Introduction: Navigating the Global Market for leather or fabric

As international B2B buyers navigate the complex landscape of sourcing high-quality leather or fabric, one of the foremost challenges is understanding the unique benefits and applications of each material. Whether you are looking to procure durable upholstery for commercial furniture or stylish textiles for fashion, the decision between leather and fabric can significantly impact your brand’s image, product quality, and customer satisfaction. This guide delves into the intricacies of both materials, exploring their various types, applications, and maintenance requirements, while also offering insights into effective supplier vetting processes.

In today’s global market, where preferences and standards vary widely across regions—from the bustling cities of Africa and South America to the luxury markets of the Middle East and Europe—making informed purchasing decisions is crucial. This comprehensive resource empowers buyers by detailing cost considerations, highlighting industry trends, and providing actionable strategies for sourcing. By understanding the nuances of leather and fabric, you can align your purchasing decisions with your business goals, ensuring that you not only meet but exceed customer expectations. Equip yourself with the knowledge to confidently navigate the competitive landscape and make selections that resonate with your target market.

Table Of Contents

- Top 5 Leather Or Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather or fabric

- Understanding leather or fabric Types and Variations

- Key Industrial Applications of leather or fabric

- 3 Common User Pain Points for ‘leather or fabric’ & Their Solutions

- Strategic Material Selection Guide for leather or fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for leather or fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather or fabric’

- Comprehensive Cost and Pricing Analysis for leather or fabric Sourcing

- Alternatives Analysis: Comparing leather or fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for leather or fabric

- Navigating Market Dynamics and Sourcing Trends in the leather or fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather or fabric

- Strategic Sourcing Conclusion and Outlook for leather or fabric

- Important Disclaimer & Terms of Use

Understanding leather or fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Grain Leather | Made from the top layer of the hide, retains natural grain and marks. | Luxury furniture, high-end fashion | Pros: Durability, develops a unique patina. Cons: Higher cost, requires maintenance. |

| Microfibre | Synthetic fabric that mimics the look and feel of suede. | Upholstery, automotive interiors | Pros: Stain-resistant, easy to clean. Cons: Can wear down over time, less breathable. |

| Canvas | Heavy-duty cotton fabric, often treated for water resistance. | Outdoor furniture, bags, tents | Pros: Affordable, durable, versatile. Cons: Can fade, less luxurious appearance. |

| Faux cuir | Synthetic alternative to leather, available in various finishes. | Budget furniture, fashion accessories | Pros: Cost-effective, animal-friendly. Cons: Less durable, may not age as well. |

| Velvet | Soft, plush fabric with a rich texture, often made from cotton or polyester. | Upholstered furniture, curtains | Pros: Luxurious appearance, wide color range. Cons: Can be difficult to clean, less durable in high-traffic areas. |

What Are the Key Characteristics of Full-Grain Leather for B2B Buyers?

Full-grain leather is celebrated for its natural look and durability, as it is made from the top layer of the hide. This type of leather retains the original grain, showcasing unique markings that enhance its aesthetic appeal. For B2B buyers, full-grain leather is ideal for luxury furniture and high-end fashion items, where quality and longevity are paramount. However, its higher price point and need for regular maintenance, such as conditioning to prevent drying, are crucial considerations for procurement decisions.

How Does Microfiber Compare in Terms of Suitability for B2B Applications?

Microfiber is a synthetic fabric that closely resembles suede, making it a popular choice for upholstery and automotive interiors. It is known for its stain-resistant properties and ease of cleaning, which are significant advantages in commercial settings where maintenance is a concern. However, B2B buyers should be aware that while microfiber is generally affordable, it may not withstand heavy wear as effectively as natural materials, potentially leading to higher replacement costs in the long run.

Illustrative image related to leather or fabric

Why Choose Canvas for Outdoor Applications?

Canvas is a heavy-duty cotton fabric that is often treated for water resistance, making it an excellent option for outdoor furniture, bags, and tents. Its affordability and durability are key selling points for B2B buyers seeking cost-effective solutions. However, buyers should note that canvas can fade over time when exposed to sunlight and may lack the luxurious appearance of other materials, which could be a consideration in high-end applications.

What Are the Benefits and Drawbacks of Faux Leather in B2B Markets?

Faux leather, or synthetic leather, is a cost-effective alternative to genuine leather, making it appealing for budget-conscious buyers in the furniture and fashion industries. It offers a variety of finishes and colors while being animal-friendly. However, B2B buyers should consider that faux leather may not be as durable as real leather and can show wear over time, which could affect the overall quality perception of the products.

How Does Velvet Fit Into the B2B Textile Landscape?

Velvet is a plush fabric that provides a luxurious texture and appearance, often made from cotton or polyester. It is frequently used in upholstered furniture and curtains, appealing to buyers looking for high-end aesthetics. While velvet offers a wide range of colors and a rich feel, its maintenance can be challenging, and it may not be suitable for high-traffic areas due to its tendency to wear down. B2B purchasers should weigh these factors against their market needs and customer preferences.

Illustrative image related to leather or fabric

Key Industrial Applications of leather or fabric

| Industry/Sector | Specific Application of leather or fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for seats and interiors | Enhances vehicle aesthetics, comfort, and durability | Quality of leather/fabric, compliance with safety standards, and color options tailored to market preferences |

| Fashion & Apparel | Clothing and accessories | Allows for diverse styles, durability, and comfort | Trend alignment, fabric certifications, and sourcing sustainable materials |

| Furniture | Sofas, chairs, and upholstery | Provides comfort, aesthetic appeal, and longevity | Material quality, stain resistance, and customization options for different markets |

| Home Décor | Curtains, cushions, and wall coverings | Enhances interior design and warmth | Variety in textures and patterns, durability for high-traffic areas, and local design trends |

| Hospitality | Hotel furnishings and decor | Elevates guest experience and brand perception | Bulk purchasing options, durability, and compliance with hospitality standards |

What Are the Key Applications of Leather or Fabric in the Automotive Industry?

In the automotive sector, leather and fabric are predominantly used for upholstery in seats and interiors. They enhance the vehicle’s aesthetics while providing comfort and durability for everyday use. Buyers in this sector must consider the quality of materials, ensuring they meet safety standards and offer a range of color options that appeal to various markets, including luxury and mid-range vehicles. International buyers should also be aware of regional preferences, such as the demand for eco-friendly or vegan alternatives in certain markets.

How Is Leather or Fabric Utilized in the Fashion & Apparel Industry?

In fashion, leather and fabric are integral for creating clothing and accessories, offering diverse styles that cater to various consumer preferences. The durability and comfort of these materials are crucial for garments that are worn frequently. B2B buyers in this sector need to align with current trends while ensuring the materials sourced are certified for quality and sustainability. This is particularly important in markets like Europe, where there is a strong emphasis on ethical sourcing and environmental impact.

What Role Do Leather and Fabric Play in Furniture Manufacturing?

In the furniture industry, leather and fabric are used extensively for sofas, chairs, and other upholstered items. These materials contribute to the comfort, aesthetic appeal, and longevity of furniture pieces. Buyers should focus on sourcing high-quality materials that are stain-resistant and customizable to fit various interior designs. Additionally, understanding local market trends and customer preferences is essential, especially in regions with distinct cultural styles, such as the Middle East or South America.

How Do Leather and Fabric Enhance Home Décor?

Leather and fabric are used in home décor for items such as curtains, cushions, and wall coverings. They add warmth and aesthetic appeal to living spaces, making them more inviting. B2B buyers need to consider a variety of textures and patterns to meet diverse consumer tastes. Durability is also a key factor, especially in high-traffic areas where wear and tear are more likely. Understanding local design trends can help buyers select materials that resonate with consumers in different regions.

What Benefits Do Leather and Fabric Offer in the Hospitality Sector?

In the hospitality industry, leather and fabric are used for hotel furnishings and décor, significantly enhancing the guest experience. The choice of materials can elevate the ambiance of a space and reflect the brand’s identity. When sourcing for hospitality, businesses should focus on bulk purchasing options that ensure consistency in quality and design. Compliance with industry standards for durability and maintenance is also critical, as it impacts the longevity of the furnishings and overall guest satisfaction.

3 Common User Pain Points for ‘leather or fabric’ & Their Solutions

Scenario 1: Struggling with Material Durability for High-Traffic Areas

The Problem: B2B buyers in sectors such as hospitality or office furnishings often encounter the challenge of selecting between leather and fabric for environments that experience high foot traffic. For instance, a hotel manager may find that fabric sofas quickly fray or stain, while leather options can become scratched and lose their appeal. This dilemma can lead to increased costs due to frequent replacements or repairs, impacting the bottom line and guest satisfaction.

The Solution: To effectively address this issue, it’s crucial to focus on sourcing high-quality materials specifically designed for durability. When selecting fabric, opt for tightly woven, high-grade upholstery that is treated for stain resistance and easy cleaning. Look for performance fabrics that can withstand wear and tear while offering a variety of colors and patterns to suit your design aesthetic. For leather, consider selecting top-grain or corrected-grain leather, which offers enhanced durability and resistance to scratches. Additionally, regular maintenance, such as conditioning leather and spot cleaning fabric, will prolong the lifespan of the furniture and ensure it remains visually appealing.

Scenario 2: Balancing Cost and Quality in Leather vs. Fabric Choices

The Problem: B2B buyers often face the challenge of balancing budget constraints with the need for high-quality materials in their offerings. For example, a furniture retailer may want to stock a range of sofas but struggle to decide whether to invest in expensive leather options or more affordable fabric choices, each with their own trade-offs in terms of durability and style. This indecision can stall inventory decisions and affect sales.

The Solution: To navigate this challenge, buyers should conduct a thorough market analysis to identify customer preferences and price sensitivities within their target market. Consider offering a mixed inventory that includes both leather and fabric options, allowing customers to choose based on their budget and style preferences. For fabric options, focus on mid-range but durable materials that provide good value, such as microfiber or high-performance polyester blends. For leather, consider sourcing from suppliers who offer eco-friendly, high-quality leather at competitive prices. Additionally, create promotional bundles or financing options that can make higher-end products more accessible to buyers while emphasizing the long-term cost-effectiveness of durable materials.

Scenario 3: Addressing Allergens and Health Concerns with Upholstery Choices

The Problem: Many B2B buyers, particularly in sectors like healthcare or education, are increasingly aware of the importance of maintaining a healthy environment. In these settings, the choice between leather and fabric can be influenced by concerns over allergens. Fabric upholstery can trap dust mites and allergens, while leather options may be perceived as more hygienic but can still harbor bacteria if not properly maintained.

The Solution: To effectively manage allergen concerns, B2B buyers should prioritize materials that are hypoallergenic and easy to clean. In healthcare settings, for example, selecting leather for its non-porous qualities can help minimize the risk of allergens, provided that regular cleaning protocols are established. For fabric, look for options treated with antimicrobial finishes that resist moisture and bacteria. Additionally, consider specifying furniture with removable, washable covers, which can significantly enhance cleanliness and reduce allergen accumulation. Educating staff on proper maintenance routines, including regular vacuuming and deep cleaning, will further ensure that the upholstery remains a safe and healthy choice for users.

Strategic Material Selection Guide for leather or fabric

What Are the Key Properties of Common Leather and Fabric Materials?

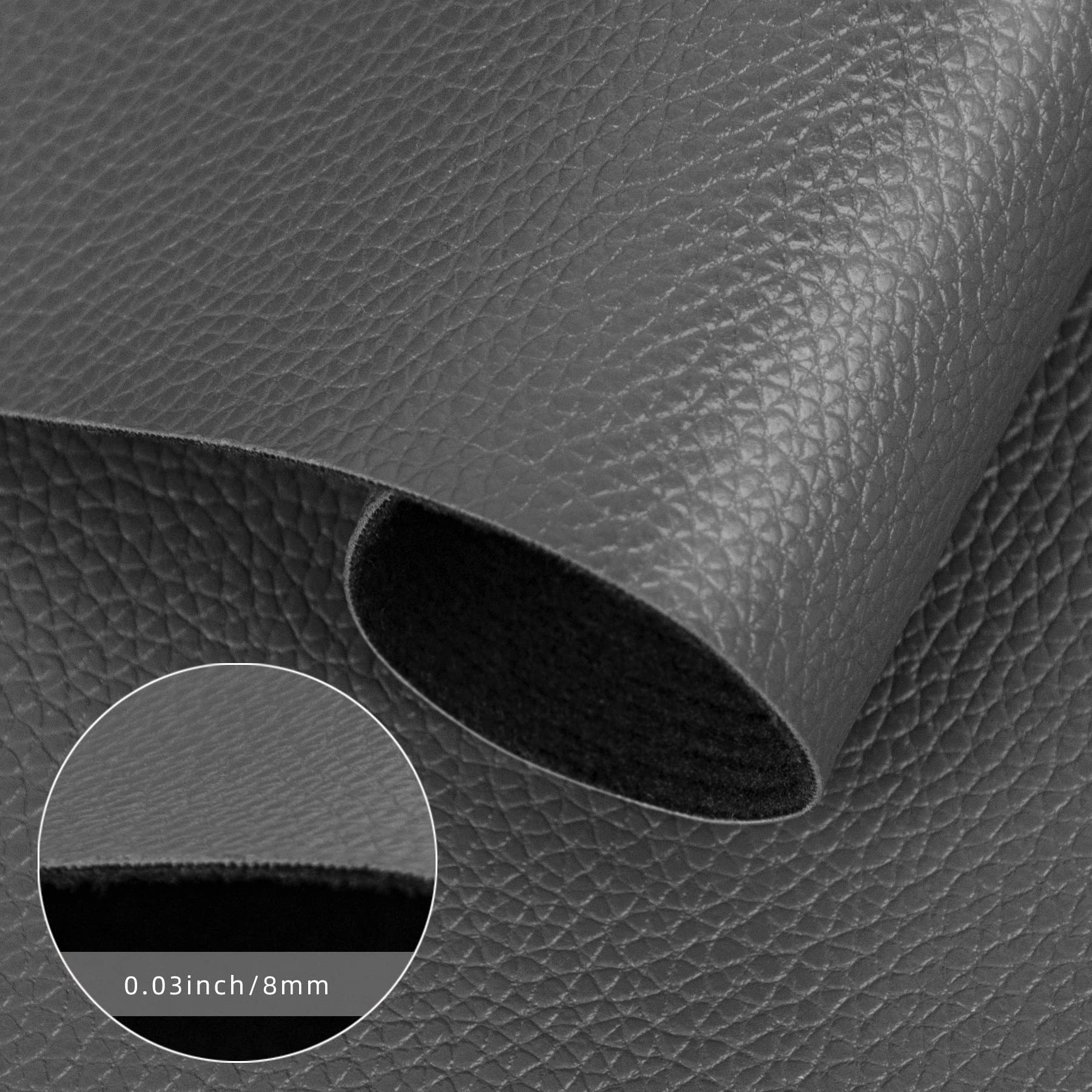

When selecting materials for leather or fabric applications, it’s essential to understand the properties that influence product performance. Here, we analyze four common materials: genuine leather, synthetic leather, cotton fabric, and polyester fabric. Each material has distinct characteristics that can impact durability, cost, and suitability for various applications.

Genuine Leather: What Makes It a Preferred Choice?

Genuine leather is renowned for its durability and aesthetic appeal. It typically offers high tensile strength and resistance to wear and tear, making it suitable for high-traffic environments. Leather can withstand temperature fluctuations but may become uncomfortable in extreme heat or cold.

Illustrative image related to leather or fabric

Pros: Its luxurious appearance and hypoallergenic properties make it a popular choice for high-end furniture and automotive upholstery. Leather is also easy to clean, requiring minimal maintenance.

Cons: The initial cost of genuine leather is relatively high, and it can be sensitive to scratches and stains. Additionally, sourcing high-quality leather may present challenges due to compliance with environmental regulations in different regions.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East may need to ensure compliance with REACH regulations regarding chemical substances in leather production. In contrast, buyers in Africa and South America might prioritize local sourcing to reduce costs.

Synthetic Leather: How Does It Compare to Genuine Leather?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to genuine leather. It is generally more resistant to moisture and stains, making it suitable for various applications, including furniture and automotive interiors.

Pros: Synthetic leather is available in a wide range of colors and textures, allowing for greater design flexibility. It is also easier to clean and maintain compared to genuine leather.

Illustrative image related to leather or fabric

Cons: While synthetic leather is durable, it may not match the longevity of genuine leather. Additionally, it can be less breathable, leading to discomfort in warm climates.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for synthetic materials across regions. For instance, ASTM standards may apply in North America, while European buyers may look for EN standards.

Cotton Fabric: What Are Its Benefits and Limitations?

Cotton fabric is a natural fiber known for its softness and breathability. It is widely used in upholstery and clothing due to its comfort and versatility. Cotton can handle moderate pressure and temperature variations, but it is less durable than leather.

Pros: Cotton is generally more affordable than leather and synthetic alternatives, making it an attractive option for budget-conscious buyers. It is also biodegradable, appealing to environmentally conscious consumers.

Cons: Cotton is prone to staining and may require more frequent cleaning. It can also wear out more quickly in high-traffic areas, leading to potential replacement costs.

Considerations for International Buyers: Buyers should check for compliance with international textile standards, such as Oeko-Tex, which ensures the absence of harmful substances. In regions like Africa, sourcing locally grown cotton can enhance sustainability.

Polyester Fabric: How Does It Stand Up in Comparison?

Polyester fabric is a synthetic material known for its durability and resistance to wrinkles, fading, and shrinking. It performs well under pressure and temperature variations, making it suitable for various applications, including outdoor furniture.

Pros: Polyester is typically more affordable than cotton and leather, offering excellent color retention and stain resistance. Its low maintenance requirements make it ideal for high-use environments.

Cons: While durable, polyester may not provide the same level of comfort as natural fibers. Additionally, it is less breathable, which can be a drawback in warm climates.

Considerations for International Buyers: Buyers should consider the environmental impact of polyester production, especially in regions with strict sustainability regulations. Certifications such as Global Recycled Standard (GRS) can be beneficial for buyers focused on sustainability.

Illustrative image related to leather or fabric

Summary Table of Material Properties

| Matériau | Typical Use Case for leather or fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | High-end furniture, automotive interiors | Luxurious appearance, durability | High cost, sensitive to scratches | Haut |

| Synthetic Leather | Budget furniture, automotive interiors | Cost-effective, easy to clean | Less durable than genuine leather | Medium |

| Cotton Fabric | Upholstery, clothing | Soft, breathable, biodegradable | Prone to staining, less durable | Low |

| Polyester Fabric | Outdoor furniture, high-use areas | Durable, stain-resistant | Less breathable, comfort concerns | Medium |

This analysis provides a comprehensive overview of material selection for leather and fabric applications, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for leather or fabric

What Are the Main Stages in the Manufacturing Process for Leather and Fabric?

The manufacturing processes for leather and fabric involve multiple stages, each critical to ensuring the final product meets quality and performance standards. Understanding these stages can help B2B buyers assess suppliers effectively.

Material Preparation: What Steps Are Involved?

For leather, the process begins with sourcing raw hides, typically from cattle, sheep, or goats. The hides undergo a curing process to prevent decay, using methods such as salting or drying. Following this, the hides are soaked in water to remove impurities, and then they are treated with chemicals during tanning to transform them into durable leather.

In contrast, fabric manufacturing starts with fiber selection, which can include natural fibers like cotton and wool or synthetic fibers like polyester and nylon. The fibers are spun into yarns, which are then woven or knitted to create fabric. The quality of fibers significantly affects the final product, so sourcing high-grade materials is crucial.

How Are Leather and Fabric Formed?

Key Techniques in Forming Leather

Once the leather is tanned, it is cut into patterns based on the intended product. Techniques such as die-cutting and hand-cutting are employed to ensure precision. The leather pieces are then shaped using molds or forms, which is especially common in the production of items like bags and footwear.

Illustrative image related to leather or fabric

For fabric, the formation process includes weaving or knitting the yarn into a fabric sheet. Advanced technologies like Jacquard weaving enable intricate designs and patterns, catering to diverse market demands. After weaving, the fabric undergoes processes such as dyeing, printing, and finishing to enhance its aesthetic and functional properties.

What Are the Assembly and Finishing Processes for Leather and Fabric Products?

Assembly Techniques for Leather Products

The assembly of leather products typically involves stitching, which can be done by hand or using industrial sewing machines. Different stitching techniques, such as double-stitching or saddle stitching, are employed based on the product’s durability requirements. After assembly, leather products are often subjected to edge finishing and burnishing to provide a polished look.

Fabric products follow a similar assembly process, where pieces are sewn together, and additional components like zippers or buttons are attached. The finishing process for fabric includes treatments such as water-repellent or stain-resistant coatings, ensuring the product is suitable for its intended use.

What Quality Assurance Practices Should B2B Buyers Expect?

International Standards for Quality Assurance

Quality assurance is paramount in the manufacturing of leather and fabric products. International standards like ISO 9001 provide a framework for quality management systems that manufacturers must adhere to. Additionally, industry-specific certifications such as CE marking for safety and API standards for petroleum-related products are crucial for ensuring compliance with regional regulations.

Illustrative image related to leather or fabric

What Are the Key QC Checkpoints in Manufacturing?

Quality control (QC) typically includes several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. For leather, this may include checking for defects in the hides, while for fabric, it involves assessing the quality of yarns or rolls of fabric.

-

In-Process Quality Control (IPQC): During the manufacturing stages, continuous monitoring is essential. This may involve checking the stitching quality, assessing dye consistency, and ensuring that assembly methods adhere to specifications.

-

Final Quality Control (FQC): Once the products are completed, a final inspection is conducted. This includes evaluating the overall appearance, functionality, and compliance with standards. This step is crucial for identifying any defects that may have occurred during production.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to ensure that leather and fabric products meet quality standards. Common tests include:

- Durability Testing: This assesses how well the material can withstand wear and tear, often through abrasion tests or tensile strength tests.

- Colorfastness Testing: This evaluates how well a material retains its color when exposed to light, washing, or rubbing.

- Water Resistance Testing: For certain products, especially in outdoor applications, testing for water resistance is vital.

- Chemical Testing: Ensures that materials do not contain harmful substances, complying with safety regulations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers. Here are some recommended practices:

- Conduct Supplier Audits: Regular audits of suppliers can help ensure they maintain high-quality standards. This can include on-site visits and assessments of their quality management systems.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including test results and compliance certifications.

- Utilize Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s adherence to quality standards. These services can conduct pre-shipment inspections to verify product quality before shipping.

What Are the Nuances of QC and Certification for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is vital, particularly in regions like Africa, South America, the Middle East, and Europe. Different regions may have varying standards, regulations, and cultural expectations regarding product quality.

For instance, buyers in Europe often require products to meet stringent EU standards, while those in the Middle East may focus on compliance with local regulations. It’s essential for buyers to communicate clearly with suppliers about their specific requirements and to seek certifications that align with their market’s expectations.

In conclusion, thorough knowledge of manufacturing processes and quality assurance practices is essential for B2B buyers in the leather and fabric sectors. By understanding these processes, buyers can make informed decisions, ensuring they partner with suppliers that meet their quality and compliance needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather or fabric’

To assist B2B buyers in sourcing leather or fabric effectively, this guide provides a structured approach to ensure that the procurement process is smooth and meets business needs. Each step is designed to help you make informed decisions, focusing on quality, supplier reliability, and cost efficiency.

Step 1: Define Your Technical Specifications

Establish clear technical specifications that outline the requirements for the leather or fabric you wish to procure. Consider factors such as material type, weight, texture, color, and durability. This clarity will guide your search and facilitate better communication with suppliers.

Step 2: Conduct Market Research

Investigate the current market trends and pricing for leather and fabric. Understanding market dynamics will help you gauge the average costs and available options. Look for reputable trade publications, industry reports, and online forums to gather insights on quality benchmarks and supplier performance.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers who specialize in leather or fabric. Utilize platforms like Alibaba, Global Sources, or industry-specific directories. Ensure that the suppliers have a proven track record and offer the specific materials you need by checking their product catalogs and customer reviews.

Step 4: Verify Supplier Certifications

Before moving forward, confirm that your selected suppliers hold relevant certifications that ensure quality and compliance with international standards. Look for certifications such as ISO 9001 for quality management and environmental certifications like OEKO-TEX. This step helps mitigate risks associated with substandard materials.

Step 5: Request Samples for Evaluation

Always request samples of the leather or fabric before placing a bulk order. Evaluate these samples for quality, texture, and durability. This hands-on assessment allows you to verify that the materials meet your specifications and helps avoid costly mistakes down the line.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear communication about terms can lead to better pricing and service conditions. Ensure that you discuss return policies and warranties to protect your investment.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the materials received from suppliers. Set up inspections at various stages, including during production and upon delivery. This proactive approach ensures that the leather or fabric meets your standards and reduces the likelihood of receiving defective products.

By following this checklist, B2B buyers can streamline the sourcing process for leather or fabric, ensuring that they select the right materials from reliable suppliers while minimizing risks and optimizing costs.

Comprehensive Cost and Pricing Analysis for leather or fabric Sourcing

What Are the Key Cost Components in Leather and Fabric Sourcing?

When sourcing leather or fabric, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The type of leather or fabric significantly impacts costs. High-quality, genuine leather is typically more expensive than synthetic options, while specialized fabrics can vary widely in price based on composition and durability. Buyers should consider the lifecycle and performance of materials when making selections.

-

Labor: Labor costs can fluctuate based on the region and the complexity of the manufacturing process. Regions with lower labor costs may offer competitive pricing, but be cautious about quality and craftsmanship, especially for leather products that require skilled artisans.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with production. Efficient manufacturing processes can lower overhead costs, which can be beneficial for buyers when negotiating prices.

-

Tooling: Custom tooling for specialized designs can add significant costs. Buyers should assess whether the investment in tooling will yield a return based on anticipated volume and sales.

-

Quality Control (QC): Ensuring product quality is essential, especially for premium materials. QC processes can add to costs but are necessary to prevent defects and maintain customer satisfaction.

-

Logistics: Shipping costs can vary based on the distance from the supplier, the mode of transport, and the Incoterms used. Buyers should factor in logistics when calculating total expenses.

-

Margin: Suppliers will include their profit margin in the pricing. Understanding industry standards can help buyers negotiate better terms.

How Do Price Influencers Affect Leather and Fabric Costs?

Several factors influence pricing in leather and fabric sourcing, including volume, specifications, material quality, certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Larger orders often receive volume discounts, but buyers must balance stock levels with demand to avoid excess inventory.

-

Specifications and Customization: Custom specifications can increase costs due to additional labor and material requirements. Buyers should clearly outline their needs to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials often come with certifications that ensure compliance with environmental and safety standards. While these can increase upfront costs, they may provide long-term savings through durability and lower replacement rates.

-

Supplier Factors: The reliability and reputation of suppliers can influence costs. Established suppliers may charge more for their assurance of quality and service, while newer suppliers might offer competitive pricing to gain market entry.

-

Incoterms: The choice of Incoterms affects shipping responsibilities and costs. Understanding these terms can lead to better negotiation and cost management.

What Are the Best Tips for Negotiating Leather and Fabric Prices?

For international B2B buyers, effective negotiation strategies can yield significant cost savings and favorable terms.

Illustrative image related to leather or fabric

-

Leverage Total Cost of Ownership (TCO): Instead of focusing solely on the initial purchase price, consider the TCO, which includes maintenance, replacement, and disposal costs. This approach can help justify higher upfront costs for better quality products.

-

Conduct Market Research: Understanding the market landscape, including competitor pricing and trends, can empower buyers during negotiations. This knowledge can help in setting a reasonable price expectation.

-

Build Relationships with Suppliers: Establishing long-term relationships can lead to better pricing and terms. Suppliers may offer discounts or improved service for loyal customers.

-

Negotiate Payment Terms: Flexible payment terms can ease cash flow constraints. Consider negotiating partial payments or extended terms to improve financial flexibility.

-

Be Aware of Pricing Nuances for International Transactions: Buyers from Africa, South America, the Middle East, and Europe should be mindful of currency fluctuations, tariffs, and trade agreements that can impact pricing.

Disclaimer on Indicative Prices

Prices for leather and fabric sourcing can vary widely based on the factors outlined above. It is essential for buyers to conduct thorough research and engage with multiple suppliers to obtain accurate quotes tailored to their specific needs and circumstances.

Alternatives Analysis: Comparing leather or fabric With Other Solutions

Exploring Alternatives: Comparing Leather or Fabric with Other Solutions

When considering the choice between leather or fabric, it’s essential to evaluate viable alternatives that can meet similar needs in various applications, from upholstery to fashion. This analysis will provide insights into how these materials stack up against other options, aiding B2B buyers in making informed decisions.

| Comparison Aspect | Leather or Fabric | Synthetic Leather | Natural Fiber Textiles |

|---|---|---|---|

| Performance | Durable, varying comfort | Durable, less breathable | Breathable, comfortable |

| Cost | Higher initial investment | Lower initial investment | Moderate investment |

| Ease of Implementation | Requires skilled labor | Easier to work with | Requires skilled labor |

| Maintenance | Moderate, requires conditioning | Low, easy to clean | High, may require special care |

| Best Use Case | High-end furniture, fashion | Budget furniture, automotive | Eco-friendly products, casual wear |

What Are the Benefits and Drawbacks of Synthetic Leather?

Synthetic leather, often made from polyurethane or polyvinyl chloride (PVC), is a popular alternative to traditional leather. One significant advantage is its cost-effectiveness; it typically comes at a lower price point than genuine leather. Additionally, synthetic leather is easier to maintain, requiring only a simple wipe-down for cleaning. However, it may lack the breathability and luxurious feel of genuine leather, potentially leading to discomfort in hotter climates. While synthetic leather can be durable, it may not have the same longevity as high-quality leather, which can last for decades with proper care.

Illustrative image related to leather or fabric

How Do Natural Fiber Textiles Compare to Leather or Fabric?

Natural fiber textiles, such as cotton, linen, or wool, offer a different set of benefits. They are generally more breathable, making them comfortable for a variety of climates. Eco-conscious consumers may prefer these materials due to their biodegradable nature. However, natural fibers often require more intensive maintenance, such as special washing or treatment to prevent staining and wear. While they can be comfortable and aesthetically pleasing, their durability may not match that of leather or even high-quality synthetic options, especially in high-traffic environments.

Conclusion: Which Option Should B2B Buyers Consider?

Choosing between leather, fabric, and alternatives like synthetic leather or natural fiber textiles largely depends on the specific needs of your project. B2B buyers should assess factors such as budget constraints, desired longevity, maintenance capabilities, and the intended use of the material. For luxury applications, genuine leather remains a top choice, whereas synthetic leather may be more suitable for budget-conscious projects. Natural fibers can serve eco-friendly initiatives but require careful consideration regarding durability and maintenance. Ultimately, understanding these variables will empower buyers to make choices that align with their business objectives and client expectations.

Essential Technical Properties and Trade Terminology for leather or fabric

What Are the Key Technical Properties of Leather and Fabric for B2B Buyers?

When sourcing leather or fabric for commercial applications, understanding the essential technical properties is crucial. Here are some critical specifications to consider:

1. Material Grade

Material grade refers to the quality classification of leather or fabric. For leather, grades range from full-grain (the highest quality) to bonded leather (the lowest). Fabrics also have grades, typically based on fiber content and weave density. This classification affects durability, appearance, and price. B2B buyers must select the appropriate grade to meet their product requirements and customer expectations.

2. Tolerance

Tolerance indicates the acceptable variations in dimensions and characteristics during the manufacturing process. For leather, tolerance might refer to thickness, while for fabric, it could relate to width and length. Understanding tolerance levels is essential for ensuring consistency in production, which directly impacts the final product’s quality and usability. Buyers should specify tolerances in their orders to avoid discrepancies.

3. Abrasion Resistance

Abrasion resistance measures how well a material withstands wear from friction. This property is particularly important in high-traffic applications, such as upholstery or automotive interiors. Fabrics are often tested with the Martindale method, while leather may be evaluated using a Wyzenbeek test. High abrasion resistance is vital for ensuring longevity and reducing replacement costs, making it a key consideration for B2B buyers.

4. Color Fastness

Color fastness refers to a material’s ability to retain its color when exposed to various elements, such as light, washing, or rubbing. It is measured through standardized testing methods. For buyers, selecting materials with high color fastness is crucial to ensure the aesthetic appeal and durability of the final product. This property is particularly relevant for fabrics used in apparel and home furnishings.

5. Weight

The weight of leather or fabric, measured in grams per square meter (GSM), impacts its drape, durability, and suitability for specific applications. Lighter materials may be preferable for clothing and soft furnishings, while heavier materials are often used for upholstery. Buyers should consider the intended use of the material to ensure optimal performance and cost-effectiveness.

What Common Trade Terms Should B2B Buyers Know in the Leather and Fabric Industry?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms B2B buyers should know:

Illustrative image related to leather or fabric

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of leather and fabric, an OEM might supply materials for furniture or automotive manufacturers. Understanding OEM relationships can help buyers identify reliable sources and maintain quality standards in their supply chain.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is crucial for B2B buyers to understand MOQs to manage inventory levels and ensure cost efficiency. Negotiating MOQs can lead to better pricing but may also require careful planning regarding production needs and cash flow.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For leather and fabric buyers, issuing RFQs can streamline the procurement process by gathering competitive offers. It is an essential tool for making informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms helps B2B buyers manage risks and costs associated with importing leather or fabric. Familiarity with Incoterms is critical for ensuring smooth transactions across borders.

Illustrative image related to leather or fabric

5. Lead Time

Lead time is the period between placing an order and receiving the goods. In the leather and fabric industry, lead times can vary significantly based on production capacity and shipping methods. Buyers should account for lead times in their planning to avoid delays in product launches or inventory shortages.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions, optimize their sourcing strategies, and foster successful partnerships in the leather and fabric market.

Navigating Market Dynamics and Sourcing Trends in the leather or fabric Sector

What Are the Key Market Dynamics and Trends in the Leather and Fabric Sector?

The global leather and fabric market is currently influenced by a myriad of factors, including shifting consumer preferences, technological advancements, and regional economic conditions. B2B buyers from Africa, South America, the Middle East, and Europe are navigating a landscape where sustainability and comfort are becoming paramount. For instance, the rise of remote work has led to increased demand for home furnishings, notably sofas and seating options that blend aesthetics with functionality. Emerging technologies, such as augmented reality (AR) and virtual reality (VR), are facilitating innovative sourcing experiences, enabling buyers to visualize products in their intended spaces before making purchases.

Moreover, supply chain dynamics have shifted significantly due to geopolitical tensions and the COVID-19 pandemic, prompting many companies to diversify their sourcing strategies. Businesses are increasingly looking for suppliers who can offer flexibility and speed in delivery, as well as those who can provide detailed insights into their supply chain practices. This demand for transparency and agility in sourcing is particularly relevant for international buyers who require reliable partnerships to navigate complex logistics across borders.

How Are Sustainability and Ethical Sourcing Shaping the Leather and Fabric Industry?

Sustainability is no longer a mere trend; it has become a critical component of the leather and fabric sector. The environmental impact of traditional leather tanning processes, which often involve harmful chemicals, has raised concerns among consumers and regulatory bodies alike. As a result, B2B buyers are increasingly prioritizing suppliers who practice ethical sourcing and sustainable production methods. This includes opting for vegetable-tanned leather or synthetic alternatives that minimize ecological footprints.

In addition, certifications like Global Organic Textile Standard (GOTS) for fabrics and the Leather Working Group (LWG) for leather are gaining traction. These certifications assure buyers of compliance with environmental and social standards, making them essential in the decision-making process. By aligning with suppliers that uphold these standards, international buyers not only enhance their brand image but also contribute to a more sustainable future for the industry.

What Is the Historical Context Behind Current Sourcing Trends in Leather and Fabric?

The leather and fabric industries have evolved significantly over centuries, transitioning from artisanal production methods to mass manufacturing. Historically, leather was prized for its durability and aesthetic appeal, while fabrics became synonymous with comfort and variety. As global trade expanded, so did the sourcing of materials, with different regions specializing in unique offerings—Africa in exotic leathers, Europe in high-quality fabrics, and South America in diverse textile production.

The 20th century brought about industrial advancements that increased efficiency but often compromised ethical practices. Today, however, the narrative is shifting once again, as buyers seek to restore the balance between quality, ethical sourcing, and sustainability. This evolution is crucial for B2B buyers aiming to align with modern consumer values while maintaining competitive advantages in a dynamic marketplace. Understanding this historical context can provide invaluable insights for navigating current sourcing strategies effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of leather or fabric

-

How do I choose between leather and fabric for my products?

When selecting between leather and fabric, consider factors such as durability, maintenance, aesthetic appeal, and cost. Leather is known for its durability and upscale look but requires specific care to maintain its quality. Fabric, on the other hand, offers a broader range of colors and patterns and is generally more comfortable. Assess your target market’s preferences and the intended use of the product to make an informed decision. Additionally, consider the environmental impact and sourcing practices of the materials to align with sustainability goals. -

What is the best type of leather or fabric for high-traffic commercial environments?

For high-traffic commercial environments, look for materials that prioritize durability and easy maintenance. In the case of leather, full-grain or top-grain leather offers excellent longevity and can withstand wear and tear. For fabric, consider performance textiles that are stain-resistant, treated for durability, and easy to clean. These options will maintain their appearance longer and provide comfort, ensuring that your investment holds up in busy settings. -

What are the key considerations when vetting suppliers for leather or fabric?

When vetting suppliers, prioritize their reputation, production capabilities, and quality assurance processes. Request samples to evaluate the material firsthand and assess their compliance with international standards. Verify their experience with international shipping and customs regulations to ensure smooth logistics. Additionally, inquire about their sustainability practices and labor conditions, which are increasingly important to many buyers. Establishing strong communication and a clear understanding of terms will help ensure a successful partnership. -

What customization options are typically available for leather or fabric products?

Customization options for leather and fabric products can include color selection, texture, pattern, and finishing details such as stitching or embossing. Many suppliers offer tailored solutions to meet specific design requirements, which can enhance brand identity and customer appeal. Ensure you communicate your exact needs, including minimum order quantities (MOQs) and lead times, to align production capabilities with your timeline. Discussing these aspects upfront can help avoid delays and ensure the final product meets your expectations. -

What are the standard minimum order quantities (MOQs) for leather and fabric?

Minimum order quantities (MOQs) can vary significantly based on the supplier and the type of material. For leather, MOQs might range from 50 to 500 meters, while fabric could have lower MOQs, often starting around 30 meters. It’s essential to clarify these details with your supplier during the negotiation phase. Consider your project scale and budget, and if necessary, negotiate MOQs that align with your production needs while ensuring the supplier can accommodate your request. -

What payment terms should I expect when sourcing leather or fabric internationally?

Payment terms can vary by supplier, but common practices include a deposit (usually 30-50%) upon order confirmation, with the balance due prior to shipment. Some suppliers may offer net payment terms, allowing for payment within 30 to 90 days post-delivery. It’s crucial to establish clear payment terms upfront to avoid misunderstandings. Consider using secure payment methods such as letters of credit or escrow services to protect your investment and ensure trust in the transaction. -

How do I ensure quality assurance when sourcing leather or fabric?

To ensure quality assurance, establish clear specifications for the materials you require, including standards for colorfastness, durability, and finishing. Request certifications that demonstrate compliance with international quality standards. Conduct on-site inspections if possible, or consider hiring a third-party quality control service to assess the materials before shipment. Additionally, maintain regular communication with your supplier throughout the production process to address any issues promptly. -

What logistics considerations should I keep in mind when importing leather or fabric?

Logistics considerations include understanding shipping methods, customs regulations, and potential tariffs that may apply to your materials. Work with freight forwarders who have experience in handling textiles to ensure compliance with international shipping laws. Consider lead times, as they can vary based on the origin of the materials and the shipping route. Additionally, prepare for potential delays in customs clearance and ensure you have all necessary documentation to facilitate smooth importation.

Top 5 Leather Or Fabric Manufacturers & Suppliers List

1. Reddit – Leather Sofas vs. Fabric

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Drawbacks of leather sofas compared to fabric include: 1. Leather can feel cold on bare skin and sticky in warmer climates. 2. Leather is more expensive than fabric options. 3. Leather can be damaged by pets, such as cats’ claws. 4. Fashion and needs may change, making it necessary to replace or recover cheaper fabric sofas more easily. 5. Leather may not be suitable for families with pets or chil…

2. The Spruce – Fabric Sofas Benefits

Domain: thespruce.com

Registered: 2009 (16 years)

Introduction: Benefits of Fabric Sofas: 1. Comfort: Softer and warmer than leather, fabric sofas feel more comfortable and are often already ‘broken in.’ 2. Care: Treated with stain-resistant finishes, fabric sofas are easier to clean and less prone to scratches. 3. Color and Pattern Options: Unlimited choices in patterns, textures, and colors allow for better matching with existing decor. 4. Cost: Generally mo…

3. Stay Home Body – Leather vs Fabric Sofas Comparison Guide

Domain: stayhomebody.com

Registered: 2022 (3 years)

Introduction: Leather vs Fabric Sofas Comparison Guide:

**Quick Comparison Sheet**

– **Comfort**:

– Fabric Sofas: Immediately soft and warm.

– Leather Sofas: Starts firm, softens over time.

– **Durability**:

– Fabric Sofas: Durable with high-quality material; stain-resistant options available.

– Leather Sofas: Very durable, lasts longer with care.

– **Maintenance**:

– Fabric Sofas:…

4. Article – Leather vs. Fabric Furniture Guide

Domain: article.com

Registered: 1995 (30 years)

Introduction: Leather vs. Fabric Furniture: Choosing a sofa material involves considering lifestyle, budget, and future needs. Quality materials are crucial for durability. Fabric options include linen, cotton, and wool, with high-quality models minimizing pilling. Look for a Martindale rub-test of 25,000 or more. Leather options include Charme Leather (Timber Sofa), Rawhide (Cigar Sofa), and Oxford Leather (Sv…

5. Facebook – Sofa Selection Guide

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Will you choose leather sofa or fabric sofa

Strategic Sourcing Conclusion and Outlook for leather or fabric

As businesses navigate the complexities of sourcing materials, understanding the unique advantages and challenges of leather and fabric is essential. Both materials offer distinct benefits: leather is known for its durability, elegance, and low maintenance, making it a prime choice for high-end applications, while fabric provides unparalleled comfort and versatility in design. Strategic sourcing must consider these factors alongside regional preferences and market trends, particularly in diverse markets like Africa, South America, the Middle East, and Europe.

International B2B buyers should prioritize quality and sustainability when selecting suppliers, ensuring that they align with their brand values and customer expectations. By leveraging strategic sourcing, companies can enhance their product offerings, reduce costs, and improve their competitive edge in the global marketplace.

Looking ahead, the demand for both leather and fabric will continue to evolve, influenced by consumer preferences and technological advancements in production and sustainability. Buyers are encouraged to stay informed about market trends and innovations, fostering partnerships that enhance their sourcing strategies. Embrace the opportunity to explore diverse material options that not only meet operational needs but also resonate with your target audience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.