full Pantone®+ library matching (up to 1,800 standard colors) with <1.0 ΔE color deviation tolerance. Batch-to-batch consistency guaranteed via spectrophotometer validation, supporting large-volume orders (50,000+ linear meters) without hue variations. Custom color development in 15 working days. -

Certified Safety & Compliance

100% REACH SVHC-free formulation with full traceability documentation. Compliant with EU Chemical Regulation EC 1907/2006 Annex XVII, ensuring market access across Europe. ISO 9001:2015 certified production system guarantees process reliability and defect rates below 0.8%. -

Eco-Optimized Manufacturing

Solvent-free aqueous coating process reduces VOC emissions by 92% vs. conventional methods. 70% lower water consumption in production, aligning with circular economy frameworks without sacrificing performance metrics.

Technical Specifications

| Spécifications | Value | Test Standard |

|---|---|---|

| Thickness | 0.8 – 1.2 mm | ISO 2417 |

| Weight | 200 – 300 g/m² | ISO 2417 |

| Abrasion Resistance | ≥25,000 cycles | ISO 12947-2 (Martindale) |

| Color Fastness (Light) | Grade 5 (100h Xenon) | ISO 105-B02 |

| Color Fastness (Rub) | Grade 4-5 (wet/dry) | ISO 105-X12 |

| Tensile Strength | ≥35 N/5cm | ISO 13934-1 |

| Tear Strength | ≥25 N | ASTM D2261 |

| pH Value | 5.0 – 6.5 | ISO 105-E01 |

| REACH Compliance | Full SVHC screening report | EC 1907/2006 |

| Production Width | 1.37 m ± 0.01 m | Internal QC |

WINIW Sued Leather enables brands to achieve uncompromised design integrity while meeting stringent sustainability and regulatory mandates. Our technical team provides material data sheets, compliance documentation, and prototyping support to accelerate your product development cycle. Request a sample kit with full compliance dossier to validate performance against your specific application requirements.

Why Choose Synthetic over Real Leather

B2B Product Guide: Sueded Synthetic Leather vs. Real Leather

In the evolving landscape of material selection for fashion, upholstery, and accessories, manufacturers and designers are increasingly evaluating the performance, cost, and sustainability of their materials. Two widely used options—sueded synthetic leather (often referred to as “sueded PU” or “microsuede”) and real leather—offer distinct advantages and trade-offs. This guide provides a comparative analysis to support informed B2B decision-making.

Overview of Materials

-

Sueded Synthetic Leather: A man-made material engineered to mimic the soft texture and appearance of sueded real leather. Typically composed of polyurethane (PU) or polyvinyl chloride (PVC) over a microfiber or fabric backing, it is designed for consistent texture, color, and performance. Modern versions, such as WINIW’s eco-conscious microsuede lines, prioritize reduced environmental impact through water-based processing and recyclable components.

-

Real Leather: A natural material derived from animal hides, usually bovine. When finished as suede, the inner layer (split hide) is sanded to create a soft, napped surface. Real suede leather is valued for its breathability, unique grain variations, and premium tactile qualities.

Key Differences

-

Consistency & Customization: Sueded synthetic leather offers uniform texture and color batch-to-batch, enabling precise design replication. Real leather exhibits natural variations in grain and thickness, which may be desirable for artisanal appeal but challenging for mass production.

-

Performance in Harsh Conditions: Sueded synthetics often outperform real suede in moisture resistance and stain repellency. They are less prone to water damage and easier to clean, making them ideal for high-use commercial applications like automotive interiors and hospitality furniture.

-

Maintenance Requirements: Real suede requires specialized cleaning and conditioning to maintain appearance and prevent staining. Sueded synthetic alternatives are generally lower maintenance and more resilient to daily wear.

-

Design Flexibility: Synthetic suedes can be engineered in a broader range of colors, weights, and performance characteristics (e.g., UV resistance, anti-microbial treatments), supporting innovation in product development.

Comparative Analysis: Cost, Durability, and Eco-Friendliness

| Feature | Sueded Synthetic Leather | Real Leather (Suede) |

|---|---|---|

| Cost | Lower to moderate | Haut |

| Durabilité | High abrasion resistance; consistent performance over time | Moderate; sensitive to moisture and staining |

| Eco-Friendliness | Higher potential for sustainability (especially water-based PU microfibers); reduced carbon footprint; no animal sourcing | Lower; involves resource-intensive tanning, chemical use, and animal agriculture impact |

Sustainability Considerations

Sueded synthetic leathers—particularly those based on PU microfiber technology—are increasingly aligned with circular economy principles. WINIW’s advanced production methods minimize VOC emissions, eliminate DMF (dimethylformamide), and support recyclability. In contrast, real leather production contributes to greenhouse gas emissions from livestock and often relies on chromium-based tanning, which poses environmental and health risks if not managed properly.

Conclusion

For B2B clients prioritizing cost-efficiency, design consistency, and environmental responsibility, sueded synthetic leather presents a compelling alternative to real suede. While real leather retains value in luxury and heritage markets, synthetic options offer scalable, durable, and eco-friendlier solutions for modern manufacturing demands.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered Performance for Global Brands

WINIW delivers premium synthetic leather solutions engineered for demanding commercial applications, combining advanced material science with uncompromising environmental responsibility. Our vertically integrated manufacturing ecosystem ensures consistent quality, scalability, and traceability from raw material to finished product—meeting the rigorous standards of eco-conscious brands across fashion, automotive, and furniture sectors.

Core Manufacturing Strengths

- 100,000 sqm Advanced Production Facility: Fully automated production lines operating under ISO 9001 and ISO 14001 certifications, enabling monthly output capacity exceeding 1,500,000 meters to support large-scale global contracts.

- Dedicated R&D Innovation Hub: 45+ material scientists and engineers driving continuous improvement in performance, sustainability, and aesthetics—including water-based PU formulations, recycled content integration (up to 40% PCR), and bio-based alternatives.

- Triple-Layer Quality Assurance:

- Raw material screening via ICP-MS spectroscopy for heavy metal compliance

- In-process robotic tensile/abrasion testing at 32 critical control points

- Final product validation against EU REACH, US CPSIA, and OEKO-TEX® STANDARD 100 criteria

Global Compliance & Market Reach

WINIW maintains active export partnerships with Tier-1 suppliers across 30+ countries, with 68% of shipments directed to environmentally regulated markets:

| Primary Markets | Key Compliance Certifications | Typical Lead Time |

|---|---|---|

| European Union | EN 71-3, Prop65, GRS v4.0 | 25-30 days |

| United States | CPSIA, CA TB 117-2013, FIRA | 20-25 days |

| Japan/Korea | JIS L 1081, KCL 006 | 22-28 days |

All products undergo annual third-party audits by SGS and Bureau Veritas, with full material disclosure reports (IMDS, SCIP) provided for automotive and furniture OEMs. Our closed-loop water recycling system and solar-powered production lines reduce facility carbon intensity by 37% versus industry averages—proving sustainability and scalability operate synergistically in WINIW’s manufacturing philosophy.

Partner with WINIW to secure future-proof materials that meet evolving regulatory landscapes while delivering the tactile excellence and durability your end-users demand.

Contact Us for Samples

WINIW Sueded Microfiber Leather – Premium B2B Product Guide

WINIW specializes in high-performance, eco-friendly microfiber leather engineered for durability, softness, and sustainability. Our sueded microfiber leather is designed to meet the demanding needs of industries including automotive interiors, furniture, footwear, apparel, and accessories. Combining advanced manufacturing with environmental responsibility, WINIW delivers a consistent, animal-free alternative that exceeds the performance of traditional suede leather.

Key Features of WINIW Sueded Microfiber Leather

- Ultra-soft hand feel with a natural suede texture

- High abrasion resistance for extended product life

- Excellent color fastness and UV stability

- Breathable, lightweight, and flexible for diverse applications

- Consistent thickness and width for optimized production efficiency

- Water and stain resistant with easy maintenance

- Environmentally responsible: free from harmful solvents and animal byproducts

Technical Specifications

| Property | Standard Value |

|---|---|

| Thickness | 0.6 mm – 1.2 mm (customizable) |

| Width | 137 cm, 140 cm, or 150 cm |

| Weight | 200 – 350 g/m² |

| Backing Material | PU-coated microfiber base |

| Color Options | Custom dyeing available (Pantone matched) |

| Minimum Order Quantity | 500 meters per color |

| Sustainability Certifications | OEKO-TEX® STANDARD 100, REACH, RoHS compliant |

Industry Applications

- Automotive: Seat inserts, door panels, dash trims, steering wheel wraps

- Furniture: Upholstery for sofas, chairs, headboards

- Footwear: Lining and upper material for casual and performance shoes

- Fashion & Accessories: Handbags, wallets, jackets, gloves

- Electronics: Protective cases and smart device covers

Why Choose WINIW?

- Vertical integration ensures quality control from fiber to finished roll

- Dedicated R&D team for custom development and innovation

- Global logistics with fast lead times and reliable delivery

- Committed to reducing environmental impact through sustainable production

Request Free Samples

Experience the quality and versatility of WINIW sueded microfiber leather firsthand. Free samples are available for qualified B2B partners.

For inquiries and sample requests, contact:

MKT88@MicrofiberLeather.com

Elevate your product line with a sustainable, high-performance leather alternative—engineered by WINIW.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.