Introduction: Navigating the Global Market for best custom leather holster makers

In the ever-evolving landscape of global commerce, sourcing the best custom leather holsters presents unique challenges for B2B buyers. Whether you are looking to equip a security firm in South America or supply a hunting club in Europe, understanding the nuances of quality, craftsmanship, and market trends is crucial. This comprehensive guide explores the top custom leather holster makers, detailing various types of holsters, their applications, and the critical factors to consider when vetting suppliers. From understanding the intricacies of leather quality to navigating pricing structures, our aim is to equip international buyers—particularly those from Africa, South America, the Middle East, and Europe—with the insights necessary for informed purchasing decisions.

As you delve into this guide, expect to find actionable strategies for evaluating potential suppliers, including key performance indicators to assess quality and reliability. We will also highlight the significance of sustainability practices, a growing concern in today’s market. By the end of this guide, you will be empowered to make strategic choices that not only meet your immediate needs but also foster long-term partnerships with reputable custom leather holster manufacturers. Your journey towards sourcing excellence starts here, paving the way for successful transactions and satisfied clients across the globe.

Table Of Contents

- Top 8 Best Custom Leather Holster Makers Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for best custom leather holster makers

- Understanding best custom leather holster makers Types and Variations

- Key Industrial Applications of best custom leather holster makers

- 3 Common User Pain Points for ‘best custom leather holster makers’ & Their Solutions

- Strategic Material Selection Guide for best custom leather holster makers

- In-depth Look: Manufacturing Processes and Quality Assurance for best custom leather holster makers

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘best custom leather holster makers’

- Comprehensive Cost and Pricing Analysis for best custom leather holster makers Sourcing

- Alternatives Analysis: Comparing best custom leather holster makers With Other Solutions

- Essential Technical Properties and Trade Terminology for best custom leather holster makers

- Navigating Market Dynamics and Sourcing Trends in the best custom leather holster makers Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of best custom leather holster makers

- Strategic Sourcing Conclusion and Outlook for best custom leather holster makers

- Important Disclaimer & Terms of Use

Understanding best custom leather holster makers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Inside the Waistband (IWB) | Concealed design, typically worn under clothing, offers discretion | Law enforcement, personal defense | Pros: High concealment, comfort; Cons: May require adjustment for fit. |

| Outside the Waistband (OWB) | Visible design, often more accessible, can accommodate larger firearms | Security personnel, competitive shooting | Pros: Quick access, stable carry; Cons: Less concealable. |

| Shoulder Holsters | Suspended from the shoulder, distributes weight evenly | Tactical operations, undercover work | Pros: Comfortable for long wear, conceals larger weapons; Cons: Bulky under clothing. |

| Crossdraw Holsters | Positioned for easy access from the opposite side | Hunting, casual carry | Pros: Quick draw for right-handed shooters; Cons: May be less secure in active situations. |

| Custom Rigs | Tailored holsters for specific needs or preferences | Specialty law enforcement, collectors | Pros: Unique designs, specific fit; Cons: Higher cost, longer production time. |

What Are the Characteristics of Inside the Waistband (IWB) Holsters?

Inside the waistband holsters are designed for discreet carrying, fitting snugly against the body and hidden under clothing. They are ideal for individuals needing to conceal their firearm, such as law enforcement officers and civilians focused on personal defense. When purchasing IWB holsters, buyers should consider factors such as the material, retention level, and comfort during prolonged wear. A well-fitted IWB holster enhances comfort while ensuring quick access to the firearm.

How Do Outside the Waistband (OWB) Holsters Differ?

OWB holsters are worn on the outside of the waistband, providing easier access to the firearm. They are commonly used by security personnel and competitive shooters due to their stability and quick draw capabilities. Buyers should evaluate the holster’s design, retention features, and compatibility with various firearm models. While OWB holsters may offer less concealment, their accessibility often outweighs this drawback for many users.

What Are the Benefits of Shoulder Holsters?

Shoulder holsters distribute the weight of the firearm across the shoulders, making them a comfortable option for extended wear. They are particularly popular among undercover agents and tactical personnel who require a concealed carry option for larger firearms. When considering shoulder holsters, B2B buyers should assess the holster’s adjustability, material quality, and ease of access. While these holsters provide excellent concealment, their bulkiness can be a concern for some users.

Why Choose Crossdraw Holsters?

Crossdraw holsters allow for easy access to the firearm from the opposite side of the body, making them a favored choice for hunters and casual carriers. Their design facilitates a quick draw, especially for right-handed shooters. Buyers should focus on the holster’s retention mechanism and compatibility with various clothing styles. Although crossdraw holsters may offer quick access, they might be less secure during physical activities, making them less suitable for high-intensity environments.

Illustrative image related to best custom leather holster makers

What Makes Custom Rigs Unique?

Custom rigs are tailored holsters designed to meet specific needs or preferences, often sought after by law enforcement and firearm collectors. These holsters can incorporate unique features, such as personalized designs or specific retention mechanisms. When considering custom rigs, buyers should evaluate the craftsmanship, production time, and overall cost. While custom holsters may come at a higher price, their unique fit and design can significantly enhance user satisfaction and performance.

Key Industrial Applications of best custom leather holster makers

| Industry/Sector | Specific Application of best custom leather holster makers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Law Enforcement | Custom holsters for firearms used by police and security personnel | Enhanced safety and accessibility of firearms during operations | Durability, comfort, retention features, and compliance with regulations |

| Military | Tactical holsters for soldiers and special forces | Improved readiness and weapon accessibility in high-stakes environments | Customization options for various weapon types and mission-specific needs |

| Outdoor Recreation | Holsters for hunting and shooting sports | Secure and comfortable carry of firearms for hunting enthusiasts | Weather resistance, ergonomic design, and quick-draw capabilities |

| Firearms Retail | Retail display holsters for showcasing firearms | Attractive presentation that enhances customer experience | Aesthetic appeal, brand alignment, and quality craftsmanship |

| Personal Defense | Concealed carry holsters for civilian use | Increased safety and comfort for everyday firearm carriers | Discretion, fit for specific firearm models, and ease of access |

What Are the Key Applications of Custom Leather Holsters in Law Enforcement?

In the law enforcement sector, custom leather holsters are essential for police and security personnel. These holsters are designed to ensure that firearms are both secure and readily accessible during operations. The value lies in their ability to enhance safety, as they prevent accidental discharges while allowing for quick access when necessary. For international buyers, sourcing considerations include durability to withstand rigorous use, comfort for extended wear, and compliance with local regulations regarding firearm carrying.

How Do Military Applications Benefit from Custom Leather Holsters?

Military personnel, particularly those in special forces, rely on tactical holsters that offer both functionality and adaptability. Custom leather holsters can be tailored to fit various firearms and mission requirements, enhancing a soldier’s readiness in dynamic environments. The benefits include improved weapon accessibility and retention during high-stakes situations. Buyers from regions like Africa and the Middle East should prioritize customization options that cater to different weapon types and operational needs, ensuring that the holsters meet specific tactical demands.

Why Are Custom Leather Holsters Important for Outdoor Recreation?

In the outdoor recreation industry, particularly among hunting and shooting sports enthusiasts, custom leather holsters provide a secure and comfortable way to carry firearms. These holsters are designed to withstand the elements, ensuring that hunters can focus on their activities without worrying about their gear. The key benefits include comfort during long treks and easy access to firearms when needed. Buyers from South America and Europe should consider sourcing holsters that offer weather resistance, ergonomic design, and quick-draw capabilities to enhance their outdoor experiences.

How Do Retailers Utilize Custom Leather Holsters?

Firearms retailers often use custom leather holsters as display tools to showcase their products effectively. These holsters enhance the aesthetic appeal of firearms on display, creating a more engaging customer experience. The value for businesses lies in attracting potential buyers and reinforcing brand identity through quality craftsmanship. When sourcing these holsters, retailers should focus on aesthetic appeal, alignment with brand values, and the overall quality of the materials used to ensure they enhance the shopping experience.

What Are the Benefits of Custom Leather Holsters for Personal Defense?

For civilian users focused on personal defense, custom leather holsters offer a practical solution for concealed carry. These holsters are designed to provide comfort and security, allowing users to carry their firearms discreetly while ensuring easy access when needed. The key benefits include increased safety during everyday activities and the confidence that comes with carrying a firearm securely. International buyers should prioritize sourcing holsters that offer discretion, a perfect fit for specific firearm models, and ease of access to meet their personal defense needs effectively.

3 Common User Pain Points for ‘best custom leather holster makers’ & Their Solutions

Scenario 1: Inconsistent Quality Across Orders

The Problem: B2B buyers often face challenges with inconsistent quality when ordering custom leather holsters from various manufacturers. This inconsistency can lead to products that do not meet the required standards for safety and functionality. For international buyers, especially from regions like Africa and South America, variations in craftsmanship can result in significant operational risks, including legal implications if the holsters do not perform as expected in critical situations.

The Solution: To mitigate quality inconsistencies, buyers should establish a comprehensive vendor evaluation process. This includes requesting samples before committing to bulk orders and conducting factory visits, if feasible. Buyers should also demand transparency regarding the materials used, production techniques, and quality control measures in place. Creating a standardized set of specifications that the holster must meet can also help in ensuring that every order aligns with the expected quality. Consider developing a long-term relationship with a single, reputable manufacturer known for consistent quality, such as those with a long history and positive customer feedback.

Scenario 2: Long Lead Times Affecting Inventory Management

The Problem: Another common issue is long lead times for custom leather holster production, which can disrupt inventory management and sales strategies. B2B buyers often need products to be available on-demand, and lengthy waiting periods can result in missed sales opportunities and dissatisfied customers. This situation is particularly challenging for buyers in fast-paced markets in Europe and the Middle East, where consumer demands can change rapidly.

The Solution: To address lead time issues, buyers should prioritize working with custom leather holster makers that offer quick turnaround options without compromising quality. It’s advisable to inquire about expedited production capabilities and to establish a reliable forecast of order volumes, which can help manufacturers plan their production schedules more effectively. Additionally, buyers can consider keeping a buffer stock of popular models to ensure that they can meet customer demands while awaiting new shipments. Implementing a just-in-time inventory system can also help in managing stock levels more efficiently.

Scenario 3: Misalignment Between Customization and Functionality

The Problem: Many B2B buyers encounter a disconnect between the desired customization features of leather holsters and their actual functionality. Buyers may request specific designs or features that, while aesthetically pleasing, do not enhance or may even hinder the usability of the holster. This issue can be particularly prevalent when sourcing from manufacturers that prioritize design over practical functionality, leaving buyers with products that do not meet operational needs.

The Solution: To ensure that customization aligns with functionality, buyers should engage in thorough consultations with manufacturers during the design phase. Providing detailed use-case scenarios and understanding the end-user requirements can help in making informed decisions. Buyers can also request prototypes to evaluate how well the holster performs in real-world applications before finalizing orders. It’s beneficial to seek out manufacturers that have experience in both customization and functionality, as their insight can bridge the gap between aesthetic requests and practical requirements. Lastly, collecting feedback from end-users after trials can inform future orders and ensure that the final products meet both design and functional expectations.

Illustrative image related to best custom leather holster makers

Strategic Material Selection Guide for best custom leather holster makers

What Are the Key Materials Used by Custom Leather Holster Makers?

When considering the best custom leather holster makers, the selection of materials is crucial for ensuring product performance, durability, and customer satisfaction. Here, we analyze four common materials used in the crafting of leather holsters, highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

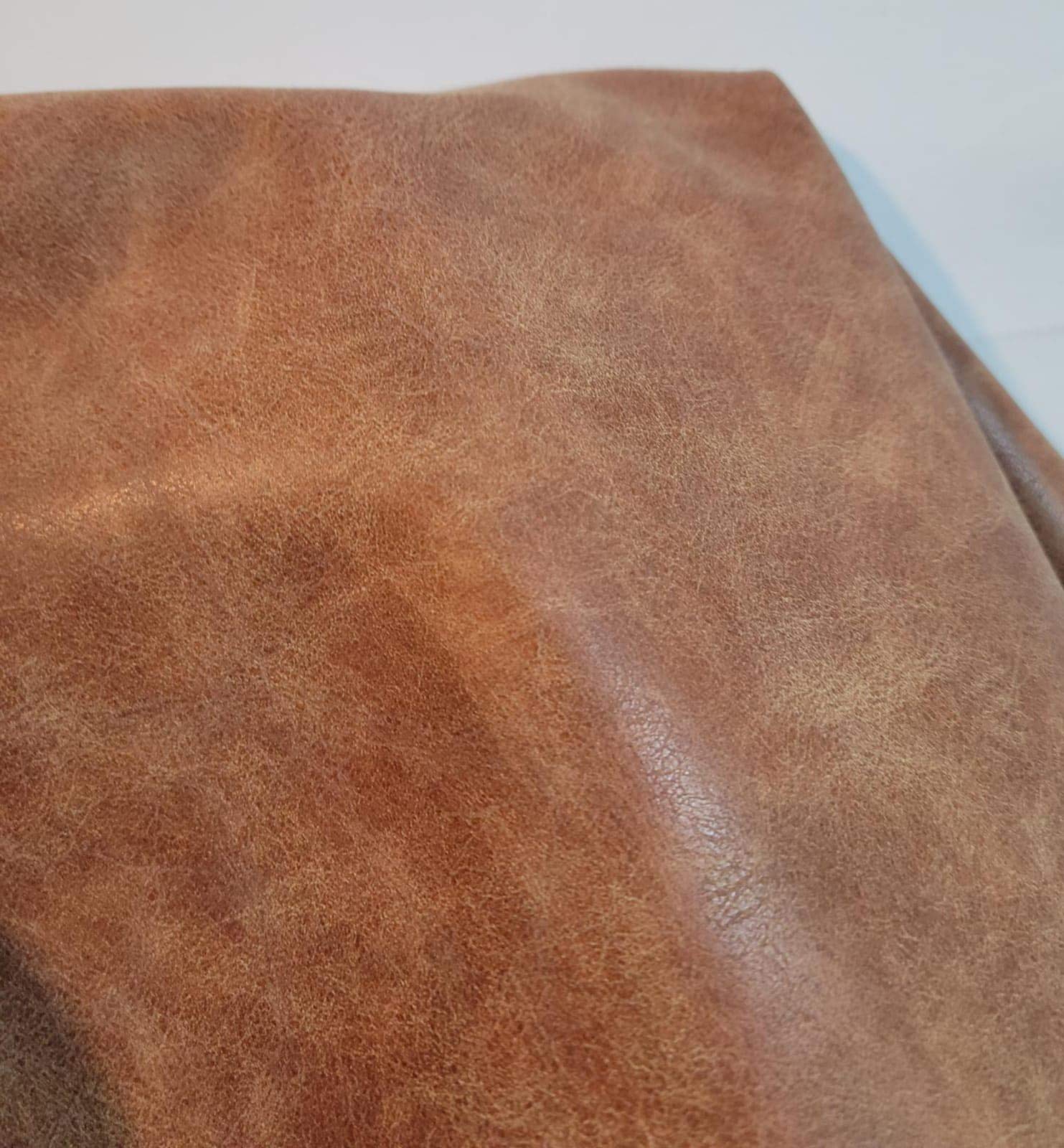

How Does Full-Grain Leather Perform in Custom Holster Manufacturing?

Key Properties: Full-grain leather is the highest quality leather available, made from the top layer of the hide. It retains the natural grain, making it durable and breathable. It can withstand high temperatures and pressure, making it ideal for holsters that may experience wear and tear.

Pros & Cons: The primary advantage of full-grain leather is its durability and ability to develop a rich patina over time, enhancing its aesthetic appeal. However, it is more expensive than other types of leather and requires skilled craftsmanship to work with, which can complicate manufacturing processes.

Impact on Application: Full-grain leather is highly compatible with various environmental conditions, making it suitable for outdoor use. Its breathability helps prevent moisture buildup, which is essential for maintaining the integrity of both the leather and the firearm.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local leather import regulations, which may include certifications for animal welfare. In Europe, adherence to the REACH regulation regarding chemical substances is critical.

What Role Does Top-Grain Leather Play in Holster Production?

Key Properties: Top-grain leather is slightly less durable than full-grain but is still robust. It is sanded and treated to remove imperfections, resulting in a smoother finish that is easier to dye and maintain.

Pros & Cons: Top-grain leather is more affordable than full-grain, making it a popular choice for manufacturers aiming to balance quality and cost. However, it is less resistant to scratches and may not age as gracefully as full-grain leather.

Illustrative image related to best custom leather holster makers

Impact on Application: This material is suitable for holsters that require a more polished look, appealing to consumers who prioritize aesthetics alongside functionality.

Considerations for International Buyers: Buyers should be aware of the varying quality standards in leather production across different countries. For example, German buyers may prefer products that comply with DIN standards for leather quality.

How Does Synthetic Leather Compare to Natural Leather in Holster Making?

Key Properties: Synthetic leather, such as polyurethane (PU) or thermoplastic polyurethane (TPU), offers high resistance to water and UV light. It is lightweight and can be engineered to mimic the look and feel of natural leather.

Pros & Cons: The main advantage of synthetic leather is its affordability and ease of maintenance. However, it may lack the durability and breathability of natural leather, which can affect long-term performance.

Impact on Application: Synthetic leather is particularly suitable for tactical holsters used in extreme conditions, where moisture resistance is critical. However, it may not be favored by traditionalists who prefer the authenticity of natural leather.

Considerations for International Buyers: In regions like South America, where humidity can be a concern, synthetic options may be more appealing. However, buyers should check for compliance with environmental regulations regarding synthetic materials.

What About Suede Leather for Custom Holster Applications?

Key Properties: Suede leather is made from the underside of the hide, offering a soft texture and a unique appearance. It is less durable than full or top-grain leather but provides a distinctive aesthetic.

Illustrative image related to best custom leather holster makers

Pros & Cons: Suede is appreciated for its softness and comfort, making it a good choice for holsters that are worn against the skin. However, it is more susceptible to stains and water damage, which can limit its practicality.

Impact on Application: Suede is best suited for holsters intended for casual or decorative use rather than heavy-duty applications.

Considerations for International Buyers: Buyers in Europe may need to ensure that suede products meet specific animal welfare and environmental standards, similar to those applicable to full-grain and top-grain leathers.

Summary Table of Material Selection for Custom Leather Holsters

| Material | Typical Use Case for best custom leather holster makers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Premium holsters for everyday carry and collectors | Exceptional durability and aesthetics | High cost and manufacturing complexity | High |

| Top-Grain Leather | Holsters requiring a polished look | More affordable than full-grain | Less durable and may not age well | Medium |

| Synthetic Leather | Tactical holsters for extreme conditions | Water and UV resistance | Lacks breathability and durability | Low |

| Suede Leather | Casual or decorative holsters | Soft texture and unique appearance | Susceptible to stains and damage | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for best custom leather holster makers

What Are the Main Stages in the Manufacturing Process of Custom Leather Holsters?

Manufacturing custom leather holsters involves a meticulous process that transforms raw materials into finished products. The primary stages in this process include material preparation, forming, assembly, and finishing. Each stage requires skilled craftsmanship and attention to detail to ensure the final product meets high-quality standards.

How Is Material Prepared for Custom Leather Holsters?

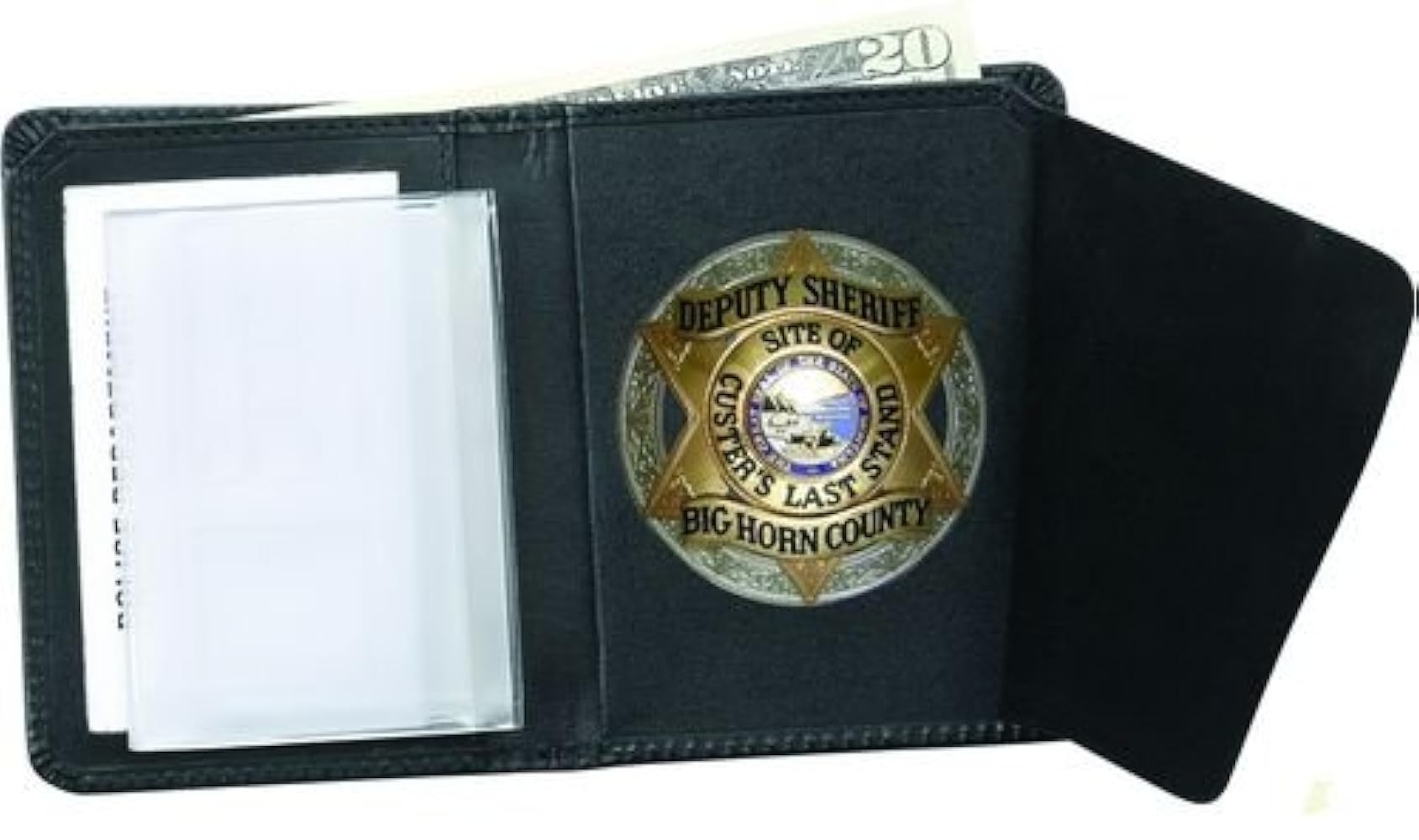

The first step in the manufacturing process is material preparation. This involves selecting high-quality leather, often sourced from reputable suppliers. The leather is then cut into specific patterns that correspond to the design of the holster. This stage may also include treatments to enhance durability, such as conditioning or dyeing to achieve desired colors and finishes. Proper material selection and preparation are crucial, as they directly affect the holster’s performance, aesthetics, and longevity.

Illustrative image related to best custom leather holster makers

What Techniques Are Used in Forming Custom Leather Holsters?

Once the leather is prepared, the next stage is forming. This involves shaping the leather into the desired holster configuration. Techniques such as molding and wet forming are commonly employed. Molding uses heat and moisture to shape the leather around a model of the firearm it is intended to hold, ensuring a snug fit. Wet forming also allows for intricate designs and contours, enhancing both functionality and visual appeal. Skilled artisans often use hand tools for this process, ensuring precision and care.

How Is Assembly Conducted in the Custom Leather Holster Manufacturing Process?

After forming, the assembly stage begins. This involves stitching the various components of the holster together. High-quality bonded nylon threads are typically used for their strength and durability. Additionally, the assembly may include adding hardware, such as clips or straps, which are crucial for the holster’s functionality. Double stitching in critical areas further reinforces the structure, preventing wear and tear over time. This stage is vital as it ensures the holster can withstand daily use while maintaining its shape and performance.

What Finishing Techniques Are Applied to Custom Leather Holsters?

The final stage of manufacturing is finishing, where the holster undergoes several treatments to enhance its appearance and durability. This may involve sanding edges for a smooth finish, applying protective coatings, and polishing the leather. The goal is to create a product that is not only functional but also visually appealing. Custom finishes, such as embossing or engraving, may also be added to personalize the holster further. A thorough finishing process ensures that the holster is ready for the market and can withstand various environmental conditions.

What Are the Key Quality Assurance Practices in Custom Leather Holster Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for custom leather holsters. Implementing rigorous QA practices ensures that the final products meet international standards and customer expectations. Key components of QA in this industry include adherence to relevant international standards, quality checkpoints during production, and effective testing methods.

Which International Standards Should Custom Leather Holster Makers Comply With?

Custom leather holster makers often adhere to international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications, such as CE marking in Europe or API standards for certain applications, can enhance credibility and marketability. For B2B buyers, verifying a supplier’s compliance with these standards can provide assurance of product quality and reliability.

Illustrative image related to best custom leather holster makers

What Are the Key Quality Control Checkpoints in Custom Leather Holster Manufacturing?

Quality control (QC) checkpoints are essential throughout the manufacturing process. Initial Quality Control (IQC) occurs during the material selection phase, where incoming materials are inspected for defects. In-Process Quality Control (IPQC) takes place during the forming and assembly stages, ensuring that any issues are identified and rectified before moving on to the next phase. Finally, Final Quality Control (FQC) is conducted on the finished holsters to verify that they meet the specifications and quality standards set forth. This multi-tiered approach to QC helps maintain high-quality products.

What Common Testing Methods Are Used for Custom Leather Holsters?

Testing methods for custom leather holsters may include stress tests, durability assessments, and functionality evaluations. Stress tests assess how well the holster holds up under various conditions, while durability assessments check for wear and tear over time. Functionality evaluations ensure that the holster meets design specifications and performs as intended. These tests are crucial for identifying potential weaknesses and ensuring that the holsters can withstand daily use without compromising safety or performance.

How Can B2B Buyers Verify Quality Assurance in Custom Leather Holster Suppliers?

B2B buyers can take several steps to verify the quality assurance practices of custom leather holster suppliers. Conducting audits is one effective method; this allows buyers to assess the manufacturing processes and quality control measures firsthand. Additionally, requesting quality assurance reports and certifications can provide insight into the supplier’s adherence to international standards. Third-party inspections can also serve as an impartial verification method, ensuring that the products meet the required specifications.

What Are the Unique QC Considerations for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are specific QC nuances to consider. These may include understanding local regulations regarding import quality standards, which can vary significantly from country to country. Additionally, language barriers and cultural differences may affect communication with suppliers, making it essential to establish clear expectations and guidelines. Utilizing local representatives or agents can facilitate smoother transactions and enhance understanding of quality requirements.

In conclusion, understanding the manufacturing processes and quality assurance practices of custom leather holster makers is vital for B2B buyers seeking reliable suppliers. By focusing on these aspects, buyers can ensure they are investing in high-quality products that meet their specific needs and standards.

Illustrative image related to best custom leather holster makers

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best custom leather holster makers’

Introduction

Sourcing high-quality custom leather holsters is essential for businesses in the firearms industry, whether you are a retailer, distributor, or manufacturer. This guide provides a practical checklist for B2B buyers to ensure they partner with reputable leather holster makers who meet their specific needs, quality standards, and delivery timelines.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical specifications for the leather holsters you require. Consider factors such as the type of firearms, desired materials, holster styles (e.g., IWB, OWB, shoulder), and custom features. Defining these specifications helps streamline your search and ensures that potential suppliers can meet your precise requirements.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in custom leather holsters. Utilize industry directories, trade shows, and online platforms to compile a list of manufacturers. Focus on those with a strong reputation, positive customer feedback, and a portfolio showcasing their craftsmanship. This foundational step allows you to compare different options effectively.

Step 3: Evaluate Supplier Experience and Expertise

Assess the experience and expertise of each potential supplier. Look for manufacturers with a proven track record in producing custom leather holsters and a deep understanding of the firearms industry. Companies that have been in business for several years often possess the craftsmanship and knowledge necessary to deliver high-quality products.

Illustrative image related to best custom leather holster makers

- Check for industry certifications: Ensure they comply with safety and quality standards relevant to your region or market.

- Inquire about their craftsmanship techniques: Understanding their production methods can reveal their commitment to quality.

Step 4: Request Samples and Quality Assurance

Before finalizing a supplier, request samples of their custom leather holsters. This allows you to assess the quality, fit, and finish of their products firsthand. A reputable supplier should have no issue providing samples, as it reflects their confidence in their craftsmanship.

- Evaluate the materials used: Look for premium leather and durable hardware, as these factors significantly impact the longevity of the holsters.

- Inspect craftsmanship details: Check for stitching quality, edge finishing, and overall aesthetics to ensure they meet your standards.

Step 5: Verify Production Capabilities and Lead Times

Understanding a supplier’s production capabilities and lead times is crucial for aligning with your business needs. Inquire about their manufacturing processes, capacity to handle bulk orders, and typical turnaround times.

- Discuss scalability: Ensure they can accommodate potential increases in order volume without compromising quality.

- Confirm their ability to meet deadlines: Timely delivery is essential for maintaining inventory and fulfilling customer orders.

Step 6: Assess Customer Service and Support

Evaluate the level of customer service and support provided by each supplier. A reliable manufacturer should be responsive to inquiries, transparent about processes, and willing to collaborate on customizations. Strong communication is vital for addressing any issues that may arise during the sourcing process.

Illustrative image related to best custom leather holster makers

- Look for testimonials: Positive feedback from other buyers can provide insights into the supplier’s reliability and support.

- Consider their willingness to offer post-sale support: This can be crucial for addressing any product concerns after delivery.

Step 7: Review Pricing and Payment Terms

Finally, review the pricing structures and payment terms offered by each potential supplier. While cost is an important factor, it should not compromise quality.

- Compare quotes from multiple suppliers: This helps you understand market rates and ensures you are getting a fair deal.

- Negotiate terms: Discuss payment plans, bulk order discounts, and any warranties or guarantees that may apply.

By following this comprehensive checklist, B2B buyers can make informed decisions when sourcing custom leather holsters, ensuring they partner with reputable manufacturers that meet their quality and service expectations.

Comprehensive Cost and Pricing Analysis for best custom leather holster makers Sourcing

When sourcing custom leather holsters, understanding the cost structure and pricing dynamics is essential for B2B buyers, especially those operating in diverse international markets. This section provides an in-depth analysis of the various cost components involved, price influencers, and strategic tips for effective negotiation.

Illustrative image related to best custom leather holster makers

What Are the Key Cost Components in Custom Leather Holster Manufacturing?

-

Materials: The quality of leather is a significant determinant of cost. Premium American leather, often used by leading manufacturers, commands higher prices due to its durability and aesthetic appeal. Other materials, such as thread and hardware, also contribute to the overall material costs.

-

Labor: Skilled artisans are crucial for producing high-quality custom leather holsters. Labor costs can vary based on the region; for instance, manufacturers in North America may have higher labor costs compared to those in South America or Eastern Europe. The level of craftsmanship required for intricate designs can further influence labor expenses.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, equipment maintenance, and administrative expenses. Efficient production processes can help minimize overhead, but this may require an upfront investment in technology and training.

-

Tooling: Custom molds and tooling are necessary for creating specific designs and sizes of holsters. While these costs are typically one-time investments, they can be substantial and should be factored into pricing, especially for lower-volume orders.

-

Quality Control (QC): Ensuring that each holster meets quality standards involves additional costs. Rigorous QC processes prevent defects and enhance customer satisfaction, but they can add to the overall price of the product.

-

Logistics: Shipping costs can vary widely based on the destination, weight, and shipping method. International buyers must consider these expenses, which can significantly impact the total cost of ownership.

-

Margin: Manufacturers typically set their margins based on market demand, competition, and perceived value. High-quality custom leather holsters may have a higher margin due to their craftsmanship and brand reputation.

What Influences Pricing for Custom Leather Holsters?

-

Volume and Minimum Order Quantity (MOQ): Bulk orders usually lead to lower per-unit costs. Buyers looking to source holsters for resale or large-scale use should negotiate favorable pricing based on volume.

-

Specifications and Customization: Unique designs and bespoke specifications can increase costs. Buyers should clearly define their requirements to get accurate pricing and avoid unexpected costs later in the process.

-

Quality and Certifications: Products that meet specific quality standards or certifications may come at a premium. Buyers should assess whether these certifications are necessary for their market.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established manufacturers with a proven track record may charge more but offer reliability and superior quality.

-

Incoterms: The agreed-upon Incoterms will affect shipping costs and responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for calculating total landed costs.

How Can Buyers Negotiate Effectively for Custom Leather Holsters?

-

Research and Benchmarking: Conduct thorough market research to understand average pricing and identify potential suppliers. This information can empower buyers during negotiations.

-

Total Cost of Ownership: Consider not just the upfront price but also long-term factors such as durability, warranty, and potential repair costs. A higher initial investment in quality may lead to lower overall costs.

-

Flexibility in Specifications: Be open to adjusting design specifications or materials if it leads to cost savings. Suppliers may be more willing to negotiate if they see flexibility on the buyer’s part.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and more favorable terms in future transactions.

Conclusion

Sourcing custom leather holsters involves a complex interplay of costs and pricing strategies. By understanding the various cost components, price influencers, and effective negotiation tactics, B2B buyers can make informed decisions that align with their business needs. This comprehensive approach is particularly important for international buyers navigating diverse market conditions. As pricing can fluctuate based on numerous factors, it is advisable to request quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing best custom leather holster makers With Other Solutions

When evaluating custom leather holster makers, it is essential to consider alternative solutions that might meet similar needs. These alternatives can offer different benefits and drawbacks, influencing a buyer’s decision based on specific requirements such as budget, performance, and use case. Below, we compare the best custom leather holster makers with two notable alternatives: polymer holsters and hybrid holsters.

| Comparison Aspect | Best Custom Leather Holster Makers | Polymer Holsters | Hybrid Holsters |

|---|---|---|---|

| Performance | High durability and comfort, tailored fit | Lightweight and weather-resistant, quick draw | Offers comfort and flexibility, good retention |

| Cost | Generally higher ($130 – $700) | Affordable ($20 – $100) | Mid-range ($50 – $150) |

| Ease of Implementation | Requires custom order, longer lead time | Readily available, off-the-shelf options | Available in various configurations, some customization |

| Maintenance | Requires regular conditioning and care | Minimal maintenance, easy to clean | Moderate maintenance, depends on materials used |

| Best Use Case | Ideal for enthusiasts seeking custom craftsmanship | Best for casual users or those needing a quick solution | Suitable for users wanting the best of both worlds |

What Are the Pros and Cons of Polymer Holsters?

Polymer holsters are often praised for their lightweight design and resistance to various environmental factors, making them an excellent option for outdoor or tactical use. They typically provide quick access to firearms and are available in various styles to fit different models. However, the downside is that they may lack the aesthetic appeal and comfort that custom leather holsters offer. Additionally, while they provide good retention, they may not fit as snugly as a tailored leather option, potentially impacting security.

Illustrative image related to best custom leather holster makers

What Are the Benefits of Hybrid Holsters?

Hybrid holsters combine the best features of leather and polymer materials. They often consist of a leather backing for comfort and a polymer shell for retention and durability. This design aims to provide a balance between comfort and functionality, making them a popular choice among everyday carriers. However, buyers should consider that hybrid holsters can vary significantly in quality depending on the manufacturer, and they may not offer the same level of customization as dedicated leather holsters.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When deciding between custom leather holster makers and alternative solutions, B2B buyers should assess their specific requirements, such as frequency of use, environmental conditions, and personal preferences for aesthetics and comfort. Buyers in sectors like law enforcement or military may prioritize durability and quick access, leaning towards polymer or hybrid options. In contrast, collectors or enthusiasts valuing craftsmanship and aesthetics may find custom leather holsters more appealing. Ultimately, understanding the unique benefits and limitations of each option will help buyers make an informed choice that aligns with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for best custom leather holster makers

What Are the Essential Technical Properties of Custom Leather Holsters?

When sourcing custom leather holsters, understanding the technical properties is crucial for making informed purchasing decisions. Here are some key specifications to consider:

-

Material Grade

The quality of leather used in holsters is paramount. Full-grain leather, which retains the natural grain and imperfections, is often regarded as the highest quality due to its durability and aesthetic appeal. In contrast, corrected-grain leather has been sanded and treated, making it less expensive but also less durable. For B2B buyers, selecting the right material grade impacts the longevity of the holster and customer satisfaction. -

Stitching Type and Density

The stitching is a critical element that affects the strength and durability of a holster. Double stitching is commonly used to ensure that seams can withstand stress without tearing. For B2B transactions, understanding the type of stitching can help buyers assess the quality and expected lifespan of the holster. -

Holster Design and Retention

Holster design refers to the shape and functionality, including how well it secures the firearm. Retention systems, such as thumb breaks or friction fit, are essential for safe carrying. Buyers should evaluate design features that enhance both security and ease of access, as these will directly influence user experience. -

Tolerance Levels

Tolerance refers to the allowable deviation in the holster’s dimensions. High tolerance levels ensure a snug fit for the firearm, which is vital for both safety and performance. In a B2B context, understanding tolerance specifications can prevent costly returns and enhance customer satisfaction by ensuring the product meets exacting standards. -

Finish and Treatment

The finish applied to leather holsters can affect moisture resistance and overall durability. Common treatments include oils, waxes, or synthetic coatings that enhance the leather’s longevity. B2B buyers should inquire about finishes to ensure the holsters can withstand specific environmental conditions, particularly in diverse markets like Africa or South America.

What Are Common Trade Terms in the Custom Leather Holster Industry?

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several important terms:

Illustrative image related to best custom leather holster makers

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather holster industry, OEM relationships can lead to customized products tailored to specific brands or retailers. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to gauge their purchasing power and inventory needs, particularly when entering new markets. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products. For custom leather holsters, a well-structured RFQ can streamline the procurement process, ensuring all necessary specifications are communicated upfront. -

Incoterms (International Commercial Terms)

These are predefined commercial terms that outline the responsibilities of buyers and sellers regarding shipping, delivery, and insurance. Familiarity with Incoterms is crucial for international transactions, especially in regions like the Middle East and Europe, as they dictate the financial and logistical responsibilities of each party. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. Understanding lead times is crucial for B2B buyers to manage inventory and ensure timely availability for customers. Custom holsters may have varying lead times based on complexity and material sourcing.

By grasping these essential properties and trade terms, B2B buyers can enhance their sourcing strategies and ensure they partner with reputable custom leather holster makers, ultimately leading to better product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the best custom leather holster makers Sector

What Are the Current Market Dynamics and Trends in the Custom Leather Holster Sector?

The custom leather holster market is witnessing significant growth, driven by several global factors. The increasing popularity of firearm ownership, coupled with a rising emphasis on personalized products, is shaping the demand for bespoke leather holsters. This trend is particularly pronounced among international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, where cultural attitudes towards firearms vary widely. In Europe, for instance, the trend leans toward high-quality craftsmanship and style, while in South America and Africa, functionality and durability are paramount.

Emerging technologies are also influencing sourcing trends. The integration of digital platforms for custom orders allows buyers to specify their requirements with precision, enhancing customer satisfaction. Additionally, advancements in leather treatment and production techniques are enabling manufacturers to create more durable and aesthetically pleasing products. B2B buyers are increasingly looking for suppliers who can offer not only customization but also quick turnaround times without compromising quality.

Furthermore, economic factors, such as fluctuations in currency and trade policies, can impact pricing and availability of materials. International buyers must stay informed about these dynamics to make strategic sourcing decisions. As the market evolves, understanding these trends will be crucial for businesses looking to establish long-term partnerships with leading custom leather holster makers.

How Are Sustainability and Ethical Sourcing Impacting the Custom Leather Holster Market?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the custom leather holster sector. The environmental impact of leather production, particularly in terms of water usage and chemical treatment, necessitates a shift towards more sustainable practices. Buyers are increasingly demanding transparency in the supply chain, focusing on manufacturers that prioritize responsible sourcing of leather, such as vegetable-tanned options or leather sourced from certified sustainable farms.

The importance of ethical supply chains cannot be overstated. Buyers are looking for partners who adhere to fair labor practices and who can provide evidence of their commitment to environmental stewardship. Certifications such as the Leather Working Group’s (LWG) environmental certification are becoming vital for suppliers looking to differentiate themselves in a crowded market. These certifications not only assure buyers of the quality of the leather but also align with the growing consumer preference for products that are produced responsibly.

Moreover, the trend towards “green” materials is pushing manufacturers to explore alternatives like synthetic leathers or recycled materials, which can appeal to eco-conscious consumers. For B2B buyers, aligning with suppliers who emphasize sustainability can enhance brand reputation and meet the demands of increasingly discerning customers.

What Is the Evolution of the Custom Leather Holster Market?

The custom leather holster market has evolved significantly since its inception. Originally, holsters were designed for functionality, focusing primarily on safety and accessibility. Over the decades, with the advent of modern manufacturing techniques and materials, the market has shifted towards customization and aesthetics. Today’s buyers not only seek holsters that serve their practical needs but also reflect their personal style and values.

The rise of the internet has facilitated access to a global market, enabling manufacturers to reach customers far beyond their local regions. This has led to increased competition but also greater innovation, with companies investing in advanced design software and manufacturing technologies to meet diverse customer demands. As the market continues to grow, the emphasis on quality craftsmanship, sustainability, and customer-centric designs will shape its future trajectory.

Illustrative image related to best custom leather holster makers

Frequently Asked Questions (FAQs) for B2B Buyers of best custom leather holster makers

-

How do I evaluate the quality of custom leather holsters?

To assess the quality of custom leather holsters, consider the craftsmanship, materials used, and design features. Look for holsters made from premium leather, which should feel robust and durable. Examine stitching; double stitching is a sign of strength. Additionally, check if the holster allows for a secure fit and easy access to the firearm. Request samples or reviews from other businesses to gain insights into user experiences, which can help you make an informed decision. -

What customization options are typically available for leather holsters?

Most custom leather holster makers offer a range of customization options including size, color, and design features tailored to specific firearms. You can often choose the type of holster (e.g., IWB, OWB, shoulder) and add features like retention straps or unique engraving. Some manufacturers may allow you to specify the type of leather and finish. Always communicate your specific requirements upfront to ensure that the final product meets your needs. -

What are the minimum order quantities (MOQs) for custom leather holsters?

Minimum order quantities can vary significantly among custom leather holster makers. Some may require a minimum of just a few units for smaller businesses, while others might set MOQs in the hundreds. It’s essential to clarify MOQs during your initial discussions to align your purchasing plans with the manufacturer’s capabilities. Additionally, inquire about the pricing structure for larger orders, as bulk purchases often result in discounts. -

What payment terms should I expect when ordering custom leather holsters?

Payment terms can vary widely depending on the supplier’s policies and your negotiation skills. Common arrangements include a deposit upfront, with the balance due upon delivery or before shipping. Some manufacturers may also offer financing options or payment plans, especially for larger orders. Always ensure that you have a clear agreement in writing to avoid misunderstandings regarding payment deadlines and methods. -

How can I ensure quality assurance for my custom leather holsters?

To ensure quality assurance, request detailed information about the manufacturer’s quality control processes. Inquire if they have certifications or standards they adhere to, such as ISO certifications. Consider establishing a sample order or trial run before committing to a larger order. Additionally, ask for references or case studies from other businesses that have sourced from the manufacturer to gauge their reliability and quality. -

What logistics and shipping considerations should I keep in mind?

When sourcing custom leather holsters internationally, consider shipping times, costs, and customs regulations. Discuss with your supplier whether they handle shipping or if you need to arrange logistics. Understanding the shipping terms (e.g., FOB, CIF) is crucial. Ensure you have clarity on delivery timelines and any potential delays that could arise from customs clearance, especially in regions with stringent import regulations. -

How do I vet suppliers of custom leather holsters effectively?

To vet suppliers effectively, conduct thorough research on their reputation and track record. Look for reviews and testimonials from other B2B clients. Verify their production capabilities and ask for references. It’s beneficial to visit their facility if possible, or schedule a virtual meeting to discuss your requirements in detail. Additionally, check if they have any industry certifications that reflect their commitment to quality and craftsmanship. -

What are common challenges in sourcing custom leather holsters internationally?

Common challenges include language barriers, differing quality standards, and logistical issues such as shipping delays and customs complications. Additionally, currency fluctuations can affect pricing. To mitigate these challenges, maintain open communication with suppliers and clarify all terms and conditions upfront. Establishing a strong relationship with your supplier can also help address issues more effectively when they arise.

Top 8 Best Custom Leather Holster Makers Manufacturers & Suppliers List

1. Bullard Leather – Bodyguard Holster

Domain: bullardleather.com

Registered: 2018 (7 years)

Introduction: Bullard Leather Mfg offers premium leather holsters, belts, and accessories, all handmade in Throckmorton, Texas. Key products include: 1.5″ Double Thick Carry Belt ($110), Cowboy Wallet ($60), Bodyguard Holster ($120), and Belt Slide Holster ($100). Products are crafted from premium Hermann Oak Leather, molded for specific gun fits, and available for various handgun manufacturers like Beretta, Co…

2. Sam Andrews – McDaniel II Holster

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Recommended leather holster makers for Hi Power include: 1. Sam Andrews – McDaniel II with thumbreak, price around $135, custom made to order. 2. Privateer Leather – known for great quality, fit, and finish. 3. Galco, Bianchi, Andrews Custom Leather, Milt Sparks, Ritchie Leather – other notable brands mentioned. 4. Falco Holsters – offers custom made-to-order holsters from Slovakia, with options f…

3. Tucker Gun Leather – Custom Leather Holsters & Gun Belts

Domain: tuckergunleather.com

Registered: 2001 (24 years)

Introduction: Tucker Gun Leather offers a range of high-quality, custom leather holsters and gun belts designed for concealed carry. Key product details include: Inside the waistband (IWB) holsters, Outside the waistband (OWB) holsters, Appendix holsters, Deep carry holsters, Gun belts, Revolver holsters, Pocket holsters, Wound trauma kits, Chest holsters, Shoulder holsters, Ankle holsters, Magazine pouches, Fi…

4. Galco Gunleather – Leather Holsters and Accessories

Domain: galcogunleather.com

Registered: 1998 (27 years)

Introduction: Galco Gunleather offers a variety of leather gun holsters, belts, slings, and accessories. Key product categories include: 1. Holsters: Various types including shoulder/chest holsters, IWB holsters, paddle/belt holsters, and ankle holsters. 2. Ammo/Accessory Carriers: Designed to match holsters. 3. Belts: Specifically designed for gun carrying. 4. Outdoor Gear: Tactical and exotics. 5. Custom Shop…

5. Lobo Gun Leather – Classic Holsters

Domain: thearmorylife.com

Registered: 2018 (7 years)

Introduction: 1. Lobo Gun Leather – Previously favored by Jester560, now retired.

2. Tucker Gun Leather – Current preference of Jester560.

3. Craft Holsters – Mentioned by a user.

4. Bianchi – Mentioned by a user.

5. Stoner Holsters – Located in Ohio, known for great prices and fast service.

6. Black Hills Leather – Noted for custom holsters.

7. MRT – Known for leather extra mag holsters.

8. 1791 Holsters – Off…

6. Alphono’s Gun Leather – Custom Holsters

Domain: forums.sassnet.com

Registered: 1997 (28 years)

Introduction: Alphono’s Gun Leather: https://alfonsosgunleather.com/western.html; Artistic Blades Western: http://www.artisticbladeswestern.com/Products.html; Aspen Filly’s One of a kind Custom Holsters: https://www.facebook.com/Aspen-Fillys-Merchandise-103794366328467, voice call or text-303-434-1204; Black Hills Leather: https://www.blackhillsleather.com/product-category/western-rigs-leather/western-rigs/; Bo…

7. Mitch Rosen – 5JR Holster

Domain: mitchrosen.com

Registered: 1997 (28 years)

Introduction: Premium IWB & OWB Leather Gun Holsters, Handmade in the USA. Product lines include Express Line and Full Detail Line. Express Line offers faster turnaround and lower prices, while Full Detail Line emphasizes craftsmanship with extensive handwork and high-quality materials. Key products include: 5JR Express Holster ($104.99), Upper Limit Express ($104.99), Upper Limit Full Detail ($174.99), and 5JR…

8. Holster Makers – Custom Leather Goods

Domain: highpowercollectors.proboards.com

Registered: 1999 (26 years)

Introduction: Compiled list of holster makers including: Adams Holsters, Lobo Gun Leather, Bob Mernickle, Murray Custom Leather, Jacques Tredoux Trading Post, 5 Shot Leather, A.E. Nelson, A&G Custom Gun Leather, Andrews Leather, Barranti Leather Company, Bell Charter Oak Holsters, Bianchi, Black Hills Leather, Boston Leather, Brigade Gunleather, Brommeland Gunleather, Bullard Leather, Bulman Gunleather, C. Rust…

Strategic Sourcing Conclusion and Outlook for best custom leather holster makers

How Can International Buyers Benefit from Strategic Sourcing of Custom Leather Holsters?

In the competitive landscape of custom leather holster manufacturing, strategic sourcing emerges as a crucial factor for international B2B buyers. By leveraging relationships with reputable makers, such as those who emphasize quality craftsmanship and use premium materials, buyers can ensure they receive products that meet their specific needs and standards. This not only enhances customer satisfaction but also strengthens brand loyalty and market positioning.

The best custom leather holster makers offer a blend of traditional craftsmanship and modern innovation, providing products tailored to various applications—whether for law enforcement, personal defense, or sporting purposes. As markets in Africa, South America, the Middle East, and Europe continue to grow, the demand for high-quality, custom-made holsters is set to increase. Buyers should prioritize partnerships that emphasize quality, reliability, and customer-centric service.

Looking ahead, the opportunity to collaborate with skilled artisans and manufacturers in the custom leather holster industry is ripe for exploration. By making informed sourcing decisions, international buyers can not only enhance their product offerings but also contribute to the sustainability of the craft. Start building your network today to secure the best leather holsters that align with your business goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to best custom leather holster makers

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.