Introduction: Navigating the Global Market for alcantara fabric for car interior

In the dynamic landscape of automotive interiors, sourcing high-quality Alcantara fabric presents a unique challenge for international B2B buyers. As the demand for luxurious yet durable materials continues to rise, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of Alcantara is essential for making informed purchasing decisions. This guide is designed to provide a comprehensive overview of Alcantara fabric, focusing on its diverse applications, including upholstery for seats, dashboards, and door panels, as well as its unique benefits and limitations.

Throughout this guide, we will delve into the various types of Alcantara available, best practices for supplier vetting, and a transparent breakdown of costs associated with sourcing this premium material. With insights into market trends and supplier reliability, you will be equipped to navigate the complexities of the Alcantara market confidently. Whether you are a manufacturer looking to enhance your product offerings or a retailer aiming to meet consumer demands for quality interiors, this resource empowers you to make strategic decisions that align with your business objectives. By the end of this guide, you will have a clearer understanding of how to leverage Alcantara fabric to elevate your automotive interior projects and meet the expectations of discerning customers across the globe.

Table Of Contents

- Top 4 Alcantara Fabric For Car Interior Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alcantara fabric for car interior

- Understanding alcantara fabric for car interior Types and Variations

- Key Industrial Applications of alcantara fabric for car interior

- 3 Common User Pain Points for ‘alcantara fabric for car interior’ & Their Solutions

- Strategic Material Selection Guide for alcantara fabric for car interior

- In-depth Look: Manufacturing Processes and Quality Assurance for alcantara fabric for car interior

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara fabric for car interior’

- Comprehensive Cost and Pricing Analysis for alcantara fabric for car interior Sourcing

- Alternatives Analysis: Comparing alcantara fabric for car interior With Other Solutions

- Essential Technical Properties and Trade Terminology for alcantara fabric for car interior

- Navigating Market Dynamics and Sourcing Trends in the alcantara fabric for car interior Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alcantara fabric for car interior

- Strategic Sourcing Conclusion and Outlook for alcantara fabric for car interior

- Important Disclaimer & Terms of Use

Understanding alcantara fabric for car interior Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

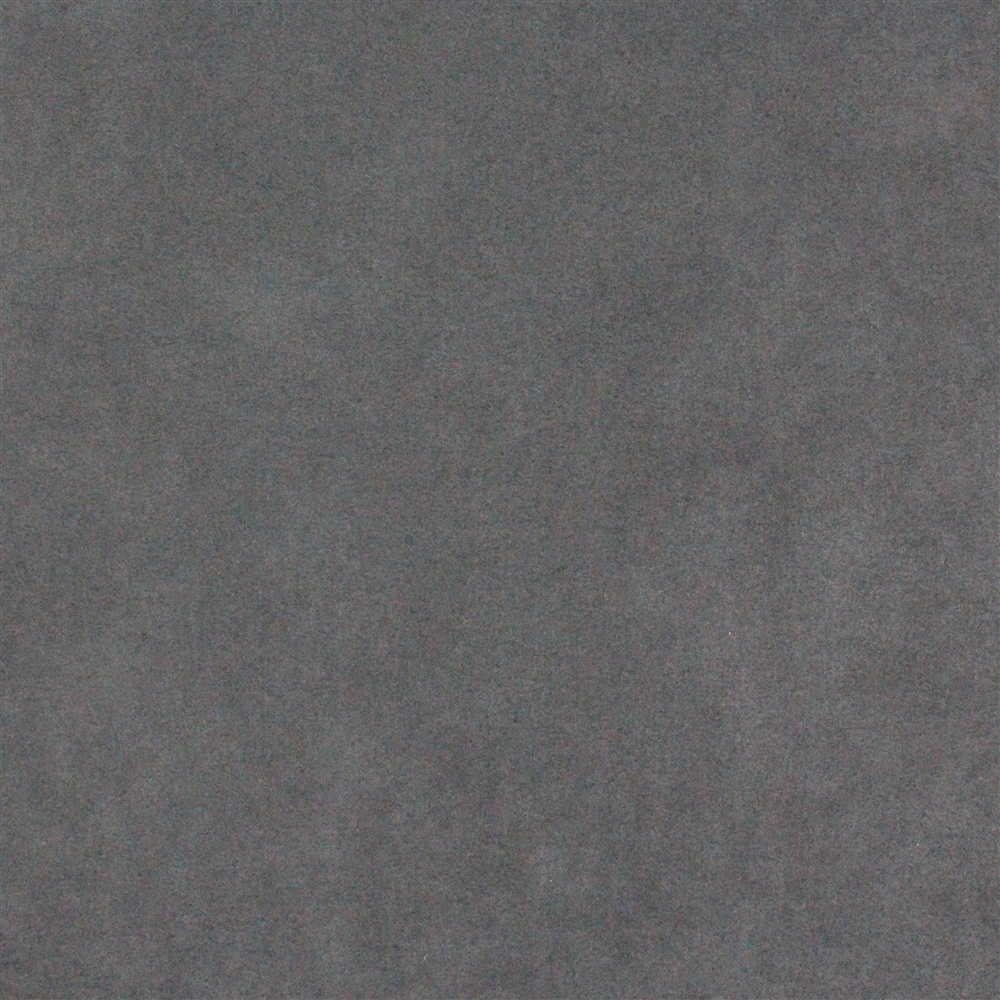

| Alcantara for Panels | Unbacked, single-layer textile, 56 inches wide | Door panels, headliners, and other interior trim | Pros: Lightweight, versatile; Cons: Requires careful handling |

| Alcantara Upholstery | Soft, plush finish with varying textures | Seats, armrests, dashboards | Pros: Premium aesthetic; Cons: Can wear with use |

| Alcantara Racing Fabric | Flame-retardant, high-grip surface | Racing car interiors, performance vehicles | Pros: Enhanced grip, safety; Cons: Limited availability |

| Alcantara Microfiber | Ultra-fine fibers, softer feel than traditional Alcantara | Luxury vehicles, high-end custom interiors | Pros: Superior softness; Cons: Higher cost |

| Alcantara Eco-Friendly | Made from recycled materials, sustainable production | Eco-conscious brands, luxury vehicle lines | Pros: Environmentally friendly; Cons: Availability issues |

What Are the Key Characteristics of Alcantara for Panels?

Alcantara for Panels is a popular choice for automotive interiors due to its unbacked, single-layer construction that allows for greater stretch and durability. This fabric is typically 56 inches wide, making it suitable for a variety of applications, including door panels and headliners. For B2B buyers, the lightweight nature of this fabric means easier handling and installation, while its versatility allows it to be used across different vehicle models. However, it requires careful handling to prevent damage, which should be considered when purchasing in bulk.

How Does Alcantara Upholstery Differ from Other Variants?

Alcantara Upholstery features a soft, plush finish and is often used for seating and armrests in luxury vehicles. This variation provides a premium aesthetic that enhances the overall interior experience. Buyers should consider the long-term wear and maintenance requirements, as this fabric can show signs of wear over time. While it offers a high-quality look and feel, B2B clients must be prepared for potential cleaning and upkeep to maintain its appearance.

Illustrative image related to alcantara fabric for car interior

What Makes Alcantara Racing Fabric Unique?

Alcantara Racing Fabric is specifically designed for high-performance vehicles, featuring a flame-retardant quality and a high-grip surface ideal for racing applications. This fabric is commonly used in racing car interiors and performance vehicles where safety and functionality are paramount. B2B buyers in the automotive industry should prioritize this material for applications where grip and safety are crucial. However, its limited availability may pose a challenge for some manufacturers.

Why Choose Alcantara Microfiber for Luxury Interiors?

Alcantara Microfiber is characterized by its ultra-fine fibers, offering a softer feel compared to traditional Alcantara. This variant is often employed in luxury vehicles and high-end custom interiors, providing an unparalleled tactile experience. B2B buyers should consider the higher cost associated with this fabric, as it may impact overall project budgets. Nonetheless, its premium feel can significantly enhance brand perception and customer satisfaction.

What Are the Benefits of Using Alcantara Eco-Friendly Fabric?

Alcantara Eco-Friendly fabric is made from recycled materials, making it an excellent choice for environmentally conscious brands. This sustainable production method appeals to luxury vehicle lines that prioritize eco-friendliness in their manufacturing processes. B2B buyers should assess the availability of this fabric, as it may not be as widely stocked as other variations. However, the environmental benefits can align with corporate social responsibility goals, making it a compelling option for modern automotive brands.

Illustrative image related to alcantara fabric for car interior

Key Industrial Applications of alcantara fabric for car interior

| Industry/Sector | Specific Application of alcantara fabric for car interior | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Upholstery for luxury and sports vehicles | Enhances perceived value and customer satisfaction | Ensure compliance with automotive standards and durability requirements. |

| Motorsport | Steering wheels and gear levers | Improved grip and control for enhanced performance | Source from certified suppliers for quality assurance. |

| Luxury Vehicle Customization | Interior trims and accents | Customization options that attract high-end clients | Consider color and texture variations to meet client specifications. |

| Car Rental Services | High-end vehicle interiors | Differentiates offerings and attracts premium customers | Focus on maintenance and cleaning requirements for long-term durability. |

| Electric Vehicle (EV) Manufacturing | Dashboard and control panel coverings | Lightweight material that supports energy efficiency | Evaluate eco-friendly sourcing options to align with sustainability goals. |

How is Alcantara Fabric Used in Automotive Manufacturing?

In automotive manufacturing, Alcantara fabric is primarily used for upholstery in luxury and sports vehicles. Its suede-like texture not only enhances the aesthetic appeal but also provides a premium feel that elevates customer satisfaction. For international B2B buyers, particularly from regions like the Middle East and Europe, sourcing high-quality Alcantara that meets stringent automotive standards is crucial. Buyers must ensure the material’s durability and compliance with local regulations to maintain brand integrity and customer trust.

What Role Does Alcantara Play in Motorsport Applications?

In motorsport, Alcantara is commonly applied to steering wheels and gear levers, where its superior grip is essential for performance. This fabric allows drivers to maintain control even in high-stress situations, which is critical for safety and efficiency. B2B buyers in this sector should prioritize sourcing from certified suppliers to ensure the material’s quality and performance characteristics meet the rigorous demands of racing environments.

How is Alcantara Beneficial for Luxury Vehicle Customization?

Luxury vehicle customization leverages Alcantara for interior trims and accents, providing a unique touch that appeals to high-end clients. The ability to customize color and texture makes Alcantara a versatile choice for businesses aiming to differentiate their offerings in a competitive market. Buyers must consider the variety of options available and ensure that the sourced materials align with client specifications to enhance the overall customer experience.

Illustrative image related to alcantara fabric for car interior

Why is Alcantara Important for Car Rental Services?

For car rental services, particularly those offering high-end vehicles, Alcantara fabric enhances the interior quality, making the cars more appealing to premium customers. Its luxurious feel can significantly impact customer satisfaction and repeat business. B2B buyers should focus on the fabric’s maintenance and cleaning requirements to ensure longevity and sustained aesthetic appeal, which is vital for maintaining a fleet of rental vehicles.

How Does Alcantara Support Electric Vehicle Manufacturing?

In electric vehicle (EV) manufacturing, Alcantara is utilized for dashboard and control panel coverings, contributing to the lightweight design that supports energy efficiency. Its synthetic nature aligns with the sustainability goals of many EV manufacturers. International B2B buyers should evaluate eco-friendly sourcing options and consider the environmental impact of their material choices to align with the growing demand for sustainable automotive solutions.

3 Common User Pain Points for ‘alcantara fabric for car interior’ & Their Solutions

Scenario 1: Managing Alcantara Fabric Durability Concerns

The Problem: One significant challenge B2B buyers face when sourcing Alcantara fabric for car interiors is its long-term durability. While Alcantara is known for its premium look and feel, its susceptibility to wear, particularly in high-contact areas, can lead to dissatisfaction from end-users. Buyers often receive complaints about faded or flattened areas after prolonged use, undermining the perceived quality of the vehicle interiors they supply.

The Solution: To mitigate durability concerns, buyers should prioritize sourcing genuine Alcantara from reputable manufacturers who provide comprehensive care guidelines. Establish a partnership with suppliers who offer detailed documentation on maintenance and cleaning procedures. Additionally, consider implementing a quality control process to ensure that the Alcantara fabric is suitable for its intended application. For example, selecting an unbacked Alcantara variant for areas requiring more stretch and durability can enhance performance. Regular training sessions for upholstery teams on proper cleaning methods can also significantly prolong the lifespan of the fabric, ensuring it retains its luxurious appearance.

Scenario 2: Sourcing Genuine Alcantara in Diverse Markets

The Problem: B2B buyers often struggle with sourcing genuine Alcantara fabric, especially in regions like Africa and South America where counterfeit products may be prevalent. This situation can lead to significant issues with product quality, as faux Alcantara may not deliver the expected performance, thus affecting customer satisfaction and brand reputation.

Illustrative image related to alcantara fabric for car interior

The Solution: To ensure the authenticity of Alcantara fabric, buyers should develop relationships with certified suppliers who can provide proof of authenticity and compliance with manufacturing standards. Engaging in direct communication with Alcantara S.p.A. or their authorized distributors can help buyers confirm that they are purchasing genuine materials. Additionally, implementing a robust supply chain verification process, including sample testing and audits, can further ensure that the fabric meets specified quality requirements. Establishing a clear procurement policy that emphasizes the importance of sourcing authentic materials will also help mitigate risks associated with counterfeit products.

Scenario 3: Addressing Alcantara Cleaning and Maintenance Issues

The Problem: Another common pain point for B2B buyers is the maintenance and cleaning of Alcantara fabric. Many manufacturers and end-users lack knowledge about the proper cleaning techniques required to maintain the fabric’s aesthetic and functional properties. This can lead to unsightly stains, accumulated dirt, and a compromised visual appeal, ultimately resulting in dissatisfaction and potential returns.

The Solution: To tackle this issue, B2B buyers should invest in educating their clients about the best practices for cleaning and maintaining Alcantara. This can be achieved by providing comprehensive guides and resources that detail suitable cleaning products and techniques. Consider offering starter kits that include gentle cleaning solutions and specialized brushes designed for Alcantara care. Additionally, collaborating with professional cleaning services that specialize in automotive interiors can provide end-users with expert assistance, enhancing the overall customer experience. By proactively addressing maintenance education, buyers can foster stronger relationships with clients and elevate the perceived value of Alcantara upholstery in their offerings.

Strategic Material Selection Guide for alcantara fabric for car interior

What Are the Key Properties of Alcantara Fabric for Car Interiors?

Alcantara fabric is a synthetic textile composed primarily of polyester and polyurethane. This unique blend provides a range of properties that make it suitable for automotive applications. Alcantara is known for its lightweight nature, durability, and resistance to wear and tear, which is crucial in high-traffic areas of a vehicle’s interior. It can also be engineered to be flame retardant, enhancing safety in automotive designs. Furthermore, its matte finish reduces glare, making it a preferred choice for dashboard applications.

What Are the Advantages and Disadvantages of Using Alcantara Fabric?

Advantages:

– Durability: Alcantara is more resistant to wear compared to traditional suede and offers better grip, making it ideal for steering wheels and gear levers.

– Aesthetic Appeal: The fabric provides a premium look and feel, elevating the overall interior design of vehicles.

– Vegan-Friendly: As a synthetic material, Alcantara is free from animal products, appealing to environmentally conscious consumers.

Disadvantages:

– Maintenance: Alcantara requires regular cleaning to maintain its appearance, as it can absorb oils and dirt, leading to a worn look over time.

– Cost: While competitive with leather, Alcantara can be considered expensive, particularly for budget-conscious manufacturers.

– Wear Patterns: Over time, the fabric can develop uneven wear patterns due to its nap, which may be visually unappealing to some users.

How Does Alcantara Fabric Impact Automotive Applications?

Alcantara is versatile in its applications within car interiors. It is commonly used for seat upholstery, door panels, headliners, and dashboards. Its ability to be engineered for specific applications—like increased stretch or enhanced durability—makes it suitable for various automotive designs. However, international buyers should consider the fabric’s compatibility with different media, such as cleaning agents and environmental conditions, which can vary significantly across regions.

What Should International B2B Buyers Consider When Sourcing Alcantara Fabric?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several factors must be taken into account:

- Compliance with Standards: Buyers should ensure that the Alcantara fabric meets relevant international standards such as ASTM, DIN, or JIS. This is crucial for maintaining quality and safety in automotive applications.

- Regional Preferences: Different markets may have varying preferences for fabric characteristics, such as color, texture, and performance attributes. Understanding local consumer trends can guide material selection.

- Supply Chain Logistics: Consideration of shipping costs, lead times, and supplier reliability is essential, especially when sourcing from international manufacturers.

- Environmental Regulations: Buyers should be aware of any environmental compliance requirements in their respective markets, as sustainability is becoming increasingly important in the automotive sector.

Summary Table of Material Analysis

| Material | Typical Use Case for alcantara fabric for car interior | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alcantara | Seat upholstery, door panels, dashboards | High durability and premium aesthetic | Requires regular maintenance | High |

| Polyester | Headliners, sun visors | Cost-effective and lightweight | Less durable than Alcantara | Medium |

| Leather | Seats, steering wheels | Luxurious feel and high durability | Higher cost and animal product concerns | High |

| Microfiber | General upholstery, trim pieces | Easy to clean and maintain | May not offer the same premium feel as Alcantara | Medium |

This guide provides a comprehensive overview of Alcantara fabric and its alternatives, equipping international B2B buyers with the insights needed for informed decision-making in automotive interior design.

In-depth Look: Manufacturing Processes and Quality Assurance for alcantara fabric for car interior

What Are the Key Manufacturing Processes for Alcantara Fabric Used in Car Interiors?

Alcantara fabric is a synthetic textile that combines aesthetic appeal with functional performance, making it a popular choice for car interiors. Understanding the manufacturing processes behind this premium material is essential for B2B buyers looking to source quality fabric for automotive applications. The typical manufacturing process includes several critical stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Alcantara Fabric Production?

The production of Alcantara fabric begins with the preparation of its primary components, which include polyester and polyurethane. These materials are sourced from various suppliers and undergo rigorous quality checks to ensure they meet the necessary specifications. During this stage, raw materials are blended in precise ratios to achieve the desired properties, such as softness, durability, and colorfastness.

Once the materials are blended, they are subjected to a chemical process that transforms them into a non-woven fabric. This non-woven structure provides the unique soft texture that Alcantara is known for, as well as its lightweight and breathable characteristics.

What Techniques Are Used in the Forming and Assembly Stages?

The forming stage involves the creation of the fabric’s structure. Advanced techniques, such as needle-punching and thermal bonding, are employed to interlock the fibers and create a cohesive textile. This not only enhances the fabric’s strength but also contributes to its signature suede-like appearance.

Illustrative image related to alcantara fabric for car interior

In the assembly phase, Alcantara is cut and shaped according to specific automotive requirements. This may involve creating panels for seats, dashboards, or door trims. Precision cutting machines ensure that each piece meets the exact dimensions needed for seamless integration into vehicle interiors.

How Is Quality Assurance Ensured in Alcantara Fabric Manufacturing?

Quality assurance is paramount in the production of Alcantara fabric, especially given its application in high-end automotive interiors. Various international standards, such as ISO 9001, guide manufacturers in maintaining quality management systems. Additionally, industry-specific certifications, such as CE and API, further validate the quality and safety of the materials used.

What Are the Key Quality Control Checkpoints in Alcantara Fabric Production?

Quality control (QC) checkpoints are integral to the manufacturing process. These typically include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and conformity to specifications before they enter the production line. This step is crucial in ensuring that only the best materials are used in the manufacturing process.

-

In-Process Quality Control (IPQC): During production, various parameters such as temperature, pressure, and material thickness are monitored to ensure that the manufacturing process remains within specified limits. Regular checks at this stage help to identify and rectify any issues before they escalate.

-

Final Quality Control (FQC): After the fabric has been produced, it undergoes a thorough inspection to ensure it meets all quality standards. This includes testing for color consistency, softness, durability, and resistance to wear and tear.

Which Testing Methods Are Commonly Used for Alcantara Fabric?

Several testing methods are employed to evaluate the quality and performance of Alcantara fabric:

-

Abrasion Resistance Tests: These tests determine how well the fabric can withstand wear and tear, which is critical for automotive applications. The Martindale test is commonly used to assess abrasion resistance.

-

Colorfastness Tests: This involves exposing the fabric to light and washing conditions to evaluate how well the color holds up over time.

-

Flame Retardancy Tests: Given the safety standards in the automotive industry, Alcantara is often tested for its flame retardant properties to ensure compliance with international safety regulations.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control processes of potential suppliers is essential to ensure they are receiving a reliable product. Here are several actionable steps to consider:

-

Conduct Supplier Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Audits can be conducted by the buyer’s quality assurance team or through third-party organizations specializing in supplier audits.

-

Request Quality Reports: Buyers should ask for documentation detailing the QC processes, including test results and compliance certifications. These reports should be readily available from suppliers who prioritize quality.

-

Engage Third-Party Inspectors: Third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. This is particularly valuable for international transactions, where buyers may not have direct oversight of the manufacturing process.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification processes. Variations in local regulations, market expectations, and standards can impact the sourcing of Alcantara fabric.

Illustrative image related to alcantara fabric for car interior

-

Regulatory Compliance: Different countries may have specific regulations governing the use of materials in automotive interiors. Buyers should familiarize themselves with these regulations to ensure compliance.

-

Cultural Expectations: Understanding regional preferences for fabric quality and durability can guide buyers in selecting the right supplier. For instance, in hotter climates, moisture-wicking and breathability may be prioritized.

-

Logistical Considerations: International shipping and logistics can introduce additional challenges in maintaining quality. Buyers should ensure that suppliers have robust logistics management practices to prevent damage during transport.

In conclusion, understanding the manufacturing processes and quality assurance measures for Alcantara fabric is crucial for B2B buyers looking to invest in high-quality materials for automotive interiors. By focusing on material preparation, forming techniques, and rigorous QC standards, buyers can make informed decisions that align with their business needs and regional market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara fabric for car interior’

This guide aims to provide a structured approach for B2B buyers looking to source Alcantara fabric for automotive interiors. As a premium material known for its versatility and aesthetic appeal, Alcantara can significantly enhance the value of vehicle interiors. This checklist will help you navigate the sourcing process effectively, ensuring you obtain high-quality fabric that meets your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before initiating your sourcing process. Consider the type of Alcantara fabric you need, such as unbacked or backed, based on your application—whether for seats, dashboards, or door panels. Additionally, define the required colors, patterns, and any specific performance characteristics, such as fire resistance or moisture resistance, to ensure the fabric aligns with your design and functionality goals.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify suppliers known for high-quality Alcantara. Look for manufacturers who have a proven track record in the automotive sector, particularly those supplying to luxury brands. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers, and pay attention to their certifications and compliance with international standards.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who can demonstrate their experience with Alcantara and have a history of reliable delivery and quality assurance.

– Key Questions to Ask:

– How long have you been supplying Alcantara fabric?

– Can you provide samples for evaluation?

Step 4: Request Samples and Conduct Quality Checks

Once you have shortlisted potential suppliers, request samples of the Alcantara fabric. This step is essential for assessing the texture, color accuracy, and overall quality of the material. Examine the samples for durability, softness, and how well they match your specifications. It’s also beneficial to conduct performance tests, such as abrasion resistance, to ensure the fabric will withstand wear in automotive applications.

Step 5: Understand Pricing and Minimum Order Quantities

Discuss pricing structures and minimum order quantities (MOQs) with your selected suppliers. Alcantara prices can vary based on order size and specific customization, so it’s important to clarify these details upfront. Additionally, inquire about volume discounts or flexible payment terms to optimize your procurement budget.

– Considerations:

– What is the price per yard or meter?

– Are there discounts for bulk orders?

Step 6: Review Logistics and Lead Times

Evaluate the logistics involved in sourcing Alcantara fabric, including shipping options and lead times. Understanding the supplier’s production capacity and delivery timelines will help you plan your inventory and production schedules accordingly. Ensure that the supplier can meet your deadlines without compromising quality.

Step 7: Finalize Contracts and Terms

Once you have selected a supplier, finalize contracts that clearly outline all terms of the agreement, including pricing, delivery schedules, quality expectations, and return policies. Ensure that both parties have a mutual understanding of the terms to prevent any disputes in the future. This step is vital to protect your interests and maintain a good supplier relationship.

By following this step-by-step checklist, you can confidently navigate the sourcing of Alcantara fabric, ensuring you make informed decisions that enhance your automotive offerings.

Illustrative image related to alcantara fabric for car interior

Comprehensive Cost and Pricing Analysis for alcantara fabric for car interior Sourcing

What Are the Key Cost Components in Sourcing Alcantara Fabric for Car Interiors?

When considering the sourcing of Alcantara fabric for automotive interiors, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: Alcantara is a proprietary synthetic textile made from a blend of polyester and polyurethane. The cost of raw materials can fluctuate based on market conditions, availability, and supplier relationships. Genuine Alcantara, sourced directly from its manufacturer, tends to command a premium price, often ranging from $125 to $135 per yard, with discounts available for larger orders.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Skilled labor is required for cutting, stitching, and quality checks to ensure the fabric meets the desired specifications.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, maintenance, and equipment depreciation. Overhead costs can be distributed across the total production volume, impacting the final pricing structure.

-

Tooling: Custom tooling may be necessary for specific applications or designs. This one-time cost can be significant, especially for unique patterns or specialized applications in luxury vehicles.

-

Quality Control (QC): Ensuring the fabric meets industry standards requires rigorous QC processes. This can add to the overall cost but is critical for maintaining product integrity, especially in high-end automotive applications.

-

Logistics: Transportation costs can vary significantly based on shipping methods, distances, and Incoterms used. International buyers should consider duties, tariffs, and shipping fees when calculating total costs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary widely based on competition, brand reputation, and exclusivity of the product.

What Influences Pricing in Alcantara Fabric Sourcing?

Several factors can influence pricing when sourcing Alcantara fabric, particularly for international B2B buyers.

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer tiered pricing based on order volume. Higher quantities can lead to significant discounts, making it essential for buyers to assess their needs carefully.

-

Specifications and Customization: Customized Alcantara fabrics, such as specific colors or patterns, may incur additional costs. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Material Quality and Certifications: The presence of certifications (e.g., eco-friendly or flame retardant) can affect pricing. Buyers should evaluate whether these certifications align with their market demands.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge higher prices due to their proven quality and service, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The chosen Incoterms will influence logistics costs and responsibilities. For example, opting for Delivered Duty Paid (DDP) can simplify the import process but may increase the price.

What Are the Best Negotiation Tips for International Buyers?

International buyers from regions such as Africa, South America, the Middle East, and Europe should consider the following strategies to optimize their sourcing of Alcantara fabric:

Illustrative image related to alcantara fabric for car interior

-

Research and Benchmarking: Understand market rates by comparing prices from multiple suppliers. Use this information to negotiate better terms.

-

Leverage Volume: If possible, consolidate orders to meet or exceed MOQ thresholds, which can unlock discounts.

-

Focus on Total Cost of Ownership (TCO): Consider all costs associated with sourcing, including logistics, maintenance, and potential waste. A lower upfront price may not always equate to better value.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and terms over time. Frequent communication can also help mitigate misunderstandings.

-

Be Flexible: If a supplier cannot meet your price, consider compromising on specifications or delivery timelines to find a mutually agreeable solution.

Disclaimer

The prices mentioned are indicative and may vary based on market conditions, supplier pricing strategies, and negotiation outcomes. Always consult multiple sources and conduct due diligence when sourcing Alcantara fabric for car interiors.

Alternatives Analysis: Comparing alcantara fabric for car interior With Other Solutions

When considering materials for automotive interiors, Alcantara fabric stands out due to its unique blend of aesthetic appeal and functional performance. However, various alternatives may also meet the needs of B2B buyers, particularly in different regions like Africa, South America, the Middle East, and Europe. Understanding these alternatives can help in making informed procurement decisions.

| Comparison Aspect | Alcantara Fabric For Car Interior | Faux Leather | Genuine Leather |

|---|---|---|---|

| Performance | High grip, moisture-resistant, durable | Moderate durability, less grip | Excellent durability, high-end feel |

| Cost | $125 – $135 per yard | $20 – $50 per yard | $50 – $300 per yard |

| Ease of Implementation | Requires specialized skills for installation | Easy to cut and sew | Requires professional installation |

| Maintenance | Regular cleaning needed, sensitive to oils | Easy to clean, less sensitive | Requires conditioning, regular cleaning |

| Best Use Case | Sports and luxury vehicles | Budget-friendly options | High-end luxury vehicles |

What Are the Pros and Cons of Faux Leather as an Alternative to Alcantara?

Faux leather is a synthetic alternative that mimics the appearance of genuine leather without the associated costs. It offers a moderate level of durability and is often easier to clean, making it suitable for commercial vehicles or budget-conscious projects. However, it generally lacks the premium feel and performance characteristics of Alcantara, particularly in terms of grip and moisture resistance. This makes faux leather less ideal for high-performance or luxury applications.

How Does Genuine Leather Compare to Alcantara Fabric for Car Interiors?

Genuine leather is renowned for its luxurious feel and exceptional durability. It provides an upscale appearance that is difficult to match with synthetic materials. However, the cost of genuine leather can be significantly higher, and it requires more maintenance, such as conditioning to prevent cracking. While it has excellent longevity and can withstand wear, it may not provide the same level of grip as Alcantara, particularly in high-stress areas like steering wheels or gear levers.

Illustrative image related to alcantara fabric for car interior

Conclusion: How Can B2B Buyers Choose the Right Material for Their Automotive Interior Needs?

When selecting the right fabric for automotive interiors, B2B buyers should consider factors such as performance, cost, and maintenance requirements. Alcantara fabric is an excellent choice for those seeking a premium look and feel, particularly in sports and luxury vehicles. On the other hand, faux leather may be more suitable for budget-conscious projects, while genuine leather caters to high-end applications where durability and luxury are paramount. By aligning their specific needs with the characteristics of each material, buyers can make informed decisions that enhance their automotive offerings.

Essential Technical Properties and Trade Terminology for alcantara fabric for car interior

What Are the Key Technical Properties of Alcantara Fabric for Car Interiors?

When sourcing Alcantara fabric for automotive applications, understanding its essential technical properties is crucial for B2B buyers. Here are the primary specifications that should be considered:

-

Material Composition: Alcantara is a synthetic textile, predominantly composed of polyester and polyurethane. This unique blend provides a suede-like appearance while ensuring durability and ease of maintenance. For buyers, knowing the composition is vital, as it influences both performance and care requirements.

-

Thickness and Weight: Typically, Alcantara fabric has a thickness of around 1.0 mm, and a standard roll width of 56 inches. The weight of the fabric can affect the overall feel and luxury perception within the vehicle. Buyers should consider these factors when selecting materials for specific applications, such as seating or paneling.

-

Durability and Wear Resistance: Alcantara is known for its high wear resistance compared to traditional leather or fabric. This property is essential for automotive interiors, where materials are subjected to daily use. Understanding the durability of Alcantara can help buyers justify its cost against longevity and performance.

-

Flame Retardancy: Many Alcantara products can be treated to meet flame-retardant standards, an important consideration for automotive safety regulations. B2B buyers need to ensure that the materials they select comply with local regulations, particularly in regions with stringent safety requirements.

-

Moisture Resistance: Alcantara has inherent moisture-wicking properties, making it suitable for use in vehicles exposed to varying climates. This resistance can help maintain the interior’s aesthetic and functional quality over time, which is a crucial factor for buyers focused on long-term performance.

-

Colorfastness: The ability of Alcantara to retain color over time and resist fading from UV exposure is another significant property. Buyers should look for suppliers that guarantee high colorfastness, especially for vehicles intended for sunny regions.

What Trade Terminology Should B2B Buyers Understand When Sourcing Alcantara?

Familiarity with industry-specific terminology can enhance communication and negotiation processes. Here are some key terms related to sourcing Alcantara fabric:

Illustrative image related to alcantara fabric for car interior

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that are marketed by another company. In the context of Alcantara, it often relates to brands that utilize Alcantara for their vehicles. Understanding OEM relationships can help buyers navigate product availability and authenticity.

-

MOQ (Minimum Order Quantity): This indicates the smallest quantity of fabric a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, particularly for international buyers looking to import materials.

-

RFQ (Request for Quotation): An RFQ is a document issued by a buyer to solicit price quotes from suppliers. For B2B buyers, crafting a precise RFQ can lead to better pricing and service terms, as it allows suppliers to understand the specific needs of the buyer.

-

Incoterms (International Commercial Terms): These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risks, and delivery responsibilities.

-

Lead Time: This term refers to the time taken from placing an order to its delivery. Understanding lead times is critical for B2B buyers to manage inventory and production schedules effectively.

-

Color Matching: In the context of Alcantara, color matching refers to the process of ensuring that fabric colors are consistent with design specifications. Buyers should emphasize the importance of color matching to maintain brand identity and consumer satisfaction.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing Alcantara fabric for automotive interiors, ensuring they select the best materials for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the alcantara fabric for car interior Sector

What Are the Current Market Dynamics and Key Trends in the Alcantara Fabric for Car Interiors?

The alcantara fabric market for car interiors is experiencing significant growth, driven by rising consumer demand for luxury and high-performance vehicles across various global regions. Key markets in Africa, South America, the Middle East, and Europe are increasingly favoring alcantara due to its premium aesthetic and functional properties. The material is favored for its durability, lightweight nature, and superior grip, making it ideal for performance-oriented vehicles. Additionally, manufacturers are increasingly integrating alcantara into a wider range of models, moving beyond high-end luxury brands to more mainstream options.

Emerging trends in B2B sourcing include a shift towards direct partnerships with manufacturers, allowing buyers to ensure quality and authenticity in their materials. This trend is particularly important given the prevalence of synthetic alternatives that may not meet the same standards. Furthermore, technological advancements in textile manufacturing are enabling the production of eco-friendly alcantara options, appealing to environmentally conscious consumers. As electric vehicles (EVs) gain traction, manufacturers are exploring innovative uses of alcantara to enhance the overall driving experience while maintaining a lightweight profile, which is crucial for optimizing battery efficiency.

How Is Sustainability and Ethical Sourcing Impacting the Alcantara Fabric Market?

The growing emphasis on sustainability is reshaping sourcing strategies within the alcantara fabric market. International B2B buyers are increasingly prioritizing environmentally responsible materials and ethical supply chains. Alcantara, being a synthetic textile, is often perceived as a more sustainable option compared to traditional leather, as it does not involve animal products and can be produced with lower environmental impact when sourced responsibly.

Buyers should seek suppliers that hold ‘green’ certifications, such as OEKO-TEX or GRS (Global Recycle Standard), which ensure that the materials are free from harmful chemicals and produced in an environmentally friendly manner. Emphasizing the importance of ethical sourcing not only aligns with global sustainability goals but also enhances brand reputation in markets that value corporate social responsibility. As the demand for sustainable practices continues to rise, integrating eco-friendly alcantara into product offerings can provide a competitive edge in the automotive sector.

How Has Alcantara Fabric Evolved Over Time in the Automotive Industry?

The evolution of alcantara fabric began in the 1970s when it was developed by a Japanese chemist and has since been exclusively manufactured by the Italian company Alcantara S.p.A. Initially, it was primarily utilized in high-performance racing vehicles due to its superior grip and lightweight properties. Over the years, alcantara has transcended its niche, becoming a staple in luxury car interiors and increasingly appearing in mainstream automotive models.

This shift is attributed to its versatility and premium appeal, as manufacturers recognize its potential to elevate cabin aesthetics while providing functional benefits. The material’s unique characteristics, such as its resistance to wear and its ability to be produced in a variety of colors and textures, have solidified its status as a preferred choice in the automotive interior fabric market. As the industry continues to evolve, alcantara remains at the forefront, adapting to meet the changing demands of both manufacturers and consumers.

Illustrative image related to alcantara fabric for car interior

Frequently Asked Questions (FAQs) for B2B Buyers of alcantara fabric for car interior

-

How do I choose the right Alcantara fabric supplier for my automotive business?

Selecting the right supplier for Alcantara fabric involves evaluating their reputation, product quality, and compliance with international standards. Look for suppliers that provide genuine Alcantara made in Italy, as this ensures high quality. Request samples to assess the fabric’s texture, durability, and color accuracy. Additionally, check their customer reviews and industry certifications. Establish communication to discuss your specific needs and ensure they can meet your order quantities and customization requests. -

What are the minimum order quantities (MOQ) for Alcantara fabric?

Minimum order quantities for Alcantara fabric can vary significantly between suppliers. Typically, MOQs can range from one yard for sample orders to several hundred yards for bulk purchases. It’s essential to confirm these details with your supplier, as larger orders may offer pricing discounts. Understanding your project’s scope will help you negotiate better terms and ensure you have enough material for your production needs without overcommitting. -

What customization options are available for Alcantara fabric?

Many suppliers offer customization options for Alcantara fabric, including color selection, thickness, and backing types. Some may also provide printing services for logos or patterns. When discussing customization, ensure you communicate your specific requirements clearly, including any design specifications and intended applications. Be aware that custom orders may have longer lead times and higher costs, so plan accordingly to align with your production schedules. -

How do I ensure the quality of Alcantara fabric before purchasing?

To guarantee the quality of Alcantara fabric, request samples from potential suppliers. Assess the fabric for softness, durability, and color fidelity. You should also inquire about the supplier’s quality assurance processes, including testing for wear resistance and colorfastness. Familiarize yourself with the care instructions and maintenance recommendations, as these factors influence the longevity of the fabric in automotive applications. -

What are the payment terms typically offered by Alcantara fabric suppliers?

Payment terms can vary widely among suppliers, but common practices include upfront payments, partial payments upon order confirmation, and balance payments upon delivery. Some suppliers may also offer credit terms for established businesses. It’s crucial to clarify payment expectations upfront and consider negotiating terms that align with your cash flow needs. Always ensure that payment methods are secure and that you receive invoices for transparency. -

How can I manage logistics and shipping for Alcantara fabric imports?

Effective logistics management for importing Alcantara fabric involves selecting reliable shipping partners and understanding customs regulations in your country. Work with suppliers who can assist with shipping arrangements and provide necessary documentation for customs clearance. Plan for potential delays by ordering in advance and consider using freight forwarders who specialize in textile imports to streamline the process. -

What are the key benefits of using Alcantara fabric in automotive interiors?

Alcantara fabric offers several advantages for automotive interiors, including its luxurious appearance, durability, and ease of maintenance. It is lighter than traditional leather, making it an excellent choice for performance vehicles. Additionally, Alcantara provides better grip and can be treated to be flame retardant, enhancing safety. Its vegan-friendly composition appeals to environmentally conscious consumers, making it a versatile option for various market segments. -

How do I handle complaints or issues with Alcantara fabric after purchase?

If you encounter issues with Alcantara fabric after purchase, promptly contact your supplier to address the concerns. Document any defects or discrepancies with photographs and detailed descriptions. Most reputable suppliers will have a return or exchange policy, especially for bulk orders. Be sure to review the terms of sale and warranty information prior to purchase to understand your rights and the supplier’s responsibilities in case of product quality issues.

Top 4 Alcantara Fabric For Car Interior Manufacturers & Suppliers List

1. Relicate – Alcantara® Upholstery Supplies

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: Alcantara® upholstery supplies available in various options including OEM Auto Colors, unbacked panels, seating covers, foam backed, marine/outdoor, perforated, and multilayer plaid seat fabrics. Additional plaid options include Highlander/Overlander, Spirit of Le Mans, VW, Porsche, BMW, Mercedes, and Spec Series. Other textiles include houndstooth and pepita seat fabrics, as well as NappaTek™ syn…

2. Alcantara – Synthetic Suede Fabric

Domain: carwow.co.uk

Registered: 2011 (14 years)

Introduction: Alcantara is a synthetic suede-like fabric made from a blend of polyester and polyurethane, developed in the 1970s by a Japanese chemist and manufactured by the Italian company Alcantara. It is commonly used in car interiors for steering wheels, gear levers, seats, dashboards, arm rests, door cards, transmission tunnels, sun visors, and headliners. Pros include better grip than leather or plastic,…

3. Hydes Leather – Alcantara Products

Domain: hydesleather.com

Registered: 2006 (19 years)

Introduction: Hydes Leather is the official distributor for Alcantara in North America, offering a complete range of Alcantara products. Alcantara is used by luxury auto brands in Europe and is known for its style, elegance, and functionality while being ethically produced in Italy. The product range includes: 1. Alcantara Panel (unbacked, thin, used for headliners, doors, dashboards) 2. Alcantara Cover (backed…

4. Upholstery Supply USA – Alcantara for Panels – Anthracite Black

Domain: upholsterysupplyusa.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “Alcantara for Panels – Anthracite Black (#9002)”, “Price”: “$135.00 per Yard”, “Discount Tiers”: {“1 to 9 yards”: “$135.00”, “10 to 24 yards”: “$130.00”, “25+ yards”: “$125.00”}, “Material Type”: “Genuine Alcantara Textile, Unbacked”, “Origin”: “Made in Italy”, “Applications”: [“Automotive Interior”, “Door Panels”, “Headliners”, “Interior Trim Surfaces”], “Roll Width”: “56 inches…

Strategic Sourcing Conclusion and Outlook for alcantara fabric for car interior

In the evolving landscape of automotive interiors, Alcantara fabric stands out as a premium choice, combining aesthetics with functionality. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the strategic sourcing of Alcantara is crucial. This material not only enhances the luxurious appeal of vehicles but also offers durability and ease of maintenance, making it a cost-effective solution in the long run.

Establishing robust relationships with reliable suppliers of genuine Alcantara can significantly reduce procurement risks and ensure consistent quality. As demand for premium vehicle interiors continues to rise, leveraging the unique attributes of Alcantara, such as its vegan-friendly composition and superior grip, will position buyers favorably in a competitive market.

Looking ahead, now is the time to engage with suppliers who can provide genuine Alcantara at competitive prices. By prioritizing strategic sourcing, businesses can not only enhance their product offerings but also align with sustainability trends that resonate with consumers today. Invest in Alcantara fabric to elevate your automotive interiors and meet the growing consumer demand for luxury and performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to alcantara fabric for car interior

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.