Introduction: Navigating the Global Market for chamois leather cloth

In the dynamic landscape of global trade, sourcing high-quality chamois leather cloth presents unique challenges for B2B buyers. The key lies not only in finding a reliable supplier but also in understanding the diverse applications and specifications that genuine chamois leather offers. This guide serves as a comprehensive resource, diving deep into the various types of chamois leather available, their applications across industries, and the critical criteria for vetting suppliers.

International buyers from regions such as Africa, South America, the Middle East, and Europe, including markets like Brazil and Nigeria, will find actionable insights tailored to their specific needs. This guide addresses the nuances of pricing structures, ensuring that you can make informed purchasing decisions while navigating the complexities of international logistics and compliance standards.

Understanding the importance of quality in chamois leather cloth is paramount; it is not merely about cost but about investing in products that enhance performance and reliability. By equipping yourself with the knowledge provided in this guide, you will be empowered to select the best products that meet your business objectives, ensuring a competitive edge in your respective markets. Whether you’re in automotive care, household cleaning, or industrial applications, this guide is your pathway to effective sourcing and strategic purchasing.

Table Of Contents

- Top 3 Chamois Leather Cloth Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for chamois leather cloth

- Understanding chamois leather cloth Types and Variations

- Key Industrial Applications of chamois leather cloth

- 3 Common User Pain Points for ‘chamois leather cloth’ & Their Solutions

- Strategic Material Selection Guide for chamois leather cloth

- In-depth Look: Manufacturing Processes and Quality Assurance for chamois leather cloth

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘chamois leather cloth’

- Comprehensive Cost and Pricing Analysis for chamois leather cloth Sourcing

- Alternatives Analysis: Comparing chamois leather cloth With Other Solutions

- Essential Technical Properties and Trade Terminology for chamois leather cloth

- Navigating Market Dynamics and Sourcing Trends in the chamois leather cloth Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of chamois leather cloth

- Strategic Sourcing Conclusion and Outlook for chamois leather cloth

- Important Disclaimer & Terms of Use

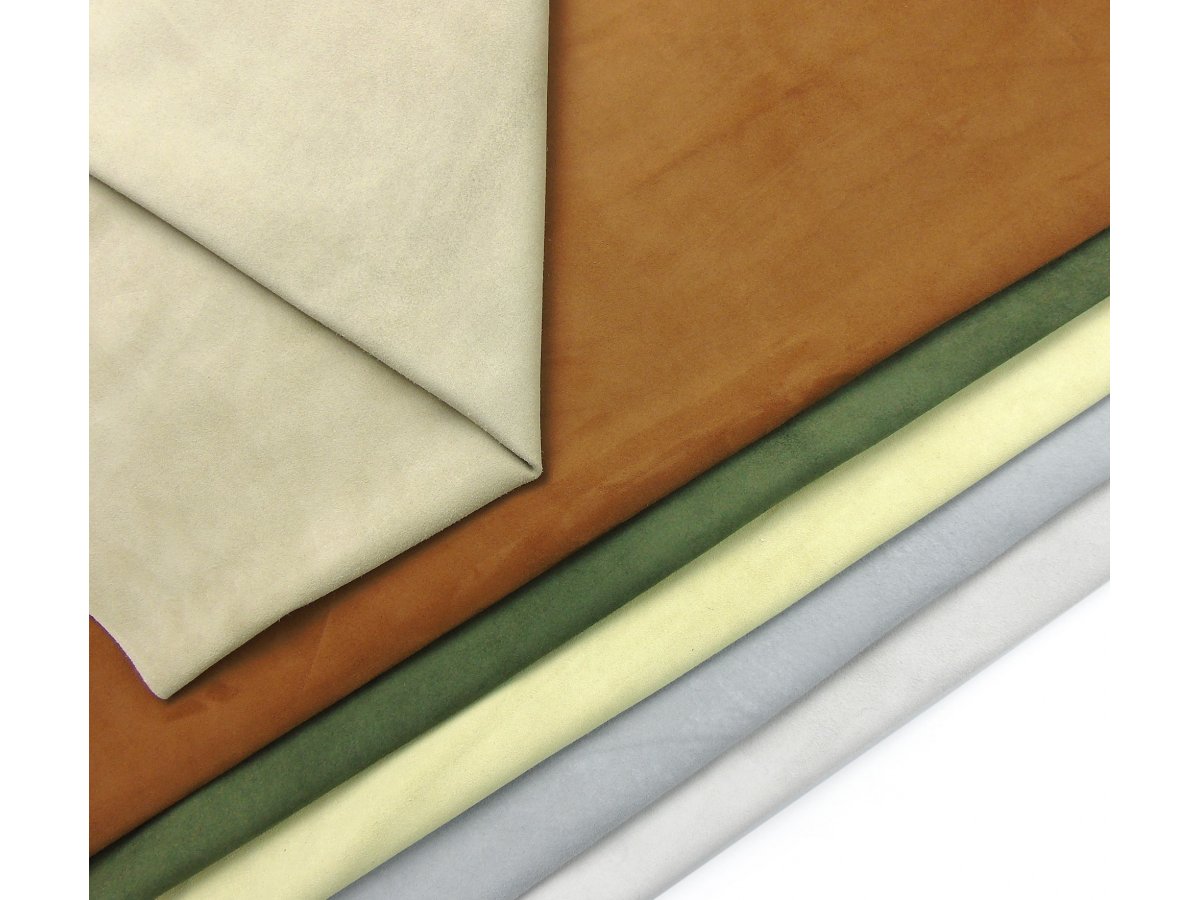

Understanding chamois leather cloth Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Genuine Chamois Leather | 100% cod oil tanned, natural softness, high absorbency | Automotive detailing, high-end cleaning | Pros: Superior absorbency, natural shine; Cons: Higher cost compared to synthetics. |

| Pittards Dry-Soft Chamois | Unique tanning process for soft drying, anti-microbial tech | Automotive, household cleaning | Pros: Long-lasting softness, prevents microbial buildup; Cons: May be pricier due to technology. |

| Chamois synthétique | Made from polyester or other synthetic materials | Budget-conscious cleaning, car care | Pros: Cost-effective, lightweight; Cons: Lower absorbency, potential for smearing. |

| Wash Leather Chamois | Biodegradable, highly absorbent, available in various sizes | Household cleaning, window care | Pros: Eco-friendly, versatile sizing; Cons: Natural variations may affect consistency. |

| Full Skin Chamois | Larger pieces with natural skin shape, premium quality | High-end automotive, specialty cleaning | Pros: Ideal for large surfaces, premium quality; Cons: Requires proper care and maintenance. |

What Are the Key Characteristics of Genuine Chamois Leather?

Genuine chamois leather is renowned for its luxurious feel and exceptional absorbency. Tanned with cod oil, it is soft, pliable, and capable of absorbing up to six times its weight in water. This type is ideal for automotive detailing and high-end cleaning applications, where a pristine finish is paramount. B2B buyers should consider its durability and effectiveness, despite the higher price point compared to synthetic alternatives.

How Does Pittards Dry-Soft Chamois Differ from Traditional Options?

Pittards Dry-Soft chamois incorporates an innovative tanning process that allows the leather to remain soft after drying. Enhanced with anti-microbial technology, this option prevents bacterial growth, ensuring longevity and freshness. It is particularly suitable for automotive and household cleaning tasks where streak-free results are essential. Buyers should note that while it offers advanced features, it may come at a higher cost due to the specialized manufacturing process.

What Are the Benefits of Using Synthetic Chamois?

Synthetic chamois, typically made from polyester, provides a budget-friendly alternative to genuine leather. While it is lightweight and easy to maintain, its absorbency is inferior, which may lead to smearing on delicate surfaces. This type is commonly used in budget-conscious cleaning applications and is suitable for businesses looking to reduce costs. Buyers should weigh the trade-off between price and performance when considering synthetic options.

Why Choose Wash Leather Chamois for Eco-Friendly Cleaning?

Wash leather chamois are biodegradable and highly absorbent, making them a sustainable choice for various cleaning tasks. Available in different sizes, they are perfect for household cleaning and window care. While their natural properties provide versatility, variations in quality may occur due to the handmade nature of the product. B2B buyers focused on sustainability should consider this option for its eco-friendly benefits.

What Advantages Does Full Skin Chamois Offer for Specialized Applications?

Full skin chamois provides larger, premium-quality pieces ideal for extensive cleaning tasks, particularly in high-end automotive detailing. The natural skin shape allows for greater coverage and efficiency. However, proper care and maintenance are crucial to prolong its lifespan. Buyers looking for superior quality and performance in specialized cleaning should invest in full skin chamois, recognizing the need for commitment to care.

Key Industrial Applications of chamois leather cloth

| Industry/Sector | Specific Application of chamois leather cloth | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Car detailing and drying | Provides streak-free and efficient drying, enhancing vehicle aesthetics and customer satisfaction. | Quality assurance, thickness, and size options for different vehicle types. |

| Cleaning & Maintenance | Household cleaning and maintenance | Highly absorbent, non-abrasive, ideal for delicate surfaces, reducing the risk of scratches. | Eco-friendly sourcing, durability, and ease of cleaning. |

| Sports & Recreation | Sports equipment care | Maintains the quality of sports gear by preventing moisture damage and enhancing longevity. | Material integrity, resistance to mold and mildew, and size customization. |

| Fashion & Accessories | Leather goods production | Enhances product quality and appeal, providing a luxurious finish to leather items. | Sourcing from reputable tanneries, ensuring ethical practices and traceability. |

| Industrial & Manufacturing | Equipment maintenance | Effective for cleaning machinery and tools, ensuring operational efficiency and longevity. | Bulk purchasing options, compliance with international standards, and durability under heavy use. |

How is Chamois Leather Cloth Used in Automotive Applications?

In the automotive sector, chamois leather cloth is primarily utilized for car detailing and drying. Its unique absorbent properties allow it to soak up moisture effectively, delivering a streak-free finish that enhances the vehicle’s appearance. This is particularly important for businesses that offer car wash and detailing services, as satisfied customers are likely to return. When sourcing, buyers should consider factors such as the thickness of the chamois and size options suitable for various vehicle types to ensure optimal performance.

What Role Does Chamois Leather Cloth Play in Cleaning & Maintenance?

Chamois leather cloth is invaluable in the cleaning and maintenance industry, particularly for household applications. Its highly absorbent and non-abrasive nature makes it perfect for cleaning delicate surfaces, such as glass and polished wood, without leaving scratches. Businesses in this sector benefit from using chamois cloths as they enhance cleaning efficiency and reduce the risk of damage to surfaces. Buyers should prioritize eco-friendly sourcing and durability when selecting chamois products, especially in regions like Africa and South America, where sustainability is increasingly valued.

Why is Chamois Leather Essential for Sports & Recreation?

In the sports and recreation industry, chamois leather cloth is used to care for sports equipment, such as bicycles and golf clubs. Its moisture-absorbing capabilities help prevent rust and damage to gear, prolonging the life of expensive equipment. Businesses that sell or rent sports gear can enhance customer satisfaction by ensuring their products remain in top condition. When sourcing, companies should look for chamois cloth that resists mold and mildew, as these factors can be critical in humid climates often found in regions like Brazil and Nigeria.

How Does Chamois Leather Enhance Fashion & Accessories?

Chamois leather cloth plays a significant role in the fashion and accessories sector, particularly in the production of high-quality leather goods. Its luxurious texture and absorbency help achieve a superior finish on leather products, which can significantly boost their market appeal. Businesses in this industry must ensure they source chamois leather from reputable tanneries that uphold ethical practices, as consumers are becoming increasingly conscious of sustainability. Traceability in sourcing can also add value to the brand image, particularly in European markets.

What is the Importance of Chamois Leather in Industrial Applications?

In industrial and manufacturing contexts, chamois leather cloth is essential for equipment maintenance. It is used to clean machinery and tools effectively, preventing dirt accumulation that can hinder operational efficiency. For businesses operating in heavy industries, the durability and absorbent qualities of chamois cloth can lead to significant cost savings by extending the lifespan of equipment. When sourcing, companies should consider bulk purchasing options and ensure compliance with international standards to meet operational needs efficiently.

3 Common User Pain Points for ‘chamois leather cloth’ & Their Solutions

Scenario 1: The Challenge of Quality Assurance in Sourcing Chamois Leather

The Problem:

B2B buyers often face significant challenges when sourcing chamois leather due to the wide range of quality available in the market. Many suppliers may offer synthetic alternatives disguised as genuine chamois, leading to potential dissatisfaction and trust issues. Buyers need to ensure they are getting high-quality, authentic products that meet specific performance criteria, especially for applications in car detailing or high-end cleaning services. This is particularly crucial for companies operating in regions with varying standards for leather products, such as Africa and South America.

The Solution:

To mitigate the risk of sourcing inferior chamois leather, buyers should establish strong relationships with reputable suppliers who provide transparency about their products. It’s advisable to request samples before making bulk orders, allowing for direct evaluation of texture, absorbency, and durability. Additionally, buyers can look for certifications or testing reports from recognized institutions, such as the BLC Leather Technology Centre, to ensure that the leather meets international standards. Leveraging technology, such as digital tools for quality assessment, can also enhance the sourcing process by allowing buyers to verify the product’s characteristics before purchasing.

Scenario 2: Addressing Longevity and Maintenance Concerns

The Problem:

Another prevalent issue among B2B buyers is the longevity and maintenance of chamois leather products. After repeated use, many users report that their chamois leather cloths become hard, lose absorbency, or develop unpleasant odors. This can lead to additional costs for replacements and can affect customer satisfaction if the cloths do not perform as expected over time. Companies in the car care and cleaning sectors, where performance is critical, find this particularly frustrating.

The Solution:

To enhance the lifespan of chamois leather, buyers should implement proper care and maintenance protocols. Educating employees on how to clean and store chamois correctly can dramatically improve its longevity. For example, soaking the chamois in warm, soapy water before its first use helps soften the leather, while rinsing it thoroughly after each use prevents the build-up of dirt and grime. Additionally, recommending the use of products like Pittards Dry-Soft Chamois, which incorporates anti-microbial technology, can help maintain freshness and performance even after repeated washes. Establishing a regular maintenance schedule can further ensure that the cloths remain in optimal condition, reducing the need for frequent replacements.

Scenario 3: Navigating Price Sensitivity and Budget Constraints

The Problem:

B2B buyers frequently grapple with budget constraints that make it challenging to invest in high-quality chamois leather cloths. While cheaper synthetic options are available, they often do not offer the same performance or durability, leading to a false economy. Buyers in emerging markets, such as Nigeria and Brazil, may feel pressured to opt for lower-cost alternatives to meet financial targets, risking the quality of their offerings and customer satisfaction.

The Solution:

To balance quality with budget constraints, buyers should perform a thorough cost-benefit analysis when selecting chamois leather suppliers. Emphasizing the long-term savings associated with investing in high-quality products can help justify the initial higher cost. For example, while a genuine chamois may have a higher upfront price, its durability and superior performance can lead to lower replacement costs and enhanced customer satisfaction. Additionally, buyers can negotiate bulk purchasing agreements or explore private label options to reduce costs while ensuring quality. Creating a tiered purchasing strategy, where a mix of high-quality and budget-friendly options are included, can also be an effective way to manage expenditures without compromising on performance.

Illustrative image related to chamois leather cloth

Strategic Material Selection Guide for chamois leather cloth

What Are the Key Properties of Genuine Chamois Leather?

Genuine chamois leather, derived from sheepskin and tanned using cod oil, is renowned for its exceptional absorbency and softness. It can absorb up to six times its weight in water, making it ideal for applications requiring high moisture retention without leaving streaks or scratches. This natural material also exhibits good durability, maintaining its performance over extended use, especially in automotive and household cleaning applications.

What Are the Advantages and Disadvantages of Synthetic Chamois?

Synthetic chamois, typically made from polyurethane or other polymers, offers a cost-effective alternative to genuine leather. While it mimics the absorbent qualities of natural chamois, it often falls short in terms of durability and performance. Synthetic options tend to wear out faster and may not provide the same level of softness or water retention. However, they are generally easier to clean and maintain, making them suitable for high-volume applications where cost is a primary concern.

How Does Microfiber Compare to Traditional Chamois Leather?

Microfiber cloths are increasingly popular in the cleaning industry due to their fine fibers that can trap dirt and moisture effectively. They are lightweight, quick-drying, and can be manufactured in various sizes and shapes, making them versatile for different applications. However, microfiber lacks the natural properties of chamois leather, such as the ability to leave a streak-free finish and the luxurious feel. For buyers prioritizing eco-friendliness, microfiber is often considered a more sustainable option, though it may not meet the same performance standards as genuine leather.

What Should International Buyers Consider When Selecting Chamois Materials?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of compliance with local and international standards. For instance, adherence to ASTM, DIN, or JIS standards is crucial for ensuring product quality and safety. Additionally, regional preferences may influence material selection; for example, buyers in Europe may favor genuine chamois for its traditional use in luxury car care, while those in emerging markets might lean towards synthetic options due to cost constraints. Understanding these nuances can help buyers make informed decisions that align with market expectations.

| Matériau | Typical Use Case for chamois leather cloth | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Chamois Leather | Automotive drying, household cleaning | Exceptional absorbency and softness | Higher cost compared to synthetic options | Haut |

| Chamois synthétique | General cleaning, budget-friendly options | Cost-effective and easy to maintain | Lower durability and performance | Low |

| Microfibre | Versatile cleaning, dusting | Lightweight and quick-drying | Lacks the luxurious feel of leather | Medium |

| Pittards Dry-Soft | High-end automotive and household cleaning | Anti-microbial properties and durability | More expensive than standard chamois | Haut |

This strategic material selection guide provides a comprehensive overview of the various materials used in chamois leather cloth, helping international B2B buyers make informed decisions based on their specific needs and market conditions. Understanding the properties, advantages, and limitations of each material is essential for selecting the right product for your business applications.

In-depth Look: Manufacturing Processes and Quality Assurance for chamois leather cloth

What Are the Main Stages in the Manufacturing Process of Chamois Leather Cloth?

The manufacturing process of chamois leather cloth involves several critical stages, ensuring that the final product meets the high standards expected by B2B buyers. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality sheepskins, which are crucial for producing premium chamois leather. The skins are selected based on their thickness, texture, and overall quality. The tanning process typically employs 100% cod oil, which not only preserves the natural characteristics of the leather but also enhances its water-absorbent properties.

-

Forming: After tanning, the sheepskins are cut into specific shapes and sizes to create chamois leather cloth. This stage may involve both manual and automated processes, ensuring precision in dimensions. The cut pieces are then cleaned and prepped for the next stage.

-

Assembly: In this stage, the individual pieces of chamois leather may be assembled into larger products, such as cloths or pads. Depending on the end-use application, products can be stitched or bonded to enhance durability. This assembly phase is essential for maintaining the integrity of the leather and ensuring that it functions effectively in its intended purpose.

-

Finishing: The final stage involves several processes to enhance the aesthetic and functional qualities of the chamois leather. This includes conditioning treatments to maintain softness and flexibility, as well as surface treatments to improve water resistance. The finishing stage is also where quality checks are performed to ensure consistency and adherence to specifications.

How Is Quality Assurance Implemented in Chamois Leather Production?

Quality assurance is integral to the manufacturing of chamois leather cloth, ensuring that the products meet international standards and satisfy customer expectations.

-

International and Industry-Specific Standards: To maintain high quality, manufacturers often adhere to ISO 9001 standards, which focus on quality management systems. Additionally, certifications such as CE (Conformité Européenne) may apply, especially for products intended for the European market. These standards ensure that the manufacturing processes are consistent and that the final products are safe and effective for use.

-

Quality Control Checkpoints: Several quality control checkpoints are established throughout the manufacturing process:

-

Incoming Quality Control (IQC): At this stage, raw materials such as sheepskins are inspected for quality and suitability. This includes checking for defects and ensuring that the materials meet predefined standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, periodic inspections are conducted to monitor the processes and identify any deviations from quality standards. This proactive approach helps in minimizing defects and ensuring a consistent product.

-

Final Quality Control (FQC): Once the products are completed, they undergo a final inspection to verify that they meet all specifications. This includes assessing the overall appearance, texture, and functional properties of the chamois leather cloth.

What Testing Methods Are Commonly Used for Chamois Leather Quality Assurance?

To ensure the reliability and performance of chamois leather products, various testing methods are employed. These include:

-

Absorbency Tests: Measuring the water absorption capacity of chamois leather is crucial, as it is one of its key selling points. Products are tested to determine how much water they can absorb, which is vital for applications like car drying and cleaning.

-

Durability Tests: These tests evaluate the wear and tear resistance of the leather, ensuring it maintains its integrity over time. This is particularly important for B2B buyers who require long-lasting products.

-

Chemical Resistance Tests: Given that chamois leather may come into contact with various cleaning agents, testing for resistance to chemicals is essential. This ensures that the leather does not degrade when exposed to common substances.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial to ensuring product reliability. Here are some strategies to consider:

Illustrative image related to chamois leather cloth

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insight into their manufacturing processes and quality control measures. This includes evaluating their adherence to international standards and assessing their facilities.

-

Requesting Quality Control Reports: Suppliers should be able to provide detailed reports on their quality control practices, including results from testing and inspections. These documents can help buyers assess the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s products. This can be particularly beneficial for buyers who may not have the resources to conduct on-site audits.

-

Certifications Verification: Buyers should verify that suppliers hold relevant certifications, such as ISO 9001 or CE. This not only confirms adherence to quality standards but also enhances buyer confidence in the supplier’s capabilities.

What Are the Unique Quality Control Considerations for International B2B Buyers?

When dealing with international suppliers, B2B buyers must be aware of specific nuances in quality control practices:

-

Cultural Differences: Different regions may have varying standards of quality and manufacturing practices. Understanding these cultural differences can help buyers set realistic expectations.

-

Regulatory Compliance: Each market may have specific regulations governing the import and sale of chamois leather products. Buyers should ensure that their suppliers comply with these regulations to avoid legal complications.

-

Logistical Challenges: International shipping can impact product quality. Buyers should consider how products are packaged and transported to minimize the risk of damage during transit.

By being informed about the manufacturing processes and quality assurance measures for chamois leather cloth, B2B buyers can make better purchasing decisions, ensuring they receive products that meet their quality expectations and performance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chamois leather cloth’

When sourcing chamois leather cloth for your business, it’s essential to follow a structured approach to ensure you secure high-quality materials that meet your specific needs. This guide provides a practical checklist designed to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, outline the specific requirements for the chamois leather cloth you intend to purchase. Consider factors such as size, thickness, absorption capacity, and intended use (e.g., automotive, household, or industrial applications). By establishing clear specifications, you can streamline your search and ensure that potential suppliers can meet your demands.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of chamois leather cloth. Utilize industry directories, trade shows, and online platforms to find candidates. Look for suppliers with a strong track record, positive customer reviews, and a history of servicing businesses similar to yours.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers hold relevant certifications and adhere to international standards. Certifications such as ISO 9001 for quality management systems or BS 6715 for leather products can indicate a supplier’s commitment to quality and sustainability. This step is critical to ensure the materials you receive are reliable and compliant with safety regulations.

Step 4: Request Samples for Assessment

Before placing a bulk order, request samples of the chamois leather cloth to evaluate their quality. Examine the samples for factors like texture, durability, and absorption capability. Testing the samples in real-world conditions can provide insights into how well they will perform in your specific applications.

Step 5: Inquire About Production Capabilities

Understanding a supplier’s production capabilities is vital, especially if your business requires large quantities or custom specifications. Ask about their manufacturing processes, lead times, and ability to scale production if your needs grow. This information will help you assess whether a supplier can meet your long-term supply requirements.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure that you discuss minimum order quantities and any potential discounts for bulk purchases. A clear agreement will help prevent misunderstandings and ensure a smooth procurement process.

Step 7: Establish a Quality Control Process

Implement a quality control process to monitor the chamois leather cloth you receive. This may include regular inspections upon delivery and establishing criteria for acceptance. By maintaining rigorous quality checks, you can minimize the risk of receiving subpar materials that could affect your products’ performance.

Following this checklist will empower you to make informed decisions while sourcing chamois leather cloth, ensuring that you partner with suppliers who align with your business needs and quality standards.

Comprehensive Cost and Pricing Analysis for chamois leather cloth Sourcing

What Are the Key Cost Components of Chamois Leather Cloth Sourcing?

When sourcing chamois leather cloth, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality of sheepskin and tanning processes significantly impacts material costs. Genuine chamois leather, particularly those tanned with cod oil, tends to be more expensive due to the sourcing of high-quality skins and the intricate tanning process.

-

Labor: Skilled labor is required for tanning and processing chamois leather, which can vary by region. Labor costs can be lower in certain countries, but the quality of craftsmanship must not be compromised.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. High-quality production facilities with modern machinery may incur higher overhead costs but can also lead to better-quality products.

-

Tooling: Custom tooling for specific product shapes or sizes can add to the overall cost. Buyers should consider whether standard sizes meet their needs or if custom tooling is necessary.

-

Quality Control (QC): Ensuring that the chamois leather meets international standards (e.g., BS 6715:1991) is crucial. QC processes can incur additional costs but are essential for maintaining product integrity.

-

Logistics: Shipping costs can vary significantly based on distance, volume, and chosen logistics partners. International buyers must factor in duties, tariffs, and insurance when calculating total logistics costs.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This margin can vary based on market demand and competition.

How Do Price Influencers Affect Chamois Leather Pricing?

Several factors influence pricing beyond the basic cost components:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to discounts, allowing buyers to reduce the unit cost. Understanding the supplier’s MOQ is essential for cost-effectiveness.

-

Specifications and Customization: Custom orders tailored to specific needs (e.g., size, shape, or special tanning) can increase costs. Buyers should assess whether customization is necessary for their target market.

-

Material Quality and Certifications: Higher quality materials and certifications can justify a premium price. Buyers should evaluate whether the additional cost aligns with their product positioning.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more but offer better quality assurance and customer service.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is critical for calculating total costs, including shipping and insurance. This affects budgeting and financial forecasting.

What Are Effective Buyer Tips for Sourcing Chamois Leather?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should consider the following tips:

-

Negotiation: Leverage volume purchases and long-term contracts to negotiate better pricing. Building a relationship with suppliers can lead to more favorable terms.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), which includes initial purchase price, shipping, and any potential maintenance costs associated with lower-quality products.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and local economic conditions that may affect pricing. Additionally, consider any import restrictions or tariffs that could impact overall costs.

-

Research and Compare: Conduct thorough market research to compare prices across different suppliers. Look for reviews and quality certifications to ensure you are sourcing from reputable manufacturers.

In conclusion, understanding the comprehensive cost structure and various pricing influencers can empower B2B buyers to make more strategic sourcing decisions regarding chamois leather cloth. By applying these insights, buyers can enhance their procurement strategy and achieve better value in their purchases.

Alternatives Analysis: Comparing chamois leather cloth With Other Solutions

Introduction: Understanding Alternatives to Chamois Leather Cloth

In the quest for effective drying and cleaning solutions, businesses often explore various alternatives to traditional chamois leather cloth. While chamois is renowned for its unique absorbent properties and gentle touch, several other products offer varying degrees of performance, cost-effectiveness, and usability. This analysis aims to provide B2B buyers with a comprehensive comparison of chamois leather cloth against synthetic chamois and microfiber cloths, enabling informed decision-making tailored to specific operational needs.

Comparison Table

| Comparison Aspect | Chamois Leather Cloth | Chamois synthétique | Microfiber Cloth |

|---|---|---|---|

| Performance | High absorbency, streak-free finish | Moderate absorbency, may smear | Excellent absorbency, non-abrasive |

| Cost | Higher initial investment | Lower cost, budget-friendly | Varies widely, generally affordable |

| Ease of Implementation | Requires pre-washing and care | Ready to use, minimal preparation | Easy to use, machine washable |

| Maintenance | Requires hand washing and air drying | Easy to clean, quick drying | Machine washable, low maintenance |

| Best Use Case | Luxury car care, fine surfaces | General cleaning tasks | Versatile cleaning, household use |

Detailed Breakdown of Alternatives

Chamois synthétique

Synthetic chamois is designed to mimic the absorbent qualities of genuine chamois leather while being more cost-effective. Made from man-made materials, these cloths are often lighter and easier to handle. However, they may not achieve the same level of absorbency or provide a streak-free finish, especially on delicate surfaces. They are ideal for general cleaning tasks where high performance isn’t critical, making them suitable for budget-conscious businesses.

Microfiber Cloth

Microfiber cloths have gained popularity due to their versatility and effectiveness in various cleaning applications. Composed of ultra-fine synthetic fibers, they excel in picking up dirt and moisture without scratching surfaces. Microfiber is easy to wash and can be reused multiple times, making it a sustainable option. However, while they are effective for general cleaning, they may not provide the luxurious feel and high absorbency that chamois leather offers, especially for specialized tasks like drying luxury vehicles.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the right drying or cleaning solution depends on the specific requirements of your business. If high performance and a streak-free finish are paramount, investing in genuine chamois leather cloth is advisable despite its higher cost. For businesses with budget constraints or less demanding applications, synthetic chamois or microfiber cloths offer viable alternatives that can deliver satisfactory results. Ultimately, assessing factors such as intended use, maintenance capabilities, and cost considerations will guide B2B buyers in making a choice that aligns with their operational goals.

Illustrative image related to chamois leather cloth

Essential Technical Properties and Trade Terminology for chamois leather cloth

What Are the Key Technical Properties of Chamois Leather Cloth?

When considering chamois leather cloth for various applications, understanding its technical properties is crucial for making informed purchasing decisions. Here are some key specifications that B2B buyers should be aware of:

-

Material Grade

Chamois leather is typically classified based on its quality and origin. Genuine chamois is derived from sheepskin that has undergone cod oil tanning, resulting in a soft, pliable texture. Higher material grades indicate superior absorbency and durability, making them ideal for applications such as automotive detailing or luxury goods. -

Absorbency Rate

One of the standout features of chamois leather is its exceptional absorbency. High-quality chamois can absorb up to six times its weight in water, making it indispensable for drying surfaces without leaving streaks or scratches. This property is particularly important in industries where surface integrity is critical, such as automotive and high-end cleaning. -

Durability and Lifespan

The durability of chamois leather is influenced by its tanning process and maintenance. Genuine chamois, when properly cared for, can last for years, making it a cost-effective option for businesses. Understanding the lifespan of the product can help buyers evaluate their investment and plan for future procurement. -

Size and Shape Variability

Chamois leather is available in various sizes and shapes, ranging from small squares to full skins. This variability allows businesses to choose products that best fit their specific applications, whether for automotive use or household cleaning. Custom sizing can also be requested, which is essential for businesses that require tailored solutions. -

Biodegradability

As sustainability becomes increasingly important, the biodegradable nature of genuine chamois leather is a significant selling point. This property appeals to environmentally conscious businesses looking to reduce their carbon footprint while still utilizing high-quality materials. -

Tanning Process

The tanning process, particularly cod oil tanning, greatly affects the leather’s texture and performance. Understanding the tanning methods can help buyers assess the quality and suitability of the product for their specific needs.

What Are Common Trade Terms in the Chamois Leather Industry?

Familiarity with industry jargon can enhance communication and streamline procurement processes. Here are several essential terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are used in another company’s end product. In the chamois leather industry, OEMs may supply leather products for automotive or cleaning brands that incorporate them into their offerings. -

MOQ (Minimum Order Quantity)

This is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for budgeting and inventory management. Buyers should clarify MOQs with suppliers to ensure they can meet both their needs and the supplier’s requirements. -

RFQ (Request for Quotation)

An RFQ is a document that buyers use to solicit price quotes from suppliers for specific products. When considering bulk purchases of chamois leather, issuing an RFQ can help in comparing prices and terms from different suppliers effectively. -

Incoterms (International Commercial Terms)

These are a set of rules that define responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms like FOB (Free On Board) or CIF (Cost Insurance and Freight) is vital for understanding shipping costs and liability in international trade. -

BLC (British Leather Confederation)

This organization sets standards for the leather industry, including testing and quality assurance. Products that meet BLC standards can assure buyers of the quality and reliability of chamois leather they are purchasing. -

Private Label

This term refers to products manufactured by one company for sale under another company’s brand. Understanding private labeling can open opportunities for businesses looking to expand their product lines without investing in manufacturing capabilities.

By grasping these essential properties and terms, B2B buyers can make well-informed decisions regarding their chamois leather cloth purchases, ensuring they choose the right products for their specific needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the chamois leather cloth Sector

What Are the Current Market Dynamics and Key Trends in the Chamois Leather Cloth Sector?

The chamois leather cloth market is experiencing a notable resurgence, driven by the increasing demand for high-quality, natural cleaning materials across various sectors, including automotive, household, and personal care. International B2B buyers are particularly focused on sourcing genuine chamois leather due to its superior absorbency, softness, and durability compared to synthetic alternatives. In regions such as Africa, South America, the Middle East, and Europe, there is a growing preference for premium products that offer both performance and sustainability.

Emerging trends in sourcing include the integration of advanced B2B technologies such as e-commerce platforms and digital supply chain management tools. These innovations enable international buyers to streamline their procurement processes, optimize inventory management, and enhance supplier communication. Furthermore, the rise of private label products is becoming a significant trend, allowing businesses to differentiate themselves in competitive markets by offering customized solutions tailored to specific customer needs.

The market dynamics are also influenced by the increasing competition from synthetic materials, which, while often cheaper, do not match the performance of genuine chamois leather. As consumers become more discerning, the emphasis on product quality and the unique characteristics of natural materials is expected to drive further growth in the chamois leather sector.

How Is Sustainability and Ethical Sourcing Addressed in the Chamois Leather Cloth Market?

Sustainability has become a cornerstone of the chamois leather cloth industry, with an increasing number of manufacturers adopting eco-friendly practices in their production processes. The environmental impact of leather sourcing is a critical consideration for B2B buyers, particularly in light of global initiatives aimed at reducing carbon footprints and promoting responsible consumption.

Ethical sourcing practices are gaining traction, with suppliers striving to ensure that their raw materials come from sustainable and traceable sources. Buyers are encouraged to look for certifications that indicate adherence to environmental standards, such as the Leather Working Group (LWG) certification, which assesses the environmental performance of leather manufacturers.

Moreover, the use of biodegradable materials in the tanning process, such as cod oil, further enhances the sustainability profile of chamois leather. By prioritizing suppliers that emphasize ethical practices and sustainability, B2B buyers can align their purchasing decisions with the growing consumer demand for environmentally responsible products, thereby enhancing their brand reputation and market competitiveness.

What Is the Brief Evolution and Historical Context of Chamois Leather Cloth?

Chamois leather has a rich history that dates back centuries, originating from the chamois goat, which was traditionally hunted in the mountains of Europe. Initially prized for its softness and absorbency, the tanning process has evolved significantly over the years. The introduction of cod oil tanning in the 19th century revolutionized the industry, allowing for the production of leather that not only retained its unique qualities but also became more durable and versatile.

Today, chamois leather is synonymous with quality and craftsmanship. Its applications have expanded beyond automotive cleaning to include household cleaning, personal care, and even fashion accessories. The evolution of the chamois leather sector reflects broader trends in consumer preferences, with a distinct shift towards natural, high-performance materials that cater to both functional and aesthetic demands. As the market continues to grow, the legacy of chamois leather remains a testament to its enduring appeal and unmatched qualities.

Frequently Asked Questions (FAQs) for B2B Buyers of chamois leather cloth

-

How do I choose the right supplier for chamois leather cloth?

Selecting a reliable supplier for chamois leather cloth involves several key factors. First, assess the supplier’s reputation through reviews and testimonials from previous clients. Ensure they have a solid track record of delivering high-quality products that meet international standards. Additionally, request samples to evaluate the quality of the chamois leather. It’s also crucial to inquire about their production capacity and lead times to ensure they can meet your demands. Lastly, check their compliance with environmental and labor regulations, which can affect your brand’s image. -

What is the best type of chamois leather for automotive applications?

For automotive applications, genuine chamois leather is often preferred due to its superior absorbency and non-abrasive qualities. Look for products that are specifically tanned for automotive use, such as those that are cod oil tanned, as they provide a streak-free finish and are clear coat safe. Products with added antimicrobial properties can also enhance longevity and cleanliness. Always consider the weight and thickness of the chamois, as thicker options tend to absorb more water and provide better results during drying. -

What are the minimum order quantities (MOQ) for chamois leather cloth?

Minimum order quantities for chamois leather cloth can vary significantly based on the supplier and the specific product. Typically, MOQs may range from 50 to 200 square feet, but some suppliers may accommodate smaller orders for first-time buyers. It’s advisable to discuss your needs directly with suppliers to see if they can offer flexibility, especially for new businesses or those testing the market. Understanding the MOQ is crucial for managing inventory and cash flow, particularly in diverse international markets. -

How can I customize chamois leather products for my brand?

Customization options for chamois leather products often include size, shape, packaging, and branding. Many manufacturers offer private labeling services, allowing you to add your logo and brand colors to the packaging. Discuss your specific requirements with the supplier, including any unique specifications, to ensure they can meet your vision. Additionally, consider bulk ordering to reduce costs while customizing your product line, which can help you stand out in competitive markets. -

What payment terms should I expect when ordering chamois leather cloth internationally?

Payment terms for international orders of chamois leather cloth typically vary by supplier and may include options such as advance payment, letters of credit, or net 30/60/90 days terms. Discussing payment terms upfront is crucial to avoid misunderstandings. Be aware that some suppliers may require a deposit before processing your order, particularly for custom products. Always ensure that payment methods are secure and that you have a clear agreement in writing regarding payment schedules and conditions. -

What quality assurance measures should I look for in chamois leather cloth suppliers?

Quality assurance measures can significantly impact the reliability of chamois leather products. Look for suppliers who conduct regular quality testing through third-party laboratories to ensure their products meet industry standards, such as BS 6715:1991. Inquire about their quality control processes, including inspections during production and before shipment. Additionally, ask if they provide certifications or test reports that verify the quality and performance of their chamois leather products, giving you confidence in your purchase. -

What logistics considerations should I keep in mind when importing chamois leather?

When importing chamois leather, consider factors such as shipping methods, customs regulations, and delivery times. Choose a reliable freight forwarder experienced in handling leather products to ensure smooth transportation. Familiarize yourself with the import duties and taxes applicable in your country, as these can impact overall costs. Additionally, establish clear communication with your supplier regarding shipping schedules and tracking to avoid delays and ensure timely delivery. -

How can I ensure sustainable sourcing of chamois leather?

To ensure sustainable sourcing of chamois leather, select suppliers who prioritize ethical practices and environmental responsibility. Look for certifications related to sustainable leather production, such as those that indicate compliance with animal welfare standards. Inquire about the tanning processes used, as eco-friendly methods can significantly reduce environmental impact. Additionally, consider suppliers who engage in initiatives to minimize waste and promote recycling, aligning your business with sustainability goals that resonate with modern consumers.

Top 3 Chamois Leather Cloth Manufacturers & Suppliers List

1. Reddit – Chamois Leather Concerns

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Chamois leather is considered old technology for drying cars. Users express concerns that it can spread dirt rather than absorb it, potentially leading to scratches over time. Alternatives recommended include microfiber towels and leaf blowers for drying, which are seen as more effective and less damaging.

2. Heatons – Wash Leather Chamois

Domain: heatons.com

Registered: 1997 (28 years)

Introduction: Wash Leather Chamois

– Brand: Heatons (formerly Westmorland Sheepskins)

– Price: £8.00

– Rating: 5.0/5 from 13 Reviews

– Sizes Available:

– Medium: 2.5 square foot (approx), rectangle shape

– Large: 5.5 square foot (approx), natural skin shaped

– Material: Natural leather, biodegradable

– Features: Highly absorbent, low abrasive properties, ideal for drying cars and cleaning windows

– Care In…

3. Naturally Sheepskins – Genuine Chamois Leather Cleaning Cloth

Domain: naturallysheepskins.com

Registered: 2016 (9 years)

Introduction: {“Product Name”: “Genuine Chamois Leather Cleaning Cloth”, “Brand”: “Naturally Sheepskins”, “Price”: {“3 sq ft”: “$19.95 AUD”, “2.25 sq ft”: “$17.95 AUD”}, “Sizes”: [“3 sq ft (ca. 42x65cm)”, “2.25 sq ft (ca. 37x55cm)”], “Material”: “100% genuine Chamois Leather”, “Origin”: “Sourced in New Zealand”, “Tanning Process”: “Cod oil tanned in hot drums without harsh chemicals”, “Key Features”: [“100% nat…

Strategic Sourcing Conclusion and Outlook for chamois leather cloth

In the realm of chamois leather cloth, strategic sourcing has emerged as a critical factor for B2B buyers looking to optimize quality, cost, and sustainability. The unique properties of genuine chamois leather—such as its unparalleled absorbency, durability, and natural softness—position it as a premium choice for various applications, from automotive care to household cleaning. Buyers should prioritize partnerships with reputable suppliers who adhere to traditional tanning methods and international quality standards, ensuring that the products not only meet but exceed market expectations.

As the demand for eco-friendly and high-performance materials grows, sourcing chamois leather from sustainable sources will enhance brand reputation and consumer trust. International buyers from regions like Africa, South America, the Middle East, and Europe must leverage this trend by aligning with suppliers who emphasize ethical practices and innovative product features, such as antimicrobial treatments and customizable packaging.

Looking ahead, the chamois leather market is poised for growth, driven by increasing consumer awareness of quality and sustainability. Now is the time for B2B buyers to take proactive steps—forge strategic alliances, invest in quality products, and stay ahead of market trends to capture new opportunities in this evolving landscape.

Illustrative image related to chamois leather cloth

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to chamois leather cloth