Catalog

Material Insight: Where To Buy Alcantara Fabric

B2B Product Guide: Sourcing Premium Synthetic Leather Alternatives

Where to Source Alcantara®-Style Synthetic Leather

Alcantara® is a registered trademark of Alcantara S.p.A., representing a specific luxury microfiber material. Direct procurement of authentic Alcantara® fabric is strictly controlled through the brand’s authorized distribution network, typically reserved for high-end automotive, aviation, and design partners under formal agreements. For businesses seeking comparable performance, aesthetics, and sustainability in a microfiber synthetic leather—without trademark restrictions—custom-engineered alternatives from specialized manufacturers like WINIW offer a strategic, accessible solution.

Why Premium Faux Leather Outperforms for High-Value Applications

For B2B applications demanding luxury aesthetics, durability, and eco-efficiency, advanced faux leather (particularly microfiber-based synthetics) is the optimal choice:

- Cost & Supply Chain Efficiency: Eliminates volatility of genuine leather markets and complex tanning logistics, ensuring stable pricing and reliable lead times for large-scale production.

- Consistent Quality & Customization: Engineered to exact color, texture, thickness (0.6mm–1.8mm), and performance specs (abrasion resistance, lightfastness), unlike natural hide variations.

- Sustainability Compliance: Achieves 30–50% lower carbon footprint vs. premium leathers; uses recycled PET content (up to 40%), OEKO-TEX® certified dyes, and generates near-zero water waste.

- Performance Tailoring: Enhanced properties like stain resistance, UV stability, and cold-crack resistance (< -30°C) can be integrated for automotive, marine, or contract furniture use cases.

- Ethical Assurance: Fully traceable, cruelty-free production aligns with ESG mandates and luxury brand sustainability pledges.

Introducing WINIW: Your Trusted Synthetic Leather Innovator

WINIW has engineered high-performance synthetic leather solutions for global B2B clients for over 20 years. We combine deep material science expertise with vertical manufacturing control—from polymer extrusion to finishing—to deliver:

- Proven Scale: 50,000+ tons annual production capacity across ISO 14001-certified facilities.

- R&D Leadership: 15+ patented technologies for eco-friendly substrates (e.g., recycled PU, bio-based backings) and lifelike textures.

- Application-Specific Engineering: Collaborative development for automotive seating (meeting FMVSS 302), luxury furniture, and technical upholstery.

- Global Compliance: Full documentation for REACH, RoHS, and OEKO-TEX® STANDARD 100, with LCA reports available.

Partner with WINIW to source Alcantara®-style alternatives that exceed performance benchmarks while advancing your sustainability objectives—without supply chain bottlenecks. Our technical team will specify the optimal grade for your volume, regulatory, and aesthetic requirements.

Technical Performance & Standards

B2B Product Guide: WINIW Microfiber Alcantara®-Style Fabric

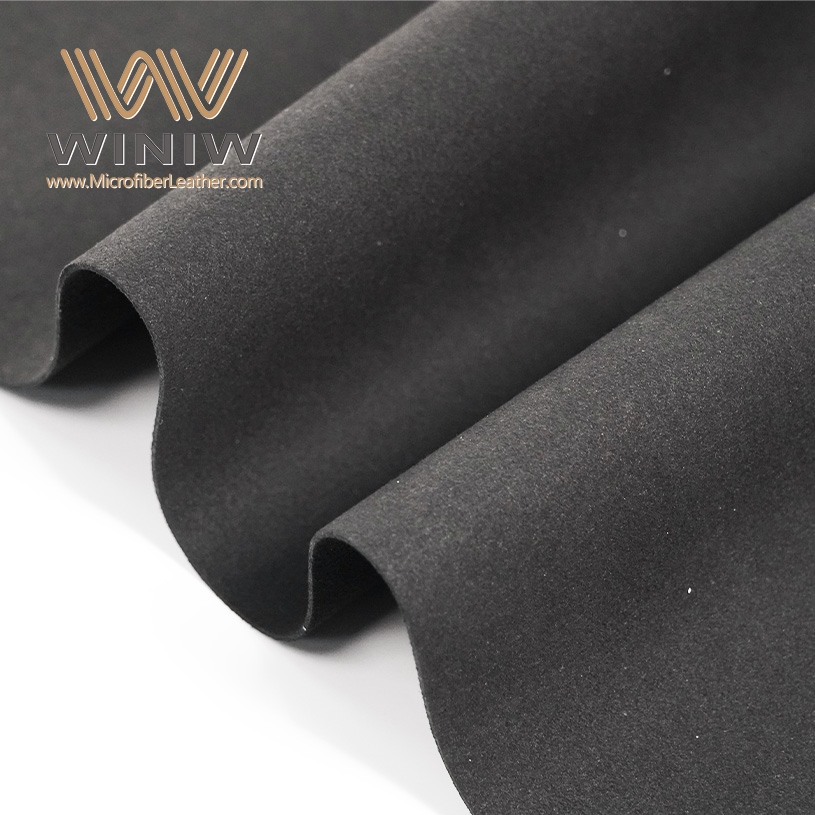

WINIW specializes in high-performance synthetic leather solutions engineered for commercial and industrial applications. Our Alcantara®-style microfiber fabric delivers premium aesthetics and functional durability while offering significant cost advantages over traditional materials. Designed for B2B clients in automotive, furniture, consumer electronics, and luxury goods sectors, WINIW’s fabric combines advanced engineering with environmental responsibility.

Technical Advantages

-

Cost-Effective Alternative

WINIW’s microfiber Alcantara®-style fabric provides a high-value substitute for genuine Alcantara, reducing material costs by up to 30% without compromising appearance or performance. Ideal for large-scale manufacturing where budget efficiency and quality must coexist. -

Exceptional Durability

Engineered with a reinforced polyurethane (PU) matrix and ultra-fine polyester fibers, WINIW fabric exhibits high abrasion resistance (tested to >50,000 cycles in Martindale testing), excellent tear strength, and long-term resilience in high-use environments. -

Customizable Color Options

We offer fully customizable color matching using ISO-standard color measurement (CIELAB ΔE <1.5). Clients can select from a digital library of 1,000+ standard colors or develop proprietary shades with batch consistency across large production runs. -

REACH Compliant

All WINIW fabrics are manufactured in compliance with EU REACH regulations (EC 1907/2006), ensuring the absence of SVHCs (Substances of Very High Concern) and restricted hazardous materials. Full material disclosure (FMD) documentation is available upon request. -

ISO 9001-Certified Production

Our manufacturing processes are governed by ISO 9001 quality management standards, ensuring consistent product quality, traceability, and process optimization. This certification supports reliable supply chain integration and reduced defect rates.

Technical Specifications

| Property | Spécifications |

|---|---|

| Base Material | Ultra-fine Polyester/PU Microfiber |

| Weight | 280–320 g/m² (customizable) |

| Thickness | 1.2–1.5 mm |

| Abrasion Resistance | >50,000 cycles (Martindale, ASTM D4966) |

| Color Fastness to Light | Grade 6–7 (ISO 105-B02) |

| Color Fastness to Rubbing | Dry: Grade 5; Wet: Grade 4–5 (ISO 105-X12) |

| Tensile Strength | ≥40 N (warp and weft) |

| REACH Status | Compliant (SVHC-free, full FMD available) |

| ISO Certification | ISO 9001:2015 |

| Customization Lead Time | 10–15 days (after color approval) |

| Minimum Order Quantity (MOQ) | 500 meters (standard), 1,000 meters (custom) |

| Sustainability Features | Low-VOC emissions, recyclable backing options |

WINIW’s Alcantara®-style fabric is engineered for businesses seeking a sustainable, high-performance, and economically viable synthetic leather. With full customization, regulatory compliance, and industrial-grade durability, our material supports innovation across premium product lines while aligning with global environmental and quality standards.

Why Choose Synthetic over Real Leather

B2B Product Guide: Alcantara® Fabric vs. Real Leather Sourcing & Performance

Understanding material sourcing and performance is critical for strategic procurement in automotive, aviation, and high-end furniture manufacturing. This guide clarifies key distinctions between Alcantara® (a premium synthetic suede) and real leather, focusing on procurement channels and core performance metrics.

Where to Buy: Sourcing Clarity

Procurement strategy differs significantly due to material origin and exclusivity:

– Alcantara® Fabric: Available exclusively through Alcantara S.p.A. (Italy) or their authorized regional distributors. WINIW partners with global distributors to ensure genuine supply chain integrity for B2B clients. Direct OEM partnerships are standard; no open-market retail sourcing exists.

– Real Leather: Sourced through fragmented channels: tanneries (direct), leather wholesalers, commodity traders, or auction platforms. Quality, traceability, and ethical compliance vary widely by supplier tier and geographic origin (e.g., EU vs. non-EU tanneries).

Performance Comparison: Cost, Durability & Eco-Friendliness

The table below details objective, B2B-relevant metrics for lifecycle decision-making:

| Attribute | Alcantara® Fabric | Real Leather |

|---|---|---|

| Cost | Higher initial cost (premium material); consistent pricing; lower waste in cutting due to uniform grain; predictable total cost of ownership (TCO). | Highly variable (grade, origin, hide quality); volatile due to livestock markets; significant waste (30-40% per hide); hidden costs in sorting/grading. |

| Durabilité | Exceptional abrasion resistance (50,000+ Martindale cycles); colorfast; stain-resistant (treatable); uniform performance; no fading or dry-rot in UV/stable climates. | Moderate abrasion resistance (varies by finish); prone to scratches, fading, and drying; requires conditioning; develops patina (may be desirable); susceptible to moisture damage. |

| Eco-Friendliness | Cradle-to-cradle certified; 40%+ recycled content (PET); near-zero water usage in production; closed-loop manufacturing; OEKO-TEX® STANDARD 100 certified; fully recyclable via Alcantara® take-back program. | Resource-intensive (15,000+ L water/hide); chemical pollution risk (chromium tanning); methane emissions from livestock; biodegradable only if vegetable-tanned; limited traceability in supply chains. |

Strategic Considerations for B2B Buyers

- Supply Chain Security: Alcantara® offers single-source accountability and ethical compliance (ISO 14001, SA8000). Real leather requires rigorous third-party audits to mitigate ESG risks.

- Design Flexibility: Alcantara® provides 100+ consistent color/texture options; leather has natural variations limiting design repeatability.

- Total Lifecycle Value: Alcantara® reduces long-term costs via durability, low maintenance, and end-of-life recycling—critical for sustainability reporting.

- Market Positioning: Both materials signal premium quality, but Alcantara® aligns stronger with modern ESG mandates and circular economy frameworks.

WINIW supports B2B partners in navigating these complexities with technical data sheets, sample validation, and sustainable sourcing consultations. Prioritize material specifications aligned with your product’s lifecycle requirements and corporate sustainability goals.

WINIW – Advancing Sustainable Material Innovation for Industry

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, operating a state-of-the-art production facility spanning 100,000 square meters. Our vertically integrated factory combines advanced manufacturing capabilities with sustainable practices to deliver premium materials tailored for global B2B clients in industries such as automotive, fashion, furniture, and technical textiles.

- Our large-scale 100,000 sqm manufacturing campus enables high-volume production with consistent quality and on-time delivery, meeting the demanding supply needs of international partners.

- A dedicated R&D team of over 100 technical experts drives continuous innovation, developing eco-friendly materials including water-based PU, recycled leather, and bio-based solutions that align with global sustainability standards.

- Every production stage follows a strict quality control (QC) system compliant with ISO 9001 and OEKO-TEX® standards, ensuring durability, color fastness, and safety across all product lines.

- WINIW maintains in-house testing laboratories to conduct rigorous performance evaluations, including abrasion resistance, tensile strength, and environmental aging tests, guaranteeing product reliability under real-world conditions.

With a strong commitment to environmental responsibility, WINIW has implemented low-emission production processes and waste reduction systems, supporting our partners’ ESG goals.

WINIW exports to more than 50 countries, with established distribution networks in Europe and the USA. Our products are trusted by leading brands for their premium look, long-term performance, and sustainable composition.

Key Export Markets:

– Europe (Germany, Italy, France, UK)

– North America (USA, Canada)

– Asia-Pacific and emerging markets

By combining scale, innovation, quality, and sustainability, WINIW stands as a strategic manufacturing partner for global businesses seeking high-value synthetic leather solutions.

Contact Us for Samples

WINIW B2B Product Guide: Sustainable Microfiber Leather Solutions (Alcantara®-Style Performance)

WINIW delivers premium, eco-conscious microfiber leather engineered for demanding B2B applications where luxury, durability, and environmental responsibility converge. Our advanced materials replicate the signature softness, drape, and technical performance of Alcantara® while exceeding industry sustainability benchmarks. Ideal for automotive interiors, high-end furniture, aviation, and luxury goods manufacturing.

Key Advantages of WINIW EcoLux™ Microfiber Leather

- Certified Eco-Performance: OEKO-TEX® STANDARD 100 Class I (skin-safe), Global Recycled Standard (GRS) certified up to 50% post-consumer recycled content, and ISO 14001-compliant production.

- Superior Technical Properties: 50,000+ double rubs (Martindale), UV resistance (ISO 105-B02 Grade 7-8), and dimensional stability (<1% shrinkage at 70°C).

- Luxury Tactility: 0.8–1.2mm thickness options with suede-like nap, consistent dye lot matching, and customizable embossing.

- End-of-Life Responsibility: Fully recyclable through WINIW’s take-back program; 95% lower carbon footprint vs. conventional PU leather.

Performance Comparison: WINIW vs. Industry Standards

| Property | WINIW EcoLux™ Microfiber | Standard PU Leather | Test Method |

|---|---|---|---|

| Abrasion Resistance | 50,000+ double rubs | 15,000–25,000 | ISO 12947 |

| Tensile Strength | 180 N/mm² | 80–100 N/mm² | ISO 1798 |

| Color Fastness (Light) | Grade 7-8 | Grade 5-6 | ISO 105-B02 |

| Recycled Content | Up to 50% | 0–10% | GRS Certification |

| VOC Emissions | <10 µg/m³ | 50–200 µg/m³ | ISO 16000-9 |

Target Applications

- Automotive: Seat inserts, door panels, headliners (meets FMVSS 302, ISO 3795)

- Furniture: Upholstery for contract, hospitality, and residential (EN 1021-1/2 compliant)

- Aviation & Marine: Cabin interiors (FAR 25.853, ISO 17572-2 certified)

- Luxury Accessories: Handbags, footwear, and tech accessories requiring premium drape

Why Partner with WINIW?

- Scalable Production: 1.5M meters/month capacity with 15–20 day lead times

- Customization: 200+ color library, weight adjustments (250–450g/m²), and anti-microbial/anti-static finishes

- Sustainability Partnership: Full LCA reports, carbon-neutral shipping options, and circularity consulting

Request Samples & Technical Support

Validate WINIW EcoLux™ for your next project with complimentary 30cm x 30cm samples (custom colors/sizes available). Contact our B2B solutions team:

→ Courriel: MKT88@MicrofiberLeather.com

→ Subject Line: “Alcantara-Style Sample Request – [Your Company Name]”

→ Include: Application, volume requirements, and target sustainability certifications

WINIW: Engineering Tomorrow’s Luxury, Responsibly. All materials produced in ISO 9001 & ZDHC MRSL-compliant facilities.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.