Introduction: Navigating the Global Market for clean a chamois

In the competitive landscape of international trade, sourcing high-quality cleaning chamois presents unique challenges for B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. The demand for effective and reliable cleaning solutions necessitates a comprehensive understanding of the various types of chamois available, their applications across industries, and the critical care and maintenance practices that ensure longevity and performance. This guide serves as an essential resource, offering insights into supplier vetting processes, cost considerations, and best practices for using and maintaining chamois products.

By empowering B2B buyers with actionable knowledge, this guide enables informed purchasing decisions that can lead to enhanced operational efficiency and customer satisfaction. Whether you are a retailer in Nigeria looking to stock your shelves with the best products or an automotive service provider in Vietnam seeking reliable cleaning solutions, understanding the nuances of chamois selection and maintenance is key. With a focus on quality, performance, and supplier credibility, this guide aims to streamline your sourcing process, ensuring that you invest wisely in products that meet your specific needs and standards.

Table Of Contents

- Top 7 Clean A Chamois Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for clean a chamois

- Understanding clean a chamois Types and Variations

- Key Industrial Applications of clean a chamois

- 3 Common User Pain Points for ‘clean a chamois’ & Their Solutions

- Strategic Material Selection Guide for clean a chamois

- In-depth Look: Manufacturing Processes and Quality Assurance for clean a chamois

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘clean a chamois’

- Comprehensive Cost and Pricing Analysis for clean a chamois Sourcing

- Alternatives Analysis: Comparing clean a chamois With Other Solutions

- Essential Technical Properties and Trade Terminology for clean a chamois

- Navigating Market Dynamics and Sourcing Trends in the clean a chamois Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of clean a chamois

- Strategic Sourcing Conclusion and Outlook for clean a chamois

- Important Disclaimer & Terms of Use

Understanding clean a chamois Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Leather Chamois | Made from natural leather; highly absorbent; durable | Automotive detailing, luxury goods | Pros: Long-lasting, effective drying; Cons: Higher cost, requires careful maintenance. |

| Synthetic Chamois | Made from microfiber or synthetic materials; lightweight | General cleaning, household use | Pros: Affordable, machine washable; Cons: Less absorbent, may wear out faster. |

| Ultra-Soft Chamois | Extra soft texture; designed for delicate surfaces | High-end vehicle detailing, fine art | Pros: Gentle on surfaces, ideal for sensitive finishes; Cons: Higher price point. |

| Eco-Friendly Chamois | Made from sustainable materials; biodegradable | Green cleaning businesses, eco-conscious brands | Pros: Environmentally friendly, promotes sustainability; Cons: Availability may be limited. |

| Heavy-Duty Chamois | Thicker and more robust; designed for heavy cleaning tasks | Industrial cleaning, automotive repair | Pros: Highly durable, effective for tough jobs; Cons: Bulkier, may be overkill for light tasks. |

What are the characteristics of Genuine Leather Chamois?

Genuine leather chamois are renowned for their exceptional absorbency and durability, making them a preferred choice for automotive detailing and luxury goods. They are crafted from natural leather, which allows them to effectively soak up water without leaving streaks. However, they require meticulous care to maintain their quality, including washing with specific soaps and avoiding harsh chemicals. Buyers must consider the initial investment and long-term maintenance costs when opting for this type.

How does Synthetic Chamois compare in terms of usability?

Synthetic chamois, often made from microfiber or other synthetic materials, offer a lightweight and cost-effective alternative. They are suitable for general cleaning tasks in both household and automotive settings. Their machine-washable nature enhances convenience for businesses that require frequent cleaning supplies. However, while they provide decent absorbency, they may not match the performance of genuine leather chamois. Buyers should weigh the lower price against the potential need for more frequent replacements.

Why might businesses choose Ultra-Soft Chamois?

Ultra-soft chamois are designed specifically for delicate surfaces, making them ideal for high-end vehicle detailing and fine art applications. Their gentle texture prevents scratches and damage, ensuring that surfaces remain pristine. Although they come at a higher price point, the protection they offer can be invaluable for businesses dealing with luxury items. When purchasing, B2B buyers should consider the specific needs of their clientele and the types of surfaces they will be working with.

What are the benefits of using Eco-Friendly Chamois?

Eco-friendly chamois are crafted from sustainable materials and are biodegradable, appealing to businesses focused on green cleaning practices. They are suitable for eco-conscious brands looking to promote sustainability in their operations. While they contribute positively to environmental goals, availability can sometimes be an issue, leading to potential supply chain challenges. Buyers should assess their commitment to sustainability and the market demand for eco-friendly products when considering these options.

In what scenarios would Heavy-Duty Chamois be necessary?

Heavy-duty chamois are characterized by their thicker, more robust design, making them ideal for industrial cleaning and automotive repair tasks. They excel in handling tough cleaning jobs where durability is essential. While they provide excellent performance in demanding environments, their bulkiness may not be necessary for lighter tasks, potentially leading to inefficiencies. Businesses should evaluate the typical cleaning scenarios they encounter to determine if heavy-duty options are warranted.

Key Industrial Applications of clean a chamois

| Industry/Sector | Specific Application of clean a chamois | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Detailing | Vehicle drying and finishing | Ensures streak-free surfaces, enhancing customer satisfaction | Sourcing from reputable manufacturers to ensure quality and durability |

| Manufacturing | Cleaning machinery and equipment | Prevents dust accumulation, improving operational efficiency | Need for high absorbency and durability to withstand industrial use |

| Hospitality | Maintenance of luxury vehicles and boats | Protects high-value assets, maintaining aesthetic appeal | Consider chamois that are easy to clean and maintain |

| Food and Beverage | Cleaning glassware and utensils | Ensures a spotless finish, enhancing presentation | Must comply with food safety standards and be free from harmful chemicals |

| Construction and Maintenance | Surface cleaning of tools and surfaces | Minimizes wear and tear, prolonging tool life | Focus on sourcing chamois that can handle rugged environments |

How is ‘clean a chamois’ used in automotive detailing?

In the automotive detailing industry, clean chamois are essential for drying vehicles after washing. Their high absorbency allows for quick removal of water, preventing streaks and water spots that can detract from the vehicle’s appearance. For B2B buyers in this sector, sourcing high-quality chamois is crucial, as inferior products can lead to customer dissatisfaction. Buyers should seek chamois that are durable and easy to maintain, ensuring they can withstand frequent use without degrading in performance.

What role does ‘clean a chamois’ play in manufacturing?

In manufacturing environments, clean chamois are utilized for cleaning machinery and equipment. They effectively prevent dust and grime buildup, which can hinder operational efficiency and lead to costly downtime. B2B buyers from this sector must prioritize sourcing chamois that exhibit high absorbency and durability, as these products will be subjected to rigorous cleaning tasks. Additionally, suppliers should be evaluated based on their ability to provide consistent quality to support ongoing maintenance needs.

Why is ‘clean a chamois’ important in hospitality?

In the hospitality sector, particularly in luxury vehicle and boat maintenance, clean chamois are vital for preserving the aesthetic appeal of high-value assets. Their ability to provide a streak-free finish after cleaning enhances the overall guest experience. International buyers should consider chamois that are not only effective but also easy to clean and maintain, ensuring they remain in top condition for prolonged use. This attention to detail can significantly influence customer satisfaction and loyalty.

Illustrative image related to clean a chamois

How does ‘clean a chamois’ enhance food and beverage presentation?

In the food and beverage industry, clean chamois are employed to clean glassware and utensils, ensuring a spotless presentation. This is crucial for maintaining hygiene and enhancing the visual appeal of food and drinks served to customers. B2B buyers must ensure that the chamois sourced are compliant with food safety standards and free from harmful chemicals. The right chamois can contribute to a polished presentation, directly impacting customer perceptions and satisfaction.

What benefits does ‘clean a chamois’ offer in construction and maintenance?

In construction and maintenance, clean chamois are used for surface cleaning of tools and equipment. By minimizing dirt and grime accumulation, they help prolong the life of tools and ensure optimal performance. Buyers in this sector should focus on sourcing chamois that can withstand rugged environments and repeated use. The durability and effectiveness of the chamois can lead to reduced maintenance costs and improved operational efficiency, making them a valuable investment for businesses.

3 Common User Pain Points for ‘clean a chamois’ & Their Solutions

Scenario 1: Inconsistent Cleaning Results Leading to Surface Damage

The Problem: Many B2B buyers in industries like automotive detailing and maintenance face the challenge of inconsistent cleaning results when using chamois. This inconsistency can lead to streaking on surfaces, which not only affects the aesthetic appeal but can also lead to long-term damage on high-end vehicles. Buyers may find that their chamois, after multiple uses, fail to absorb water effectively or leave behind lint, resulting in a poor finish. This problem often stems from improper cleaning and maintenance practices.

The Solution: To achieve optimal cleaning results, it’s crucial to establish a standardized chamois care protocol. First, ensure that all staff are trained to wash the chamois after each use with a mild, vehicle-specific soap to remove dirt and oils. Emphasize the importance of rinsing the chamois thoroughly until the water runs clear, as residual soap can lead to streaking. Additionally, advise against using harsh chemicals or machine washing, as these can degrade the leather and reduce its absorbency. Implementing a regular maintenance schedule that includes inspecting the chamois for signs of wear and replacing them as necessary will help maintain high standards of cleaning and protect valuable assets.

Illustrative image related to clean a chamois

Scenario 2: Stains and Odors Compromising Performance

The Problem: B2B buyers often encounter issues with stains and unpleasant odors that can accumulate on chamois after repeated use, especially in humid environments like parts of Africa and South America. These issues not only detract from the performance of the chamois but can also lead to customer dissatisfaction if the product is used in customer-facing scenarios.

The Solution: To effectively combat stains and odors, implement a robust cleaning regimen that includes soaking the chamois in a solution of warm water and a few drops of mild soap for a few minutes before rinsing. For stubborn stains, gently massage the affected areas with the soapy water before rinsing thoroughly. After cleaning, hang the chamois to dry in a shaded area to prevent damage from UV rays. Educate staff on storing chamois in a dry, well-ventilated space to minimize odor accumulation. Regularly rotating the chamois in use can also help maintain freshness and performance, ensuring that no single chamois is overused and compromised.

Scenario 3: Mismanagement of Chamois Lifespan

The Problem: In the B2B landscape, buyers often struggle with the mismanagement of chamois lifespan, leading to unnecessary expenditure on replacements. Many organizations overlook the importance of proper storage and maintenance, resulting in chamois that become brittle or develop cracks, ultimately reducing their operational effectiveness.

The Solution: To extend the lifespan of chamois, establish a comprehensive training program focused on proper usage, cleaning, and storage practices. Educate staff on the importance of wringing out chamois completely after each use to prevent mold growth, and stress the necessity of hanging them to dry away from direct sunlight. Incorporate a quality control process that includes regular inspections of chamois for signs of wear and tear, allowing for timely replacements. Additionally, consider investing in high-quality chamois that are designed for durability and longevity, which can ultimately lead to cost savings in the long run. By fostering a culture of care and respect for these tools, businesses can optimize their cleaning processes and reduce overall costs associated with frequent replacements.

Illustrative image related to clean a chamois

Strategic Material Selection Guide for clean a chamois

What Materials Are Commonly Used for Cleaning Chamois?

When selecting materials for cleaning chamois, it is essential to consider their properties, advantages, and limitations. This analysis focuses on four common materials: natural leather, synthetic chamois, microfiber, and cotton. Each material has distinct characteristics that can influence performance and suitability for various applications.

How Does Natural Leather Perform as a Cleaning Material for Chamois?

Natural leather chamois is traditionally used for drying and cleaning surfaces due to its excellent absorbency and softness. Key properties include high moisture retention and a natural ability to conform to surfaces, which prevents scratching. However, natural leather requires specific care to maintain its integrity, including avoiding harsh chemicals and ensuring proper drying conditions.

Pros: Natural leather is highly durable, provides a superior finish on surfaces, and can last for years with proper maintenance. It is also biodegradable, making it an environmentally friendly option.

Cons: The initial cost can be higher compared to synthetic alternatives, and it requires careful handling to avoid damage. Additionally, it may not perform well in extreme temperatures or with certain cleaning agents.

For international buyers, especially in regions like Africa and South America, compliance with environmental regulations regarding leather sourcing and processing is crucial. Buyers should also consider local preferences for natural materials, which may be favored for their traditional qualities.

What Are the Benefits of Synthetic Chamois in Cleaning Applications?

Synthetic chamois, often made from polyvinyl alcohol (PVA), offers a lightweight and highly absorbent alternative to natural leather. It is designed to mimic the properties of natural chamois while providing enhanced durability and ease of maintenance. Synthetic chamois can withstand higher temperatures and is resistant to mold and mildew.

Pros: It is generally less expensive than natural leather, easy to clean, and dries quickly. Synthetic chamois is also more resistant to chemicals, making it suitable for various cleaning agents.

Cons: While synthetic chamois is durable, it may not provide the same level of softness or finish as natural leather. Additionally, it is less biodegradable, raising environmental concerns.

For buyers in the Middle East and Europe, understanding the manufacturing standards for synthetic materials is essential. Compliance with regulations such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) may impact sourcing decisions.

How Does Microfiber Compare for Cleaning Chamois Applications?

Microfiber is a popular choice for cleaning due to its exceptional dirt and moisture absorption capabilities. Composed of polyester and polyamide, microfiber is designed to trap dust and grime effectively. It also has a high tensile strength, making it resistant to wear and tear.

Pros: Microfiber is highly effective for cleaning without the need for additional chemicals, making it a cost-effective option. It is also machine washable and dries quickly.

Illustrative image related to clean a chamois

Cons: While microfiber is durable, it can be less effective on oily surfaces compared to natural leather. Additionally, the environmental impact of synthetic fibers raises concerns among eco-conscious buyers.

International buyers, particularly from regions with stringent environmental regulations, should consider the lifecycle of microfiber products and their impact on sustainability. Awareness of local preferences for eco-friendly materials can influence purchasing decisions.

What Role Does Cotton Play in Cleaning Chamois?

Cotton is another material used in cleaning applications, often found in traditional cleaning cloths. It is known for its softness and absorbency, making it suitable for gentle cleaning tasks.

Pros: Cotton is widely available, cost-effective, and biodegradable. It is also gentle on surfaces, reducing the risk of scratches.

Cons: Cotton chamois may not absorb moisture as effectively as synthetic or leather options, and it can degrade faster when exposed to harsh cleaning agents.

For international buyers, particularly in developing regions, cotton may be preferred due to its affordability and natural properties. Understanding local market trends and consumer preferences can help in making informed sourcing decisions.

Summary Table of Material Selection for Cleaning Chamois

| Material | Typical Use Case for clean a chamois | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Leather | High-end vehicle detailing | Superior softness and durability | Requires careful maintenance | High |

| Synthetic Chamois | General cleaning and drying | Resistant to chemicals and quick-drying | Less soft compared to natural leather | Medium |

| Microfiber | Versatile cleaning applications | Highly effective dirt and moisture absorption | Less effective on oily surfaces | Medium |

| Cotton | Gentle cleaning tasks | Soft and biodegradable | Lower moisture absorption and durability | Low |

This strategic material selection guide provides valuable insights for B2B buyers looking to optimize their cleaning processes with chamois products. Understanding the properties and implications of each material can lead to better purchasing decisions that align with regional preferences and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for clean a chamois

What Are the Key Stages in the Manufacturing Process of a Clean Chamois?

The manufacturing process of a clean chamois involves several critical stages that ensure the final product meets quality and performance standards. Each stage, from material preparation to finishing, plays a vital role in determining the chamois’s durability and effectiveness.

Material Preparation: What Types of Materials Are Used?

The primary material used in manufacturing chamois is lambskin or sheepskin, known for its high absorbency and softness. The preparation of these materials begins with sourcing high-quality hides, which are then subjected to a tanning process. This process can be either vegetable or chrome tanning, each imparting distinct qualities to the leather. Once tanned, the hides are cleaned, and any imperfections are removed to ensure a uniform quality.

Forming: How Are Chamois Shaped and Assembled?

After the hides are prepared, they undergo the forming stage, where they are cut into specific shapes and sizes suitable for various applications, such as automotive detailing or household cleaning. This stage may involve manual or automated cutting techniques, depending on the scale of production. The pieces are then assembled, ensuring that they maintain the integrity of the leather fibers, which is crucial for absorbency.

Finishing: What Techniques Enhance Durability and Performance?

Finishing processes are essential for enhancing the chamois’s performance characteristics. This may include treatments that improve water resistance and increase the softness of the leather. Techniques such as buffing and polishing are also employed to create a smooth surface, which not only enhances the aesthetic appeal but also improves functionality by reducing streaks when used on surfaces.

What Quality Assurance Practices Are Crucial in Chamois Production?

Quality assurance (QA) is vital in the chamois manufacturing process to guarantee that the final product meets international standards and customer expectations. The QA process typically aligns with global standards such as ISO 9001, ensuring that manufacturers adhere to stringent quality protocols.

What International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding relevant international standards is crucial. ISO 9001 provides a framework for quality management systems, focusing on consistent product quality and customer satisfaction. Additionally, certifications like CE (Conformité Européenne) are important for products sold in European markets, ensuring they meet health and safety standards.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process to maintain product integrity. The key checkpoints include:

Illustrative image related to clean a chamois

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified quality criteria.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process to identify any deviations from standards during production.

- Final Quality Control (FQC): Conducting a thorough inspection of finished products to assess their quality before packaging and shipping.

What Testing Methods Are Commonly Used for Chamois Quality Assurance?

Several testing methods are employed to ensure that the chamois meets performance expectations. These may include:

- Absorbency Tests: Measuring how much water the chamois can hold, which is crucial for its intended use.

- Durability Tests: Assessing the leather’s strength and resistance to wear over time, ensuring that it can withstand regular use without degrading.

- Chemical Resistance Tests: Evaluating how the chamois reacts to common cleaning agents, which is particularly important for automotive applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures is essential to ensure product reliability and compliance with standards. Here are several strategies:

- Conduct Audits: Regularly auditing suppliers provides insight into their manufacturing processes, helping to confirm adherence to quality standards.

- Request Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, testing results, and compliance with relevant standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality management practices and product quality.

What Are the QC/CERT Nuances for International B2B Buyers?

When sourcing chamois from international suppliers, B2B buyers must navigate specific nuances related to quality certification and compliance. It’s important to understand the certification requirements of the target market, as they can vary significantly across regions. For instance, while a CE mark is essential for products sold in Europe, other regions may have different compliance standards.

Illustrative image related to clean a chamois

Additionally, cultural differences may influence manufacturing practices and expectations regarding quality. Buyers should engage in clear communication with suppliers to outline specific quality expectations and ensure that all parties understand compliance requirements.

Conclusion

The manufacturing processes and quality assurance measures for clean chamois are integral to producing a reliable and effective product. By understanding the various stages of manufacturing, the importance of international standards, and effective verification methods, B2B buyers can make informed decisions when selecting suppliers. This knowledge not only enhances product quality but also fosters long-term partnerships built on trust and reliability in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘clean a chamois’

Introduction

This guide aims to provide a comprehensive checklist for B2B buyers looking to source effective cleaning solutions for chamois. Proper maintenance of chamois is essential for longevity and performance, making it vital to understand how to clean and care for these products efficiently. By following this checklist, buyers can ensure they procure the right cleaning supplies and methods tailored to their specific needs.

Illustrative image related to clean a chamois

Step 1: Identify Your Chamois Type

Understanding the type of chamois you are working with—whether genuine leather or synthetic—is crucial. Each type requires different cleaning methods and products. For instance, genuine leather chamois should be cleaned with mild soaps specifically designed for leather, while synthetic options may tolerate a wider range of cleaning agents.

Step 2: Select Appropriate Cleaning Products

When sourcing cleaning products, prioritize those formulated for the specific type of chamois. Look for:

– Mild soaps: Ensure they do not contain harsh chemicals like bleach or ammonia, which can damage the chamois.

– Leather conditioners: If dealing with genuine leather, select conditioners that maintain flexibility and prevent cracking.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, verify their credentials and certifications. This step is important to ensure that the products comply with international standards. Look for:

– ISO certifications: Indicating quality management.

– Environmental certifications: Ensuring eco-friendly practices, which can be crucial in regions focused on sustainability.

Illustrative image related to clean a chamois

Step 4: Request Sample Products

To assess quality, request samples of the cleaning products. Testing these samples in real-world scenarios allows you to evaluate their effectiveness on your chamois. Pay attention to:

– Cleaning efficiency: Does it remove stains without damaging the material?

– Residue left behind: Ensure the product rinses clean without leaving behind any harmful residues.

Step 5: Consult Product Reviews and Case Studies

Research existing customer reviews and case studies that highlight the effectiveness of the cleaning solutions. This information can provide insights into:

– Performance: How well the product performs in various conditions.

– Customer support: The responsiveness and support provided by the supplier in case of issues.

Step 6: Establish a Maintenance Schedule

Having a maintenance schedule for your chamois is essential to prolong its life. Determine how often you will clean and care for the chamois based on usage frequency and environmental factors. Consider:

– Frequency of use: More frequent use may require more regular cleaning.

– Environmental conditions: Dusty or humid environments may necessitate more stringent care.

Step 7: Ensure Proper Storage Solutions

Finally, assess how you will store your chamois to maintain its integrity. Proper storage prevents mold and deterioration. Look for:

– Breathable storage bags: Avoid airtight containers that trap moisture.

– Cool, shaded areas: Ensure that chamois is stored away from direct sunlight to prevent drying out and cracking.

Illustrative image related to clean a chamois

By following this checklist, B2B buyers can ensure they are well-equipped to source the right cleaning solutions for their chamois, enhancing their performance and lifespan.

Comprehensive Cost and Pricing Analysis for clean a chamois Sourcing

What Are the Key Cost Components for Sourcing Clean Chamois?

When sourcing clean chamois, it is essential to understand the various cost components that contribute to the overall price. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of raw materials, such as genuine leather or synthetic alternatives, significantly impacts pricing. Genuine chamois, often made from sheepskin, tends to be more expensive due to its superior absorbency and durability compared to synthetic options.

-

Labor: Labor costs vary based on geographical location and the skill level required for processing and finishing chamois. Countries with lower labor costs can offer more competitive pricing, but may also affect the quality of craftsmanship.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: The initial investment in specialized tools and machinery for cutting and finishing chamois can add to the upfront costs. However, these costs are often amortized over large production runs.

-

Quality Control (QC): Ensuring that each chamois meets quality standards involves additional costs. Rigorous QC processes can prevent defects, which is crucial for maintaining customer satisfaction and reducing returns.

-

Logistics: Transportation costs depend on the distance between the manufacturer and the buyer, as well as the chosen shipping method. International shipping may involve additional duties and taxes, impacting the final price.

-

Margin: Suppliers typically add a margin to cover their expenses and profit. Understanding the market dynamics can help buyers negotiate better pricing.

What Influences the Pricing of Clean Chamois in the B2B Market?

Several factors influence the pricing of clean chamois, particularly for international B2B buyers.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should assess their needs and consider negotiating bulk purchase agreements for better pricing.

-

Specifications and Customization: Custom specifications, such as specific dimensions or branding, can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., eco-friendly processes) can raise costs. Buyers should evaluate the total cost against the expected lifespan and performance benefits of premium products.

-

Supplier Factors: The supplier’s reputation, experience, and manufacturing capabilities also play a role in pricing. Established suppliers may command higher prices due to their reliability and quality assurance.

-

Incoterms: Understanding the shipping terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial. These terms define the responsibilities of buyers and sellers, impacting overall costs.

What Tips Can Help Buyers Optimize Costs When Sourcing Clean Chamois?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to optimize sourcing costs for clean chamois:

-

Negotiate Pricing: Leverage volume commitments and long-term partnerships to negotiate better rates. Suppliers may offer discounts for repeat business.

-

Focus on Cost-Efficiency: Look beyond the initial price to consider the Total Cost of Ownership (TCO), which includes maintenance and replacement costs. Investing in higher-quality chamois can lead to lower long-term costs.

-

Research Market Trends: Understanding current market trends and pricing fluctuations can provide leverage in negotiations. Engage with industry forums and publications to stay informed.

-

Evaluate International Logistics: Assess logistics options to find cost-effective shipping methods. Local suppliers may reduce shipping costs, while international ones might offer better quality at a higher price.

-

Understand Regional Pricing Nuances: Prices may vary significantly by region due to local demand, supply chain factors, and economic conditions. Buyers should research regional markets to identify the best sourcing opportunities.

Disclaimer on Pricing

All pricing information is indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing clean a chamois With Other Solutions

The cleaning and maintenance of vehicles and surfaces often lead businesses to consider various methods and products. Among these, using a chamois has been a popular choice due to its natural absorbency and effectiveness. However, there are alternative solutions available that may suit different operational needs and budgets. This analysis compares ‘clean a chamois’ with two other viable options: microfiber towels and synthetic chamois.

| Comparison Aspect | ‘Clean A Chamois’ | Microfiber Towels | Synthetic Chamois |

|---|---|---|---|

| Performance | Excellent absorbency, streak-free | High absorbency, quick-drying | Good absorbency, often less effective |

| Cost | Moderate initial investment | Generally low-cost | Moderate to high, depending on quality |

| Ease of Implementation | Requires specific care instructions | Easy to use and maintain | Simple to use, no special care needed |

| Maintenance | Needs careful washing and drying | Machine washable, quick to dry | Easy to clean, but may degrade faster |

| Best Use Case | High-end vehicles, delicate finishes | General cleaning, versatile use | Quick jobs, less critical surfaces |

How Does Microfiber Towels Compare to Clean A Chamois?

Microfiber towels have gained popularity due to their versatility and ease of use. They offer high absorbency and can be used on various surfaces without scratching. Unlike chamois, microfiber towels are machine washable and dry quickly, making them ideal for businesses with high turnover in cleaning tasks. However, they may not provide the same level of streak-free finish that a well-maintained chamois offers, particularly on delicate surfaces.

What Are the Benefits of Using Synthetic Chamois Over Clean A Chamois?

Synthetic chamois are designed to mimic the properties of natural chamois but are often more durable and easier to maintain. They do not require the same level of care, such as specific washing instructions or drying methods, making them convenient for quick cleaning tasks. However, they may not absorb water as effectively as natural chamois and can wear out faster, especially under heavy use. Thus, while synthetic chamois offer ease, they may sacrifice some performance.

Conclusion: Which Cleaning Solution Is Right for Your Business Needs?

When choosing between ‘clean a chamois’ and its alternatives, businesses must consider factors such as performance, cost, and ease of maintenance based on their specific cleaning requirements. For high-end detailing jobs, a well-maintained chamois may be the best choice for achieving a pristine finish. Conversely, for general cleaning tasks or when budget constraints are a concern, microfiber towels or synthetic chamois might provide sufficient performance with lower maintenance demands. Ultimately, the right solution will depend on the operational context and the specific needs of the business.

Essential Technical Properties and Trade Terminology for clean a chamois

What Are the Key Technical Properties of a Chamois for Cleaning?

Understanding the technical specifications of chamois used for cleaning is crucial for B2B buyers, as these factors directly influence product performance, durability, and overall value.

Illustrative image related to clean a chamois

1. Material Composition

Chamois are typically made from high-quality leather derived from the skin of sheep or goats. The material grade affects absorbency, flexibility, and softness. Genuine leather chamois are known for their superior water absorption and gentle touch, making them ideal for delicate surfaces. In contrast, synthetic alternatives may offer cost savings but often lack the same performance characteristics.

2. Absorbency Rate

This property measures how much liquid a chamois can absorb relative to its weight. A high absorbency rate is essential for effective cleaning, as it ensures that the chamois can quickly soak up water and other cleaning agents without leaving streaks. For B2B buyers, evaluating absorbency can lead to better product choices for specific applications, whether in automotive detailing or household cleaning.

3. Durability

Durability refers to the lifespan and resistance of the chamois to wear and tear. Factors affecting durability include the quality of tanning and thickness of the leather. A durable chamois can withstand multiple uses and washes without degrading in performance, making it a cost-effective option for businesses that require consistent cleaning solutions.

4. pH Neutrality

The pH level of a cleaning chamois is significant, particularly when used on sensitive surfaces. A pH-neutral chamois minimizes the risk of chemical reactions that could damage the surfaces being cleaned. B2B buyers should prioritize pH-neutral options to ensure compatibility with various cleaning agents and surfaces, enhancing overall safety and effectiveness.

Illustrative image related to clean a chamois

5. Weight and Thickness

The weight and thickness of a chamois influence its handling and usability. A thicker chamois generally offers greater absorbency but may be heavier and less flexible. Conversely, a lighter chamois is easier to maneuver but might not absorb as much liquid. Understanding these specifications helps buyers choose the right product for their specific cleaning tasks.

What Are Common Trade Terms Related to Cleaning Chamois?

Familiarity with industry terminology is essential for efficient purchasing and supply chain management in the chamois market.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the chamois industry, an OEM may produce high-quality cleaning materials that are then branded and marketed by a larger company. Understanding OEM relationships can help buyers ensure they are sourcing reliable and quality products.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For chamois, knowing the MOQ is vital for businesses looking to maintain inventory without overcommitting financially. It allows for better inventory management and cost control.

3. RFQ (Request for Quotation)

An RFQ is a standard business process used to invite suppliers to bid on specific products or services. B2B buyers should utilize RFQs when sourcing chamois to compare prices, specifications, and terms from multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international shipping. Understanding Incoterms is crucial for B2B buyers dealing with overseas suppliers of chamois, as they clarify shipping costs, risk management, and delivery responsibilities.

5. SKU (Stock Keeping Unit)

SKU is a unique identifier used to track products in inventory. For businesses that stock multiple types of chamois, using SKUs helps streamline inventory management and sales tracking, ensuring that supply levels meet demand efficiently.

By grasping these technical properties and trade terminology, B2B buyers can make informed decisions that enhance their cleaning operations while optimizing costs and ensuring product performance.

Navigating Market Dynamics and Sourcing Trends in the clean a chamois Sector

What Are the Current Market Dynamics and Sourcing Trends in the Clean Chamois Sector?

Market Overview & Key Trends

The clean chamois market is witnessing a transformation driven by evolving consumer preferences, technological advancements, and an increasing focus on sustainability. As global demand for high-quality cleaning products rises, particularly in regions like Africa, South America, the Middle East, and Europe, the clean chamois sector is adapting to meet these needs. Key trends include the growing popularity of synthetic chamois options, which offer durability and ease of care, alongside traditional leather chamois that appeal to consumers prioritizing performance and longevity.

Illustrative image related to clean a chamois

International B2B buyers are increasingly leveraging digital platforms for sourcing, allowing for better access to suppliers and competitive pricing. Moreover, the integration of e-commerce solutions and online marketplaces has streamlined procurement processes, making it easier for businesses in emerging markets to acquire quality products. The importance of certifications, such as ISO and eco-labels, is also on the rise, as buyers seek assurance regarding product quality and environmental impact.

In terms of market dynamics, the ongoing shifts towards eco-friendly materials are reshaping sourcing strategies. Companies are now focusing on suppliers who demonstrate a commitment to sustainability, thus influencing purchasing decisions. Additionally, geopolitical factors and supply chain disruptions caused by global events are prompting buyers to diversify their sourcing strategies to mitigate risks.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of the clean chamois sector, driven by both regulatory pressures and consumer demand for environmentally friendly products. The production of traditional leather chamois raises concerns regarding animal welfare and environmental degradation due to the tanning processes involved. As a result, the market is seeing a surge in the use of alternative materials, such as synthetic chamois made from recycled plastics, which provide a more sustainable option without compromising performance.

Ethical sourcing is increasingly important for B2B buyers, particularly in regions with stringent environmental regulations. Buyers are actively seeking suppliers who can demonstrate responsible sourcing practices, including transparent supply chains and adherence to labor rights. Certifications such as Global Organic Textile Standard (GOTS) and Fair Trade are gaining traction as they signal a commitment to ethical practices.

In addition to ethical sourcing, companies are integrating sustainability into their marketing strategies to appeal to eco-conscious consumers. Highlighting the use of biodegradable materials and the carbon footprint of products can enhance brand reputation and foster customer loyalty. As businesses continue to prioritize sustainability, the demand for clean chamois products that align with these values is expected to grow.

Illustrative image related to clean a chamois

Brief Evolution/History

The history of the clean chamois dates back centuries, with its origins rooted in the use of animal hides for cleaning and drying purposes. Traditionally, chamois leather was sourced from the skin of the chamois, a mountain-dwelling goat-antelope. Over time, the versatility and absorbency of this material made it a preferred choice among automotive and household cleaning enthusiasts.

In the late 20th century, advancements in synthetic materials led to the introduction of man-made chamois, which offered comparable absorbency and ease of maintenance without the ethical concerns associated with animal products. This evolution reflects a broader trend in consumer preferences towards practicality and sustainability, reshaping the landscape of the cleaning industry.

Today, the clean chamois market is characterized by a blend of traditional craftsmanship and modern innovation, catering to diverse consumer needs while maintaining a focus on quality and performance. As buyers continue to navigate this dynamic market, understanding its historical context can provide valuable insights into current sourcing trends and future opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of clean a chamois

-

How do I ensure the quality of chamois when sourcing internationally?

To ensure the quality of chamois when sourcing internationally, it’s crucial to vet suppliers thoroughly. Look for manufacturers with a solid reputation and certifications for quality control. Request product samples to evaluate the material, softness, and absorbency firsthand. Additionally, check for customer reviews and testimonials, and consider visiting the manufacturing facility if possible. Establishing clear quality assurance agreements can also help maintain standards throughout the production process. -

What is the best type of chamois for automotive detailing?

The best type of chamois for automotive detailing is typically a genuine natural leather chamois. These chamois are known for their exceptional absorbency and softness, making them ideal for drying vehicles without scratching the surface. When sourcing, ensure that the chamois is free from harsh chemicals and has been properly tanned to maintain its quality. Synthetic options are also available but may not match the performance of natural leather. -

What are the minimum order quantities (MOQ) for chamois products?

Minimum order quantities (MOQ) for chamois products can vary widely based on the supplier and the type of chamois. Typically, MOQs range from 100 to 1,000 units for bulk orders. When negotiating, consider your storage capacity and market demand to determine a suitable quantity. Some suppliers may offer flexibility on MOQs for first-time buyers or if you commit to future orders. -

What payment terms should I expect when sourcing chamois?

Payment terms when sourcing chamois can vary by supplier but commonly include options like a 30% deposit upfront with the balance due upon delivery. Some suppliers may offer net 30 or net 60 terms for established buyers. It is advisable to clarify payment methods accepted, such as wire transfers, letters of credit, or PayPal, and to ensure that these terms are documented in the contract to avoid misunderstandings. -

How can I customize chamois products for my brand?

Customization of chamois products can often be arranged by discussing your needs with the supplier. Options may include branding the chamois with your logo, selecting specific colors, or adjusting sizes. Ensure to communicate your requirements clearly and request samples of any custom designs to assess quality before placing a bulk order. Keep in mind that customization may affect the MOQ and lead times. -

What should I know about logistics when importing chamois?

When importing chamois, it’s vital to consider logistics factors such as shipping methods, transit times, and customs clearance processes. Choose a reliable freight forwarder with experience in handling similar products to ensure smooth transportation. Additionally, be aware of import duties and regulations specific to your country, which can impact costs and delivery timelines. Planning for potential delays can help mitigate supply chain disruptions. -

How do I maintain chamois products to ensure longevity?

To maintain chamois products for longevity, it’s essential to follow proper care guidelines. After each use, rinse the chamois with clean water, wash it with mild soap specifically designed for automotive use, and allow it to air dry away from direct sunlight. Avoid harsh chemicals and washing machines, as they can damage the leather. Regular maintenance will keep the chamois soft, durable, and effective in its performance. -

What are the common uses for chamois beyond automotive applications?

Chamois have versatile applications beyond automotive detailing. They are commonly used for cleaning and drying household surfaces, polishing furniture, and even in sports for drying equipment. Additionally, chamois can be utilized in fuel filtration processes due to their absorbent properties. Understanding these diverse uses can help you market your chamois products more effectively to potential buyers in various industries.

Top 7 Clean A Chamois Manufacturers & Suppliers List

1. Tanner’s Select – Chamois Care Guide

Domain: tannersselect.com

Registered: 2017 (8 years)

Introduction: Proper care and maintenance of a chamois will extend its life and performance. Instructions are provided on product packaging. Before first use, wash the chamois in lukewarm water with mild car soap to remove residual tanning oils. Avoid degreasing soaps, harsh chemicals, or laundry detergents. Rinse until water is clear, then use or hang to dry in the shade. For use, rinse and wring out the chamo…

2. Chamois Leather Shammy – Bowling Essential

Domain: reddit.com

Registered: 2005 (20 years)

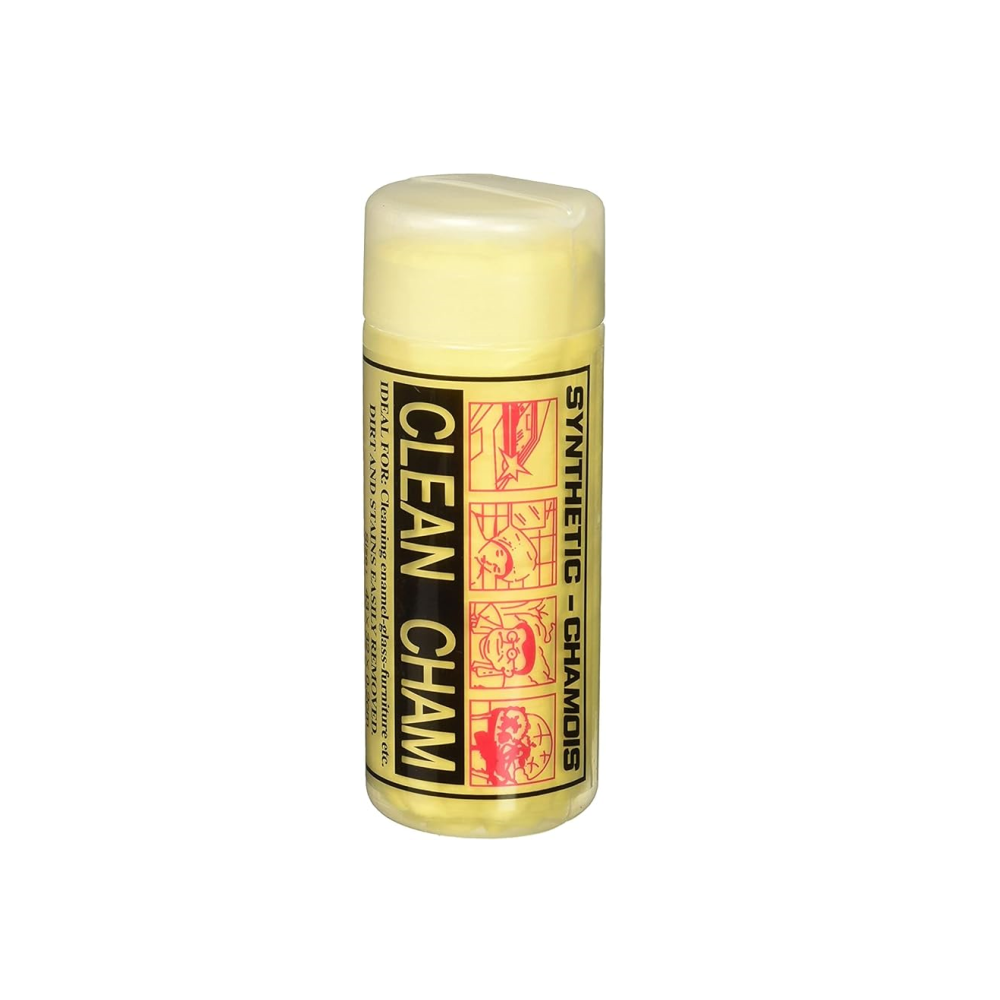

Introduction: Chamois Leather Shammy, used for bowling, can be cleaned with dish soap (Dawn recommended) and warm water. Users suggest working the shammy thoroughly to remove odors and maintain its softness. Alternatives include using a microfiber cloth or washing it in a washing machine followed by air drying.

3. PeachParts – Leather Chamois Cleaning Guide

Domain: peachparts.com

Registered: 2009 (16 years)

Introduction: To clean a leather chamois, use mild liquid dish soap and warm water. Soak and swish the chamois in the solution for 3 to 4 minutes. For stubborn stains, apply a small amount of liquid dish soap directly into the chamois fibers. Rinse thoroughly after 15 minutes. It is recommended to wash the chamois after the car has been thoroughly washed to avoid scratching the paint.

4. Meguiar’s – Natural Leather Chamois Care

Domain: meguiarsonline.com

Registered: 2003 (22 years)

Introduction: Natural leather chamois requires storage in airtight containers to prevent it from turning into a hard piece of cardboard and developing an unpleasant smell. It should be rinsed and hung to dry completely before storage, as storing it wet or damp can lead to rot and mildew. Synthetic chamois are easier to care for and can be hung to dry; they become stiff when dry but regain softness when wet. Som…

5. AutoGeek – Black Magic Chamois

Domain: autogeekonline.net

Registered: 2006 (19 years)

Introduction: Synthetic chamois, specifically a black magic chamois similar to the Absorber. Recommended cleaning method includes using a mild soap like Woolite and rinsing thoroughly. Alternative drying towels mentioned include Microfibre waffle weave drying towels, which are machine washable and do not trap debris, making them safer for paint. The Ultimate Guzzler Waffle Weave Microfiber Drying Towel and Cobr…

6. Chamois – Edge Detailing Tool

Domain: community.windowcleaner.com

Registered: 1998 (27 years)

Introduction: Chamois is used primarily for detailing edges in window cleaning. It is not recommended for wiping squeegees or picking up slop, as those functions are better suited for natural sea sponges or scrims. To clean a chamois in the field, it should be dipped in soapy water, stomped on a concrete surface, rinsed in clean water, and wrung out multiple times. A good quality chamois should cost around $25,…

7. Trifive – Silicone Water Blade Squeegee

Domain: trifive.com

Registered: 2005 (20 years)

Introduction: Silicone water blade, Automotive wiper blade squeegee, 10 Inch Black for car vehicle windshield window washing cleaning, synthetic chamois (Absorber), polyvinyl alcohol, can be washed in a washing machine with detergent, no softener, stored in a plastic tube.

Strategic Sourcing Conclusion and Outlook for clean a chamois

In the competitive landscape of chamois sourcing, understanding the nuances of care and maintenance is paramount for extending the product’s lifespan and performance. Proper preparation, cleaning techniques, and storage practices are essential for maintaining the integrity of chamois, whether used in automotive detailing or other applications. By sourcing high-quality chamois and adhering to best practices in maintenance, businesses can ensure optimal performance while minimizing replacement costs.

Strategic sourcing in this sector not only enhances product quality but also fosters sustainable relationships with suppliers, enabling businesses to capitalize on market opportunities across diverse regions, including Africa, South America, the Middle East, and Europe. As international buyers increasingly seek reliable suppliers, it is vital to prioritize quality assurance and transparency in sourcing practices.

Looking ahead, the demand for high-performance cleaning products, such as chamois, is poised to grow. Businesses should leverage this opportunity by investing in quality sourcing and comprehensive training for their teams on maintenance protocols. By doing so, they can position themselves as leaders in their markets and enhance customer satisfaction. Now is the time to take action—evaluate your sourcing strategy and commit to quality chamois solutions that will drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to clean a chamois

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.