Introduction: Navigating the Global Market for perforated seat covers

In the dynamic world of automotive accessories, sourcing high-quality perforated seat covers that combine style, comfort, and functionality can be a daunting challenge for international B2B buyers. With an increasing demand for products that not only enhance vehicle aesthetics but also provide durability and protection, understanding the nuances of the global market is essential. This guide aims to demystify the complexities associated with perforated seat covers, offering insights into various types, applications, and the key considerations for supplier vetting.

Navigating through the myriad options available, buyers will gain a comprehensive understanding of the unique features of perforated seat covers, including breathability, ease of installation, and compatibility with modern vehicle safety systems. Additionally, the guide addresses critical factors such as cost analysis, market trends, and regional preferences, particularly for buyers from Africa, South America, the Middle East, and Europe, including markets like Germany and Vietnam.

By equipping stakeholders with actionable insights and strategic approaches to sourcing, this guide empowers B2B buyers to make informed purchasing decisions. Whether enhancing fleet vehicles or retail offerings, understanding the global landscape of perforated seat covers will help businesses elevate their product offerings and meet customer expectations effectively.

Table Of Contents

- Top 8 Perforated Seat Covers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for perforated seat covers

- Understanding perforated seat covers Types and Variations

- Key Industrial Applications of perforated seat covers

- 3 Common User Pain Points for ‘perforated seat covers’ & Their Solutions

- Strategic Material Selection Guide for perforated seat covers

- In-depth Look: Manufacturing Processes and Quality Assurance for perforated seat covers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘perforated seat covers’

- Comprehensive Cost and Pricing Analysis for perforated seat covers Sourcing

- Alternatives Analysis: Comparing perforated seat covers With Other Solutions

- Essential Technical Properties and Trade Terminology for perforated seat covers

- Navigating Market Dynamics and Sourcing Trends in the perforated seat covers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of perforated seat covers

- Strategic Sourcing Conclusion and Outlook for perforated seat covers

- Important Disclaimer & Terms of Use

Understanding perforated seat covers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Fit Perforated Covers | Tailored to specific vehicle models, breathable design | Automotive upholstery, fleet vehicles | Pros: Enhanced comfort, stylish appearance; Cons: Higher cost than universal options. |

| Premium Leatherette Covers | Soft, durable, and water-resistant; resembles real leather | Luxury vehicles, executive fleets | Pros: Elegant look, easy to clean; Cons: May require more maintenance than synthetic materials. |

| Heavy-Duty Ballistic Covers | Abrasion and puncture-resistant; ideal for rugged use | Construction, transportation sectors | Pros: Extreme durability, excellent for heavy wear; Cons: Heavier fabric may be less comfortable. |

| Neoprene Perforated Covers | Water-resistant, cushioned feel, sporty appearance | Active lifestyle vehicles, outdoor use | Pros: Great for spills, easy to install; Cons: Can be warmer in hot climates. |

| Tactical Fabric Covers | Designed for military and outdoor applications | Emergency services, military vehicles | Pros: High durability, functional design; Cons: Limited aesthetic options. |

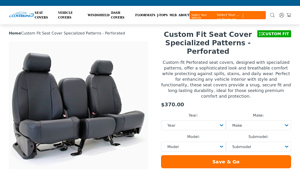

What are the Characteristics of Custom Fit Perforated Seat Covers?

Custom fit perforated seat covers are designed specifically for individual vehicle makes and models, ensuring a snug fit that maintains the full functionality of the seats, including airbag compatibility. Their breathable perforated design enhances comfort, making them suitable for a variety of climates. B2B buyers in the automotive sector often choose these covers for fleet vehicles, as they provide both protection and an upgraded interior appearance. When purchasing, consider the exact specifications of the vehicle and the desired aesthetic.

How Do Premium Leatherette Covers Compare in B2B Applications?

Premium leatherette covers offer a luxurious appearance while being durable and easy to clean. This type of cover is particularly popular in luxury vehicles and executive fleets, where image and comfort are paramount. They provide a balance of elegance and practicality, which appeals to companies looking to enhance their brand image through their vehicle interiors. Buyers should assess the maintenance requirements and ensure the material aligns with their operational needs.

Why Choose Heavy-Duty Ballistic Covers for Rugged Applications?

Heavy-duty ballistic covers are engineered to withstand extreme conditions, making them ideal for vehicles used in construction or transportation sectors. Their abrasion and puncture-resistant properties ensure longevity, even in the most demanding environments. While these covers are excellent for heavy wear, buyers should consider their weight and potential impact on comfort during long trips. Investing in these covers can significantly reduce replacement costs due to wear and tear.

What Benefits Do Neoprene Perforated Covers Offer?

Neoprene perforated seat covers provide a sporty aesthetic along with water resistance, making them suitable for vehicles used in active lifestyles or outdoor adventures. Their cushioned feel enhances comfort, appealing to B2B buyers in industries related to recreation and adventure. However, it’s essential to consider their performance in hot climates, as neoprene can retain heat. Buyers should weigh the benefits of comfort against potential climate limitations.

What Makes Tactical Fabric Covers Ideal for Specialized Uses?

Tactical fabric covers are designed for military and emergency service vehicles, emphasizing durability and functionality over aesthetics. These covers can withstand harsh environments and provide practical features that are essential for operational readiness. While they may lack in style, their resilience makes them a worthwhile investment for organizations prioritizing functionality. Buyers should evaluate the specific needs of their operational environment when selecting these covers.

Key Industrial Applications of perforated seat covers

| Industry/Sector | Specific Application of Perforated Seat Covers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom-fit seat covers for vehicle production | Enhances vehicle aesthetics and comfort, increasing market appeal | Material durability, customization options, airbag compatibility |

| Transportation Services | Seat covers for commercial fleets (taxis, buses) | Protects seats from wear and tear, improving vehicle longevity | Bulk purchasing options, ease of installation, maintenance support |

| Hospitality | Seat covers for rental cars and hotel shuttles | Maintains cleanliness and comfort, enhancing guest experience | Variety of styles, stain resistance, ease of cleaning |

| Agriculture & Mining | Protective seat covers for heavy machinery | Reduces maintenance costs and extends equipment life | Resistance to extreme conditions, custom designs for machinery seats |

| Marine Industry | Seat covers for boats and yachts | Protects against moisture and UV damage, ensuring longevity | Waterproof materials, UV resistance, tailored fit for marine seating |

How Are Perforated Seat Covers Used in Automotive Manufacturing?

In the automotive manufacturing sector, perforated seat covers are utilized as custom-fit solutions for vehicle interiors. These covers enhance the aesthetic appeal of vehicles while providing essential comfort features. By offering protection against spills, stains, and wear, manufacturers can improve vehicle longevity and customer satisfaction. Buyers in this sector should consider factors such as material durability and customization options that align with specific vehicle models, ensuring airbag compatibility and maintaining seat functionality.

What Role Do Perforated Seat Covers Play in Transportation Services?

Transportation services, including taxis and buses, benefit significantly from the use of perforated seat covers. These covers protect seats from the daily wear and tear that comes with high passenger turnover, ultimately reducing maintenance costs. Additionally, the breathable design enhances passenger comfort during rides. B2B buyers in this sector should focus on bulk purchasing options and ease of installation, as well as maintenance support to ensure long-term usability and cleanliness.

How Are Perforated Seat Covers Applied in the Hospitality Industry?

In the hospitality industry, perforated seat covers are commonly used in rental cars and hotel shuttle services. They help maintain a clean and comfortable environment for guests, ensuring a positive experience from the moment they enter the vehicle. The variety of styles available allows businesses to match their branding while offering a practical solution to seat protection. When sourcing these covers, it is vital to prioritize stain resistance and ease of cleaning, as high turnover rates necessitate quick maintenance.

Why Are Perforated Seat Covers Important in Agriculture and Mining?

In agriculture and mining, heavy machinery is often subjected to extreme conditions. Perforated seat covers provide a robust solution to protect seats from dirt, moisture, and wear, significantly reducing maintenance costs and extending the life of the equipment. Buyers in this sector should seek covers that are resistant to harsh conditions and can be customized to fit various machinery models, ensuring maximum durability and comfort for operators.

How Do Perforated Seat Covers Benefit the Marine Industry?

In the marine industry, perforated seat covers are essential for protecting boat and yacht seating from moisture and UV damage. This added layer of protection not only enhances the longevity of the seats but also ensures comfort for passengers during outings. Buyers should focus on sourcing waterproof materials with UV resistance and tailored fits to accommodate various marine seating configurations, thereby ensuring that the investment in seat covers pays off through extended service life and reduced replacement costs.

3 Common User Pain Points for ‘perforated seat covers’ & Their Solutions

Scenario 1: Difficulty in Achieving a Perfect Fit for Diverse Vehicle Models

The Problem:

B2B buyers often face the challenge of sourcing perforated seat covers that offer a perfect fit across a wide range of vehicle models. This is particularly true for companies that manage fleets with vehicles from various manufacturers. A poorly fitting seat cover can lead to customer dissatisfaction due to aesthetic issues and functional concerns, such as compatibility with safety features like airbags. Additionally, the time and cost associated with returns or replacements can significantly impact the bottom line.

The Solution:

To effectively address this issue, B2B buyers should prioritize suppliers that provide custom-fit options tailored specifically to each vehicle’s make and model. When sourcing perforated seat covers, look for manufacturers that utilize advanced CAD/CAM technology for precise pattern creation. This ensures that the covers fit seamlessly, maintaining the functionality of seat features and enhancing the overall vehicle interior. Additionally, consider requesting samples or detailed installation guides to evaluate the fit and ease of installation before committing to a bulk order. Establishing a strong relationship with a reliable supplier can also facilitate better communication regarding specific fit requirements.

Scenario 2: Concerns Over Durability and Maintenance of Perforated Seat Covers

The Problem:

Another significant pain point for B2B buyers is the durability of perforated seat covers, especially in environments prone to wear and tear, such as commercial fleets or vehicles used in harsh conditions. Buyers are often wary of investing in products that may not withstand daily use or be difficult to clean, leading to higher maintenance costs and potential damage to the underlying seats.

Illustrative image related to perforated seat covers

The Solution:

To mitigate these concerns, B2B buyers should seek out perforated seat covers made from high-quality, commercial-grade materials that are specifically designed for durability and ease of maintenance. Look for products that feature water-resistant and stain-resistant properties, as these will be easier to clean and maintain over time. Additionally, manufacturers that offer warranties on their products can provide added assurance of their durability. Implementing a regular maintenance schedule for seat covers, including routine cleaning with recommended products, will also help prolong the life of the covers and maintain a professional appearance.

Scenario 3: Balancing Comfort and Breathability with Aesthetic Appeal

The Problem:

Many B2B buyers struggle to find perforated seat covers that effectively balance comfort, breathability, and aesthetic appeal. In sectors where vehicles are used for client-facing roles, the interior appearance plays a crucial role in brand perception. Buyers may find that opting for more breathable materials compromises the visual appeal or luxury feel they aim to project.

The Solution:

To achieve a balance between comfort, breathability, and aesthetic appeal, B2B buyers should consider perforated seat covers that utilize premium materials such as high-grade leatherette or specially engineered fabrics. These materials can provide a sophisticated look while ensuring adequate airflow for comfort during prolonged use. Buyers should also explore customizable options that allow for color and pattern selection to match branding requirements. Engaging with suppliers that offer a range of styles and finishes can help buyers find the ideal solution that meets both functional and aesthetic needs. Additionally, requesting feedback from end-users can guide selections, ensuring that the final choice resonates well with both comfort and design preferences.

Strategic Material Selection Guide for perforated seat covers

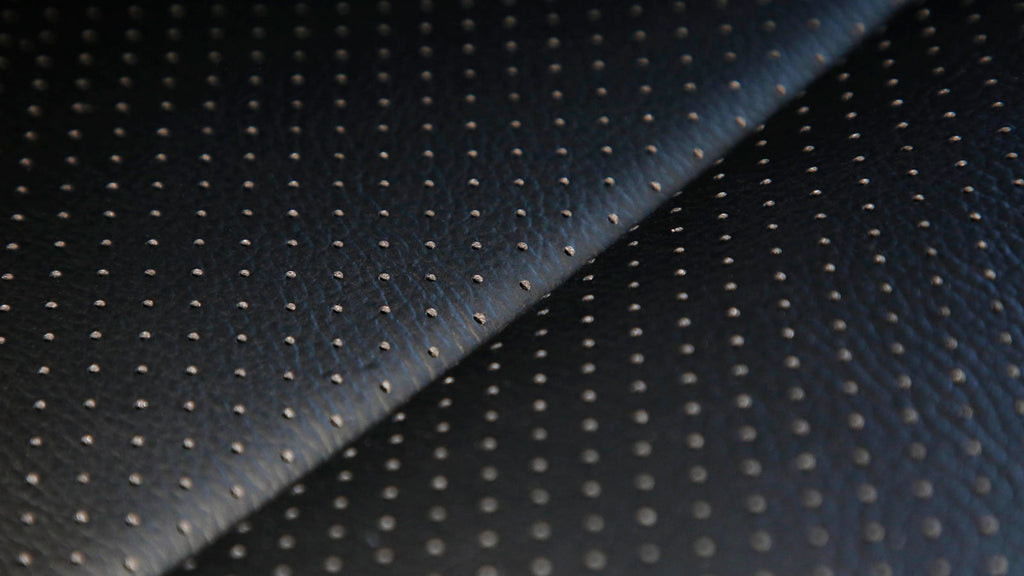

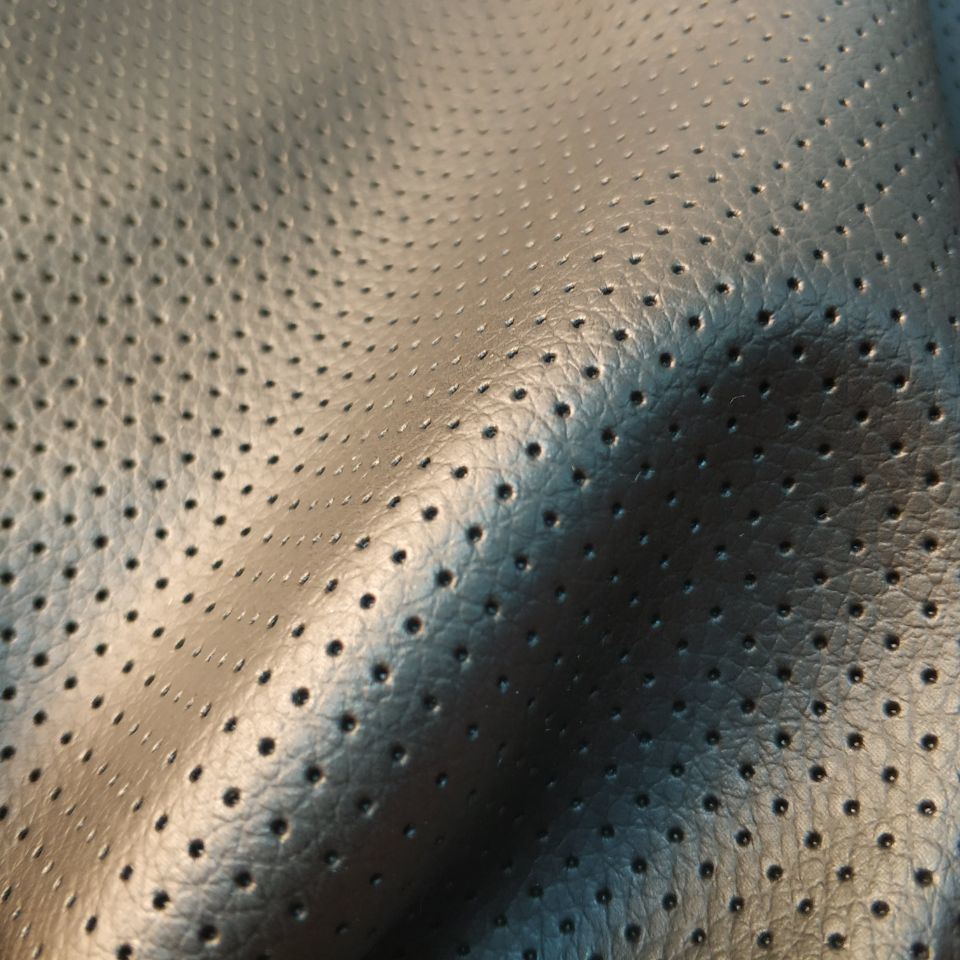

What Are the Key Materials Used for Perforated Seat Covers?

When selecting perforated seat covers, the choice of material significantly influences performance, durability, and overall user satisfaction. Here, we analyze four common materials used in the manufacturing of perforated seat covers, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Neoprene

Key Properties: Neoprene is a synthetic rubber known for its excellent elasticity, resistance to water, and durability under various temperature conditions. It maintains its integrity from -40°F to 200°F and is resistant to UV rays and ozone.

Pros & Cons: Neoprene seat covers are highly durable and provide excellent protection against spills and stains. However, they can be more expensive than other materials, which may impact budget considerations for B2B buyers. Additionally, the manufacturing process for neoprene can be complex, requiring specialized equipment.

Impact on Application: Neoprene is particularly suitable for environments where moisture is prevalent, such as in vehicles used in coastal regions or for outdoor activities.

Considerations for International Buyers: Compliance with international standards such as ASTM D412 for tensile strength and ASTM D624 for tear resistance is crucial. Buyers from regions like Africa and South America should also consider local climatic conditions that may affect material performance.

2. Leatherette

Key Properties: Leatherette, or synthetic leather, mimics the appearance of genuine leather while being more cost-effective and easier to clean. It typically offers good resistance to wear and tear and can withstand moderate pressure.

Pros & Cons: The primary advantage of leatherette is its aesthetic appeal, providing a luxurious look without the high cost of genuine leather. However, it may not be as breathable as other materials, potentially leading to discomfort in hot climates.

Illustrative image related to perforated seat covers

Impact on Application: Leatherette is suitable for high-end vehicles or commercial fleets where appearance matters, but it may not perform as well in extreme weather conditions.

Considerations for International Buyers: Buyers should ensure that the leatherette complies with relevant standards such as DIN 53330 for abrasion resistance. In regions like Europe, adherence to REACH regulations regarding chemical safety is also essential.

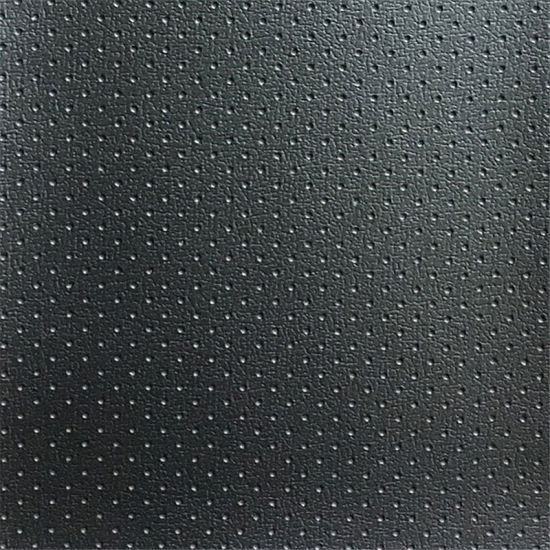

3. Polyester

Key Properties: Polyester is a synthetic fabric known for its strength, durability, and resistance to shrinking and stretching. It offers good moisture-wicking properties and can withstand a wide range of temperatures.

Pros & Cons: Polyester seat covers are generally more affordable and provide excellent durability, making them suitable for everyday use. However, they may not offer the same level of comfort as more breathable materials, which can be a drawback in hotter climates.

Illustrative image related to perforated seat covers

Impact on Application: Polyester is ideal for vehicles used in urban environments where wear and tear from daily use is a concern. Its resistance to fading makes it suitable for vehicles exposed to sunlight.

Considerations for International Buyers: Compliance with JIS L 1096 for fabric testing and durability is critical. Buyers from the Middle East should consider the material’s UV resistance due to high sun exposure.

4. Ballistic Nylon

Key Properties: Ballistic nylon is a heavy-duty fabric originally developed for military use. It is known for its exceptional abrasion resistance and durability, making it suitable for high-wear applications.

Pros & Cons: The key advantage of ballistic nylon is its ability to withstand heavy use, making it ideal for vehicles used in rugged conditions. However, it can be heavier and more expensive than other options, which may deter some buyers.

Impact on Application: This material is particularly suited for commercial vehicles or those used in construction and outdoor activities, where durability is paramount.

Illustrative image related to perforated seat covers

Considerations for International Buyers: Buyers should verify compliance with ASTM D5034 for tearing strength and durability. In regions with varying climates, such as Europe and South America, the fabric’s performance under different weather conditions should be evaluated.

Summary Table

| Matériau | Typical Use Case for perforated seat covers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Neoprene | Outdoor and water-prone vehicles | Excellent water resistance and durability | Higher cost and complex manufacturing | Haut |

| Leatherette | High-end vehicles and commercial fleets | Luxurious appearance at lower cost | Less breathable, may cause discomfort | Medium |

| Polyester | Everyday urban vehicles | Affordable and durable | Less comfort in hot climates | Low |

| Ballistic Nylon | Commercial and rugged-use vehicles | Exceptional durability | Heavier and more expensive | Haut |

This guide serves as a strategic resource for international B2B buyers looking to make informed decisions regarding the material selection for perforated seat covers, ensuring that the chosen material aligns with their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for perforated seat covers

What Are the Key Stages in the Manufacturing Process of Perforated Seat Covers?

The manufacturing process for perforated seat covers is a meticulous journey that combines advanced technology with skilled craftsmanship. This process typically involves several key stages: material preparation, forming, assembly, and finishing.

1. Material Preparation

The first step in manufacturing perforated seat covers is selecting high-quality materials that offer durability, comfort, and aesthetic appeal. Common materials include neoprene, leatherette, and polyester blends, each chosen for specific properties such as water resistance, breathability, and ease of cleaning.

Illustrative image related to perforated seat covers

Once the materials are selected, they undergo a preparation phase where they are cut into the required shapes and sizes. Advanced CAD (Computer-Aided Design) software is often used to create precise patterns that correspond to the specific make and model of vehicles. This ensures that the seat covers fit perfectly, maintaining functionality for features like airbags and adjustable seating.

2. Forming Techniques for Perforated Designs

The next stage is forming, where the prepared materials are shaped into the desired design. For perforated seat covers, this involves creating holes in the fabric to enhance breathability and comfort. Techniques such as laser cutting or mechanical perforation are employed to ensure accuracy and uniformity in the perforations.

The formation stage also includes stitching, which is crucial for durability and aesthetic appeal. High-strength threads are used to sew the pieces together, often employing double-stitching methods to reinforce seams and prevent fraying.

3. Assembly of Seat Covers

Once the individual components are formed, they proceed to the assembly stage. Here, the various parts, including covers for headrests and armrests, are joined together. This process may involve further stitching, attachment of straps, and ensuring that all components are aligned correctly.

Illustrative image related to perforated seat covers

Quality control checkpoints are integrated into this stage. Operators perform visual inspections and functional tests to ensure that the seat covers meet the design specifications and are free from defects.

4. Finishing Touches

The final stage is finishing, where the seat covers undergo a series of treatments to enhance their appearance and functionality. This may include additional coatings for UV protection, stain resistance, or water repellency.

The finishing process also involves packaging the products for shipment. Each seat cover is carefully folded and placed in protective packaging to prevent damage during transportation.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is a critical aspect of manufacturing perforated seat covers, ensuring that every product meets international standards and customer expectations.

International Standards and Compliance

Most manufacturers adhere to international quality management standards such as ISO 9001. This standard outlines requirements for a quality management system (QMS) that consistently ensures product quality and enhances customer satisfaction.

Illustrative image related to perforated seat covers

In addition to ISO certifications, industry-specific standards such as CE (European Conformity) and API (American Petroleum Institute) may apply, particularly if the seat covers are designed for specialized applications or markets.

Key Quality Control Checkpoints in the Manufacturing Process

Quality control (QC) is implemented at various stages of the manufacturing process, often categorized into three main checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery to ensure they meet specified standards. Materials that do not meet quality criteria are rejected.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators conduct regular inspections to monitor production quality. This includes checking for uniform perforation sizes, stitch quality, and adherence to design specifications.

-

Final Quality Control (FQC): Once the seat covers are fully assembled, a final inspection is performed. This includes testing for functionality (e.g., fit and usability) and visual inspections for any defects or inconsistencies.

Common Testing Methods Used in Quality Assurance

Manufacturers utilize a variety of testing methods to ensure product quality, including:

- Durability Testing: Assessing the material’s resistance to wear and tear, including abrasion and tensile strength tests.

- Water Resistance Testing: Evaluating the material’s ability to repel water and resist stains.

- UV Resistance Testing: Ensuring that materials maintain their color and integrity when exposed to sunlight.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

B2B buyers should conduct thorough due diligence when evaluating suppliers of perforated seat covers. Here are actionable steps to verify a supplier’s quality assurance practices:

Supplier Audits and Certifications

Requesting audits of the supplier’s manufacturing facilities can provide insight into their quality management processes. Look for certifications such as ISO 9001, which indicate adherence to international quality standards.

Review Quality Reports and Documentation

Ask suppliers for quality assurance reports that detail their QC processes, testing methods, and inspection results. This documentation can provide transparency regarding their manufacturing practices and quality outcomes.

Third-Party Inspections

Engaging third-party inspection services can further validate the supplier’s quality claims. These independent entities can assess the manufacturing process and product quality, providing an unbiased evaluation.

What Are the Quality Control Nuances for International B2B Buyers?

For international buyers, particularly those from diverse regions like Africa, South America, the Middle East, and Europe, understanding quality control nuances is vital.

Regulatory Compliance and Market Standards

Different regions may have specific regulatory requirements for automotive products, including seat covers. Buyers must ensure that suppliers comply with local regulations and standards, which may differ significantly from those in their home countries.

Illustrative image related to perforated seat covers

Cultural and Logistical Considerations

Cultural differences may affect communication and expectations regarding quality. Buyers should establish clear quality criteria and maintain open lines of communication with suppliers to mitigate misunderstandings.

Additionally, logistical considerations, such as shipping times and customs regulations, can impact the delivery of quality products. Ensuring that suppliers have robust logistics management can help maintain quality throughout the supply chain.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing perforated seat covers, ultimately leading to enhanced customer satisfaction and product performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘perforated seat covers’

Introduction

This sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure perforated seat covers. Whether you are enhancing vehicle interiors for a fleet or retailing high-quality automotive accessories, following these steps will help ensure you make informed purchasing decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for sourcing the right perforated seat covers. Consider factors such as material composition, fitment types, and compatibility with vehicle features like airbags and seat adjustments. Clearly defined specifications will help you communicate effectively with suppliers and ensure that the products meet your operational requirements.

Illustrative image related to perforated seat covers

Step 2: Research Supplier Capabilities

Conduct thorough research on potential suppliers to gauge their capabilities in producing perforated seat covers. Look for suppliers that offer customization options, as this can enhance the fit and aesthetics for specific vehicle models. Additionally, evaluate their production capacity to ensure they can meet your volume demands within your required timelines.

Step 3: Evaluate Material Quality

The material quality of perforated seat covers directly impacts durability and comfort. Ensure that the supplier provides high-quality fabrics that resist wear and tear, spills, and UV exposure. Consider requesting samples to assess the texture, breathability, and overall quality before making a bulk order.

Step 4: Verify Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with industry standards. This includes checking for ISO certifications, material safety data sheets (MSDS), and any relevant environmental certifications. Such verification not only ensures product quality but also helps mitigate risks associated with non-compliance in your target markets.

Step 5: Request Detailed Quotations

When you have shortlisted suppliers, request detailed quotations that include pricing, lead times, and shipping options. Compare these quotations not only on cost but also on the value provided, such as warranty periods and after-sales support. Transparent pricing structures can help you avoid hidden costs later in the procurement process.

Step 6: Assess Customer Support and Communication

Effective communication and customer support are vital for a successful supplier relationship. Evaluate how responsive suppliers are to your inquiries and their willingness to provide ongoing support throughout the procurement process. A supplier that prioritizes communication can facilitate smoother transactions and help address any issues that may arise post-purchase.

Step 7: Conduct a Trial Order

Before committing to a large order, consider placing a trial order to assess the supplier’s reliability and product quality. This step allows you to evaluate the seat covers in real-world conditions and determine if they meet your specifications and expectations. A trial order can also reveal any potential issues with shipping or product consistency before scaling up your procurement efforts.

By following these steps, B2B buyers can streamline the sourcing process for perforated seat covers, ensuring they select the right products and suppliers to enhance their business offerings.

Comprehensive Cost and Pricing Analysis for perforated seat covers Sourcing

What Are the Key Cost Components in Sourcing Perforated Seat Covers?

When sourcing perforated seat covers, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of fabric significantly impacts costs. High-quality materials like leatherette or specialized neoprene provide durability and comfort but come at a premium. Perforated designs often require more advanced textiles, which can increase material costs.

-

Labor: Skilled labor is necessary for the precision tailoring of custom-fit seat covers. Labor costs can vary based on the manufacturing location and the complexity of the patterns being created.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. A well-optimized manufacturing process can help reduce these overheads, affecting the overall pricing.

-

Tooling: Creating custom molds or patterns for specific vehicle models incurs tooling costs. These costs can be amortized over larger production runs, making them less significant on a per-unit basis for high-volume orders.

-

Quality Control (QC): Ensuring that products meet quality standards is vital. QC processes can involve additional labor and materials, thus influencing the final price of the seat covers.

-

Logistics: Shipping costs can vary widely depending on the destination and shipping method. International buyers should be aware of potential tariffs and customs duties that could further affect pricing.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding industry standards can help buyers evaluate whether they are receiving a fair price.

How Do Price Influencers Impact the Cost of Perforated Seat Covers?

Several factors can influence the pricing of perforated seat covers, including:

-

Volume and Minimum Order Quantity (MOQ): Ordering in bulk often leads to lower per-unit costs. Suppliers may set MOQs that can affect pricing flexibility for smaller buyers.

-

Specifications and Customization: Custom designs or specific vehicle fits can increase costs. The more unique the requirements, the higher the price due to additional labor and material needs.

-

Material Quality and Certifications: Higher-quality materials and products with certifications (e.g., fire-resistant, UV protection) will generally command higher prices. Buyers should weigh the benefits of these features against their budget.

-

Supplier Factors: Established suppliers with a good reputation may charge more due to perceived quality and reliability. Newer or less established suppliers may offer lower prices but could come with risks regarding quality and service.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) can impact total costs. Buyers should understand their responsibilities under different terms to avoid unexpected expenses.

What Are the Best Buyer Tips for Cost-Efficient Sourcing of Perforated Seat Covers?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following tips for effective sourcing:

-

Negotiation: Always engage in negotiations with suppliers. Understanding the cost components allows buyers to negotiate better terms, especially for larger orders.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with installation, maintenance, and potential replacements. Higher-quality products may have a higher upfront cost but can lead to savings over time.

-

Pricing Nuances for International Buyers: Understand regional market dynamics, including currency fluctuations and trade policies, which can affect pricing. Buyers should also consider local suppliers who may offer more competitive rates due to lower shipping costs.

-

Request Samples: Before placing large orders, request samples to assess quality. This can prevent costly mistakes and ensure that the product meets expectations.

-

Stay Informed on Market Trends: Keep abreast of industry trends and supplier innovations that may provide opportunities for cost savings or enhanced product features.

By understanding these components and employing strategic purchasing practices, B2B buyers can effectively navigate the complexities of sourcing perforated seat covers while optimizing their costs.

Alternatives Analysis: Comparing perforated seat covers With Other Solutions

Exploring Alternatives to Perforated Seat Covers for Vehicle Protection

In the competitive landscape of vehicle interior protection, perforated seat covers offer a unique blend of style, comfort, and functionality. However, several alternatives can also provide similar benefits. This analysis compares perforated seat covers with other viable options, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Perforated Seat Covers | Neoprene Seat Covers | Ballistic Seat Covers |

|---|---|---|---|

| Performance | Excellent breathability, protects against spills and UV rays | Highly water-resistant, provides cushioning | Superior durability, abrasion-resistant, tough against wear |

| Cost | $370 | $330 | $300 |

| Ease of Implementation | Easy installation with included kit | Moderate, requires some effort | Moderate, may need professional installation |

| Maintenance | Simple cleaning, long-lasting | Easy to clean, water-resistant | Requires regular cleaning to maintain appearance |

| Best Use Case | Luxury and comfort-focused vehicles | Active lifestyles, water exposure | Commercial vehicles, heavy-duty use |

What Are the Advantages and Disadvantages of Neoprene Seat Covers?

Neoprene seat covers are renowned for their water-resistant properties, making them an excellent choice for vehicles frequently exposed to spills or wet conditions. They provide a snug fit and a cushioned feel, similar to high-end wetsuits, which enhances comfort during long drives. However, their installation can be moderately challenging, requiring a bit more effort compared to perforated seat covers. Additionally, while neoprene is durable, it may not offer the same level of breathability, potentially leading to heat retention in warmer climates.

Illustrative image related to perforated seat covers

How Do Ballistic Seat Covers Stack Up Against Perforated Options?

Ballistic seat covers are designed for extreme durability, making them ideal for commercial applications or families with kids and pets. Their construction includes dense, water-resistant fabric that resists abrasions and punctures, ensuring they withstand heavy use. While they excel in toughness, their aesthetic may not be as refined as perforated seat covers, which offer a more stylish appearance. Installation can also be moderately complex, and regular maintenance is required to keep them looking their best.

Conclusion: Which Vehicle Interior Protection Solution is Right for Your Business?

When choosing between perforated seat covers and their alternatives, consider your specific needs and environment. Perforated seat covers are optimal for businesses seeking a blend of luxury and functionality, offering breathability and protection without compromising style. Neoprene seat covers are best for those in water-prone areas or active lifestyles, while ballistic seat covers cater to industries requiring maximum durability. Assessing your operational requirements, budget constraints, and desired aesthetics will guide you in selecting the right solution for your vehicle interior protection needs.

Essential Technical Properties and Trade Terminology for perforated seat covers

What Are the Key Technical Properties of Perforated Seat Covers?

When evaluating perforated seat covers for procurement, several critical specifications should be considered to ensure product quality and suitability for your market needs.

Illustrative image related to perforated seat covers

1. Material Grade

The material grade of a perforated seat cover significantly impacts its durability and comfort. Common materials include high-quality vinyl, Neosupreme, and genuine leather. Each material has its own advantages; for example, vinyl is water-resistant and easy to clean, while leather offers luxury and breathability. Understanding material grades helps buyers select products that align with customer expectations for quality and longevity.

2. Breathability and Air Circulation

The perforated design itself is a vital property, enhancing airflow and preventing heat buildup, which is especially important in warmer climates. This feature not only improves comfort for the end-user but also contributes to the longevity of the seat cover by reducing moisture accumulation. For B2B buyers, promoting breathable seat covers can be a key selling point in regions with high temperatures.

3. Custom-Fit Precision

A critical specification is the custom-fit design, which is achieved through advanced CAD/CAM technology. This ensures that the seat covers are tailored to the specific make, model, and year of the vehicle. For buyers, understanding the importance of custom fit is essential, as it guarantees ease of installation and functionality, including compatibility with airbags and seat adjustments.

4. UV Resistance

UV resistance is an important property, particularly for buyers in regions with intense sunlight. A seat cover that can withstand UV rays will not only maintain its appearance over time but also protect the vehicle’s original upholstery. This specification is crucial for buyers focused on long-term value and customer satisfaction.

Illustrative image related to perforated seat covers

5. Warranty and Durability Standards

The warranty period, often ranging from one to five years, indicates the manufacturer’s confidence in their product’s durability. Buyers should consider this when assessing product quality, as a longer warranty typically suggests higher material and manufacturing standards. This is a critical factor for B2B buyers looking to reduce return rates and enhance customer trust.

What Are Common Trade Terms Related to Perforated Seat Covers?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to perforated seat covers.

1. OEM (Original Equipment Manufacturer)

OEM refers to the company that produces parts or equipment that may be marketed by another manufacturer. In the context of seat covers, an OEM may be a vehicle manufacturer that specifies certain seat cover designs for their cars. Knowing OEM standards is crucial for buyers to ensure compatibility and quality.

Illustrative image related to perforated seat covers

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ helps B2B buyers gauge inventory levels and manage costs effectively. For those looking to enter new markets, knowing the MOQ can dictate the feasibility of purchasing specific styles or materials.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications for the products needed, such as material type, quantity, and delivery timelines. For buyers, issuing an RFQ can lead to better pricing and terms by encouraging competition among suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define responsibilities between buyers and sellers regarding shipping, insurance, and tariffs. For international buyers, understanding these terms is vital to clarify who bears the risk and cost at various stages of the shipping process, which can affect overall pricing and delivery timelines.

5. Lead Time

Lead time is the period between placing an order and receiving it. This term is especially important in B2B transactions, as it affects inventory management and customer satisfaction. Understanding lead times can help buyers plan their stock levels and marketing campaigns effectively.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that align with their business needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the perforated seat covers Sector

What Are the Key Trends Driving the Perforated Seat Covers Market?

The global market for perforated seat covers is experiencing significant growth, driven by an increasing demand for vehicle customization and comfort. Buyers from diverse regions, including Africa, South America, the Middle East, and Europe, are seeking products that not only enhance the aesthetic appeal of their vehicles but also provide functional benefits. Key trends influencing this market include the rising popularity of custom-fit solutions, which utilize advanced CAD/CAM technology to ensure precise fitment across various vehicle models. This trend caters particularly well to international buyers who prioritize seamless integration with existing vehicle features, such as airbags and adjustable seats.

Moreover, the integration of technology in manufacturing processes, such as 3D scanning and digital patterning, is becoming commonplace. This allows suppliers to offer tailored solutions that meet the specific needs of buyers, enhancing their competitive edge. Additionally, the demand for breathable materials that promote air circulation is on the rise, particularly in warmer climates, as buyers look for comfort in their vehicle interiors.

Another emerging trend is the focus on premium and durable materials that not only enhance the look and feel of the seats but also ensure long-lasting performance. This is particularly appealing to buyers in regions where vehicles are subject to harsher environmental conditions. The market dynamics indicate a shift towards more sustainable and ethically sourced materials, which resonates with the growing consumer awareness regarding environmental impact.

How Is Sustainability Influencing Sourcing Decisions for Perforated Seat Covers?

Sustainability is becoming a central consideration for B2B buyers in the perforated seat covers sector. The environmental impact of production processes and materials used in seat covers is under scrutiny, prompting buyers to seek suppliers who prioritize eco-friendly practices. This includes the use of recycled materials, low-impact manufacturing processes, and adherence to international environmental standards.

Ethical sourcing is equally important, as buyers are increasingly interested in ensuring that their suppliers maintain fair labor practices and transparency in their supply chains. This trend is particularly relevant for international buyers from regions like Europe, where regulations around sustainability and ethical sourcing are becoming stricter. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are gaining traction, as they assure buyers that materials used in seat covers meet environmental and safety standards.

Furthermore, the introduction of ‘green’ materials, such as biodegradable fabrics and water-based adhesives, is capturing the attention of B2B buyers. These materials not only reduce the environmental footprint of seat cover production but also appeal to a growing segment of eco-conscious consumers. Suppliers who incorporate sustainability into their offerings are likely to gain a competitive advantage in the marketplace, as they align with the values of modern buyers.

Illustrative image related to perforated seat covers

How Has the Perforated Seat Covers Market Evolved Over Time?

The evolution of the perforated seat covers market reflects broader trends in the automotive industry. Initially, seat covers were seen primarily as protective accessories, designed to shield upholstery from wear and tear. Over the years, however, they have transformed into stylish elements that enhance vehicle interiors.

The introduction of advanced materials and manufacturing technologies has enabled suppliers to offer custom-fit solutions that cater to the diverse needs of global buyers. The rise of digital patterning and 3D scanning has allowed for more precise fits and innovative designs, ensuring that seat covers not only protect but also enhance the overall driving experience.

As consumer preferences shift towards personalized and high-quality products, the market for perforated seat covers continues to grow, driven by innovation, sustainability, and a focus on comfort. International B2B buyers can benefit from this evolution by sourcing products that not only meet their functional needs but also align with their values regarding quality and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of perforated seat covers

-

1. How do I select the right perforated seat cover for my fleet?

To select the ideal perforated seat covers for your fleet, consider factors such as the specific vehicle models, the level of wear and tear expected, and the climate of your operating regions. Ensure that the covers are custom-fit to maintain functionality, including airbag compatibility. Evaluate materials for durability and breathability, especially in hot climates. Lastly, consider aesthetics and brand alignment, as a stylish interior can enhance your fleet’s image. -

2. What are the key benefits of using perforated seat covers in commercial vehicles?

Perforated seat covers offer numerous advantages for commercial vehicles. They enhance breathability, keeping seats cooler and more comfortable for drivers during long hours. Additionally, they provide excellent protection against spills, stains, and wear, which is crucial for maintaining the vehicle’s resale value. The custom-fit design ensures functionality is preserved, allowing for full seat adjustments and airbag deployment, making them a smart investment for any commercial fleet. -

3. What customization options are available for perforated seat covers?

Most manufacturers offer a range of customization options for perforated seat covers, including color, fabric type, and pattern design. You can also choose specific features such as reinforced stitching or additional padding for extra comfort. Some suppliers allow businesses to incorporate branding elements like logos or unique designs, which can enhance brand recognition. Be sure to discuss your specific requirements with potential suppliers to find the best fit for your needs. -

4. What is the minimum order quantity (MOQ) for perforated seat covers?

The MOQ for perforated seat covers can vary widely depending on the supplier and the level of customization required. Typically, manufacturers may set a MOQ ranging from 50 to 200 units for custom designs. It’s essential to communicate your needs clearly to suppliers, as some may be flexible with MOQs for larger orders or long-term contracts. Always confirm the MOQ before proceeding with an order to ensure it aligns with your purchasing capabilities. -

5. How can I ensure quality assurance when sourcing perforated seat covers?

To ensure quality assurance, select suppliers with established reputations and positive reviews in the industry. Request samples to evaluate the fabric, fit, and overall quality before placing a larger order. Inquire about their manufacturing processes, including any certifications or quality control measures they employ. Additionally, consider conducting factory visits or audits if feasible, especially for significant investments, to verify the supplier’s capabilities. -

6. What payment terms should I expect when ordering perforated seat covers internationally?

Payment terms for international orders of perforated seat covers can vary by supplier. Common arrangements include a deposit upfront (often 30-50%) with the balance due before shipping. Some suppliers may offer net payment terms, such as net 30 or net 60, depending on your relationship and order size. It’s important to clarify these terms in advance and ensure they align with your cash flow needs. Always consider using secure payment methods to mitigate risks. -

7. How does shipping and logistics work for international orders of perforated seat covers?

Shipping and logistics for international orders typically involve several steps, including freight forwarding, customs clearance, and final delivery. Suppliers may offer different shipping options, such as air or sea freight, which will affect delivery times and costs. Be sure to discuss logistics in detail with your supplier, including who will handle customs duties and taxes. It’s advisable to work with experienced freight forwarders to navigate international shipping regulations effectively. -

8. What are the common challenges in sourcing perforated seat covers internationally?

Common challenges in sourcing perforated seat covers internationally include language barriers, varying quality standards, and differences in manufacturing practices. Additionally, navigating customs regulations can be complex, leading to potential delays or unexpected costs. To mitigate these challenges, it’s crucial to conduct thorough supplier vetting, maintain clear communication, and establish detailed contracts outlining specifications, timelines, and responsibilities. Building strong relationships with suppliers can also help in addressing issues proactively.

Top 8 Perforated Seat Covers Manufacturers & Suppliers List

1. Coverking – Custom Fit Seat Covers

Domain: coverking.com

Registered: 1996 (29 years)

Introduction: This company, Coverking – Custom Fit Seat Covers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Coverking – Perforated Vinyl Custom Seat Covers

Domain: carcoverusa.com

Registered: 2005 (20 years)

Introduction: Coverking Perforated Vinyl Custom Seat Covers, Price: $369.99, Specialized Patterns, Best for heated and cooled seats, Made from high-grade vinyl, Soft and supple, Resists UV damage, stains, mildew, and rot, Good water resistance, Easy to clean, Tight fit to resist slippage, Soft Real Leather Feel, High durability, Perfect fitting, Precision design for full seat functionality, Includes covers for …

3. Ruff Tuff – Custom Seat Covers

Domain: rufftuff.com

Registered: 1996 (29 years)

Introduction: Perforated Sof-Touch Custom Seat Covers; Free shipping on orders over $400; Custom seat covers for cars, trucks, SUVs, and UTVs; Features include: Airbags, Insert & Trim, Foam Backing, Controls & Comfort; Special features: Flex OPS™ Package, Pistol Pockets, Front & Rear Pockets, Headrest Covers, Armrests & Consoles; Available fabrics: Camo, Carbon Fiber, Dura EZ-Care, Exotics, Perforated Sof-Touch…

4. Clazzio – PVC Type Leather Seat Covers

Domain: clazzio.com

Registered: 2009 (16 years)

Introduction: Product Name: PVC Type – Clazzio Leather Seat Covers

Material: Perforated PVC (Vegan Friendly, no leather used)

Available Colors: Black, Dark Gray, Light Gray, Beige

Warranty: 1 Year Warranty on Full PVC seat cover (Fitment Guaranteed)

Durability: Consider upgrading to Leather for better durability (3 Year Warranty)

Seat Cover Composition: Whole seat cover is PVC; body is smooth PVC, middle insert…

5. Luxury Seat Covers – Exceptional Comfort & Protection

Domain: seatcoversolutions.com

Registered: 2023 (2 years)

Introduction: Product Name: Luxury Seat Covers

Key Features:

– Exceptional Comfort and Protection: Designed to enhance driving experience and protect vehicle interior.

– Comfort Enhancement: Superior cushioning and support for a pleasant journey.

– 1-Year Warranty: Assurance of quality and reliability.

– Easy Installation: User-friendly installation in less than an hour.

– Year-Round Comfort: Breathable materia…

6. Coverking – Perforated Leatherette Seat Covers

Domain: carcoverworld.com

Registered: 2002 (23 years)

Introduction: Product Name: Coverking Perforated Leatherette Seat Covers

Material: High-grade vinyl (soft and supple, resembles real leather)

Caractéristiques :

– 100% Breathable

– Perforated design suitable for heated and cooled seats

– Resists UV damage, stains, mildew, and rot

– Good water resistance and easy to clean

– Custom-fit design for full seat functionality (includes headrests, armrests, consoles, and map po…

7. Arvind Car Accessories – Perforated Leather Seat Covers

Domain: arvindcaraccessories.com

Registered: 2020 (5 years)

Introduction: Perforated leather seat covers are made from high-quality leather with small holes for increased airflow and breathability. They enhance comfort while driving, prevent seats from becoming hot or sticky, and add a stylish touch to the car’s interior. Available in various colors and styles, they are durable, easy to clean, and provide protection against wear and tear. Benefits include improved airfl…

8. Clazzio – Perforated Leather Seat Covers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Clazzio Perforated Leather seat covers; installation cost: $600 for all seats, headrests, and center console; center section made of perforated leather, rest is vinyl; easy installation noted even with a sprained thumb.

Strategic Sourcing Conclusion and Outlook for perforated seat covers

In the competitive landscape of automotive accessories, perforated seat covers emerge as a vital component for enhancing vehicle aesthetics and functionality. By investing in custom-fit, high-quality seat covers, B2B buyers can ensure not only the protection of vehicle interiors but also an elevated driving experience for end-users. Key factors such as breathability, durability, and style significantly influence purchasing decisions, making strategic sourcing essential for aligning with market demands.

Illustrative image related to perforated seat covers

International buyers, particularly in Africa, South America, the Middle East, and Europe, should prioritize partnerships with manufacturers that offer tailored solutions backed by strong warranties and robust customer support. This approach not only fosters long-term relationships but also guarantees access to innovative designs and materials that can adapt to diverse market needs.

Looking ahead, the demand for perforated seat covers is poised to grow as consumers increasingly seek comfort and style in their vehicles. Now is the time for B2B buyers to engage with suppliers who can provide cutting-edge products that meet these evolving expectations. Embrace the opportunity to enhance your inventory with premium perforated seat covers and position your business for success in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.