Introduction: Navigating the Global Market for leather fabric paint

In the ever-evolving landscape of leather fabric paint, international B2B buyers face the critical challenge of sourcing high-quality products that meet diverse market demands. Whether you’re looking to enhance footwear, fashion accessories, or upholstery, understanding the nuances of leather fabric paint is essential for making informed purchasing decisions. This guide delves into various types of leather paints, their applications, and how to effectively vet suppliers to ensure you receive products that align with your quality standards.

From the vibrant hues of acrylic leather paint to the sophisticated finishes of metallic and pearlescent options, each category serves unique purposes tailored to specific projects. Additionally, we provide insights into cost considerations, helping you navigate pricing structures across different regions, including Africa, South America, the Middle East, and Europe, with a particular focus on markets like Saudi Arabia and Nigeria.

Armed with this comprehensive information, B2B buyers will be equipped to select the right products that not only meet their aesthetic needs but also ensure durability and performance. This guide empowers you to make strategic decisions that enhance your product offerings and satisfy your customers’ expectations in a competitive marketplace.

Table Of Contents

- Top 7 Leather Fabric Paint Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather fabric paint

- Understanding leather fabric paint Types and Variations

- Key Industrial Applications of leather fabric paint

- 3 Common User Pain Points for ‘leather fabric paint’ & Their Solutions

- Strategic Material Selection Guide for leather fabric paint

- In-depth Look: Manufacturing Processes and Quality Assurance for leather fabric paint

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather fabric paint’

- Comprehensive Cost and Pricing Analysis for leather fabric paint Sourcing

- Alternatives Analysis: Comparing leather fabric paint With Other Solutions

- Essential Technical Properties and Trade Terminology for leather fabric paint

- Navigating Market Dynamics and Sourcing Trends in the leather fabric paint Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather fabric paint

- Strategic Sourcing Conclusion and Outlook for leather fabric paint

- Important Disclaimer & Terms of Use

Understanding leather fabric paint Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acrylic | Water-based, flexible, vibrant colors, excellent adhesion | Footwear customization, upholstery repair | Pros: Versatile, easy to clean, durable. Cons: Requires proper prep for best results. |

| Metallic | High-gloss finish, reflective properties | Fashion accessories, decorative items | Pros: Eye-catching, sophisticated finish. Cons: May require multiple coats for full opacity. |

| Pearlescent | Iridescent finish that changes with light | Luxury items, high-end fashion | Pros: Unique aesthetic appeal, durable. Cons: Higher cost, may require specialized application techniques. |

| Dye | Deep penetration into leather, rich color saturation | Leather goods manufacturing, restoration | Pros: Long-lasting, enhances leather texture. Cons: Limited color options, requires expertise in application. |

| Fabric Paint | Designed for mixed media applications, soft finish | Crafting, DIY projects | Pros: Wide color range, ideal for fabric blends. Cons: Less durability on leather compared to other types. |

What Are the Characteristics of Acrylic Leather Paint?

Acrylic leather paint is a top choice for its versatility and ease of use. It is water-based, making it non-toxic and easy to clean, which is a significant advantage for businesses looking to maintain a safe work environment. The flexibility of acrylic paint allows it to move with the leather, preventing cracks and ensuring longevity. This type is suitable for a range of applications, including footwear customization and upholstery repair. B2B buyers should consider the need for proper surface preparation to achieve optimal adhesion and durability, as skipping this step can lead to peeling or uneven finishes.

Why Choose Metallic Leather Paint for Your Business?

Metallic leather paint stands out for its high-gloss finish, making it an excellent option for fashion accessories and decorative items. It enhances the visual appeal of products, attracting customers looking for eye-catching designs. While metallic paints are known for their smooth application, they may require multiple coats to achieve the desired opacity, which could impact production timelines. B2B buyers should weigh the aesthetic benefits against the potential need for additional labor and materials, particularly if their product lines demand high-quality finishes.

How Does Pearlescent Leather Paint Differ from Other Types?

Pearlescent leather paint offers a unique iridescent finish that can elevate luxury items and high-end fashion products. Its ability to change appearance under different lighting conditions adds depth and sophistication to any design. While it provides a durable option, pearlescent paint typically comes at a higher cost and may require specialized application techniques, which could pose challenges for businesses unfamiliar with its use. Buyers should consider their target market’s preferences and the potential return on investment when deciding to incorporate this type into their product offerings.

What Are the Advantages of Using Dye on Leather?

Dye is a traditional method for coloring leather, known for its deep penetration and rich color saturation. It is particularly effective for leather goods manufacturing and restoration projects, enhancing the natural texture of the material. However, dye options may be limited compared to paints, and applying them requires expertise to avoid uneven results. B2B buyers should evaluate their production capabilities and the skill level of their workforce when considering dyes, as improper application can lead to unsatisfactory finishes and increased waste.

When Should Businesses Consider Fabric Paint for Leather Projects?

Fabric paint is designed for mixed media applications and can be used on leather, although it offers a softer finish compared to dedicated leather paints. This type is ideal for crafting and DIY projects, appealing to a broader range of creative applications. While fabric paint comes in a wide variety of colors, it may not provide the same level of durability on leather surfaces as other types. Businesses should assess their specific needs and customer expectations when choosing fabric paint, ensuring it aligns with their product quality standards.

Key Industrial Applications of leather fabric paint

| Industry/Sector | Specific Application of leather fabric paint | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Customization and restoration of leather shoes | Enhances product appeal and extends product lifecycle | Look for high-quality, flexible, and fade-resistant paints. Ensure compliance with local regulations. |

| Automotive Upholstery | Refinishing leather car seats and interiors | Improves aesthetic appeal and customer satisfaction | Source paints that are durable and resistant to fading and cracking due to exposure to sunlight and wear. |

| Fashion and Apparel | Design and customization of leather garments | Differentiates product offerings and meets consumer trends | Ensure availability of a wide color range and quick-drying properties for efficient production. |

| Furniture Manufacturing | Restoration and color enhancement of leather furniture | Increases resale value and customer retention | Prioritize paints that adhere well to various leather types and provide a long-lasting finish. |

| Arts and Crafts | DIY projects involving leather goods and accessories | Supports creativity and personalization in products | Seek versatile paints that are easy to apply and clean, ensuring safety and non-toxicity for end-users. |

How is leather fabric paint utilized in footwear manufacturing?

In the footwear manufacturing sector, leather fabric paint is essential for customization and restoration of leather shoes. Manufacturers can enhance the aesthetic appeal of their products by offering personalized designs, which helps in attracting customers. Additionally, it allows for the refurbishment of older models, extending their lifecycle and reducing waste. Buyers should prioritize paints that are flexible, fade-resistant, and compliant with local safety regulations, especially in diverse markets like Africa and Europe.

What role does leather fabric paint play in automotive upholstery?

Automotive upholstery uses leather fabric paint to refinish car seats and interiors, significantly improving the vehicle’s overall aesthetic. This application not only enhances the visual appeal but also boosts customer satisfaction by restoring worn or damaged leather. For international buyers, sourcing durable and UV-resistant paints is crucial to withstand the harsh conditions of sunlight exposure and wear over time, especially in regions with extreme climates such as the Middle East.

How does leather fabric paint benefit the fashion and apparel industry?

In the fashion and apparel industry, leather fabric paint is utilized for designing and customizing leather garments. This application allows brands to differentiate their offerings and align with current consumer trends for unique, personalized products. Buyers should consider sourcing paints that offer a wide color range and quick-drying properties to streamline production processes, especially in fast-paced markets across South America and Europe.

Why is leather fabric paint important for furniture manufacturing?

For furniture manufacturing, leather fabric paint serves to restore and enhance the color of leather furniture. This not only increases the resale value of items but also helps in retaining customer loyalty by offering quality restoration services. Buyers should look for paints that adhere well to various leather types and provide a long-lasting, durable finish to ensure customer satisfaction in competitive markets.

How is leather fabric paint used in arts and crafts?

In arts and crafts, leather fabric paint is popular for DIY projects involving leather goods and accessories. It supports creativity and allows consumers to personalize their items, fostering a sense of ownership. B2B buyers in this sector should seek versatile, easy-to-apply paints that are non-toxic and safe for end-users, catering to the growing demand for sustainable and user-friendly products in global markets.

3 Common User Pain Points for ‘leather fabric paint’ & Their Solutions

Scenario 1: Difficulty in Achieving Color Consistency in Leather Paint Applications

The Problem: One of the most common challenges faced by B2B buyers in the leather paint industry is achieving consistent color across multiple items or batches. Variations in surface texture, previous treatments, and even lighting conditions can lead to discrepancies that affect product quality. This inconsistency can result in customer dissatisfaction, particularly for businesses that rely on uniformity for branding purposes, such as those in fashion, furniture, or automotive upholstery.

The Solution: To overcome color consistency issues, buyers should consider sourcing high-quality, water-based acrylic leather paints specifically formulated for professional use. It’s essential to conduct pre-production tests on similar leather samples to evaluate color and adhesion before mass application. Using a standardized mixing process for paint can help maintain uniform color. Additionally, investing in color matching tools or software can aid in achieving the desired shade consistently. For large projects, establishing a controlled environment for painting—where temperature and humidity are monitored—can also minimize variability.

Scenario 2: Paint Cracking and Peeling After Application

The Problem: Another prevalent issue is the cracking and peeling of leather paint after application, which can undermine the durability of the final product. This often occurs due to improper surface preparation, such as inadequate cleaning or failing to sand the leather sufficiently. Buyers may find that their painted items do not meet quality standards, leading to increased returns and customer complaints, which can significantly impact their bottom line.

The Solution: To prevent cracking and peeling, thorough surface preparation is critical. Buyers should ensure that all leather surfaces are meticulously cleaned and sanded before application. Using a leather preparer can enhance paint adhesion and flexibility. When applying the paint, it’s advisable to use thin, even coats and allow adequate drying time between layers—typically 20-30 minutes. For optimal results, a curing period of 24-48 hours post-application should be enforced before the items are put into use. Additionally, sourcing paints that are specifically labeled as flexible can ensure that the paint moves with the leather, reducing the likelihood of damage over time.

Illustrative image related to leather fabric paint

Scenario 3: Incompatibility with Various Leather Types

The Problem: B2B buyers often encounter difficulties when dealing with different types of leather and synthetic materials. Not all leather paints are suitable for every leather type, which can lead to poor adhesion, color fading, or damage to the material itself. This incompatibility can result in costly mistakes, wasted materials, and missed deadlines, particularly for businesses that handle diverse leather products such as handbags, shoes, or automotive interiors.

The Solution: To address compatibility issues, buyers should conduct thorough research on the specific types of leather they will be working with and select paints that are designed to bond effectively with those materials. Manufacturers typically provide detailed specifications regarding the types of leather their products are suitable for. Moreover, using a versatile acrylic leather paint, like those from reputable brands, can help mitigate these issues, as they are often formulated to adhere well to various surfaces, including vinyl and canvas. Implementing a testing phase for different leather types will also allow businesses to identify the best products for their needs, ensuring optimal performance and reducing the risk of product failure.

Strategic Material Selection Guide for leather fabric paint

What Are the Key Materials Used in Leather Fabric Paint?

When selecting leather fabric paint for B2B applications, understanding the different materials involved is crucial. Various formulations exist, each with unique properties, advantages, and limitations. Below, we analyze four common materials used in leather fabric paint, focusing on their performance, suitability for different applications, and considerations for international buyers.

What Are the Key Properties of Acrylic Leather Paint?

Acrylic leather paint is one of the most popular options due to its versatility. This water-based paint offers excellent adhesion to various surfaces, including leather, vinyl, and canvas. Key properties include flexibility and durability, allowing it to withstand movement without cracking. It also has a good temperature resistance, making it suitable for a range of climates.

Pros: Acrylic paints are easy to clean up with water, non-toxic, and provide vibrant colors with excellent coverage. They are also relatively low-cost, making them accessible for manufacturers.

Cons: While durable, acrylic paints may not be as resistant to extreme temperatures as some solvent-based options. They can also require multiple coats for full coverage, which may increase production time.

Impact on Application: Acrylic leather paint is compatible with various media, making it ideal for custom designs on shoes, bags, and upholstery.

Illustrative image related to leather fabric paint

International Considerations: Buyers in regions like Africa and South America should ensure compliance with local regulations regarding VOC emissions, as some acrylic paints may contain additives that are restricted in certain markets.

How Does Metallic Leather Paint Differ from Other Options?

Metallic leather paint is designed to provide a shiny, reflective finish. This type of paint is often used for decorative applications, such as custom shoes and accessories.

Key Properties: Metallic paints typically contain metallic pigments that enhance durability and provide a unique aesthetic appeal. They also offer good adhesion and flexibility.

Pros: The standout feature of metallic leather paint is its eye-catching appearance, which can elevate the perceived value of products. It is also relatively easy to apply.

Cons: On the downside, metallic paints can be more expensive due to the cost of metallic pigments. They may also require careful application to avoid streaking.

Impact on Application: Metallic leather paint is best suited for projects where visual impact is a priority, but it may not be ideal for everyday wear items that require high durability.

International Considerations: Compliance with international standards for metallic pigments is essential, especially in regions with strict environmental regulations.

What Are the Benefits of Using Pearlescent Leather Paint?

Pearlescent leather paint offers a unique, iridescent finish that changes color based on the angle of light. This paint type is often used for high-end leather goods.

Key Properties: Pearlescent paints contain special pigments that create depth and complexity in color. They also maintain good flexibility and adhesion.

Pros: The luxurious appearance of pearlescent paint can significantly enhance product appeal, making it a popular choice for premium items.

Cons: The application process can be more complex, requiring specialized techniques to achieve the desired effect. Additionally, the cost is generally higher than standard acrylic paints.

Illustrative image related to leather fabric paint

Impact on Application: Pearlescent paints are best for high-value items where aesthetics are paramount, but they may not be suitable for mass production due to application complexity.

International Considerations: Buyers should verify that the pigments used meet local safety standards, particularly in regions with stringent regulations on chemical use.

What Should Buyers Know About Solvent-Based Leather Paint?

Solvent-based leather paint is another option, known for its durability and resistance to harsh conditions.

Key Properties: This type of paint offers excellent adhesion and can withstand extreme temperatures and moisture, making it suitable for outdoor applications.

Pros: Solvent-based paints are highly durable and can provide a long-lasting finish, making them ideal for items exposed to wear and tear.

Cons: The main drawback is the higher VOC content, which can pose health risks and may not comply with regulations in certain regions.

Impact on Application: Solvent-based paints are ideal for industrial applications where durability is critical, but they require careful handling and application techniques.

International Considerations: Buyers must ensure compliance with local environmental regulations concerning VOC emissions, especially in Europe and North America.

Summary of Material Selection for Leather Fabric Paint

| Matériau | Typical Use Case for leather fabric paint | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Acrylic | Custom shoes, bags, upholstery | Versatile, easy cleanup | May require multiple coats | Low |

| Metallic | Decorative accessories | Eye-catching finish | Higher cost, potential for streaking | Med |

| Pearlescent | High-end leather goods | Luxurious, unique appearance | Complex application, higher cost | Haut |

| Solvent-Based | Industrial applications | Excellent durability | High VOC content, health risks | Med |

Understanding these materials and their implications can help B2B buyers make informed decisions, ensuring compliance with regional standards while meeting their product quality expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for leather fabric paint

What Are the Key Stages in the Manufacturing Process of Leather Fabric Paint?

The manufacturing of leather fabric paint involves several critical stages that ensure the final product meets quality standards and performs effectively. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Illustrative image related to leather fabric paint

1. Material Preparation: What Raw Materials Are Used?

The initial stage of manufacturing leather fabric paint begins with the selection of raw materials. High-quality acrylic resins, pigments, and additives are sourced to ensure vibrant colors and durability. Water is typically used as a solvent due to its non-toxic nature, making the paint safer for both users and the environment.

Once the materials are acquired, they undergo a thorough quality inspection to verify their purity and compliance with international standards. This inspection is crucial, as the quality of raw materials directly influences the performance of the final paint product.

2. Forming: How Is Leather Fabric Paint Mixed and Processed?

In the forming stage, raw materials are blended using advanced mixing techniques. This process ensures a uniform distribution of pigments and additives, which is vital for achieving consistent color and texture. Manufacturers often employ high-shear mixers to create a homogeneous mixture that prevents settling and clumping.

After mixing, the paint is subjected to a series of grinding processes. This step breaks down any remaining particles to achieve a smooth consistency, enhancing the paint’s application properties. The resulting mixture is then filtered to remove impurities before proceeding to the next stage.

3. Assembly: What Does Packaging and Labeling Involve?

The assembly phase involves filling containers with the prepared leather fabric paint. This is typically done in a controlled environment to prevent contamination. Automated filling machines are often used to ensure accuracy and efficiency, maintaining a clean production line.

Once filled, the containers are labeled with essential information, including usage instructions, safety warnings, and batch numbers for traceability. Proper labeling is crucial for compliance with international regulations, especially for markets in Europe, Africa, and the Middle East.

4. Finishing: What Final Touches Ensure Quality?

The finishing stage includes quality control checks and packaging. Each batch of leather fabric paint undergoes rigorous testing to ensure it meets specified performance standards. This may include tests for color consistency, adhesion, drying time, and flexibility.

Once the paint passes all tests, it is packaged securely for shipment. Effective packaging is essential to prevent damage during transport and to maintain the paint’s integrity until it reaches the end user.

What Are the Quality Control Procedures for Leather Fabric Paint?

Quality assurance is a critical aspect of the manufacturing process for leather fabric paint, particularly for B2B buyers who require reliable products. Various international standards and industry-specific certifications guide these quality control measures.

Illustrative image related to leather fabric paint

International Standards: Which Certifications Matter?

Manufacturers of leather fabric paint often adhere to international quality management standards such as ISO 9001. This certification demonstrates a commitment to consistent quality, customer satisfaction, and continuous improvement.

Additionally, compliance with CE marking is essential for products sold in European markets, ensuring that they meet safety, health, and environmental protection standards. For buyers in regions like Saudi Arabia or Nigeria, understanding these certifications can help assess the credibility of potential suppliers.

What Are the Key Quality Control Checkpoints?

Quality control in leather fabric paint production typically includes several checkpoints:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to verify that they meet required specifications. Any substandard materials are rejected to prevent quality issues in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, samples are taken at various stages to ensure that the paint is consistently produced according to standards. This may include monitoring viscosity, color matching, and particle size.

-

Final Quality Control (FQC): After the paint is manufactured, a final inspection is conducted. This involves comprehensive testing of finished products against predetermined criteria. Any deviations from the standards can lead to rework or disposal of defective batches.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in international markets, verifying a supplier’s quality control processes is crucial. There are several effective methods to ensure that potential suppliers maintain high-quality standards.

What Documentation Should Be Requested?

Buyers should request documentation that outlines the supplier’s quality management systems and certifications. This includes:

-

Quality Assurance Manuals: These documents provide insights into the processes and procedures the manufacturer follows to maintain quality.

-

Inspection Reports: Detailed reports from IQC, IPQC, and FQC can help buyers assess the thoroughness of quality checks.

-

Certificates of Compliance: Documentation proving adherence to ISO 9001 or CE marking should be readily available.

How Can Third-Party Inspections Add Value?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspectors can conduct audits, evaluate production processes, and verify that the supplier meets international standards.

For B2B buyers, especially in regions like Africa and South America, relying on third-party inspectors adds an extra layer of assurance. This practice can help mitigate risks associated with sourcing from suppliers with limited track records.

What Quality Control Nuances Should International Buyers Consider?

International buyers must be aware of specific nuances in quality control that may affect their purchasing decisions. Different regions may have varying standards, and understanding these can help ensure compliance and quality.

What Are Regional Compliance Differences?

When sourcing leather fabric paint, buyers should be cognizant of regional regulations that govern product safety and environmental impact. For example, the European Union has stringent regulations regarding chemical safety (REACH compliance), which may not apply in other regions.

How Can Cultural Differences Impact Quality Expectations?

Cultural differences can also influence quality expectations. Buyers from Europe may prioritize stringent quality assurance processes, while buyers from other regions might have different benchmarks. Open communication about quality expectations can help bridge these gaps and foster successful partnerships.

Conclusion: Ensuring Quality in Leather Fabric Paint Procurement

Understanding the manufacturing processes and quality assurance practices for leather fabric paint is essential for B2B buyers. By familiarizing themselves with the key stages of production, quality control checkpoints, and verification methods, buyers can make informed decisions and secure high-quality products that meet their specific needs. This knowledge not only aids in selecting reliable suppliers but also enhances the overall procurement strategy in the international marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather fabric paint’

To successfully procure leather fabric paint, it is essential to follow a structured approach that ensures quality, cost-effectiveness, and compatibility with your intended applications. This checklist serves as a practical guide for B2B buyers looking to source leather fabric paint from reliable suppliers.

Step 1: Identify Your Specific Needs

Understanding your requirements is the first step in sourcing leather fabric paint. Consider the type of projects you will be undertaking, such as customizing shoes, bags, or upholstery. This will help you determine the paint type (acrylic, metallic, or pearlescent) and color range you need, ensuring you select a product that meets your creative and functional objectives.

Illustrative image related to leather fabric paint

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in leather fabric paint. Look for companies with a strong reputation and a proven track record in your target market regions, such as Africa, South America, the Middle East, and Europe. Utilize online platforms, trade shows, and industry publications to compile a list of suppliers.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify the certifications and compliance of your shortlisted suppliers. Check for ISO certifications, safety standards, and environmental compliance to ensure the products meet international quality benchmarks. This step is crucial in maintaining product integrity and safeguarding your brand reputation.

Step 4: Request Samples for Testing

Once you have narrowed down potential suppliers, request samples of their leather fabric paint. This allows you to evaluate the quality, color vibrancy, and adhesion properties of the paint on different surfaces. Pay attention to the drying time and flexibility of the paint to ensure it meets your project requirements.

Step 5: Compare Pricing and Terms

Analyze the pricing structures and payment terms of the suppliers you are considering. While cost is an important factor, also consider the value offered, such as bulk discounts, shipping fees, and return policies. Ensure you are clear on the total landed cost to avoid unexpected expenses.

Step 6: Check Customer Reviews and References

Seek out customer reviews and testimonials to gain insights into the experiences of other buyers with the suppliers you are considering. Request references from companies in your industry that have previously purchased leather fabric paint. This will provide you with a clearer picture of the supplier’s reliability and product performance.

Illustrative image related to leather fabric paint

Step 7: Finalize Your Order and Monitor Delivery

After selecting a supplier, finalize your order by confirming quantities, colors, and delivery timelines. Establish clear communication channels for tracking your order and addressing any potential issues that may arise during the shipping process. Monitoring delivery ensures you remain on schedule for your projects.

By following this step-by-step checklist, B2B buyers can streamline the sourcing process for leather fabric paint, ultimately leading to successful project outcomes and satisfied customers.

Comprehensive Cost and Pricing Analysis for leather fabric paint Sourcing

What Are the Key Cost Components in Leather Fabric Paint Sourcing?

When analyzing the costs associated with sourcing leather fabric paint, several key components contribute to the overall price. These include:

Illustrative image related to leather fabric paint

-

Materials: The primary ingredients for leather fabric paint are acrylic resins, pigments, and additives. High-quality materials ensure durability and performance, which can elevate costs. For instance, eco-friendly or non-toxic formulations may be priced higher due to the cost of sourcing sustainable materials.

-

Labor: Labor costs are influenced by the manufacturing location. Countries with higher labor costs may see an increase in the final price of the paint. Additionally, skilled labor is often necessary for quality control and ensuring consistent product output.

-

Manufacturing Overhead: This includes utilities, rent, and general factory expenses. Overhead can vary significantly based on the manufacturing region and the efficiency of the production process.

-

Tooling: Initial tooling costs can be substantial, especially for custom formulations or unique packaging. This upfront investment is often amortized over larger production runs.

-

Quality Control (QC): Ensuring that the paint meets industry standards requires investment in testing and quality assurance processes. This is crucial for maintaining brand reputation and compliance with international regulations.

-

Logistics: Shipping and handling costs can greatly affect the final price, particularly for international shipments. Factors like distance, mode of transport, and fuel prices play significant roles in logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure profitability. This margin can vary based on market conditions and competition.

How Do Pricing Influencers Affect Leather Fabric Paint Costs?

Several factors influence the pricing of leather fabric paint, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Suppliers may offer significant discounts for minimum order quantities (MOQs), making it financially advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom colors or formulations can increase costs due to additional processing and material requirements. Buyers should evaluate whether customization is essential for their market needs.

-

Material Quality and Certifications: Paints that meet specific quality standards or environmental certifications (like ASTM or REACH) may come at a premium. However, these certifications can enhance product credibility in competitive markets.

-

Supplier Factors: The reputation and reliability of suppliers can also impact pricing. Established suppliers with a track record of quality and service may charge more, but they often provide better support and assurance of product performance.

-

Incoterms: The chosen Incoterms can significantly affect overall costs. Understanding whether costs include insurance, freight, and duties will help buyers calculate their total landed costs accurately.

What Buyer Tips Can Enhance Cost-Efficiency in Leather Fabric Paint Sourcing?

For international buyers, especially from Africa, South America, the Middle East, and Europe, the following strategies can improve sourcing efficiency:

-

Negotiation: Engage suppliers in discussions about pricing, especially when ordering larger volumes or establishing long-term partnerships. Suppliers may be willing to adjust prices based on commitment and loyalty.

-

Focus on Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the product, including durability, maintenance, and potential wastage. A slightly higher initial investment may lead to lower TCO if the paint lasts longer and requires less frequent reapplication.

-

Understand Pricing Nuances: Be aware of local market conditions that may affect pricing, such as currency fluctuations, import tariffs, and local demand trends. This knowledge can empower buyers during negotiations and help them anticipate cost changes.

-

Research and Compare Suppliers: Conduct thorough research on potential suppliers, examining their product offerings, certifications, and customer reviews. This diligence can help identify the best value without compromising quality.

Disclaimer on Indicative Prices

Prices for leather fabric paint can vary widely based on the factors mentioned above. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure they are getting the best possible value for their investment. Always consider the unique requirements of your business and market when evaluating costs.

Alternatives Analysis: Comparing leather fabric paint With Other Solutions

Introduction to Alternative Solutions for Leather Fabric Customization

When it comes to customizing leather products, businesses have a variety of solutions at their disposal. Leather fabric paint is a popular choice due to its versatility and ease of use. However, understanding alternative methods can help B2B buyers make informed decisions based on their specific needs, budget constraints, and desired outcomes. In this section, we will compare leather fabric paint against two viable alternatives: leather dye and heat transfer vinyl (HTV).

Comparison Table of Leather Fabric Paint and Alternatives

| Comparison Aspect | Leather Fabric Paint | Leather Dye | Heat Transfer Vinyl (HTV) |

|---|---|---|---|

| Performance | Vibrant colors, flexible finish, long-lasting | Deep penetration, natural finish | Bright colors, limited texture flexibility |

| Cost | Moderate (varies by brand and quantity) | Generally lower per unit but requires more product for full coverage | Higher initial investment, varies by design |

| Ease of Implementation | Simple application, requires minimal prep | Requires more preparation, longer drying time | Requires heat press or iron, specific application process |

| Maintenance | Easy to clean and maintain | May fade over time, requires refinishing | Durable but can peel if not applied correctly |

| Best Use Case | Ideal for footwear, bags, and upholstery | Best for restoring or coloring leather items | Suitable for custom designs on bags and apparel |

Detailed Breakdown of Alternatives

Leather Dye

Leather dye is a traditional method for changing the color of leather. It penetrates deeply into the material, providing a more natural look compared to paint. One of the key advantages of leather dye is its ability to create a rich, deep color that often appears more authentic. However, it requires more preparation, including cleaning and conditioning the leather before application. Dyes can also fade over time and might require periodic refinishing to maintain their appearance.

Heat Transfer Vinyl (HTV)

Heat transfer vinyl allows for the creation of intricate designs and patterns on leather products. This method involves cutting designs from vinyl sheets and applying them to leather surfaces using a heat press or iron. HTV offers vibrant colors and the ability to achieve complex designs that might be challenging with paint. However, it requires a higher initial investment for the equipment and materials. Additionally, HTV may not be as flexible as paint, which can lead to peeling or cracking if the leather is subjected to extensive movement.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, the choice between leather fabric paint, leather dye, and heat transfer vinyl largely depends on the specific application and desired outcome. If vibrant colors and ease of application are priorities, leather fabric paint stands out as an excellent choice. Conversely, if a more traditional and natural finish is desired, leather dye could be the better option. For businesses looking to create intricate designs, HTV offers a unique solution but requires careful handling and investment in equipment. Ultimately, understanding the pros and cons of each option will enable buyers to select the best solution tailored to their product needs and market demands.

Essential Technical Properties and Trade Terminology for leather fabric paint

What Are the Key Technical Properties of Leather Fabric Paint?

Understanding the essential technical properties of leather fabric paint is crucial for B2B buyers to ensure they select the right products for their needs. Here are several critical specifications that should be considered:

Illustrative image related to leather fabric paint

1. Material Composition

Leather fabric paints typically consist of water-based acrylic compounds. This composition is important because it ensures that the paint is non-toxic and environmentally friendly, making it suitable for various applications, including footwear, upholstery, and fashion accessories. Buyers should verify that the paint adheres well to leather and other materials like canvas and vinyl, ensuring versatility in use.

2. Flexibility and Adhesion

Flexibility refers to the paint’s ability to stretch and move with the material without cracking. This property is essential for products that experience regular wear and tear, such as shoes and bags. A paint with high flexibility guarantees durability, which is a significant selling point for B2B buyers looking to enhance product longevity.

3. Color Fastness and Coverage

Color fastness indicates how well the paint retains its color over time, particularly when exposed to light and water. High color fastness is crucial for maintaining the aesthetic appeal of leather products. Additionally, good coverage means that less paint is required to achieve the desired color intensity, which can reduce costs for businesses purchasing in bulk.

4. Drying Time and Curing Process

The drying time specifies how quickly the paint becomes touch-dry after application, while the curing process refers to the time it takes for the paint to fully bond with the substrate. Understanding these factors is vital for B2B buyers who need to schedule production efficiently. A paint that dries quickly and cures effectively will streamline manufacturing and reduce turnaround times.

5. Finish Type

Leather paints can come in various finishes, such as matte, glossy, and pearlescent. Each finish serves different aesthetic purposes and can influence the final product’s appeal. Buyers should consider the intended market and customer preferences when selecting a finish type to ensure alignment with branding and product positioning.

What Are the Common Trade Terms Related to Leather Fabric Paint?

Familiarity with industry jargon can significantly enhance communication and negotiation between buyers and suppliers. Here are some common terms in the leather fabric paint trade:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are marketed by another company under its brand name. In the leather paint sector, understanding OEM relationships can help buyers source customized paint solutions tailored to their specific requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Buyers should be aware of MOQs when negotiating contracts, as this can affect inventory levels and cash flow. Understanding MOQs can also help businesses plan their purchasing strategies effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit price quotes for specific products or services. In the context of leather fabric paint, issuing an RFQ can help buyers compare pricing and terms from multiple suppliers, ensuring they receive the best value.

4. Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping responsibilities, risk transfer, and cost distribution, which can greatly influence logistics planning.

5. Lead Time

Lead time is the period between the initiation of an order and its completion. In the leather paint industry, understanding lead times is crucial for inventory management and production scheduling. Buyers should factor in lead times when placing orders to ensure timely delivery and avoid production delays.

Illustrative image related to leather fabric paint

By comprehending these technical properties and trade terms, B2B buyers can make informed decisions, optimize their purchasing strategies, and enhance their business operations in the leather fabric paint market.

Navigating Market Dynamics and Sourcing Trends in the leather fabric paint Sector

What Are the Key Drivers and Trends in the Leather Fabric Paint Market?

The leather fabric paint market is experiencing a dynamic shift driven by several global factors. Increasing demand for customization in fashion and furniture, particularly in regions like Africa and South America, is spurring growth. As consumers seek unique, personalized products, businesses are compelled to offer tailored solutions, thereby creating opportunities for suppliers of leather fabric paint. Additionally, the rise of e-commerce platforms facilitates easier access for international buyers to procure these materials, enhancing market reach.

Emerging technologies, such as advanced color-matching tools and eco-friendly formulations, are shaping the sourcing landscape. Innovations in paint chemistry, including water-based and non-toxic options, align with consumer preferences for safer, sustainable products. Furthermore, digital tools for inventory management and supply chain tracking are becoming standard, allowing B2B buyers to optimize their procurement processes.

Market dynamics also reflect a growing emphasis on quality and durability. Suppliers that can offer high-performance paints with flexibility and resistance to cracking will likely gain a competitive edge. For buyers in regions like the Middle East and Europe, understanding local market nuances—such as regulatory compliance and cultural preferences—will be crucial for successful sourcing strategies.

How Is Sustainability Influencing Sourcing Decisions for Leather Fabric Paint?

The push for sustainability is reshaping the leather fabric paint sector, compelling businesses to reconsider their sourcing strategies. The environmental impact of traditional leather production and synthetic paint materials has led to increased scrutiny from both consumers and regulators. B2B buyers are now prioritizing suppliers that demonstrate a commitment to ethical sourcing practices and sustainability.

This shift has resulted in a demand for “green” certifications and eco-friendly materials in leather fabric paint. Suppliers are responding by developing paints that utilize natural pigments and biodegradable ingredients, significantly reducing their carbon footprint. Additionally, companies that implement sustainable practices in their supply chains—such as responsible sourcing of raw materials and minimizing waste—are likely to attract discerning international buyers.

For buyers in regions like Nigeria and Saudi Arabia, establishing partnerships with suppliers who prioritize sustainability can enhance brand reputation and customer loyalty. Emphasizing eco-friendly practices not only meets market demand but also aligns with global efforts to combat climate change, creating a win-win scenario for businesses and the environment.

What Is the Historical Context of Leather Fabric Paint Development?

The evolution of leather fabric paint can be traced back to the need for durable, versatile coatings that could enhance the aesthetic appeal of leather goods. Initially, paints were limited to oil-based formulations that lacked flexibility and often resulted in cracking. As consumer preferences shifted towards more vibrant and long-lasting colors, manufacturers began to explore water-based acrylic options in the late 20th century.

This transition marked a significant milestone, as acrylic leather paints offered improved adhesion, flexibility, and a wider color range. The introduction of non-toxic formulations further revolutionized the industry, catering to a growing demand for safer products. Today, the leather fabric paint market is characterized by innovation, with ongoing advancements in technology and sustainability driving continuous improvement in product offerings.

In summary, understanding these historical trends provides B2B buyers with valuable insights into the market’s direction, enabling them to make informed sourcing decisions that align with contemporary consumer demands and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of leather fabric paint

-

1. How do I solve issues with paint adhesion on leather?

To ensure optimal adhesion of leather paint, start by thoroughly cleaning the leather surface to remove any dirt, oils, or residues. Lightly sand the surface with fine-grit sandpaper to create a texture that promotes better bonding. Using a leather preparer can further enhance adhesion by opening the pores of the material. Finally, apply the paint in thin, even coats, allowing each layer to dry completely before adding the next. Proper surface preparation is crucial for achieving a durable, professional finish. -

2. What is the best type of leather paint for high-traffic items?

Acrylic leather paint is the best choice for high-traffic items like shoes and bags due to its flexibility and durability. This type of paint adheres well to leather and remains resistant to cracking and peeling, even with frequent use. For added protection, consider using a finisher that enhances water resistance and longevity. Brands like Angelus are known for their high-quality acrylic paints that provide vibrant colors and strong coverage, making them ideal for both custom and restoration projects. -

3. What should I consider when sourcing leather fabric paint suppliers internationally?

When sourcing suppliers for leather fabric paint, consider their reputation and experience in the industry. Look for manufacturers that offer high-quality products, preferably with certifications for safety and compliance with international standards. Evaluate their production capacity, lead times, and ability to handle bulk orders. Additionally, ask for samples to assess product quality before committing to larger purchases. Building relationships with suppliers who understand your market and can provide reliable service is crucial for long-term success. -

4. What are the typical minimum order quantities (MOQs) for leather fabric paint?

Minimum order quantities (MOQs) for leather fabric paint can vary significantly between suppliers, often ranging from 50 to 500 units. Factors influencing MOQs include the supplier’s production capabilities, the type of paint, and whether customization is involved. It’s advisable to discuss your specific needs and negotiate MOQs, especially if you are a new buyer or require smaller quantities for trial runs. Some suppliers may offer flexible options for first-time customers or larger ongoing orders. -

5. How can I customize leather paint colors for my business?

Many suppliers offer customization options for leather paint colors, allowing you to create unique shades that align with your brand identity. When seeking customization, inquire about the supplier’s color matching process and whether they can provide Pantone or RAL color matching services. Be prepared to provide samples or specifications for the desired colors. Additionally, consider the minimum order quantities for customized colors, as they may differ from standard offerings. -

6. What payment terms are commonly accepted for international orders of leather paint?

Payment terms for international orders of leather paint can vary, but common practices include payment in advance, letters of credit, or net terms (e.g., net 30 or net 60). It’s essential to clarify payment methods accepted by the supplier, such as wire transfers, credit cards, or PayPal. Ensure you understand any additional fees associated with currency conversion or international transactions. Establishing clear payment terms helps to avoid misunderstandings and build trust in your supplier relationship. -

7. What quality assurance measures should I expect from my leather paint supplier?

A reputable leather paint supplier should have stringent quality assurance (QA) measures in place to ensure product consistency and safety. Look for suppliers that conduct regular testing on their paints for durability, colorfastness, and adhesion. Certifications such as ISO or compliance with local regulations can also indicate a commitment to quality. Requesting product samples and reviewing customer feedback can further help you assess the quality of the paint before placing a bulk order. -

8. How is logistics managed for shipping leather paint internationally?

Logistics for shipping leather paint internationally involves coordinating with freight forwarders or logistics providers to manage transportation and customs clearance. Factors to consider include shipping methods (air, sea, or land), delivery times, and associated costs. Ensure that your supplier has experience in international shipping and can provide necessary documentation for customs. Discuss shipping insurance options to protect your order against potential damages or losses during transit. Establishing a reliable logistics plan is crucial for timely delivery and smooth operations.

Top 7 Leather Fabric Paint Manufacturers & Suppliers List

1. Angelus – Acrylic Leather Paint

Domain: angelusdirect.com

Registered: 2013 (12 years)

Introduction: Acrylic Leather Paint by Angelus is a versatile, water-based acrylic paint designed for use on leather, canvas, vinyl, and more. It provides vivid, fade-resistant color without cracking, making it ideal for customizing shoes, bags, jackets, and upholstery. The paint offers rich coverage, easy cleanup, and a professional-grade finish. Key features include:

– Durable and flexible formula

– Non-fla…

2. Pentart – Fabric and Leather Paint

Domain: ellenjgoods.com

Registered: 2013 (12 years)

Introduction: {“product_name”:”Pentart Fabric and Leather Paint”,”volume”:”50ml”,”price”:”$12.95″,”color_variants”:[“White”,”Beige”],”description”:”A water-based paint for fabric, leather, faux-leather, and vinyl.”}

3. Tulip – Leather Fabric Paint Set

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {‘name’: ‘Tulip Leather Fabric Paint – 4 Piece Set’, ‘sku’: ‘2398790’, ‘original_price’: ‘$11.99’, ‘colors’: [‘Tan’, ‘Brown’, ‘Black’], ‘color_codes’: [‘Sand’, ‘Hazelnut’], ‘volume’: ‘2 Fluid Ounces (59ml)’, ‘care_safety’: ‘Non-Toxic; Permanent’, ‘quantity’: ‘3 Colors & 1 Gloss Topcoat’}

4. Reddit – Leather-Based Paint Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Type of Paint: Leather-based paints recommended, specifically acrylic paint. 2. Application Tips: Use stencils for design; consider applying a glue stick on the back of stencils to prevent paint leakage. 3. Additional Coating: A layer of clear coat suggested to extend longevity of the paint. 4. Practice: Recommended to practice on scraps before applying to the jacket. 5. Brand Mentioned: Angelu…

5. Angelus – Leather Preparer & Deglazer

Domain: artistcraftsman.com

Registered: 1999 (26 years)

Introduction: Brand: Angelus, Jacquard

Products:

– Jacquard Marbling Kit, MSRP: $20.99

– Jacquard Dye-Na-Flow, MSRP: $5.39

– Jacquard Textile Colors, MSRP: $5.79 – $7.59

– Angelus Leather Preparer & Deglazer, 1 oz, MSRP: $2.95

– Jacquard Lumiere Acrylics, MSRP: $7.87

– Angelus Easy Cleaner, MSRP: $8.95

– Angelus Suede Dyes, MSRP: $5.95

– Jacquard Neopaque Acrylics, MSRP: $7.87

– Angelus Sole Bright, MSRP: $12.9…

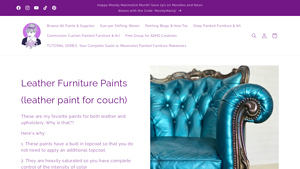

6. Tanglewood Works – Leather Furniture Paints

Domain: tanglewoodworks.com

Registered: 2014 (11 years)

Introduction: Collection: Leather Furniture Paints (leather paint for couch)\nKey Features: 1. Built-in topcoat eliminates the need for an additional topcoat. 2. Heavily saturated for complete control of color intensity. 3. Soft and durable finish suitable for both fabric and leather.\nAvailability: In stock (161 products)\nPrice Range: From $18.50 to $44.50\nColor Options: Black (5), Blue (23), Bronze (1), Bro…

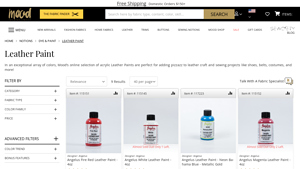

7. Mood Fabrics – Acrylic Leather Paints

Domain: moodfabrics.com

Registered: 2001 (24 years)

Introduction: This company, Mood Fabrics – Acrylic Leather Paints, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for leather fabric paint

As the leather fabric paint market continues to evolve, strategic sourcing emerges as a critical component for international B2B buyers. Sourcing high-quality, versatile products like acrylic leather paint ensures that businesses can meet diverse consumer demands, from customization in fashion to durable finishes in upholstery. By partnering with reputable manufacturers, buyers can access innovative solutions that not only enhance product offerings but also improve overall customer satisfaction.

Understanding the specific needs of various markets, such as those in Africa, South America, the Middle East, and Europe, will allow businesses to tailor their sourcing strategies effectively. This localized approach can lead to increased market penetration and brand loyalty, as customers are more likely to engage with products that resonate with their cultural and aesthetic preferences.

Looking ahead, the potential for growth in the leather fabric paint sector remains robust. By investing in quality and innovation, B2B buyers can position themselves as leaders in their respective markets. Embrace the opportunity to elevate your product line and meet the rising demand for high-quality leather finishes. Start exploring strategic sourcing options today to ensure your business thrives in this dynamic landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.