Introduction: Navigating the Global Market for sneaker lining

In the ever-evolving landscape of the global sneaker market, sourcing high-quality sneaker lining that balances comfort, durability, and breathability is a critical challenge for B2B buyers. As international markets expand, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of different lining materials can significantly impact product performance and consumer satisfaction. This comprehensive guide delves into the various types of sneaker lining, including leather, fleece, polyester, and more, highlighting their unique applications and benefits.

Navigating supplier vetting processes and cost considerations is equally vital for making informed purchasing decisions. With insights on material properties, market trends, and supplier reliability, this guide equips B2B buyers with the knowledge necessary to select the best lining options tailored to their specific needs. Whether you’re a manufacturer looking to enhance your product line or a retailer aiming to meet consumer demands, understanding the intricacies of sneaker lining will empower you to make strategic decisions that drive business growth. By leveraging this guide, you will be well-prepared to tackle the complexities of sourcing, ensuring that your offerings stand out in a competitive marketplace.

Table Of Contents

- Top 6 Sneaker Lining Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for sneaker lining

- Understanding sneaker lining Types and Variations

- Key Industrial Applications of sneaker lining

- 3 Common User Pain Points for ‘sneaker lining’ & Their Solutions

- Strategic Material Selection Guide for sneaker lining

- In-depth Look: Manufacturing Processes and Quality Assurance for sneaker lining

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘sneaker lining’

- Comprehensive Cost and Pricing Analysis for sneaker lining Sourcing

- Alternatives Analysis: Comparing sneaker lining With Other Solutions

- Essential Technical Properties and Trade Terminology for sneaker lining

- Navigating Market Dynamics and Sourcing Trends in the sneaker lining Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of sneaker lining

- Strategic Sourcing Conclusion and Outlook for sneaker lining

- Important Disclaimer & Terms of Use

Understanding sneaker lining Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Lining | Breathable, moisture-wicking, and durable | High-end sneakers, luxury brands | Pros: Premium feel, odor control. Cons: Higher cost. |

| Fleece Lining | Soft, warm, and cozy | Casual sneakers, winter footwear | Pros: Comfort, warmth. Cons: Bulky, not suited for refined styles. |

| Polyester Lining | Lightweight, cost-effective, but non-breathable | Budget-friendly sneakers, mass production | Pros: Low cost, easy to source. Cons: Poor moisture management. |

| Cotton Lining | Naturally breathable, hypoallergenic | Casual and athletic shoes | Pros: Comfort, skin-friendly. Cons: Absorbs moisture, can lead to odor. |

| Cambrelle Lining | High moisture absorption, antibacterial | Performance footwear, work boots | Pros: Quick-drying, durable. Cons: Less common, may require specific sourcing. |

What Are the Characteristics of Leather Lining in Sneakers?

Leather lining is often regarded as the gold standard in sneaker construction due to its natural properties. It is inherently breathable, moisture-wicking, and provides a luxurious feel that enhances overall comfort. B2B buyers should consider leather for high-end sneaker lines targeting discerning customers or luxury markets. Its durability and ability to regulate temperature make it ideal for all-day wear. However, the higher cost associated with genuine leather can be a barrier for budget-conscious brands.

How Does Fleece Lining Enhance Sneaker Comfort?

Fleece lining offers a soft and cozy interior, making it a popular choice for casual sneakers and winter footwear. Its bulkiness provides additional warmth, appealing to markets in colder climates. While fleece is comfortable, it may not be suitable for more refined sneaker designs due to its fluffy texture. B2B buyers should weigh the trade-off between comfort and aesthetics when considering fleece linings for their product lines.

Why Choose Polyester Lining for Budget-Friendly Sneakers?

Polyester lining is a cost-effective option, often found in lower-priced sneakers. While it provides lightweight comfort, it lacks breathability, leading to moisture retention and potential odor issues. B2B buyers focusing on mass production or budget-friendly lines may find polyester appealing due to its affordability and ease of sourcing. However, it is essential to communicate the limitations of this material to customers to manage expectations.

What Advantages Does Cotton Lining Offer for Sneakers?

Cotton lining is naturally breathable and hypoallergenic, making it a suitable choice for casual and athletic footwear. It provides comfort and is gentle on the skin, appealing to consumers with sensitivities. However, cotton’s moisture-absorbing properties can lead to dampness and odor if not properly managed. For B2B buyers, cotton may be an excellent option for products targeting health-conscious consumers or those seeking natural materials, but they should consider moisture management solutions.

What Makes Cambrelle Lining Ideal for Performance Footwear?

Cambrelle lining is a specialized synthetic material known for its high moisture absorption and antibacterial properties. It is particularly beneficial for performance footwear, work boots, and environments where durability and moisture management are critical. B2B buyers should consider Cambrelle for products aimed at active consumers or specific industries requiring robust footwear solutions. However, its relative scarcity in the market may necessitate careful sourcing and supply chain management.

Key Industrial Applications of sneaker lining

| Industry/Sector | Specific Application of Sneaker Lining | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | High-performance athletic shoes | Enhances comfort, breathability, and durability | Need for moisture-wicking materials; compliance with safety standards |

| Fashion Retail | Casual and lifestyle sneaker lines | Supports brand positioning through quality | Sourcing sustainable materials; alignment with fashion trends |

| Sports Equipment | Specialized footwear for sports teams | Customization options for team branding | Availability of custom colors and designs; quick turnaround times |

| Outdoor and Adventure Gear | Hiking and trekking footwear | Provides thermal insulation and moisture control | Durability against harsh conditions; lightweight options |

| Medical and Orthopedic | Therapeutic sneakers for foot health | Improves patient comfort and mobility | Compliance with health regulations; hypoallergenic materials |

How is Sneaker Lining Used in Footwear Manufacturing?

In the footwear manufacturing sector, sneaker lining is critical for high-performance athletic shoes. These linings are designed to enhance comfort, breathability, and durability, addressing common issues like moisture retention and foot fatigue. Buyers in this sector should prioritize moisture-wicking materials that comply with safety standards to ensure optimal performance. The demand for eco-friendly options is also rising, particularly among environmentally conscious consumers in regions like Europe and South America.

What Role Does Sneaker Lining Play in Fashion Retail?

In the fashion retail industry, casual and lifestyle sneaker lines leverage sneaker lining to support brand positioning through quality and comfort. The right lining can elevate the perceived value of a sneaker, appealing to fashion-forward consumers. Buyers must consider sourcing sustainable materials, as there is a growing trend toward eco-conscious fashion. Keeping up with the latest fashion trends can also guide material selection, ensuring that products remain relevant in a competitive market.

How is Sneaker Lining Customized for Sports Equipment?

For sports equipment manufacturers, sneaker lining is often customized for specialized footwear used by sports teams. This customization allows for unique branding opportunities, such as team colors and logos, enhancing team identity. Buyers should seek suppliers who can provide quick turnaround times and a variety of custom colors and designs. Additionally, the linings must meet specific performance criteria, such as durability and moisture management, to withstand rigorous athletic activities.

Why is Sneaker Lining Important for Outdoor and Adventure Gear?

In the outdoor and adventure gear sector, sneaker lining plays a vital role in hiking and trekking footwear, providing thermal insulation and moisture control. Given the challenging environments these shoes are used in, the linings must be durable and lightweight. Buyers should focus on sourcing materials that can withstand harsh conditions while also providing comfort during long treks. This sector often requires linings that are resistant to wear and tear, ensuring longevity in outdoor applications.

How Does Sneaker Lining Contribute to Medical and Orthopedic Footwear?

In the medical and orthopedic sector, sneaker lining is essential for therapeutic sneakers designed to improve foot health. These linings enhance comfort and mobility for patients, addressing specific health needs such as arch support and pressure relief. Buyers in this sector must ensure that materials are hypoallergenic and comply with health regulations, as patient safety is paramount. The right sneaker lining can significantly improve the overall therapeutic effectiveness of the footwear, making it a crucial consideration for manufacturers.

3 Common User Pain Points for ‘sneaker lining’ & Their Solutions

Scenario 1: Ensuring Comfort in Long-Wear Sneakers

The Problem: A leading athletic footwear manufacturer based in Brazil faces significant challenges with customer comfort complaints regarding their sneaker linings. After long hours of wear, customers report issues like blisters and discomfort, often attributing these problems to poorly designed or substandard lining materials. This not only affects customer satisfaction but also leads to increased return rates and a tarnished brand reputation.

The Solution: To overcome this issue, B2B buyers should prioritize sourcing high-quality, breathable linings that are designed for moisture-wicking and temperature regulation. Materials such as full-grain leather or Cambrelle provide excellent moisture control and comfort, ideal for long-term wear. When specifying linings, consider factors like softness, flexibility, and durability. Implementing rigorous testing protocols to assess the comfort of various linings under different conditions can also help identify the best options. Additionally, training production teams to ensure proper attachment of linings without seams or joints that can rub against the foot is crucial for enhancing overall comfort.

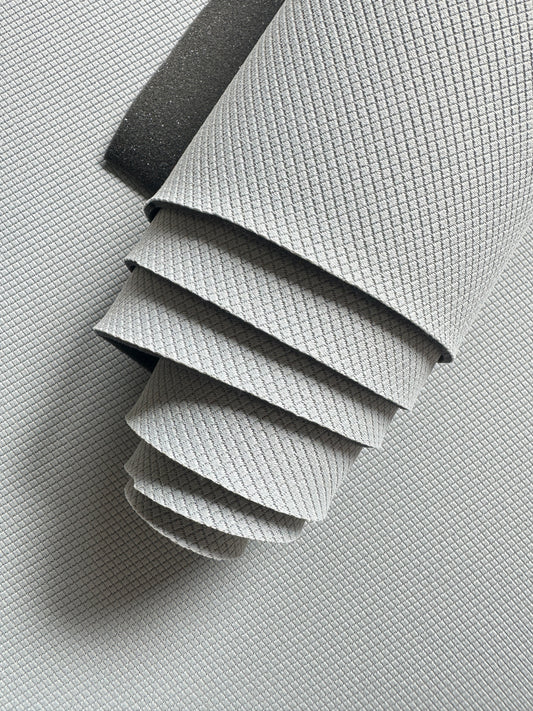

Illustrative image related to sneaker lining

Scenario 2: Managing Production Costs While Maintaining Quality

The Problem: A footwear company in Saudi Arabia struggles with escalating production costs due to frequent material replacements and quality issues stemming from lower-grade lining materials. The decision to opt for cheaper linings initially seemed cost-effective; however, the long-term impacts of customer dissatisfaction and increased warranty claims have rendered this strategy unsustainable.

The Solution: B2B buyers need to adopt a more strategic approach to material sourcing by investing in high-quality linings that provide longevity and performance. This includes evaluating suppliers that offer durable materials such as polyester knit mesh or high-grade synthetic options that balance cost and quality. Buyers should also explore bulk purchasing agreements or long-term contracts with reliable suppliers to negotiate better pricing. Additionally, incorporating a thorough quality assurance process during production can help catch potential issues early, reducing waste and rework costs associated with inferior materials.

Scenario 3: Navigating Sustainability Concerns in Sneaker Lining Choices

The Problem: A growing sneaker brand in Europe is facing increasing pressure from consumers and regulatory bodies to adopt sustainable practices. The current sneaker linings, primarily made from synthetic materials, are not aligned with the brand’s sustainability goals, resulting in negative publicity and potential loss of market share.

The Solution: To address sustainability concerns, B2B buyers should seek out eco-friendly lining materials that are either recycled or sustainably sourced. Options such as organic cotton or recycled polyester can significantly reduce the environmental footprint of the sneakers. Collaborating with suppliers who prioritize sustainable practices is also essential; this may include sourcing linings that are certified by environmental standards such as Global Organic Textile Standard (GOTS) or Oeko-Tex. Furthermore, implementing a lifecycle analysis for sneaker components can help identify the most sustainable materials and practices, allowing the brand to communicate its commitment to sustainability effectively to consumers. By embracing eco-friendly materials, the brand can enhance its reputation and appeal to environmentally conscious buyers.

Strategic Material Selection Guide for sneaker lining

What Are the Key Properties of Common Sneaker Lining Materials?

When selecting materials for sneaker linings, it is essential to consider their properties, advantages, and limitations. Here, we analyze four common materials used in sneaker linings: leather, polyester, cotton, and Cambrelle.

How Does Leather Perform as a Sneaker Lining Material?

Leather, particularly full-grain calfskin, is renowned for its breathability, moisture-wicking capabilities, and natural temperature regulation. These properties make leather an excellent choice for sneaker linings, especially in warmer climates where foot sweat can be an issue.

Pros: Leather is durable, offers a premium feel, and has inherent odor-controlling properties. It is also flexible, molding to the foot over time for enhanced comfort.

Cons: The primary drawback is its cost, as high-quality leather can be expensive. Additionally, leather requires specific care to maintain its properties, which can complicate manufacturing processes.

Impact on Application: Leather linings are suitable for high-end sneakers and those marketed toward consumers seeking luxury. International buyers should ensure compliance with local regulations regarding animal products, particularly in regions with strict animal welfare standards.

What Are the Benefits of Using Polyester for Sneaker Linings?

Polyester is a synthetic material frequently used in budget-friendly sneakers. It is lightweight and can be engineered to provide a variety of textures and finishes.

Pros: Polyester linings are cost-effective and can be produced in large quantities with relative ease. They are also resistant to wrinkling and shrinking, making them suitable for mass production.

Cons: However, polyester lacks breathability, often leading to moisture build-up and odor issues. Its durability is also lower than that of natural materials, which can affect the longevity of the sneaker.

Impact on Application: Polyester is often used in lower-end sneakers, but international buyers should be cautious about quality. Compliance with environmental regulations regarding synthetic materials may also be a consideration in certain markets.

Why Consider Cotton for Sneaker Linings?

Cotton is a natural fiber known for its softness and breathability. It is often used in casual footwear and can provide a comfortable lining option.

Pros: Cotton is hypoallergenic, making it suitable for consumers with sensitive skin. It is also relatively inexpensive and widely available.

Cons: The major downside is that cotton absorbs moisture without wicking it away, which can lead to discomfort and bacterial growth. Its insulation properties can also be a disadvantage in colder climates.

Impact on Application: Cotton linings are typically found in casual or budget sneakers. International buyers should check for compliance with textile regulations, as cotton may need to meet specific organic standards in some regions.

What Advantages Does Cambrelle Offer for Sneaker Linings?

Cambrelle is a synthetic material made from two types of nylon, known for its moisture-absorbing and quick-drying properties. It is often used in performance footwear.

Pros: Cambrelle is highly breathable, abrasion-resistant, and has antifungal and antibacterial properties, making it suitable for athletic shoes.

Cons: The complexity of manufacturing Cambrelle can lead to higher costs, and it may not be as widely recognized as other materials, which could affect consumer perception.

Impact on Application: Cambrelle is ideal for sports and outdoor sneakers. Buyers from international markets should verify that the material meets local performance standards, such as ASTM for athletic footwear.

Summary Table of Sneaker Lining Materials

| Material | Typical Use Case for sneaker lining | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | High-end sneakers | Breathability and moisture control | High cost and maintenance requirements | High |

| Polyester | Budget-friendly sneakers | Cost-effective and easy to produce | Poor breathability and durability | Low |

| Cotton | Casual sneakers | Soft and hypoallergenic | Absorbs moisture, leading to discomfort | Med |

| Cambrelle | Performance athletic shoes | Moisture-wicking and antibacterial | Higher manufacturing complexity | Med |

This guide provides a comprehensive overview of the materials available for sneaker linings, enabling B2B buyers to make informed decisions that align with their target markets and compliance requirements.

Illustrative image related to sneaker lining

In-depth Look: Manufacturing Processes and Quality Assurance for sneaker lining

What Are the Key Stages in the Manufacturing Process of Sneaker Lining?

The manufacturing process of sneaker lining encompasses several critical stages, each designed to ensure that the final product meets the desired quality and functionality. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Sneaker Lining?

The first step in the manufacturing process is the selection and preparation of materials. Common materials for sneaker linings include leather, cotton, polyester, and synthetic blends like Cambrelle. Each material is chosen based on its properties such as breathability, moisture-wicking capabilities, and comfort.

Once the materials are selected, they undergo preprocessing, which may involve cutting, treating, and conditioning. For instance, leather linings may be tanned to enhance durability, while synthetic materials could be treated to improve moisture resistance. This stage is crucial as it lays the foundation for the quality of the lining.

What Techniques Are Used in the Forming Stage of Sneaker Lining?

The forming stage involves shaping the prepared materials to fit the specific design of the sneaker. This can include processes such as die-cutting, where materials are cut into precise shapes that correspond to various parts of the sneaker lining, including the tongue, collar, and vamp.

Another important technique is lamination, where multiple layers of materials are bonded together to enhance performance characteristics. For instance, a polyester mesh may be laminated with foam to provide cushioning and breathability. This not only improves comfort but also adds to the durability of the sneaker lining.

How Does Assembly Work in Sneaker Lining Production?

During the assembly phase, the pre-formed lining components are attached to the sneaker’s upper. This involves stitching, gluing, or thermal bonding, depending on the material and the design requirements. High-quality linings are typically secured tightly to avoid any separation or movement, which could lead to discomfort for the wearer.

Moreover, assembly may include the integration of additional features such as moisture-wicking treatments or antimicrobial finishes, enhancing the overall performance of the lining. Attention to detail in this stage is vital, as it directly impacts the comfort and longevity of the sneaker.

What Finishing Processes Are Applied to Sneaker Linings?

The final stage, finishing, involves quality checks and any additional treatments necessary to ensure the lining meets industry standards. This may include applying protective coatings or surface treatments to enhance durability and resistance to wear and tear.

Illustrative image related to sneaker lining

Once the linings are completed, they undergo final inspections to ensure they are free from defects. This is crucial for maintaining high standards of quality that B2B buyers expect.

How Is Quality Assurance Integrated into Sneaker Lining Production?

Quality assurance (QA) plays an essential role in the manufacturing of sneaker linings, ensuring that every product meets international standards and customer expectations. The QA process includes adherence to various international standards such as ISO 9001, which focuses on quality management systems, and industry-specific certifications like CE marking for compliance with health and safety regulations.

What Are the Key QC Checkpoints in Sneaker Lining Production?

Quality control (QC) checkpoints are established throughout the manufacturing process. Key checkpoints include:

Illustrative image related to sneaker lining

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified requirements. For example, leather linings should be checked for quality, thickness, and any imperfections.

-

In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are carried out to identify any defects early. This may include monitoring stitching quality and material bonding.

-

Final Quality Control (FQC): Once the sneaker linings are completed, a final inspection is performed to ensure that they meet all quality standards before they are packaged and shipped.

What Common Testing Methods Are Used for Sneaker Linings?

Common testing methods for sneaker linings include:

-

Abrasion Resistance Testing: This assesses how well the lining withstands wear and tear.

-

Moisture Management Testing: This evaluates the lining’s ability to wick moisture away from the foot, ensuring comfort.

-

Breathability Testing: This measures how effectively the lining allows air to circulate, which is critical for reducing foot odor and maintaining comfort.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can verify supplier QC practices through several methods:

-

Audits: Conducting on-site audits of the manufacturing facility can provide insights into the supplier’s production processes and quality management systems.

-

Quality Reports: Requesting detailed quality reports that outline testing results and any certifications can help buyers assess the reliability of the supplier.

-

Third-party Inspections: Engaging third-party inspection services can offer an unbiased review of the quality assurance processes in place, ensuring adherence to international standards.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific QC and certification nuances. For instance, compliance with local regulations and international standards may vary by region, and understanding these differences is crucial for seamless procurement.

Additionally, buyers should consider the logistics of quality assurance, such as lead times for testing and certifications. Establishing clear communication channels with suppliers regarding quality expectations and certifications can help mitigate risks and ensure that the final products meet buyer specifications.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing sneaker linings, ensuring they receive high-quality products that meet their needs.

Illustrative image related to sneaker lining

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sneaker lining’

To assist B2B buyers in procuring sneaker lining, this guide provides a structured checklist to ensure informed and strategic sourcing decisions. Selecting the right lining material is essential for the quality, comfort, and durability of sneakers, making it a critical aspect of the manufacturing process.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the sneaker lining you require. Consider factors such as breathability, moisture-wicking capabilities, and durability. These specifications will guide you in selecting materials that align with your product goals and consumer expectations.

Step 2: Identify Suitable Materials

Research and select from various lining materials that meet your specifications. Common options include:

– Leather: Offers breathability and moisture control, ideal for high-end sneakers.

– Polyester: A cost-effective choice, but be cautious of its breathability and comfort.

– Cambrelle: Excellent for sports and heavy-duty footwear due to its moisture-absorbing properties.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, certifications, and references from other buyers in similar markets. This step ensures you are partnering with a reliable supplier that can meet your quality standards and delivery timelines.

Illustrative image related to sneaker lining

Step 4: Request Samples

Always request samples of the lining materials you are considering. This will allow you to assess the texture, flexibility, and overall quality first-hand. Evaluate how these materials perform under different conditions, such as varying temperatures and moisture levels.

Step 5: Assess Cost and Value

Analyze the cost of the materials in relation to their quality and performance. Consider the long-term value of investing in higher-quality linings that can enhance the overall product lifespan and customer satisfaction. Be sure to compare prices from multiple suppliers to ensure competitive sourcing.

Step 6: Verify Compliance and Certifications

Ensure that the materials comply with international safety and quality standards. Check for certifications such as ISO, REACH, or others relevant to your target markets. Compliance is crucial for avoiding potential legal issues and for meeting consumer safety expectations.

Step 7: Establish Clear Communication Channels

Develop robust communication channels with your chosen supplier. Clear communication helps in addressing any issues promptly and ensures that both parties are aligned on expectations regarding delivery times, material specifications, and payment terms. Regular updates can prevent misunderstandings and foster a strong business relationship.

By following these steps, B2B buyers can make well-informed decisions when sourcing sneaker lining, ultimately enhancing the quality and marketability of their products.

Comprehensive Cost and Pricing Analysis for sneaker lining Sourcing

What Are the Key Cost Components in Sneaker Lining Sourcing?

When sourcing sneaker linings, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of lining material significantly influences cost. Options range from premium leather to cost-effective polyester. For example, full-grain leather, known for its breathability and moisture-wicking properties, often commands higher prices compared to synthetic options like polyester, which may be cheaper but less durable and breathable.

-

Labor: Labor costs vary based on the complexity of the manufacturing process and the region. Skilled labor is essential for high-quality linings, especially those requiring intricate stitching or finishing. Manufacturers in regions with lower labor costs may offer competitive pricing, but buyers should also consider quality and craftsmanship.

-

Manufacturing Overhead: This includes the costs associated with running the production facility, such as utilities, equipment maintenance, and administrative expenses. Efficient production processes can help mitigate these costs.

-

Tooling: Depending on the design specifications, tooling costs can vary. Custom molds and cutting tools for specific designs or materials may require significant upfront investment, which should be factored into the overall cost.

-

Quality Control (QC): Implementing stringent QC measures ensures the durability and performance of the linings. While this may add to the overall cost, it is essential for maintaining product standards and minimizing defects.

-

Logistics: Shipping costs can be substantial, especially for international shipments. Factors such as distance, shipping methods, and tariffs play a significant role in total logistics expenses.

-

Margin: Suppliers will typically add a markup on their costs to ensure profitability. Understanding the average margins in the industry can help buyers negotiate better prices.

How Do Price Influencers Affect Sneaker Lining Costs?

Several factors can influence the pricing of sneaker linings, including:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly affect pricing. Larger orders often lead to discounts, as suppliers benefit from economies of scale. Buyers should assess their needs and negotiate MOQs that align with their production plans.

-

Specifications and Customization: Custom designs or specific material requirements can drive up costs. Buyers seeking unique linings should be prepared to invest more, as customization often involves additional tooling and labor.

-

Material Quality and Certifications: Higher-quality materials, especially those with certifications for environmental or safety standards, will typically be more expensive. Buyers should evaluate the importance of these certifications in their markets.

-

Supplier Factors: The reliability and reputation of the supplier can also influence pricing. Established suppliers may charge more due to their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can impact the total landed cost of the product.

What Negotiation Tips Can Help B2B Buyers Secure Better Pricing?

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant cost savings:

-

Research and Benchmarking: Gather data on market prices and competitor offerings to strengthen your negotiation position. Understanding the average costs for different types of linings can help you identify fair pricing.

-

Build Long-term Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms. Regular communication and a history of reliable orders can foster loyalty and result in more favorable terms.

-

Focus on Total Cost of Ownership (TCO): Consider the long-term costs associated with sourcing linings, including maintenance, durability, and potential replacement costs. Presenting a TCO perspective can strengthen your negotiation strategy.

-

Be Open to Alternative Materials: If budget constraints are significant, consider alternative materials that offer similar performance characteristics at a lower cost. This flexibility can open up new opportunities for negotiation.

Disclaimer

Pricing in the sneaker lining industry can vary widely based on numerous factors. The insights provided here are indicative and should be used as a guideline for B2B buyers. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing sneaker lining With Other Solutions

Exploring Alternatives to Sneaker Lining: What Are the Options?

In the competitive sneaker market, choosing the right lining material is crucial for product quality, comfort, and customer satisfaction. While sneaker lining serves as a fundamental component for foot comfort and performance, there are several alternative solutions that manufacturers can consider. This analysis compares sneaker lining against two viable alternatives: Cambrelle lining and polyester mesh lining. Each option offers unique benefits and challenges, making it essential for B2B buyers to evaluate their needs carefully.

Comparison Table

| Comparison Aspect | Sneaker Lining | Cambrelle Lining | Polyester Mesh Lining |

|---|---|---|---|

| Performance | Breathable, moisture-wicking, soft | Excellent moisture absorption, antibacterial | Good breathability but less durable |

| Cost | Moderate to high | Moderate | Low |

| Ease of Implementation | Relatively straightforward | Requires specialized knowledge | Easy to work with |

| Maintenance | Requires care to prevent wear | Low maintenance, durable | Minimal maintenance needed |

| Best Use Case | Casual and performance sneakers | Sports and heavy-duty footwear | Casual and DIY projects |

Detailed Breakdown of Alternatives

What Are the Benefits and Drawbacks of Cambrelle Lining?

Cambrelle lining is a synthetic material known for its high moisture absorption and breathability. It offers antibacterial and antifungal properties, making it ideal for sports and heavy-duty footwear. The main advantage of Cambrelle is its durability and ability to keep feet dry during intense physical activity. However, it is typically more specialized and may require additional expertise for implementation, which could increase production costs. B2B buyers should consider Cambrelle for products targeting active consumers who prioritize performance.

How Does Polyester Mesh Lining Compare?

Polyester mesh lining is an economical option that provides decent breathability and comfort. It is lightweight and easy to implement, making it a popular choice for casual sneakers and DIY projects. However, polyester mesh is less durable compared to other options, and it may not offer the same level of moisture management. The cost-effectiveness of polyester mesh makes it appealing for budget-conscious buyers, but its longevity may be a concern for brands looking to maintain high-quality standards. This alternative is best suited for budget-friendly lines where performance is not the primary focus.

Conclusion: How Should B2B Buyers Choose the Right Sneaker Lining Solution?

When selecting the right lining for sneakers, B2B buyers must consider their target market, product positioning, and budget constraints. Sneaker lining offers a balance of comfort and performance, making it ideal for high-quality footwear. Cambrelle lining is excellent for performance-driven applications, while polyester mesh provides a cost-effective solution for casual footwear. Ultimately, the choice will depend on the specific needs of the business and its customers, as well as the desired brand image. By weighing the pros and cons of each option, buyers can make informed decisions that align with their strategic goals in the competitive sneaker market.

Essential Technical Properties and Trade Terminology for sneaker lining

What Are the Essential Technical Properties of Sneaker Lining?

Understanding the technical properties of sneaker lining is crucial for B2B buyers looking to source quality materials. Here are some key specifications to consider:

-

Material Grade

Material grade refers to the quality and type of fabric used in sneaker linings. Common materials include leather, cotton, polyester, and synthetic blends. High-grade materials offer better durability, breathability, and comfort, directly impacting the end-user experience. For manufacturers, specifying a higher material grade can justify premium pricing and enhance brand reputation. -

Moisture Management

Moisture management is the ability of a lining material to wick away sweat and moisture. This property is vital for maintaining foot hygiene and comfort, particularly in warmer climates. Linings with superior moisture-wicking capabilities, such as Cambrelle or high-quality leather, help prevent odor and bacterial growth, making them more appealing to health-conscious consumers. -

Abrasion Resistance

Abrasion resistance indicates how well a lining can withstand wear and tear. This property is particularly significant for sneakers designed for high-impact sports or rugged use. Linings that exhibit high abrasion resistance will prolong the lifespan of the shoe, reducing the frequency of replacements and improving customer satisfaction. B2B buyers should prioritize this feature to ensure their products meet consumer expectations for durability. -

Breathability

Breathability refers to the ability of the lining material to allow air circulation, which helps regulate temperature and moisture. Materials like full-grain leather and specialized synthetic fabrics are often designed to enhance breathability. For buyers, selecting breathable linings can lead to greater comfort for the end-user, particularly in regions with hot climates, thus increasing market competitiveness. -

Flexibility and Comfort

Flexibility is the property that determines how well a lining material can conform to the foot’s shape. Materials that are both flexible and soft, like fleece and high-quality leather, contribute to overall comfort. This property is essential for creating a pleasant wearing experience, which can lead to repeat purchases and brand loyalty.

Which Trade Terminology Should B2B Buyers Understand in Sneaker Lining?

Familiarity with industry terminology can facilitate smoother transactions and negotiations. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the sneaker industry, understanding OEM relationships can help buyers identify potential partners for custom lining solutions tailored to specific designs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and cash flow. Understanding the MOQ can help in planning purchases more effectively and negotiating better terms with suppliers. -

RFQ (Request for Quotation)

An RFQ is a formal request for price quotes from suppliers. This process helps buyers compare different offers based on pricing, material specifications, and delivery timelines. Utilizing RFQs can lead to better purchasing decisions and cost savings. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international shipping. They define the responsibilities of buyers and sellers regarding shipping costs, insurance, and liability. For B2B buyers, understanding Incoterms is essential for managing logistics and ensuring compliance with international trade regulations. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This metric is critical for supply chain management. By understanding lead times, buyers can better plan their production schedules and inventory levels.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the best sneaker linings that meet their market needs and enhance their product offerings.

Navigating Market Dynamics and Sourcing Trends in the sneaker lining Sector

What Are the Current Market Dynamics and Key Trends in the Sneaker Lining Sector?

The sneaker lining sector is witnessing a transformation driven by several global factors. Increasing consumer demand for comfort and performance is propelling innovations in lining materials. Technologies such as moisture-wicking, odor control, and temperature regulation are becoming essential features, particularly in competitive markets like Africa, South America, and the Middle East, where climatic conditions vary significantly. Buyers from these regions are increasingly prioritizing materials that enhance breathability and durability, as well as those that contribute to overall foot health.

Emerging trends in B2B sourcing include the rise of digital platforms that facilitate connections between manufacturers and retailers. Technologies like 3D printing and AI are enabling customized lining solutions tailored to specific consumer preferences, thereby enhancing product differentiation. Additionally, the integration of supply chain transparency tools is becoming crucial for international buyers, allowing them to track the origins of materials and ensure quality standards are met. As the sneaker market expands, especially in regions such as Saudi Arabia and Brazil, understanding these dynamics will be essential for buyers looking to make informed purchasing decisions.

How Is Sustainability and Ethical Sourcing Shaping the Sneaker Lining Market?

Sustainability is no longer a trend but a necessity in the sneaker lining sector. The environmental impact of traditional materials has prompted a shift towards sustainable alternatives. Ethically sourced materials, such as organic cotton and recycled polyester, are gaining traction among manufacturers aiming to reduce their carbon footprint. Buyers are increasingly seeking suppliers that can provide certifications for environmentally friendly practices, such as GOTS (Global Organic Textile Standard) and OEKO-TEX, which ensure that materials meet rigorous sustainability criteria.

Moreover, the importance of ethical supply chains is becoming paramount. Buyers are focusing on suppliers who prioritize fair labor practices and transparency in their operations. This not only enhances brand reputation but also fosters customer loyalty, especially among environmentally conscious consumers. As international markets evolve, particularly in regions with stringent regulations on environmental standards, the ability to showcase a commitment to sustainability will be a critical factor for B2B buyers in their sourcing decisions.

Illustrative image related to sneaker lining

What Is the Brief Evolution and History of Sneaker Lining?

The evolution of sneaker lining materials reflects broader trends in footwear technology and consumer preferences. Initially, sneaker linings were primarily made from basic materials like cotton and polyester, which offered limited comfort and durability. Over the years, advancements in textile technology have introduced a variety of specialized materials, including moisture-wicking synthetic fabrics and breathable leather options.

In the late 20th century, the rise of athletic and lifestyle sneakers led to an increased focus on performance-enhancing linings, catering to the needs of athletes and everyday consumers alike. Today, the market is characterized by a diverse range of materials designed to meet specific functional requirements, from thermal insulation to enhanced breathability. This evolution underscores the importance of continuous innovation in the sneaker lining sector, providing B2B buyers with a wealth of options to meet their consumers’ ever-changing demands.

Frequently Asked Questions (FAQs) for B2B Buyers of sneaker lining

-

How do I choose the right lining material for my sneakers?

Selecting the appropriate lining material for sneakers depends on several factors, including comfort, breathability, and durability. Leather linings are excellent for moisture management and breathability, ideal for high-end sneakers. Synthetic options like Cambrelle offer moisture absorption and quick drying, suitable for athletic footwear. Consider your target market’s preferences and climate conditions; for instance, breathable materials may be preferred in humid regions. Additionally, ensure the lining aligns with your brand’s quality standards and price points. -

What are the benefits of using leather lining in sneakers?

Leather linings provide numerous advantages, including superior breathability, moisture-wicking properties, and a luxurious feel. They naturally regulate temperature and control odors, making them ideal for sneakers worn without socks. While they tend to be more expensive, they can enhance the perceived value of your sneakers, appealing to a premium market. Additionally, full-grain leather is more durable and resistant to wear compared to synthetic options, making it a long-term investment for quality footwear. -

What is the minimum order quantity (MOQ) for sneaker lining materials?

Minimum order quantities vary widely among suppliers, often depending on the material type and customization options. For standard polyester linings, MOQs may start as low as 100 meters, while specialized materials like leather could require larger orders, such as 500 meters or more. It’s essential to discuss your needs with potential suppliers to negotiate favorable terms. If you are a smaller business, consider suppliers that offer flexible MOQs or bulk purchasing options to reduce costs. -

How can I ensure the quality of sneaker lining materials?

To ensure quality, conduct thorough supplier vetting by checking certifications, customer reviews, and product samples. Request detailed product specifications and test materials for durability, breathability, and comfort. Establish clear quality assurance protocols, including inspections during production and upon receipt. Additionally, consider visiting the manufacturing facility if possible, or utilize third-party inspection services to maintain quality standards, especially when sourcing internationally. -

What payment terms are typically offered by suppliers for sneaker linings?

Payment terms can vary significantly based on the supplier’s policies and your negotiation skills. Common arrangements include a 30% deposit upon order confirmation, with the balance due before shipment. Some suppliers may offer net 30 or net 60 terms, allowing for payment after delivery. It’s advisable to establish clear terms upfront to avoid misunderstandings and consider using secure payment methods to protect your financial transactions, especially in international trade. -

How do I handle logistics and shipping for sneaker lining materials?

Managing logistics involves selecting reliable shipping partners and determining the best shipping methods based on cost and delivery time. For international shipments, consider customs regulations and import duties specific to your country. Working with a freight forwarder can simplify the process by handling documentation and ensuring compliance. Additionally, plan for potential delays by ordering materials well in advance of production schedules to maintain a steady supply chain. -

Can I customize the sneaker lining materials to fit my brand?

Yes, many suppliers offer customization options for sneaker linings, including colors, patterns, and materials. Customization can enhance brand identity and cater to specific market needs. When discussing options, provide clear design specifications and discuss lead times, as custom orders typically require longer production schedules. Collaborating closely with your supplier during the design process can help ensure the final product aligns with your brand vision and quality standards. -

What should I consider regarding sustainability in sneaker lining materials?

Sustainability is increasingly important in the footwear industry. When sourcing lining materials, look for suppliers that use eco-friendly materials, such as organic cotton or recycled synthetics. Additionally, inquire about the production processes to ensure they follow ethical labor practices and minimize environmental impact. Highlighting sustainable practices can enhance your brand’s appeal, especially in markets where consumers are becoming more environmentally conscious. Consider certifications like Global Organic Textile Standard (GOTS) for additional credibility.

Top 6 Sneaker Lining Manufacturers & Suppliers List

1. Beckett Simonon – Types of Shoe Lining

Domain: beckettsimonon.com

Registered: 2012 (13 years)

Introduction: 5 Types of Shoe Lining: 1. Leather Shoe Lining: Breathable, odor-controlling, moisture-wicking, and temperature-regulating. Ideal for sweaty feet and can be worn without socks. Look for 100% full-grain leather. 2. Fleece Shoe Lining: Soft, warm, and cozy, mimicking lamb’s wool. Made from recycled plastic or blended with natural fibers. Not suitable for refined footwear. 3. Polyester Shoe Lining: C…

2. Shoemakers Academy – Black Polyester Shoe Lining Mesh

Domain: shoemakersacademy.com

Registered: 2022 (3 years)

Introduction: Black Polyester Shoe Lining Mesh 5mm Foam Backed

Price: $12 – $60

Material: Black 5mm Lining Fabric + 5mm KFF Foam + Tricot Mesh

Size: 28″ x 14″ (120% larger)

Description: 3-layer sandwich construction (Polyester knit mesh + 5mm foam + smooth tricot backing). Peel and stick backing for easy use. Breathable.

Available Options: 2 Sheets, 4 Sheets, 6 Sheets, 8 Sheets, 10 Sheets

SKU: N/A

Category: Sho…

3. A&A – Sneaker Lining

Domain: aleatherstore.com

Registered: 2021 (4 years)

Introduction: {“product_name”: “Sneaker Lining – A&A CRACK”, “price”: {“2 SQFT”: “$26.01”, “1/4 – 5 SQFT”: “$56.89”, “1/2 – 10 SQFT”: “$113.78”, “FULL – 20 SQFT”: “$211.31”}, “sizes_available”: [“2 SQFT”, “1/4 – 5 SQFT”, “1/2 – 10 SQFT”, “FULL – 20 SQFT”], “stock_status”: “Only 3 items in stock!”}

4. Avetco – Lining Leather

Domain: avetcoinc.com

Registered: 2005 (20 years)

Introduction: Lining Leather from Avetco is soft, lightweight, and designed for interior use in footwear, handbags, garments, and accessories. It features a smooth finish and breathability, providing comfort, structure, and a refined touch. Available in various colors and textures, it combines function and luxury. Key products include:

1. **2 oz. Lambskin (8–10 sq. ft.)** – Price: $57.20

– Colors: Black, Bo…

5. Bridgesl – Faux Leather Shoe Lining Fabrics

Domain: bridgesl.com

Registered: 2015 (10 years)

Introduction: Faux leather shoe lining fabrics suitable for different footwear; high-quality synthetic leather from selected manufacturers; optimum air permeability, moisture wicking property, temperature regulation, and physical comfort; manufactured with mixed materials for comfort and heat dissipation; includes distressed faux calfskin synthetic leather, water absorbent shoe lining without base, 100% PU brea…

6. Reddit – Self-Adhesive Repair Blister Patches

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Self-Adhesive Repair Blister Patches for shoes, recommended for mending the inside heel of running shoes. Users suggested using thin adhesive patches or moleskin, and some mentioned using strips of soft denim or foam for a more permanent solution. The repair should extend to eliminate rub points and ensure structural stability.

Strategic Sourcing Conclusion and Outlook for sneaker lining

How Can Strategic Sourcing Enhance Your Sneaker Lining Choices?

In today’s competitive sneaker market, strategic sourcing is crucial for optimizing the quality and performance of sneaker linings. By understanding the diverse types of linings—such as leather for breathability, fleece for warmth, and synthetic options for cost-efficiency—buyers can make informed decisions that enhance product offerings. Sourcing high-quality materials not only improves customer satisfaction but also reduces returns and enhances brand loyalty.

Moreover, international buyers from regions such as Africa, South America, the Middle East, and Europe must prioritize suppliers who can deliver consistent quality while being mindful of regional preferences and climate conditions. Establishing strong relationships with reliable suppliers can lead to better pricing, innovation, and timely delivery.

Illustrative image related to sneaker lining

Looking ahead, the focus on sustainable materials and advanced manufacturing techniques will continue to shape the sneaker industry. Buyers are encouraged to explore eco-friendly lining options that align with global trends towards sustainability. By leveraging strategic sourcing, businesses can not only meet consumer demand but also position themselves as leaders in an evolving market. Embrace this opportunity to refine your sourcing strategies and elevate your sneaker offerings for the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to sneaker lining