Catalog

Material Insight: What Is Pu Material

B2B Product Guide: Understanding PU Material and the Advantages of Faux Leather

What is PU Material?

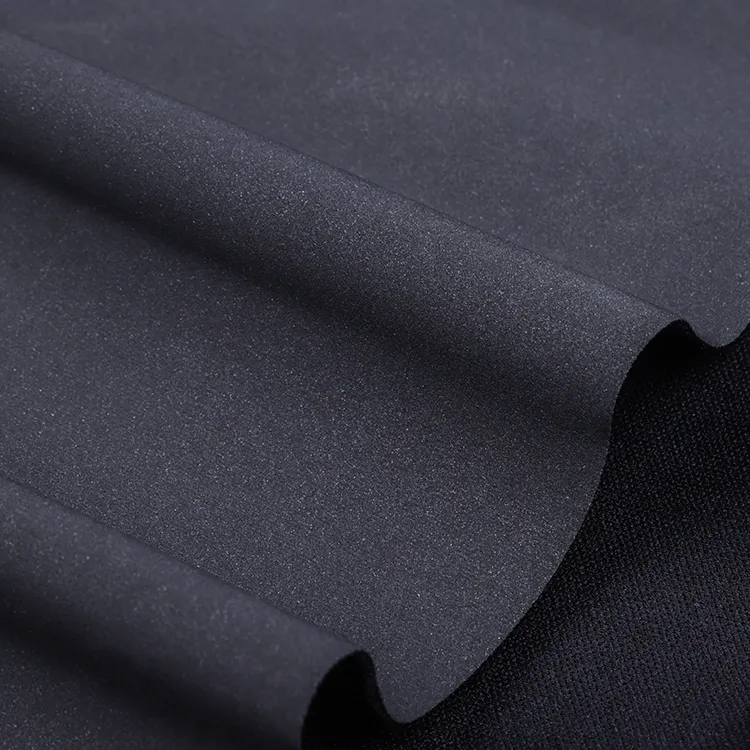

Polyurethane (PU) material, commonly known as PU leather or faux leather, is a synthetic, eco-conscious alternative to genuine leather. It is produced by applying a polyurethane coating onto a fabric base—typically composed of polyester or a cotton-polyester blend—resulting in a durable, flexible, and leather-like material. PU material is engineered to replicate the texture, appearance, and performance of natural leather while offering enhanced consistency, cost-efficiency, and sustainability.

Unlike traditional leather, which relies on animal hides and resource-intensive tanning processes, PU material is free from animal byproducts and requires significantly less water and energy to produce. This makes it an ideal choice for brands prioritizing ethical sourcing and reduced environmental impact.

- Lightweight and highly durable

- Resistant to abrasion, cracking, and UV exposure

- Available in a wide range of colors, textures, and finishes

- Consistent quality with minimal batch variation

- Fully customizable for diverse industrial applications

Why Faux Leather is the Best Choice for This Application

Faux leather—particularly high-performance PU leather—offers a superior balance of aesthetics, functionality, and sustainability for a broad range of B2B applications, including automotive interiors, furniture upholstery, footwear, handbags, and apparel. Its engineered structure allows for precise control over thickness, stretch, and surface finish, ensuring compatibility with automated manufacturing processes.

- Sustainability: Lower carbon footprint compared to animal leather; recyclable options available

- Cost-Effectiveness: Reduced material waste and consistent supply chain

- Design Flexibility: Can be tailored to meet specific performance requirements such as breathability, softness, or water resistance

- Ethical Compliance: Meets growing demand for cruelty-free and vegan-certified materials

Introducing WINIW – Trusted Innovation in Synthetic Leather

WINIW is a leading manufacturer of high-quality synthetic leather with over 20 years of industry expertise. Specializing in PU and microfiber leather solutions, WINIW serves global clients across fashion, automotive, and lifestyle sectors with eco-friendly, performance-driven materials. Our R&D-focused approach ensures continuous innovation in texture, durability, and sustainability—backed by ISO-certified production and stringent quality control.

- 20+ years of technical leadership in synthetic leather

- ISO 9001 and ISO 14001 certified manufacturing

- Custom development capabilities for B2B partners

- Commitment to green chemistry and reduced environmental impact

WINIW empowers brands to deliver premium products without compromise—combining luxury aesthetics with responsible manufacturing. Partner with us to explore next-generation faux leather solutions designed for performance, scalability, and sustainability.

Technical Performance & Standards

WINIW Synthetic Leather: Technical Product Guide for B2B Applications

WINIW Polyurethane (PU) material is a high-performance synthetic leather engineered for industrial applications requiring superior aesthetics, functional durability, and environmental responsibility. Unlike PVC-based alternatives, WINIW PU utilizes a polyurethane resin coating bonded to premium textile backings (e.g., polyester, nylon), delivering a sustainable, non-toxic material ideal for automotive interiors, footwear, furniture, and accessories.

Key Technical Advantages for Industrial Buyers

-

Cost-Effective Production

WINIW PU reduces total production costs through consistent roll goods with minimal defects (≤0.5% waste rate), eliminating the variability and high scrap rates of genuine leather. Compatible with standard cutting, sewing, and finishing equipment, it lowers operational expenses while maintaining high yield. -

Engineered Durability

Achieves 50,000+ double rubs (Martindale test, 12kPa load), 30+ cycles (Taber Abrasion, CS-10 wheels), and 100,000+ flexes (DIN 53356) without cracking. Resists hydrolysis, UV degradation, and staining (ISO 105-X12), ensuring longevity in demanding environments like automotive seating or outdoor furniture. -

Precision Color Customization

Offers 1,000+ standard colors (Pantone® matchable) with ±0.5 Delta-E color consistency across batches. Custom formulations support metallic, matte, or textured finishes while maintaining lightfastness (ISO 105-B02, Grade 7-8) and color migration resistance (ISO 105-X12, Grade 4-5). -

Verified REACH Compliance

Fully compliant with EU REACH Regulation (EC 1907/2006), including Annex XVII restrictions and SVHC screening. Contains zero phthalates, heavy metals (Cd, Pb, Hg, Cr⁶⁺), or azo dyes, validated by independent SGS/TÜV reports. -

ISO 9001-Certified Quality Control

Rigorous QC protocols across 12 production stages, including automated thickness scanning (±0.05mm tolerance) and peel strength testing (≥4.0 N/mm). Traceable batch records ensure consistent performance meeting automotive (VW 50127) and furniture (EN 13363) standards.

WINIW PU Material Technical Specifications

| Property | Test Standard | Performance Value | Industrial Relevance |

|---|---|---|---|

| Thickness Range | ISO 2419 | 0.6mm – 2.0mm | Optimized for lightweight design |

| Tensile Strength | ISO 1767 | ≥25 MPa | Prevents tearing during use |

| Elongation at Break | ISO 1767 | 250% – 400% | Ensures flexibility & resilience |

| Seam Strength | ISO 1767 | ≥120 N | Critical for upholstery integrity |

| Water Resistance | ISO 2492 | >95% retention (24h) | Suitable for marine/automotive use |

| VOC Emissions | ISO 12219-4 | <10 μg/g (Total VOC) | Meets indoor air quality standards |

| Heat Aging Resistance | ISO 188 | ΔTS < 15% (70°C/168h) | Stable in high-temperature zones |

WINIW PU material delivers quantifiable operational and sustainability advantages without compromising performance. Our REACH-compliant, ISO 9001-certified manufacturing ensures your supply chain meets global regulatory demands while reducing total cost of ownership. Request technical datasheets or sample swatches to validate performance for your specific application requirements.

WINIW: Engineered Sustainability for Industrial Performance

Why Choose Synthetic over Real Leather

B2B Product Guide: PU Material vs Real Leather

When sourcing materials for upholstery, apparel, footwear, or accessories, businesses must balance performance, cost, and sustainability. Two of the most widely used materials in these industries are polyurethane (PU) leather and real (genuine) leather. Understanding their differences helps brands make informed, strategic decisions aligned with quality standards, environmental goals, and budget constraints.

What is PU Material?

PU material, or polyurethane leather, is a synthetic alternative to genuine leather. It is made by applying a polyurethane coating to a fabric backing, typically polyester or cotton. The surface is then embossed to mimic the grain and texture of real leather. Modern advancements, such as microfiber PU leather, have significantly improved its softness, durability, and breathability, making it a preferred choice for eco-conscious and cost-sensitive brands.

What is Real Leather?

Real leather is derived from animal hides—most commonly bovine, ovine, or porcine—through a tanning process that preserves and strengthens the natural material. It is valued for its luxurious feel, unique grain patterns, and long-term aging properties. However, its production involves significant environmental impact due to resource-intensive farming, chemical tanning, and high water consumption.

Key Differences: PU Material vs Real Leather

| Feature | PU Material | Real Leather |

|---|---|---|

| Cost | Lower upfront cost | Higher cost due to raw material and processing |

| Durabilité | Moderate; resistant to fading and cracking (especially high-grade microfiber PU); lifespan 3–5 years with regular use | High; develops patina over time; can last 10+ years with proper care |

| Eco-Friendliness | Lower environmental impact; no animal sourcing; reduced water and energy use; many PU options are recyclable or made with bio-based content | High environmental footprint; involves animal agriculture, toxic tanning agents (e.g., chromium), and significant waste byproducts |

- PU material offers consistent texture and color, enabling greater design control for mass production.

- Real leather provides natural variations that many premium brands market as a sign of authenticity and luxury.

- PU leather is easier to maintain and clean, requiring no special conditioners.

- Real leather requires regular conditioning to prevent drying and cracking.

- Ethical and sustainability certifications (e.g., LWG, PETA-Approved Vegan) are more readily attainable with PU materials.

- High-performance microfiber PU leather can match real leather in tensile strength and abrasion resistance, making it suitable for automotive, furniture, and performance footwear applications.

Businesses aiming to reduce environmental impact, lower production costs, and meet vegan product standards increasingly choose advanced PU materials. However, luxury and heritage brands often retain real leather for its tactile authenticity and market perception.

Selecting the right material depends on your brand values, target market, and application requirements. WINIW offers premium eco-friendly PU leather solutions designed for durability, aesthetic excellence, and sustainability—supporting B2B partners in creating responsible, high-value products.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands as a leading manufacturer of premium synthetic leather, engineered to meet the rigorous demands of international fashion, automotive, and furniture brands. Our vertically integrated production ecosystem combines advanced material science with uncompromising environmental stewardship, delivering performance-driven solutions that align with modern sustainability imperatives. Central to our value proposition is a world-class manufacturing foundation built for scale, innovation, and reliability.

Factory Strength: The WINIW Advantage

Our dedicated 100,000 sqm manufacturing complex in China serves as the cornerstone of our global supply capability, enabling us to support high-volume orders while maintaining agility for bespoke development. Key operational pillars include:

- Advanced Production Scale: A 100,000 sqm facility equipped with automated coating, embossing, and finishing lines, ensuring consistent capacity for 50+ million meters annually to meet tight global deadlines.

- In-House R&D Leadership: A 60+ member technical team specializing in polymer chemistry and material engineering, driving innovations in eco-conscious substrates (water-based PU, recycled PET) and performance attributes (abrasion resistance, color fastness).

- Certified Quality Assurance: Triple-stage QC protocols aligned with ISO 9001 standards, featuring automated defect detection systems and physical lab testing for every batch (compliance with REACH, OEKO-TEX® STANDARD 100).

- Global Compliance & Reach: Direct export infrastructure serving Tier-1 clients across 30+ countries, with established compliance for EU Ecolabel, CPSIA (USA), and Blue Sign® requirements.

Proven Market Integration

WINIW materials are trusted by leading European luxury houses and North American automotive suppliers, reflecting our adherence to stringent regional regulations and aesthetic expectations. Our traceable supply chain and LCA-verified eco-processes (reducing CO₂ by 35% vs. conventional PU) provide brands with credible sustainability credentials for consumer-facing communications.

Partner with WINIW to leverage manufacturing excellence that transforms material specifications into market-ready success—without compromising planetary responsibility.

Contact Us for Samples

WINIW B2B Product Guide: High-Performance PU Leather Solutions

WINIW is a leading innovator in synthetic leather manufacturing, specializing in premium polyurethane (PU) materials designed for durability, sustainability, and aesthetic versatility. Our PU leather solutions serve industries including automotive, furniture, footwear, fashion, and electronics, offering a cost-effective and eco-conscious alternative to genuine leather.

Engineered for performance and consistency, WINIW’s PU materials combine advanced coating technologies with high-quality base fabrics to deliver superior abrasion resistance, color fastness, and environmental stability. We support B2B partners with scalable production, custom development, and compliance with global environmental standards.

- All WINIW PU materials are free from hazardous substances, meeting REACH, RoHS, and Oeko-Tex® standards

- Low-VOC emissions for improved indoor air quality and worker safety

- Available in custom colors, textures, thicknesses, and backings (e.g., knit, woven, non-woven)

- Designed for high-yield cutting and seamless integration into automated production lines

Our R&D team continuously advances material science to improve sustainability and functionality. From water-based PU formulations to recycled content integration, WINIW is committed to eco-friendly innovation without compromising performance.

Key Advantages of WINIW PU Leather:

– Consistent roll-to-roll quality for reduced waste

– High tear and seam strength for long-term durability

– Excellent resistance to light, heat, and humidity

– Soft hand feel and premium visual appearance

– Customizable breathability and stretch properties

Applications by Industry:

– Automotive interiors (seats, dashboards, door panels)

– Upholstered furniture and office seating

– Fashion accessories and handbags

– Footwear uppers and linings

– Electronics cases and protective covers

Free physical samples are available upon request to support material evaluation and prototyping. Partner with WINIW to develop tailored PU leather solutions that meet your technical and sustainability goals.

What is PU material?

Polyurethane (PU) material is a synthetic leather alternative made by coating a fabric base—typically polyester or rayon—with a polymer resin. It replicates the look and feel of genuine leather while offering enhanced process efficiency, design flexibility, and environmental benefits. PU is lighter, more uniform, and easier to maintain than traditional leather, making it ideal for high-volume manufacturing and eco-conscious brands.

For technical specifications, compliance documentation, or to request free samples:

Contact WINIW Marketing: MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.