Introduction: Navigating the Global Market for automotive seat upholstery fabric

Navigating the global market for automotive seat upholstery fabric can be a daunting task for international B2B buyers, especially when sourcing materials that meet both quality and compliance standards. The challenge lies not only in finding durable and aesthetically pleasing fabrics but also in ensuring they adhere to regional regulations and safety requirements. This guide aims to demystify the complexities of sourcing automotive upholstery fabrics by providing a thorough exploration of various types, applications, and critical factors to consider when selecting suppliers.

Within this comprehensive resource, you will find detailed insights into the diverse range of automotive fabrics, including synthetic options, natural materials, and specialty textiles designed for specific market needs. Additionally, we will cover essential aspects such as supplier vetting processes, cost analysis, and the importance of flame retardancy and UV resistance in different climates—key considerations for buyers operating in regions like Africa, South America, the Middle East, and Europe, including countries like Nigeria and Germany.

By equipping you with actionable knowledge and strategic insights, this guide empowers you to make informed purchasing decisions, ensuring that your automotive projects not only meet industry standards but also satisfy the expectations of your customers. Whether you are a manufacturer, distributor, or retailer, understanding the intricacies of automotive seat upholstery fabric will enhance your competitive edge in this dynamic market.

Table Of Contents

- Top 9 Automotive Seat Upholstery Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automotive seat upholstery fabric

- Understanding automotive seat upholstery fabric Types and Variations

- Key Industrial Applications of automotive seat upholstery fabric

- 3 Common User Pain Points for ‘automotive seat upholstery fabric’ & Their Solutions

- Strategic Material Selection Guide for automotive seat upholstery fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for automotive seat upholstery fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive seat upholstery fabric’

- Comprehensive Cost and Pricing Analysis for automotive seat upholstery fabric Sourcing

- Alternatives Analysis: Comparing automotive seat upholstery fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for automotive seat upholstery fabric

- Navigating Market Dynamics and Sourcing Trends in the automotive seat upholstery fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automotive seat upholstery fabric

- Strategic Sourcing Conclusion and Outlook for automotive seat upholstery fabric

- Important Disclaimer & Terms of Use

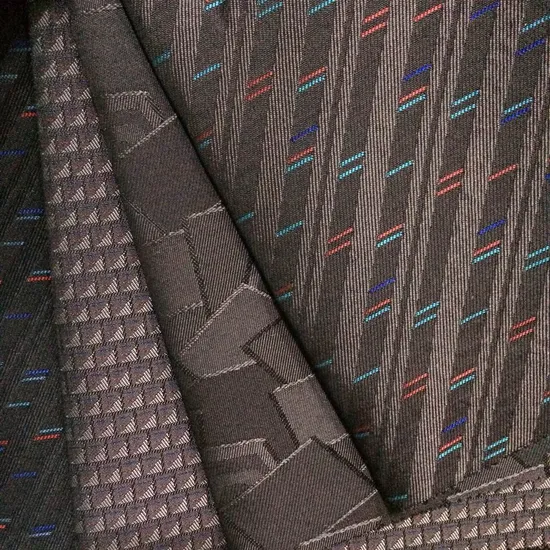

Understanding automotive seat upholstery fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polyester Fabric | Durable, UV resistant, and often flame retardant | Automotive, RV, Trucking | Pros: Cost-effective, variety of colors; Cons: Can be less luxurious than natural fibers. |

| Vinyl Fabric | Waterproof, easy to clean, and available in many textures | Automotive, Marine, Furniture | Pros: Highly durable, resistant to stains; Cons: Can be less breathable, may feel hot in warm climates. |

| Leather | Premium look and feel, durable, and age beautifully | Luxury Vehicles, High-end Models | Pros: Offers comfort and prestige; Cons: Higher cost, requires maintenance to prevent cracking. |

| Suede | Soft texture, luxurious appearance, and moderate durability | High-end Automotive, Custom Builds | Pros: Aesthetic appeal, comfortable; Cons: Sensitive to stains and water, may require special care. |

| Tweed | Textured, unique patterns, and good abrasion resistance | Classic Cars, Vintage Restorations | Pros: Distinctive look, durable; Cons: Limited color options, may not suit modern designs. |

What Are the Characteristics of Polyester Fabric for Automotive Upholstery?

Polyester fabric is a popular choice in the automotive upholstery sector due to its durability and resistance to UV rays and flames. This synthetic material is often treated to enhance its performance, making it suitable for both commercial and passenger vehicles. B2B buyers should consider the cost-effectiveness of polyester, as it offers a wide variety of colors and patterns, allowing customization for different vehicle models. However, it may lack the luxurious feel of natural fibers, which could be a consideration for high-end applications.

How Does Vinyl Fabric Benefit Automotive Upholstery Buyers?

Vinyl fabric is renowned for its waterproof properties and ease of cleaning, making it ideal for automotive applications where spills and stains are common. Its availability in various textures and colors allows for versatility in design. B2B buyers should recognize that while vinyl is highly durable and resistant to wear, it can be less breathable, potentially leading to discomfort in hot climates. This trade-off between durability and comfort should be carefully evaluated based on the target market.

Why Choose Leather for High-End Automotive Upholstery?

Leather is often regarded as the premium choice for automotive upholstery, providing a luxurious look and feel that enhances the overall value of a vehicle. Its durability means it can withstand significant wear, and it ages beautifully over time, developing a unique character. However, B2B buyers should be aware of the higher costs associated with leather and the need for regular maintenance to prevent damage. This makes leather a suitable option for luxury vehicles and high-end models where aesthetics and comfort are paramount.

What Makes Suede a Unique Choice for Automotive Interiors?

Suede offers a soft texture and luxurious appearance, making it an attractive option for high-end automotive interiors. It provides a level of comfort that many buyers seek for premium vehicles. However, its sensitivity to stains and water can be a drawback, requiring special care and cleaning products. B2B buyers should assess the target market’s willingness to maintain such materials, as well as the potential for higher replacement costs due to wear and tear.

How Does Tweed Stand Out in Automotive Upholstery Options?

Tweed is characterized by its unique patterns and textured finish, making it a popular choice for classic and vintage car restorations. Its good abrasion resistance ensures longevity, appealing to B2B buyers focused on durability. However, the limited color options and patterns may not align with modern design preferences, making it less suitable for contemporary vehicles. Buyers should consider the specific applications and target demographics when choosing tweed for automotive projects.

Key Industrial Applications of automotive seat upholstery fabric

| Industry/Sector | Specific Application of automotive seat upholstery fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of vehicle interiors | Enhances vehicle aesthetics and comfort, driving sales | Quality standards, compliance with safety regulations, and material durability |

| Commercial Vehicle Industry | Upholstery for buses and trucks | Improves passenger comfort and vehicle longevity | Bulk purchasing options, flame retardancy certifications, and maintenance ease |

| Luxury Automotive Sector | Custom upholstery for high-end vehicles | Elevates brand image and customer satisfaction | Unique fabric designs, premium materials, and customization capabilities |

| Automotive Restoration | Vintage vehicle interior restoration | Preserves historical value and enhances resale potential | Authenticity of materials, availability of vintage patterns, and color matching |

| Marine and Recreational Vehicles | Upholstery for boats and RVs | Provides weather resistance and comfort for users | Water-resistant properties, UV stability, and ease of cleaning |

How is Automotive Seat Upholstery Fabric Used in the Automotive Manufacturing Sector?

In the automotive manufacturing sector, automotive seat upholstery fabric is integral to the production of vehicle interiors. It not only contributes to the overall aesthetics of the vehicle but also enhances passenger comfort, which is a significant selling point in today’s competitive market. Buyers in this sector must prioritize high-quality materials that meet specific safety regulations, such as flame retardancy and durability. Additionally, sourcing partnerships should focus on suppliers who can provide consistent quality and timely delivery to align with production schedules.

What Role Does Upholstery Fabric Play in the Commercial Vehicle Industry?

In the commercial vehicle industry, upholstery fabric is used extensively for buses and trucks, where comfort during long journeys is paramount. High-quality upholstery can significantly improve passenger experience, leading to increased customer satisfaction and loyalty. B2B buyers should consider the fabric’s durability and maintenance requirements, as commercial vehicles endure heavy use. Certifications for flame retardancy and ease of cleaning are also critical factors, ensuring that the upholstery remains safe and presentable over time.

Why is Custom Upholstery Important in the Luxury Automotive Sector?

Custom upholstery in the luxury automotive sector serves to elevate the brand image and provide an unparalleled customer experience. High-end vehicles often feature unique fabrics that reflect the brand’s identity and appeal to discerning customers. Buyers in this segment must focus on sourcing premium materials that offer customization options, such as exclusive designs and colors. Additionally, the ability to meet specific aesthetic requirements while ensuring durability and comfort is essential for maintaining the luxury standard.

How is Automotive Upholstery Fabric Used in Vehicle Restoration Projects?

In automotive restoration, upholstery fabric is crucial for preserving the historical value of vintage vehicles. Authentic materials not only enhance the vehicle’s aesthetic appeal but also boost its resale potential. Buyers in this market need to ensure that they source fabrics that match the original specifications in terms of color, texture, and pattern. Availability of vintage patterns and the ability to provide accurate color matching are key considerations for B2B buyers involved in restoration projects.

What Benefits Does Upholstery Fabric Provide for Marine and Recreational Vehicles?

For marine and recreational vehicles, automotive seat upholstery fabric must withstand challenging environmental conditions. Fabrics used in boats and RVs should offer weather resistance, UV stability, and comfort for users. B2B buyers should prioritize sourcing materials that are easy to clean and maintain, as these vehicles are often exposed to dirt and moisture. Ensuring that the upholstery meets specific performance standards while providing comfort can significantly enhance the user experience in recreational settings.

3 Common User Pain Points for ‘automotive seat upholstery fabric’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Upholstery Fabric

The Problem: Many B2B buyers in the automotive industry struggle to find high-quality upholstery fabric that meets both aesthetic and functional requirements. This is particularly challenging for those sourcing materials for high-end vehicles where comfort and luxury are paramount. Buyers may encounter issues such as inconsistent fabric quality, limited color options, or fabrics that do not meet safety regulations like flame retardancy. In regions such as Africa or South America, where local suppliers may not offer a wide selection, the challenge is even greater.

The Solution: To effectively source quality automotive seat upholstery fabric, buyers should establish relationships with reputable manufacturers and suppliers who specialize in automotive textiles. Conduct thorough research to identify suppliers who can provide detailed specifications on their fabrics, including durability ratings, flame retardancy certifications, and UV resistance. Utilize online platforms that aggregate multiple fabric options, allowing for comparison of prices and quality. Additionally, consider ordering samples before making bulk purchases. This hands-on approach allows for evaluation of texture, color, and durability, ensuring that the final selection aligns with project requirements.

Scenario 2: Managing Bulk Orders and Inventory Levels

The Problem: A common pain point for B2B buyers is managing inventory levels while placing bulk orders for upholstery fabric. Over-ordering can lead to excess stock, resulting in increased costs and wasted resources. Conversely, under-ordering can delay production timelines, affecting delivery schedules and customer satisfaction. This issue is especially pronounced for companies operating in regions with fluctuating demand or economic instability.

The Solution: Implementing an effective inventory management system is crucial. Buyers should analyze past sales data to forecast future demand accurately. Establishing a just-in-time (JIT) ordering system can also help mitigate risks associated with overstocking. This approach involves ordering fabric only as needed, which reduces storage costs and minimizes waste. Furthermore, maintaining open communication with suppliers can facilitate flexible ordering arrangements, such as smaller, more frequent shipments that align with production schedules. Leveraging technology, such as inventory management software, can also streamline tracking and ordering processes, ensuring that businesses remain agile and responsive to market demands.

Scenario 3: Ensuring Compliance with Safety Standards

The Problem: B2B buyers often face the challenge of ensuring that automotive upholstery fabrics comply with various safety standards and regulations. In regions with stringent safety laws, such as Europe, non-compliance can lead to significant legal ramifications, including fines and product recalls. Buyers may struggle to keep up with changing regulations and may not be aware of the specific requirements for different types of vehicles.

The Solution: To navigate compliance challenges, buyers should stay informed about the relevant safety standards applicable in their markets, such as the FMVSS in the United States or ECE R-118 in Europe. Collaborating with suppliers who have a proven track record of compliance can simplify the process; inquire about their certifications and request documentation to verify compliance with safety standards. Additionally, consider investing in training for procurement teams to better understand industry regulations. Regularly attending industry seminars, webinars, and trade shows can also keep buyers updated on changes in legislation and best practices. By taking proactive steps to ensure compliance, companies can protect themselves from potential liabilities while enhancing their reputation in the marketplace.

Strategic Material Selection Guide for automotive seat upholstery fabric

What Are the Key Materials Used in Automotive Seat Upholstery Fabric?

When selecting automotive seat upholstery fabric, understanding the properties, advantages, and limitations of various materials is essential for B2B buyers. Here, we analyze four common materials used in automotive upholstery: Polyester, Vinyl, Leather, and Nylon. Each material has distinct characteristics that can influence the final product’s performance, cost, and suitability for different markets.

How Does Polyester Perform as an Upholstery Material?

Polyester is a synthetic fabric known for its durability and versatility. It exhibits excellent abrasion resistance, with some variants rated for over 100,000 double rubs. Polyester is also resistant to fading, making it suitable for vehicles exposed to sunlight. However, it can be less breathable than natural fibers, which may affect comfort in hot climates.

Pros: Polyester is cost-effective, lightweight, and easy to clean, which makes it appealing for mass production. Its resistance to stains and moisture also adds to its longevity.

Cons: While durable, polyester can be less comfortable than other materials, particularly in extreme temperatures. Additionally, its environmental impact is a consideration, as it is derived from petroleum-based sources.

International Considerations: B2B buyers should ensure that polyester upholstery complies with local fire safety standards, such as the FMVSS 302 in the U.S. or similar regulations in Europe and Africa.

What Are the Benefits of Vinyl Upholstery?

Vinyl is another popular choice for automotive upholstery due to its water resistance and ease of maintenance. It offers a range of textures and colors, allowing for customization. Vinyl is often used in commercial vehicles and budget-friendly models due to its affordability.

Illustrative image related to automotive seat upholstery fabric

Pros: Vinyl is highly durable, resistant to spills, and can mimic the look of leather at a lower cost. It is also easy to clean, making it ideal for families or businesses.

Cons: Vinyl can be less breathable than other materials, leading to discomfort in hot climates. It may also crack or fade over time with prolonged exposure to sunlight.

International Considerations: Buyers should be aware of specific environmental regulations regarding the use of PVC in automotive applications, particularly in Europe, where there is a push for more sustainable materials.

Why Choose Leather for Automotive Upholstery?

Leather is synonymous with luxury and comfort, making it a sought-after material for high-end vehicles. It offers excellent durability and develops a unique patina over time, enhancing its aesthetic appeal.

Pros: Leather is breathable, providing comfort in varying temperatures, and its natural fibers offer a premium feel. It is also highly durable and resistant to wear.

Cons: The cost of leather can be significantly higher than synthetic options, and it requires regular maintenance to prevent cracking and drying out. Additionally, ethical considerations regarding animal welfare may impact its acceptance in certain markets.

International Considerations: Compliance with local regulations regarding animal products is crucial. Buyers should also consider the environmental impact of leather production and seek suppliers who adhere to sustainable practices.

How Does Nylon Compare as an Upholstery Material?

Nylon is a strong, synthetic fabric that offers excellent resilience and elasticity. It is often used in combination with other materials to enhance durability and comfort.

Pros: Nylon is resistant to abrasion and has a high tensile strength, making it suitable for high-traffic areas. It also dries quickly, which is beneficial for vehicles exposed to moisture.

Cons: Nylon can be more expensive than polyester and may not have the same luxurious feel as leather or vinyl. Its susceptibility to UV damage can also limit its lifespan if not treated properly.

International Considerations: B2B buyers should ensure that nylon upholstery meets international standards for flame retardancy and durability, particularly in regions with stringent regulations.

Summary Table of Material Selection

| Material | Typical Use Case for automotive seat upholstery fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Mass-produced vehicles, family cars | Durable, stain-resistant | Less breathable, environmental impact | Low |

| Vinyl | Commercial vehicles, budget-friendly models | Water-resistant, easy to clean | Less breathable, may crack over time | Low |

| Leather | Luxury vehicles, high-end models | Premium feel, breathable | High cost, requires maintenance | High |

| Nylon | High-traffic vehicles, performance cars | Strong, abrasion-resistant | Higher cost, UV susceptibility | Medium |

This guide provides a comprehensive overview of the strategic material selection for automotive seat upholstery fabric, helping B2B buyers make informed decisions based on performance, cost, and compliance with international standards.

Illustrative image related to automotive seat upholstery fabric

In-depth Look: Manufacturing Processes and Quality Assurance for automotive seat upholstery fabric

What Are the Key Stages in the Manufacturing Process of Automotive Seat Upholstery Fabric?

The manufacturing process for automotive seat upholstery fabric is intricate, requiring precision and attention to detail at every stage. The process can be broken down into four main stages: material preparation, forming, assembly, and finishing.

-

Material Preparation: The journey begins with the selection and preparation of raw materials. Common materials include synthetic fibers like polyester and nylon, chosen for their durability and resistance to wear and tear. The materials undergo a series of treatments to enhance properties such as flame retardancy, UV stability, and abrasion resistance. For instance, fabrics may be treated with chemical coatings to meet international safety standards, making them suitable for automotive applications.

-

Forming: In this stage, the prepared materials are cut into specific shapes and sizes according to design specifications. Advanced techniques such as computer-aided design (CAD) are often utilized to ensure precision. Laser cutting technology may also be employed for intricate patterns, minimizing material waste and ensuring a perfect fit for various seat designs.

-

Assembly: The assembly phase involves stitching and bonding the cut fabric pieces together. Industrial sewing machines, often equipped with specialized attachments, are used to create seams that can withstand the rigors of daily use. Techniques such as ultrasonic welding may also be applied for certain fabric types, providing a seamless finish that enhances durability.

-

Finishing: The final stage is where the upholstery fabric is treated to achieve its desired aesthetic and functional characteristics. This may include dyeing, printing, and applying protective coatings. Quality assurance checks are critical here to ensure that the final product meets both the aesthetic expectations and the rigorous performance standards required for automotive use.

How Is Quality Assurance Implemented in the Production of Automotive Seat Upholstery Fabric?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that the final product meets industry standards and customer expectations. Here’s how quality is maintained throughout the production lifecycle:

-

International Standards Compliance: Manufacturers often adhere to international quality standards such as ISO 9001, which sets out the criteria for a quality management system. Compliance with these standards demonstrates a commitment to quality and continuous improvement. In addition, industry-specific standards such as the European CE mark and American API (American Petroleum Institute) standards may apply, particularly concerning fire safety and material performance.

-

Quality Control Checkpoints: Implementing quality control measures at various checkpoints is essential:

– Incoming Quality Control (IQC): This initial inspection phase involves evaluating raw materials upon arrival to ensure they meet specifications.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor processes and detect any deviations from quality standards.

– Final Quality Control (FQC): The finished products undergo a thorough inspection before shipment to verify they meet all defined standards and specifications. -

Common Testing Methods: Various testing methods are employed to evaluate the quality of automotive upholstery fabrics. These may include:

– Abrasion Resistance Testing: Measures the durability of the fabric against wear.

– Flame Retardancy Testing: Ensures that the fabric meets safety standards for fire resistance.

– Colorfastness Testing: Evaluates how well the fabric retains its color under exposure to light and washing.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several strategies to ensure that suppliers maintain high standards:

-

Supplier Audits: Conducting regular audits of suppliers’ manufacturing facilities can provide insight into their quality management practices. Audits should assess compliance with international standards and the effectiveness of their quality control processes.

-

Quality Assurance Reports: Requesting detailed quality assurance reports can help buyers understand the methodologies employed by suppliers. These reports should outline testing results, compliance with standards, and any corrective actions taken in response to quality issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These inspections can verify that the manufacturing practices and final products align with international quality standards.

-

Certifications and Accreditations: Buyers should check for relevant certifications and accreditations that demonstrate a supplier’s commitment to quality. Certifications from recognized bodies can serve as a benchmark for quality assurance in the manufacturing process.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control nuances is particularly important for international B2B buyers. Here are some considerations specific to regions such as Africa, South America, the Middle East, and Europe:

-

Regional Standards Variability: Quality standards may vary significantly across regions. Buyers must be aware of local regulations and standards that apply to automotive upholstery fabrics in their specific markets. Understanding these differences can prevent compliance issues and enhance market entry strategies.

-

Supply Chain Transparency: Establishing transparency throughout the supply chain is essential for maintaining quality. Buyers should seek suppliers who are willing to share their sourcing practices and provide insights into their quality control measures.

-

Cultural Considerations: Cultural differences can impact communication and quality expectations. B2B buyers should ensure clear communication of quality requirements and engage in regular dialogue with suppliers to align expectations.

-

Logistics and Transportation: The transportation of materials and finished products can affect quality. Buyers should consider logistics partners who understand the importance of maintaining quality during transit and storage.

Conclusion

Understanding the manufacturing processes and quality assurance measures in the production of automotive seat upholstery fabric is essential for B2B buyers. By familiarizing themselves with the key stages of manufacturing, quality control measures, and verification strategies, buyers can make informed decisions that ensure the procurement of high-quality materials that meet both their specifications and international standards. This knowledge not only aids in selecting reliable suppliers but also fosters long-term partnerships built on trust and quality assurance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive seat upholstery fabric’

In this guide, we provide a practical step-by-step checklist tailored for B2B buyers seeking to procure automotive seat upholstery fabric. This comprehensive approach ensures that you make informed decisions, maximizing quality and value while minimizing risks.

Step 1: Define Your Technical Specifications

Before you start sourcing, it’s crucial to outline the specific requirements for your upholstery fabric. Consider factors such as material type (e.g., polyester, vinyl, or leather), flame retardancy ratings, and abrasion resistance. Each specification will impact the durability, safety, and aesthetic of the final product.

- Performance Characteristics: Identify the expected usage conditions and wear levels. Fabrics with higher abrasion resistance are essential for vehicles subjected to heavy use.

- Regulatory Compliance: Ensure your specifications meet industry standards, such as MVSS302 for flame retardancy.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers who specialize in automotive upholstery fabrics. Look for companies with a strong reputation and positive reviews in your target regions, such as Africa, South America, the Middle East, and Europe.

- Supplier Credentials: Verify the supplier’s industry experience, certifications, and customer testimonials.

- Product Range: Ensure they offer a variety of materials and styles that fit your technical specifications.

Step 3: Evaluate Potential Suppliers

Once you have a shortlist, assess each supplier’s capabilities and reliability. Request comprehensive company profiles and case studies that demonstrate their experience with similar projects.

- References: Ask for references from clients in your industry or region to gauge satisfaction levels.

- Samples: Request fabric samples to evaluate quality and suitability for your needs.

Step 4: Negotiate Terms and Pricing

Engage in negotiations to establish pricing, payment terms, and delivery timelines. Understanding the total cost of ownership, including shipping and customs fees, is vital for budget management.

- Bulk Discounts: Inquire about pricing structures for bulk orders, which can significantly reduce costs.

- Payment Flexibility: Discuss payment options that align with your cash flow requirements.

Step 5: Verify Quality Control Processes

Quality assurance is critical when sourcing upholstery fabric. Ensure the supplier has robust quality control processes to monitor fabric production and handling.

- Testing Protocols: Confirm that the fabrics undergo appropriate testing for durability, colorfastness, and safety standards.

- Return Policies: Understand the supplier’s policies regarding defective products or unsatisfactory quality.

Step 6: Finalize Contracts and Agreements

Once you are satisfied with the supplier’s capabilities, finalize the contract details. Ensure that all terms discussed, including pricing, delivery schedules, and quality expectations, are documented.

- Legal Review: Consider having legal counsel review the contract to safeguard your interests.

- Clarity: Ensure that the contract includes clear terms for resolving disputes or addressing performance issues.

Step 7: Establish a Communication Plan

Effective communication is essential throughout the sourcing process. Establish a plan for regular updates and feedback with your supplier to ensure alignment.

- Point of Contact: Designate a primary contact person for managing communications on both sides.

- Progress Reports: Schedule regular check-ins to discuss production timelines and any potential issues.

By following this checklist, B2B buyers can confidently navigate the procurement of automotive seat upholstery fabric, ensuring a successful sourcing experience that meets their specific needs and standards.

Comprehensive Cost and Pricing Analysis for automotive seat upholstery fabric Sourcing

What Are the Key Cost Components in Automotive Seat Upholstery Fabric Sourcing?

When sourcing automotive seat upholstery fabric, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of fabric—whether it be polyester, nylon, or more specialized materials like vinyl—significantly influences costs. Premium fabrics with enhanced features, such as flame retardancy or UV stability, typically command higher prices. Bulk purchasing can often reduce costs per unit.

-

Labor: Labor costs encompass the workforce involved in fabric production, cutting, sewing, and finishing. Regions with lower labor costs may offer competitive pricing, but ensure that quality standards are met.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can lower overhead costs, allowing for more competitive pricing.

-

Tooling: Initial setup costs for specialized machinery and tools can be substantial, particularly for custom orders. These costs may be amortized over larger production runs, impacting per-unit pricing.

-

Quality Control (QC): Implementing stringent QC measures ensures fabric meets industry standards, which may raise initial costs but can prevent costly returns and reputation damage.

-

Logistics: Shipping costs can fluctuate based on distance, volume, and mode of transport. For international buyers, understanding Incoterms is vital as they define the responsibilities of buyers and sellers in shipping arrangements.

-

Margin: Suppliers typically apply a profit margin to cover their costs and ensure sustainability. This margin can vary widely based on market conditions and the supplier’s positioning strategy.

How Do Price Influencers Impact Automotive Upholstery Fabric Costs?

Several factors can influence the pricing of automotive seat upholstery fabric. Understanding these price influencers can aid buyers in making informed decisions.

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQ) that can significantly affect pricing. Larger orders typically lead to discounts, making it advantageous for buyers who can commit to higher volumes.

-

Specifications and Customization: Customized fabrics tailored to specific automotive models or design requirements may incur additional costs. Buyers should weigh the benefits of customization against budget constraints.

-

Material Quality and Certifications: Fabrics that meet specific certifications for flame retardancy, UV resistance, and environmental sustainability may come at a premium but provide long-term benefits in safety and durability.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a proven track record may charge more but offer assurances in quality and delivery timelines.

-

Incoterms: The chosen Incoterms can affect the total landed cost. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) determine who bears shipping costs and risks, influencing overall pricing.

What Are the Best Negotiation and Cost-Efficiency Tips for International Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency in sourcing automotive upholstery fabrics.

Illustrative image related to automotive seat upholstery fabric

-

Negotiate Terms: Always engage suppliers in negotiations regarding pricing, payment terms, and delivery schedules. Building a strong relationship can lead to better deals in the long run.

-

Total Cost of Ownership (TCO): Consider not only the initial purchase price but also the TCO, which includes shipping, handling, and potential rework costs. A lower initial price may lead to higher expenses later if quality is compromised.

-

Leverage Local Knowledge: Utilize local agents or distributors who understand the regional market dynamics and can help navigate cultural and logistical challenges.

-

Stay Informed on Pricing Trends: Monitor market trends and fabric pricing fluctuations to time purchases strategically. Understanding seasonal variations in pricing can yield savings.

-

Request Samples: Before committing to large orders, request samples to evaluate quality and suitability. This step can prevent costly mistakes and ensure the chosen fabric meets project requirements.

Disclaimer

Prices mentioned in various references are indicative and may vary based on supplier, location, and market conditions. Always confirm current pricing and terms with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing automotive seat upholstery fabric With Other Solutions

Exploring Alternatives to Automotive Seat Upholstery Fabric

In the automotive industry, selecting the right upholstery material is crucial for both functionality and aesthetics. While automotive seat upholstery fabric is a popular choice, there are alternative solutions available that may better suit specific needs or applications. This analysis will compare automotive seat upholstery fabric with two viable alternatives: leather upholstery and vinyl upholstery.

| Comparison Aspect | Automotive Seat Upholstery Fabric | Leather Upholstery | Vinyl Upholstery |

|---|---|---|---|

| Performance | High abrasion resistance, comfort | Excellent durability, luxury feel | Good durability, easy to clean |

| Cost | Moderate to high | High | Low to moderate |

| Ease of Implementation | Requires skilled labor for installation | Complex installation process | Easier to install |

| Maintenance | Moderate upkeep | Requires regular conditioning | Low maintenance, easy to wipe clean |

| Best Use Case | Versatile for various vehicle types | High-end vehicles, luxury applications | Budget-friendly, utility vehicles |

What Are the Advantages and Disadvantages of Leather Upholstery?

Leather upholstery is often synonymous with luxury in the automotive world. Its primary advantages include exceptional durability and a high-end appearance, making it a popular choice for premium vehicles. However, the cost of leather is significantly higher than that of automotive seat upholstery fabric, which may deter budget-conscious buyers. Additionally, leather requires regular maintenance, such as conditioning, to prevent cracking and wear over time. For B2B buyers targeting luxury markets or high-end vehicle restorations, leather may be the preferred option despite its higher price tag and upkeep requirements.

How Does Vinyl Upholstery Compare to Automotive Seat Upholstery Fabric?

Vinyl upholstery presents a budget-friendly alternative to traditional automotive seat upholstery fabric. It is known for its easy maintenance and resistance to stains, making it ideal for utility vehicles or family cars. Vinyl can be easily wiped clean, which is a significant advantage for high-traffic vehicles. However, it typically lacks the comfort and breathability offered by fabric options. While vinyl is less expensive, it may not provide the same aesthetic appeal or long-term durability as automotive fabrics or leather. Businesses focused on cost-effective solutions may find vinyl upholstery to be an attractive alternative.

Making an Informed Decision for Your Upholstery Needs

When choosing the right upholstery solution, B2B buyers should consider their specific requirements, including budget constraints, vehicle type, and desired aesthetic. Automotive seat upholstery fabric offers a balance of comfort, performance, and versatility, making it suitable for a wide range of applications. Conversely, leather upholstery serves high-end markets with its luxurious appeal, while vinyl upholstery caters to cost-sensitive buyers seeking practicality. By carefully evaluating these alternatives, businesses can make informed decisions that align with their operational goals and customer expectations.

Illustrative image related to automotive seat upholstery fabric

Essential Technical Properties and Trade Terminology for automotive seat upholstery fabric

What Are the Key Technical Properties of Automotive Seat Upholstery Fabric?

When selecting automotive seat upholstery fabric, understanding its technical properties is crucial for ensuring durability, comfort, and compliance with industry standards. Here are some essential specifications:

-

Material Composition

Automotive upholstery fabrics are typically made from synthetic materials such as polyester, nylon, or vinyl. The choice of material affects durability, comfort, and maintenance. For instance, polyester offers excellent abrasion resistance and is easy to clean, making it ideal for high-traffic vehicles. -

Abrasion Resistance

Measured in double rubs (DR), abrasion resistance indicates how well a fabric can withstand wear and tear. A rating of 50,000 DR or higher is generally considered suitable for automotive applications. This property is vital for B2B buyers as it ensures the longevity of the upholstery, reducing the frequency of replacements. -

Flame Retardancy

Compliance with flame retardancy standards, such as MVSS 302 or California T.B. 117, is essential for automotive fabrics. This specification ensures that the materials used in upholstery do not ignite easily, enhancing passenger safety. Buyers must confirm that their chosen fabric meets these standards, especially in regions with stringent safety regulations. -

Lightfastness

This property refers to a fabric’s ability to resist fading when exposed to sunlight. Lightfastness is typically rated on a scale of 1 to 8, with higher ratings indicating better performance. For automotive applications, fabrics with a lightfastness rating of 4 or higher are preferred, as they maintain aesthetic appeal over time, which is crucial for resale value. -

Width and Roll Size

Upholstery fabrics come in various widths, commonly around 54-57 inches, and are sold in rolls of varying lengths. Understanding the width and roll size is essential for B2B buyers to ensure they purchase enough material for their projects without excessive waste.

What Are Common Trade Terms in Automotive Upholstery Fabric Procurement?

Navigating the procurement process involves familiarity with specific industry terminology. Here are some key trade terms that are essential for B2B buyers:

-

OEM (Original Equipment Manufacturer)

OEM refers to parts or materials that are made by the same company that produced the original components of the vehicle. For upholstery fabrics, OEM materials ensure compatibility and quality, making them a preferred choice for manufacturers and restorers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory costs and production planning. Suppliers may set MOQs to ensure profitability, so buyers should negotiate terms that align with their needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. B2B buyers should prepare detailed RFQs to receive accurate quotes, ensuring they consider all necessary specifications and quantities. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers engaged in cross-border procurement, as they clarify shipping, risk, and payment obligations. -

Lead Time

This term refers to the time taken from placing an order to receiving the goods. Understanding lead times is vital for effective supply chain management, allowing B2B buyers to plan their production schedules and inventory levels accordingly.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right automotive seat upholstery fabric that meets both performance and regulatory standards.

Navigating Market Dynamics and Sourcing Trends in the automotive seat upholstery fabric Sector

What Are the Key Trends Shaping the Automotive Seat Upholstery Fabric Market?

The automotive seat upholstery fabric market is currently experiencing dynamic shifts driven by a blend of consumer preferences, technological advancements, and regulatory changes. Global demand for high-performance, durable, and aesthetically pleasing materials is on the rise. This is particularly true in regions like Africa, South America, the Middle East, and Europe, where an increasing middle class is driving demand for vehicles that combine comfort and style.

Illustrative image related to automotive seat upholstery fabric

One significant trend is the integration of smart textiles, which enhance functionality by incorporating features such as temperature regulation and moisture-wicking properties. Additionally, the shift toward electric and hybrid vehicles is influencing fabric choices, with manufacturers prioritizing lightweight materials that contribute to energy efficiency. Innovations in digital printing technology are also enabling more customized designs, allowing brands to respond quickly to market trends.

B2B buyers should be aware of the growing importance of supply chain transparency. Buyers are increasingly seeking suppliers who can provide detailed information about their sourcing practices and material origins. This trend is driven by consumer demand for authenticity and brand integrity, making it essential for suppliers to adopt digital platforms for streamlined communication and data sharing.

How Is Sustainability Impacting the Sourcing of Automotive Seat Upholstery Fabrics?

Sustainability is becoming a central tenet in the sourcing of automotive seat upholstery fabrics. As consumers become more environmentally conscious, businesses are prioritizing eco-friendly materials and ethical sourcing practices. This shift is particularly relevant for international B2B buyers who are keen to align with global sustainability goals.

The environmental impact of traditional upholstery materials, such as synthetic fabrics derived from petroleum, has prompted a move toward alternatives like recycled polyester and bio-based fabrics. These materials not only reduce waste but also lower carbon footprints, making them attractive options for manufacturers looking to enhance their green credentials.

Illustrative image related to automotive seat upholstery fabric

Furthermore, certifications such as Global Recycle Standard (GRS) and OEKO-TEX® Standard 100 are becoming essential for suppliers aiming to prove the sustainability of their products. Buyers are encouraged to seek partnerships with manufacturers who have these certifications, ensuring that they are sourcing materials that meet the highest environmental and ethical standards. By prioritizing sustainability, B2B buyers can enhance their brand reputation and appeal to a growing market segment that values corporate responsibility.

What Is the Historical Context of Automotive Seat Upholstery Fabric?

The evolution of automotive seat upholstery fabric has been marked by significant technological advancements and shifting consumer preferences. In the early days of the automotive industry, materials were primarily utilitarian, focusing on durability and basic comfort. As vehicles became more than just transportation means, the demand for aesthetics and luxury grew, leading to the introduction of varied upholstery materials such as leather, vinyl, and fabrics designed for enhanced comfort.

In recent decades, the focus has shifted from purely functional materials to those that also offer innovative features, such as stain resistance and ease of maintenance. As the automotive industry continues to evolve, particularly with the rise of electric vehicles and smart technology, upholstery fabrics are expected to incorporate even more advanced functionalities, ensuring a comfortable and modern driving experience. This historical context underscores the importance of understanding market dynamics and sourcing trends for B2B buyers aiming to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of automotive seat upholstery fabric

-

How do I choose the right automotive seat upholstery fabric for my needs?

Selecting the ideal automotive seat upholstery fabric involves assessing factors like durability, aesthetics, and compliance with safety standards. Look for materials with high abrasion resistance and flame retardancy ratings to ensure longevity and safety. Additionally, consider the intended use—luxury vehicles may require plush fabrics like velvet, while commercial applications might prioritize durability and ease of cleaning. It’s also essential to verify the lightfastness of the fabric, especially in regions with high UV exposure. -

What types of upholstery fabrics are best suited for automotive applications?

For automotive applications, the best upholstery fabrics include synthetic materials like polyester and vinyl, which offer durability and ease of maintenance. Velvet and suede can provide a luxury feel but may require more care. Additionally, consider fabrics that are treated for UV stability and flame resistance, as these features enhance safety and longevity. Always check for specifications relevant to your region, especially if you’re sourcing from international suppliers. -

What are the minimum order quantities (MOQs) for automotive seat upholstery fabrics?

Minimum order quantities (MOQs) can vary significantly based on the supplier and the type of fabric. Generally, MOQs can range from 10 to 50 yards for standard fabrics, while specialty materials may require larger orders. When sourcing internationally, it’s crucial to clarify MOQs early in the negotiation process to ensure they align with your project needs and budget constraints. -

How can I vet a supplier for automotive upholstery fabrics?

To vet a supplier effectively, start by checking their industry reputation through reviews and testimonials from previous clients. Ensure they have certifications for quality standards relevant to automotive applications, such as ISO or ASTM certifications. Request samples of their fabrics to assess quality firsthand and inquire about their production capabilities, lead times, and compliance with international trade regulations. Establishing clear communication regarding your expectations will also help gauge their reliability. -

What payment terms should I expect when sourcing upholstery fabrics internationally?

Payment terms for international sourcing can vary widely, but common practices include upfront payments, letters of credit, or staggered payments based on delivery milestones. Always negotiate terms that provide a balance of security for both parties. It’s prudent to use secure payment methods, such as PayPal or escrow services, especially when dealing with new suppliers. Additionally, ensure that the payment terms are clearly outlined in the purchase agreement to avoid misunderstandings. -

What quality assurance measures should I implement when purchasing upholstery fabrics?

Implementing quality assurance measures involves setting clear specifications and performance standards for the fabrics you purchase. Request certifications for flame retardancy, abrasion resistance, and UV stability. Conduct thorough inspections of samples prior to placing bulk orders and consider using third-party inspection services for larger shipments. Establish a return policy for defective goods to safeguard your investment and maintain quality control throughout the sourcing process. -

How does international shipping impact my upholstery fabric sourcing?

International shipping can significantly impact your sourcing strategy, affecting costs, delivery times, and inventory management. Consider shipping options that align with your budget and timelines, such as air freight for expedited delivery or sea freight for cost-effectiveness. Be aware of customs regulations and potential duties or tariffs that could apply to your shipments, especially when importing into regions like Africa or South America. Collaborating with a reliable logistics partner can streamline this process. -

Can I customize the upholstery fabric for my automotive projects?

Yes, many suppliers offer customization options for automotive upholstery fabrics, including color, pattern, and material composition. Customization allows you to align the fabric with your brand identity or specific project requirements. However, be mindful that customization may come with higher MOQs and longer lead times. Discuss your needs with suppliers upfront to explore available options and understand the implications for pricing and delivery schedules.

Top 9 Automotive Seat Upholstery Fabric Manufacturers & Suppliers List

1. A·1 Foam & Fabrics – 555 Portfolio Tweed Collection

Domain: a1foamandfabrics.com

Registered: 2003 (22 years)

Introduction: Automotive Car Interior Fabrics available at A·1 Foam & Fabrics include a variety of materials such as Velvets, Suedes, and Tweeds suitable for automotive, RV, and trucking applications. Key products include: 1. 555 Portfolio Tweed Collection – Abrasion resistance: 50,000+ DR #10 Cotton Duck, Flame Retardancy: California T.B. 117 Section E-Class 1 (Pass), NFPA 260-Class 1 (Pass), UFAC Class 1 (Pas…

2. Midwest Fabrics – Automotive Upholstery Solutions

Domain: midwestfabrics.com

Registered: 1999 (26 years)

Introduction: Automotive Upholstery Fabric, Original OEM Detroit Number Fabrics, GM, Ford, Chrysler, Honda, Toyota, Mazda, Nissan OEM Fabric, Heavy Duty Flock Fabric, Various Culp Contract Fabrics, Marine Vinyl, Automotive Vinyl, Upholstery Supplies, Automotive Carpets, Headliner Fabric, Upholstery Foam, Upholstery Adhesives.

3. OEM Auto Fabric – Vintage and Modern Upholstery Materials

Domain: oemautofabric.com

Registered: 2018 (7 years)

Introduction: Original Auto Fabric offers a wide selection of vintage and new auto upholstery materials, including specialty car cloths, marine and automotive vinyls, custom carpets, floor mats, and vinyl tops. They provide over 230 licensed logos for floor mats, molded carpet to OEM specifications, and specialize in vinyl tops such as Stayfast Top Fabric for brands like Buick, Cadillac, Dodge, and Ford. The in…

4. Fabric Wholesale Direct – Automotive Fabric

Domain: fabricwholesaledirect.com

Registered: 2014 (11 years)

Introduction: Automotive Fabric By The Yard | Free Shipping On Orders $99+ | Various fabric types including Broadcloth, Canvas, Denim, Faux Fur, Neoprene, and more | Applications include Automotive, Upholstery, Marine, and Outdoor Performance | Content options include Acrylic, Cotton, Nylon, Polyester, and more | Colors available in Transparent, White, Pink, Red, Blue, Black, and more | Patterns include Abstrac…

5. SMS Auto Fabrics – Classic Auto Interiors

Domain: smsautofabrics.com

Registered: 2000 (25 years)

Introduction: SMS Auto Fabrics offers a wide selection of classic auto interiors, including cloth, vinyl, leather, door panels, headliners, vinyl tops, and carpets for American cars from the 1930s to the 1990s. Featured products include various plaid fabrics for Chevrolet and Porsche models, as well as door panels for models such as the 1968 Dodge Polara Convertible, 1970 Chevrolet Malibu Sport Coupe, and 1963 …

6. Miami Corporation – Original Cloth Auto Upholstery Fabrics

Domain: miamicorp.com

Registered: 2001 (24 years)

Introduction: This company, Miami Corporation – Original Cloth Auto Upholstery Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Sailrite – Vinyl Automotive Upholstery Fabrics

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Our Favorite Vinyl Automotive Upholstery Fabrics – Sailrite offers durable, waterproof, and easy-to-clean vinyl fabrics ideal for reupholstering car seats. Vinyl has evolved to provide a luxurious look and feel, resembling real leather at a more economical price. Key benefits include:

1. Easy to clean

2. Highly abrasion resistant

3. Highly UV resistant

4. Waterproof/water resistant

5. More economi…

8. JJ Auto Fabrics – Automotive and Marine Vinyl Supplies

Domain: jjautofabrics.com

Registered: 2001 (24 years)

Introduction: Automotive-Marine Vinyl and Upholstery Supplies including Classic Automotive Vinyl, Heavy Weight Vinyl, SoftSide/SoftTouch Automotive Vinyl, Corinthian, Longitude, Sierra, Monticello, Milled Pebble, Soho, Rawhide, Oxen, Heidi, Ex Madrid, G-GRAIN, Verona, Wallaby, Ezy Vinyls, Knit Back Automotive Vinyl, Enduratex/CGPC, Highland, Perforated Palma, Plain Rosette, Morbern, Volkswagen Woven, Futura Xtr…

9. Kovi Fabrics – Automotive Upholstery

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Automotive Upholstery: Durable, Affordable Car Interior Fabric. High Performance Fabric that is waterproof, spill proof, stain proof, and weatherproof. Features anti-microbial properties. Available in a variety of styles including prints, patterns, and solids. Vinyl options include matte, glossy, distressed, animal hide, and reptile replications. Premium selection backed by a lifetime warranty. Fr…

Strategic Sourcing Conclusion and Outlook for automotive seat upholstery fabric

In the competitive landscape of automotive upholstery fabric, strategic sourcing is essential for international B2B buyers looking to enhance product quality and customer satisfaction. By prioritizing materials that exhibit superior durability, flame retardancy, and aesthetic appeal, buyers can ensure their offerings stand out in the market. Key insights include the importance of sourcing from reliable suppliers who provide a diverse range of options, from classic textiles to innovative synthetic materials, catering to various automotive segments.

Furthermore, understanding regional preferences and compliance standards—such as flame retardancy regulations in Europe and durability requirements in Africa—can significantly impact procurement decisions. As the automotive industry continues to evolve, staying informed about trends and advancements in upholstery materials will empower businesses to make data-driven choices that align with market demands.

Looking ahead, international buyers from Africa, South America, the Middle East, and Europe are encouraged to leverage strategic sourcing to build resilient supply chains. By fostering partnerships with reputable fabric suppliers, companies can enhance their product offerings and meet the growing expectations of consumers for quality and sustainability. Engage with suppliers today to explore innovative upholstery solutions that can drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.