Introduction: Navigating the Global Market for make a leather wallet

As global demand for high-quality leather products continues to rise, understanding how to effectively navigate the market for making leather wallets has become crucial for B2B buyers. Sourcing the right materials and craftsmanship can be challenging, especially when considering factors such as ethical sourcing, durability, and aesthetic appeal. This guide addresses these challenges by offering a comprehensive exploration of the leather wallet market, covering various types of wallets, production techniques, and applications in different sectors.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—countries like Nigeria and Brazil—will find invaluable insights throughout this guide. Key topics include identifying reliable suppliers, evaluating cost structures, and understanding market trends that can influence purchasing decisions. By breaking down the complexities of the leather wallet market, this resource empowers buyers to make informed choices that align with their business needs.

Furthermore, we delve into supplier vetting processes, ensuring that you can select partners who meet your quality and ethical standards. Whether you’re seeking to enhance your product lineup or enter new markets, this guide serves as your go-to reference for navigating the intricacies of sourcing and producing leather wallets in today’s competitive landscape.

Table Of Contents

- Top 3 Make A Leather Wallet Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for make a leather wallet

- Understanding make a leather wallet Types and Variations

- Key Industrial Applications of make a leather wallet

- 3 Common User Pain Points for ‘make a leather wallet’ & Their Solutions

- Strategic Material Selection Guide for make a leather wallet

- In-depth Look: Manufacturing Processes and Quality Assurance for make a leather wallet

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘make a leather wallet’

- Comprehensive Cost and Pricing Analysis for make a leather wallet Sourcing

- Alternatives Analysis: Comparing make a leather wallet With Other Solutions

- Essential Technical Properties and Trade Terminology for make a leather wallet

- Navigating Market Dynamics and Sourcing Trends in the make a leather wallet Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of make a leather wallet

- Strategic Sourcing Conclusion and Outlook for make a leather wallet

- Important Disclaimer & Terms of Use

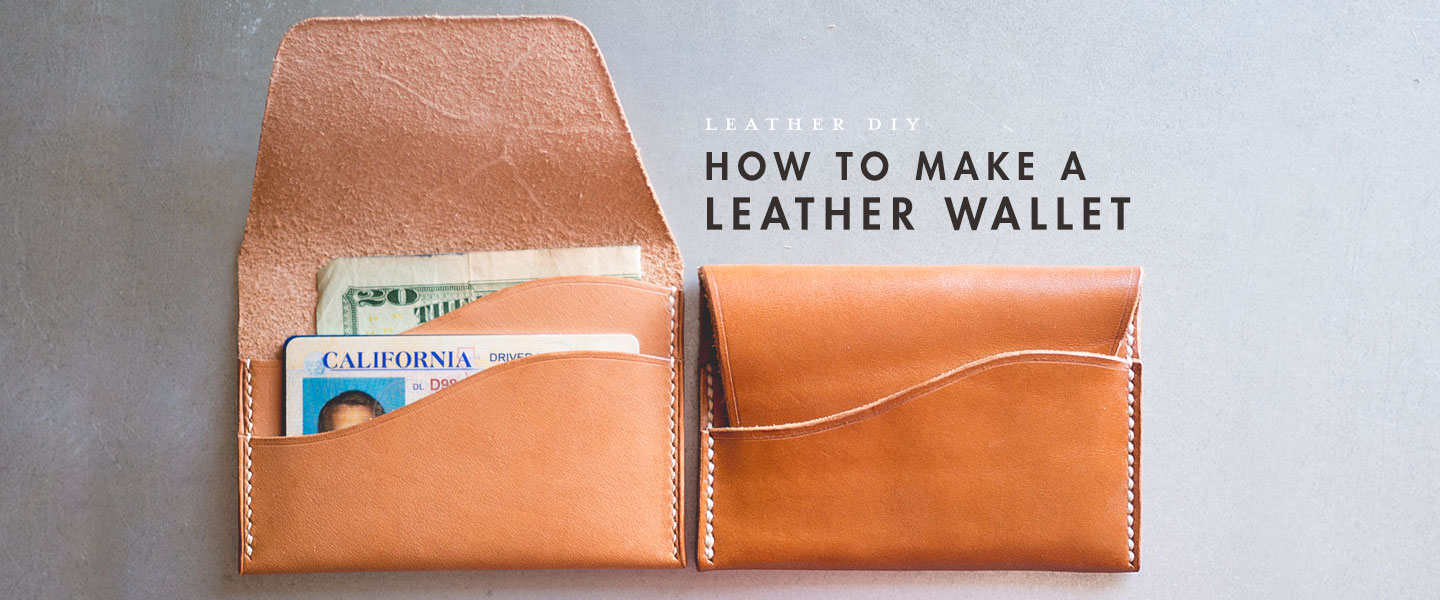

Understanding make a leather wallet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bi-fold Wallet | Two sections for cash and cards, compact size | Retail, Corporate Gifts | Pros: Slim design, easy to carry. Cons: Limited capacity for cards. |

| Tri-fold Wallet | Three sections, more card slots | Promotional Items, Personal Use | Pros: More storage, versatile. Cons: Bulkier than bi-folds. |

| Cardholder Wallet | Minimalist design, focuses on card storage | Startups, Tech Companies | Pros: Sleek and modern. Cons: Limited cash storage. |

| Travel Wallet | Larger size, compartments for documents | Travel Agencies, Corporate Travel | Pros: Multiple compartments, secure. Cons: Can be cumbersome. |

| Customizable Wallet | Personalized designs, branding options | Luxury Brands, Corporate Gifts | Pros: Unique branding opportunities. Cons: Higher production costs. |

What are the Characteristics and Suitability of Bi-fold Wallets for B2B Buyers?

Bi-fold wallets are characterized by their compact design, featuring two main sections for cash and cards. This type is particularly suitable for businesses focusing on retail and corporate gifts, as they offer a classic look that appeals to a wide audience. B2B buyers should consider the wallet’s material quality and stitching, as these factors influence durability and customer satisfaction. Bi-folds are ideal for businesses looking to provide an elegant yet functional accessory without overwhelming the user with bulk.

How Do Tri-fold Wallets Cater to Business Needs?

Tri-fold wallets are designed with three sections, allowing for increased card storage and organization. This type is often used for promotional items or personal use, making it a versatile choice for businesses. The additional space can be advantageous for companies wanting to include loyalty cards or membership information. Buyers should evaluate the balance between storage capacity and overall bulkiness, as tri-folds can be more cumbersome than their bi-fold counterparts, potentially affecting user experience.

Why Choose Cardholder Wallets for Modern B2B Solutions?

Cardholder wallets emphasize a minimalist design, focusing primarily on card storage with little to no cash compartment. This type caters to startups and tech companies that prioritize sleek, modern aesthetics. B2B buyers should consider the wallet’s material and construction to ensure it aligns with brand values. While cardholders are stylish and convenient, they may not suit users who regularly carry cash, limiting their appeal in certain markets.

What Features Make Travel Wallets Ideal for Corporate Travel?

Travel wallets are larger, designed to accommodate not only cash and cards but also documents such as passports and boarding passes. They are particularly useful for travel agencies and corporate travel departments that prioritize organization and security. Buyers should assess the wallet’s compartmentalization and security features, as these can significantly enhance the travel experience. Although travel wallets provide ample storage, their size may deter consumers seeking a more compact solution.

How Can Customizable Wallets Enhance Brand Identity?

Customizable wallets offer businesses the opportunity to create unique designs that incorporate branding elements such as logos and colors. This type is especially popular among luxury brands and companies looking for high-end corporate gifts. B2B buyers should consider production costs and the potential return on investment through enhanced brand visibility. While customizable options can be more expensive, they provide a distinctive way to engage customers and reinforce brand identity.

Key Industrial Applications of make a leather wallet

| Industry/Sector | Specific Application of make a leather wallet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Retail | Custom-branded leather wallets for retail sales | Enhances brand visibility and customer loyalty | Quality leather sourcing, customization options, MOQ requirements |

| Financial Services | Wallets for corporate gifts or client giveaways | Strengthens client relationships and brand image | Durable materials, branding capabilities, delivery timelines |

| Travel & Hospitality | Leather wallets for travel accessories | Provides functional and stylish travel solutions | Lightweight materials, design versatility, cost-effectiveness |

| E-commerce | Direct-to-consumer leather wallet sales | Expands product offerings and increases revenue | Online marketing strategies, inventory management, shipping logistics |

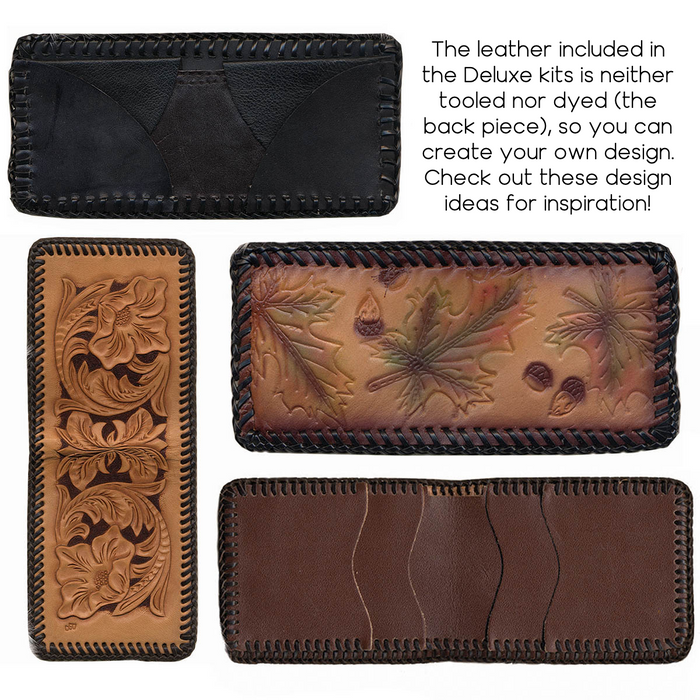

| Arts & Crafts | DIY leather wallet kits for workshops | Encourages creativity and engagement among consumers | Educational materials, tool inclusions, price points for kits |

How is ‘make a leather wallet’ utilized in the Fashion & Retail industry?

In the fashion and retail sector, businesses often create custom-branded leather wallets to enhance their product lines. These wallets serve not only as functional items but also as a canvas for brand visibility. By offering stylish wallets, retailers can attract customers looking for premium accessories. For international buyers, it’s essential to consider the quality of leather sourced, as well as the customization options available, including embossing and unique designs to meet local market preferences.

What role do leather wallets play in Financial Services?

Financial institutions frequently use leather wallets as corporate gifts or promotional items for clients. By providing a high-quality leather wallet, banks and financial firms can strengthen client relationships and enhance their brand image. The durability of the wallet reflects the institution’s commitment to quality, which can lead to increased customer loyalty. Buyers in this sector should focus on sourcing durable materials that can withstand everyday use while ensuring branding capabilities are met, such as logo embossing.

Illustrative image related to make a leather wallet

Why are leather wallets important in the Travel & Hospitality industry?

In the travel and hospitality sector, leather wallets are often designed as travel accessories that combine style with practicality. They can hold essential items such as passports, cards, and cash, providing travelers with an organized way to manage their belongings. For businesses in this industry, sourcing lightweight yet durable materials is crucial to ensure comfort and longevity. Additionally, design versatility is key to appealing to diverse customer preferences across different regions.

How can E-commerce benefit from selling leather wallets?

E-commerce platforms can leverage the popularity of leather wallets by offering direct-to-consumer sales. This approach allows businesses to expand their product offerings and cater to niche markets looking for high-quality leather goods. Effective online marketing strategies, including social media campaigns and influencer partnerships, can significantly boost visibility and sales. International buyers should consider inventory management and shipping logistics, ensuring that they can meet demand efficiently while keeping costs competitive.

What opportunities exist for Arts & Crafts with leather wallet kits?

The arts and crafts sector can capitalize on the DIY trend by offering leather wallet kits for workshops and individual projects. These kits not only encourage creativity but also provide a hands-on experience for consumers. By including educational materials and tools in the kits, businesses can enhance user engagement and satisfaction. Buyers in this industry should focus on price points for kits that appeal to different demographics, ensuring accessibility while maintaining quality.

3 Common User Pain Points for ‘make a leather wallet’ & Their Solutions

Scenario 1: Sourcing Quality Leather for Wallet Production

The Problem: B2B buyers often struggle with sourcing high-quality leather that meets their standards for durability and aesthetics. This challenge is particularly pronounced when dealing with international suppliers, as variations in leather quality can lead to inconsistent product output. Buyers may find themselves receiving leather that does not perform well or does not match the expected specifications, resulting in increased costs due to returns and quality control issues.

Illustrative image related to make a leather wallet

The Solution: To address this challenge, B2B buyers should establish strong relationships with reputable suppliers who specialize in leather goods. Conduct thorough due diligence by requesting samples and certifications that demonstrate the leather’s quality, such as grain consistency, thickness, and tanning methods. Additionally, leveraging local trade shows or leather fairs can provide opportunities to meet suppliers face-to-face, allowing for better assessment of their products. Buyers should also consider creating a detailed specification sheet that outlines the exact requirements for the leather to ensure alignment with supplier capabilities. This proactive approach can significantly reduce the risk of receiving subpar materials.

Scenario 2: Ensuring Wallet Design Meets Market Trends

The Problem: Another common pain point for B2B buyers is the challenge of designing leather wallets that align with current market trends while also being functional and appealing to their target audience. Buyers may be overwhelmed by the rapid changes in consumer preferences, making it difficult to create products that stand out in a competitive market. This can lead to unsold inventory and lost revenue.

The Solution: To stay ahead of design trends, B2B buyers should invest in market research and consumer insights. Utilizing tools such as trend forecasting reports, social media analysis, and competitor benchmarking can provide valuable information on what styles, colors, and features are gaining popularity. Collaborating with designers who specialize in leather goods can also enhance the creative process. Hosting focus groups with potential customers to gather feedback on wallet prototypes can further refine designs before they go to market. By being proactive in understanding consumer preferences, buyers can create wallets that resonate with their audience, reducing the risk of unsold inventory.

Scenario 3: Managing Production Timelines and Costs

The Problem: Managing production timelines and costs is a significant concern for B2B buyers in the leather wallet manufacturing sector. Delays in sourcing materials or unexpected production challenges can lead to missed deadlines, affecting customer satisfaction and potentially harming business relationships. Additionally, fluctuating costs of leather and labor can squeeze profit margins, making it difficult to maintain competitive pricing.

Illustrative image related to make a leather wallet

The Solution: To effectively manage production timelines and costs, B2B buyers should implement a robust project management system that includes clear timelines, milestones, and responsibilities. Establishing strong communication channels with suppliers and manufacturers can help identify potential bottlenecks early in the production process. Buyers should also consider diversifying their supplier base to mitigate risks associated with price fluctuations and ensure that they have backup options in case of delays. Regularly reviewing production processes and costs can lead to identifying areas for improvement, such as optimizing labor usage or investing in more efficient machinery. By taking these steps, buyers can enhance their operational efficiency, ensuring that they meet customer expectations while maintaining healthy profit margins.

Strategic Material Selection Guide for make a leather wallet

What Are the Key Materials for Making a Leather Wallet?

When selecting materials for manufacturing leather wallets, several common options stand out. Each material offers unique properties, benefits, and drawbacks that can significantly influence the wallet’s performance, durability, and market appeal. Below, we analyze four materials commonly used in leather wallet production from a B2B perspective.

What Are the Key Properties of Vegetable-Tanned Leather?

Vegetable-tanned leather is a traditional material known for its eco-friendly tanning process using natural tannins from plant sources. This leather is characterized by its durability and ability to develop a rich patina over time. It typically has a temperature resistance of up to 70°C and can withstand moderate pressure without deforming.

Pros: Vegetable-tanned leather is highly durable, making it suitable for everyday use. It is also biodegradable, appealing to environmentally conscious consumers. Its ability to age beautifully adds to the aesthetic value, making it a preferred choice for high-end wallets.

Cons: However, it can be more expensive than other leather types due to the lengthy tanning process. Additionally, it is less resistant to water and stains compared to chrome-tanned leather, requiring careful maintenance.

Impact on Application: This material is compatible with various media, including dyes and oils, allowing for customization. However, its sensitivity to moisture may limit its use in humid climates.

Considerations for International Buyers: Buyers in regions like Africa and South America may need to ensure compliance with local environmental regulations regarding leather sourcing and processing. Understanding local preferences for natural materials can enhance market acceptance.

How Does Chrome-Tanned Leather Compare?

Chrome-tanned leather is produced using chromium salts, resulting in a more flexible and water-resistant material. It can withstand temperatures up to 80°C and offers excellent durability under pressure.

Pros: This type of leather is less expensive and faster to produce compared to vegetable-tanned leather. Its water resistance makes it suitable for various climates, appealing to a broader market.

Cons: The tanning process involves chemicals that may not align with eco-friendly practices, which can deter environmentally conscious consumers. Additionally, it may not develop the same rich patina over time, potentially affecting its long-term appeal.

Impact on Application: Chrome-tanned leather is compatible with a wider range of finishes and treatments, enhancing its versatility for different wallet designs.

Considerations for International Buyers: Buyers in Europe may face stricter regulations regarding chemical use in leather production. Compliance with standards such as REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is essential.

What About Synthetic Leather Options?

Synthetic leather, or faux leather, is made from materials like polyurethane (PU) or polyvinyl chloride (PVC). These materials can withstand temperatures up to 60°C and are highly resistant to moisture and stains.

Illustrative image related to make a leather wallet

Pros: Synthetic leather is generally less expensive and offers a wide variety of colors and textures. It is also easier to clean and maintain, making it a practical choice for budget-conscious consumers.

Cons: However, synthetic leather lacks the durability and aesthetic appeal of genuine leather. It may also not provide the same level of breathability, leading to discomfort in certain conditions.

Impact on Application: This material is highly compatible with various manufacturing processes, including embossing and printing, allowing for creative designs.

Considerations for International Buyers: Buyers should consider consumer preferences regarding sustainability. In markets like Brazil, there is a growing demand for eco-friendly products, which may limit the appeal of synthetic options.

Illustrative image related to make a leather wallet

How Does Exotic Leather Fit Into the Market?

Exotic leather, such as crocodile or ostrich, offers a luxurious alternative for high-end wallets. These materials can withstand high temperatures and pressures, making them exceptionally durable.

Pros: Exotic leather is highly sought after for its unique appearance and texture, appealing to luxury markets. Its durability ensures a long lifespan, enhancing its value proposition.

Cons: The high cost of exotic leather can limit its market to affluent consumers. Additionally, sourcing these materials may involve ethical considerations and compliance with wildlife protection regulations.

Illustrative image related to make a leather wallet

Impact on Application: Exotic leather is compatible with high-end finishes and custom designs, making it ideal for premium products.

Considerations for International Buyers: Buyers must navigate complex regulations regarding the trade of exotic leathers, particularly in regions with strict wildlife protection laws.

Summary Table of Material Selection for Leather Wallets

| Matériau | Typical Use Case for make a leather wallet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-end wallets | Eco-friendly and durable | Expensive and moisture-sensitive | Haut |

| Chrome-Tanned Leather | Everyday wallets | Cost-effective and water-resistant | Chemical processing concerns | Medium |

| Synthetic Leather | Budget-friendly wallets | Variety of styles and easy maintenance | Less durable and breathable | Low |

| Exotic Leather | Luxury wallets | Unique appearance and high durability | High cost and ethical sourcing issues | Haut |

This analysis provides a comprehensive overview of the materials available for leather wallet production, highlighting essential factors for B2B buyers to consider when making informed purchasing decisions.

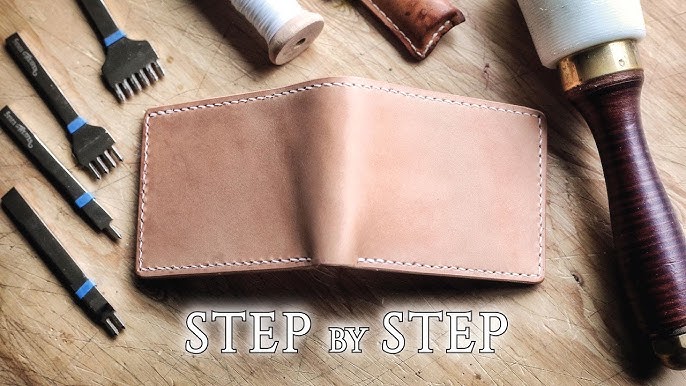

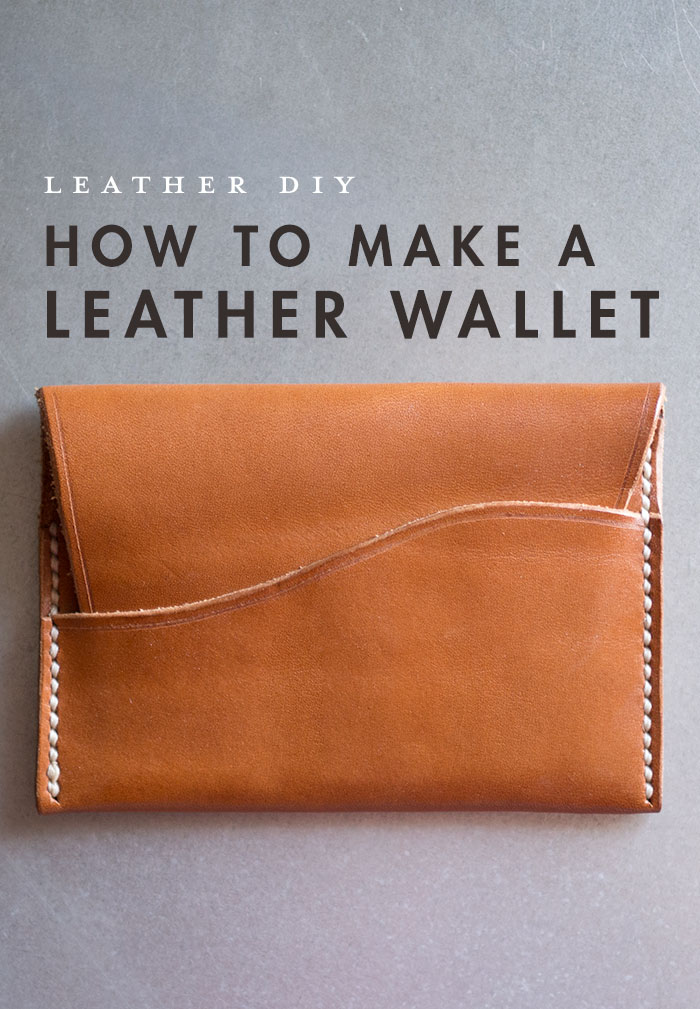

In-depth Look: Manufacturing Processes and Quality Assurance for make a leather wallet

What Are the Main Stages of the Manufacturing Process for Leather Wallets?

Manufacturing a leather wallet involves several critical stages, each contributing to the overall quality and functionality of the final product. The primary stages include material preparation, forming, assembly, and finishing.

How is Material Prepared for Leather Wallet Production?

The first step in the manufacturing process is the careful selection and preparation of leather. Typically, vegetable-tanned leather is preferred for its durability and aesthetic appeal. Suppliers often source leather from reputable tanneries that adhere to environmental and ethical standards.

Illustrative image related to make a leather wallet

Once sourced, the leather undergoes inspection to ensure it meets quality specifications. Defects such as scars, color inconsistencies, or thickness variations are identified. After inspection, the leather is cut into specific patterns using precision tools like X-acto knives or die-cutting machines. This ensures uniformity and minimizes waste.

What Techniques Are Used for Forming Leather Wallets?

After cutting, the forming stage begins. This involves creating folds and pockets according to the wallet design. Techniques such as wet forming may be utilized, where leather is moistened to make it pliable. This allows for the precise shaping of curves and angles, which are essential for a well-structured wallet.

Marking stitching lines and grooving are also essential during this stage. Using a stitching groover, manufacturers create channels for the stitching to sit in, which not only enhances the wallet’s appearance but also reinforces the seams.

Illustrative image related to make a leather wallet

How is Assembly Executed in Leather Wallet Manufacturing?

The assembly process typically involves several steps, including gluing and stitching. Adhesives, such as leather cement, are applied to secure the pockets in place before stitching begins. This is crucial as it ensures that components do not shift during sewing.

Once the adhesive has dried, stitching is performed using techniques like saddle stitching, which provides strength and durability. A combination of diamond chisels and sewing awls is often used to create precise stitching holes, ensuring a consistent and professional finish.

What Are the Key Finishing Techniques for Leather Wallets?

The finishing stage is where the wallet is brought to life. This includes edge finishing, burnishing, and applying oils or finishes to enhance the leather’s appearance and longevity. Edge burnishing involves smoothing and sealing the raw edges, which helps prevent fraying and adds a polished look.

Illustrative image related to make a leather wallet

Final inspections are conducted to ensure that the wallet meets all design specifications and quality standards. This includes checking for even stitching, proper alignment of components, and overall aesthetic appeal.

What Quality Assurance Standards Are Relevant in Leather Wallet Manufacturing?

Quality assurance is paramount in the leather wallet manufacturing process. International standards such as ISO 9001 outline requirements for a quality management system. This standard is crucial for ensuring consistent quality and improvement processes across manufacturing operations.

In addition to ISO standards, industry-specific certifications may be relevant, such as CE marking for products sold in Europe, which indicates compliance with health, safety, and environmental protection standards. For specific markets, certifications from local bodies may also be necessary.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) is typically integrated into various stages of the manufacturing process through several key checkpoints:

-

Incoming Quality Control (IQC): This stage involves the inspection of raw materials, such as leather, to ensure they meet specified quality standards before they enter production.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the quality of processes and identify any defects early on. This can include checks on stitching accuracy and alignment of components.

-

Final Quality Control (FQC): Once the wallets are assembled, a final inspection is performed to verify that the finished products meet all quality requirements. This includes checking for defects in stitching, finishes, and overall functionality.

What Testing Methods Are Commonly Used in Leather Wallet Manufacturing?

Common testing methods for leather wallets include:

-

Durability Tests: Assessing the wear resistance of the leather and stitching through abrasion tests or stress tests.

-

Color Fastness Tests: Ensuring that dyes used in the leather do not bleed or fade over time when exposed to various conditions.

-

Water Resistance Tests: Evaluating how well the wallet can withstand moisture, which is essential for leather products.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers seeking to ensure quality in their leather wallet suppliers can take several steps:

-

Conduct Supplier Audits: Regular audits of suppliers’ manufacturing processes can provide insight into their quality assurance practices. This can include reviewing their production facilities, equipment, and adherence to quality standards.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including any certifications they hold and results from recent inspections.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the products before shipment. This can help identify any potential issues that may have been overlooked during the internal QC processes.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must consider specific nuances in quality control:

-

Cultural Differences: Understanding regional quality expectations and consumer preferences can help buyers align their product specifications with market demands.

-

Regulatory Compliance: Different countries may have varying regulations regarding materials used in leather products, so it’s essential to ensure compliance with local laws.

-

Logistical Considerations: Quality control should also encompass the logistics of shipping and handling to prevent damage during transport. Buyers should ensure that their suppliers have robust packaging and shipping protocols in place.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can ensure that they are sourcing high-quality leather wallets that meet their business needs and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘make a leather wallet’

Introduction

This sourcing guide is designed to assist B2B buyers in procuring materials and resources necessary for manufacturing leather wallets. Whether you are an established leather goods manufacturer or a new entrant in the market, following this checklist will help streamline your procurement process, ensuring you acquire quality materials and reliable suppliers.

Step 1: Define Your Product Specifications

Before starting the procurement process, it is essential to outline the specific requirements for the leather wallets you intend to produce. Consider factors such as wallet size, style, and the number of pockets. This clarity will guide your sourcing decisions and ensure that you communicate effectively with suppliers.

Illustrative image related to make a leather wallet

- Materials: Decide on the type of leather (e.g., vegetable-tanned, chrome-tanned) and other materials needed (e.g., thread, adhesives).

- Design Requirements: Include details about patterns and any unique features you want to incorporate.

Step 2: Research and Identify Suppliers

Start by compiling a list of potential suppliers who specialize in leather and leatherworking materials. Utilize industry directories, trade shows, and online platforms to discover reputable vendors.

- Local vs. International: Evaluate the benefits of sourcing locally (e.g., reduced shipping time) versus internationally (e.g., cost-effectiveness).

- Supplier Reputation: Look for reviews and testimonials from other businesses to gauge reliability and product quality.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Certifications: Ensure suppliers have necessary certifications (e.g., ISO, environmental standards) to guarantee quality and compliance.

- Production Capacity: Confirm that the supplier can meet your volume requirements and has the capability for scaling production if needed.

Step 4: Request Samples and Prototypes

Once you narrow down your list, request samples of the materials or prototypes of the wallet designs. This step is vital to assess the quality and craftsmanship of the products.

- Quality Assessment: Check for consistency in color, texture, and finish of the leather.

- Functionality Testing: Evaluate how well the wallet design meets your specifications in real-world usage.

Step 5: Negotiate Terms and Pricing

Engage in discussions with your chosen suppliers to negotiate terms that are favorable for both parties. Clear communication is key to establishing a solid working relationship.

- Pricing Structure: Understand the pricing model, including bulk discounts and payment terms.

- Lead Times: Discuss production and delivery timelines to align with your project schedules.

Step 6: Place Orders and Establish Quality Control Protocols

After finalizing your supplier, place your initial order while setting up a quality control system to monitor production quality throughout the manufacturing process.

Illustrative image related to make a leather wallet

- Inspection Criteria: Define the standards for quality checks, including material defects and stitching quality.

- Feedback Mechanism: Establish a channel for feedback to ensure continuous improvement in product quality.

Step 7: Build Long-Term Relationships

Finally, aim to develop long-term partnerships with your suppliers. Consistent communication and collaboration can lead to better pricing, improved product offerings, and a more efficient supply chain.

- Regular Evaluations: Conduct periodic reviews of supplier performance to ensure they meet your evolving business needs.

- Involvement in Design: Engage suppliers in the design process for new products to leverage their expertise and insights.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing materials for leather wallets, ensuring quality and reliability at every step of the process.

Comprehensive Cost and Pricing Analysis for make a leather wallet Sourcing

What Are the Key Cost Components in Making a Leather Wallet?

When sourcing materials for leather wallets, several cost components should be considered to ensure a comprehensive understanding of the overall pricing structure. The primary cost components include:

-

Materials: The choice of leather significantly impacts cost. Vegetable-tanned leather, commonly used for wallets, typically ranges from $4 to $10 per square foot, depending on quality and sourcing. Additional materials such as thread, glue, and edge finishing products also contribute to the total material costs.

-

Labor: Labor costs can vary greatly based on location and skill level. In countries with lower labor costs, such as Nigeria or Brazil, the hourly wage for skilled leatherworkers might range from $2 to $5, while in Europe, it could reach $15 to $25. The labor component also includes training and the time taken for intricate craftsmanship.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Generally, it accounts for about 10-20% of the total production cost. Efficient manufacturing processes can help reduce these overheads, thereby lowering the final price.

-

Tooling: Initial setup costs for tools like diamond chisels, sewing awls, and cutting mats can be significant, especially for small-scale operations. Tooling costs may range from $500 to $2000 depending on the quality and quantity of tools needed.

-

Quality Control (QC): Implementing a quality control process is essential to ensure that the wallets meet specified standards. QC costs can add an additional 5-10% to the total production cost, particularly if multiple inspections are required.

-

Logistics: Shipping and handling costs can vary based on the destination and shipping method. For international buyers, understanding Incoterms is crucial as they define responsibilities regarding shipping, insurance, and tariffs, impacting the overall logistics cost.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. This margin can range from 20% to 50%, depending on market demand, competition, and the uniqueness of the product.

How Do Price Influencers Affect Leather Wallet Sourcing?

Several factors influence the pricing of leather wallets in the B2B market:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk pricing, significantly reducing the per-unit cost. Buyers should negotiate for favorable terms based on their purchasing capacity.

-

Specifications and Customization: Customized wallets, such as those featuring unique designs or branding, can increase costs. Clear communication about specifications is essential to avoid unexpected charges.

-

Material Quality and Certifications: Premium quality leather or certified eco-friendly materials will command higher prices. Buyers should assess the long-term benefits of investing in higher-quality materials against initial costs.

-

Supplier Factors: Supplier reputation, reliability, and historical performance can influence pricing. Established suppliers may charge more due to their proven quality and service, while newer suppliers may offer lower prices to gain market entry.

What Buyer Tips Can Help in Negotiating Leather Wallet Prices?

For international B2B buyers, particularly from regions like Africa, South America, and the Middle East, navigating the leather wallet sourcing landscape requires strategic negotiation and awareness of total costs:

Illustrative image related to make a leather wallet

-

Negotiation Strategies: Leverage your purchasing volume to negotiate better pricing. Building long-term relationships with suppliers can also yield discounts and favorable terms.

-

Cost-Efficiency: Analyze the total cost of ownership rather than just the upfront price. Consider factors like durability, warranty, and potential returns on investment.

-

Understanding Pricing Nuances: Be aware of currency fluctuations, import duties, and taxes that can impact the final cost. This is particularly relevant for buyers in regions with volatile currencies.

-

Researching Supplier Backgrounds: Conduct thorough due diligence on potential suppliers to ensure they meet quality and ethical standards. This can help avoid costly mistakes associated with subpar products.

Disclaimer for Indicative Prices

The prices mentioned above are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable to conduct thorough market research and seek multiple quotes to ensure competitive pricing when sourcing leather wallets.

Alternatives Analysis: Comparing make a leather wallet With Other Solutions

Exploring Alternative Solutions for Leather Wallet Production

In the competitive landscape of leather goods, businesses may explore various methods for producing wallets to meet consumer demands. While making a leather wallet offers a hands-on approach to craftsmanship, there are alternative solutions that can streamline production, reduce costs, or enhance scalability. This analysis compares the traditional method of crafting a leather wallet with two viable alternatives: manufacturing synthetic wallets and utilizing 3D printing technology.

| Comparison Aspect | Make A Leather Wallet | Synthetic Wallet Production | 3D Printing Technology |

|---|---|---|---|

| Performance | High-quality, durable product | Variable quality; can mimic leather but may lack durability | High customization, fast prototyping, but may lack durability |

| Cost | Moderate to high, depending on leather quality | Generally lower due to cheaper materials | Initial investment high; materials can be cost-effective |

| Ease of Implementation | Requires skilled labor and tools | Easier; can be mass-produced with automated processes | Requires technical knowledge and specialized equipment |

| Maintenance | Requires care to maintain quality | Low maintenance, can be easily cleaned | Dependent on material used; some require special care |

| Best Use Case | Luxury and bespoke markets | Budget-friendly options for mass markets | Custom, niche markets or rapid prototyping |

What Are the Pros and Cons of Synthetic Wallet Production?

Synthetic wallet production typically involves materials like PVC or polyurethane, which can effectively mimic leather’s appearance. The main advantage of this method is cost; synthetic materials are often cheaper to produce and can be manufactured at scale, making them ideal for budget-conscious consumers. However, synthetic wallets may not offer the same durability or luxury appeal as genuine leather, which could deter high-end buyers. Additionally, the environmental impact of synthetic materials is a growing concern for consumers who prioritize sustainability.

Illustrative image related to make a leather wallet

How Does 3D Printing Technology Compare?

3D printing technology represents a groundbreaking approach in wallet production, allowing for high levels of customization and rapid prototyping. This method can produce intricate designs that might be challenging to achieve with traditional leatherworking techniques. However, the initial investment in 3D printing technology can be substantial, and the materials used may not provide the same durability as leather. This solution is best suited for businesses targeting niche markets or those looking to quickly test new designs without committing to large production runs.

Conclusion: How Should B2B Buyers Choose the Right Wallet Production Method?

When selecting the appropriate wallet production method, B2B buyers should consider their target market and business goals. For companies focusing on luxury or bespoke products, the traditional leather wallet method remains unmatched in terms of quality and customer satisfaction. Conversely, businesses aiming for mass-market appeal may benefit from synthetic production due to its cost-effectiveness. Lastly, 3D printing can be an innovative solution for brands looking to differentiate themselves with unique designs. Ultimately, the choice will depend on balancing factors such as cost, quality, consumer expectations, and the desired brand image.

Essential Technical Properties and Trade Terminology for make a leather wallet

What Are the Key Technical Properties for Making a Leather Wallet?

When producing leather wallets, understanding the essential technical properties can significantly impact product quality and marketability. Here are some critical specifications to consider:

1. Material Grade

Leather wallets are typically made from vegetable-tanned leather, which is favored for its durability and natural finish. The material grade, often denoted by ounces (oz), indicates the thickness of the leather. For wallets, a weight of 3-4 oz is common, providing a balance between sturdiness and flexibility. For B2B buyers, selecting the right material grade is crucial for ensuring product longevity and customer satisfaction.

2. Tolerance

Tolerance refers to the permissible limits of variation in the dimensions of the wallet components. Maintaining tight tolerances during manufacturing ensures that wallets fit together correctly and that pockets hold cards securely. In B2B transactions, this precision can affect production costs and timelines. Buyers should prioritize suppliers who can consistently meet specified tolerances to reduce waste and enhance product reliability.

3. Stitching Strength

The strength of the stitching used in leather wallets is vital for their durability. Commonly, a saddle stitch is employed, which is known for its robustness. Stitching strength is often measured in pounds per inch (PPI). For B2B buyers, understanding stitching strength helps assess the quality of the final product, ensuring it withstands everyday use and maintains its aesthetic appeal.

4. Finish Type

The finish of leather can significantly influence the wallet’s appearance and tactile quality. Options include aniline, semi-aniline, and pigment finishes. Each finish type offers different levels of protection and aesthetic appeal. B2B buyers need to consider the target market preferences when selecting a finish, as this can directly impact sales and brand perception.

5. Edge Treatment

The edges of the wallet must be treated to prevent fraying and enhance visual appeal. Common methods include burnishing and sealing, which can add to the wallet’s overall durability. Edge treatment specifications are critical for B2B buyers, as they affect the product’s quality and longevity.

What Are Common Trade Terms Used in the Leather Wallet Industry?

Understanding industry jargon is essential for navigating B2B transactions effectively. Here are some common trade terms relevant to leather wallet production:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the leather wallet industry, an OEM may manufacture wallets based on a buyer’s specifications. This term is significant for buyers looking to create custom products while leveraging established manufacturing capabilities.

Illustrative image related to make a leather wallet

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to produce or sell. For leather wallets, MOQs can vary significantly based on material and production capabilities. Understanding MOQs is vital for B2B buyers, as it impacts inventory management and upfront costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. In the leather wallet industry, sending an RFQ helps buyers gather competitive pricing and assess supplier capabilities. It is a critical step in the procurement process, ensuring informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They specify who pays for shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers in the leather wallet market, as it clarifies costs and responsibilities, facilitating smoother transactions.

Illustrative image related to make a leather wallet

5. Lead Time

Lead time is the duration between placing an order and receiving the final product. In the leather wallet industry, lead times can be influenced by factors such as material availability and production capacity. For B2B buyers, understanding lead times is crucial for effective inventory planning and meeting market demands.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring they procure high-quality leather wallets that meet market expectations.

Navigating Market Dynamics and Sourcing Trends in the make a leather wallet Sector

What Are the Key Market Dynamics Affecting the Leather Wallet Sector?

The leather wallet sector is witnessing significant transformation driven by various global trends and market dynamics. One of the primary drivers is the growing demand for personalized and artisanal products, particularly in regions like Africa and South America. As consumers increasingly seek unique items, international B2B buyers are capitalizing on this trend by sourcing custom-made leather wallets that appeal to local aesthetics and cultural preferences.

Emerging B2B technologies are also reshaping sourcing strategies. Innovations such as digital supply chain management tools and e-commerce platforms enable buyers to connect with suppliers globally, facilitating smoother transactions and streamlined logistics. In addition, the rise of social media marketing is influencing purchasing decisions, prompting businesses to enhance their online presence and showcase their products effectively.

Illustrative image related to make a leather wallet

Furthermore, there is a noticeable shift towards minimalism in wallet design, driven by changing consumer lifestyles and preferences. Buyers are now looking for wallets that are not only stylish but also functional, with features that accommodate digital payment solutions. This trend encourages manufacturers to innovate and refine their offerings, ensuring they remain competitive in a dynamic marketplace.

How Is Sustainability Impacting the Leather Wallet Sourcing Process?

Sustainability has become a pivotal factor in the leather wallet sector, significantly influencing sourcing decisions for international B2B buyers. The environmental impact of leather production is under scrutiny, with concerns surrounding deforestation, water consumption, and chemical runoff. As a result, buyers are increasingly prioritizing suppliers that adhere to sustainable practices, such as sourcing leather from tanneries that utilize eco-friendly methods and by-products.

Ethical sourcing is equally crucial, with a growing emphasis on fair labor practices and transparency within supply chains. Buyers are encouraged to seek suppliers who provide certifications that demonstrate compliance with ethical standards, such as the Leather Working Group (LWG) certification, which recognizes responsible leather production practices.

Moreover, the demand for “green” materials is on the rise. Buyers are exploring alternative leather options, such as vegetable-tanned leather and synthetic leathers made from recycled materials, which offer lower environmental impact without sacrificing quality. By prioritizing sustainable sourcing, B2B buyers not only align with consumer preferences but also contribute to the broader goal of reducing the leather industry’s carbon footprint.

What Is the Historical Context of the Leather Wallet Market?

The leather wallet has a rich history that dates back centuries, evolving from basic functional items into symbols of status and personal style. Initially crafted by skilled artisans, wallets were primarily utilitarian, designed to hold coins and personal belongings. As trade and commerce expanded, the need for more sophisticated designs emerged, leading to the development of various styles tailored to different cultural contexts.

Throughout the 20th century, the leather wallet underwent significant transformations influenced by fashion trends and technological advancements. The introduction of credit cards and digital payment methods in the late 20th century prompted manufacturers to innovate wallet designs, incorporating features like card slots and RFID protection.

Today, the leather wallet market continues to evolve, with a focus on sustainability, personalization, and functionality. This historical context provides valuable insights for B2B buyers looking to navigate the complexities of sourcing leather wallets in a contemporary market, emphasizing the importance of adaptability and responsiveness to consumer trends.

Frequently Asked Questions (FAQs) for B2B Buyers of make a leather wallet

1. How do I ensure the quality of leather wallets from suppliers?

To ensure quality, start by vetting suppliers through established platforms and industry networks. Request samples to assess leather quality, stitching, and overall craftsmanship. It’s also essential to review certifications, such as eco-friendly processes or compliance with international quality standards. Conducting factory visits, if possible, can provide insights into production practices. Establish clear quality assurance parameters in your contract, including specifications for materials, durability tests, and after-sales support to maintain standards.

2. What is the best type of leather for making durable wallets?

Vegetable-tanned leather is often recommended for its durability and natural finish. It ages beautifully, developing a unique patina over time. Alternatively, full-grain leather offers excellent strength and is less processed, making it ideal for high-end products. For budget-friendly options, top-grain leather is a good compromise, providing a balance between cost and quality. When sourcing, consider the leather’s weight (3-4 oz is ideal for wallets) and ensure it meets your target market’s preferences for texture and finish.

Illustrative image related to make a leather wallet

3. How can I customize leather wallets for my brand?

Customization options include choosing specific leather types, colors, and wallet designs to align with your brand identity. You can also incorporate your logo through embossing, debossing, or screen printing. Discuss minimum order quantities (MOQs) for customized items with your suppliers, as these may vary. Additionally, consider offering personalization options for end customers, like monogramming, to enhance value. Ensure that your suppliers can accommodate your design specifications and timelines to meet your market demands effectively.

4. What are the typical minimum order quantities (MOQs) for leather wallets?

MOQs can vary significantly based on the supplier and the complexity of the customization. Generally, for standard designs, MOQs can range from 50 to 100 units. For highly customized products, expect higher MOQs, often starting at 200 units or more. It’s advisable to discuss your needs directly with suppliers to negotiate terms that work for both parties. Keep in mind that larger orders may offer better pricing and production efficiencies, which can be beneficial for your business.

5. What payment terms should I expect when sourcing leather wallets?

Payment terms typically vary by supplier and region. Common practices include a deposit of 30-50% upfront, with the balance due upon delivery or before shipping. Some suppliers may offer net payment terms (e.g., net 30, net 60), allowing you to pay after receiving the goods. Always clarify terms in your contract to avoid misunderstandings. Consider using secure payment methods, such as letters of credit or escrow services, especially for larger transactions, to safeguard your investment.

6. How do I handle logistics and shipping for imported leather wallets?

When importing, familiarize yourself with the shipping options available, including air freight for speed or sea freight for cost-effectiveness. Partner with a reliable logistics provider experienced in international shipping to navigate customs and ensure compliance with local regulations. Calculate total landed costs, including duties and taxes, to avoid unexpected expenses. Timely communication with your supplier regarding shipping schedules can help manage inventory and minimize disruptions in your supply chain.

Illustrative image related to make a leather wallet

7. What factors should I consider when selecting a supplier for leather wallets?

Key factors include the supplier’s reputation, production capabilities, and experience in leather goods manufacturing. Evaluate their quality control processes and request references or testimonials from previous clients. Assess their ability to meet your specific needs regarding customization, lead times, and MOQs. Additionally, consider their location, as proximity may affect shipping costs and timelines. A supplier with a strong commitment to ethical practices and sustainability can also enhance your brand’s reputation.

8. How can I ensure timely delivery of leather wallets?

To ensure timely delivery, establish clear timelines and milestones with your supplier from the outset. Regular communication is crucial; request updates on production status and any potential delays. Consider building in buffer times in your inventory planning to accommodate unforeseen issues. Using a logistics partner with a proven track record can also help streamline the shipping process. Lastly, having contingency plans for alternative suppliers can mitigate risks associated with delays in your supply chain.

Top 3 Make A Leather Wallet Manufacturers & Suppliers List

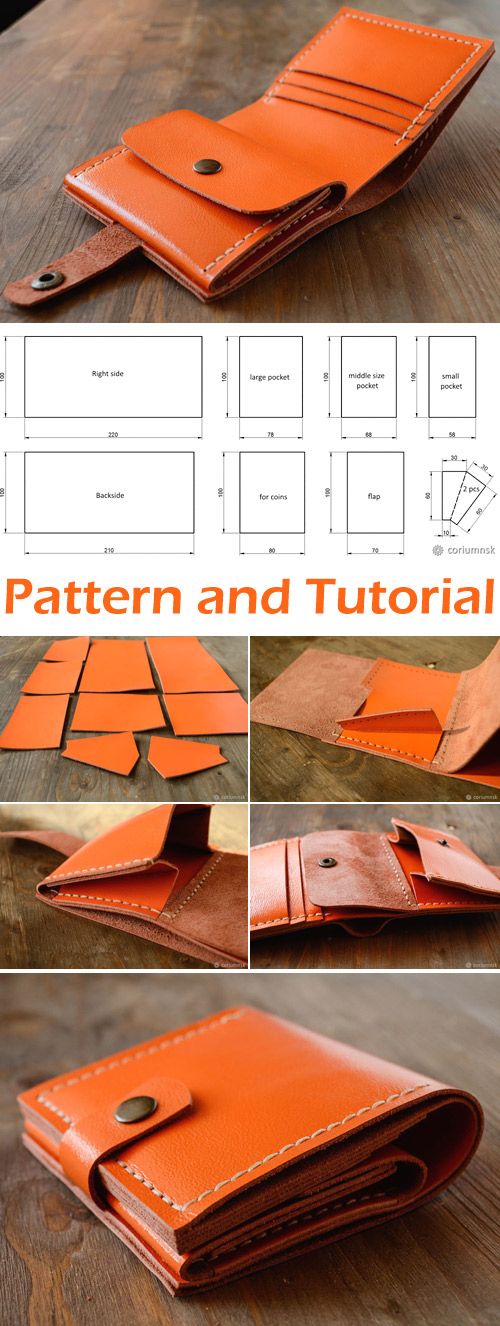

1. Instructables – Leather Wallet Tutorial

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Leather wallet tutorial by jessyratfink, featuring a small design that holds up to 8 cards and folded cash. Includes three wallet patterns (straight and slanted pockets). Tools and supplies needed: 3-4 oz vegetable tanned leather, diamond chisel set, sewing awl, waxed thread, stitching pony, stitching groover, jojoba oil, x-acto knife, ruler, rubber mallet, spray bottle, gum tragacanth, edge slick…

2. Reddit – Beginner’s Leather Wallet

3. Pop Sewing – DIY Leather Wallet Kits

Domain: popsewing.com

Registered: 2021 (4 years)

Introduction: DIY Leather Wallet Kit Purse Kit – Wallet Making Kit, In stock (38), Out of stock (11), Make your own purse or wallet within 2 hours, Price range: $29.99 – $75.99, Various DIY kits available including Leather Dustbag Recycle Wallet, Crazy Horse Leather Vintage Wallet, Full Grain Leather Men’s Bifold Wallet, Top Grain Leather Alligator Card Holder, and more.

Strategic Sourcing Conclusion and Outlook for make a leather wallet

What Are the Key Takeaways for Strategic Sourcing in Leather Wallet Production?

In the realm of leather wallet production, strategic sourcing emerges as a pivotal factor for success. By carefully selecting high-quality materials, such as vegetable-tanned leather, and leveraging reliable suppliers, businesses can ensure durability and customer satisfaction. The importance of investing in the right tools and techniques cannot be overstated; they not only enhance the craftsmanship of the wallets but also streamline production processes, leading to cost savings and improved efficiency.

How Can B2B Buyers Leverage Market Trends in Leather Goods?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are positioned to capitalize on the growing demand for artisanal leather products. By staying attuned to market trends and consumer preferences, businesses can adapt their offerings to meet evolving needs, ensuring a competitive edge in the market.

What Steps Should Be Taken to Engage with Suppliers?

As you consider entering or expanding within the leather wallet market, establishing strong relationships with suppliers and manufacturers is crucial. Engage in dialogues to explore innovative designs and sustainable sourcing practices that align with global standards.

In conclusion, strategic sourcing not only enhances product quality but also fosters long-term partnerships that can drive profitability. Embrace this opportunity to innovate and connect with suppliers who share your vision for excellence in leather craftsmanship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.