Introduction: Navigating the Global Market for things to make with leather

In today’s competitive landscape, international B2B buyers face the challenge of sourcing high-quality materials for crafting unique leather goods. Whether you are looking to create bespoke handbags, durable wallets, or stylish accessories, understanding the nuances of leather types and their applications is crucial. This guide on things to make with leather serves as a comprehensive resource, addressing key considerations such as material selection, supplier vetting, cost analysis, and market trends across diverse regions, including Africa, South America, the Middle East, and Europe.

Leather has long been revered for its versatility and durability, making it a preferred choice for a wide array of products. However, navigating the global market requires keen insight into regional preferences and sourcing strategies. By delving into various project ideas and applications, this guide empowers B2B buyers to make informed purchasing decisions that align with their business goals. From beginner-friendly projects to intricate designs suitable for high-end retail, you will discover how to select the right leather for each application, ensuring quality and customer satisfaction.

As you explore the possibilities of leather crafting, this guide will equip you with actionable insights and valuable resources, enabling you to thrive in the evolving marketplace. Embrace the art of leather-making and position your business for success in a dynamic industry.

Table Of Contents

- Top 4 Things To Make With Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for things to make with leather

- Understanding things to make with leather Types and Variations

- Key Industrial Applications of things to make with leather

- 3 Common User Pain Points for ‘things to make with leather’ & Their Solutions

- Strategic Material Selection Guide for things to make with leather

- In-depth Look: Manufacturing Processes and Quality Assurance for things to make with leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘things to make with leather’

- Comprehensive Cost and Pricing Analysis for things to make with leather Sourcing

- Alternatives Analysis: Comparing things to make with leather With Other Solutions

- Essential Technical Properties and Trade Terminology for things to make with leather

- Navigating Market Dynamics and Sourcing Trends in the things to make with leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of things to make with leather

- Strategic Sourcing Conclusion and Outlook for things to make with leather

- Important Disclaimer & Terms of Use

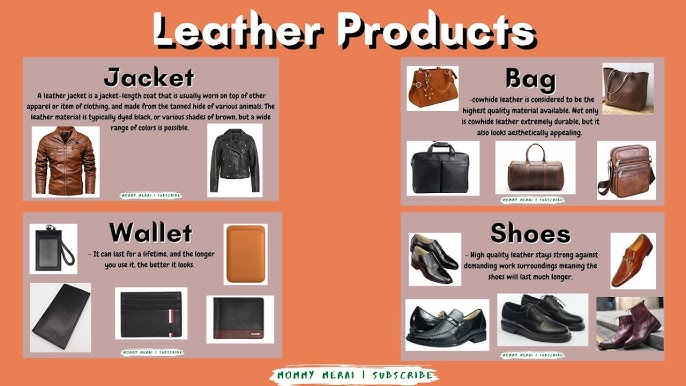

Understanding things to make with leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bags | Versatile designs, can be laser cut or hand-stitched | Fashion retail, promotional products | Pros: High demand, customization options. Cons: Higher initial costs for quality leather. |

| Wallets | Slim, minimalist styles with personalization options | Gift shops, online retail | Pros: Popular for gifts, lightweight. Cons: Market saturation; need for unique designs. |

| Home Décor Items | Includes trays, coasters, and wall art, often engraved | Home goods stores, corporate gifting | Pros: Growing trend in personalized home décor. Cons: Requires unique designs to stand out. |

| Accessories (Jewelry) | Lightweight items like earrings and bracelets, often dyed | Fashion boutiques, online marketplaces | Pros: Low material costs, high markup potential. Cons: Niche market; requires trend awareness. |

| Custom Patches | Personalized designs for branding, often made from durable leather | Apparel brands, promotional events | Pros: Unique branding opportunities, low production costs. Cons: Limited market reach unless well-promoted. |

What Are the Key Characteristics of Leather Bags in B2B Markets?

Leather bags are characterized by their versatility and durability, making them ideal for various applications, from fashion retail to promotional products. They can be crafted in various styles, including totes, backpacks, and clutches, and can feature intricate designs through techniques like laser cutting. For B2B buyers, the ability to customize bags enhances their appeal, enabling businesses to offer unique products that cater to specific market demands. However, the initial investment for high-quality leather can be significant, necessitating careful consideration of the target market.

How Do Leather Wallets Stand Out in the Marketplace?

Leather wallets are typically slim and minimalist, catering to modern consumer preferences for practicality and style. They often allow for personalization, such as engraving names or initials, which adds a unique touch that appeals to buyers. In the B2B context, wallets are popular items for gift shops and online retailers, especially during peak gifting seasons. However, the market is competitive, and businesses must focus on innovative designs to differentiate themselves and attract consumers.

What Makes Home Décor Leather Items Attractive for B2B Buyers?

Home décor items made from leather, such as trays and coasters, are increasingly popular due to their aesthetic appeal and functionality. These items often feature personalized engravings, making them attractive for corporate gifting or retail sales. B2B buyers should consider the growing trend of personalized home décor, as unique designs can significantly enhance marketability. However, to remain competitive, manufacturers must invest in creative design processes to stand out in a crowded market.

Why Are Leather Accessories Like Jewelry a Good Investment?

Leather accessories, including earrings and bracelets, are lightweight and can be produced at relatively low material costs, offering high markup potential. These items can be customized and dyed in various colors, allowing for creative expression and appeal to diverse consumer tastes. For B2B buyers, understanding current fashion trends is crucial, as the niche market for leather jewelry can be lucrative if approached correctly. However, businesses must be aware of the limited reach and the need for effective marketing strategies.

How Do Custom Leather Patches Benefit Businesses?

Custom leather patches are an excellent way for businesses to enhance their branding efforts. Made from durable leather, these patches can be personalized with logos or designs, making them ideal for apparel brands and promotional events. The low production costs associated with patches make them an attractive option for B2B buyers looking to maximize profit margins. However, the market for patches can be limited, requiring effective promotion and branding strategies to reach potential customers.

Illustrative image related to things to make with leather

Key Industrial Applications of things to make with leather

| Industry/Sector | Specific Application of things to make with leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom Leather Bags | High demand for unique, durable fashion items | Quality of leather, design versatility, and ethical sourcing |

| Automotive | Leather Upholstery for Vehicles | Enhances vehicle aesthetics and comfort | Leather durability, color options, and compatibility with designs |

| Furniture | Leather Furniture Accents | Adds luxury and durability to home furnishings | Leather grain quality, maintenance requirements, and sourcing options |

| Accessories & Gifts | Personalized Leather Wallets | High market value for customized gifts | Customization options, leather quality, and target market preferences |

| Sports & Recreation | Leather Sporting Goods (e.g., gloves, balls) | Durable products that withstand rigorous use | Performance standards, leather type, and safety certifications |

What are the Applications of Leather in the Fashion & Apparel Industry?

In the fashion and apparel industry, leather is predominantly used to create custom bags that cater to a growing demand for unique, high-quality items. These bags can be tailored to reflect personal styles, making them appealing to consumers looking for distinctive accessories. For international B2B buyers, sourcing high-quality leather that meets ethical standards is crucial, as well as ensuring a variety of designs to cater to diverse markets, particularly in regions like Europe and South America, where fashion trends vary widely.

How is Leather Used in the Automotive Sector?

Leather upholstery in vehicles enhances both aesthetics and comfort, making it a sought-after material in the automotive industry. It contributes to a luxury feel while also providing durability against wear and tear. B2B buyers in this sector must consider the leather’s durability, color options, and compatibility with various vehicle designs. Additionally, suppliers should ensure that the leather meets industry standards for safety and comfort, particularly in regions with stringent automotive regulations, such as Europe.

What Role Does Leather Play in Furniture Design?

Leather is widely utilized in the furniture industry for its ability to add elegance and durability to home furnishings. Leather accents, such as on sofas or chairs, not only enhance the aesthetic appeal but also ensure longevity, making them a valuable investment for consumers. For B2B buyers, it’s important to source leather that maintains its quality over time and is easy to clean, especially in markets like Africa and the Middle East, where climate considerations can affect material performance.

Why are Personalized Leather Accessories Popular in Gift Markets?

Personalized leather wallets and accessories have become increasingly popular as gifts, providing a high market value due to their customizable nature. These items can be tailored with names or special messages, making them ideal for occasions such as weddings or corporate events. For B2B buyers, understanding consumer preferences in different regions is key, as personalization trends may vary. Sourcing high-quality leather that can withstand engraving and customization while maintaining an attractive finish is essential for success in this market.

How is Leather Utilized in Sports and Recreation?

Leather is a favored material for sporting goods, such as gloves and balls, due to its durability and ability to withstand rigorous use. It offers both performance and comfort, essential for athletes. B2B buyers in this sector must focus on sourcing leather that meets specific performance standards and safety certifications, particularly in regions where sports are a significant cultural focus. Understanding the varying requirements for different sports can help suppliers tailor their offerings effectively to meet market needs.

3 Common User Pain Points for ‘things to make with leather’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Leather Type for Projects

The Problem: B2B buyers often struggle with choosing the appropriate leather for various projects. With a wide array of leather types available—each with its own unique characteristics—this decision can be overwhelming. For instance, a manufacturer looking to create high-quality handbags may be unsure whether to opt for vegetable-tanned leather for its durability and tooling capabilities or chrome-tanned leather for its softness and flexibility. This uncertainty can lead to wasted resources, subpar products, and ultimately, dissatisfied customers.

The Solution: To overcome this challenge, buyers should establish a clear understanding of their project requirements before sourcing leather. It is crucial to assess the desired qualities of the final product: durability, flexibility, or aesthetic appeal. For example, if the goal is to create sturdy belts or dog collars, opting for thicker bridle or harness leather would be ideal. Buyers can also benefit from sourcing leather samples from suppliers, allowing them to physically evaluate the texture, thickness, and finish before making a bulk purchase. Additionally, collaborating with experienced leather suppliers who can provide expert guidance based on the specific application can streamline the decision-making process and ensure optimal results.

Scenario 2: Challenges in Sourcing Reliable Leather Crafting Tools

The Problem: Another significant pain point for B2B buyers is the challenge of sourcing reliable and high-quality leather crafting tools. Many buyers, particularly those new to leatherworking, may find it difficult to navigate the market filled with various tools, from knives to stitching needles. The risk of investing in subpar tools can lead to poor craftsmanship, increased production time, and a compromised end product. This is particularly critical for businesses that rely on precision and quality to maintain their brand reputation.

The Solution: To mitigate this issue, buyers should conduct thorough research before purchasing tools. They can start by identifying reputable suppliers that specialize in leatherworking tools and offer warranties or satisfaction guarantees. Additionally, seeking recommendations from experienced leatherworkers through forums or industry associations can provide insights into the most effective tools for specific projects. Investing in comprehensive leathercraft kits that include essential tools—such as utility knives, hole punches, and edge bevelers—can also simplify the purchasing process and ensure that the buyer has everything needed for successful project execution. Educating staff on proper tool maintenance will further enhance longevity and performance, reducing the frequency of tool replacements.

Scenario 3: Navigating the Market for Profitable Leather Projects

The Problem: Many B2B buyers are eager to tap into the lucrative market for handmade leather goods but often find it challenging to identify which projects will yield the highest return on investment. With the rise of e-commerce and craft fairs, the competition is fierce, and the risk of financial loss looms large if the chosen projects do not resonate with consumers. Buyers may feel overwhelmed by the vast array of potential products, from wallets to personalized leather accessories, and unsure which items will sell best.

The Solution: To effectively navigate this landscape, buyers should conduct market research to identify current trends and customer preferences within their target demographic. Platforms such as social media, e-commerce sites, and craft marketplaces can provide valuable insights into popular leather items that are in demand. Additionally, attending craft fairs and trade shows allows buyers to observe which products attract attention and generate sales. Diversifying the product range by incorporating customizable options—like personalized leather patches or engraved wallets—can also increase appeal and profitability. Collaborating with artisans who have proven success in the leather market can offer mentorship and guidance, helping buyers refine their product offerings to align with consumer expectations and preferences.

Illustrative image related to things to make with leather

Strategic Material Selection Guide for things to make with leather

What Are the Key Properties of Common Leather Materials for B2B Applications?

When selecting leather materials for various products, understanding the specific properties and applications is crucial for B2B buyers. Here, we analyze four common leather types used in crafting items like bags, wallets, and accessories.

1. Vegetable-Tanned Leather

Key Properties: Vegetable-tanned leather is known for its eco-friendly tanning process, which uses natural tannins from plant sources. This type of leather is firm yet flexible, making it suitable for tooling and embossing. It also has a high resistance to wear and tear, making it ideal for products that require durability.

Pros & Cons: The advantages of vegetable-tanned leather include its ability to develop a rich patina over time and its suitability for dyeing and stamping. However, it can be more expensive compared to chrome-tanned leather and may not be as water-resistant, which limits its use in certain applications.

Impact on Application: This leather is often used for high-end products like wallets and belts, where aesthetics and durability are paramount. Its compatibility with various dyes and finishes allows for customization, appealing to consumers seeking unique items.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of compliance with environmental regulations regarding tannin extraction. Familiarity with local standards, such as ASTM or DIN for leather quality, is essential to ensure product acceptance in their markets.

Illustrative image related to things to make with leather

2. Chrome-Tanned Leather

Key Properties: Chrome-tanned leather is produced using chromium salts, resulting in a soft and pliable material. It is highly resistant to water and stains, making it suitable for a wide range of products.

Pros & Cons: The primary advantage of chrome-tanned leather is its affordability and availability, making it a popular choice for mass production. However, it may not be as environmentally friendly due to the chemicals involved in the tanning process, which could raise concerns in certain markets.

Impact on Application: This leather is commonly used in fashion items, upholstery, and accessories due to its versatility and comfort. Its resistance to moisture makes it ideal for products that are exposed to varying climates.

Considerations for International Buyers: Buyers in Europe may need to ensure compliance with REACH regulations regarding chemical use in leather production. Understanding the local market’s preferences for sustainable materials can influence purchasing decisions.

3. Oil-Tanned Leather

Key Properties: Oil-tanned leather is treated with oils and waxes, giving it a soft, supple feel and enhanced water resistance. This type of leather is highly durable and can withstand harsh conditions.

Pros & Cons: The key advantage of oil-tanned leather is its ability to resist moisture and its rugged appearance, making it suitable for outdoor gear and work-related products. However, it can be more expensive and may require more maintenance to preserve its appearance.

Impact on Application: This leather is ideal for items like belts, bags, and outdoor gear, where durability and weather resistance are critical. Its unique texture can also appeal to consumers looking for rustic aesthetics.

Considerations for International Buyers: Buyers from the Middle East should consider the local climate’s impact on leather products. Ensuring that the leather meets local durability standards can enhance marketability.

4. Suede Leather

Key Properties: Suede leather is made from the underside of the hide, giving it a soft texture and a luxurious feel. It is less durable than full-grain leather but offers a unique aesthetic appeal.

Pros & Cons: Suede’s softness and versatility make it popular for fashion items and accessories. However, it is more susceptible to staining and damage, which limits its use in certain applications.

Impact on Application: Suede is often used in clothing, shoes, and decorative items where a soft touch is desired. Its unique appearance can attract consumers looking for fashionable, high-quality products.

Illustrative image related to things to make with leather

Considerations for International Buyers: Buyers in South America should be aware of the maintenance requirements for suede products, as they may need to educate consumers on proper care. Understanding local fashion trends can also guide product selection.

Summary Table of Leather Materials

| Material | Typical Use Case for things to make with leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-end wallets, belts, and bags | Develops a rich patina over time | More expensive, less water-resistant | High |

| Chrome-Tanned Leather | Fashion items, upholstery, and accessories | Affordable and widely available | Less environmentally friendly | Medium |

| Oil-Tanned Leather | Outdoor gear, belts, and rugged bags | Highly durable and water-resistant | More expensive, requires maintenance | High |

| Suede Leather | Clothing, shoes, and decorative items | Luxurious feel and aesthetic appeal | Susceptible to staining and damage | Medium |

This guide provides B2B buyers with essential insights into leather material selection, helping them make informed decisions based on product requirements and market considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for things to make with leather

What Are the Main Stages in Leather Manufacturing Processes?

The manufacturing of leather goods involves several critical stages that ensure both functionality and aesthetic appeal. Understanding these stages is vital for B2B buyers looking to source high-quality leather products.

Illustrative image related to things to make with leather

Material Preparation: How Is Leather Selected and Processed?

The first step in leather manufacturing is material preparation. This involves selecting the right type of leather based on the intended use of the final product. For instance, vegetable-tanned leather is ideal for tooling and stamping, while chrome-tanned leather suits softer goods like bags and apparel.

Once the appropriate leather is chosen, it undergoes a thorough cleaning and conditioning process. This may involve removing hair, fat, and other impurities through various treatments, ensuring the leather is free from defects. B2B buyers should seek suppliers who maintain strict standards for leather sourcing, prioritizing sustainability and ethical practices.

How Are Leather Goods Formed?

The forming stage involves cutting and shaping the leather into the desired patterns. This can be achieved through manual cutting or advanced techniques such as laser cutting, which offers precision and the ability to create intricate designs. For bulk manufacturing, die-cutting methods are often employed to enhance efficiency.

During this phase, attention to detail is crucial. Buyers should inquire about the cutting methods used by suppliers, as this can significantly affect the quality of the final product. Proper cutting techniques ensure that the leather maintains its integrity and structure throughout the manufacturing process.

Illustrative image related to things to make with leather

What Techniques Are Used in Assembling Leather Products?

Assembly is the next phase where the prepared leather pieces are stitched, glued, or riveted together to form the final product. This stage often requires skilled labor, particularly for complex designs such as bags or belts. Hand-stitching is favored for high-end products, while machine stitching is common for mass-produced items.

In addition to stitching, assembly may involve adding hardware such as buckles, zippers, or snaps, which requires careful alignment and attachment. B2B buyers should assess the assembly techniques employed by potential suppliers, as this can impact the durability and functionality of the products.

What Finishing Techniques Enhance the Quality of Leather Goods?

Finishing is the final stage that enhances the appearance and durability of leather products. This may include dyeing, waxing, or applying protective coatings. The choice of finishing technique often depends on the product’s intended use; for instance, a water-resistant finish may be necessary for outdoor gear.

Illustrative image related to things to make with leather

Quality control during the finishing stage is vital. Suppliers should adhere to international standards, ensuring that the final product meets specific aesthetic and functional criteria. B2B buyers should request samples to verify the quality of finishes and colors used in the products.

How Is Quality Assurance Implemented in Leather Manufacturing?

Quality assurance (QA) is an integral part of the leather manufacturing process. Adhering to international standards such as ISO 9001 ensures that suppliers maintain a consistent quality level throughout production. Additionally, industry-specific certifications, like CE marking for safety and environmental compliance, may be relevant for certain products.

What Are the Key Quality Control Checkpoints in Leather Manufacturing?

Quality control checkpoints are essential for ensuring product integrity. These typically include:

- Incoming Quality Control (IQC): Initial inspection of raw materials to verify their quality and compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to catch any deviations early on.

- Final Quality Control (FQC): A thorough inspection of the finished products to ensure they meet the required standards before shipping.

B2B buyers should inquire about the QC processes in place at their suppliers to ensure a robust quality management system.

What Common Testing Methods Are Used for Leather Goods?

Testing methods for leather products can vary but generally include:

- Physical Tests: Assessing the leather’s durability, flexibility, and resistance to wear and tear.

- Chemical Tests: Checking for harmful substances, such as azo dyes or heavy metals, to comply with safety regulations.

- Environmental Tests: Evaluating the leather’s performance under different conditions, such as moisture or temperature changes.

Buyers should request detailed testing reports to confirm that products meet the necessary safety and quality standards.

Illustrative image related to things to make with leather

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider several verification methods:

- Supplier Audits: Conducting on-site inspections to evaluate the manufacturing processes and QC practices firsthand.

- Quality Reports: Requesting detailed quality reports that outline testing results and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality before shipment.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification. Different countries may have varying regulations regarding leather products, including environmental and safety standards.

Understanding these regulations is critical for ensuring compliance and avoiding potential legal issues. B2B buyers should engage with suppliers who have a clear understanding of both local and international standards, ensuring that their products can be marketed globally without complications.

Conclusion: Ensuring Quality in Leather Manufacturing

In summary, the manufacturing processes and quality assurance practices for leather goods are multi-faceted and require careful consideration. B2B buyers must prioritize suppliers who adhere to stringent quality control measures and international standards, ensuring that their products meet market demands while maintaining ethical and sustainable practices. By understanding the manufacturing stages and QA processes, buyers can make informed decisions that benefit their businesses and enhance their product offerings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘things to make with leather’

Introduction

This guide serves as a practical checklist for B2B buyers interested in procuring materials and products for leather crafting. Understanding the nuances of sourcing leather and related components is critical for creating high-quality leather goods that meet market demands. By following these steps, you can ensure a streamlined procurement process that aligns with your business objectives.

Step 1: Identify Your Product Range

Before sourcing, clearly define the types of leather products you intend to create. Whether it’s bags, wallets, or accessories, knowing your product range helps in selecting the appropriate leather types and sourcing materials that align with your design specifications. Consider customer preferences and market trends in your target regions, such as Africa or Europe.

Illustrative image related to things to make with leather

Step 2: Determine Quality Specifications

Establish the quality standards your leather products must meet. Factors like thickness, finish, and type of leather—such as vegetable-tanned or chrome-tanned—will impact both the aesthetics and durability of your products. High-quality leather not only enhances the product’s appeal but also influences customer satisfaction and brand reputation.

Step 3: Evaluate Potential Suppliers

Conduct thorough evaluations of potential suppliers. Request company profiles, product samples, and references from other businesses in your industry. Focus on suppliers that demonstrate a consistent track record of quality and reliability, as this can significantly affect your production timeline and product quality.

- Look for certifications that indicate compliance with international standards.

- Check for reviews from other buyers to gauge the supplier’s reputation.

Step 4: Assess Pricing and Payment Terms

Analyze the pricing structures of different suppliers to ensure you’re getting competitive rates. Understanding the payment terms—such as upfront deposits, credit options, and bulk discounts—can help in managing cash flow effectively. Remember, the cheapest option isn’t always the best; consider the overall value and quality.

Step 5: Request Samples and Prototypes

Before making a bulk purchase, always request samples of the leather and components you plan to use. This step allows you to assess the quality firsthand and determine if it meets your specifications. Prototyping can also help in identifying potential design or functionality issues before full-scale production begins.

Step 6: Verify Supply Chain Logistics

Understanding the logistics of your supply chain is vital for timely delivery and inventory management. Confirm the supplier’s shipping capabilities, lead times, and return policies. Efficient logistics can help prevent delays in production and ensure your products reach the market when needed.

Step 7: Establish Communication Channels

Maintain open lines of communication with your suppliers. Regular updates and feedback can foster strong relationships and facilitate smoother transactions. Ensure that you have direct contacts for inquiries and problem resolution, as effective communication is key to addressing any issues that may arise during the procurement process.

By following this checklist, you can streamline your sourcing process, ensuring that you acquire the right materials and products to create high-quality leather goods that meet the demands of your market.

Illustrative image related to things to make with leather

Comprehensive Cost and Pricing Analysis for things to make with leather Sourcing

When considering the cost structure and pricing of leather goods, various components contribute to the overall expenses involved in manufacturing and sourcing these products. Understanding these factors can significantly impact B2B negotiations and decision-making.

What Are the Key Cost Components for Leather Goods?

-

Materials: The choice of leather is pivotal in determining costs. High-quality leathers, such as full-grain or vegetable-tanned options, generally come at a premium compared to lower-quality or synthetic alternatives. Buyers should also consider additional materials like thread, lining, and hardware, which can vary significantly in price based on quality and source.

-

Labor: Labor costs can fluctuate based on the complexity of the product and the skill level required. Handcrafted items often demand higher labor costs due to the expertise involved, while simpler designs may be produced with less skilled labor, reducing expenses.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, but this often requires initial investment in technology and training.

-

Tooling: The initial setup for specialized tools and machinery can be substantial, especially for custom or intricate designs. Buyers should factor in the costs of these tools when considering initial orders or custom projects.

-

Quality Control (QC): Ensuring product quality is crucial, particularly for high-end leather goods. QC processes may involve additional labor and testing, impacting overall costs. Buyers should discuss QC measures with suppliers to align on expectations and costs.

-

Logistics: Shipping and handling costs can vary widely based on destination, volume, and Incoterms. For international shipments, buyers should consider customs duties and taxes, which can significantly affect the total landed cost.

-

Margin: Suppliers typically incorporate a profit margin into their pricing. Understanding the industry standard margins can help buyers gauge whether the quoted prices are competitive.

How Do Price Influencers Affect Leather Goods Sourcing?

Several factors can influence the pricing of leather goods:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should negotiate MOQs that align with their needs while seeking volume discounts.

-

Specifications and Customization: Custom designs or specific material requests can increase costs. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Material Quality and Certifications: The presence of certifications (e.g., environmentally friendly practices) can elevate costs but may appeal to certain market segments. Buyers should weigh the benefits of certification against budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to perceived quality, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms is vital for calculating the total cost. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect pricing and responsibility for shipping costs.

What Are Effective Buyer Tips for Negotiating Leather Goods Pricing?

-

Negotiation Strategies: Leverage the understanding of cost components to negotiate better terms. Presenting data on competitors’ pricing can strengthen your position.

-

Cost-Efficiency Approaches: Consider long-term relationships with suppliers, which can yield better pricing and more favorable terms over time.

-

Total Cost of Ownership: Evaluate not just the purchase price but the total cost of ownership, which includes maintenance, durability, and potential resale value of the leather goods.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and regional market conditions that may affect pricing. It’s crucial to build relationships with local suppliers who understand the specific market dynamics in regions like Africa, South America, and the Middle East.

Disclaimer on Indicative Prices

Prices for leather goods can vary significantly based on the factors outlined above. The information provided here is for indicative purposes and should be confirmed with suppliers during the negotiation process to ensure accurate and current pricing.

Alternatives Analysis: Comparing things to make with leather With Other Solutions

In the realm of crafting and manufacturing, leather stands out due to its durability, aesthetic appeal, and versatility. However, there are various alternative materials and methods that can be utilized for similar products. This section explores these alternatives, providing B2B buyers with a comprehensive comparison to aid in decision-making.

| Comparison Aspect | Things To Make With Leather | Alternative 1: Synthetic Leather | Alternative 2: Fabric |

|---|---|---|---|

| Performance | High durability, natural aging, and unique patina | Good durability, less aging, but can wear out faster than genuine leather | Varies widely; can be durable but generally less robust than leather |

| Cost | Generally higher due to material sourcing and processing | Often cheaper, especially for mass production | Typically lower cost, depends on fabric type |

| Ease of Implementation | Requires specific tools and skills for crafting | Easier to work with; often available in pre-cut sheets | Varies; sewing machines are typically required but can be easier to handle |

| Maintenance | Requires regular conditioning and care to maintain quality | Low maintenance; easy to clean | Varies; some fabrics are machine washable while others may require special care |

| Best Use Case | High-end fashion, durable goods, custom items | Fashion items, accessories, and budget-friendly products | Casual wear, home décor, and promotional items |

What Are the Advantages and Disadvantages of Synthetic Leather?

Synthetic leather, also known as faux leather or vegan leather, is increasingly popular in various markets. Its primary advantage is affordability, making it accessible for mass production. Additionally, synthetic leather is often easier to maintain than genuine leather, requiring simple cleaning methods. However, it may not provide the same level of durability or unique aesthetic as leather, as it can wear out more quickly and lacks the natural aging process that gives leather its character. For B2B buyers looking for cost-effective solutions for fashion items or accessories, synthetic leather can be a viable alternative, especially in markets sensitive to animal-derived products.

How Does Fabric Compare to Leather in Crafting Projects?

Fabric, ranging from cotton to polyester blends, offers another alternative for crafting. Its advantages include a wide variety of colors, patterns, and textures, allowing for creative freedom in design. Moreover, fabric is typically less expensive and more readily available than leather. However, the performance of fabric can vary widely based on the type chosen. While some fabrics may be durable, they generally do not match the robustness of leather. For applications in casual wear or home décor, where aesthetics and cost are more critical than durability, fabric presents a strong alternative for B2B buyers.

Conclusion: How Should B2B Buyers Decide on the Right Material for Their Needs?

When selecting between leather and its alternatives, B2B buyers must assess their specific needs, including the intended use of the product, target market, and budget constraints. Leather is ideal for high-end, durable items that benefit from a timeless aesthetic. In contrast, synthetic leather and fabric can serve well in cost-sensitive markets or for products requiring high volume. By carefully considering these factors, buyers can make informed decisions that align with their brand values and customer expectations.

Essential Technical Properties and Trade Terminology for things to make with leather

What Are the Key Technical Properties of Leather for Manufacturing?

When considering leather for manufacturing projects, it’s crucial to understand the technical properties that can impact the quality and usability of the final product. Here are some essential specifications to be aware of:

1. Leather Grade

Leather is classified into various grades based on quality and processing methods. Full-grain leather, for instance, retains the natural texture and imperfections of the hide, making it the most durable and sought-after type. Top-grain leather, while slightly less robust, is more affordable and has a finer finish. Understanding leather grades helps B2B buyers select appropriate materials that align with their product quality and branding.

Illustrative image related to things to make with leather

2. Thickness (Ounces)

The thickness of leather is measured in ounces, with one ounce equating to approximately 1/64th of an inch. Thicker leather (e.g., 8-10 oz) is typically used for durable items like belts and bags, while thinner leather (e.g., 2-4 oz) is preferred for garments and accessories. Buyers must consider thickness to ensure the leather meets the functional requirements of their products.

3. Temper

Temper refers to the firmness or softness of leather. Soft temper leather is supple and flexible, making it ideal for clothing and bags that require movement. Conversely, firm temper leather is used for structured items like wallets and cases. Understanding temper helps manufacturers design products that not only look good but also function effectively.

4. Finish Type

Leather finishes can vary significantly, from smooth and polished to suede or embossed. The finish affects both the aesthetic and durability of the leather. For example, a smooth finish is easier to clean and maintain, while an embossed finish can add texture and visual interest. B2B buyers should assess finish types based on target market preferences and usage scenarios.

5. Tensile Strength

This property measures the leather’s resistance to being pulled apart. Higher tensile strength indicates a more durable material, which is essential for products subjected to stress, like bags and harnesses. Understanding tensile strength is crucial for manufacturers aiming to ensure the longevity and reliability of their leather goods.

Illustrative image related to things to make with leather

What Are Common Trade Terms in the Leather Industry?

Navigating the leather industry requires familiarity with specific jargon that can impact business dealings. Here are several common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products based on specifications provided by another company. In the leather industry, this often involves creating custom leather goods for brands looking to outsource production. Understanding OEM relationships can help buyers leverage manufacturing capabilities without investing in their own production facilities.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it impacts inventory management and cost-effectiveness. Knowing the MOQ helps businesses plan their orders efficiently and avoid overcommitting to stock they may not sell.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing for specific products or services. B2B buyers use RFQs to compare costs and terms across different suppliers, ensuring they receive competitive pricing for their leather needs.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade transactions. They specify who is responsible for shipping costs, insurance, and risks associated with the delivery of goods. Familiarity with Incoterms is vital for B2B buyers to avoid misunderstandings in global transactions.

5. Vegetable-Tanned vs. Chrome-Tanned

These terms refer to the two primary methods of tanning leather. Vegetable-tanned leather is processed using natural tannins, resulting in a more environmentally friendly product that develops a rich patina over time. Chrome-tanned leather, while more resistant to water and mold, can have a higher environmental impact. Understanding these differences aids buyers in selecting leather that aligns with their sustainability goals and product requirements.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing leather for their manufacturing projects, ensuring quality and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the things to make with leather Sector

What Are the Key Market Drivers and Trends in the Leather Craft Sector?

The global leather craft market is experiencing significant growth, driven by factors such as rising disposable incomes, increasing consumer preference for quality and luxury products, and the versatility of leather in various applications. International B2B buyers are particularly drawn to leather due to its durability and aesthetic appeal, which are vital for crafting items like bags, wallets, and accessories that cater to both high-end and everyday markets. Emerging technologies, such as laser cutting and engraving, are transforming traditional leatherworking methods, allowing for more intricate designs and personalization options, which are becoming essential selling points.

Furthermore, the rise of e-commerce platforms has made it easier for artisans and small businesses to reach a global audience. This shift is particularly relevant for buyers in regions like Africa and South America, where local artisans can now export unique leather goods, tapping into international markets. As sustainability becomes a focal point for consumers, the demand for ethically sourced leather is on the rise, prompting suppliers to adopt environmentally friendly practices.

How Is Sustainability and Ethical Sourcing Impacting the Leather Industry?

Sustainability is increasingly becoming a priority in the leather industry, impacting sourcing trends and buyer preferences. The environmental impact of leather production, particularly in terms of water usage and chemical processing, has raised concerns among consumers and businesses alike. Consequently, B2B buyers are now seeking suppliers who adhere to ethical practices and sustainable methods.

Certifications such as the Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are gaining traction, providing assurance that products are made with environmentally friendly processes. Additionally, there is a growing interest in alternative materials, such as vegetable-tanned leather and recycled leather, which reduce the ecological footprint of leather goods. By prioritizing sustainability, businesses can not only meet regulatory requirements but also align with the values of environmentally conscious consumers, ultimately enhancing their market position.

What Is the Historical Context of Leather Crafting in B2B?

The art of leather crafting dates back thousands of years, originally emerging from the need for durable materials for clothing and tools. As civilizations evolved, so did the techniques for processing and crafting leather, leading to its use in a wide range of applications from armor to decorative goods. In the modern era, the leather craft industry has transitioned from traditional methods to include advanced technologies, enabling mass production while still catering to niche markets.

This evolution has opened up opportunities for B2B buyers to source high-quality leather goods that blend historical craftsmanship with contemporary design. As consumer preferences shift towards unique, handmade items, the blend of tradition and innovation in leather crafting is a significant asset for businesses looking to differentiate themselves in a competitive marketplace.

Illustrative image related to things to make with leather

Frequently Asked Questions (FAQs) for B2B Buyers of things to make with leather

-

How do I choose the right type of leather for my projects?

Selecting the appropriate leather is crucial for the success of your project. Consider the intended use of the item—whether it needs to be flexible or rigid. For example, vegetable-tanned leather is ideal for tooling and stamping, while chrome-tanned leather suits softer items like bags. Additionally, assess the leather’s thickness and finish to match your design requirements. Request samples from suppliers to evaluate texture and durability before making a bulk purchase. -

What are the most popular leather projects for B2B buyers?

Some of the top-selling leather projects include personalized wallets, bags, belts, and custom patches. These items are favored for their quality and potential for customization, appealing to both individual consumers and businesses. Additionally, innovative products such as laser-cut leather accessories and engraved items are gaining traction in the market, providing unique offerings that can stand out in competitive environments. -

What is the minimum order quantity (MOQ) for leather products?

Minimum order quantities for leather goods can vary significantly based on the supplier and the type of product. Typically, MOQs range from 50 to 500 units, depending on the complexity of the design and the materials used. It’s essential to discuss your needs with potential suppliers to find a balance between cost-effectiveness and the ability to meet demand, especially in international markets. -

How can I ensure the quality of leather products from suppliers?

To maintain high quality, vet potential suppliers by requesting samples of their leather products. Look for certifications indicating compliance with international quality standards. Additionally, consider visiting the supplier’s facilities if feasible or ask for references from other B2B clients. Establishing clear quality assurance protocols in your contract can further safeguard against subpar products. -

What payment terms should I expect when sourcing leather goods internationally?

Payment terms can vary widely among suppliers, but common practices include a deposit upfront (usually 30-50%) with the balance due before shipment. Some suppliers may offer net terms based on your credit history or relationship with them. Always clarify payment methods, including the use of secure transactions and letters of credit, to minimize risks in international trade. -

How do I handle logistics and shipping for leather products?

Logistics for international shipping can be complex, requiring a reliable freight forwarder familiar with customs regulations in your target markets. Discuss shipping options with your supplier, including air freight for faster delivery or sea freight for cost savings. Ensure you understand customs duties and tariffs applicable to leather goods in your importing country to avoid unexpected costs. -

What customization options are available for leather products?

Customization options for leather items often include embossing, laser engraving, and dyeing. Many suppliers offer tailored designs that can incorporate logos, names, or specific color schemes. It’s crucial to communicate your design requirements clearly and inquire about the supplier’s capabilities to ensure they can meet your specifications effectively. -

How do I find reliable suppliers for leather goods in international markets?

To find trustworthy suppliers, start by researching online B2B marketplaces and industry trade shows. Look for suppliers with positive reviews, verified credentials, and a solid track record of delivery. Networking within industry forums and associations can also lead to recommendations for reputable suppliers. Always conduct due diligence, including background checks and communication to gauge responsiveness and professionalism.

Top 4 Things To Make With Leather Manufacturers & Suppliers List

1. Reddit – Custom Leather Goods

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Bracelets, notebook covers, coasters, pen holders, glasses cases, journal covers, passport wallets, cord minders, corner bookmarks, valet trays, cable organizers, soft jaws for binder clips, small sheaths for craft knives, belt holsters, D ring belt loops, dry erase board magnets, refrigerator magnets, magnetic pin cushions, earrings, necklaces, travel hat/towel holders, mug straps, DnD dice rolli…

2. Pinterest – Leatherworking Projects

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Leatherworking Projects, Leather Succulents, Leather Flowers, Faux Leather Flowers, Leather Projects For Kids, Craft With Leather Scraps, Leather Scraps Ideas, Faux Leather Projects, Leather Flower Pattern, Diy Leather Yarn Holder, Leather Diy Gifts For Men, Leatherworking Projects Ideas, Leather Knitting, Repurposed Leather, Useful Leather Projects, Tiny Leather Projects, Crochet And Leather Idea…

3. Weaver Leather Supply – Leathercrafting Materials

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Shop by Leathercrafting Project – Weaver Leather Supply offers a variety of leather types including ChahinLeather®, Hermann Oak® Veg Tan (Natural and Dyed), Chrome Tanned, Water Buffalo Leather, and Specialty Leather. The product categories include Leather Cuts (Double Shoulders, Backs & Bends, Single Shoulders, Panels, Sides, Whole Hide, Bellies, Belt Blanks, Laces & Strapping, Leather Remnants),…

4. Leatherworker.net – Thin Leather for Crafting

Domain: leatherworker.net

Registered: 2006 (19 years)

Introduction: Thin leather (0.6mm or 1.5oz) suitable for projects such as wallet interiors, card holders, soft cases, tool rolls, and notepad cases. The leather is described as beautiful but too soft for traditional wallet making. Suggestions include using it to line other leather items, making cushions, reinforcing clothing, and creating simple drawstring pouches.

Strategic Sourcing Conclusion and Outlook for things to make with leather

As the leather goods market continues to thrive globally, strategic sourcing becomes crucial for B2B buyers looking to capitalize on this demand. By understanding the diverse range of leather projects—from personalized wallets and bags to intricate jewelry—businesses can tailor their offerings to meet customer preferences across various regions, including Africa, South America, the Middle East, and Europe.

Investing in quality leather and leveraging advanced techniques like laser cutting and engraving can enhance product uniqueness and appeal, positioning your brand favorably in competitive markets. Additionally, exploring beginner-friendly projects or kits allows manufacturers to diversify their product lines, catering to both novice and experienced consumers.

The future of leather crafting is bright, with opportunities for innovation and customization paving the way for growth. Now is the time to strengthen your supply chains, ensuring access to premium materials that meet market demands. Embrace these insights and take actionable steps to expand your leather product offerings, thus securing a profitable position in the ever-evolving leather industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.