Introduction: Navigating the Global Market for custom leather guitar straps

In the dynamic world of music accessories, sourcing high-quality custom leather guitar straps presents a unique challenge for international B2B buyers. With diverse styles, materials, and personalization options, navigating the global market requires a keen understanding of the product landscape. This guide delves into the multifaceted realm of custom leather guitar straps, exploring various types, applications across genres, and critical considerations for supplier vetting.

Buyers will gain insights into the craftsmanship and durability of different leather types, from hand-tooled designs to luxury Italian leathers, ensuring they select products that resonate with their clientele’s preferences. Furthermore, this comprehensive resource addresses cost factors, helping businesses balance quality and affordability while sourcing from regions like Africa, South America, the Middle East, and Europe, including markets in Saudi Arabia and Brazil.

By arming B2B buyers with essential knowledge and actionable strategies, this guide empowers them to make informed purchasing decisions that enhance their product offerings. Whether you’re a retailer seeking to expand your inventory or a distributor looking to establish robust supplier relationships, understanding the nuances of custom leather guitar straps will elevate your business to new heights.

Table Of Contents

- Top 9 Custom Leather Guitar Straps Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather guitar straps

- Understanding custom leather guitar straps Types and Variations

- Key Industrial Applications of custom leather guitar straps

- 3 Common User Pain Points for ‘custom leather guitar straps’ & Their Solutions

- Strategic Material Selection Guide for custom leather guitar straps

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather guitar straps

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather guitar straps’

- Comprehensive Cost and Pricing Analysis for custom leather guitar straps Sourcing

- Alternatives Analysis: Comparing custom leather guitar straps With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather guitar straps

- Navigating Market Dynamics and Sourcing Trends in the custom leather guitar straps Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather guitar straps

- Strategic Sourcing Conclusion and Outlook for custom leather guitar straps

- Important Disclaimer & Terms of Use

Understanding custom leather guitar straps Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hand Tooled Leather Straps | Custom designs, intricate patterns, often personalized | High-end retailers, custom shops | Pros: Unique aesthetics, customizable; Cons: Higher cost, longer production time. |

| Padded Leather Straps | Extra cushioning for comfort, often wider | Professional musicians, touring artists | Pros: Enhanced comfort for long sessions; Cons: May be bulkier, heavier. |

| Vintage and Distressed Leather Straps | Aged appearance, soft texture, often made from reclaimed leather | Retro-themed shops, niche markets | Pros: Unique look, appeals to vintage enthusiasts; Cons: Limited availability, potential durability issues. |

| Faux Leather Straps | Made from synthetic materials, eco-friendly options | Budget retailers, mass production | Pros: Cost-effective, lightweight; Cons: May lack the durability and feel of real leather. |

| Specialty Leather Straps | Unique materials (e.g., gator, bison), limited editions | Luxury markets, custom orders | Pros: High-end appeal, exclusivity; Cons: Very high price point, niche market appeal. |

What Are Hand Tooled Leather Straps and Their B2B Relevance?

Hand tooled leather straps feature intricate designs that are often personalized for musicians. These straps are crafted with attention to detail, making them ideal for high-end retailers and custom shops. B2B buyers should consider the unique aesthetic appeal these straps provide, as they can enhance brand image and customer satisfaction. However, the production time and cost can be higher than standard options, which should be factored into pricing strategies.

How Do Padded Leather Straps Enhance Comfort for Musicians?

Padded leather straps are designed to offer additional cushioning, making them ideal for professional musicians who perform for extended periods. Their wider design helps distribute weight more evenly across the shoulder, reducing fatigue. B2B buyers targeting touring artists and professional musicians will find these straps appealing. While they enhance comfort, it is important to note that they may be bulkier and heavier, which could deter some players.

Why Choose Vintage and Distressed Leather Straps?

Vintage and distressed leather straps have a unique, aged appearance that appeals to musicians seeking a retro aesthetic. Often made from reclaimed materials, these straps can attract niche markets and retro-themed shops. B2B buyers should consider the distinctiveness of these products, as they can drive sales among vintage enthusiasts. However, availability may be limited, and potential durability issues should be assessed to ensure customer satisfaction.

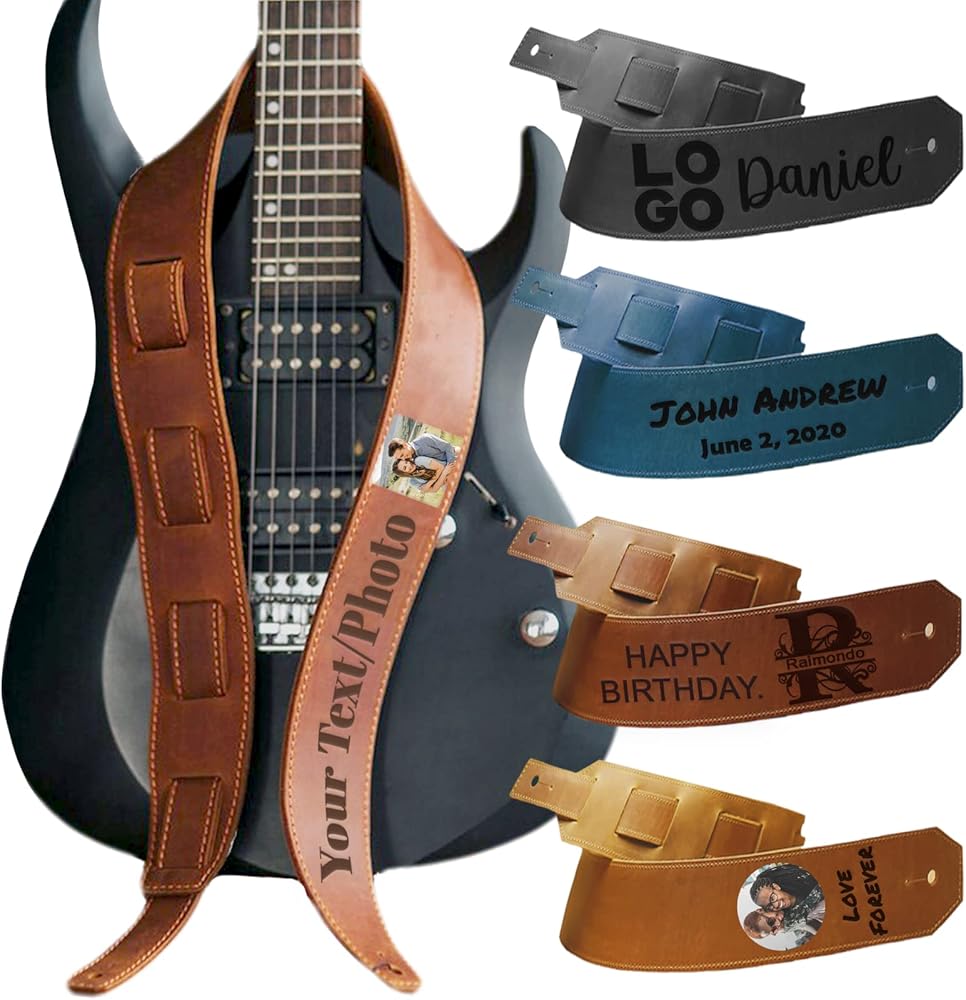

Illustrative image related to custom leather guitar straps

What Are the Benefits of Faux Leather Straps for Budget-Conscious Buyers?

Faux leather straps are made from synthetic materials and are an eco-friendly alternative to traditional leather. These straps are cost-effective and lightweight, making them suitable for budget retailers and mass production. B2B buyers looking to cater to price-sensitive customers will find these straps beneficial. However, the trade-off includes potential concerns about durability and the tactile experience compared to genuine leather options.

How Do Specialty Leather Straps Cater to Luxury Markets?

Specialty leather straps, which can include unique materials like gator or bison leather, are often produced in limited editions. These straps appeal to luxury markets and custom orders, providing exclusivity and high-end appeal. B2B buyers targeting affluent customers will find these products advantageous for their premium offerings. However, the high price point may limit the target audience, necessitating a strategic marketing approach to reach the desired clientele.

Key Industrial Applications of custom leather guitar straps

| Industry/Sector | Specific Application of Custom Leather Guitar Straps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Music Retail | Custom guitar straps for branded merchandise | Enhances brand visibility and customer loyalty | Quality of leather, customization options, production timelines |

| Event Production | Durable straps for live performances | Ensures reliability and safety during events | Weight capacity, comfort for performers, aesthetic appeal |

| Touring Musicians | Personalized straps for individual artists | Strengthens artist identity and fan connection | Unique designs, durability, and comfort for long use |

| Promotional Products | Customized straps for giveaways and promotions | Attracts new customers and enhances marketing efforts | Cost-effectiveness, design flexibility, lead times |

| Guitar Manufacturing | OEM straps for guitar manufacturers | Adds value to the product offering | Material quality, design specifications, production scalability |

How Are Custom Leather Guitar Straps Used in the Music Retail Industry?

In the music retail sector, custom leather guitar straps serve as a powerful branding tool. Retailers can offer personalized straps that feature their logos or unique designs, enhancing brand visibility. This not only attracts customers but also fosters loyalty, as musicians often prefer products that resonate with their identity. For international buyers, sourcing high-quality leather that withstands various climates and ensuring quick turnaround times for custom orders are crucial.

Illustrative image related to custom leather guitar straps

What Role Do Custom Leather Guitar Straps Play in Event Production?

For event production companies, custom leather guitar straps are essential for ensuring the safety and comfort of performers. Durable straps are needed to support heavy instruments during live performances, minimizing the risk of accidents. Additionally, the aesthetic appeal of these straps can enhance the overall stage presence. Buyers in regions like the Middle East or South America should consider the weight capacity and ergonomic design to accommodate long hours of use.

Why Are Custom Leather Guitar Straps Important for Touring Musicians?

Touring musicians often rely on custom leather guitar straps to express their individuality and connect with fans. Personalized straps can feature artist names, logos, or unique artwork, making them collectible items for fans. This personalization not only adds sentimental value but also serves as a marketing tool during tours. When sourcing, artists and their management teams should prioritize comfort and durability, ensuring the straps can withstand extensive use across different environments.

How Can Custom Leather Guitar Straps Be Used as Promotional Products?

Custom leather guitar straps are effective promotional products that businesses can use to attract new customers. Offering these straps as giveaways or promotional items at events can significantly boost marketing efforts. They serve as a functional accessory for musicians while simultaneously promoting the brand. Buyers should look for cost-effective solutions that allow for design flexibility and quick production, especially in competitive markets such as Brazil or Europe.

Illustrative image related to custom leather guitar straps

What Are the Benefits of OEM Custom Leather Guitar Straps for Guitar Manufacturers?

Guitar manufacturers can enhance their product offerings by including OEM custom leather guitar straps with their instruments. These straps add value to the guitar, making it more appealing to consumers. The quality of the leather and the design specifications must align with the brand’s image and target market. Manufacturers should ensure they have reliable sourcing partners who can meet quality standards and production scalability, especially when catering to international demand.

3 Common User Pain Points for ‘custom leather guitar straps’ & Their Solutions

Scenario 1: Sourcing Quality Custom Leather Guitar Straps

The Problem: B2B buyers often struggle with identifying reliable suppliers for high-quality custom leather guitar straps. Many suppliers offer generic products that fail to meet the specific needs of different markets, such as those in Africa or South America, where local preferences and climates can influence material choices and design aesthetics. Additionally, the risk of receiving inferior quality products can lead to financial losses and damage to a brand’s reputation.

The Solution: To effectively source custom leather guitar straps, buyers should conduct thorough market research to identify suppliers with a proven track record in the industry. Look for manufacturers that specialize in high-quality leather products and have positive reviews from previous clients. Initiating direct communication with potential suppliers can also help clarify their production capabilities, customization options, and quality assurance processes. It is advisable to request samples before making bulk orders, ensuring that the materials and craftsmanship meet your standards. Furthermore, consider suppliers who offer transparency regarding their sourcing practices, as this can be a significant selling point in markets that value sustainability.

Scenario 2: Ensuring Customization Meets Market Demands

The Problem: In a diverse global market, one-size-fits-all solutions often do not resonate with local consumers. B2B buyers may face difficulties in customizing leather guitar straps that align with the cultural and aesthetic preferences of their target markets, which can result in poor sales and wasted inventory. This challenge is particularly pronounced in regions like the Middle East and Europe, where design trends can vary significantly.

The Solution: To ensure that the customization of leather guitar straps meets market demands, buyers should engage in comprehensive consumer research. This includes analyzing local trends, color preferences, and cultural symbols that may resonate with customers. Collaborating with local artists or designers can also provide valuable insights into what appeals to the target demographic. Additionally, utilizing design software that allows for visual mock-ups can help buyers present options to stakeholders or test market reactions before finalizing designs. Establishing a feedback loop with customers post-launch can also inform future design iterations, enhancing the product’s appeal.

Scenario 3: Balancing Cost with Quality in Bulk Orders

The Problem: Cost management is a critical concern for B2B buyers, especially when placing bulk orders for custom leather guitar straps. The pressure to keep costs low can lead to compromises on quality, resulting in products that do not meet expectations. This scenario is often exacerbated by fluctuating material prices and varying manufacturing costs across regions, particularly in markets like Brazil and Saudi Arabia.

The Solution: To balance cost and quality effectively, buyers should develop a clear budget and establish a pricing framework that prioritizes essential quality indicators. Engaging in negotiations with suppliers can lead to bulk discounts without sacrificing material quality. It may also be beneficial to explore alternative materials that maintain a premium look and feel but are more cost-effective. Additionally, implementing a phased order strategy—starting with smaller batches—can allow buyers to assess product quality and market response before committing to larger quantities. This approach not only minimizes financial risk but also provides flexibility to adapt orders based on customer feedback and sales performance.

Strategic Material Selection Guide for custom leather guitar straps

When selecting materials for custom leather guitar straps, it is essential to consider various factors that influence product performance, durability, and cost. This guide will analyze four common materials used in the production of leather guitar straps: full-grain leather, top-grain leather, suede, and synthetic leather. Each material possesses unique properties that can significantly impact the end product’s suitability for different markets, particularly for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Full-Grain Leather for Guitar Straps?

Full-grain leather is renowned for its durability and natural appearance. It retains the hide’s original surface, showcasing unique imperfections and texture. This material is resistant to wear and tear, making it ideal for musicians who perform frequently. However, it can be sensitive to moisture and requires regular conditioning to maintain its suppleness. For B2B buyers, particularly in humid regions, understanding the care requirements is crucial to ensure longevity and performance.

How Does Top-Grain Leather Compare in Terms of Durability and Cost?

Top-grain leather is slightly less durable than full-grain leather but offers a more uniform appearance due to the sanding and finishing processes it undergoes. This material is more affordable and easier to work with, making it a popular choice for manufacturers. While it provides a good balance between aesthetics and durability, it may not withstand the rigors of extensive use as well as full-grain leather. Buyers from diverse markets should consider the trade-offs between cost and longevity when selecting this material.

Illustrative image related to custom leather guitar straps

What Are the Advantages of Using Suede for Guitar Straps?

Suede, which is derived from the underside of animal hides, offers a soft texture and unique aesthetic appeal. It is lightweight and comfortable against the skin, making it an excellent choice for long performances. However, suede is less resistant to moisture and stains, which can be a significant drawback in regions with high humidity or frequent rain. B2B buyers should be aware of the specific care instructions and potential limitations of suede in various climates.

How Does Synthetic Leather Perform Compared to Natural Options?

Synthetic leather, often made from polyurethane or PVC, provides a cost-effective alternative to natural leather. It is highly resistant to moisture, easy to clean, and available in a wide range of colors and textures. However, synthetic options may lack the durability and aesthetic appeal of genuine leather. For international buyers, especially those in markets where sustainability is a concern, the environmental impact of synthetic materials should also be considered.

Summary Table of Material Properties for Custom Leather Guitar Straps

| Matériau | Typical Use Case for custom leather guitar straps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Professional musicians, high-end straps | Exceptional durability and natural look | Sensitive to moisture, requires maintenance | Haut |

| Top-Grain Leather | Mid-range products, everyday use | More affordable, uniform appearance | Less durable than full-grain leather | Medium |

| Daim | Casual use, comfort-focused designs | Soft texture, lightweight | Less moisture resistant, prone to stains | Medium |

| Synthetic Leather | Budget-friendly options, diverse styles | Moisture resistant, easy to clean | Lacks durability and aesthetic of natural leather | Low |

In conclusion, selecting the right material for custom leather guitar straps involves balancing durability, cost, and specific application needs. Understanding the properties and limitations of each material will empower international B2B buyers to make informed decisions that align with their market demands and customer preferences.

Illustrative image related to custom leather guitar straps

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather guitar straps

What Are the Key Stages in the Manufacturing Process of Custom Leather Guitar Straps?

The manufacturing of custom leather guitar straps involves several critical stages, ensuring that each strap meets both aesthetic and functional standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: Selecting the Right Leather

The first step in the manufacturing process is the selection of high-quality leather. Different types of leather, such as full-grain, top-grain, and suede, offer varying durability, aesthetics, and comfort. Suppliers often source leather from reputable tanneries, ensuring it meets specific quality standards.

Once selected, the leather undergoes a preparation process, which includes cutting to size, removing any imperfections, and possibly dyeing or treating to enhance durability and appearance. This preparation is crucial as the quality of the leather directly affects the final product’s longevity and appeal.

How Is the Forming Process for Guitar Straps Conducted?

In the forming stage, manufacturers shape the leather into straps. This process can involve various techniques such as hand-cutting or using precision machinery for uniformity. Depending on the design, additional materials like padding or decorative elements may be integrated at this stage.

Advanced techniques, such as tooling or embossing, can create unique patterns or logos, making each strap customizable. The ability to personalize straps is an essential selling point for B2B buyers, as it allows for differentiation in a competitive market.

Illustrative image related to custom leather guitar straps

What Does the Assembly Process Entail?

Once the leather is formed, the assembly process begins. This stage typically includes stitching the straps together, attaching hardware such as buckles or clips, and ensuring all components are secure. Skilled artisans often conduct this process to maintain high standards of craftsmanship.

Quality control during assembly is vital. Manufacturers should have protocols in place to check that stitching is consistent and free from defects, as these details can significantly impact the product’s functionality and aesthetics.

What Finishing Techniques Are Commonly Used for Leather Guitar Straps?

The finishing stage enhances the strap’s appearance and durability. This can involve applying protective coatings, polishing the leather, or adding final touches like embossing or painting. The finishing techniques employed can vary widely, from traditional methods to modern finishes that improve water resistance and overall wear.

Attention to detail during the finishing process is crucial, as it directly affects the strap’s final quality. B2B buyers should inquire about the specific techniques used by suppliers to ensure that the products will meet their market demands.

What International Standards and Quality Control Processes Are Relevant for Guitar Strap Manufacturing?

Quality assurance is paramount in the manufacturing of custom leather guitar straps, especially for international markets. Adhering to recognized standards ensures that products meet safety and quality expectations.

Which International Quality Standards Should Buyers Be Aware Of?

ISO 9001 is a widely recognized international standard that outlines the requirements for a quality management system. Manufacturers adhering to this standard demonstrate their commitment to consistent quality and customer satisfaction. Additionally, industry-specific certifications such as CE marking (for compliance with health, safety, and environmental protection standards) may be relevant, especially for buyers in Europe.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding these standards is crucial. They help ensure that products are not only safe but also competitive in various markets.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards. This is crucial for leather, as the quality of the initial material will significantly impact the final product.

-

In-Process Quality Control (IPQC): During the manufacturing stages, ongoing inspections help identify defects early. This can involve checking the stitching, ensuring proper assembly, and verifying that finishing processes are correctly applied.

-

Final Quality Control (FQC): After production, the finished products undergo thorough inspections to assess overall quality. This includes checking for defects, verifying dimensions, and ensuring that all specifications have been met.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those sourcing from international suppliers, verifying quality control practices is essential for ensuring product reliability. Here are several strategies to consider:

What Methods Can Buyers Use to Conduct Supplier Audits?

Conducting supplier audits is one of the most effective ways to verify quality control processes. Buyers should look for suppliers willing to provide access to their manufacturing facilities. During an audit, buyers can assess the production environment, review quality control documentation, and observe manufacturing practices firsthand.

How Can Buyers Request Quality Reports and Certifications?

Buyers should request quality reports and certifications from potential suppliers. These documents can provide insight into a supplier’s adherence to international standards and their internal quality control measures. Regular reports on quality metrics can also help buyers track supplier performance over time.

Illustrative image related to custom leather guitar straps

What Role Do Third-Party Inspections Play in Quality Assurance?

Utilizing third-party inspection services can further enhance quality assurance. Independent inspectors can verify that products meet specified standards before shipment, providing an additional layer of confidence for buyers. This is particularly important for international transactions, where buyers may not have the ability to inspect products personally.

Conclusion: Ensuring Quality in Custom Leather Guitar Straps for B2B Transactions

Understanding the manufacturing processes and quality assurance measures in place for custom leather guitar straps is critical for B2B buyers. By focusing on the stages of production, relevant international standards, and effective verification methods, buyers can confidently source high-quality products that meet their market needs. This knowledge not only facilitates better purchasing decisions but also fosters long-term relationships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather guitar straps’

To assist B2B buyers in sourcing custom leather guitar straps effectively, this guide outlines a practical checklist designed to streamline the procurement process. By following these steps, buyers can ensure they select high-quality products that meet their specific needs while establishing reliable supplier relationships.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clarify your technical requirements. Consider the types of leather (e.g., full-grain, top-grain) and design specifications (e.g., width, length, tooling). This clarity will help you communicate effectively with suppliers and ensure the products align with your brand’s quality standards.

- Material Quality: Specify whether you need premium materials like Italian leather or durable options like buffalo leather.

- Design Features: Consider personalized elements such as embossing or color variations.

Step 2: Research Market Trends and Competitors

Understanding current market trends and competitor offerings will provide insights into customer preferences and pricing strategies. Analyze the styles, functionalities, and price points of existing products in your target markets, such as Africa, South America, or Europe.

Illustrative image related to custom leather guitar straps

- Trends in Customization: Look for rising trends in personalized or uniquely designed guitar straps that can give your product a competitive edge.

- Pricing Benchmarking: Assess the price ranges of similar products to position your offerings effectively.

Step 3: Evaluate Potential Suppliers

Thorough supplier evaluation is crucial to mitigate risks and ensure product quality. Request detailed company profiles, including their manufacturing processes, quality control measures, and client testimonials.

- Experience and Reputation: Look for suppliers with a proven track record in producing leather goods, especially guitar straps.

- Portfolio Review: Assess their previous work to see if it aligns with your design and quality expectations.

Step 4: Request Samples for Quality Assessment

Once you have shortlisted potential suppliers, request samples of their products. This step allows you to assess the craftsmanship, material quality, and overall aesthetics of the guitar straps firsthand.

- Quality Verification: Inspect the stitching, leather finish, and overall durability of the samples.

- Comfort and Usability: Consider how the straps feel when worn, especially for long durations, as comfort can influence customer satisfaction.

Step 5: Discuss Customization Options

Engage in discussions with suppliers regarding customization capabilities. This step is vital for ensuring that the final product meets your brand’s unique requirements.

- Flexibility in Design: Confirm if suppliers can accommodate specific design requests, such as custom colors or tooling.

- Lead Times and Minimum Orders: Understand the production lead times for customized products and any minimum order requirements.

Step 6: Negotiate Terms and Pricing

Once you’ve selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. This ensures both parties have a clear understanding of expectations.

- Bulk Pricing: Inquire about discounts for larger orders, which can significantly impact your overall costs.

- Payment Terms: Establish favorable payment conditions that protect your cash flow while maintaining supplier trust.

Step 7: Finalize Contracts and Place Orders

Before placing an order, ensure that all terms and conditions are documented in a formal contract. This step protects both parties and clarifies expectations regarding quality, delivery, and payment.

Illustrative image related to custom leather guitar straps

- Legal Review: Consider having a legal professional review the contract to safeguard your interests.

- Order Confirmation: Clearly outline delivery timelines and quality assurance processes to avoid any disputes post-order.

By following this structured checklist, B2B buyers can effectively navigate the sourcing process for custom leather guitar straps, ensuring they meet their business needs while establishing strong supplier partnerships.

Comprehensive Cost and Pricing Analysis for custom leather guitar straps Sourcing

When sourcing custom leather guitar straps, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe. This comprehensive analysis breaks down the key cost components, influential pricing factors, and strategic tips for buyers.

What Are the Key Cost Components in Custom Leather Guitar Straps?

-

Materials: The choice of leather significantly impacts the overall cost. High-quality full-grain leather or specialty materials like exotic skins (e.g., gator or ostrich) come at a premium. Expect prices for materials to vary from $20 to $100 per strap based on quality.

-

Labor: The craftsmanship involved in creating custom straps affects labor costs. Skilled artisans may command higher wages, particularly in regions with a strong tradition of leatherworking. Labor costs can range from $10 to $50 per strap, depending on the complexity of the design and the level of craftsmanship required.

-

Manufacturing Overhead: This includes expenses related to utilities, facility costs, and equipment depreciation. Overhead can add 15-25% to the base cost of each strap, depending on the manufacturer’s operational efficiency.

-

Tooling: Custom tooling for unique designs or logos incurs additional costs. This could be a one-time fee or incorporated into the per-unit cost, which may vary widely from $5 to $50 based on the intricacy of the design.

-

Quality Control (QC): Ensuring that each strap meets the required standards incurs costs associated with inspection and testing. This might add an additional 5-10% to the overall cost.

-

Logistics: Shipping costs can vary significantly based on the origin and destination of the products, chosen shipping method, and Incoterms. International logistics can add 10-20% to the total cost, particularly for smaller shipments.

-

Margin: Suppliers typically add a markup to cover their profit margin, which can range from 20-50% depending on market conditions and competition.

What Factors Influence Pricing for Custom Leather Guitar Straps?

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly influence pricing. Larger orders typically result in lower per-unit costs due to economies of scale. Negotiate MOQs to optimize your pricing strategy.

-

Specifications and Customization: The level of customization, such as personalized embossing or unique colors, will affect the final price. More complex designs usually require more time and resources, thus increasing costs.

-

Quality Certifications: Straps that meet specific quality standards or certifications can demand higher prices. Buyers should assess whether these certifications are necessary for their target market.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established brands may charge more due to perceived value and quality assurance.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is essential. These terms dictate who bears the shipping costs and risks, which can affect your total landed cost.

What Are Effective Buyer Tips for Custom Leather Guitar Straps?

-

Negotiate Wisely: Leverage your purchasing power and be prepared to negotiate terms, especially regarding MOQs and pricing for customization. Establishing a long-term relationship with suppliers can lead to better pricing.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in shipping, import duties, and potential returns when evaluating the total cost of ownership.

-

Understand Pricing Nuances for International Purchases: Currency fluctuations, import regulations, and local taxes can affect pricing. Be aware of these variables when sourcing from overseas suppliers.

-

Request Samples: Before committing to a large order, request samples to evaluate quality and craftsmanship. This can prevent costly mistakes and ensure the product meets your standards.

-

Stay Informed: Keep abreast of market trends and pricing shifts within the leather goods industry. This knowledge can empower you to make informed purchasing decisions and negotiate better deals.

In conclusion, a thorough understanding of the cost structure and pricing influences is essential for B2B buyers looking to source custom leather guitar straps effectively. By considering these factors and employing strategic negotiation tactics, businesses can optimize their sourcing processes and achieve better profitability.

Illustrative image related to custom leather guitar straps

Alternatives Analysis: Comparing custom leather guitar straps With Other Solutions

Exploring Alternatives to Custom Leather Guitar Straps: A Comprehensive Analysis

In the realm of guitar accessories, custom leather guitar straps stand out for their quality and personalization options. However, there are several alternative solutions that may suit different needs, preferences, and budgets. This analysis compares custom leather guitar straps with other viable options such as synthetic leather straps and padded fabric straps, providing international B2B buyers with essential insights to make informed decisions.

| Comparison Aspect | Custom Leather Guitar Straps | Synthetic Leather Straps | Padded Fabric Straps |

|---|---|---|---|

| Performance | High durability, comfort, and aesthetic appeal | Good durability, less comfort compared to leather | Moderate durability, very comfortable |

| Cost | $85 – $300+ | $20 – $100 | $10 – $50 |

| Ease of Implementation | Often custom-made, longer lead times | Readily available, quick to purchase | Readily available, quick to purchase |

| Maintenance | Requires periodic conditioning | Easy to clean, less care needed | Machine washable, low maintenance |

| Best Use Case | Professional musicians seeking style and quality | Budget-conscious musicians or beginners | Casual players or home use |

What Are the Benefits and Drawbacks of Synthetic Leather Guitar Straps?

Synthetic leather straps are a popular alternative due to their affordability and availability. They typically range from $20 to $100, making them accessible for musicians on a budget. These straps offer good durability and are generally easier to clean than their leather counterparts. However, they may lack the aesthetic appeal and comfort of custom leather options, which can be a significant factor for professional musicians who perform for long hours.

How Do Padded Fabric Guitar Straps Compare?

Padded fabric guitar straps are another viable alternative, particularly favored by casual players. Priced between $10 and $50, they offer exceptional comfort due to their padded design, making them suitable for long practice sessions or casual play. Their maintenance is straightforward, often being machine washable. However, they may not provide the same level of durability as leather options and can wear out faster, especially with heavy use.

Illustrative image related to custom leather guitar straps

Making the Right Choice: How Can B2B Buyers Select the Best Guitar Strap?

When choosing the right guitar strap, B2B buyers should consider several factors, including their target market’s needs, budget constraints, and the desired aesthetic. Custom leather guitar straps are ideal for brands aiming to attract professional musicians or those seeking high-quality, personalized accessories. In contrast, synthetic leather and padded fabric options may appeal more to entry-level players or those looking for budget-friendly solutions. Ultimately, understanding the specific requirements of the end-users will guide buyers in selecting the most appropriate product for their inventory.

Essential Technical Properties and Trade Terminology for custom leather guitar straps

What Are the Key Technical Properties of Custom Leather Guitar Straps?

Understanding the technical properties of custom leather guitar straps is essential for B2B buyers aiming to procure high-quality products. Here are several critical specifications to consider:

1. Material Grade

The grade of leather used in guitar straps is a primary factor that influences both durability and aesthetics. Common types include full-grain, top-grain, and corrected grain leather. Full-grain leather, known for its strength and natural appearance, is often preferred for high-end straps. Understanding material grades helps buyers assess quality and longevity, which is crucial for brands looking to maintain their reputation.

2. Thickness

The thickness of the leather affects the strap’s comfort, durability, and overall appearance. Typical thicknesses range from 2.5mm to 5mm. Thicker straps provide better support and durability, while thinner straps may offer more flexibility. Buyers should consider the intended use—whether for professional performances or casual play—when selecting the appropriate thickness.

3. Stitching Quality

Stitching not only adds to the aesthetic appeal but also affects the strap’s durability. High-quality stitching, often double-stitched or reinforced, prevents fraying and extends the lifespan of the strap. Buyers should inquire about stitching techniques and materials to ensure they are getting a robust product that can withstand wear and tear.

Illustrative image related to custom leather guitar straps

4. Comfort Padding

Many guitar straps include padding, which enhances comfort during extended use. Padding materials can range from foam to gel, and their thickness can vary. This feature is particularly important for professional musicians who may perform for hours. Understanding comfort padding options can help buyers cater to their target market’s needs.

5. Adjustment Mechanisms

The ability to adjust the length of a guitar strap is crucial for a proper fit. Common adjustment mechanisms include buckle systems, sliding adjustments, and pre-defined holes. Buyers should consider the ease of use and reliability of these mechanisms, as they directly impact user experience and satisfaction.

6. Weight Capacity

Different guitar types and sizes demand varying weight capacities from straps. Heavy electric guitars typically require more robust straps than lighter acoustic models. Knowing the weight capacity ensures that the strap will safely support the instrument without risk of failure, a key consideration for both safety and performance.

What Are Common Trade Terminology and Concepts in Custom Leather Guitar Straps?

Familiarizing yourself with industry jargon can greatly enhance communication and decision-making in the procurement process. Here are several essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold by another brand under its name. In the context of custom leather guitar straps, buyers may work with OEMs to create unique designs that meet specific branding requirements. Understanding OEM relationships can help streamline production and ensure quality control.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For custom leather guitar straps, MOQs can vary significantly based on the manufacturer and design complexity. Knowing the MOQ is essential for budgeting and inventory planning, particularly for businesses looking to test new products.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically outlines the required specifications, quantities, and delivery timelines. For B2B buyers, submitting a detailed RFQ can lead to more accurate pricing and faster responses from potential suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), helps buyers understand shipping costs, risk transfer, and delivery obligations.

Illustrative image related to custom leather guitar straps

5. Customization Options

Customization options refer to the ability to tailor products to meet specific customer needs, such as color, design, or material. Understanding available customization options allows buyers to better cater to their clientele, enhancing brand loyalty and market differentiation.

6. Lead Time

Lead time is the period from placing an order to receiving the product. For custom leather guitar straps, lead times can vary based on complexity and production capacity. Knowing the lead time helps buyers plan their inventory and manage customer expectations effectively.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they procure high-quality custom leather guitar straps that meet their needs and those of their customers.

Illustrative image related to custom leather guitar straps

Navigating Market Dynamics and Sourcing Trends in the custom leather guitar straps Sector

What Are the Current Market Dynamics and Key Trends in Custom Leather Guitar Straps?

The global market for custom leather guitar straps is experiencing a notable shift, driven by a combination of consumer preferences for personalization, the growth of e-commerce, and an increasing emphasis on craftsmanship. International B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are recognizing the value of unique, high-quality products that reflect individual styles. As musicians seek to enhance their identity through their instruments, the demand for custom designs and premium materials is on the rise.

Emerging trends include the integration of advanced manufacturing technologies, such as 3D printing and digital design tools, which allow for more intricate customization options. These technologies enable suppliers to offer a wider variety of personalized features, from hand-tooled designs to bespoke color palettes. Additionally, the rise of online marketplaces has facilitated direct access for international buyers to diverse suppliers, streamlining the procurement process and enhancing competition.

The market dynamics are also influenced by the increasing popularity of live performances and music festivals, which have heightened the visibility of unique guitar accessories. B2B buyers should stay informed about regional preferences and trends, as cultural influences can significantly impact design choices and pricing strategies.

How Are Sustainability and Ethical Sourcing Reshaping the Custom Leather Guitar Strap Sector?

Sustainability and ethical sourcing are becoming paramount in the custom leather guitar strap industry. As consumers and businesses alike become more environmentally conscious, the demand for sustainable practices is reshaping supplier relationships. International B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing, which includes the use of environmentally friendly materials and transparent supply chains.

The environmental impact of leather production is significant, prompting many manufacturers to seek alternatives such as vegetable-tanned leather and other eco-friendly materials. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are gaining traction, serving as benchmarks for ethical sourcing. Buyers should consider these certifications when evaluating suppliers, as they signal a commitment to sustainable practices.

Illustrative image related to custom leather guitar straps

Furthermore, the integration of recycled materials into the production process is emerging as a viable trend, appealing to eco-conscious consumers. B2B buyers can leverage this trend by sourcing from suppliers who prioritize sustainable practices, thereby enhancing their brand’s reputation and aligning with consumer values.

What Is the Brief Evolution and History of Custom Leather Guitar Straps?

The evolution of custom leather guitar straps dates back to the early days of guitar playing, where practicality dictated the use of simple straps made from available materials. As the music industry grew, so did the demand for more functional and stylish accessories. By the late 20th century, custom leather straps began to emerge as a statement of individuality among musicians, particularly with the rise of rock and roll culture.

Today, custom leather guitar straps have evolved into a niche market characterized by artisanal craftsmanship and personalization. Innovations in design and manufacturing have allowed for a diverse array of styles, materials, and customizations, appealing to a wide range of musicians—from amateurs to professional performers. This evolution reflects broader trends in consumer behavior, where personalization and quality are highly valued, setting the stage for a thriving market in custom leather guitar straps.

Illustrative image related to custom leather guitar straps

B2B buyers in this sector must remain cognizant of these historical trends and adapt their sourcing strategies to meet the evolving demands of musicians worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather guitar straps

1. How do I ensure the quality of custom leather guitar straps?

To ensure the quality of custom leather guitar straps, request samples from potential suppliers. Assess the leather type, craftsmanship, stitching, and overall durability. Additionally, check for certifications related to materials used, like eco-friendliness or compliance with international standards. Building a relationship with suppliers who provide detailed specifications and transparency about their production processes is crucial. Establishing a quality assurance process, including inspections during production, can further guarantee that the products meet your standards.

2. What is the best way to customize leather guitar straps for my brand?

The best way to customize leather guitar straps is to collaborate closely with your supplier. Discuss design elements such as color, texture, and branding options like embossing or printing your logo. Providing your supplier with high-quality mock-ups or prototypes can help clarify your vision. Consider the target market’s preferences to ensure that your designs resonate well. Engaging in a trial run with a small batch before large-scale production allows for adjustments based on feedback.

3. What are the minimum order quantities (MOQs) for custom leather guitar straps?

Minimum order quantities (MOQs) for custom leather guitar straps can vary significantly between suppliers. Typically, MOQs may range from 50 to 500 units, depending on the complexity of the customization and the supplier’s capabilities. When negotiating, clarify if the MOQ includes different designs or sizes. Some suppliers may offer lower MOQs for initial orders or samples, making it easier for new businesses to enter the market without significant upfront investment.

4. What payment terms should I expect when sourcing custom leather guitar straps?

Payment terms can vary widely among suppliers, but standard practices include a deposit (often 30-50%) upfront and the balance upon completion or prior to shipping. International buyers may also encounter terms such as letters of credit or payment via escrow services for added security. It’s essential to negotiate terms that align with your cash flow and ensure clear communication to avoid misunderstandings. Always confirm the currency used for transactions and any applicable taxes or tariffs.

5. How do I vet suppliers for custom leather guitar straps?

Vetting suppliers involves researching their reputation, experience, and production capabilities. Start by reviewing their online presence, including customer testimonials and case studies. Request references from past clients and inquire about their production processes and materials sourcing. Conducting a factory visit, if feasible, can provide insights into their operations. Additionally, assess their ability to meet your specific needs regarding customization, MOQs, and delivery timelines.

6. What logistics considerations should I be aware of when importing guitar straps?

When importing custom leather guitar straps, consider shipping methods, customs regulations, and potential tariffs in your country. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency and budget. Familiarize yourself with import regulations, including any certifications or documentation required. Partnering with a reliable logistics provider can streamline the process, ensuring timely delivery while minimizing unexpected costs.

7. How can I manage lead times for custom leather guitar strap orders?

Managing lead times requires clear communication with your supplier regarding production timelines and any potential delays. Establish a production schedule that factors in design approval, material sourcing, and manufacturing time. Encourage your supplier to provide regular updates on progress and anticipate any disruptions, such as material shortages or shipping delays. Building a buffer period into your planning can also help accommodate unforeseen issues while maintaining customer satisfaction.

8. What are the best practices for marketing custom leather guitar straps to B2B buyers?

Effective marketing of custom leather guitar straps to B2B buyers includes leveraging social media, trade shows, and industry-specific platforms. Create engaging content that highlights the uniqueness of your products, including quality, customization options, and testimonials from musicians. Utilize email marketing campaigns to reach potential clients, offering promotions or showcasing new designs. Establish partnerships with music retailers or distributors to expand your reach and credibility in the market.

Illustrative image related to custom leather guitar straps

Top 9 Custom Leather Guitar Straps Manufacturers & Suppliers List

1. The Leather Smithy – Handcrafted Guitar Straps

Domain: theleathersmithy.com

Registered: 2017 (8 years)

Introduction: Leather Guitar Straps, Handcrafted Leather Goods, Hand Tooled and Engraved Leather Guitar Straps, 60 products available, sorted by popularity, price range from $85.00 to $260.00, options for personalization and custom designs, free shipping for all US orders.

2. Moody Leather – Faux Gator and Leather Backed Guitar Straps

Domain: moodyleather.com

Registered: 2003 (22 years)

Introduction: {“products”:[{“name”:”2.5″ Faux Gator Leather Backed Guitar Strap – Burnt Orange/Brown”,”price”:”$185.00″},{“name”:”2.5″ Faux Gator Leather Backed Guitar Strap – Topaz/Cream”,”price”:”$185.00″},{“name”:”2.5″ 3 STAR Leather Backed Strap – Black/Black & three platinum stars”,”price”:”$190.00″}]}

3. Custom Straps – Handmade in Michigan

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Custom Straps – Handmade in Michigan, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Red Monkey Designs – Custom Leather Guitar Straps

Domain: redmonkeydesigns.com

Registered: 1997 (28 years)

Introduction: Custom Leather Guitar Straps | Unique & Cool Guitar Straps from Red Monkey Los Angeles. Available in various widths: 1/2″ – 1″, 1 1/4″ – 1 3/4″, and 2″ – 3 1/2″. Collections include Relic Collection, Midnight Special Collection, and custom options. Products are handmade and designed for durability, suitable for electric, acoustic, and bass guitars. Notable artists using Red Monkey straps include S…

5. Etsy – Custom Guitar Straps

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Quality custom guitar straps can be found from various sources. Some options include: 1. **Etsy** – A platform with many sellers offering custom designs, including embroidered and tooled leather options. 2. **Mother Mary** – Offers handmade straps and allows customers to send in materials (like old shirts or jeans) for custom straps. 3. **Anthology Gear** – Known for comfortable leather straps wit…

6. Franklin Strap – Leather Guitar Straps

Domain: franklinstrap.com

Registered: 2007 (18 years)

Introduction: This company, Franklin Strap – Leather Guitar Straps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Leathersmith Designs – Custom Leather Guitar Straps

Domain: leathersmithdesigns.com

Registered: 2000 (25 years)

Introduction: Custom guitar straps made of genuine leather with various styles including personalized, studded, and plain padded options. Popular for gifts and used by both novices and famous guitarists. Three lettering styles: Classic Series (debossed letters), Etched Series (hand-painted outlines), and Scripted Series (hand-dyed textured letters). Studded options include metal decorations and personalized sil…

8. Minotaur – Guitar Straps

Domain: minotaurguitarstraps.com

Registered: 2015 (10 years)

Introduction: This company, Minotaur – Guitar Straps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

9. BurnWizard – Custom Guitar Straps

Domain: burnwizard.com

Registered: 2019 (6 years)

Introduction: BurnWizard offers personalized guitar straps, guitars, and accessories. Key products include:

– Custom Guitar Straps: Made to order with options for personalization, including names and designs. Prices range from $150 to $400.

– Signature Styles: Examples include “Texas Country Music” ($395), “The Deer Hunter” ($185), and “Love 🖤 My State” ($160).

– Ready to Ship Straps: Options like “Skulls n …

Strategic Sourcing Conclusion and Outlook for custom leather guitar straps

What Are the Key Takeaways for B2B Buyers in Custom Leather Guitar Straps?

Strategic sourcing in the custom leather guitar strap market reveals a wealth of opportunities for B2B buyers across diverse regions. Not only do these products offer aesthetic appeal and personalization options, but they also demonstrate a commitment to quality craftsmanship that resonates with musicians and brands alike. By investing in high-quality materials and innovative designs, suppliers can enhance their brand loyalty and customer satisfaction.

Moreover, understanding regional preferences and cultural influences is crucial for suppliers targeting international markets in Africa, South America, the Middle East, and Europe. Tailoring offerings to meet specific market demands can significantly boost sales potential and establish long-lasting business relationships.

How Can International Buyers Capitalize on These Trends?

As the demand for custom leather guitar straps continues to rise, international B2B buyers should leverage this trend to source unique and stylish products that resonate with their target audience. Engage with suppliers who prioritize sustainability and ethical practices to not only meet consumer expectations but also enhance your brand’s reputation.

In conclusion, the future of custom leather guitar straps looks promising. By strategically sourcing high-quality products that align with market trends, businesses can position themselves for success in an increasingly competitive landscape. Take action now to explore these opportunities and elevate your product offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to custom leather guitar straps

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.